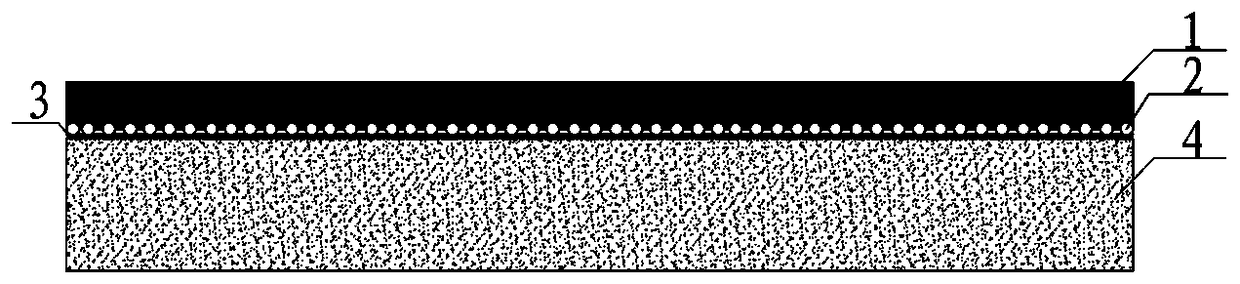

Pavement structure for concrete bridge deck and construction method thereof

A bridge deck pavement and construction method technology, which is applied to the direction of on-site paved concrete pavement, bridges, bridge parts, etc., can solve the problem of shear failure of asphalt concrete pavement that cannot meet the requirements of bridge lightweight design and environmental load , poor control of the amount of spreading, etc., to achieve the effects of preventing sliding and cracking, inhibiting cracking, good fatigue resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

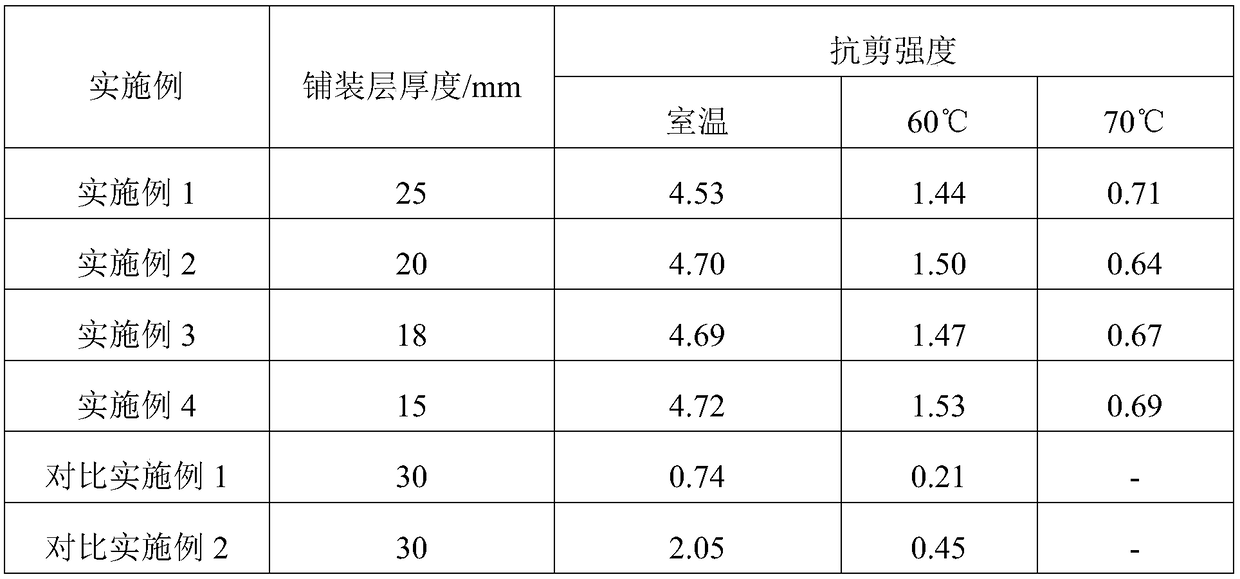

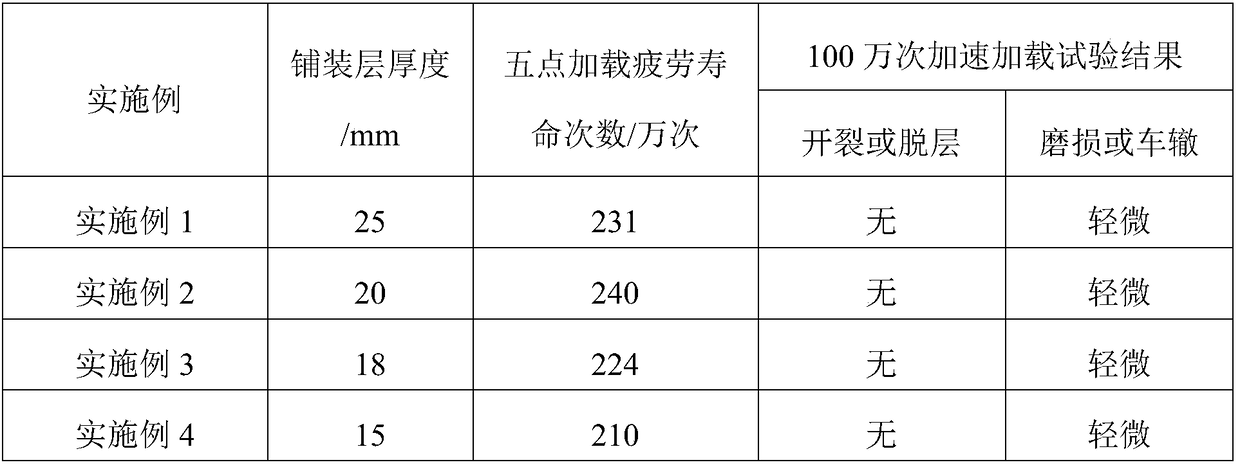

Embodiment 1

[0043] A pavement method for a concrete bridge deck pavement structure, comprising the steps of:

[0044] (1) Sand blast the concrete bridge deck, recycle shot materials, and clean up debris on the bridge deck.

[0045] (2) Brush epoxy resin (purchased from Wuxi Huaou Chemical Co., Ltd., model: E128) on the cleaned and dried concrete bridge surface. Add 10% asbestos powder (purchased from Shijiazhuang Huabang Mineral Products Co., Ltd., model: 325 mesh), 5% asbestos fiber (purchased from Shijiazhuang Huabang Mineral Products Co., Ltd., model: 4mm) in epoxy resin A component ) and 0.5% coupling agent (purchased from Shanghai Kaiyin Chemical Co., Ltd., brand: Dow Corning Z-6011), after stirring evenly, add B component, and then quickly brush on the concrete bridge surface. The amount of epoxy resin is 2.0kg / m 2 , The coating thickness is about 1.8mm. Complete the spreading of polymer resin particles within 20 minutes of brushing the epoxy resin cushion layer, and the spreadin...

Embodiment 2

[0048] A pavement method for a concrete bridge deck pavement structure, comprising the steps of:

[0049] (1) Carve grooves on the concrete bridge deck with a depth of 2mm and an interval of 10mm. Clean the bridge deck with a high-pressure water gun.

[0050] (2) Brush epoxy resin (commercially purchased from Wuxi Huaou Chemical Co., Ltd., model E128) on the cleaned dry concrete bridge surface. Add 13% expanded vermiculite (purchased from Shijiazhuang Huabang Mineral Products Co., Ltd., model: 100 orders), 6% glass fiber (purchased from Jiangsu Kangdafu New Material Technology Co., Ltd., Model: E grade 4mm) and 0.5% γ-(2,3-glycidyloxy) propyltrimethoxysilane coupling agent (purchased from Nanjing Dimont Chemical Co., Ltd., brand: KH560), stir well and add Component B, then quickly brush on the concrete deck. The amount of epoxy resin for brushing is 2.5kg / m 2 ; The thickness of the coating is about 2.0mm. Complete the spreading of polymer resin particles within 30 minutes...

Embodiment 3

[0053] A pavement method for a concrete bridge deck pavement structure, comprising the steps of:

[0054] (1) Sand blast the concrete bridge deck, recycle shot materials, and clean up debris on the bridge deck.

[0055] (2) On the dry concrete bridge surface after cleaning, brush epoxy resin (purchased from Wuxi Huaou Chemical Co., Ltd., model E128) and polyurethane (commercially available from Bayer, Germany) PU 401) mixed resin cushion (mass ratio 3:2). Add 10% expanded vermiculite (purchased from Shijiazhuang Huabang Mineral Products Co., Ltd., model: 100 mesh), 10% glass fiber (purchased from Jiangsu Kangdafu New Material Technology Co., Ltd., Model: E grade 3mm) and 0.8% of γ-(2,3-epoxypropoxy)propyltrimethoxysilane coupling agent (purchased from Nanjing Dimont Chemical Co., Ltd., brand: KH560), stir well and add Component B, then quickly brush the mixed resin over the grit blasted reactive powder concrete. The amount of mixed resin is 2.0kg / m 2 , The coating thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com