Cable-stayed bridge provided with curved single pylon with double cable planes

A double-cable plane, cable-stayed bridge technology, applied in the field of cable-stayed bridges, can solve the problems of increasing the difficulty of design and construction, the weight of concrete bridge towers, and the complex force and structure, achieving unique visual experience and improving construction. Convenience, the effect of enhanced bending and torsional stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

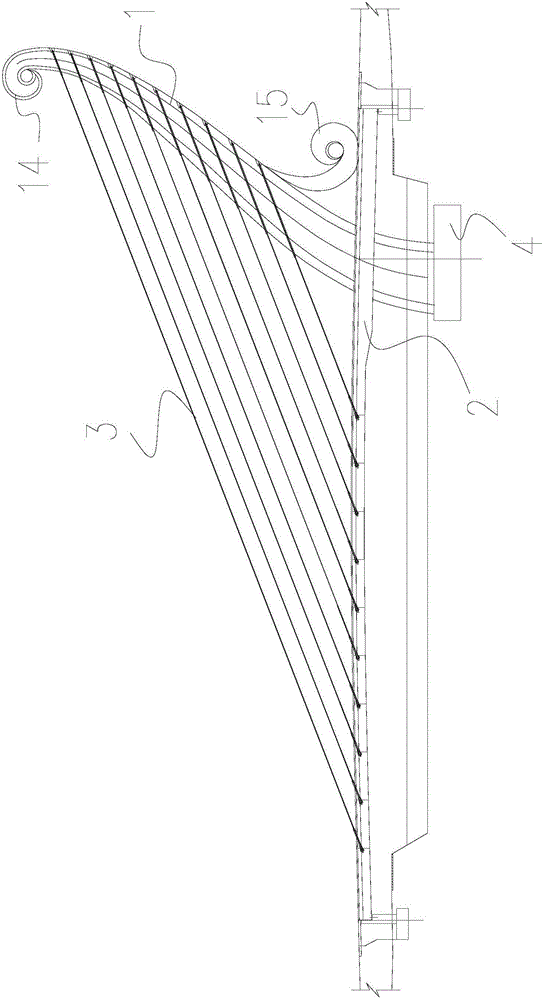

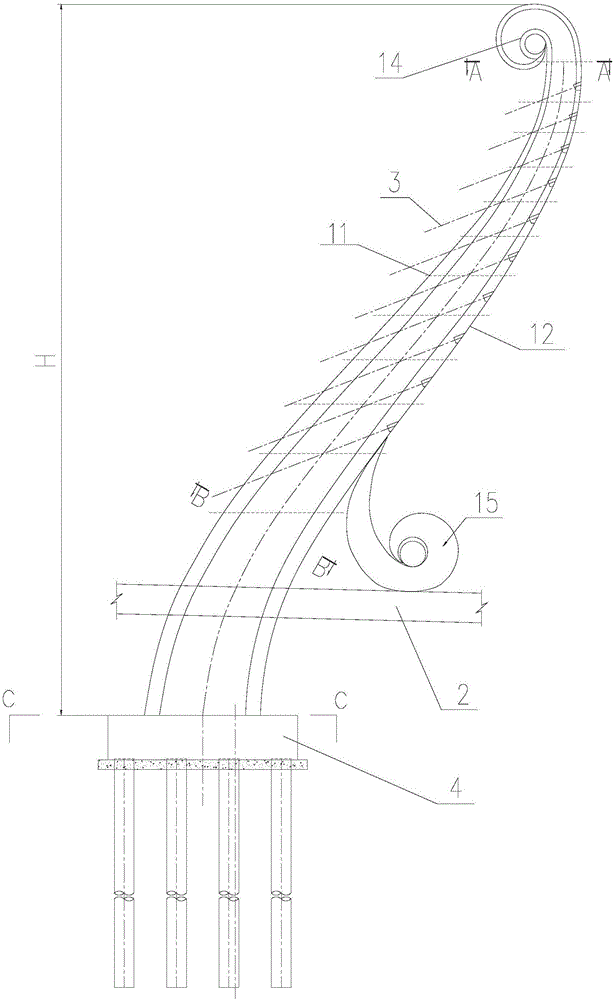

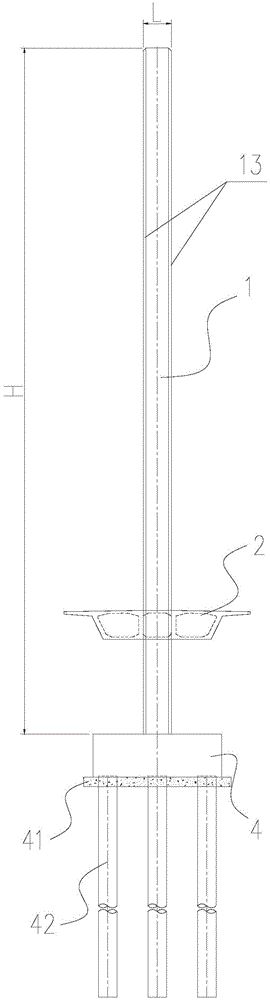

[0023] see Figure 1 to Figure 6 , the cable-stayed bridge with curved single-tower double-cable planes of the present invention comprises a main tower 1, a main girder 2, stay cables 3 and caps 4, wherein:

[0024] Both the up-cable surface 11 and the back-cable surface 12 of the main tower 1 are curved surfaces with varying curvature but constant width, and the longitudinal inclination angles of the up-cable surface 11 and the back-cable surface 12 of the main tower 1 are different and gradually increase with the construction of the main tower. Segmental changes, the longitudinal inclination angle of the rope-climbing surface 11 and the cable-back surface 12 located in the middle of the main tower 1 is the smallest, which is 50°, and the angle of the rope-climbing surface 11 and the cable-back surface 12 located at the bottom and top of the main tower 1 is the smallest. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com