Method for improving wall-thickness uniformity during large-sized thick-wall pipe vertical hot extrusion process

A technology of vertical extrusion and thick-walled pipes, which is applied in the direction of metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problem of uneven wall thickness of large-diameter thick-walled pipes, and improve the uniformity of wall thickness , prolong the service life and save the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The main components of the nickel-based heat-resistant alloy in the embodiment of the present invention are as follows: C: 0.03%; Cr: 24.1%; Co: 19.8%; Si: 0.05%; Mn: 0.07%; Al: 1.45%; Ti: 1.38%; Nb: 1.2%; B: 0.002%; Zr: 0.08%; P: 0.001%; S: 0.0005%; Ni is the balance and unavoidable impurity element. The product specification is a large-diameter thick-walled heat-resistant alloy pipe with an outer diameter of Φ460mm and a wall thickness of 80mm.

[0045] According to the above composition, the invention produces a tube blank with an outer diameter of Φ945mm x wall thickness of 320mm x 1000mm through VIM smelting + VAR self-consumption of a furnace of 7 tons of nickel-based heat-resistant alloy.

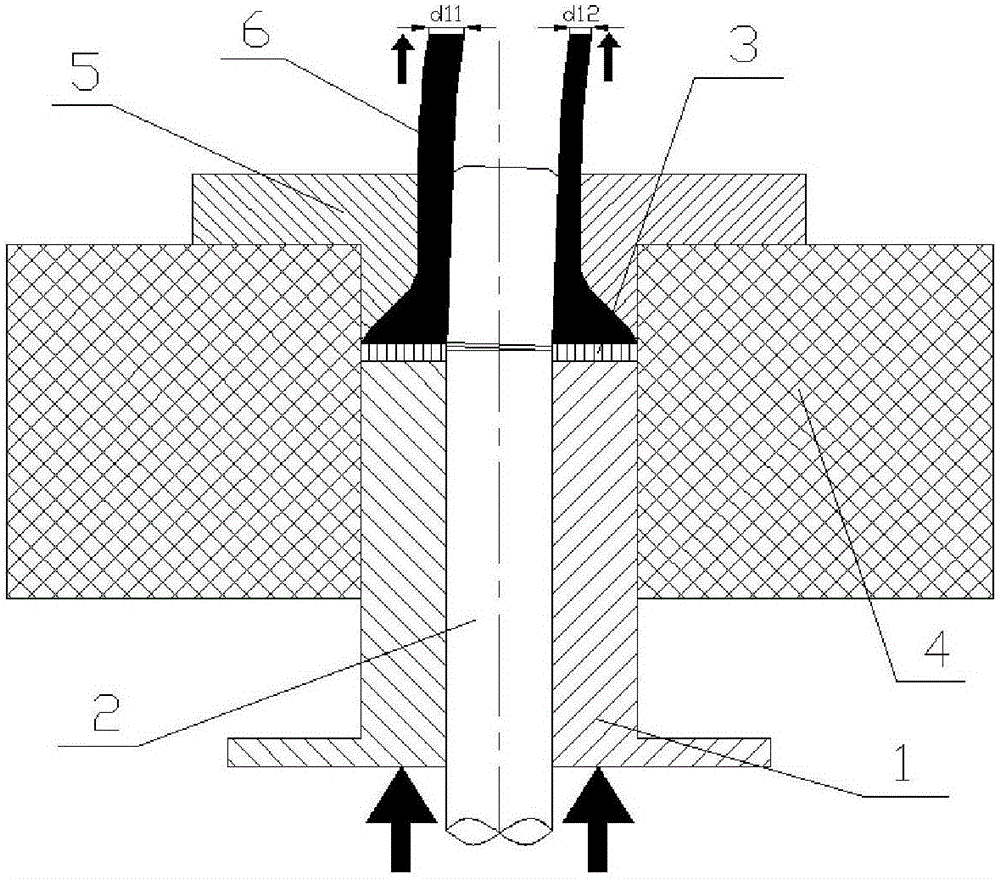

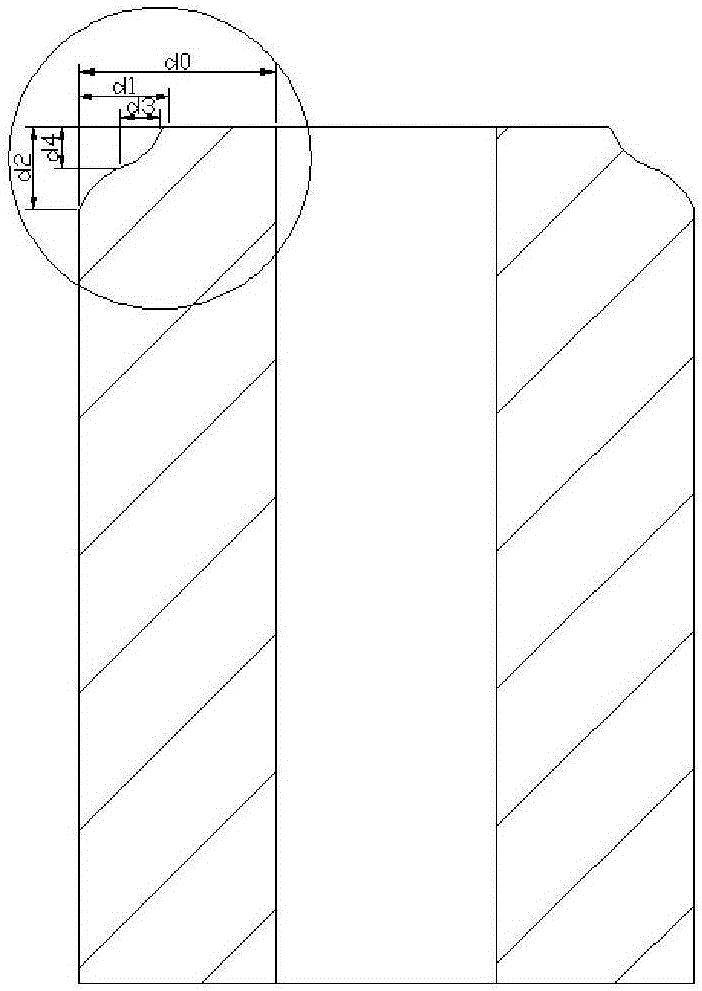

[0046] The special process of the present invention is as follows: the tube blank is hollow cylindrical, and the extrusion front end is processed into a specific shape matching the extrusion die, see Figure 4 . The mold preheating temperature is 390°C. The furnace temper...

Embodiment 2

[0049] Example 9 of the present invention: Cr-3W-3Co series martensitic heat-resistant steel (ferritic system) The weight percentage of the main components is: C: 0.080%; Cr: 8.99%; Si: 0.30%; Mn: 0.50%; Co: 3.01 %; W: 2.81%; V: 0.21%; Nb: 0.53%; N: 0.008%; B: 0.014%; Cu: 0.8%; impurity elements. The product specification is a large-diameter thick-wall heat-resistant steel pipe with an outer diameter of Φ590mm×a wall thickness of 90mm.

[0050] The present invention smelts 40 tons of molten steel according to the above-mentioned composition EAF+LF+VD process, casts 3 steel ingots, selects two for comparison hot extrusion, and makes tube blanks with outer diameter Φ1080mm×wall thickness 330mm×length 1400mm respectively. One is implemented according to the existing technology; the other is implemented according to the process of the present invention, that is, the tube blank extrusion front end is processed into a specific shape, the lower limit extrusion temperature is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com