Electric heating module and system for building plate and road facing plate

A board surface and electric heating technology, applied in electric heating systems, heating systems, buildings, etc., can solve the problems of exposure to the outside, and achieve the effect of increasing the closeness and the convenience of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

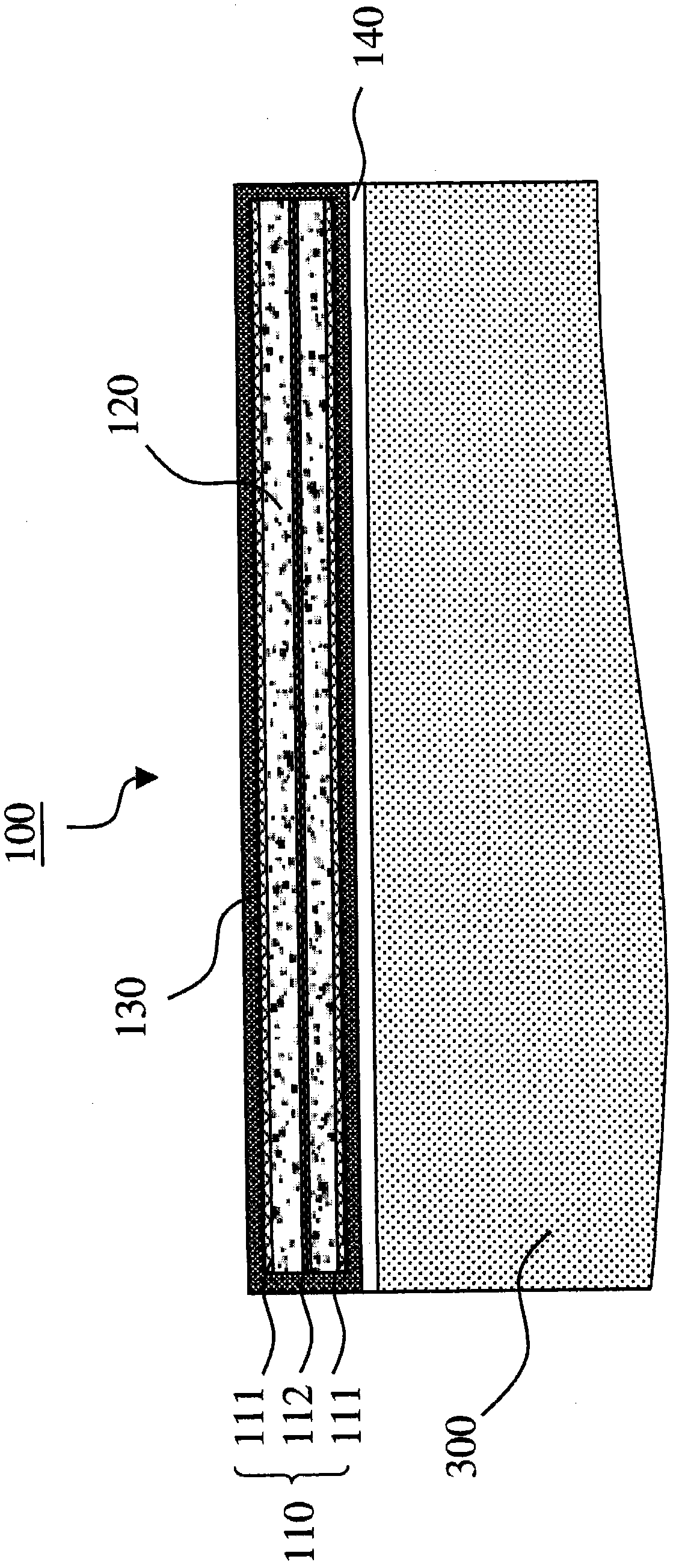

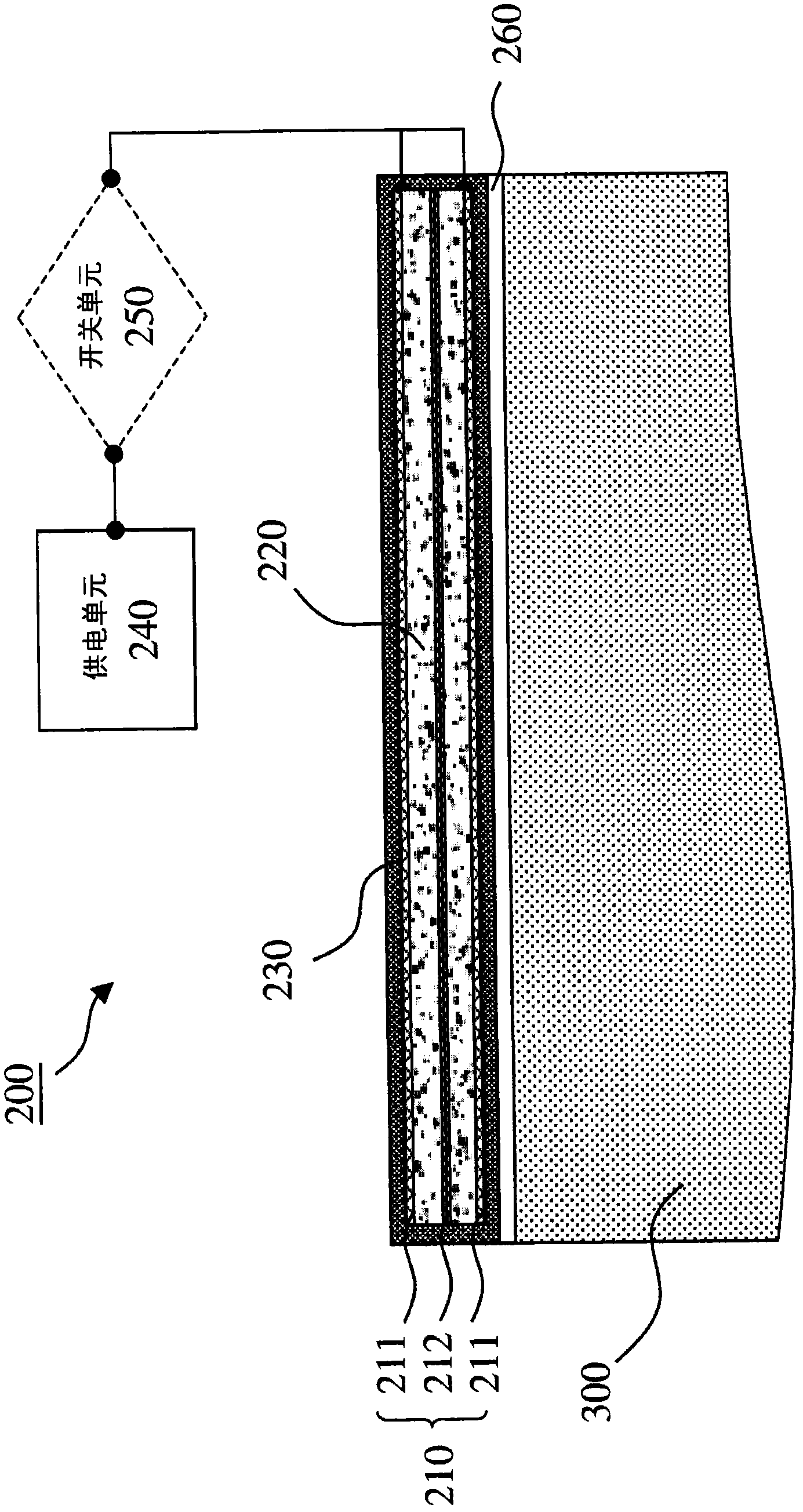

[0031] The invention will be described in detail below with reference to the drawings. refer to figure 2 , is a schematic diagram of an embodiment of the structure board electric heating module of the present invention. According to the present invention, the structure panel electrothermal module 100 is disposed on the surface of a structure panel 300 to emit heat energy. The structure panel electrothermal module 100 is at least composed of an electrode unit 110 , a conductive concrete 120 , and a concrete protection layer 130 .

[0032] Wherein, the electrode unit 110 includes two first electrode layers 111 and a second electrode layer 112 that roughly cover the entire surface area of the structure, and the two first electrode layers 111 and the second electrode layer 112 are parallel to the structure. The board surfaces 300 are arranged parallel to each other, and the two first electrode layers 111 are respectively arranged on the upper and lower sides of the second ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com