Angle swage block and forging technology using same

A technology of angle and process, applied in forging equipment and its application fields, can solve problems such as poor control of metal flow direction, difficulty in anvil processing, and no consideration of enhancing the compaction effect of large forgings, so as to eliminate existing defects and prevent new defects The effect of generation and deformation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides an angled anvil and a forging process using the angled anvil. The present invention will be further described below through the description of the drawings and specific implementation methods.

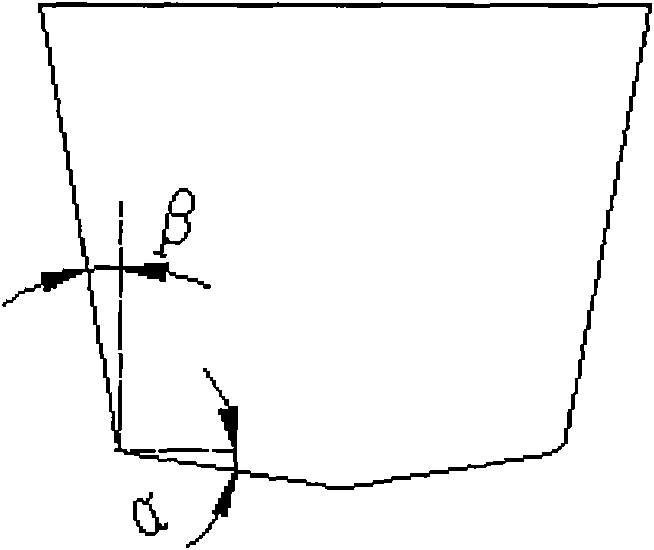

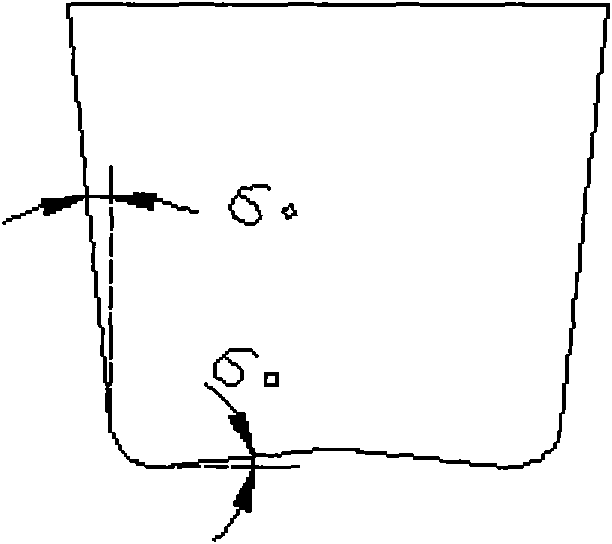

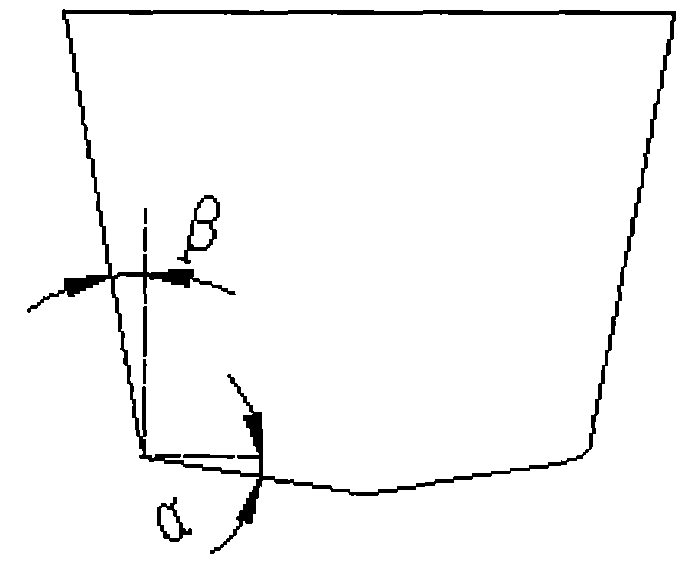

[0024] figure 1 Schematic diagram of the cross-section of an angled anvil. The angled anvil is a columnar body with the same cross section at each position. Its working surface consists of 4 surfaces, which are the upper surface, the left side, the right side and the lower surface: the upper surface is a plane; the left side and the right side are inclined planes, and the vertical direction The included angle is the same, set to β, and 0°≤β≤12°, this lateral angle makes the metal at the contact position between the forging and the angled anvil easy to flow, and slows down the deformation gradient distribution generated by the anvil angle, thereby avoiding cracks; the lower surface is a curved surface, the curved surface is left-right symmetrical,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com