Anti-overturning structure for single-pier bridge girder

An anti-overturning, single-column pier technology, applied in the direction of bridges, bridge parts, bridge maintenance, etc., can solve the problems of large specific gravity, narrow bridge deck, small self-weight, etc., to improve the anti-overturning performance, good construction convenience, and excellent economy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

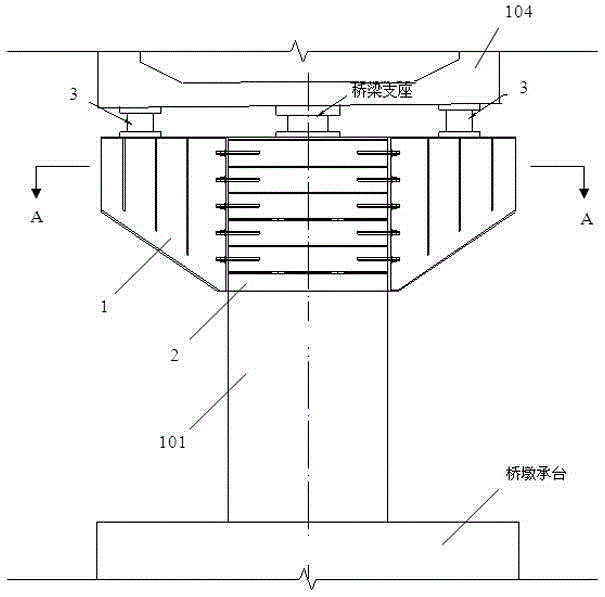

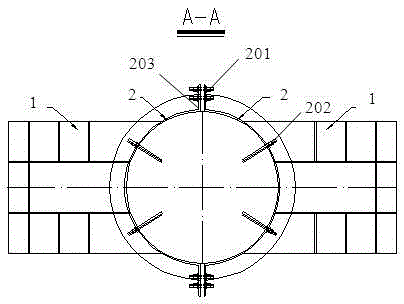

[0026] based on the following Figure 1 ~ Figure 4 , specifically explain the preferred embodiment of the present invention.

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a single column pier bridge anti-overturning structure, comprising:

[0028] A steel hoop structure, which is set on the pier column 101, the steel hoop structure includes two steel hoops 2 with the same structure, and several pairs of high-strength bolts 201 arranged at the joint 203 of the steel hoop 2, and A number of anchor bolts 202 are set in the reserved holes on the steel hoop 2. The pair of high-strength bolts 201 combine the steel hoop 2 into an integral steel hoop structure. The anchor bolts 202 fix the steel hoop mechanism and the bridge pier column 101;

[0029] Two steel corbels 1 are welded to two steel hoops 2 respectively;

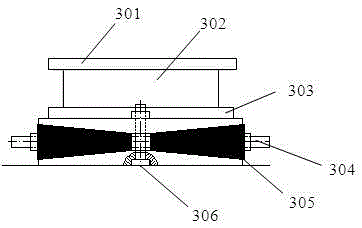

[0030] The intelligent support 3 is arranged between the steel corbel 1 and the bridge girder bottom 104, the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com