Waste rock bag roadside support method for anchoring low coal seam with strong roof

A technology of hard roof and roadside support, which is used in earth-moving drilling, filling, safety devices, etc., can solve the problems of high cost of filling materials such as concrete, local stress concentration of filling body, and complicated construction process, so as to improve the initial support. The effect of protecting strength, reducing gaps, enhancing integrity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

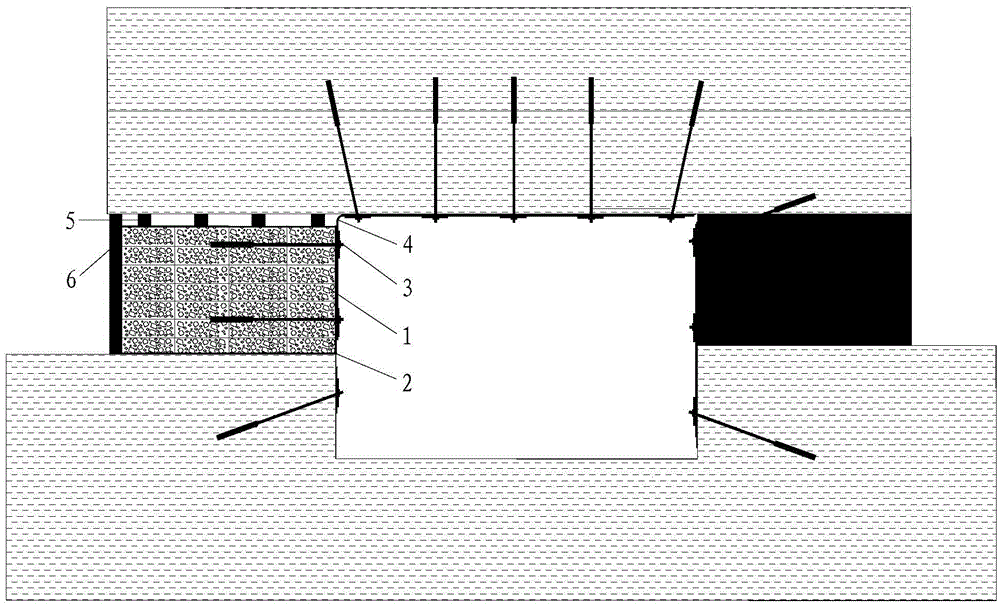

Embodiment 1

[0037] As the working face advances, the top-cut log pillars 6 are arranged along the empty side of the filling body next to the lane, the pillar diameter is not less than 150mm, the height is not less than 1200mm, and the spacing is 1.0m. The pillar and the roof are connected by wooden wedges, and the top-cut pillar No withdrawal for permanent support;

[0038] Then build and fill the bag, clean the bottom of the roadway to the hard bottom before building, and then lay the plastic double-resistance net 2 on the bottom of the roadway, roll the remaining part, and tie the gangue with a woven bag for the construction work. The gaps between are filled with clay bags to reduce air leakage in the mined-out area. The side of the filling body after lining the filling body is vertical to the top and bottom plate into a plane, the filling step is 2.0m, the filling width is 2.5m, and the width of the left lane is the same as the original roadway width Similarly, when the height of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com