Involute-gear rolling mold and forming technology

A technology of involute gears and rolling, which is applied to gears, rollers, household appliances, etc., can solve the problems of tooth profile accuracy and performance degradation, and achieve less uneven deformation, balanced force, and avoid tooth profile accuracy Super poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

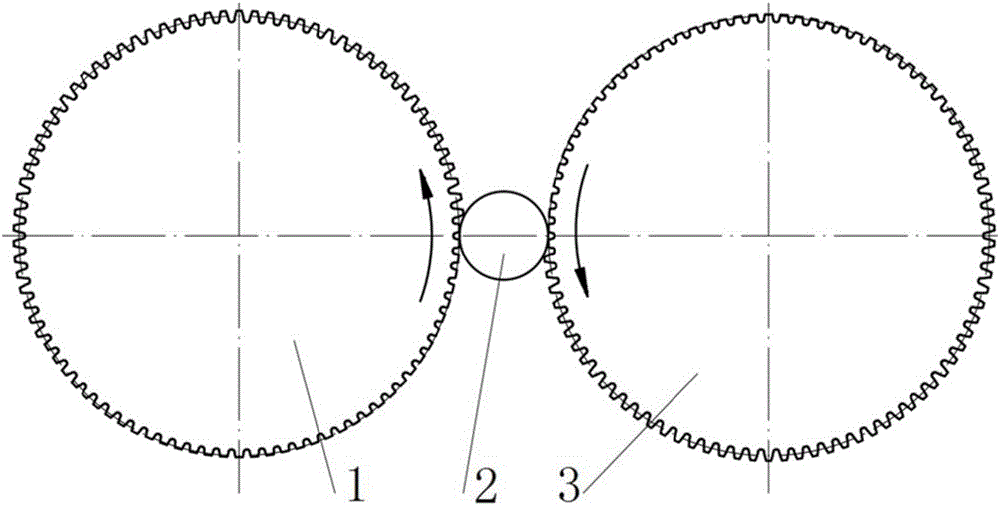

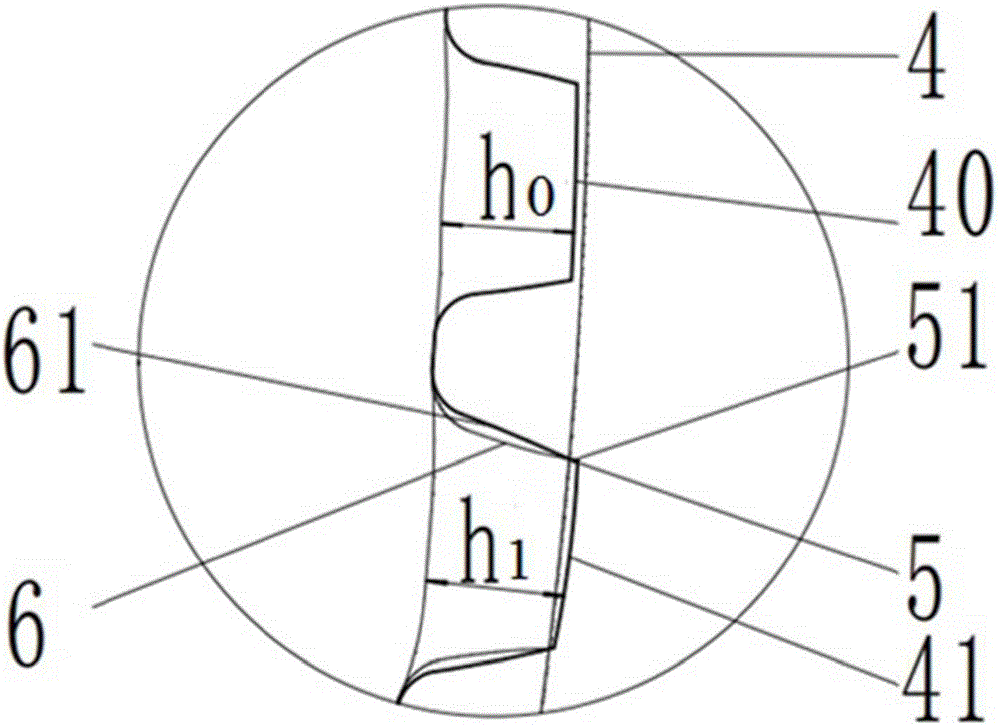

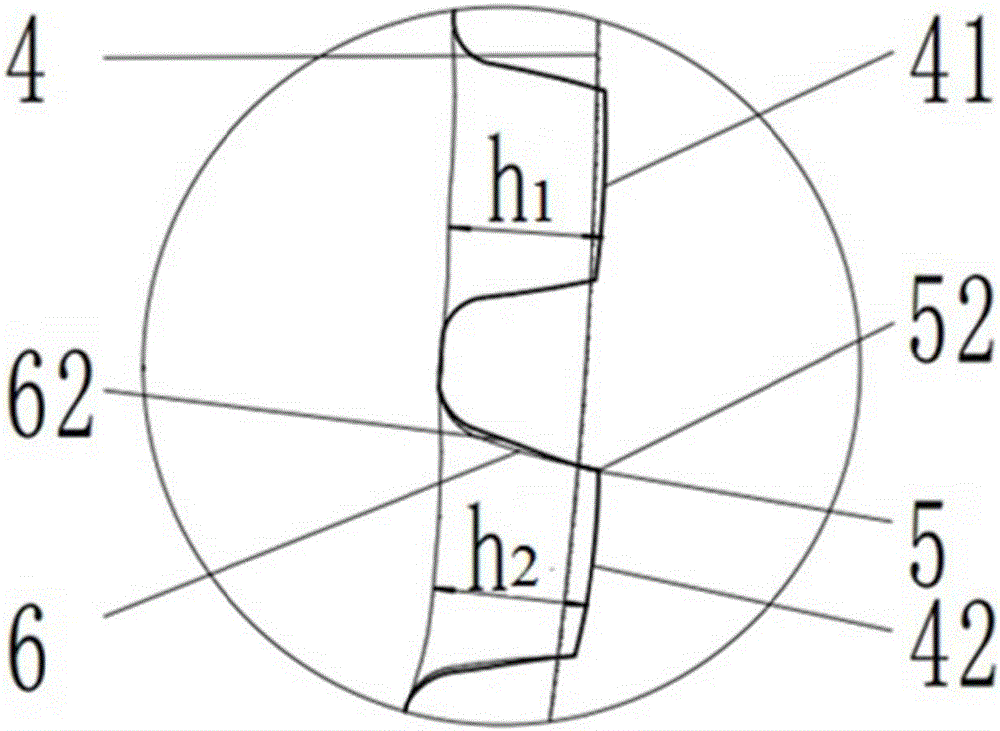

[0028] see Figure 1 to Figure 3 As shown, an involute gear rolling die of the present invention includes a first rolling die 1 and a second rolling die 3, the number of teeth of the first rolling die 1 and the second rolling die 3 is the same, both are Z1 , the modulus is the same, both are m; the first rolling die 1 and the second rolling die 3 are arranged in parallel and at intervals; the first rolling die 1 is provided with the 0th pass tooth area and the 1st pass tooth area in sequence , 2nd pass tooth area...Nth pass tooth area. The number of teeth and the modulus of the target gear obtained after the blank 2 is rolled by the first rolling die 1 and the second rolling die 3 are Z2, m.

[0029] The tooth profile in the tooth area is the same for each pass. The angle difference between the teeth on the first rolling die and the corresponding teeth on the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com