Lubricant for hot extrusion molding titanium alloy pipe as well as preparation method and application thereof

A technology of lubricants and titanium alloys, applied in the direction of lubricating compositions, additives, coatings, etc., can solve the problems of poor fluidity of glass lubricants, peeling and cracking, etc., to ensure bond strength and anti-oxidation effect, improve High temperature viscosity, the effect of avoiding bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: A heat squeezed-type titanium alloy tube in this example is a lubricant according to the mass fraction of 36.5 parts of SIO 2 , 3 copies of Al 2 O 3 23 copies of B 2 O 3 , 19 serving NA 2 O, 6 copies of CaO, 3 serving MgO, 5 parts of BAO, 3 copies of ZnO and 1.5 parts of LIO were prepared.

Embodiment 2

[0029] Example 2: The method of preparing a thermal extrudent titanium alloy tube according to Example 1 is carried out by the following steps:

[0030] First, put the SIO 2 , Al 2 O 3 , B 2 O 3 NA 2 O, CaO, MgO, BAO, ZnO and LIO were mixed uniform, and then heated from 1 h at 1300 ° C for 1 h to give a glass liquid;

[0031] Second, pour the glass fluid into the cold water, cold quench into glass particles, after drying at 25 ° C for 1 h, add absolute ethanol for spherical mill, to obtain glass powder having a particle size of 75 μm, after drying at 60 ° C for 1 h after 200 Sieves to get lubricants.

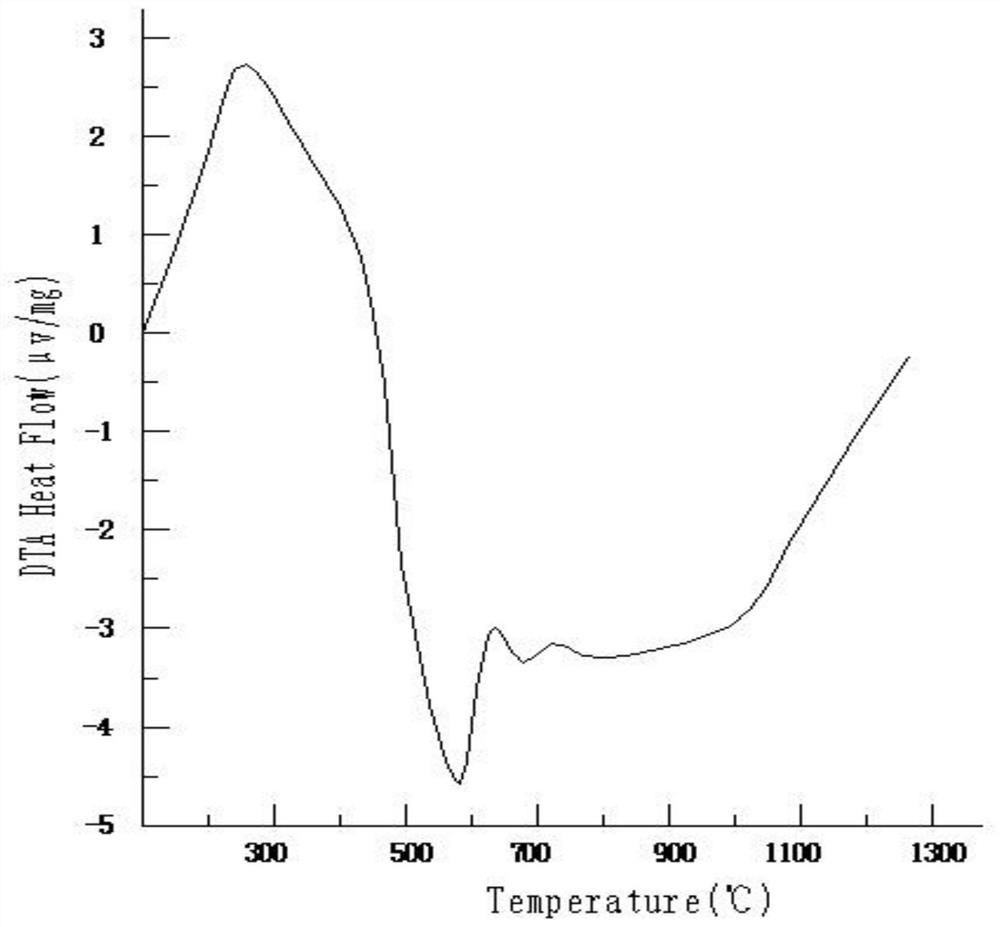

[0032] The lubricant produced by Example 2 was tested, and the specific parameters were: the heating rate was 10 ° C / min, the atmosphere was air, resulting in figure 1 The DTA test diagram shown. From figure 1 It can be seen that there is a softening temperature in 580 ° C. Some weak thermal peaks appeared in the temperature range of 620 ° C ~ 750 ° C, which may be due to the ar...

Embodiment 3

[0033] Example 3: Application of a thermal extrudent type titanium alloy tube according to Example 1, the specific steps are as follows:

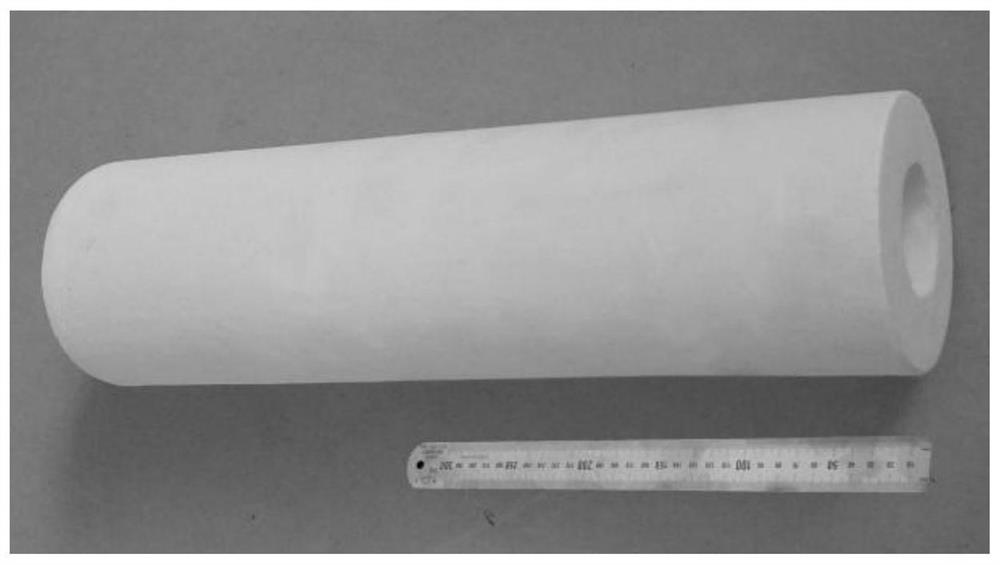

[0034] The heat squeezing-type titanium alloy tube of 24 parts of Example 1 was uniform with 38 parts of the silicone acrylic resin and 38 parts of water, and then applied to the size specification The outer surface of the hollow titanium alloy tube is 0.15 mm, and the thickness is dried at room temperature at 25 ° C to obtain a coating, the size specification is Slider titanium alloy.

[0035] This embodiment is dry and completely after drying. figure 2 As shown, from figure 2 It can be seen that the protective lubricating material is removed evenly in the surface of the titanium alloy, has a certain bond strength, and there is no adverse phenomenon such as bubbling, cracking surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com