Heat-conducting graphene silicone grease and preparation method thereof

A technology of thermal conductive silicone grease and graphene, which is applied in the field of materials, can solve problems such as difficulties, and achieve the effects of reducing interface thermal resistance, improving heat conduction, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

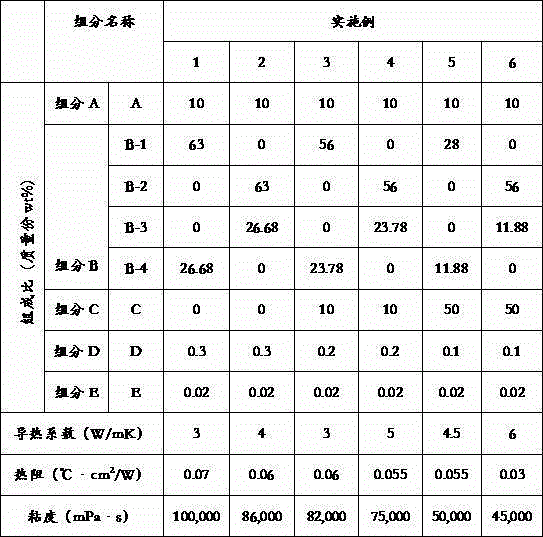

[0040] The present invention will be described in more detail with a series of examples and comparative examples below.

[0041] Graphene thermally conductive silicone grease of the present invention can be prepared by following components and methods:

[0042] A graphene heat-conducting silicone grease is composed of organopolysiloxane (A), heat-conducting filler (B), graphene slurry (C), surface treatment agent (D) and thixotropic agent (E) in a certain weight percentage ratio Prepared by mixing.

[0043] Graphene thermal grease is prepared from the following raw materials:

[0044] Organopolysiloxane (A)5~60wt%

[0045] Thermally conductive filler (B) 10~90wt%

[0046] Graphene slurry (C) 5~80wt%

[0047] Surface treatment agent (D) 0.01~50wt%

[0048] Thixotropic agent (E)0.01~1wt%

[0049] Wherein the graphene slurry (C) is prepared from the following raw materials:

[0050] Organopolysiloxane (A) 1~80wt%

[0051] Graphene powder (F) 1~50wt%

[0052] Surface trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com