Offset lifting slip device and method

A sliding device and sliding technology, applied in the direction of construction and building structure, can solve the problems of difficulty in ensuring the overall stability of the structure, difficulty in guaranteeing the overall stability of the roof, unsatisfactory construction period and economy, and achieve optimal construction. Process, high rigidity, and the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

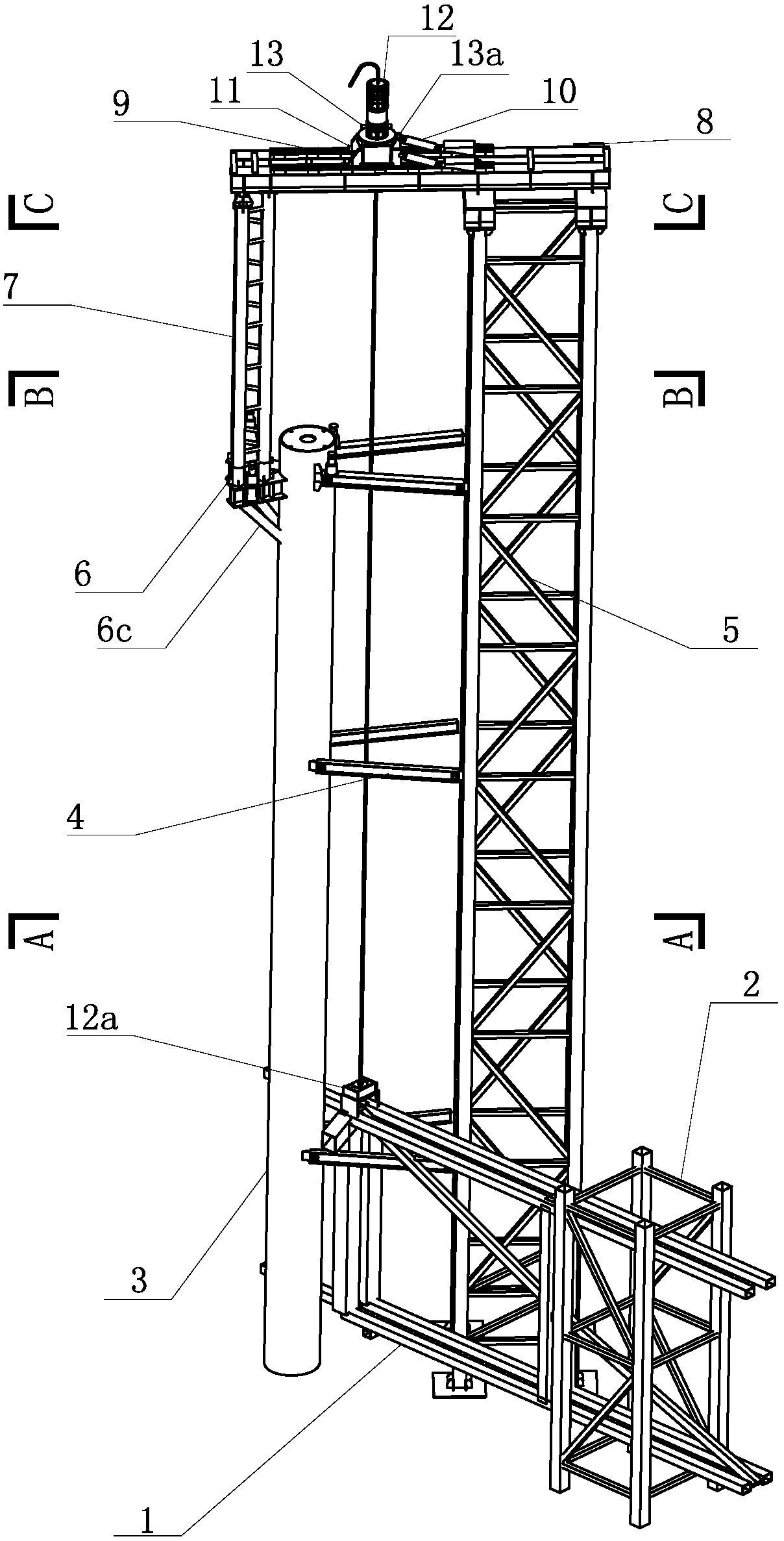

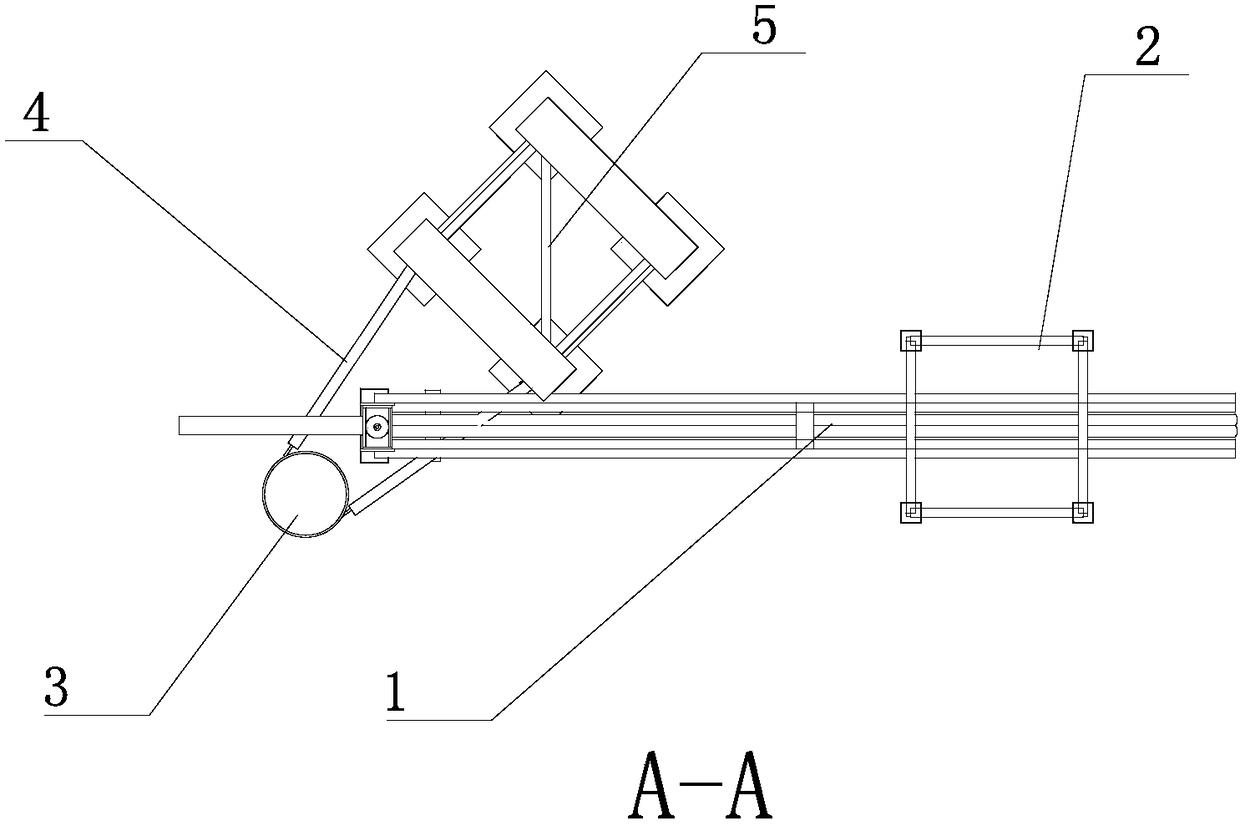

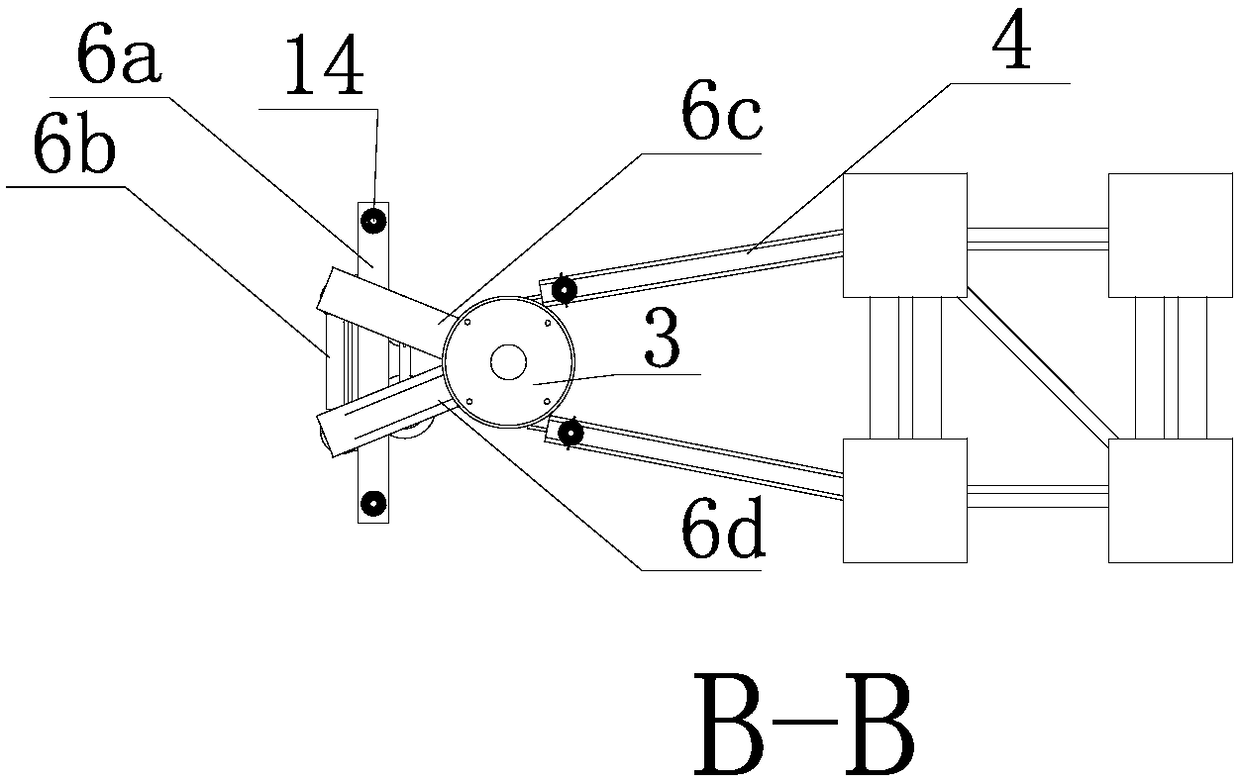

[0040] Examples of the present invention are Figure 1-9 As shown, the specific implementation is described in further detail.

[0041] Such as Figure 1-9 The offset lifting and sliding method shown is one of the examples of the present invention. The structural elevation of the highest point of the roof (excluding the skylight) is 35.5m, and the structural elevation of the lowest point is 30.5m. The station building is a reinforced concrete frame-prestressed steel truss roof structure system, supported by reinforced concrete columns and steel columns, and is composed of 14 transverse trusses and 4 longitudinal trusses. The size of the roof structure is 165m×92m, and its projected area is about 15180m 2, the main height of the truss is 4m, and the cantilever structure is composed of secondary trusses and sealed steel beams around the roof, and the maximum length of the cantilever reaches 12m.

[0042] Using the method of offset lifting and sliding, making full use of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com