LED candle lamp dissipating heat by utilizing bottom-up free mobility of air

An LED candle light, bottom-up technology, applied in the direction of lampshade, lighting and heating equipment, components of lighting devices, etc., can solve the problem that the heat dissipation effect of the LED candle light cannot reach an ideal state, the working efficiency of the LED candle light is not high, Electromagnetic interference is difficult to deal with and other problems, to achieve the effect of scientific and reasonable heat dissipation design, rapid and effective heat dissipation, and good electromagnetic interference problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiment:

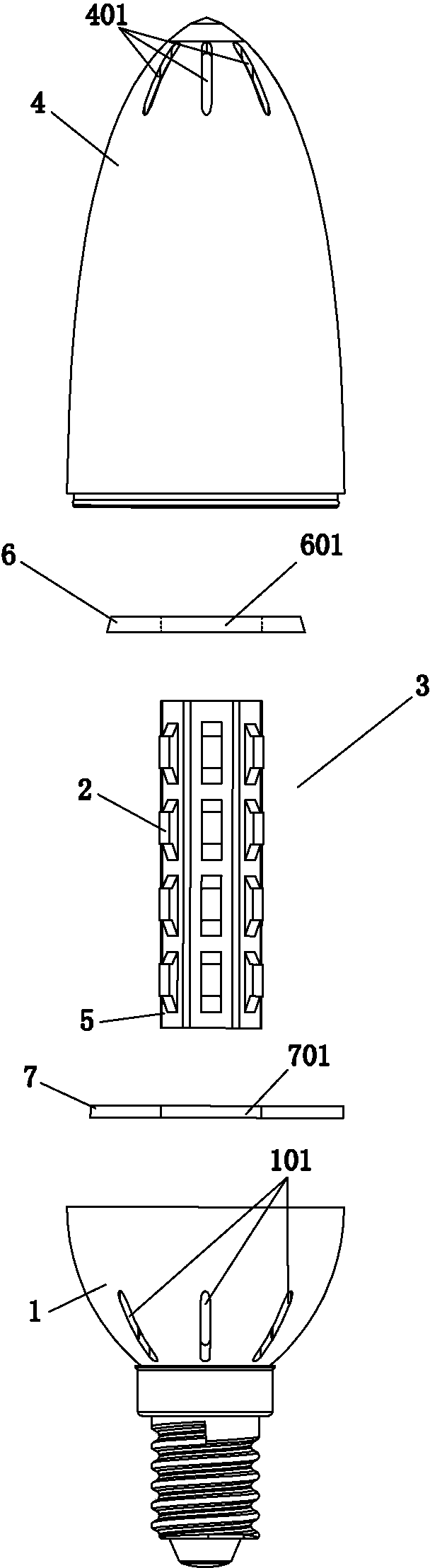

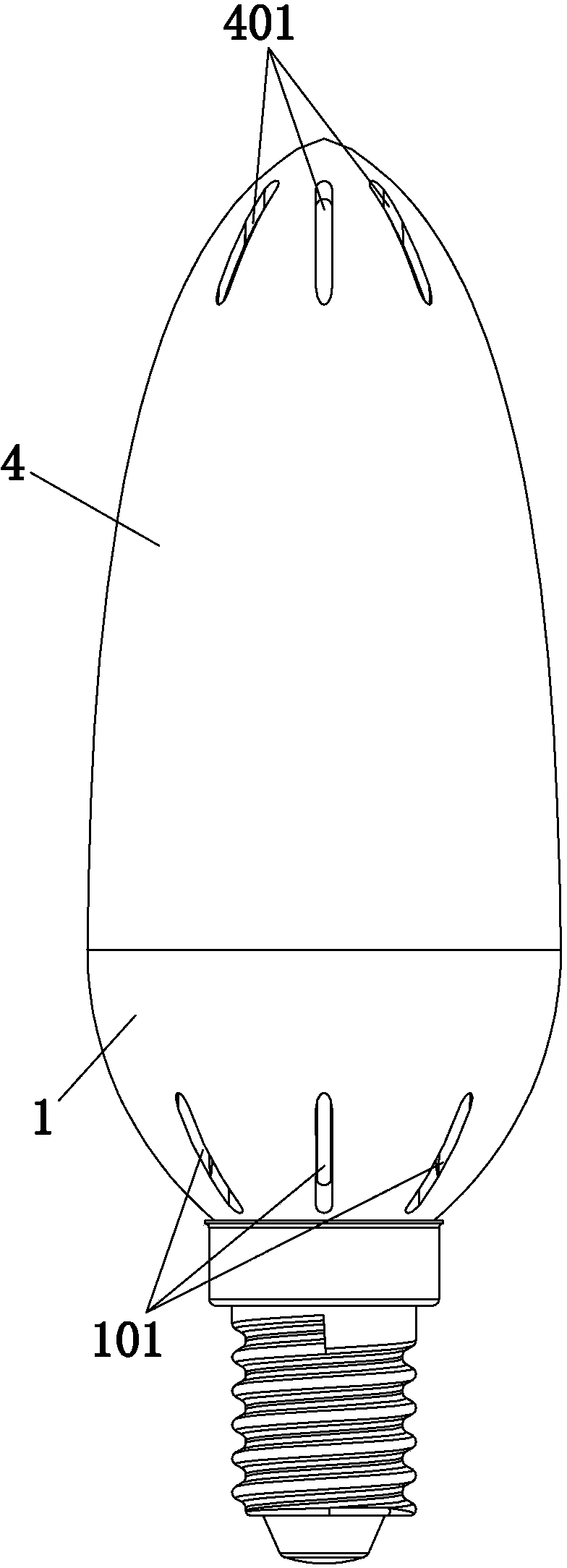

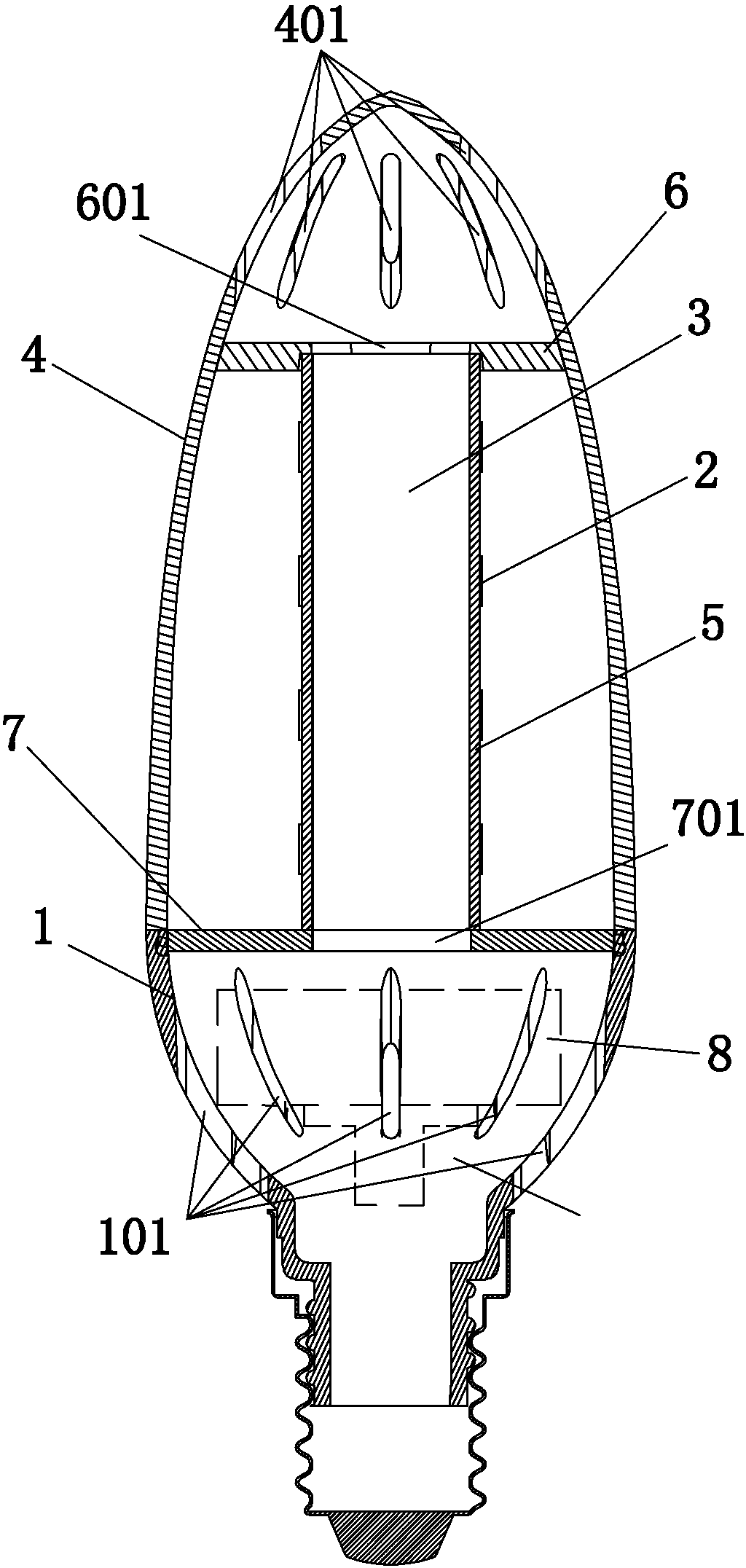

[0011] See attached figure 1 To attach image 3 As shown, the LED candle lamp described in this embodiment uses air to flow freely from bottom to top to dissipate heat, which includes a lamp cup 1, LED lamp beads 2, heat conducting columns 3, an upper partition 6, a metal lower partition 7, Candle-shaped lampshade 4 and flexible circuit board 5, LED lamp beads 2 are arranged on the flexible circuit board 5, and the flexible circuit board 5 is closely attached to the surface of the heat conduction column 3, and there is a slot inside the lamp cup 1, which is fixedly placed on the slot The LED power supply 8 corresponding to the slot, the heat conduction column 3 is a cylindrical structure that penetrates up and down, the upper partition 6 is provided with an upper ventilation hole 601, and the metal lower partition 7 is provided with a lower ventilation hole 701. The heat co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com