Short-process rolling method for cold-rolled 5182 alloy tank cover material

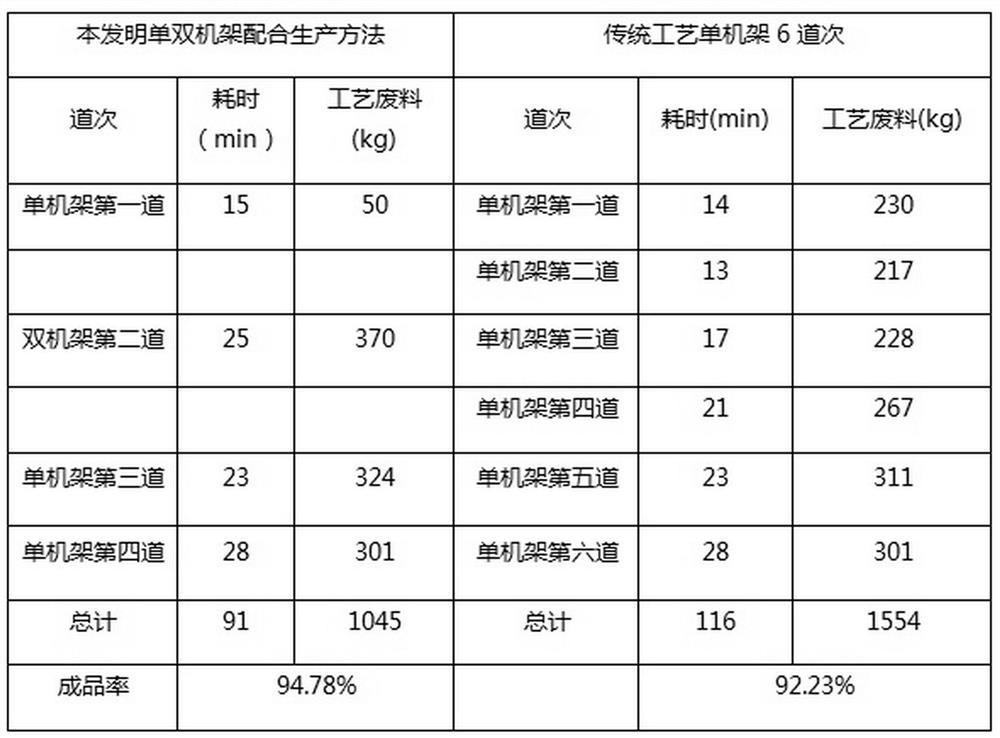

A short process, can lid technology, used in metal rolling and other directions, can solve the problems of reducing product yield, increasing bump defects, and increasing machine times, so as to improve yield, enhance lubrication and cooling effects, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the present invention is a short-process rolling method of cold-rolled 5182 alloy can lid material. First, the can lid base material is melted and casted, sawed, baht surface, soaked, and (1+4) hot continuous rolling. Thickness is 2.8mm can lid sheet material, and the can lid sheet material of making is carried out cold-rolling processing simultaneously, wherein the sheet material is carried out cold-rolling processing and comprises the following steps:

[0027] Step 1, single-stand blanking: transfer the plate to a single stand, and perform single-stand cold rolling, and the thickness of the plate after single-stand cold rolling is converted from 2.8mm to 1.38mm, so as to realize the blanking process of the plate, and then Realize the first cold rolling process to the plate;

[0028] Step 2, double-stand edge trimming: this pass must be produced by a double-stand cold rolling mill, and the plate processed in step 1 is transferred to the double-stand, and ...

Embodiment 2

[0032] Embodiment two, on the basis of embodiment one, in order to improve the cold-rolled quality, avoid raising the pass rate of the product, strengthen the cold-rolled effect, all add cooling process after the plate is processed through step one and step two, make the plate after rolling The temperature is lowered to below 60°C for subsequent operations. This embodiment provides a specific cooling method. The cold-rolled plate is placed in an elevated warehouse for blowing and cooling. The opening of the cooling valve is greater than 65%, and the cooling time is After 48 hours, the temperature of the plate was cooled to below 60°C.

Embodiment 3

[0033] Embodiment 3, on the basis of Embodiment 2, as the diameter of the roll decreases, the contact arc between the roll and the rolling piece decreases, the contact area also decreases, the influence of external friction decreases, the unit rolling force decreases and the load decreases at the same time, The torque of the rolling mill will also be reduced, so in step 1, billets are rolled with work rolls with a diameter of less than 420mm to reduce the rolling force and torque, so as to obtain the maximum processing rate of non-finished products in a single pass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com