Method for constructing reservoir dam

A technology for reservoirs and dams, applied in dams, barrages, weirs, etc., can solve problems such as uncoordinated deformation and force, dam body stability and deformation, and inability to prevent seepage layers, etc., to ensure dam body stability and reduce The effect of uneven deformation of the dam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

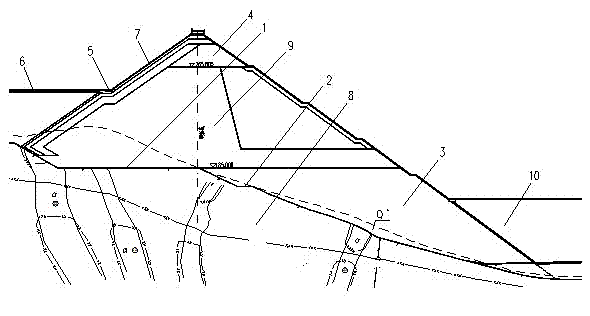

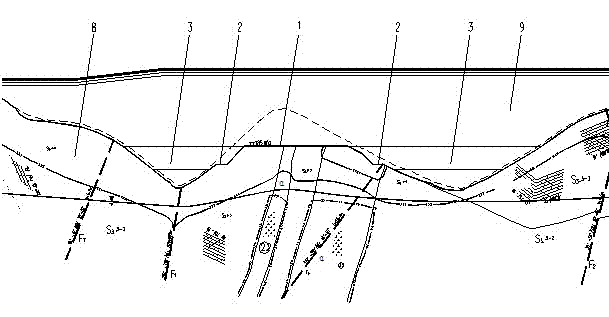

[0024] see figure 1 and figure 2 . This embodiment relies on the main dam project of the upper reservoir of the Liyang Pumped Storage Power Station. The main dam of the Upper Reservoir is a reinforced concrete face rockfill dam with a crest elevation of 295.00m, a crest width of 10m, a maximum dam height of 165.00m (at the dam axis), and a crest length of 1113.20m. The surface-to-slope ratio is 1:1.45. The cross-section of the dam foundation 8 is W-shaped, the middle of the W represents a mountain ridge, and the bottom of the W represents two ravines; the longitudinal slope of the foundation is greater than 17°.

[0025] (1) Cut the raised part of the mountain ridge into a platform 1 with a width of about 110m and a height of about 30m; excavate a horizontal platform 2 with a width of about 10m along the longitudinal slope of the foundation.

[0026] (2) The dam body 9 is filled on the dam foundation treated in step (1). During the dam construction process, the bottom and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com