Patents

Literature

281results about How to "Improve construction convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

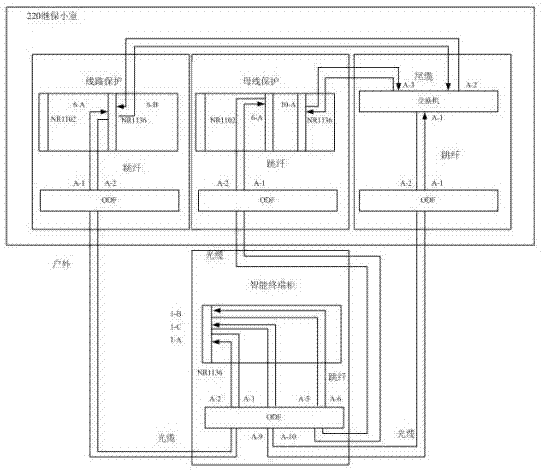

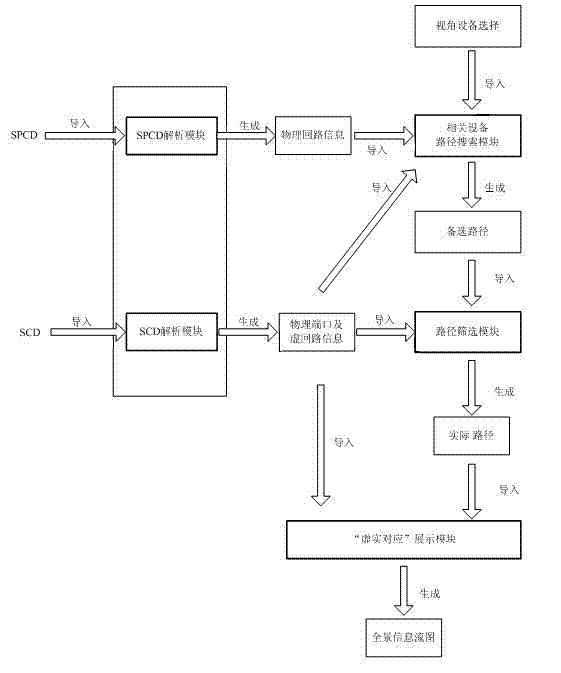

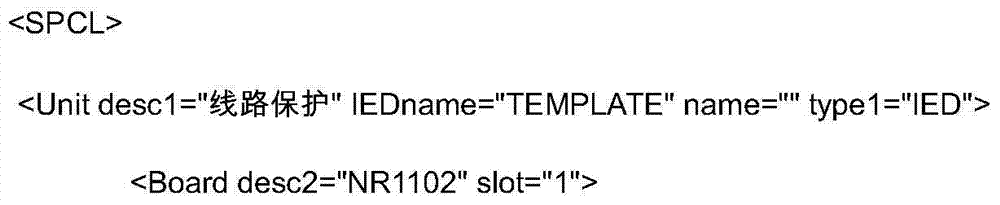

Secondary system physical loop modeling and void and actuality correspondence method of intelligent substation

ActiveCN104732021AEasy to findImprove developmentData processing applicationsSpecial data processing applicationsComputer architectureSmart substation

The invention discloses a secondary system physical loop modeling method of an intelligent substation. The secondary system physical loop modeling method of the intelligent substation includes the steps that firstly, a designer of an equipment manufacturer configures a physical loop IPCD file through a configuration tool, and a device board card and a physical end port in the IPCD file are described; secondly, a design unit solidifies the IPCD file into a cabinet model, then cable connection among cabinets and optical fiber connection among devices are designed, a substation physical loop SPCD description file is finished, and decoupling design of a logic loop and a physical loop is realized. According to the secondary system physical loop modeling and void and actuality correspondence method of the intelligent substation, an SCD file and an SPCD file correspond to each other in a void and actuality correspondence mode when a design graph is finished, void and actuality integration design description is also realized, design efficiency and accuracy are improved, many kinds of application software can be more easily developed and customized based on a solid loop model file, the engineering on-site debug method is enriched, and construction efficiency and convenience are improved.

Owner:STATE GRID CORP OF CHINA +5

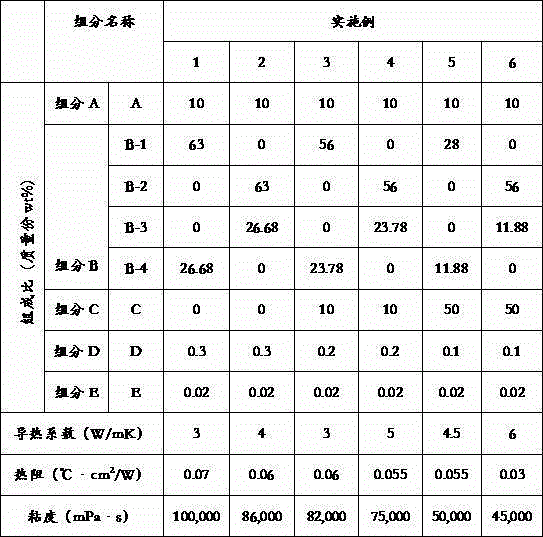

Heat-conducting graphene silicone grease and preparation method thereof

The invention relates to heat-conducting graphene silicone grease. The heat-conducting graphene silicone grease is prepared from raw materials in percentage by weight as follows: 5wt%-60wt% of organopolysiloxane, 10wt%-90wt% of heat-conducting filler, 5wt%-80wt% of graphene slurry, 0.01wt%-50wt% of a surface treatment agent and 0.01wt%-1wt% of a thixotropic agent, wherein the graphene slurry is prepared from raw materials in percentage by weight as follows: 1wt%-80wt% of organopolysiloxane, 1wt%-50wt% of graphene powder, 0.01wt%-50wt% of a surface treatment agent and 10wt%-90wt% of a solvent. The heat-conducting graphene silicone grease shows the high heat conductivity and has the excellent liquidity, so that the heat-conducting graphene silicone grease has the good convenient construction performance; meanwhile, the heat-conducting graphene silicone grease can sufficiently fit with pits in surfaces of heaters and radiators, accordingly, the interface heat resistance is reduced, heat transfer of the heaters is improved, and service lives of the heaters are prolonged.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

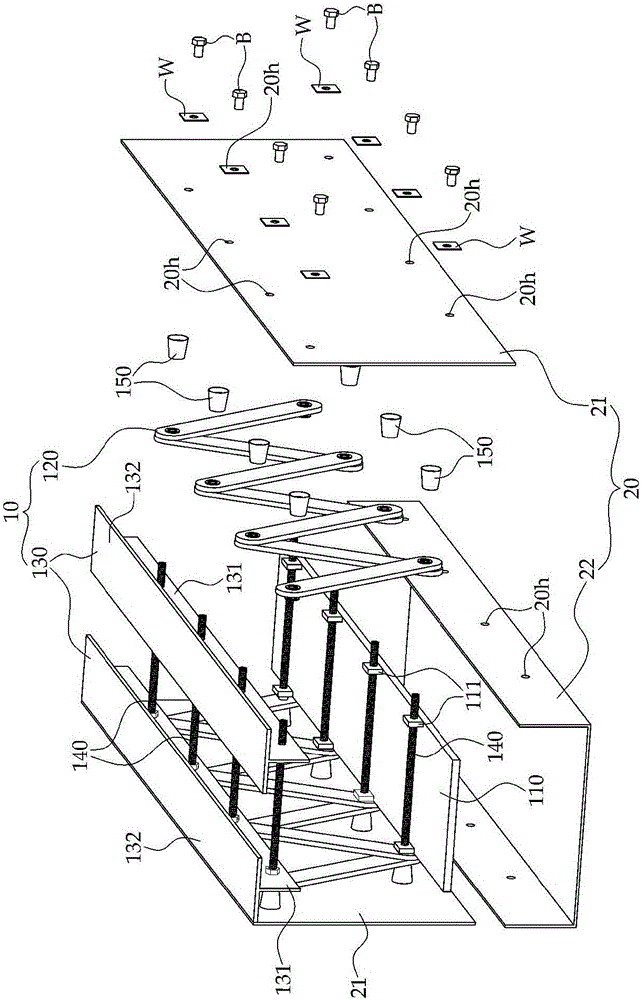

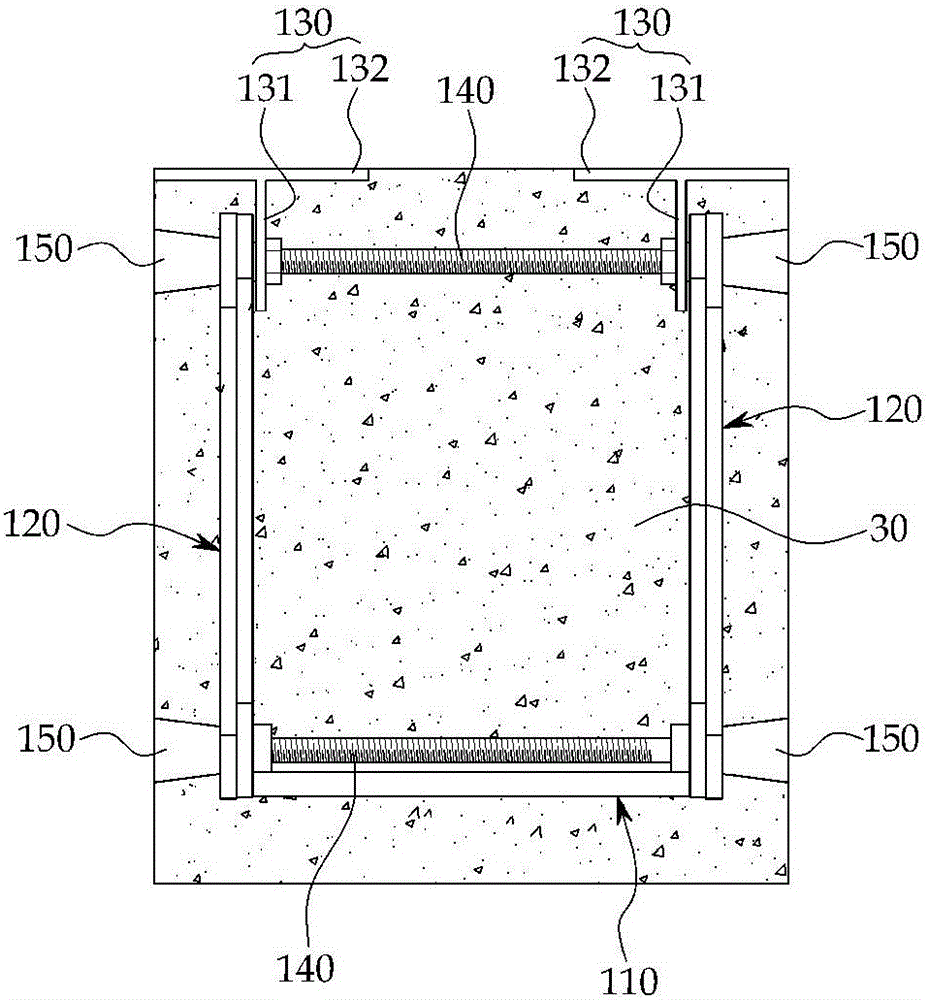

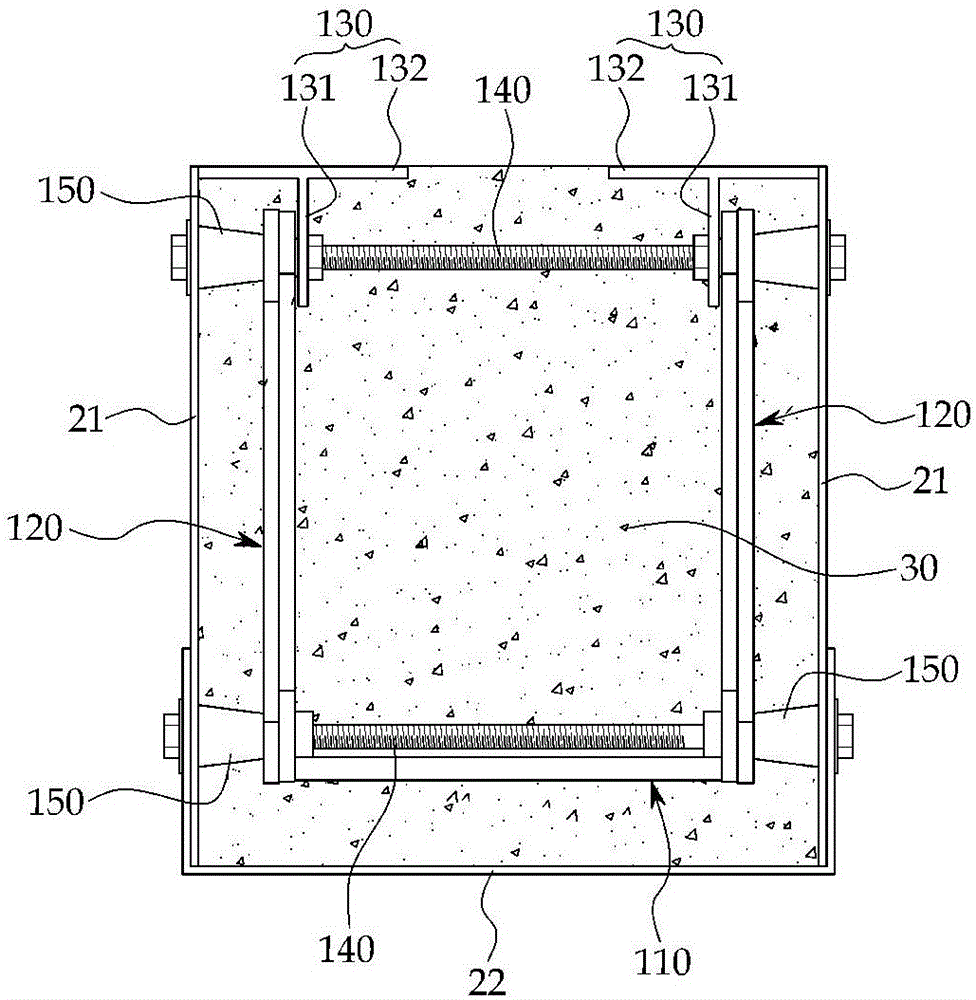

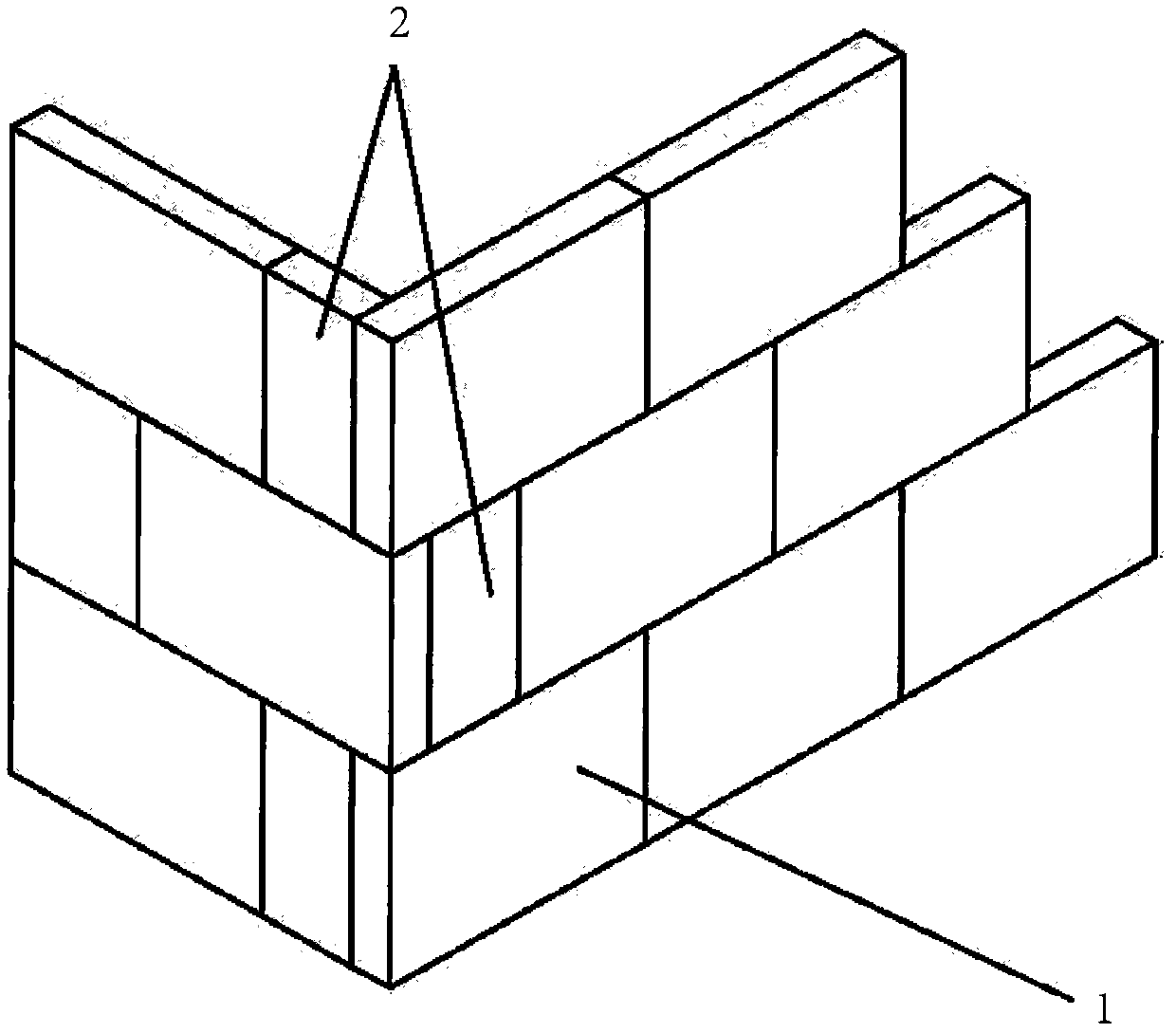

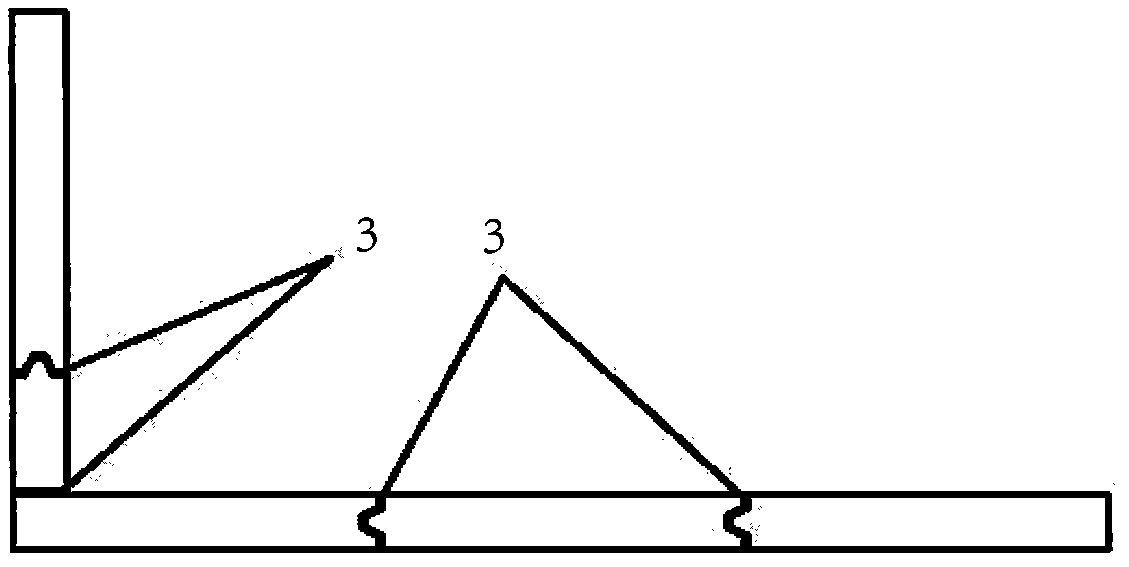

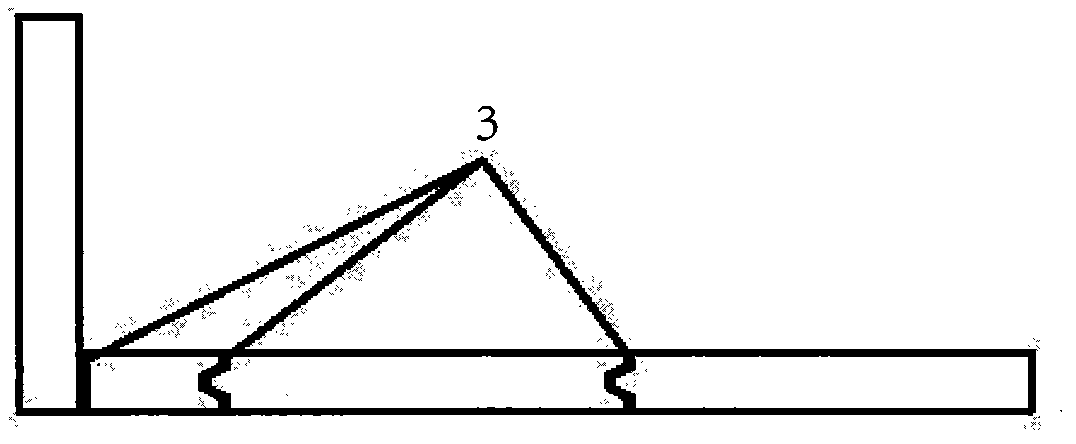

Prefabricated Truss-Embedded Composite Beam

InactiveCN105888134ALarge operating spaceImprove construction convenienceFloorsLoad-supporting elementsSteel barComposite beams

The invention provides a prefabricated truss-embedded composite beam. The beam with a sheathing board comprises: a combined truss. The truss comprises: a lower chord which is configured in a plate shape with a fixed thickness; a pair of foldable web members which are configured in a zigzag shape by connecting ends of multiple flat steel bars, and have lower ends coupled to both ends of the width direction of the lower chord after the screw rods coupled to the lower chord penetrate through holes formed on joints of the flat steel bars and D-cones are externally coupled; a pair of upper chords which are configured so as to comprise a vertical plate having coupling holes perforated therein at certain intervals along the longitudinal direction, and a horizontal plate configured on the upper end of the vertical plate, and which are coupled to the pair of foldable web members after the screw rods penetrate the coupling holes of the vertical plate and the upper through holes of the foldable web member and the D-cones are externally coupled; the sheathing board which is configured so as to accommodate the combined truss within the cross section thereof and to have a U-shaped cross section with an opened upper surface, and is fixed to the combined truss after bolt holes are perforated at positions corresponding to the D-cones coupled to the upper chord and the lower chord of the prefabricated truss and bolts are externally coupled to the D-cones through the bolt holes; and concrete which is integrated with the prefabricated truss by being placed within the cross section of the sheathing board. The sheathing board is removed by loosening the bolts after the concrete is cured.

Owner:权容觐

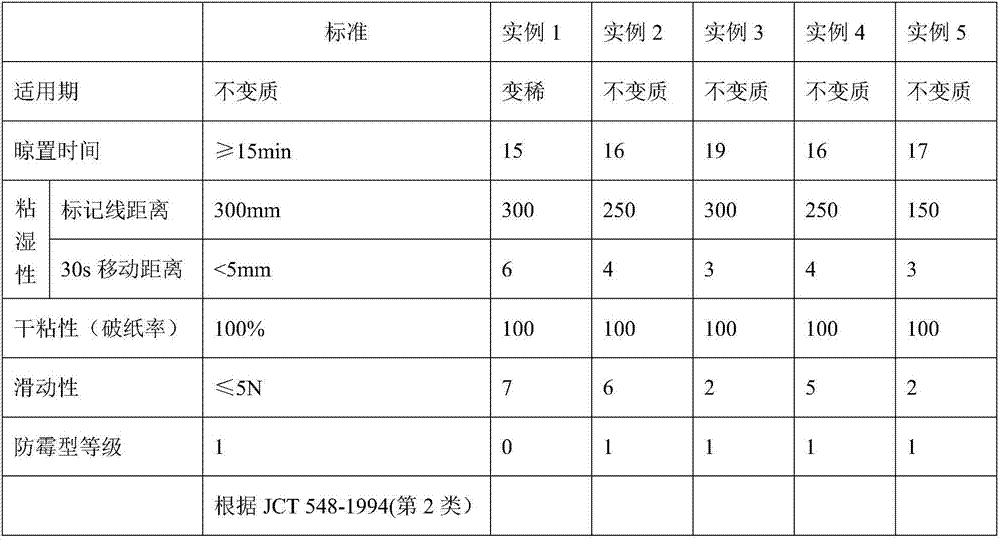

High-grade adhesive for wallpaper and wall cloth

InactiveCN107022325AAvoid irritationGuaranteed consistency adaptabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAdhesive

The invention relates to a high-grade adhesive for wallpaper and wall cloth. The adhesive is prepared from 45-60 parts by weight of waterborne polymer resin serving as a main material, and 30-50 parts by weight of filler, 0.2-0.7 part by weight of a thickening agent, 0.1-0.3 part by weight of a defoaming agent, 0.1-0.3 part by weight of a wetting and dispersing agent, 0.1-0.4 part by weight of a plasticizer, 0.5-1.0 part by weight of a stabilizer, 0.5-2.0 parts by weight of a thixotropic agent, 0.1-0.5 part by weight of a preservative and 2-20 parts by weight of deionized water which are taken as auxiliary materials. After the technical scheme is adopted, the adhesive facilitates construction, and has the advantages of being good in bonding force with a base material, water-resistant and alkali-resistant, good in durability, healthy and environment-friendly, and the like. By means of filler selection and grading optimization, the strength and weather resistance of the adhesive are improved. The stability of the adhesive is improved by means of other additives and formula optimization.

Owner:福享天下科技集团有限公司

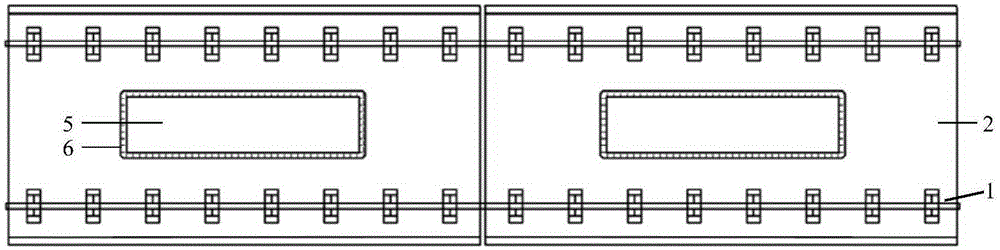

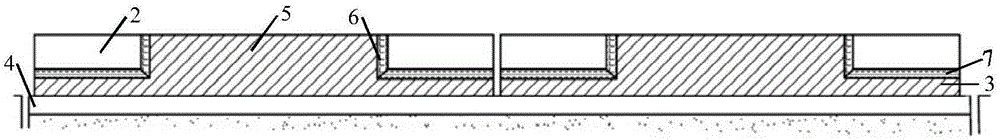

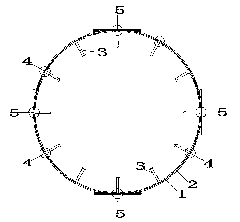

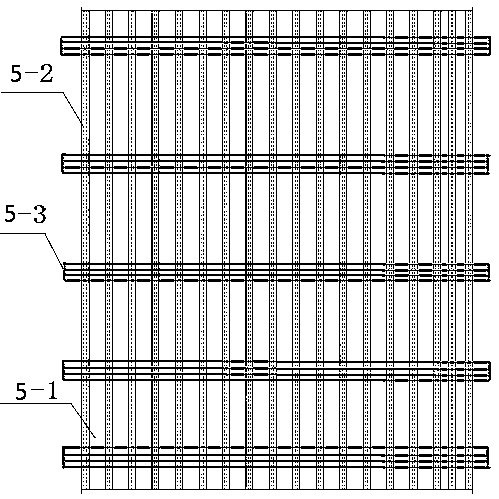

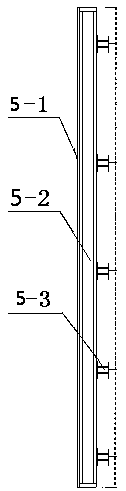

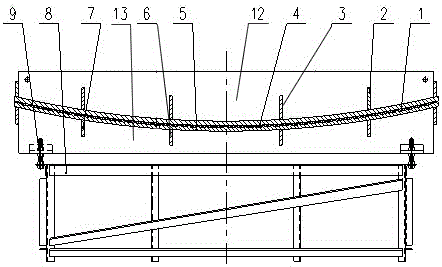

Novel slab ballastless track structure

InactiveCN105200868AReduce tensile stressIncrease the tensile stressBallastwayTemperature stressHigh intensity

The invention relates to a novel prefabricated slab ballastless track structure for high-speed railways and urban rail transit. The novel prefabricated slab ballastless track structure comprises rails, fasteners, prefabricated track slabs, under-slab filling and adjusting layers, a base and limiting bosses, wherein the track slabs are of a middle hollowed-out frame structure (through holes), the bosses (5) are arranged on the base (4) corresponding to the middle through holes of the prefabricated track slabs, and the limiting bosses (5) are single or multiple. The novel prefabricated slab ballastless track structure has the advantages that the pulling stress to the adjusting layers can be reduced, the track slabs bear larger pulling stress and the high-strength large-rigidity functions of the track slabs can be fully performed; since the track slabs are provided with through holes, the manufacturing cost is reduced, the longitudinal temperature stress to the track slabs is also relieved and the warping of the corners of the unit slab track structure is greatly reduced; since the limiting bosses are located in the middles of the track slabs, the replacement of parts such as the track slabs and the repair and treatment such as elevation and deviation correction in case of non-uniform settlement of tracks are facilitated.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

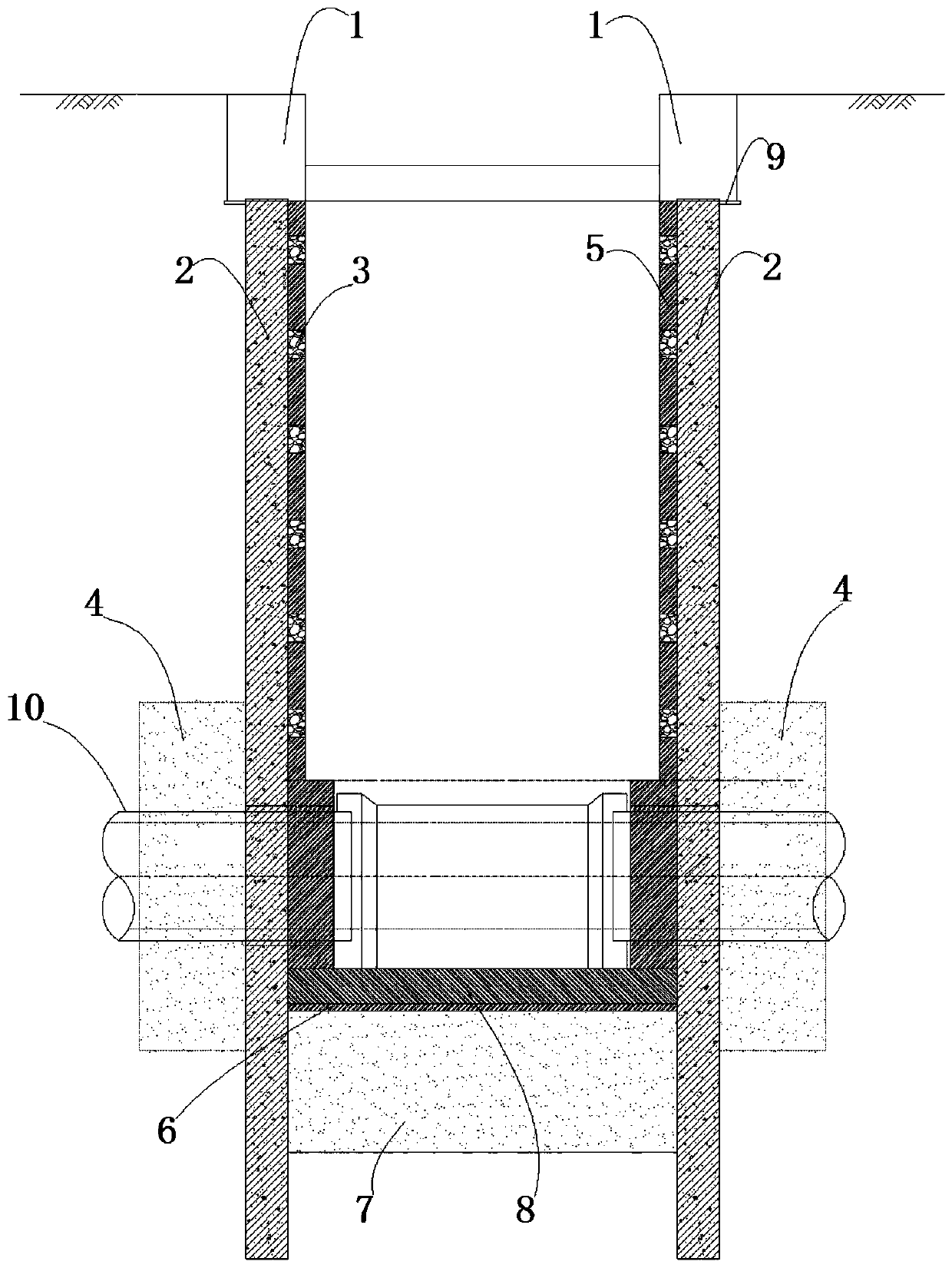

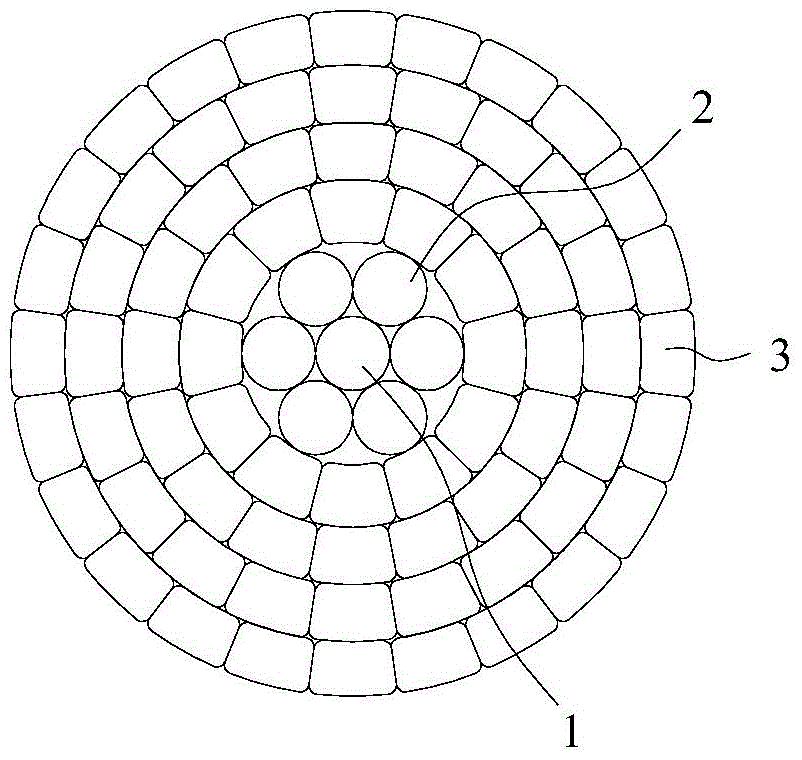

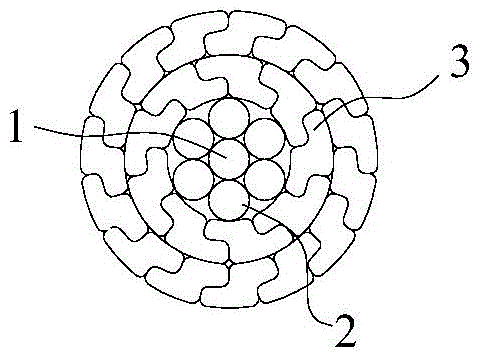

Pipe-jacking working well applicable to desert waterless sand area and construction method

PendingCN109797778AGood effectLarge pile diameterArtificial islandsShaft sinkingStructural engineeringEngineering

The invention provides a pipe-jacking working well applicable to desert waterless sand area and a construction method. The pipe-jacking working well is characterized in that a plurality of bore pilesare circumferentially uniformly arranged around the circle center the working well to form the main protecting and stress structure of the working well, a crown beam is arranged at the top of each bored pile, each circular crown beam and the working well are of a concentric circle structure, a liner is located on the inner side of each bored pile and vertically arranged along the depth direction of the working well, hidden beams are embedded into each liner and arranged at intervals along the length direction of the liner from top to bottom, a bottom plate is located at the bottom of the working well, a well bottom reinforcing jet grouting pile is arranged below the bottom plate, and hole reinforcing jet grouting piles located at positions where jacking pipe joints enter and exit holes arearranged on the outer sides of the bored piles. The pipe-jacking working well has the advantages that soil stability during excavation can be guaranteed by the bored piles, and the bored piles can bear large counter force needed by pipe-jacking construction; the liners can increase sand stability among the piles and evenly transmits horizontal load to the bored piles.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

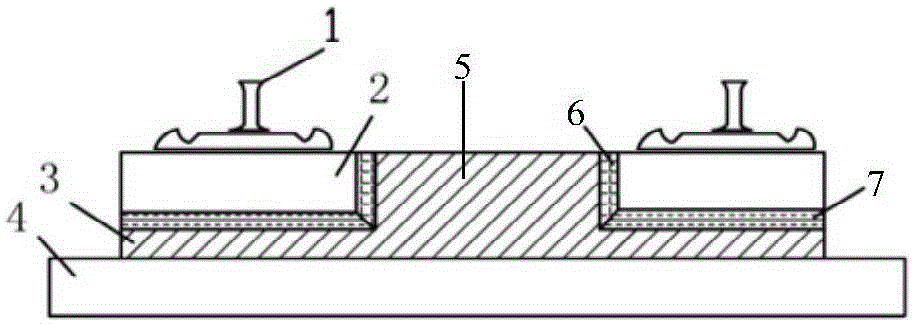

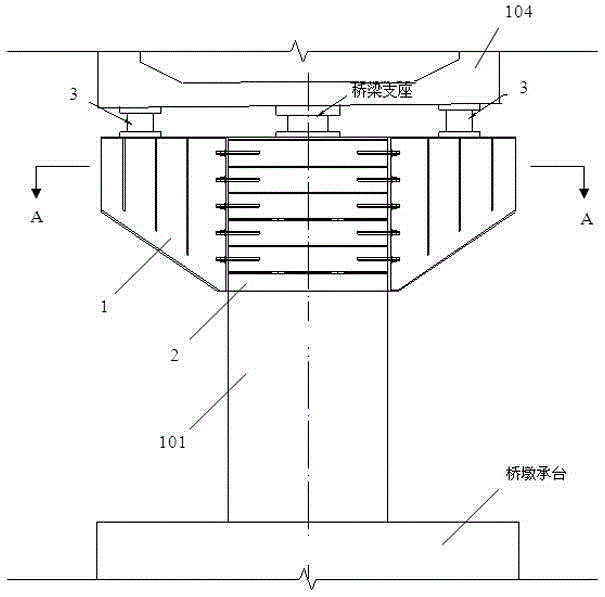

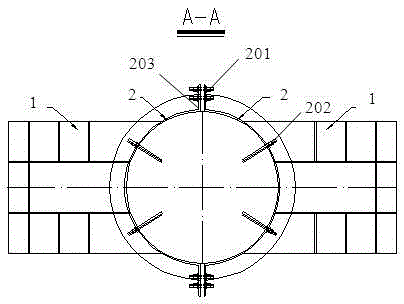

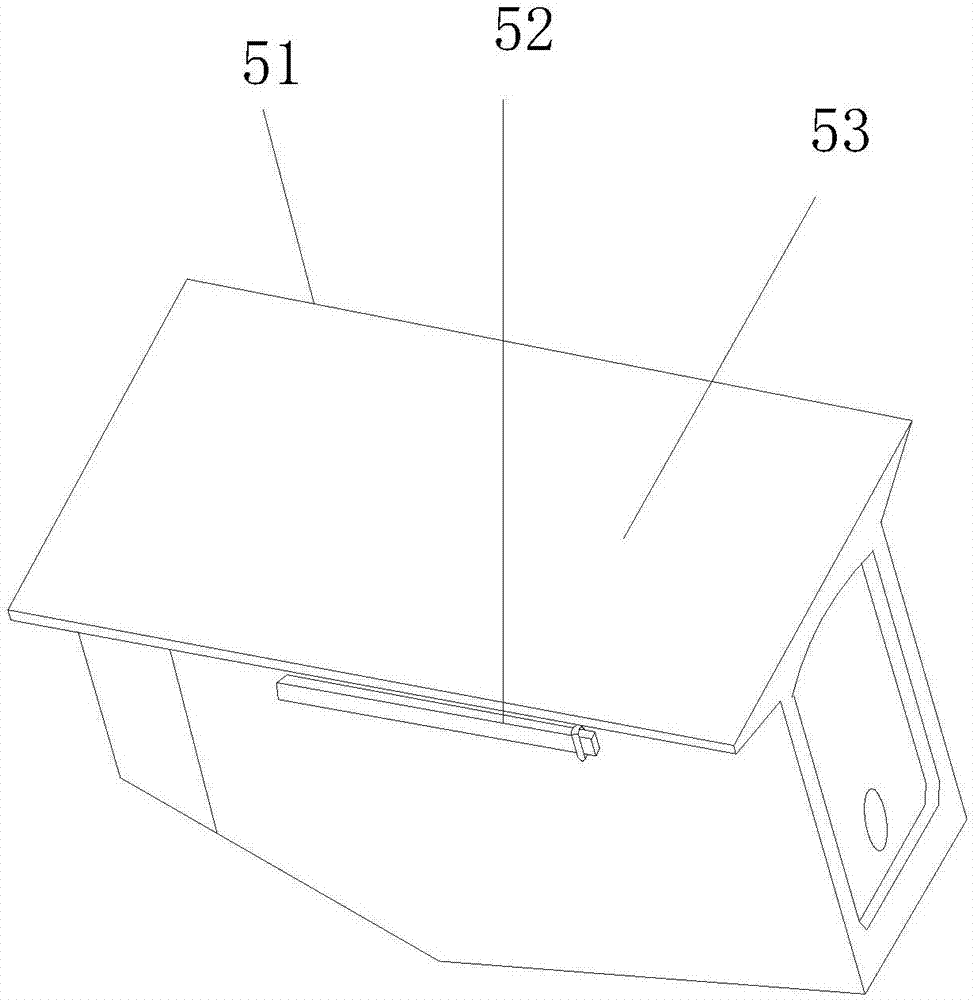

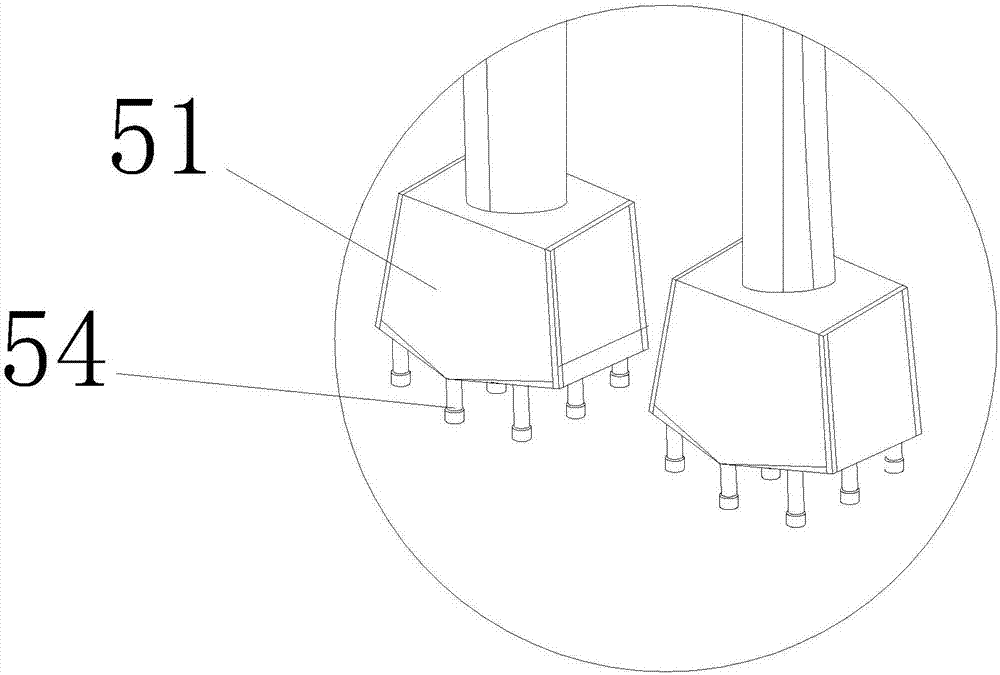

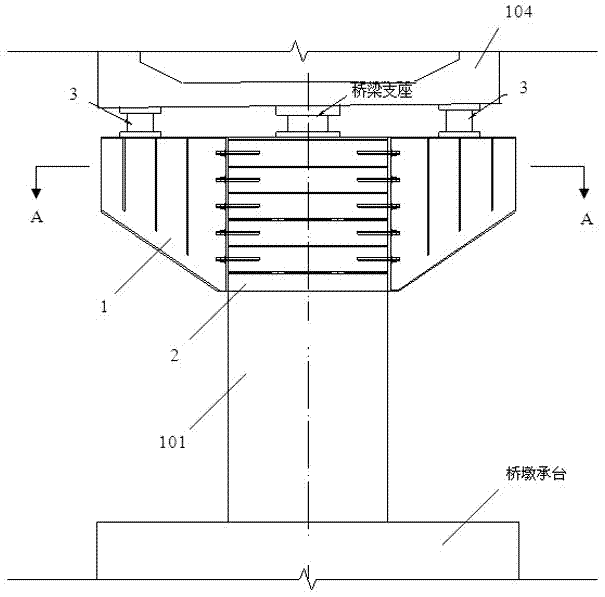

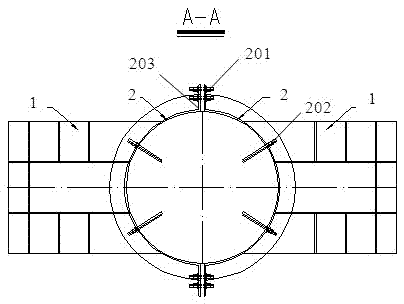

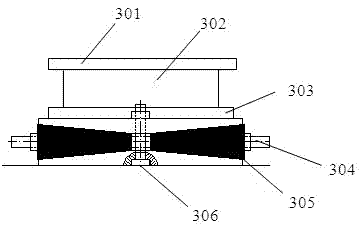

Anti-overturning structure for single-pier bridge girder

InactiveCN105421250AImprove anti-overturn performanceGood construction convenienceBridge structural detailsBridge erection/assemblyMaterials scienceBuilding construction

The invention discloses an anti-overturning structure for a single-pier bridge girder. The anti-overturning structure comprises a steel girdle structure arranged on a pier stand column in a sleeving mode. The steel girdle structure comprises two steel girdles with the same structure, a plurality of opposite-pulling high-strength bolts arranged on the joints of the steel girdles and a plurality of anchor bolts arranged in preformed holes in the steel girdles. The opposite-pulling high-strength bolts enable the steel girdles to be combined into the integral steel girdle structure. The steel girdle mechanism and the pier stand column are fixed through the anchor bolts. Two steel brackets are welded to the two steel girdles. The height of an intelligent supporting base arranged between the steel brackets and the bottom of the bridge girder is adjustable, and it is ensured that the upper surface of the intelligent supporting base is tightly attached to the bottom of the bridge girder and the lower surface of the intelligent supporting base is tightly attached to the steel brackets. According to the anti-overturning structure for the single-pier bridge girder, the anti-overturning performance of the single-pier bridge girder is improved; the anti-overturning structure has good construction convenience, wide applicability and excellent economy.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

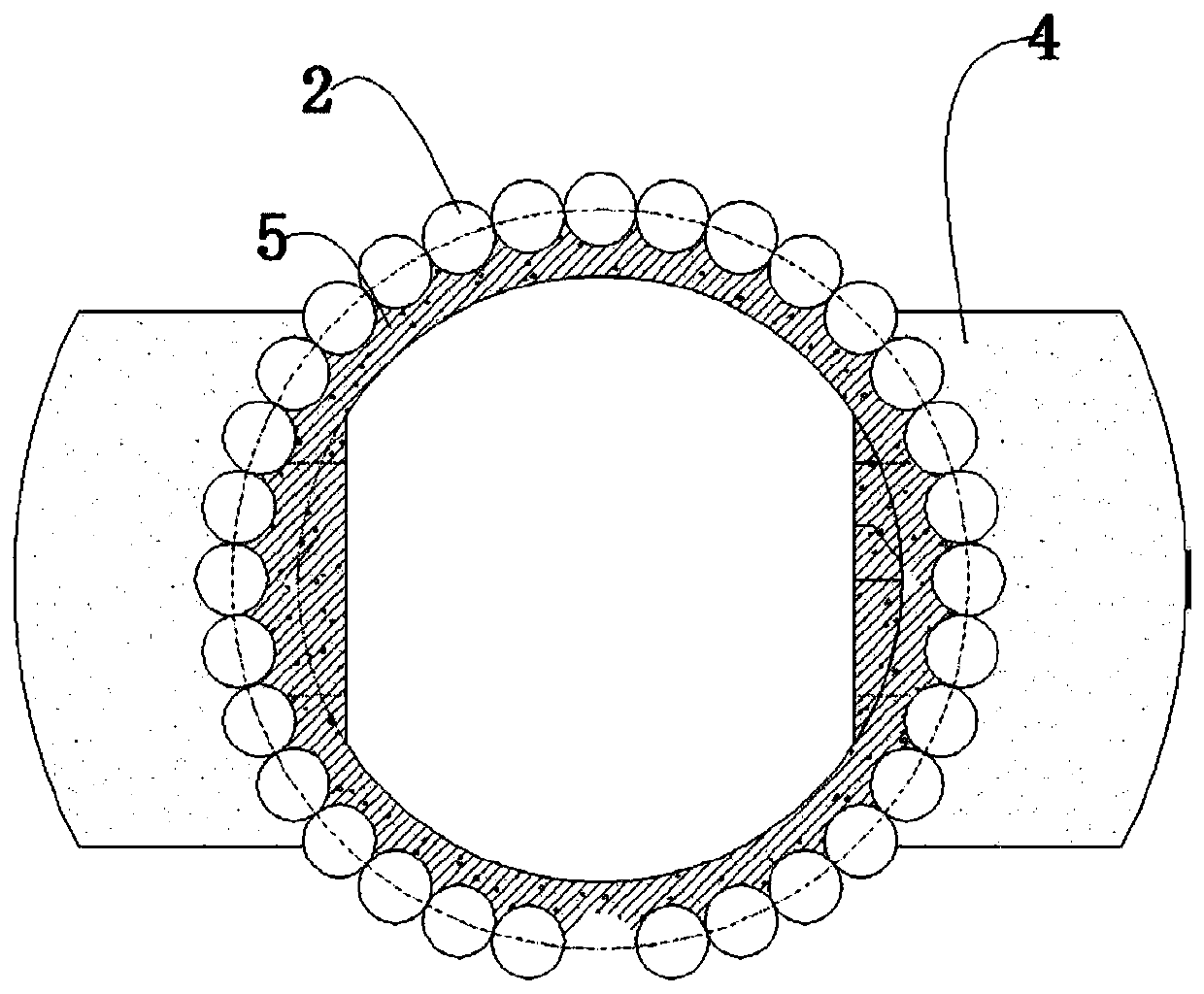

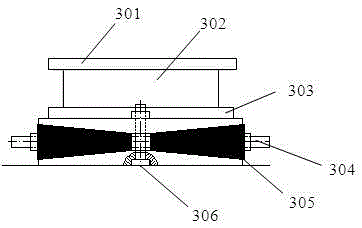

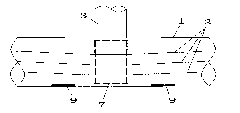

Pre-stress construction method of parallel steel stranded wire assembled cable in annular sealed steel pipe

InactiveCN101798874ASave operating spaceReduced anchorage spaceBuilding reinforcementsBuilding material handlingSteel tubeSingle hole

The invention discloses a pre-stress construction method of a parallel steel stranded wire assembled cable in an annular sealed steel pipe, and provides a reasonable, feasible, economic, simple and convenient pre-stress construction method aiming at the stay cable in the annular sealed steel pipe. By adopting the steel stranded wire assembled cable, the annular sealed steel pipe is internally provided with a one-way separation steering gear and a bidirectional cross separation steering gear; a guide hole channel of the steering gear and an end anchored hole are arranged in the consistent manner of a rectangle or similar rectangle. When the steel stranded wires penetrate through the annular sealed steel pipe one by one, the steel stranded wire, the guide hole channel of the steering gear and the end anchored hole are arranged in a mode of one-to-one correspondence, so that the steel stranded wires of the assembled cables in the same beam are parallel to each other to form the parallel steel stranded wire assembled cable. The end part of the stay cable is anchored by a single-hole anchorage, and the steel stranded wires of the assembling cable in the same beam are stretched by a small-size jack one by one. An anti-loosening press plate and a protective hood are arranged outside the anchorage to prevent a clamping piece from loosening under the low-stress state and protect the end part of the stay cable.

Owner:SOUTHEAST UNIV

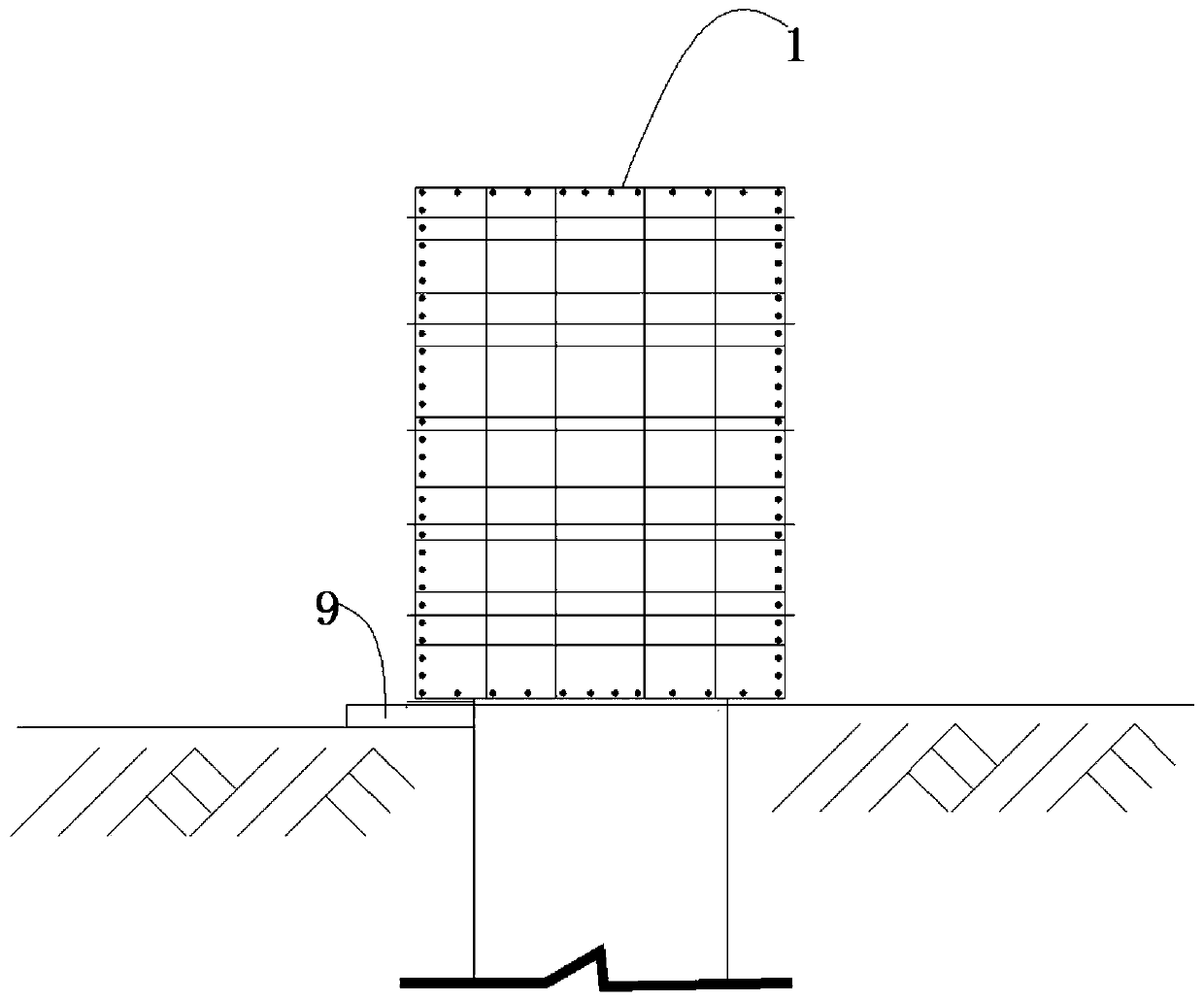

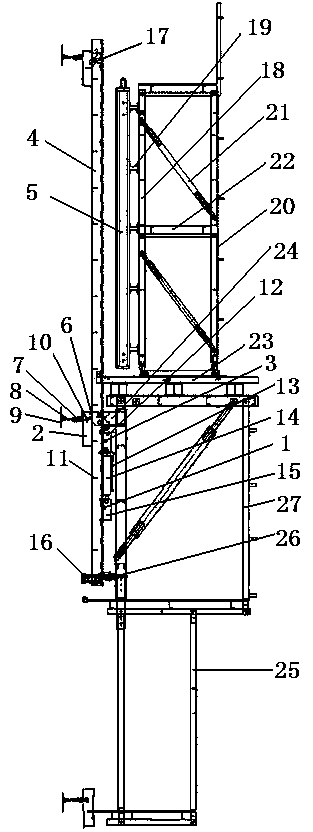

Hydraulic formwork climbing device

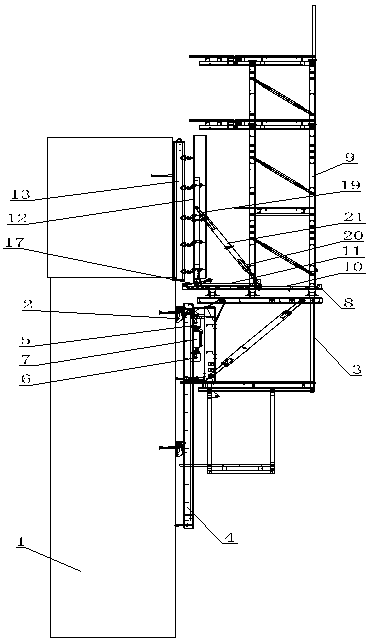

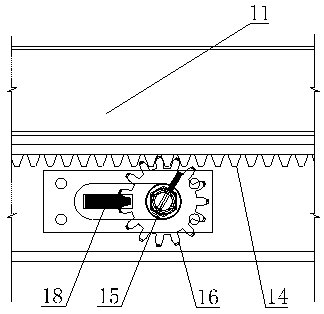

PendingCN110388048AAvoid separationThere will be no partial voidsForms/shuttering/falseworksHydraulic cylinderMechanical engineering

The invention discloses a hydraulic formwork climbing device which comprises a plurality of wall-attached hanging brackets fixed to a wall body. A formwork climbing lower frame body is hung on the wall-attached hanging brackets, a formwork climbing guide rail capable of being hung on the wall-attached hanging brackets is arranged in the formwork climbing lower frame body in a penetrating manner, the formwork climbing guide rail is provided with an upper reversing box and a lower reversing box, the upper reversing box is fixedly connected with the formwork climbing lower frame body, a hydrauliccylinder is connected between the upper reversing box and the lower reversing box, and the hydraulic cylinder achieves alternative wall-attached climbing of the formwork climbing lower frame body andthe formwork climbing guide rail on the wall-attached hanging brackets through the upper reversing box and the lower reversing box; and a main operation platform is paved on the top of the formwork climbing lower frame body, a formwork climbing upper frame body and a mold plate rail are installed on the main operation platform, a sliding seat is arranged on the mold plate rail in a sliding manner, a mold plate moving back edge is mounted on the sliding seat, a mold plate is installed on the mold plate moving back edge, and the sliding seat is driven by a driving assembly to move along the mold plate rail, so that the mold plate is synchronously driven to be closed or retreated. The hydraulic formwork climbing device has the advantages of convenient construction and high safety.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG +1

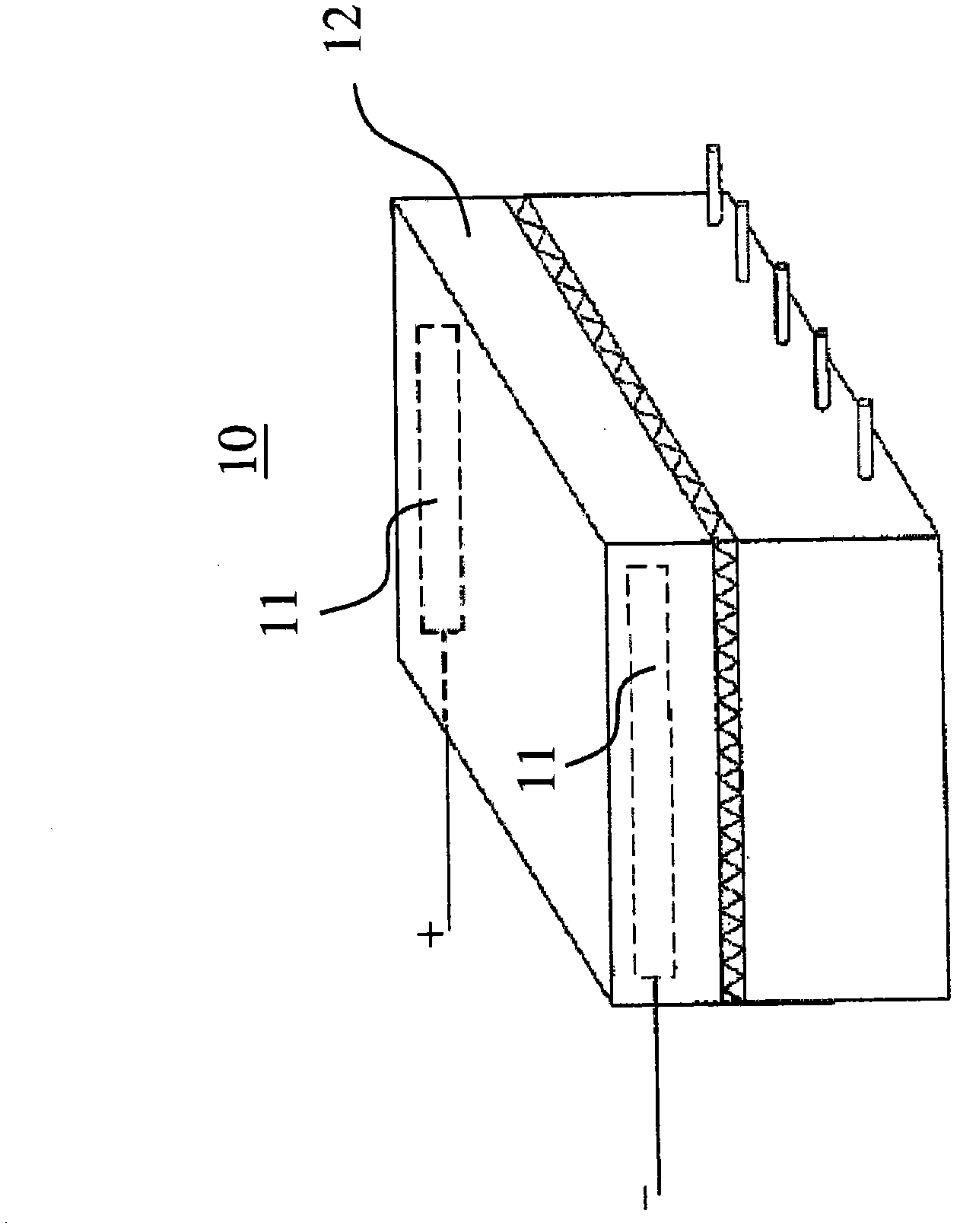

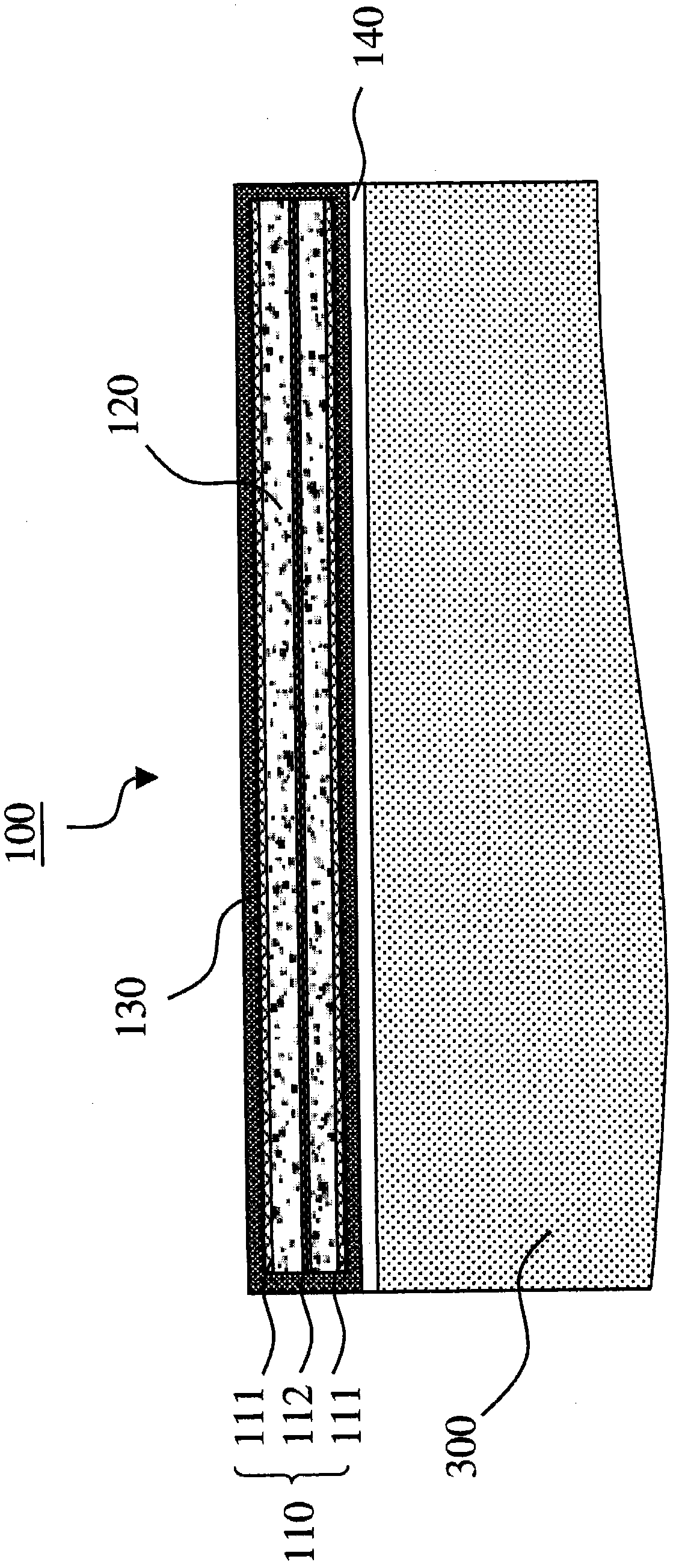

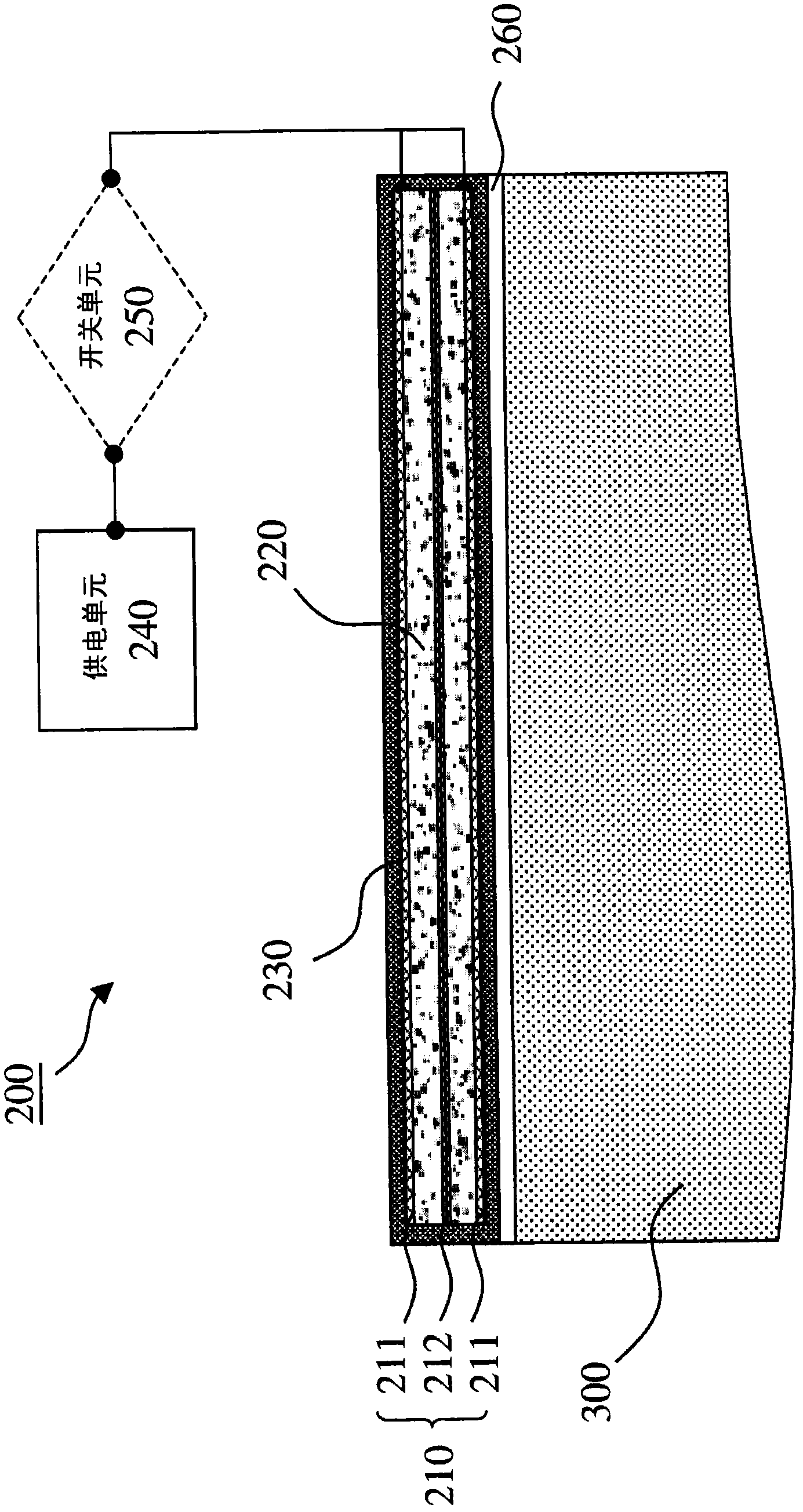

Electric heating module and system for building plate and road facing plate

InactiveCN102865617ANo risk of electric shockHigh densityLighting and heating apparatusElectric heating systemThermal energyElectrical resistance and conductance

The invention relates to an electric heating module and an electric heating system for building plates and road facing plates. The electric heating module is arranged on the surface of a structure plate, so as to enable the structure plate to emit heat. Through a first electrode layer and a second electrode layer which approximately cover the surface of the entire structure plate and are arranged in parallel, power is obtained from an external power supply unit, current is enabled to pass through conductive concrete between electrode units to generate heat by using resistance of the conductive concrete, the temperature of the structure plate is increased and a comfortable indoor environment is provided to users.

Owner:E TECH INT

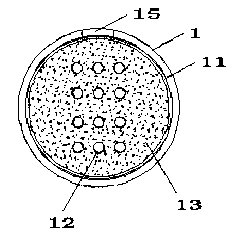

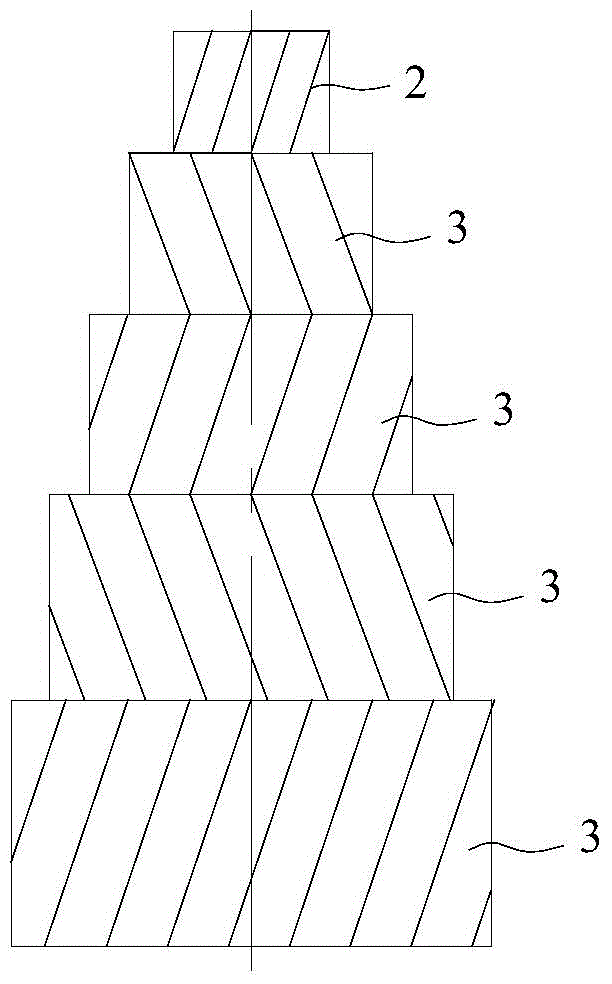

Stranded carbon fiber composite core soft aluminum wire and fabrication method thereof

ActiveCN104134483AImprove structural strengthGood flexibilityNon-insulated conductorsPower cablesFiberUltimate tensile strength

The invention discloses a stranded carbon fiber composite core soft aluminum wire and a fabrication method thereof. The stranded carbon fiber composite core soft aluminum wire comprises a wire core and a conductive layer wrapping the wire core, wherein the wire core comprises a carbon fiber main core and a plurality of carbon fiber auxiliary cores which are spirally and tightly stranded at the outer side of the carbon fiber main core, and the conductive layer comprises at least one soft aluminum wire layer, the soft aluminum wire layer comprises a plurality of soft aluminum wires which are spirally and tightly stranded at the outer side of the wire core. Since the wire core consisting of the carbon fiber main core and the plurality of carbon fiber auxiliary cores stranded at the outer side of the carbon fiber main core serves as a bearing aggregate of the whole wire and replaces a single carbon fiber (bar-shaped) composite core in the traditional structure, the stranded carbon fiber composite core soft aluminum wire had good flexibility, and smooth progress of engineering can be guaranteed; at the same time, the stranded carbon fiber composite core soft aluminum wire has favorable sag performance and is more suitable for an extra-large span line; in addition, due to improvement of the structural strength and flexibility of the wire core, a crimp-type tension fitting can be adopted and has better safety and construction convenience than a wedge locking type tension fitting adopted by the soft aluminum wire of the single carbon fiber (bar-shaped) composite core.

Owner:FOGANG XINYUAN HENGYE CABLE TECH CO LTD

Reflective insulating fire-retardant coating for waterproof roll, and preparation method and use thereof

ActiveCN103173088AImprove fire safetyImprove insulation effectFireproof paintsRoof covering using flexible materialsPolymer scienceAcrylic resin

The invention relates to a reflective insulating fire-retardant coating for a waterproof roll, and a preparation method and use thereof. The coating comprises the following material formulas by weight percent of 20-25% of styrene-ethylene-butene-styrene butadiene styrene block copolymer, 8-15% of terpene resin, 5-10% of acrylic resin, 10-15% of n-butyl acetate, 10-15% of titanium dioxide, 1-8% of hollow microsphere, 5-8% of halogen-free flame retardant phosphate, 5-10% of antimonous oxide, 5-15% of talcum powder, 0.5-1% of antioxidant, 0.3-0.8% of defoamer, and 20-35% of 200# solvent oil, wherein the sum of weight percents of all materials is 100%. The coating disclosed by the invention can be directly matched with the waterproof roll, has an excellent insulating fire-retardant property, and can be used for effectively improving the fire security and the thermal insulating property of the rolled roofing material.

Owner:中建材苏州防水研究院有限公司

Green and environment-friendly wall system

ActiveCN103214225AEasy to installEliminate the plastering processWallsCeramicwareAdhesiveFire resistance

The invention provides a green and environment-friendly wall system which is composed of a plurality of rectangular gypsum blocks by splicing. Splicing places are connected by using a cured gypsum block adhesive. The gypsum blocks are obtained through the steps that: a gypsum raw material is stirred with water, and casting and shaping are carried out. The rectangular edges of the gypsum block are provided with concave recesses and convex keys. The gypsum block adhesive is powdery, and is formed by using a gypsum raw material. Before use, the gypsum block adhesive is well mixed with water. From a raw material selection process, a production process, and a site construction process, to a waste recovery process, the wall system completely satisfies a sustainable development goal. The system is a completely environment-friendly novel construction material. The system has the advantages of sound insulation, fire resistance, light weight, high strength, convenient construction, low application space occupation, and the like. The system is a low-carbon, environment-friendly, and healthy novel wall system satisfying development requirements of the time.

Owner:嘉信(香港)研发有限公司

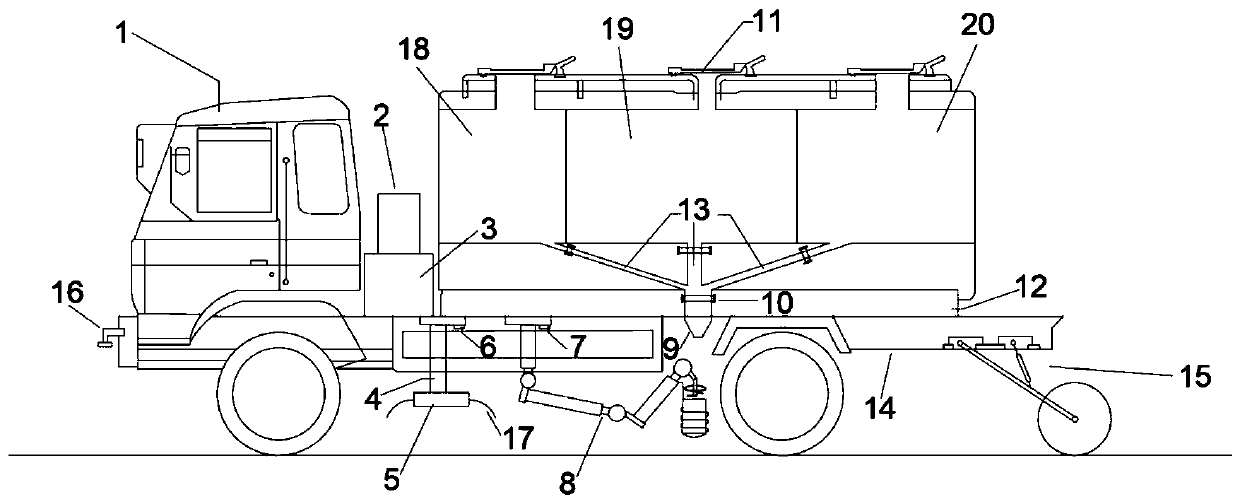

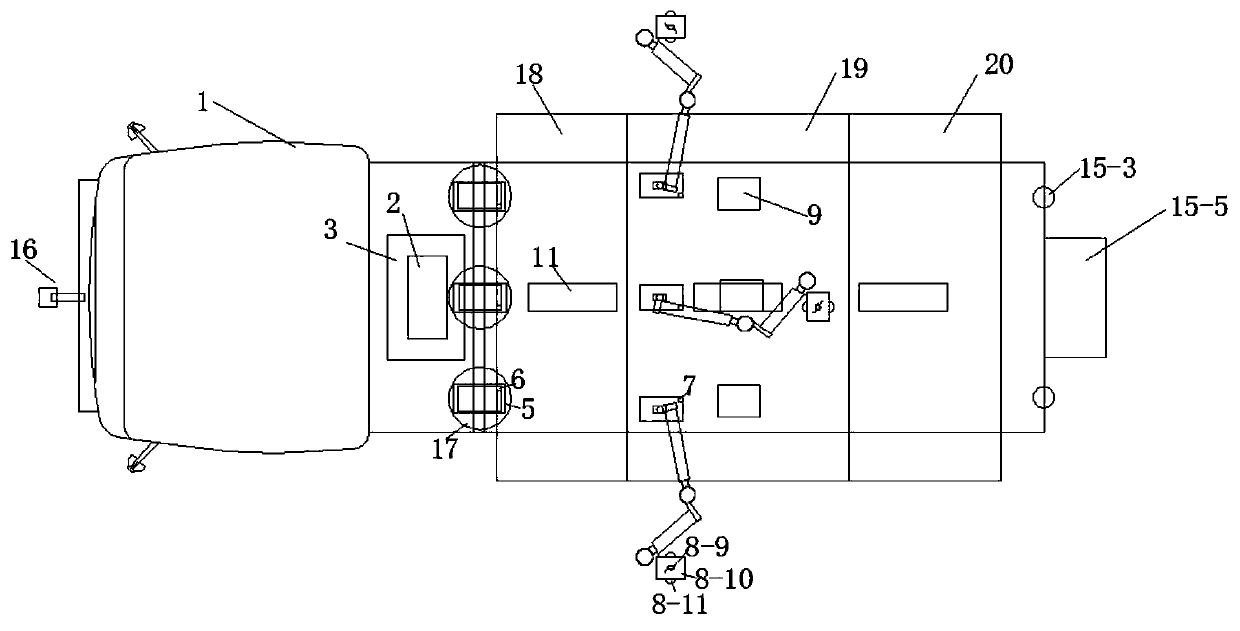

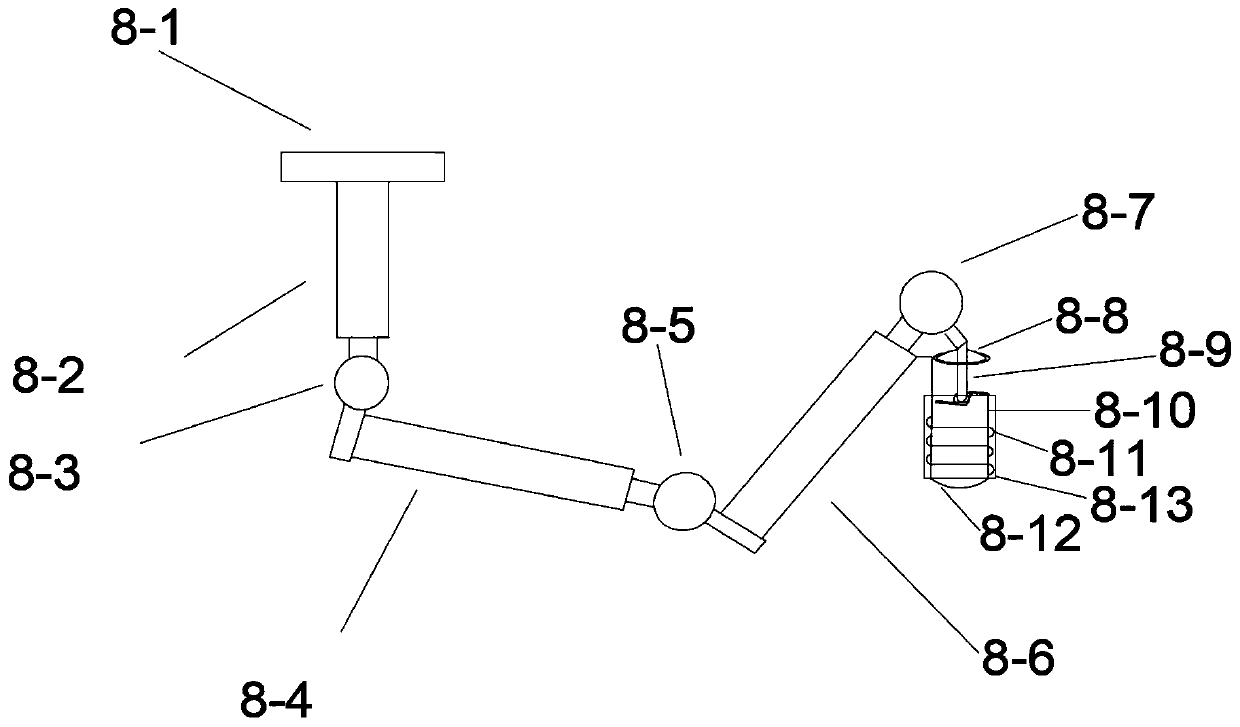

Construction method of asphalt pavement pit slot repairing vehicle based on electromagnetic heating

ActiveCN110700065AImprove repair qualityAffect the repair effectRoads maintainenceRepair materialStructural engineering

The invention discloses a construction method of an asphalt pavement pit slot repairing vehicle based on electromagnetic heating. The construction method comprises the following steps: detecting a pavement pit slot; starting the bituminous pavement pit slot repairing vehicle to move on the pavement, and scanning the road condition of the pavement by a pavement scanner at the front part of the vehicle body; preheating the pavement; processing, and adding a repairing material and flattening; the asphalt pit slot repairing capsule in the storage bin is discharged from a discharge port, the material falls into a stirring container in the repairing mechanical arm structure, then the material is subjected to induction heating through an induction coil wound on the stirring container, and then the position of the preheated pit slot is inducted through a temperature inductor to be filled and flattened; vibrating and compacting; cleaning and acceptance. The asphalt pavement pit slot repairing vehicle based on electromagnetic heating is combined with the pit slot repairing capsule to conduct electromagnetic induction repairing on the pit slot in the asphalt concrete pavement, and rapid repairing of the asphalt concrete pavement is achieved.

Owner:HEFEI UNIV OF TECH

Offset lifting slip device and method

The invention belongs to the field of steel structure construction, and particularly relates to an offset lifting slip device and method. A lifting supporting frame is arranged on a structure main body steel column; an assembled jig frame is erected on a floor, and main body roof trusses are assembled into an overall structure; the overall roof trusses are lifted to be arranged below a load-bearing track beam; hydraulic jacking and pushing driving equipment is connected with a lifting load-bearing beam through a pin shaft, the hydraulic jacking and pushing driving equipment is started, and thelifting load-bearing beam is jacked and pushed to slip to a calculated elevation on the load-bearing track beam; and four jacks are used on the structure main body steel column for jacking lower chords of the roof trusses, a lifter equipment device is shut down, all the jacks unload the main body roof trusses in place in synchronous and in-step modes, and the main body roof trusses and the structure main body steel column are fixedly connected, so that construction is completed. According to the offset lifting slip device and method, working at heights is reduced, safety is improved, the efficiency is high, and the cost of measures is saved.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

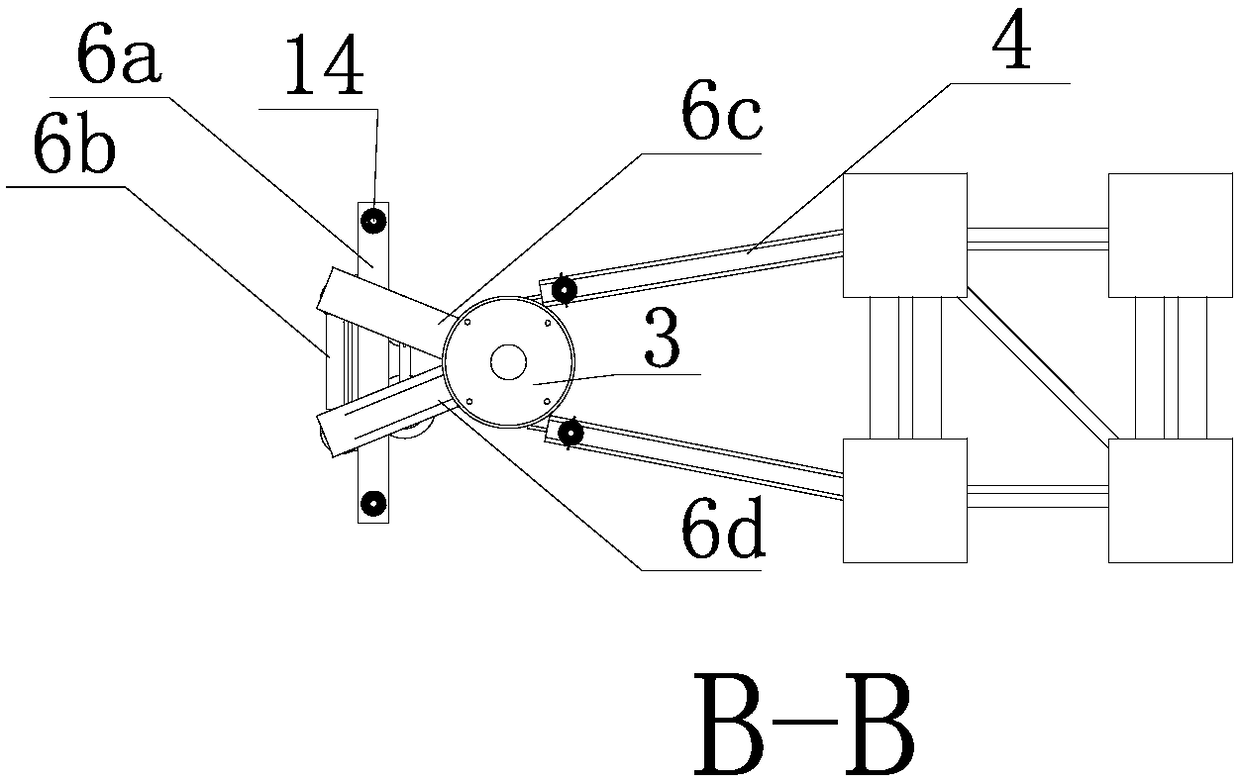

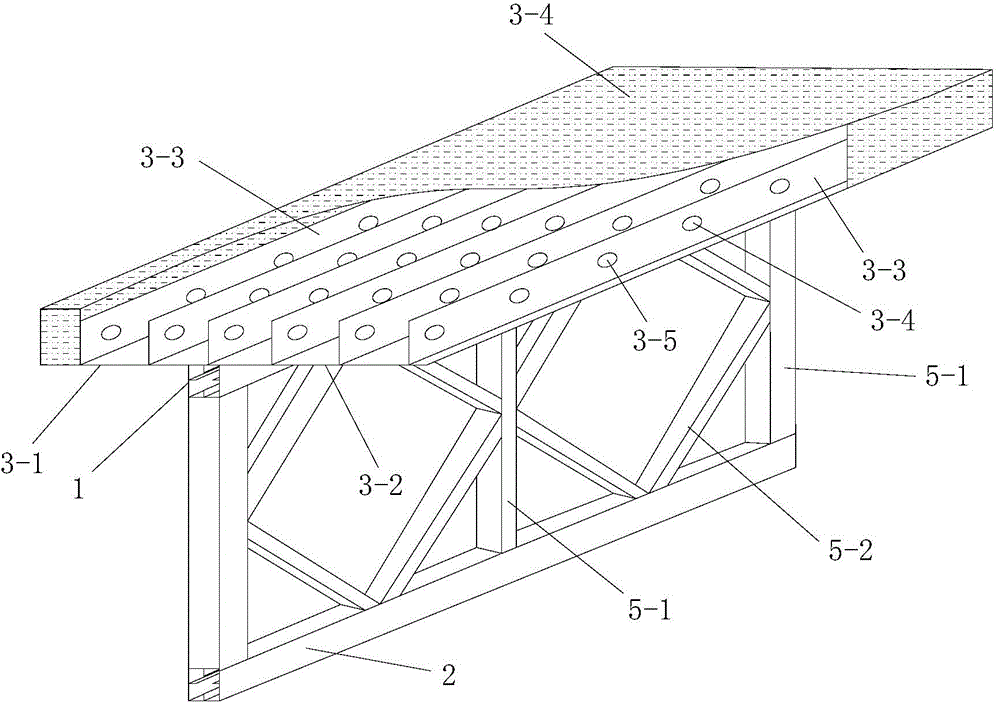

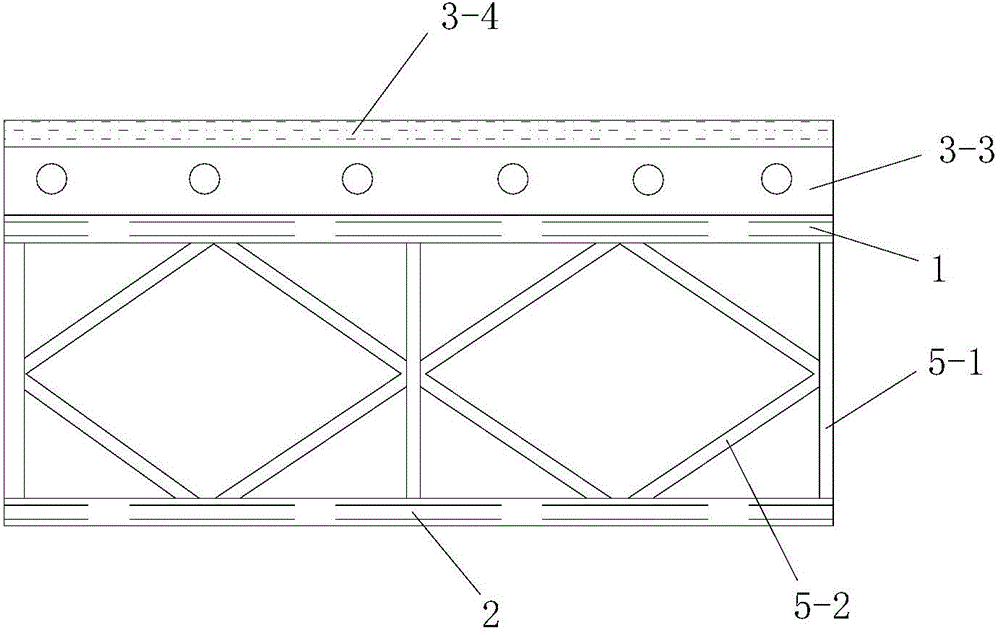

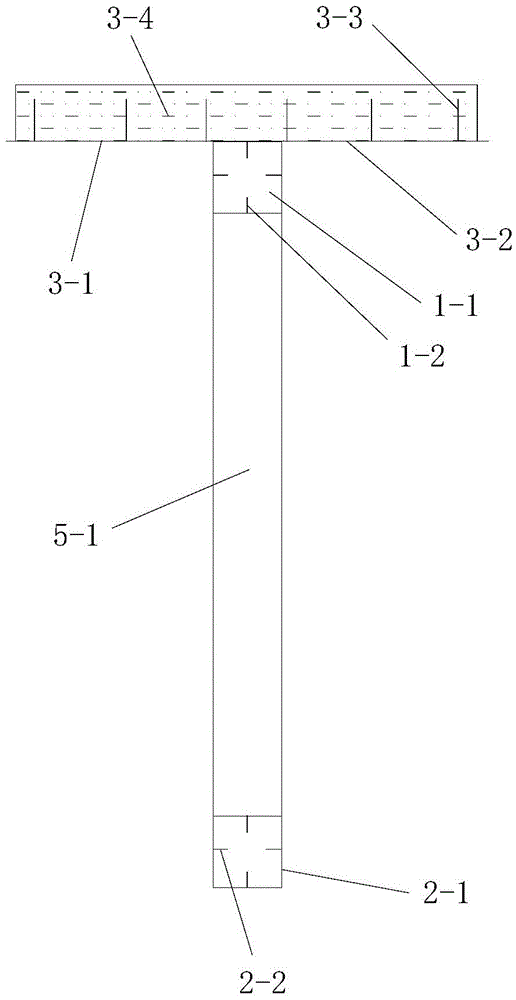

T-shaped plate girder segment prefabricating unit based on steel truss and combined bridge deck slab

InactiveCN104088221ASimple structureReasonable designBridge structural detailsSheet steelBridge deck

The invention discloses a T-shaped plate girder segment prefabricating unit based on a steel truss and a combined bridge deck slab. The T-shaped plate girder segment prefabricating unit comprises a lower force bearing structure and the combined bridge deck slab arranged on the lower force bearing structure, and the combined bridge deck slab and the lower force bearing structure are both arranged in the longitudinal bridge direction; the lower force bearing structure is a planar truss composed of an upper chord rod, a lower chord rod and a web rod, the upper chord rod comprises a first rectangular steel tube, and the lower chord rod comprises a second rectangular steel tube; the combined bridge deck slab comprises a bottom supporting steel plate, a plurality of upper longitudinal ribs arranged on the bottom supporting steel plate, and a concrete bridge deck slab arranged on the bottom supporting steel plate in a pouring mode, the upper longitudinal ribs are arranged in the concrete bridge deck slab in a pouring mode, and the upper longitudinal ribs are long-strip-shaped steel plates with the middles provided with a plurality of through holes; the bottom supporting steel plate is a rectangular supporting steel plate formed by connecting a left extension steel plate, a right extension steel plate and a first rectangular steel tube. The T-shaped plate girder segment prefabricating unit is simple in structure, reasonable in design, easy and convenient to construct, good in overall mechanical property and capable of improving the structure accuracy and construction convenience of a steel and concrete combined bridge.

Owner:CHANGAN UNIV

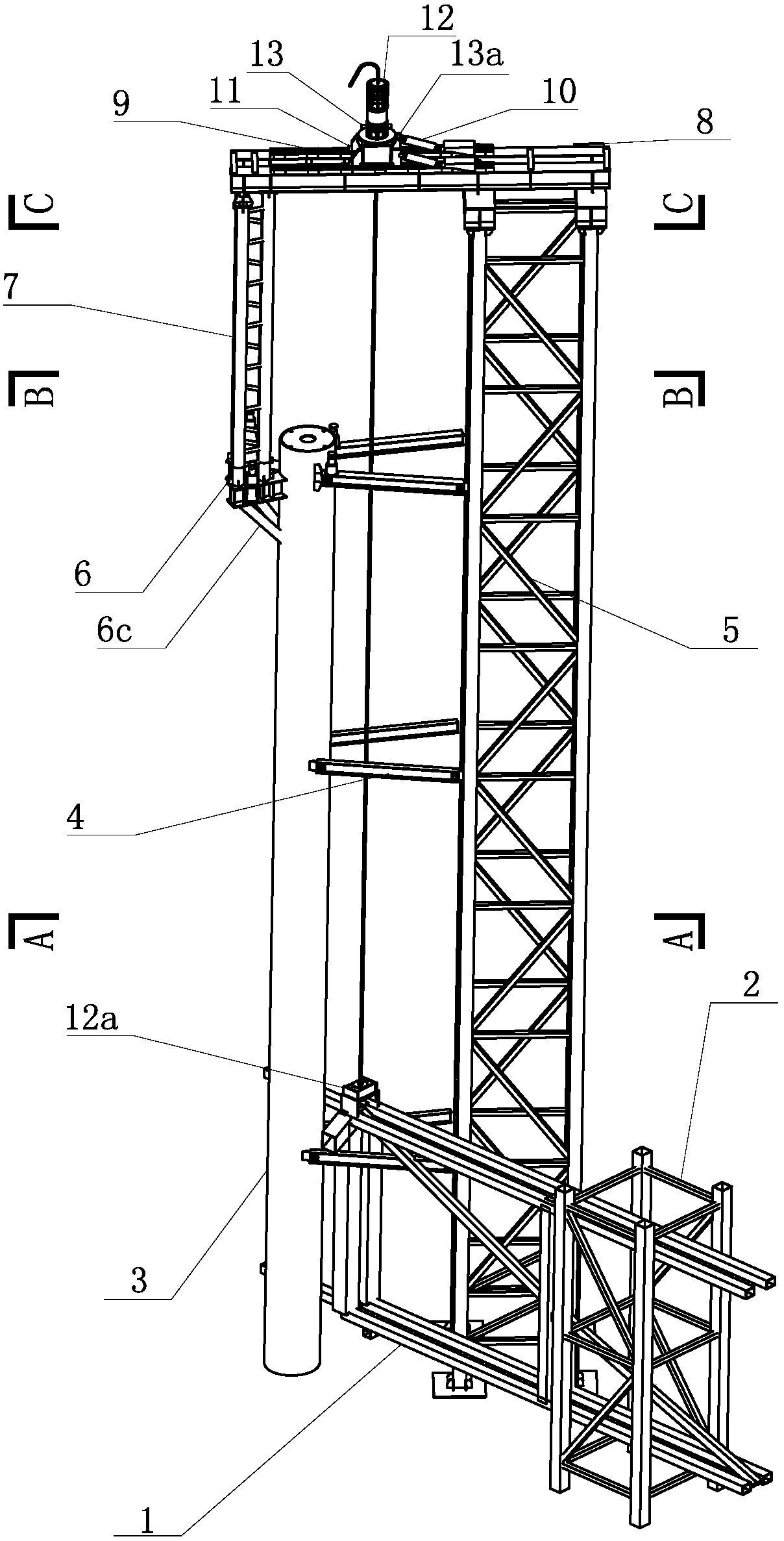

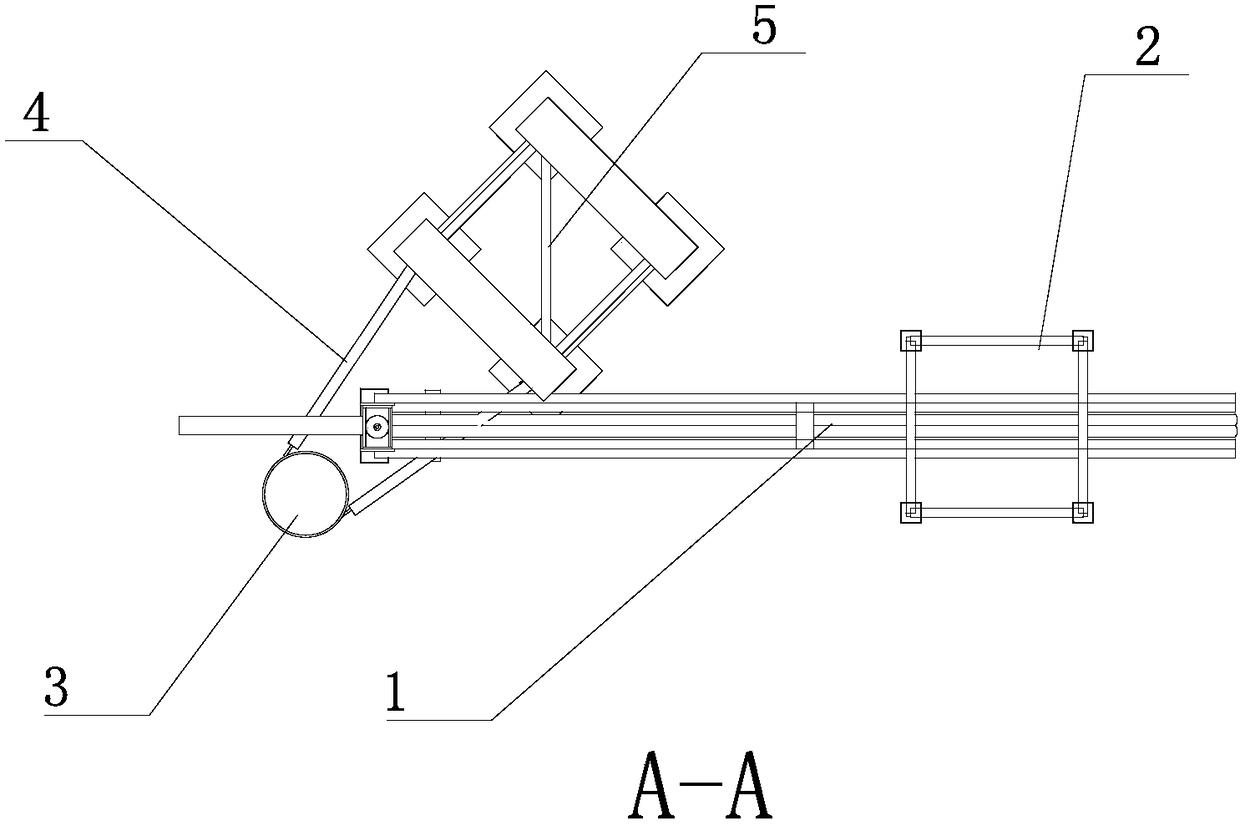

Coastal environment high pier hydraulic self-creeping formwork construction method

PendingCN111119060AEasy to operateImprove securityBridge structural detailsBridge erection/assemblyPurlinShaped beam

The invention discloses a coastal environment high pier hydraulic self-creeping formwork construction method. The method comprises the steps of tower column starting section construction, tower columnfirst section construction, hydraulic creeping formwork installation, tower column second section construction, tower column remaining section construction and creeping formwork removal, the hydraulic creeping formwork comprises an embedded part mechanism embedded in a high pier wall, and a frame body mechanism comprises a lower hanging bracket and a bearing frame; the formwork installation comprises a formwork consisting of a panel, a woodworking I-shaped beam and a steel enclosing purlin, a movable template bracket and a backward moving device; a hydraulic power mechanism comprises an upperreversing box, a lower reversing box, a hydraulic pump and a hydraulic oil cylinder which are connected with the guide rail in a sliding manner; the guide rail is composed of two steel channels and guide rail stair stops, and the upper reversing pawl of the upper reversing box and the lower reversing pawl of the lower reversing box are arranged between the guide rail stair stops. The constructionmethod is convenient to operate, high in safety and convenient to construct, working hours and construction sites are saved, and formwork bumping damage is reduced; and the formwork is recycled, theworkload of hoisting machinery is greatly reduced, and the construction process is stable, synchronous and safe.

Owner:YANJIAN GRP CO LTD +1

Preparation method for environment-friendly plasterboard

The invention discloses a preparation method for an environment-friendly plasterboard, belonging to the technical field of plasterboards. The preparation method comprises the following steps: (1) preparation of gypsum having undergone oxidative desulfurization; (2) preparation of modified fiber reinforced particles; (3) preparation of a base material; (4) preparation of mixed slurry; (5) preparation of a semi-finished product; and (6) preparation of the finished plasterboard. The preparation method provided by invention is convenient to operate and low in cost; and the prepared plasterboard has good water resistance, low water absorption rate and high strength and is not prone to coming off.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

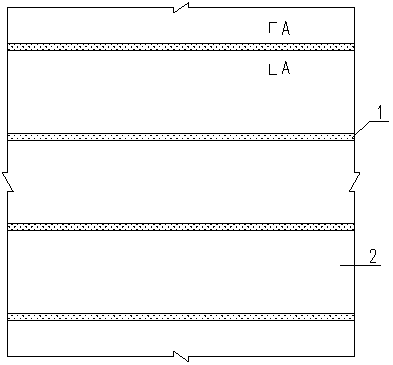

Structure and method for multipoint suspending laying construction of tunnel waterproof board

ActiveCN103790601ARealize multi-point suspensionQuality assuranceUnderground chambersTunnel liningArchitectural engineeringMultiple point

The invention relates to a structure and method for multipoint suspending laying construction of a tunnel waterproof board. By the adoption of the characteristic that hook-face bands and loop-face bands of hook-and-loop fasteners can adhere to each other and be separated from each other freely, the hook-face bands are fixed to a basic face in parallel according to a preset interval, the loop-face bands are fixed to the back face of the waterproof board in parallel according to a preset interval, after the waterproof board is laid on the basic face, the hook-face bands and the loop-face bands are arranged in a mutually intersecting mode, overlapping points are automatically formed between the hook-face bands and the loop-face bands and are adhesive points, suspending points between the waterproof board and the basic face are formed by the multiple adhesive points, and therefore the waterproof board is effectively suspended through the multiple points. The suspending points do not need to be set manually, point localization in the construction process is not necessary either, the quality of the portion, on the suspending points, of the waterproof board is guaranteed, the looseness margin of waterproof board laying operation can be well controlled, the construction operability and the construction convenience are good, and negative influence on the quality of suspending and laying construction of the waterproof board due to non-smoothness and irregularity of the laying basic face of the waterproof board is avoided.

Owner:FUZHOU PLANNING DESIGN & RES INST

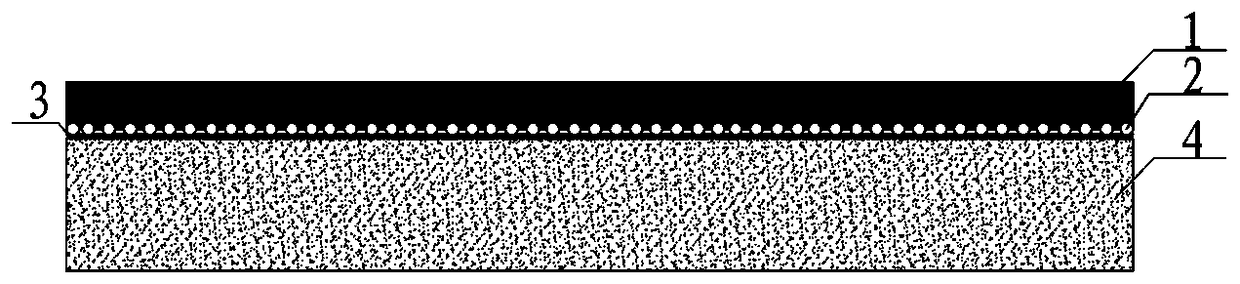

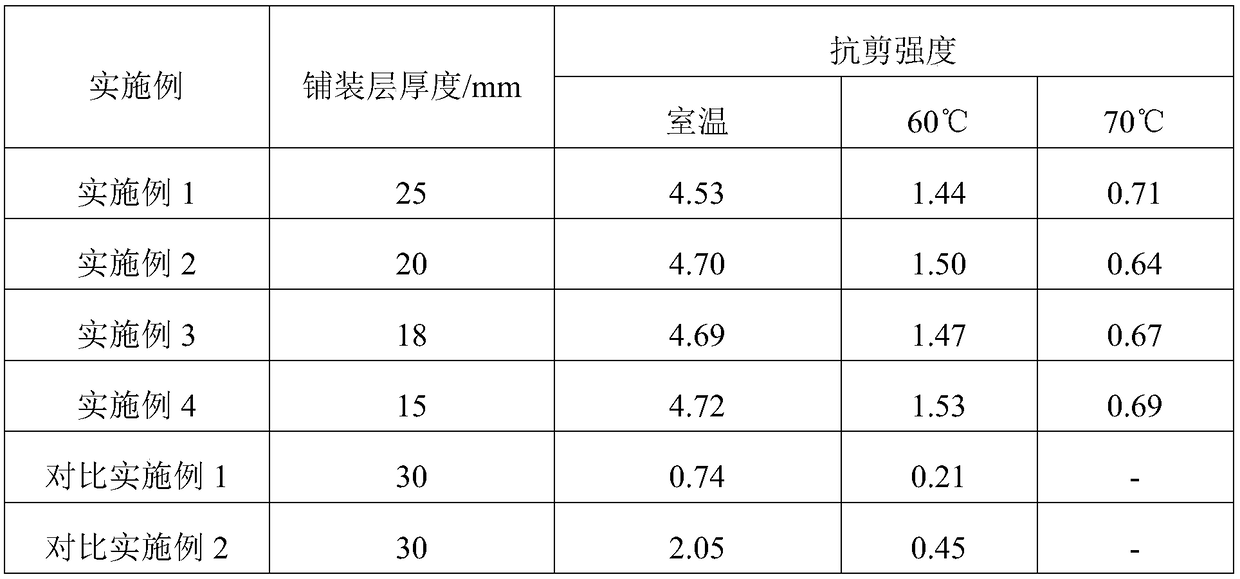

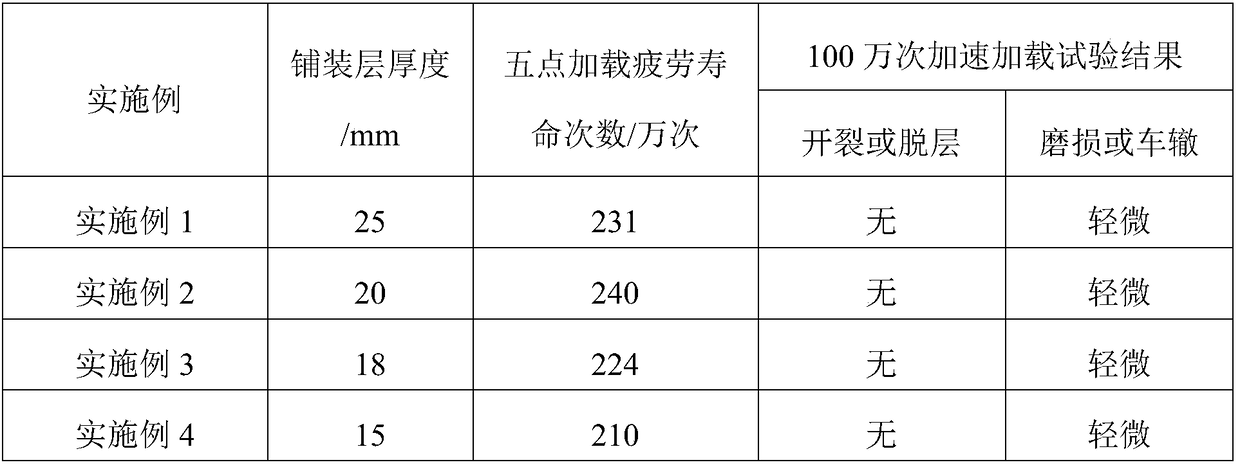

Pavement structure for concrete bridge deck and construction method thereof

InactiveCN108824120AImprove impact resistanceImprove shear resistanceIn situ pavingsBridge structural detailsSurface layerPolymer resin

The invention provides a pavement structure for a concrete bridge deck. The pavement structure is characterized by successively comprising a resin cushion layer, a polymer resin particle bonding layerand an ultra-thin asphalt pavement layer from the concrete bridge deck to the surface layer, wherein the concrete bridge deck and the ultra-thin asphalt pavement layer are bonded through the resin cushion layer and polymer resin particles, and total pavement thickness is 15-25 mm. The pavement structure of the invention has the advantages of thin overall thickness, light weight, good bonding performance among the layers, and high shear strength, and is beneficial for improving the durability of a bridge pavement layer.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

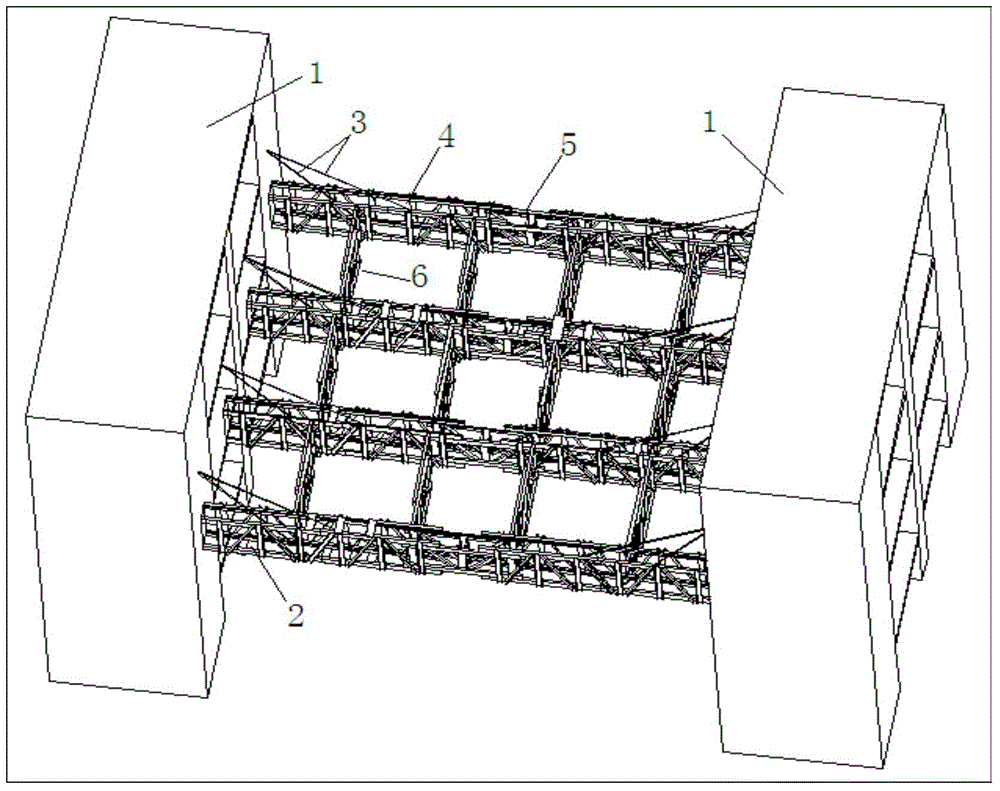

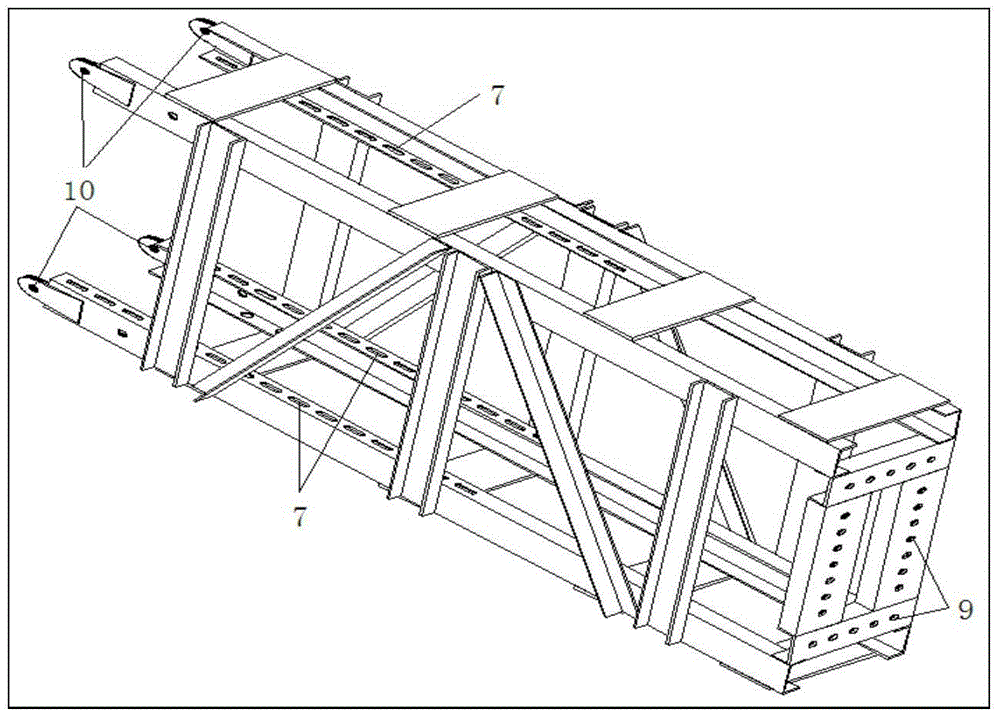

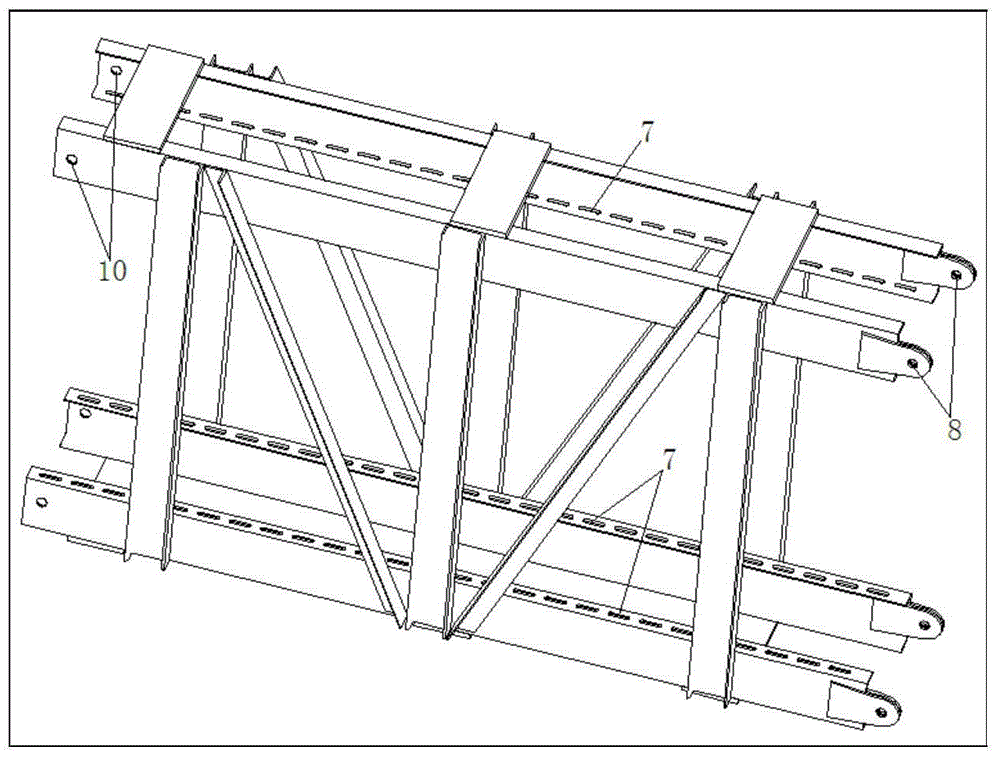

Steel truss formwork support structure for suspended structure and installing method of steel truss formwork support structure

The invention discloses a steel truss formwork support structure for a suspended structure and an installing method of the steel truss formwork support structure. A main stress component of a system consists of a rectangular space truss, and comprises end part trusses, truss standard sections, connecting trusses and diagonal draw bars, wherein each end part truss is used at a connecting part of each truss end part and a main body structure; each truss standard section is used for truss extension; each connecting truss is used in a position, with the length being smaller than that of one truss standard section, of the middle part of each truss and is used for connecting the truss standard sections arranged at the two sides; each diagonal draw bar is made of novel level-3 steel; and the length of each diagonal draw bar can be regulated through rotating a corresponding sleeve arranged at the end part. The support system adopts industrialized and standardized production, can be repeatedly used, has high economical efficiency, and can adapt to formwork supporting of connected suspended structures with different spans and different structural forms. An installing method of adopting cable-stayed suspension installation and laying an operation platform during the installation is adopted, so that the integral stability of the whole support system in the installing process can be improved; the construction is convenient; and the safety is high.

Owner:SINOMA INT ENG

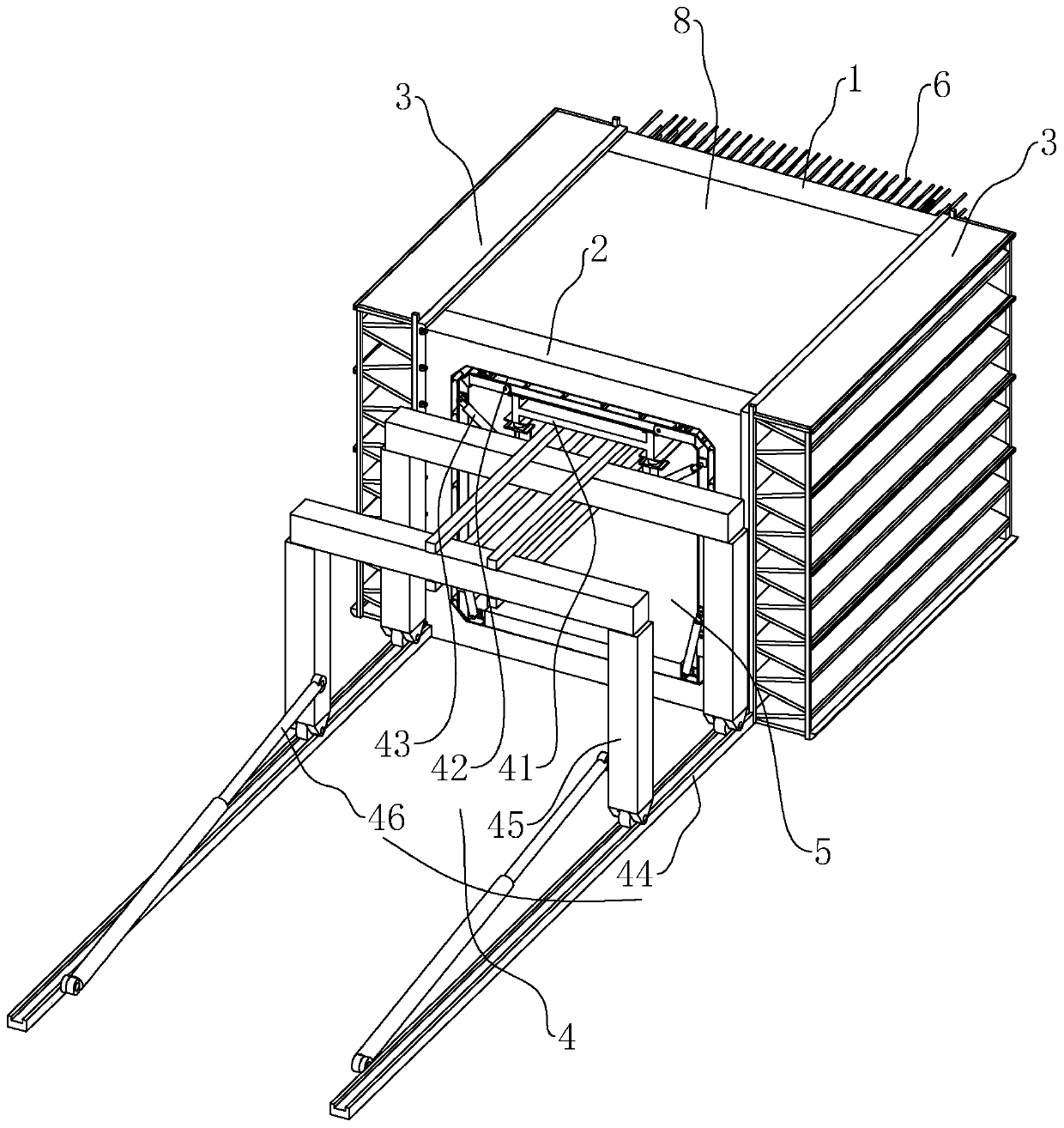

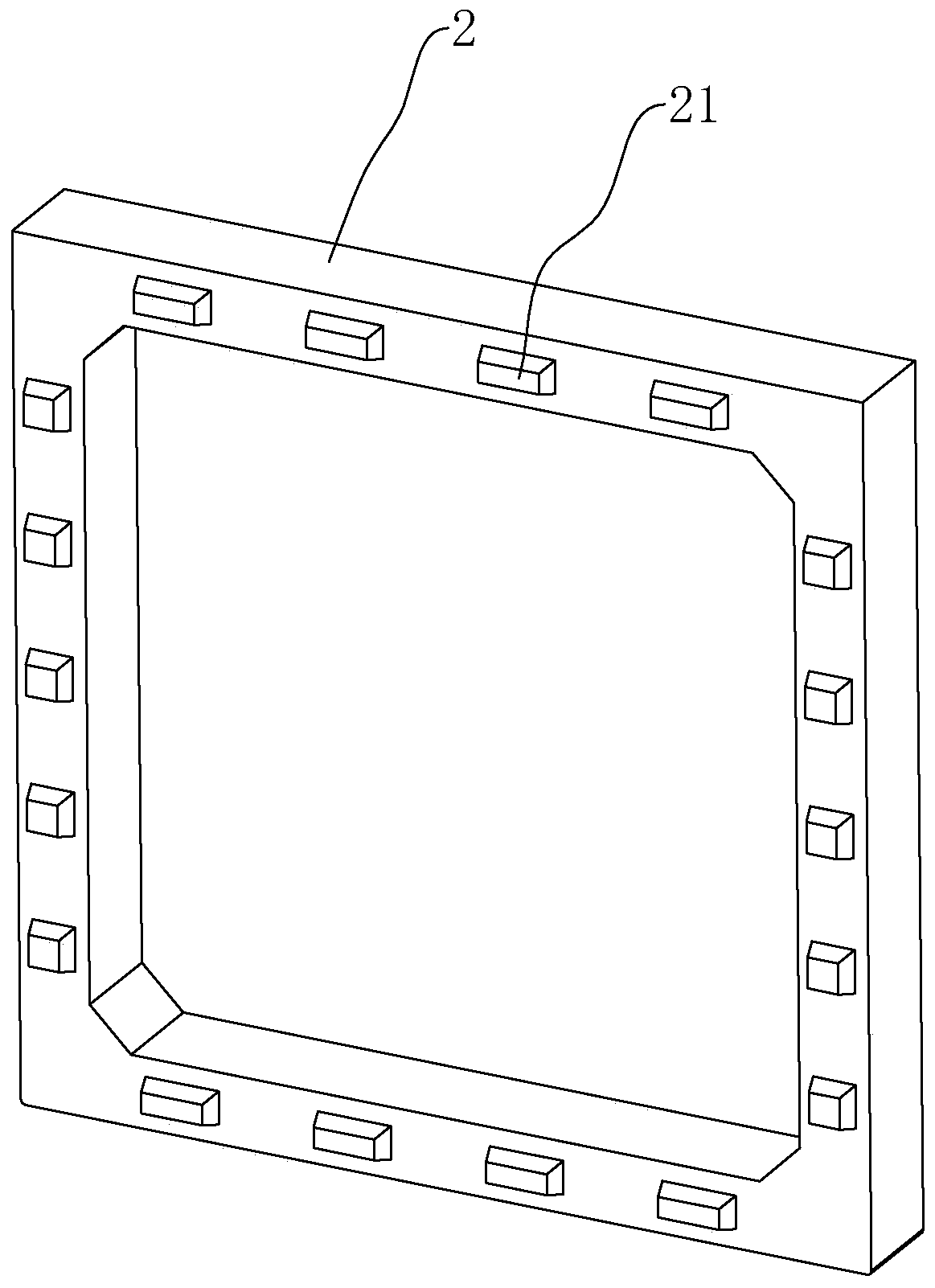

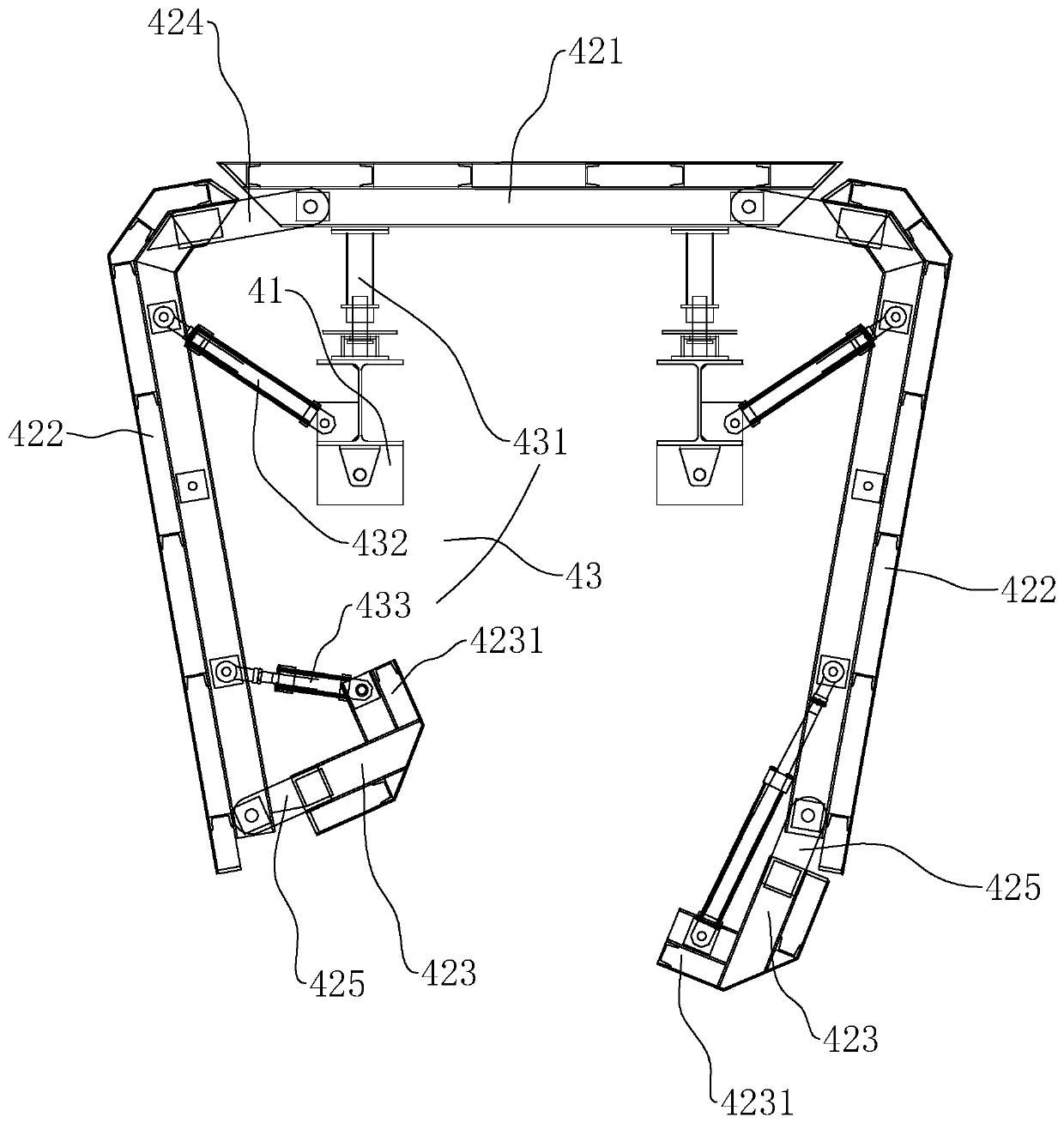

Prefabricated mould for pipe gallery and construction method for pipe gallery

InactiveCN109958143ASimplify the assembly processImprove construction convenienceArtificial islandsMouldsRebarPrefabrication

The invention discloses a prefabrication mould for a pipe gallery, and relates to the technical field of engineering moulds. According to the key points of the technical scheme, the prefabrication mould comprises a fixed end mould body, a movable end mould body, an outer side mould body, an inner mould body and a bottom mould body, wherein the movable end mould body and the fixed end mould body are arranged at the two ends of the outer side mould body correspondingly, the movable end mould body is hinged to the outer side mould body, the inner mould body and the bottom mould body are combinedand arranged in the outer side mould body, and a forming space is formed between the inner mould body and the bottom mould body after the inner mould body and the bottom mould body are combined with the outer side mould body. The two ends of the inner mold body abut against the fixed end mold body and the movable end mold body, reinforcing steel bars are embedded in the forming space, the reinforcing steel bars penetrate through the fixed end mold body, the fixed end mold body is installed at the end of the outer mold body, a plurality of reinforcing steel bar hole positions for the reinforcing steel bars extending out are formed in the fixed end mold body, and the reinforcing steel bar hole positions correspond to the reinforcing steel bars. By extending the embedded steel bars out of thesteel bar hole positions, the steel bars are exposed after the pipe gallery is formed, construction of each section of the pipe gallery during splicing is convenient, the mould assembly is convenient, and the advantage of improving the construction convenience is achieved.

Owner:厦门三航混凝土有限公司 +3

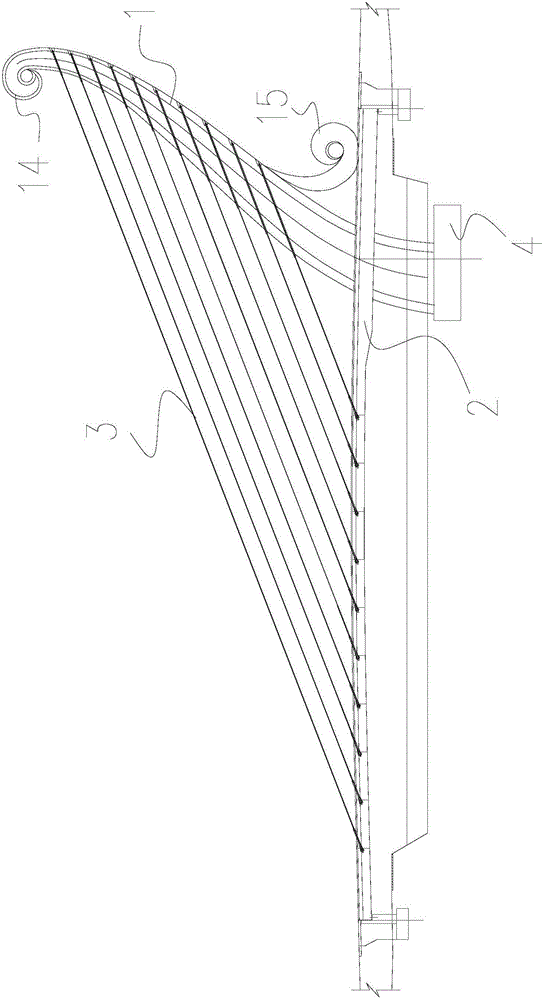

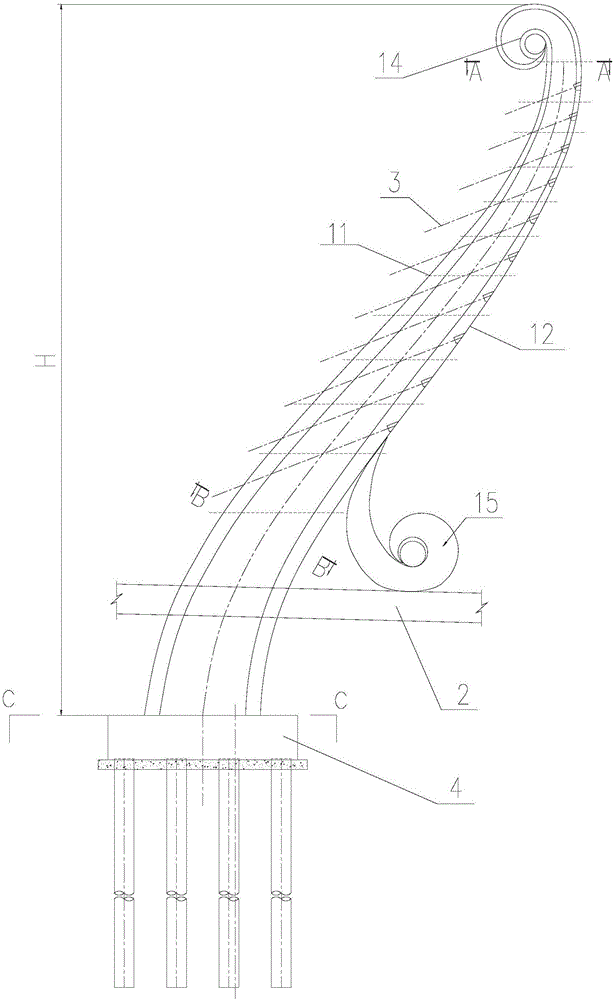

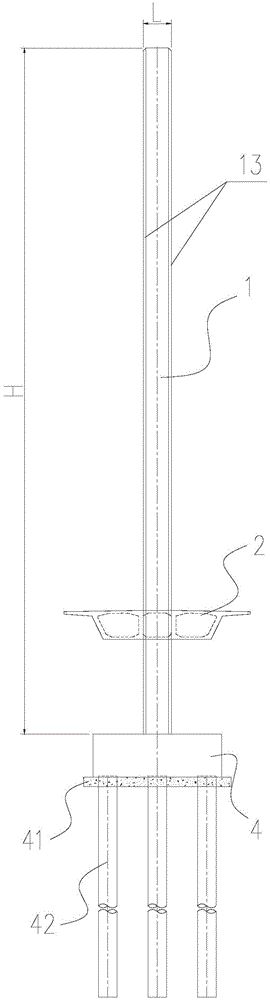

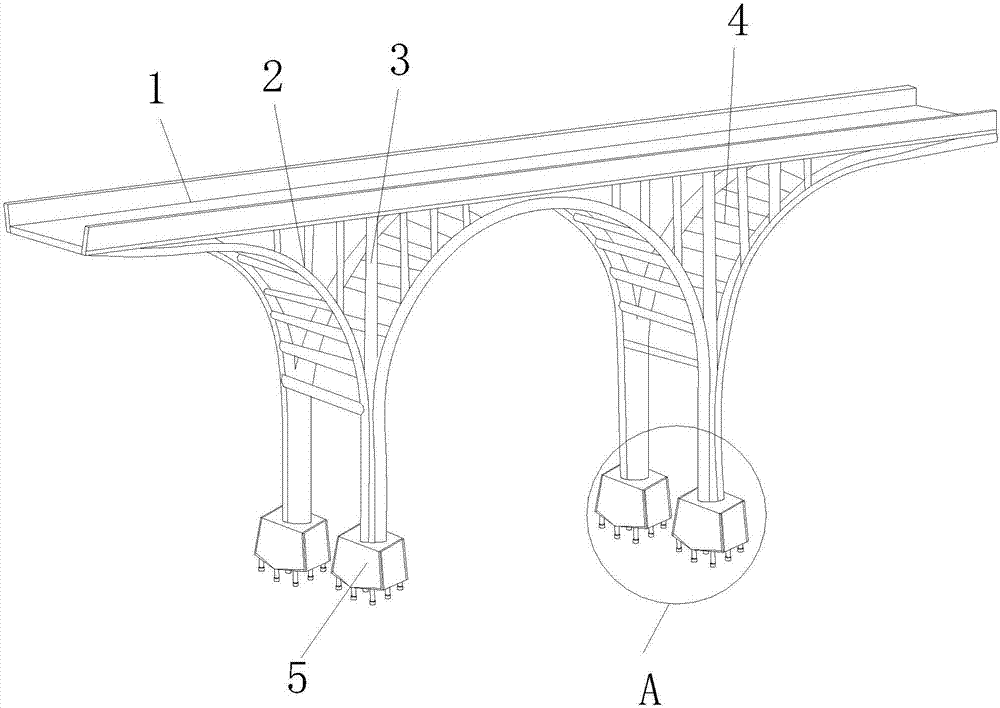

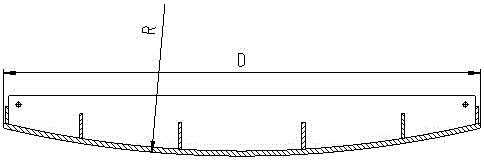

Cable-stayed bridge provided with curved single pylon with double cable planes

ActiveCN105839511AImprove carrying capacityImprove construction convenienceCable-stayed bridgeBridge structural detailsCable stayedSlant angle

The invention discloses a cable-stayed bridge provided with curved single pylon with double cable planes. The bridge comprises a main pylon, a main beam, stay cables and a cushion cap, wherein the cable facing plane and the cable backing plane of the main pylon are cambered surfaces with variable curvature and unchangeable width, longitudinal slant angles are different and change section by section along with construction of the main pylon, the longitudinal slant angle in the middle section of the main pylon is at least 50 degrees, and the longitudinal slant angles at the bottom and the top of the pylon are about 90 degrees; two side surfaces of the main pylon are planes, the widths of the two sides surface of the main pylon gradually get smaller from bottom to top, and accordingly, the cross sections of the main pylon gradually linearly get smaller from the bottom to the top of the pylon in the height direction; the main pylon is a solid section with four chamfered sides, the lengths of chamfers of the main pylon are gradually linearly changed from 150 cm to 50 cm from the bottom to the top of the pylon in height direction, and the widths of the chamfers are all 30 cm; the main beam and the main pylon are integrated through concrete pouring; ten pairs of stay cables are arranged between the main pylon and the main beam. The cable-stayed bridge is reasonable in structure, attractive in appearance and strong in stress sense and gives people a unique visual feeling.

Owner:CCCC THIRD HARBOR ENG +2

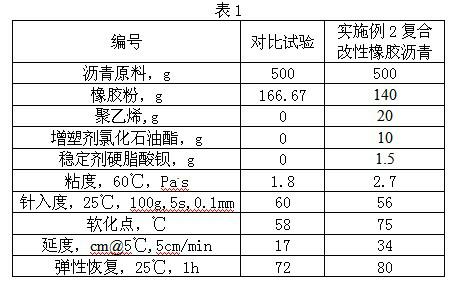

New composite modified rubber asphalt and preparation process thereof

InactiveCN102086305AImprove scalabilityImprove fatigue resistanceIn situ pavingsBuilding insulationsPolymer scienceStearic acid

The invention belongs to the technical field of asphalt and particularly relates to new composite modified rubber asphalt and a preparation process thereof. The new composite modified rubber asphalt is prepared from the following raw materials in parts by weight: 100 parts of matrix asphalt, 25-30 parts of rubber powder, 3-5 parts of polyethylene, 1-3 parts of chlorinated petroleum ester and 0.2-0.4 part of barium stearate. In the new composite modified rubber asphalt of the invention, chlorinated petroleum ester is used to increase the expansion properties and fatigue resistances of rubber powder and polyethylene; and calcium stearate is added to improve the oxidation resistance and stability of rubber asphalt, increase the construction convenience of rubber asphalt and expand the application range of rubber asphalt.

Owner:尹泽珲

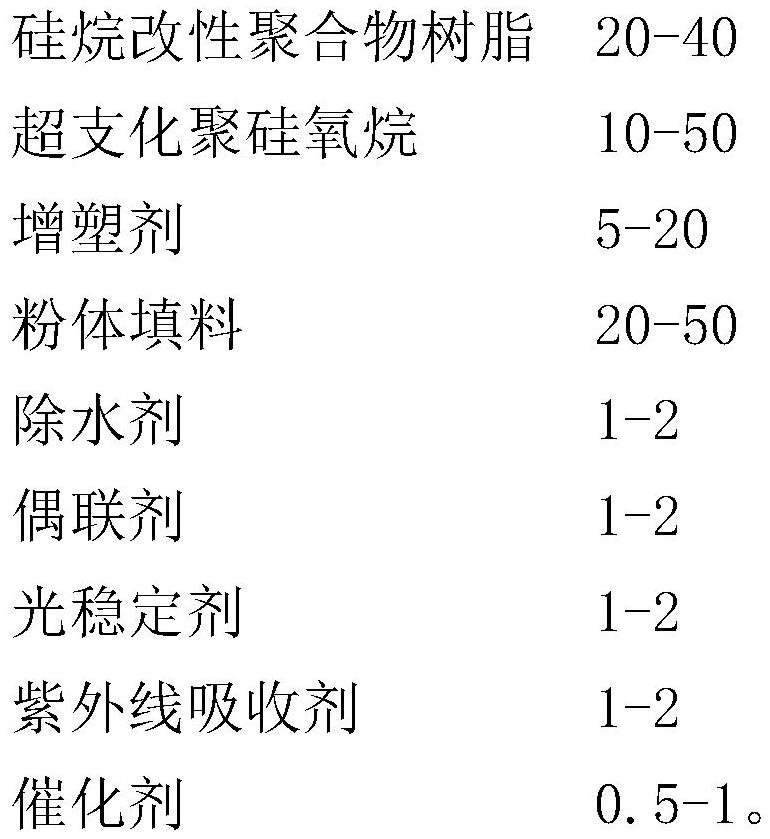

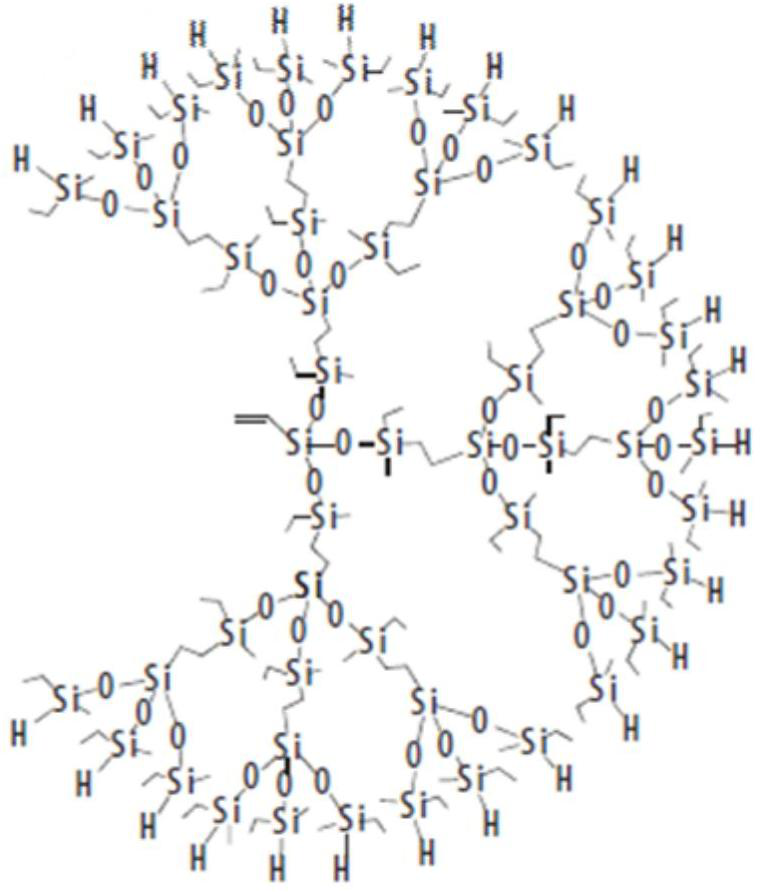

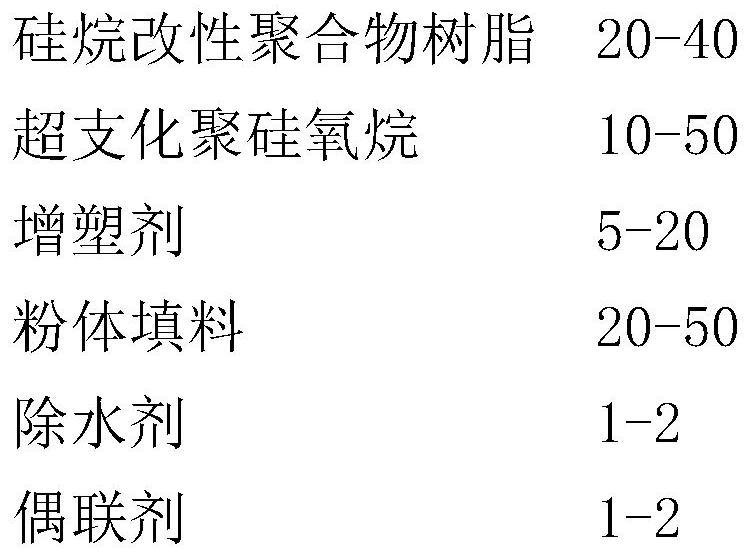

High-strength self-leveling silane modified waterproof coating and preparation method thereof

ActiveCN111763469AHigh viscosityImprove mechanical propertiesPolyurea/polyurethane coatingsPolyether coatingsPolymer sciencePtru catalyst

The invention relates to a high-strength self-leveling silane modified waterproof coating. The coating is prepared from the following components in parts by mass: silane modified polymer resin, hyperbranched polysiloxane, a plasticizer, a powder filler, a water removal agent, a coupling agent, a light stabilizer, an ultraviolet light absorber and a catalyst. The hyperbranched polysiloxane is addedinto a system, so the viscosity and the mechanical property of the silane modified coating are greatly improved, and thus, the construction convenience and the storage stability of the coating are improved. Due to the introduction of the hyperbranched polysiloxane, Si-O-Si bonds in the system are greatly increased, and the heat resistance and weather resistance of the silane modified coating areobviously improved. The hyperbranched polysiloxane and the end groups of common silane modified resin react and are cross-linked, so the mechanical properties of the silane modified coating can be further improved, and the stability of the system is better.

Owner:上海三棵树防水技术有限公司

Municipal road structure by river under overpass

InactiveCN107326799AImprove construction convenienceSolve the slow construction speedBridge structural detailsRight triangleWater flow

The invention discloses a riverside municipal road structure under a viaduct, which comprises a viaduct upper road surface, arc-shaped support rods, vertical connecting rods, horizontal cross bars, and bridge piers, and the viaduct upper road surface is supported by more than two arc-shaped The rod and the pier are fixed together, and the two arc-shaped support rods parallel to the front and rear are welded with horizontal bars, and one end of the vertical connecting rod is embedded in the road surface of the viaduct, and the vertical connection The other end of the rod is welded to the top surface of the arc-shaped support rod, and there are structures such as a sinking fixing device, an anti-shock vertical plate, a concrete filling device, a first support stand, and a second support stand to improve the impact resistance of the water flow of the present invention. It will not be skewed due to the impact of water flow over time. It is integrated with concrete pouring, which has low density and increased firmness. Improve construction convenience and speed.

Owner:泉州圆创机械技术开发有限公司

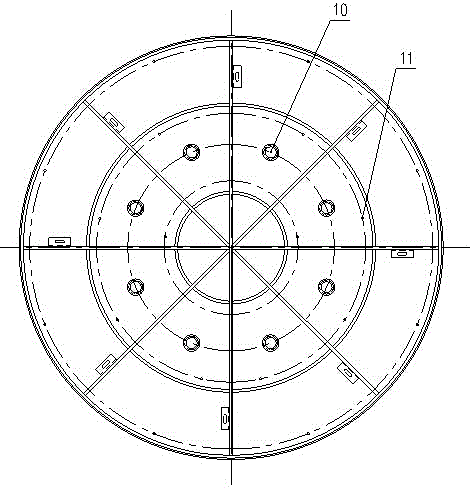

Bridge rotating construction rotating spherical hinge with self-centering function

ActiveCN106192775AIncrease stiffnessThere will be no stuck problemsBridge erection/assemblyVertical loadMachining

Provided is a bridge rotating construction rotating spherical hinge with a self-centering function. An upper spherical hinge convex spherical surface is matched with a lower spherical hinge concave spherical surface. Automatic positioning of a structure is achieved under the effect of the self weight and vertical loads, intermediate hinge pins are not arranged, the machining, manufacturing and assembling cost is saved, the manufacturing period is shortened, and the situation that hinge pins are stuck in the rotating process is avoided. Through improvement of the spherical hinge structure, the structural rigidity of the spherical hinge is improved, the spherical hinge can be conveniently mounted, the requirement for rotating construction of a high-bearing bridge structure is met, and construction convenience and reliability are improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP +1

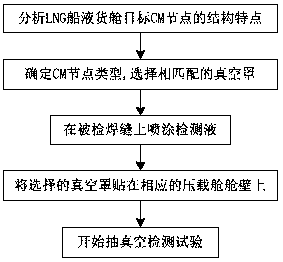

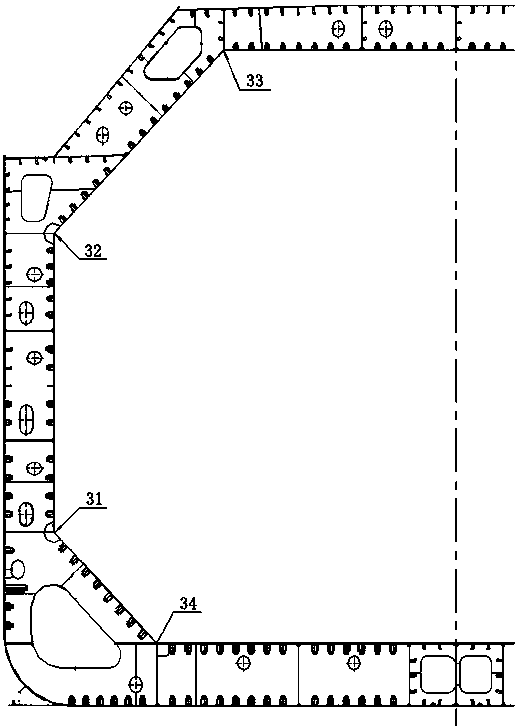

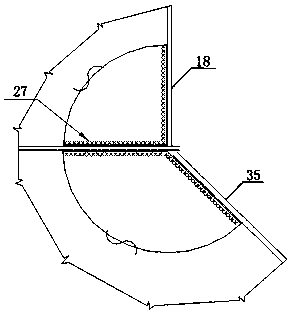

Airtightness detection method of CM node area of liquid cargo tank of LNG ship

InactiveCN108020380AFast tightness testConvenient and effective leak detectionDetection of fluid at leakage pointMeasurement of fluid loss/gain rateMarine engineeringBallast tank

The invention discloses an airtightness detection method of a CM node area of a liquid cargo tank of an LNG ship. The method comprises: a structural characteristic of a target CM node of a liquid cargo tank of an LNG ship is analyzed; on the basis of the structural characteristic of the target CM node, a CM node type is determined and a matched vacuum cover is selected based on the CM node type; and detection liquid is sprayed on a detected weld joint, the selected vacuum cover is in close contact with a corresponding ballast tank wall, and then vacuumization detection is started. According tothe invention, while related ship structures of the ballast tank do not form a complete tank, airtightness detection is carried out on the CM node area quickly and conveniently, so that time is earned for follow-up construction of the LNG ship containment system and the construction period of the LNG ship is shortened. Moreover, the CM node can be detected at the forming process of any construction stage like the segmentation stage and the main stage and restrictions on the construction state, the segmentation placing state, and the welding mode are eliminated.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

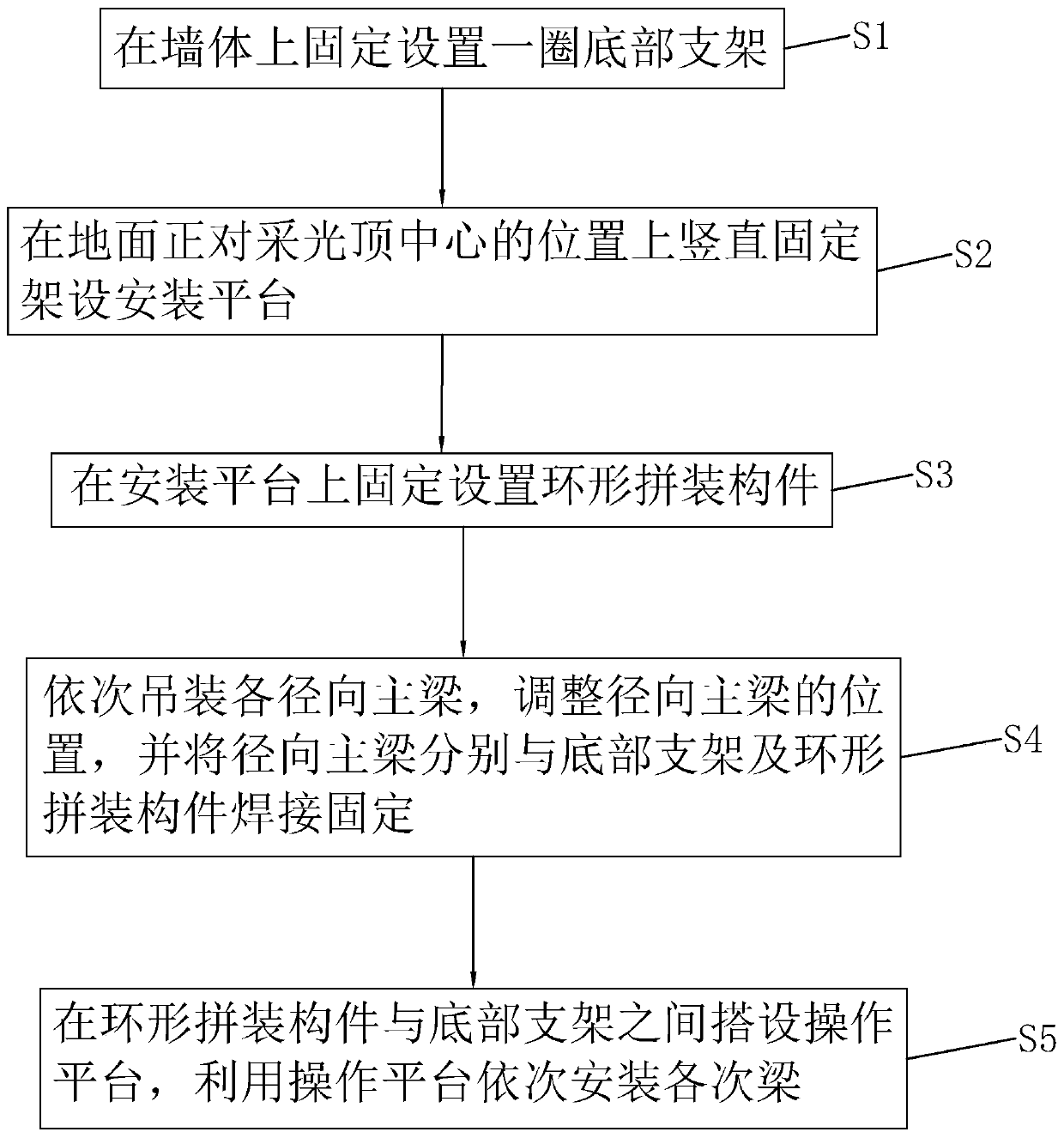

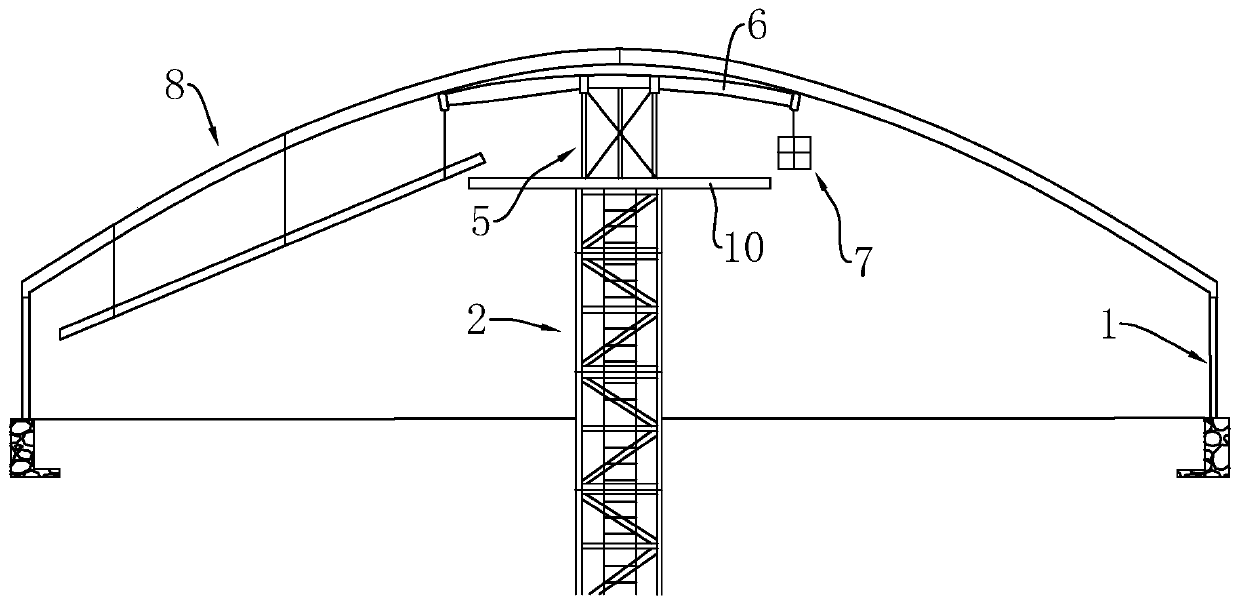

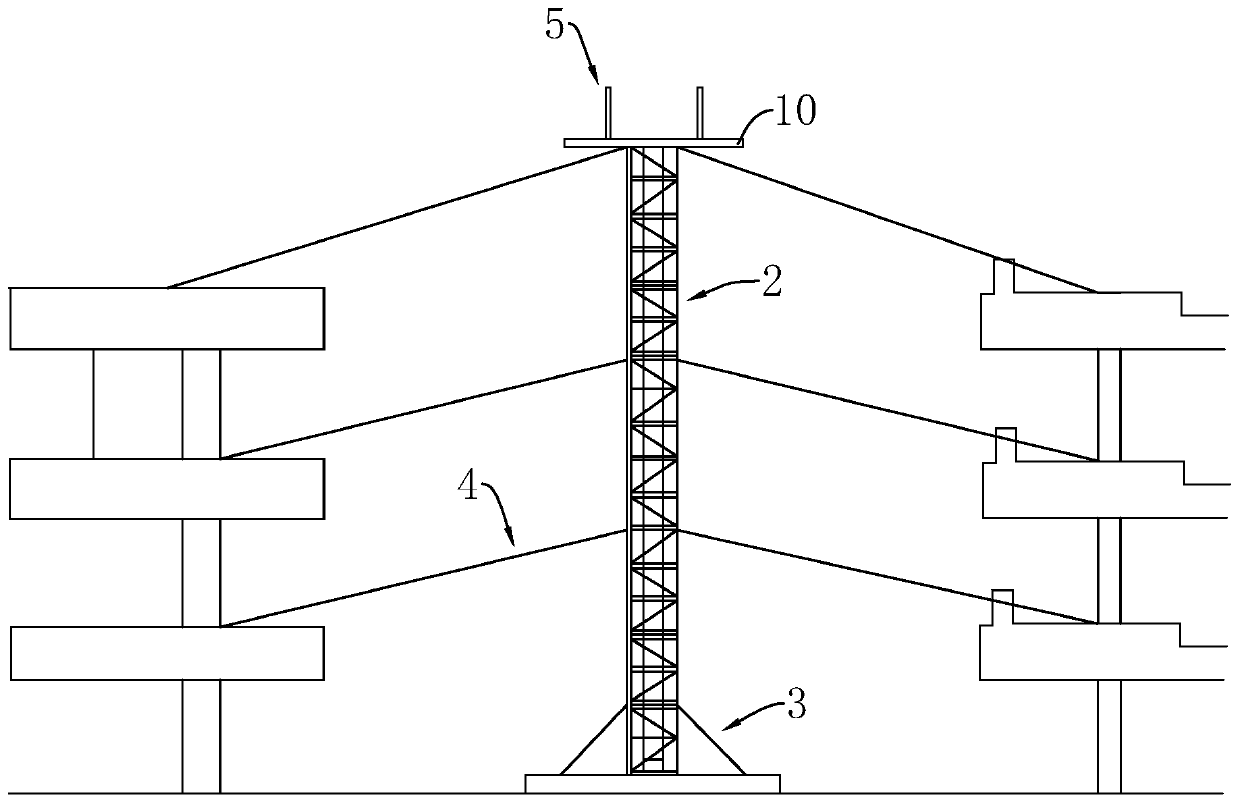

Daylighting roof steel structure mounting method

InactiveCN109695317AImprove construction efficiencyImprove construction convenienceRoof covering using slabs/sheetsBuilding roofsEngineeringUltimate tensile strength

The invention discloses a daylighting roof steel structure mounting method and relates to the technical field of building daylighting roofs. The mounting method comprises the following steps: fixedlyarranging a circle of bottom bracket on a wall, vertically and fixedly erecting a mounting platform in a position, over against the center of the daylighting roof, on the ground, fixedly arranging built-up member on the mounting platform, sequentially hoisting radial main beams, adjusting positions of the radial main beams, welding and fixing the radial main beams to the bottom bracket and the annular built-up member, setting up an operating platform between the annular built-up member and the bottom bracket, and sequentially mounting secondary beams using the operating platform. The daylighting roof steel structure mounting method is convenient in construction and short in construction period, saves a space, and can lower construction cost, ensure structural strength of a daylighting roofand adequately ensure safety.

Owner:THE FIRST CONSTR CO LTD OF CHINA CONSTR FIRST GRP +1

Anti-overturning strengthening method for single-column pier bridge

InactiveCN105442460AImprove anti-overturn performanceImprove economyBridge erection/assemblyBridge strengtheningElectric signalCeramic

The invention provides an anti-overturning strengthening method for a single-column pier bridge. The method comprises the following steps: pre-assembling a steel hoop and a steel corbel into an overall steel structure; lifting the overall steel structure formed by the steel hoop and the steel corbel to the top of a bridge pier upright column by using a lifting device; fixing the overall steel structure formed by the steel hoop and the steel corbel to the top of the bridge pier upright column; placing a plurality of intelligent supports on the steel corbel; enabling a bridge support and the intelligent supports at two sides to form a 'seesaw' structure; adjusting the heights of the intelligent supports to enable the upper surfaces of the intelligent supports to be tightly laminated with a bridge beam bottom and enable the lower surfaces of the intelligent supports to be tightly laminated with the steel corbel; and acquiring electric signals generated by piezoelectric ceramics in the intelligent supports in real time so as to judge whether the intelligent supports have the phenomena of disengagement and deflection. The anti-overturning strengthening method provided by the invention improves the anti-overturning performance of the single-column pier bridge and has relatively good construction convenience, relatively wide applicability and excellent economical efficiency.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com