Anchor rod combined anti-floating system

An anchor and system technology, applied in sheet pile walls, protection devices, buildings, etc., can solve the problem of structural bottom plate, column rupture and damage accidents, less composite components and combination forms, and failure of anti-floating anchor rod and anchor cable force, etc. problems, to achieve good construction convenience, reduce uneven deformation, and good structural reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

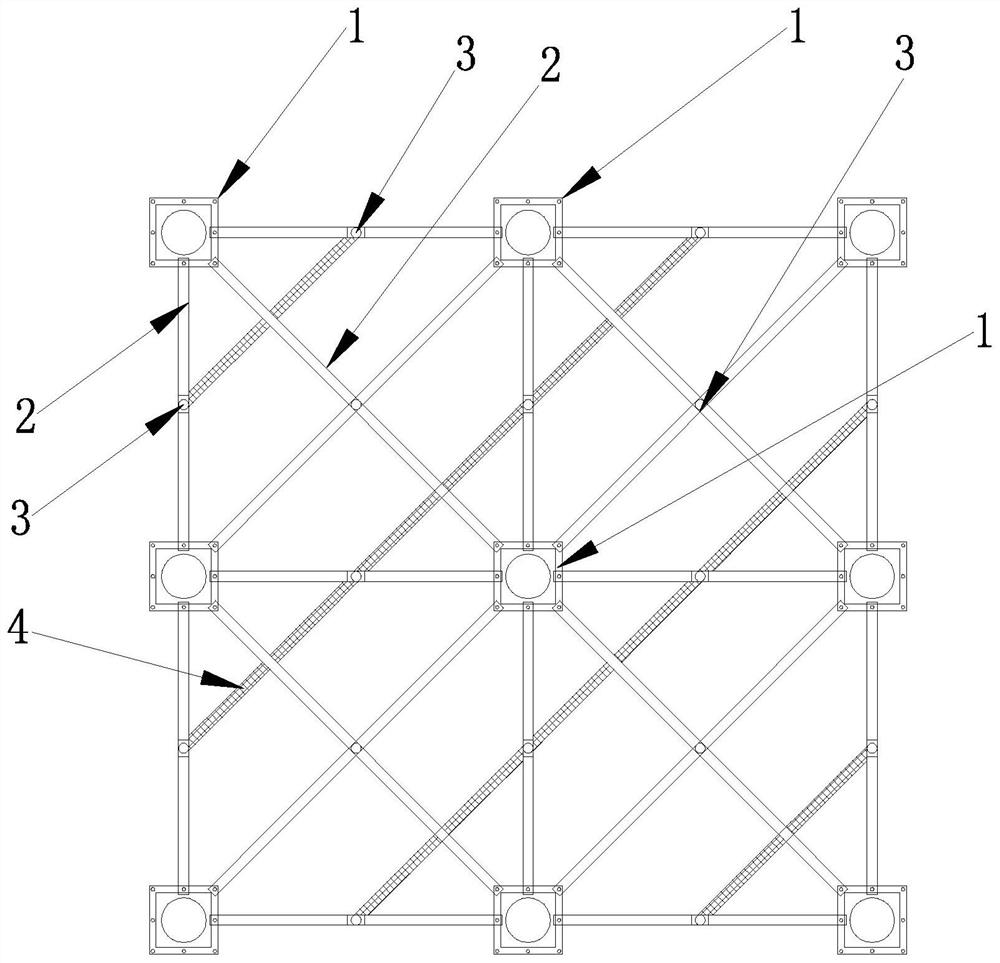

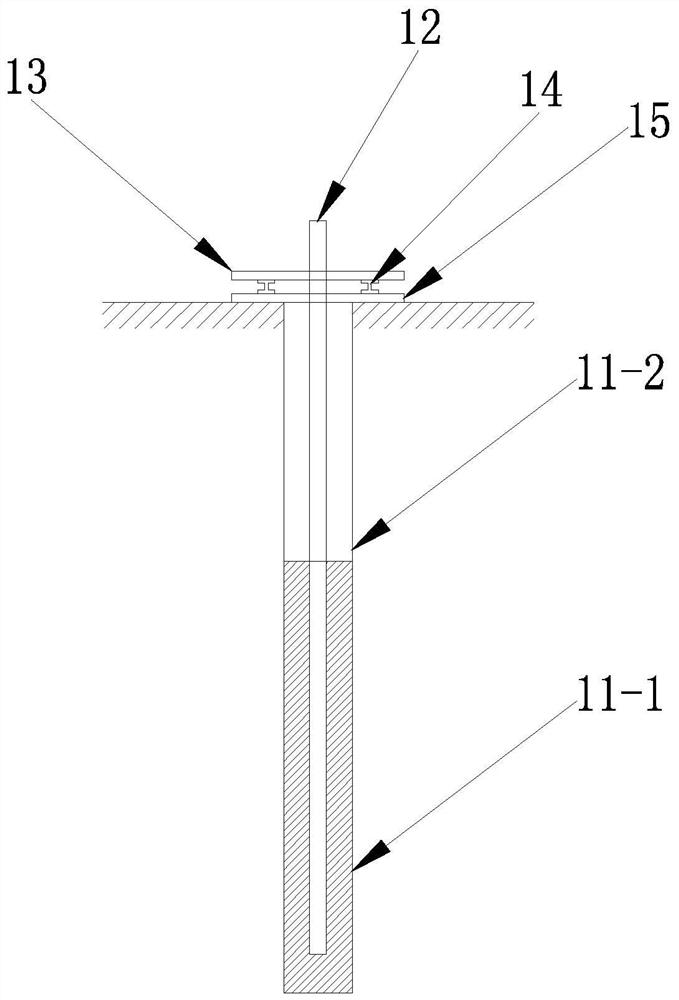

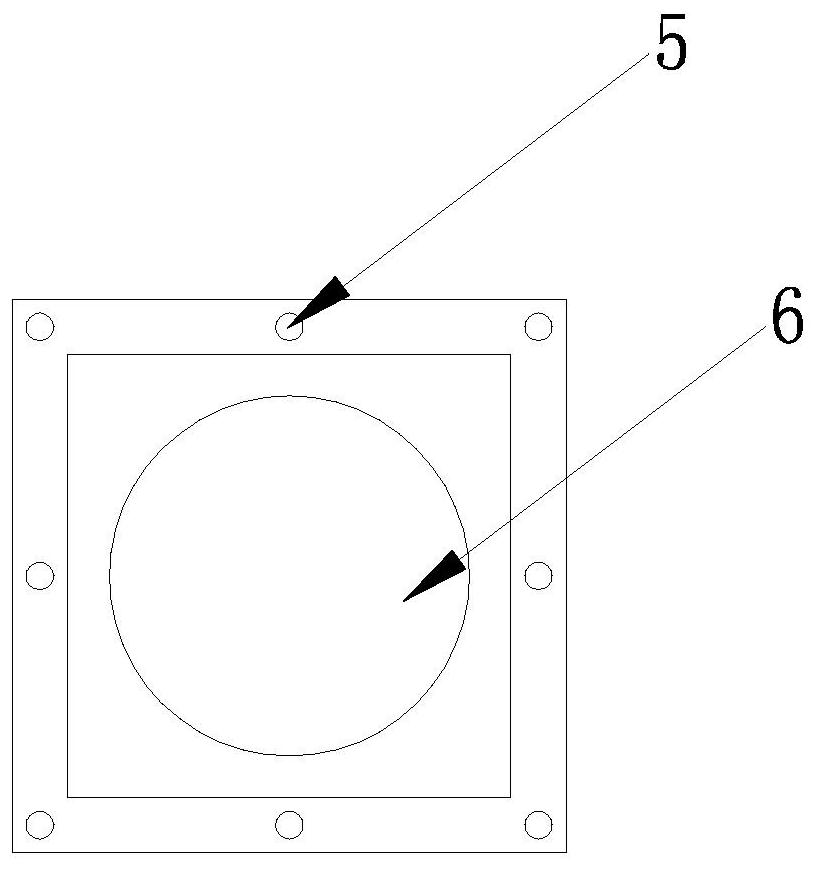

[0026] Example: such as Figure 1-4 As shown, the present invention discloses an anchor combination anti-floating system, including: several main anti-floating anchor assemblies 1, channel steel purlins 2, anchor holes 3 of auxiliary anchoring components and supporting purlins 4; wherein, the main anti-floating anchor The component 1 includes a drill hole 11, a bolt body 12, a polygonal backing plate 13, an I-shaped spacer 14 and a conventional backing plate 15; the I-shaped spacer 14 mainly includes a bolt through hole 5 and an anchor hole 6; the polygonal spacer An anchor hole 6 is formed in the middle of the plate 13 and the conventional backing plate 15, the anchor body 12 is penetrated in the anchor hole 6, and several I-shaped pads 14 are assembled between the polygonal backing plate 13 and the conventional backing plate 15; Yes, the borehole 11 includes an anchoring section 11-1 and a free section 11-2; the anchoring section 11-1 is used to fasten the anchor body 12; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com