Structure of rubber sealing ring radial sealing connector with automatic centering section

A rubber sealing ring, self-centering technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of torsional deformation and tearing of the sealing ring, abnormal wear of the contact surface of the sealing ring, and large extrusion deformation of the sealing ring. , to reduce uneven deformation, improve reliability, reduce torsion and tear failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

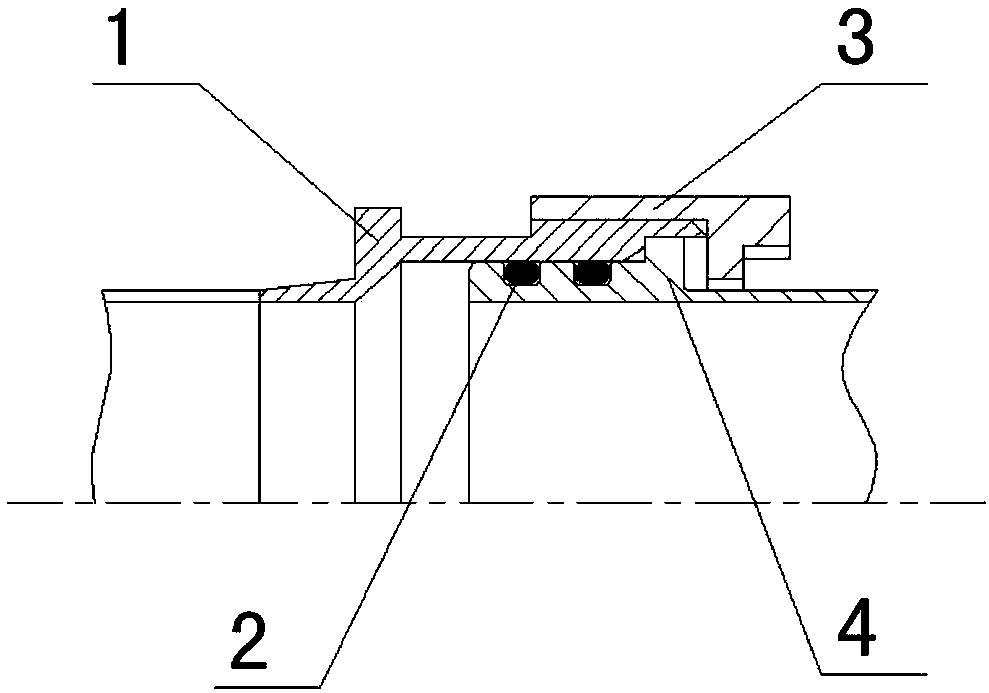

[0017] The present invention provides a structure of radial sealing joint of rubber sealing ring with self-centering section, which is characterized in that: the structure of radial sealing joint of rubber sealing ring with self-centering section includes light hole bushing Joint, rubber sealing ring, outer casing nut, flat head joint with sealing ring groove;

[0018] The sealing structure has the following technical features: 1) Increase the structural size of the sealing ring installation groove to ensure enough space to adapt to the oil absorption volume expansion of the sealing ring, the internal stress of the sealing ring is stable, and can adapt to the installation requirements of sealing rings of different materials. 2) After the sealing ring is installed, the deformation and stress are uniform everywhere on the circumference, which improves the sealing effect. 3) After installation, the center of each structural part is consistent, which reduces the risk of wear and t...

Embodiment 2

[0024] The present invention provides a structure of radial sealing joint of rubber sealing ring with self-centering section, which is characterized in that: the structure of radial sealing joint of rubber sealing ring with self-centering section includes light hole bushing Joint, rubber sealing ring, outer casing nut, flat head joint with sealing ring groove;

[0025] The sealing structure has the following technical features: 1) Increase the structural size of the sealing ring installation groove to ensure enough space to adapt to the oil absorption volume expansion of the sealing ring, the internal stress of the sealing ring is stable, and can adapt to the installation requirements of sealing rings of different materials. 2) After the sealing ring is installed, the deformation and stress are uniform everywhere on the circumference, which improves the sealing effect. 3) After installation, the center of each structural part is consistent, which reduces the risk of wear and t...

Embodiment 3

[0030] The present invention provides a structure of radial sealing joint of rubber sealing ring with self-centering section, which is characterized in that: the structure of radial sealing joint of rubber sealing ring with self-centering section includes light hole bushing Joint, rubber sealing ring, outer casing nut, flat head joint with sealing ring groove;

[0031] The sealing structure has the following technical features: 1) Increase the structural size of the sealing ring installation groove to ensure enough space to adapt to the oil absorption volume expansion of the sealing ring, the internal stress of the sealing ring is stable, and can adapt to the installation requirements of sealing rings of different materials. 2) After the sealing ring is installed, the deformation and stress are uniform everywhere on the circumference, which improves the sealing effect. 3) After installation, the center of each structural part is consistent, which reduces the risk of wear and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com