New composite modified rubber asphalt and preparation process thereof

A compound modification, rubber asphalt technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of difficult to meet market demand, poor compatibility between asphalt and rubber powder, low production volume, etc. Convenience of construction, enhanced expansion and contraction performance and anti-fatigue ability, and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The new composite modified rubber asphalt is made of the following raw materials: 500g of base asphalt, 125g of rubber powder, 15g of polyethylene, 5g of chlorinated petroleum ester and 1g of barium stearate.

[0011] The following steps are used in the preparation: add polyethylene and rubber powder to the base asphalt at 175°C and mix evenly, then add chlorinated petroleum esters, pass through a shearing machine to form a mixture, and send the mixture into the aging tank for aging at 175°C for 30 minutes. The stirring speed of the aging tank is 90 rpm, and barium stearate is finally added to keep for 60 min.

Embodiment 2

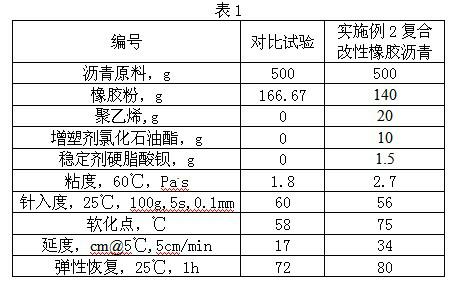

[0013] The new composite modified rubber asphalt is made of the following raw materials: 500 g of base asphalt, 140 g of rubber powder, 20 g of polyethylene, 10 g of chlorinated petroleum ester and 1.5 g of barium stearate.

[0014] The following steps are used in the preparation: add polyethylene and rubber powder to the base asphalt at 178°C and mix evenly, then add chlorinated petroleum esters, and form a mixture through a shearing machine, and send the mixture into the aging tank for aging at 178°C for 35 minutes. The stirring speed of the aging tank is 100 rpm, and finally barium stearate is added to keep for 80 min.

Embodiment 3

[0016] The new composite modified rubber asphalt is made of the following raw materials: 500 g of base asphalt, 150 g of rubber powder, 25 g of polyethylene, 15 g of chlorinated petroleum ester and 2 g of barium stearate.

[0017] The following steps are used in the preparation: add polyethylene and rubber powder to the base asphalt at 180°C and mix evenly, then add chlorinated petroleum esters, and form a mixture through a shearing machine, and send the mixture into the aging tank for aging at 180°C for 40 minutes. The stirring speed of the aging tank was 110 rpm, and finally barium stearate was added to keep for 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com