High concrete slab rock-fill dam dam-filling space-time pre-settlement control method

A face rockfill dam and rockfill body technology, which is applied in the direction of dams, barrages, barrages, etc., can solve the impact of unsafe operation of the rockfill dam body, cracks in the concrete face, and uneven settlement deformation of the rockfill body of the dam body To avoid cracks in concrete panels, ensure safe and stable operation, and reduce uneven deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

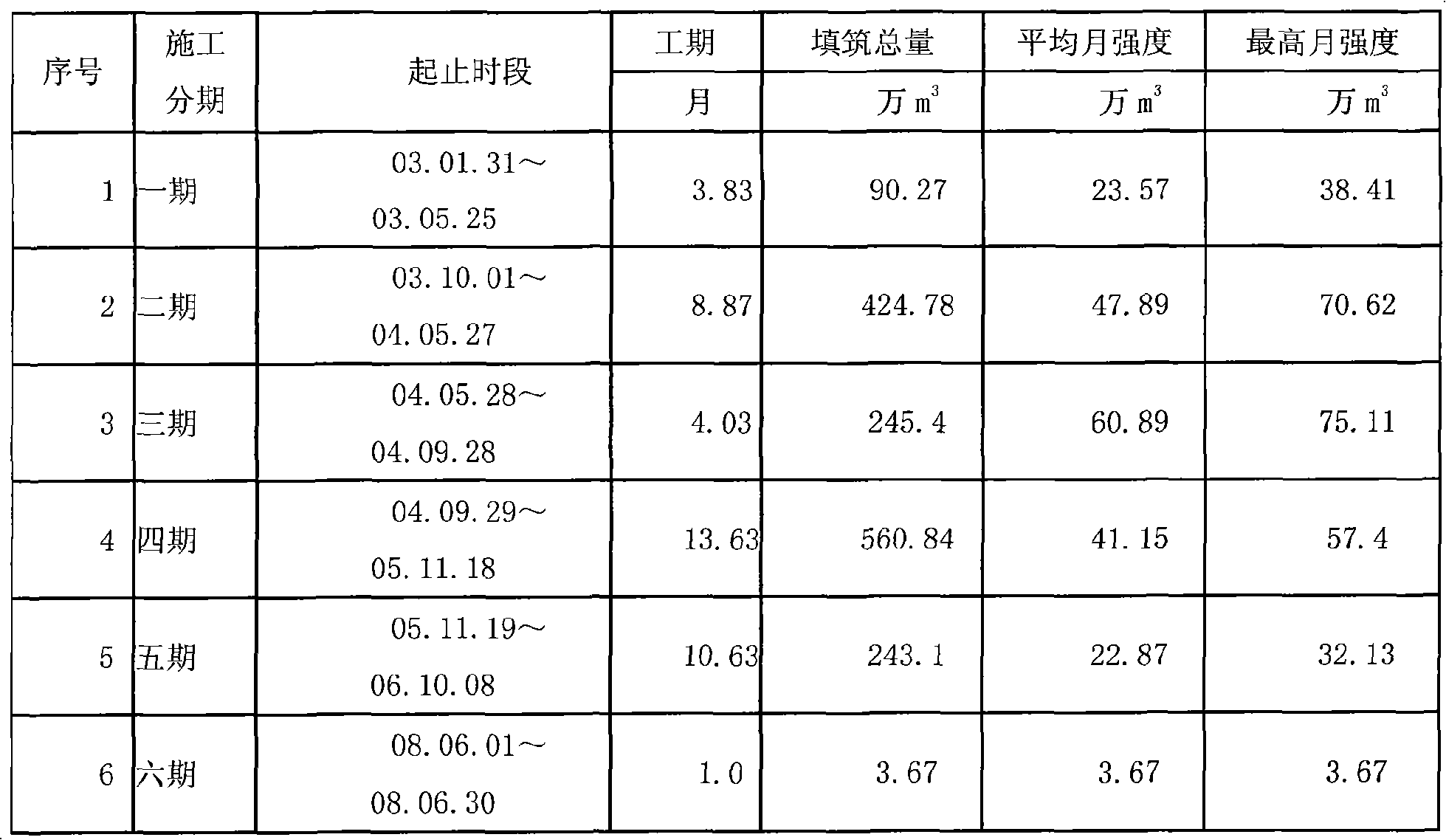

[0015] Table 1 Filling stages and intervals of high rockfill dam body with time-space pre-settlement control method

[0016]

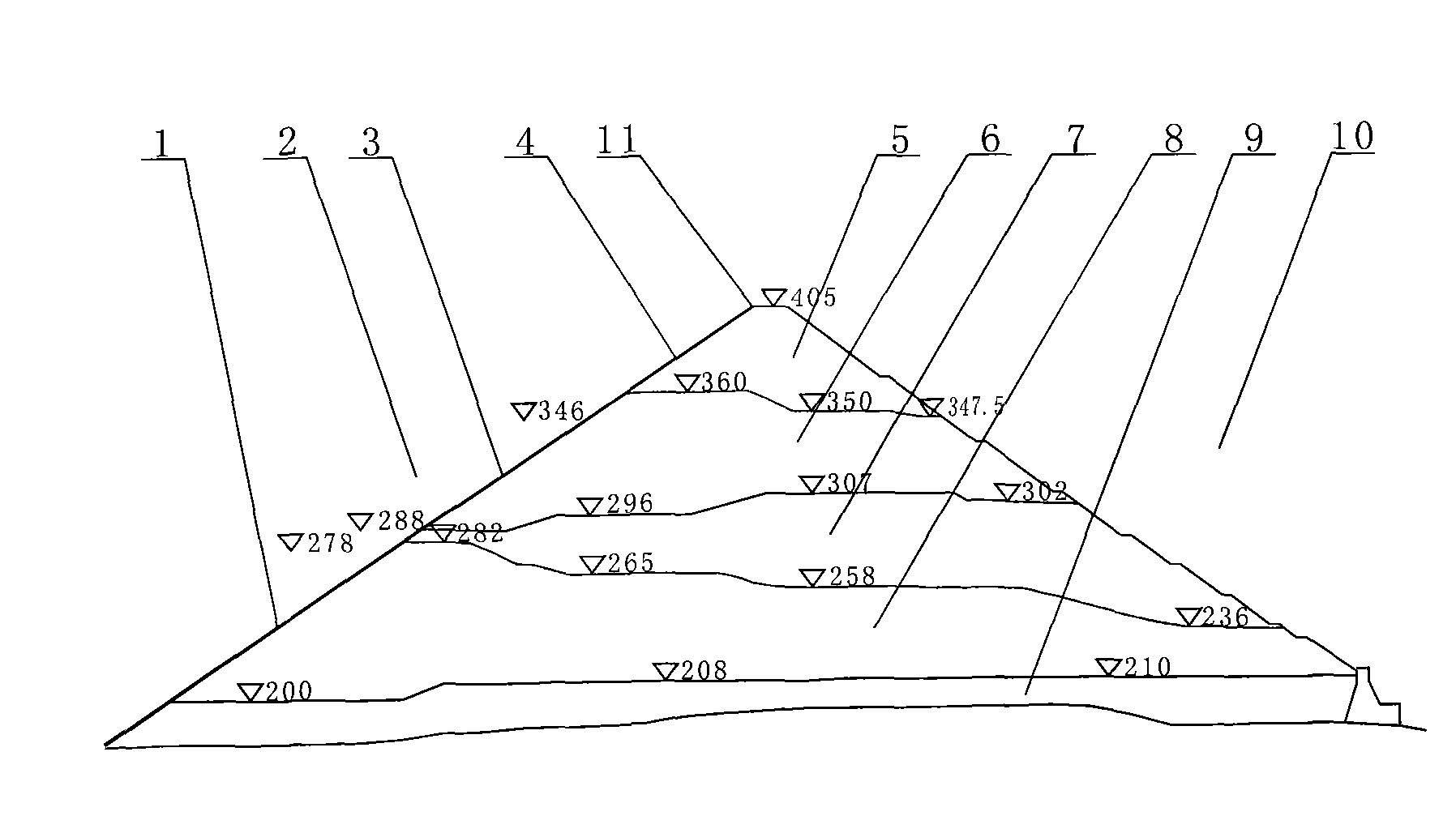

[0017] The main construction steps of the space-time pre-settlement control method for the filling of high face rockfill dams are as follows: figure 1 and as shown in Table 1:

[0018] exist figure 1 In , marker 2 is upstream and marker 10 is downstream. In general, the filling of the dam body is divided into six phases, namely Phase I construction area 9, 8. 7. Phase IV construction area 6, The fifth-phase construction area 5 and the sixth-phase construction area 11; the concrete panel construction is divided into three phases, that is, the first-phase panel 1, the second-phase panel 3 and the third-phase panel 4.

[0019] The interval between the first and second phases of the rockfill dam is nearly 5 months, the continuous high-intensity construction is adopted between the third and fifth phases of rockfill dam filling, and the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com