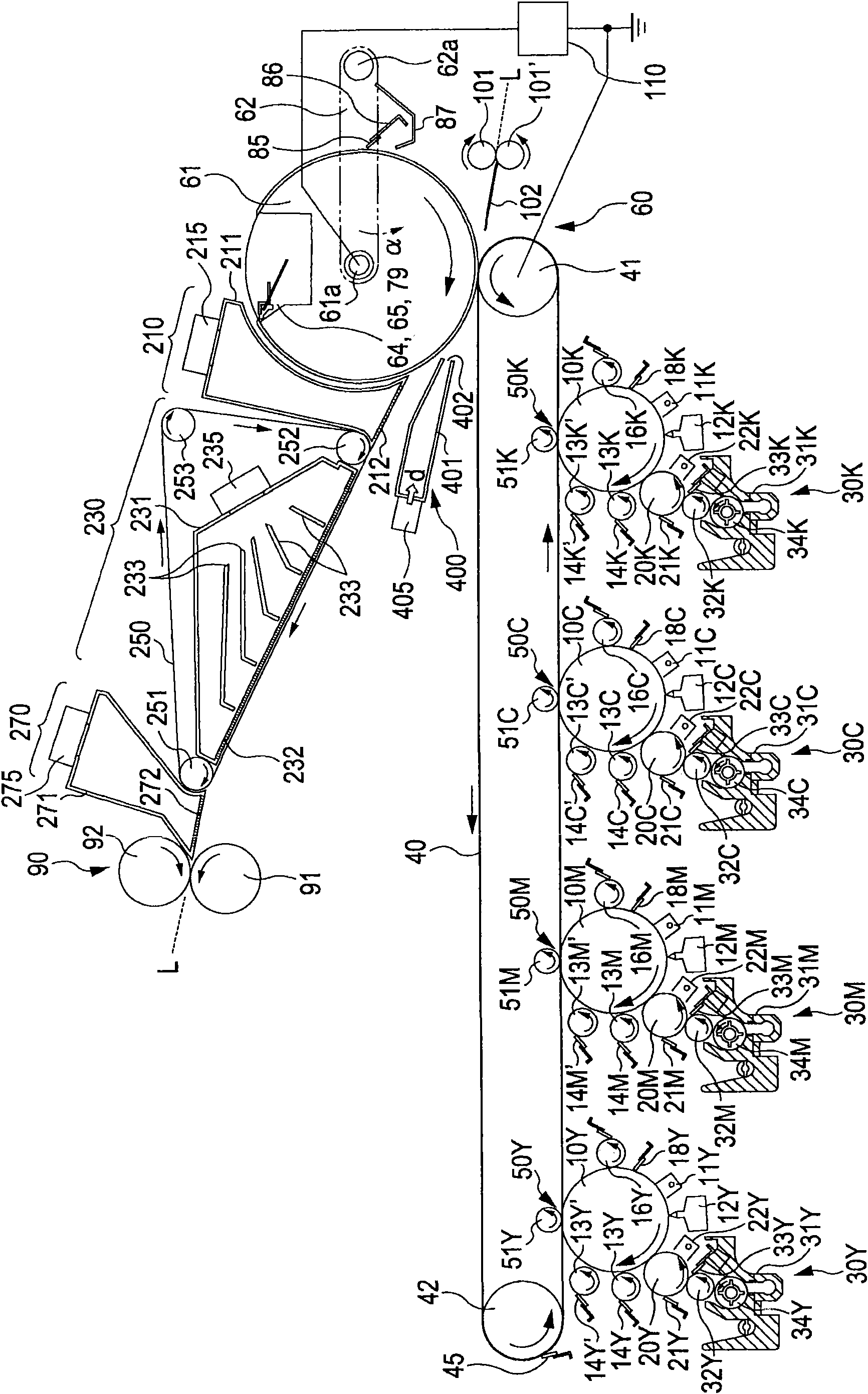

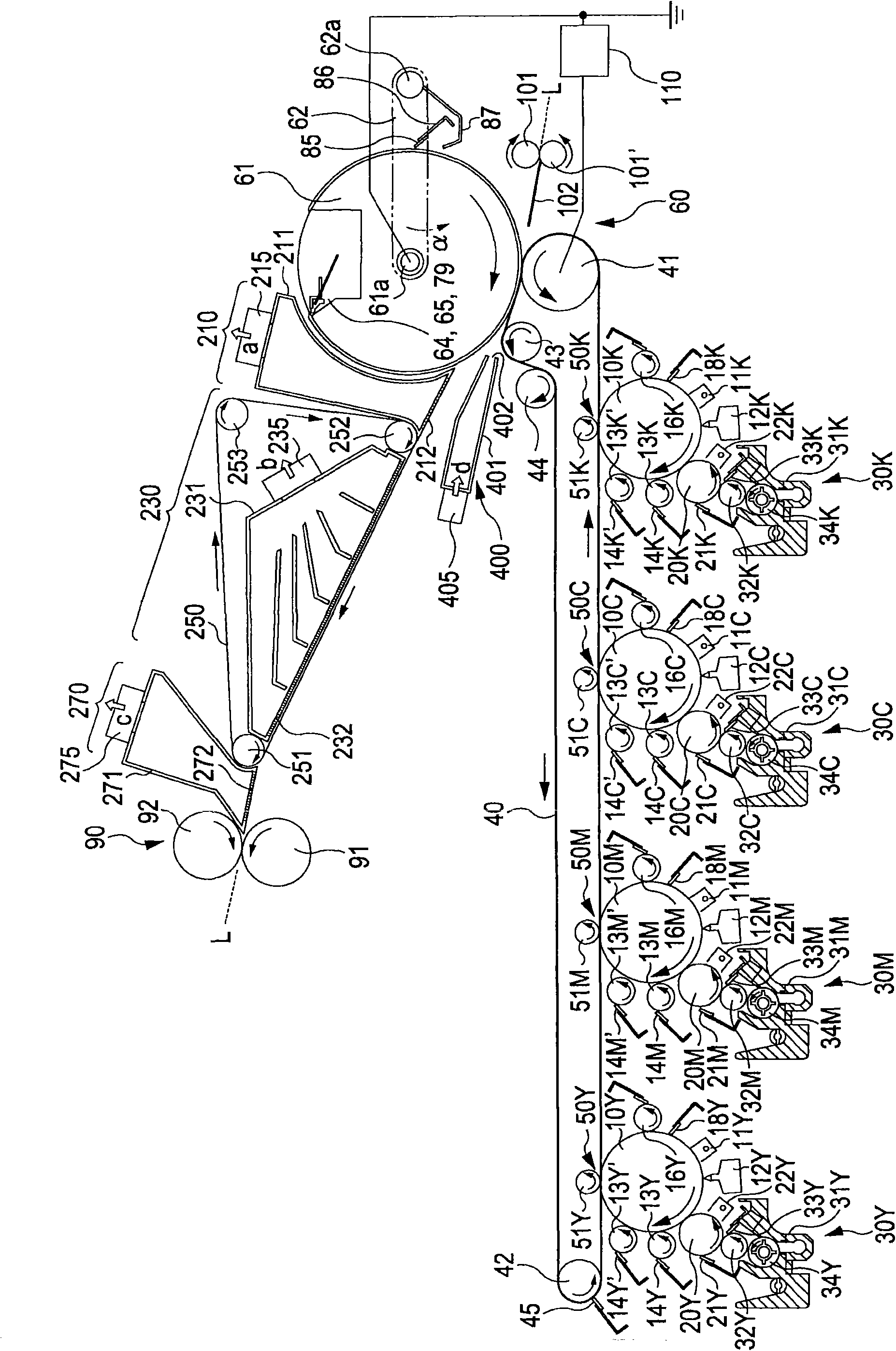

Transfer apparatus, image forming apparatus, and image forming method

An image and transfer member technology, applied in the field of transfer devices, can solve the problems of stress concentration skew and shortened life, and achieve the effects of preventing accumulated skew, reducing offset, and reducing skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

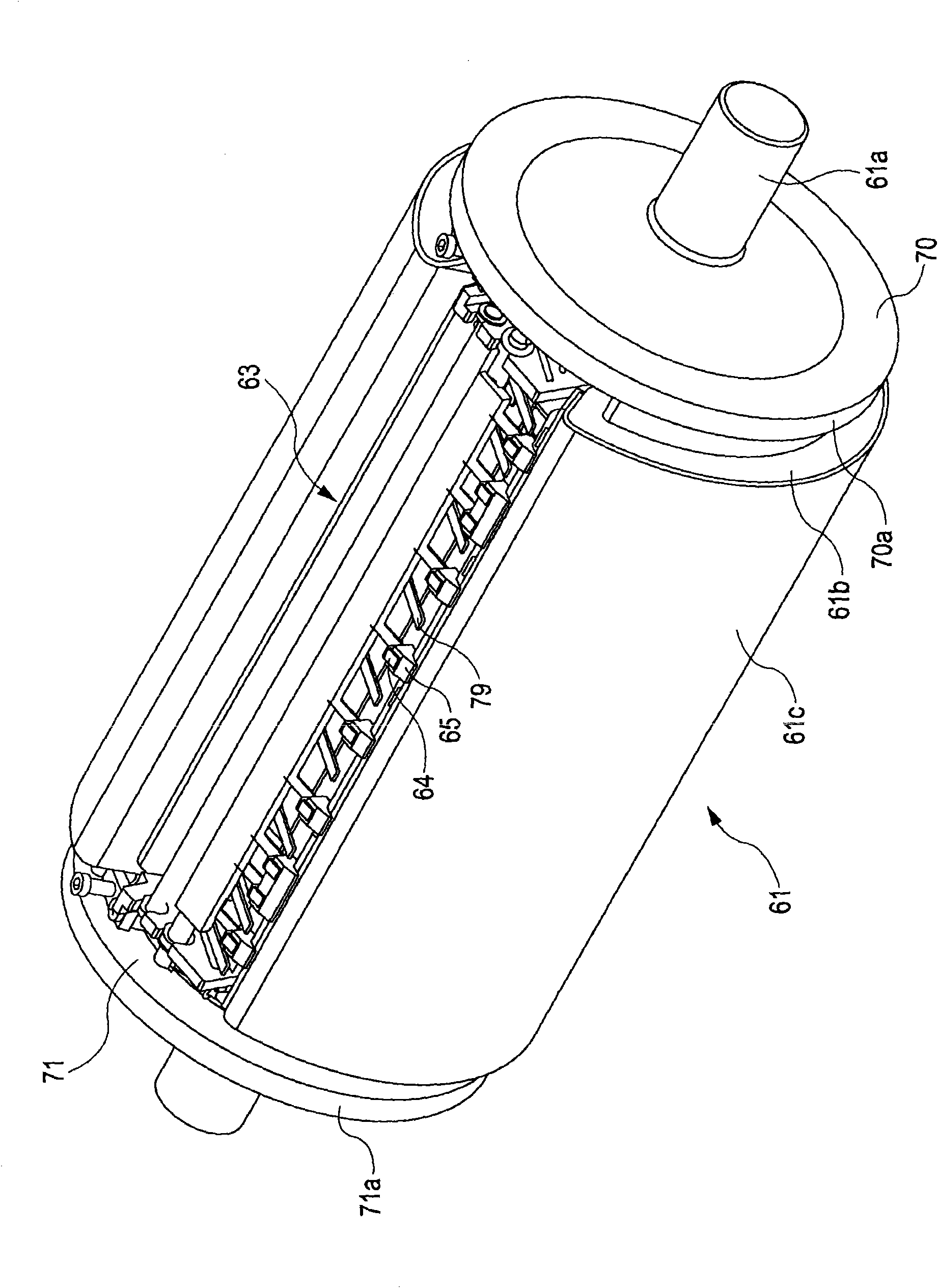

[0105] The rubber sheet 61c of Example 1 has the following structure.

[0106] Structure: single layer

[0107] Volume resistivity: 1×10 10 (Ω·cm)

[0108] Material: polyurethane rubber,

[0109] Film thickness: 0.5mm

[0110] Conductive Materials: Ionically Conductive Materials

[0111] Sheet surface hardness: JISA90°

[0112] In addition, the intermediate transfer belt 40 of Example 1 has the following structure.

[0113] Structure: single layer belt

[0114] Material: Polyimide resin

[0115] Film thickness: 100μm

[0116] Conductive material: Electron conductive material (carbon)

[0117] As a result of using such a rubber sheet 61c and the intermediate transfer belt 40 in the image forming apparatus of the first embodiment having a single-pinch structure, the secondary transfer property to coated paper can be improved.

Embodiment 2

[0119] The rubber sheet 61c of Example 2 has a two-layer structure and has the following structure.

[0120] Structure: 2 layers (Young's modulus 2GPa)

[0121] Volume resistivity: 1×10 7 (Ω·cm)

[0122] ·Substrate layer

[0123] Material: Polyimide

[0124] Film thickness: 90μm

[0125] Conductive material: Electron conductive material (carbon)

[0126] · Elastic layer

[0127] Material: polyurethane rubber

[0128] Film thickness: 3.0mm

[0129] Conductive material: Electron conductive material (carbon)

[0130] Sheet surface hardness: JISA35°

[0131] In addition, the Young's modulus of the rubber sheet 61c should just be 2-5 GPa. In addition, the conductive material of the rubber sheet 61c may be a mixed conductive material containing an ion conductive material or an electronic conductive material (carbon) and an ion conductive material. Furthermore, the rubber hardness may be 30° to 70°.

[0132] In addition, the intermediate transfer belt 40 of Example 2 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com