Cold machining method for GH4099 high-temperature alloy wire

A technology of high-temperature alloy wire and cold processing, applied in metal processing equipment, manufacturing tools, hammers, etc., can solve the problems of increasing production costs of enterprises, affecting economic benefits, and damage to the surface of wire materials, so as to reduce uneven deformation and excellent surface quality , the effect of uniform distribution of tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0024] A1. Place the hot-rolled bar with a diameter of φ10mm in a heat treatment furnace with a protective atmosphere for solution heat treatment; the temperature of the solution heat treatment is 1150°C, and the holding time of the solution heat treatment is 60min; the bar after solution heat treatment carry out air cooling;

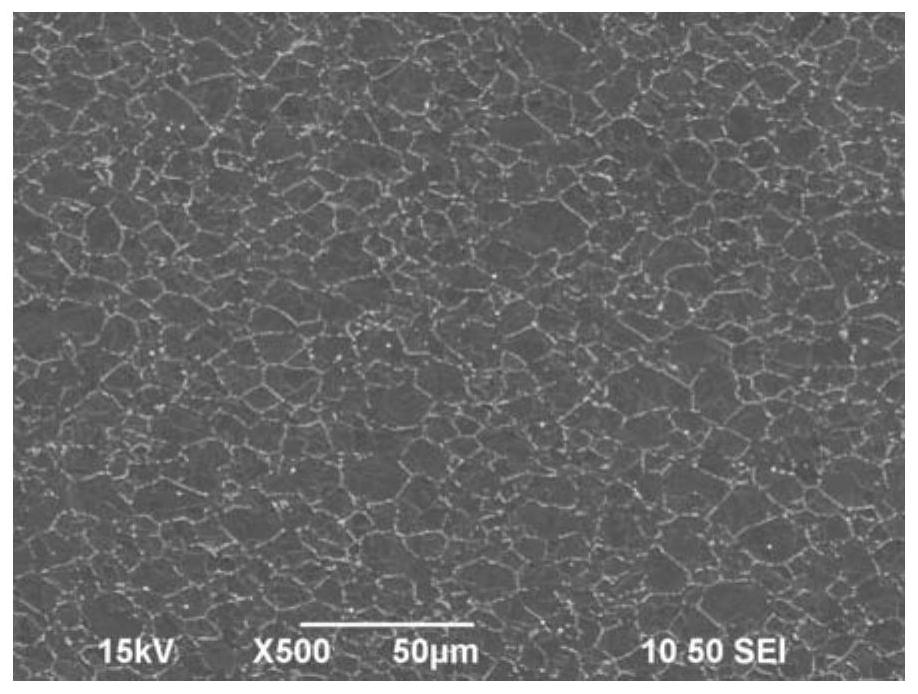

[0025] B1, the φ10mm bar after the solution heat treatment described in the above step A1 is passed through φ10mm → φ7.8mm (deformation 39%) → φ6.5mm (deformation 31%) → φ5.3mm (deformation) using a swaging machine weight 36%)→φ4.3mm (deformation 34%) four-pass rotary forging reduction treatment, vacuum annealing treatment is carried out in a vacuum heat treatment furnace after each pass reduction, and the vacuum degree is -3 Pa, the annealing temperature is 1050°C, the holding time is 30min, and the annealing cooling method is filled with argon for cooling;

[0026] C1. The annealed wire material of φ4.3mm obtained in step B1 is subjected to the last p...

specific Embodiment 2

[0029] A2. Place the hot-rolled bar with a diameter of φ8mm in a heat treatment furnace with a protective atmosphere to carry out solution heat treatment; the temperature of the solution treatment is 1130° C., and the holding time of the solution treatment is 60 minutes;

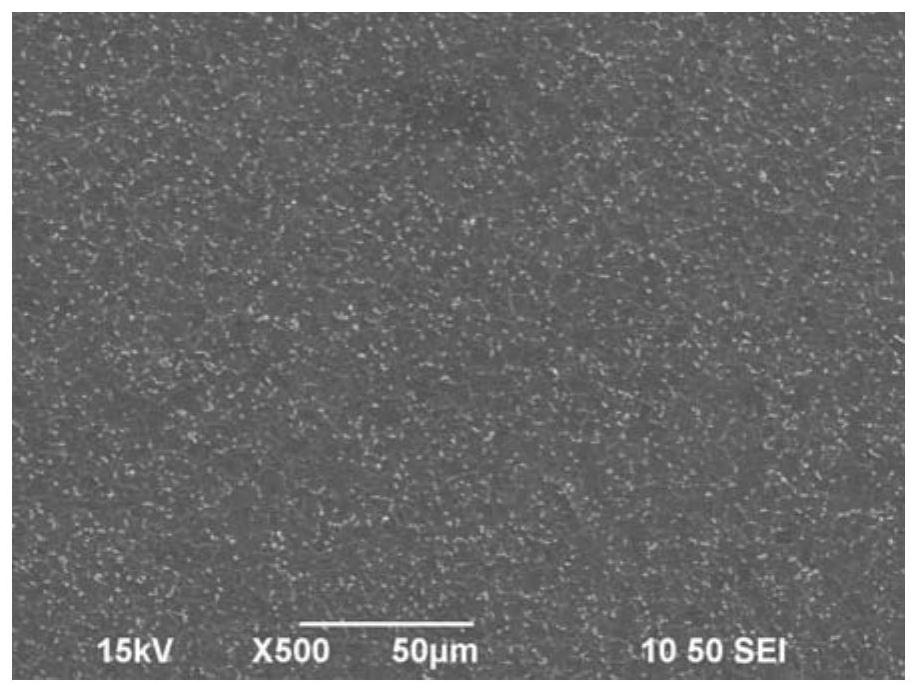

[0030] B2, the φ8mm bar after the solid solution treatment described in the above step A2 is passed through φ8mm→φ6.3mm (deformation 38%)→φ5.0mm (deformation 37%)→φ4.0mm (deformation) by swaging machine 36%)→φ3.2mm (deformation 36%) four-pass rotary forging diameter reduction treatment, vacuum annealing treatment is carried out in a vacuum heat treatment furnace after each pass diameter reduction, and the vacuum degree is -3 Pa, the annealing temperature is 1050°C, the holding time is 30min, and the annealing cooling method is filled with argon for cooling;

[0031] C2. The annealed wire material of φ3.2mm obtained in step B2 is subjected to the last pass of swaging to reduce the diameter to φ3mm (12% deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com