Structure and method for multipoint suspending laying construction of tunnel waterproof board

A technology of tunnel waterproof board and construction method, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as unfavorable waterproof quality, difficult operation, narrow construction space, etc., and achieve strong construction operability, good construction convenience, Controlling the Effect of Slack Allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

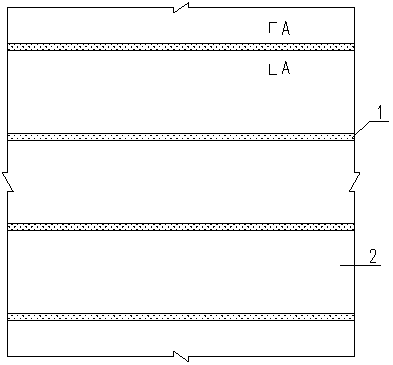

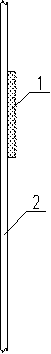

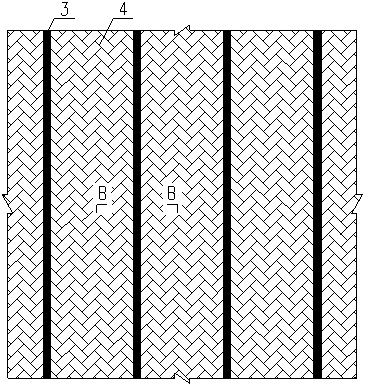

[0032] Such as Figure 1~6 As shown, a multi-point suspension laying construction structure of a tunnel waterproof board includes a base surface 4 and a waterproof board 2, and the base surface 4 is fixedly provided with a plurality of hook surface belts 3 distributed in parallel at predetermined intervals. On the back of the board 2 facing the base surface 4, there are fixedly arranged a plurality of loop surface belts 1 distributed in parallel at predetermined intervals. Laying on the base surface 4, the overlapping point formed automatically between the loop surface belt 1 and the hook surface belt 3 is the bonding point, and the multiple intersections between the multiple loop surface belts 1 and the multiple hook surface belts 3 The bonding points form the suspension points 7 between the waterproof board 2 and the base surface 4 to realize multi-point suspension of the waterproof board 2 .

[0033] In the embodiment of the present invention, the hook surface belt 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com