Double-row pile structure with cored horizontal rotary jet grouting pile on pile body

A technology of horizontal jetting piles and double-row piles, which is applied in foundation structure engineering, sheet pile wall, excavation, etc., can solve the problems of large displacement of piles and weak anti-overturning ability, and achieves increased anti-overturning ability and rigidity, and saves money. Project cost and effect of controlling pile displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

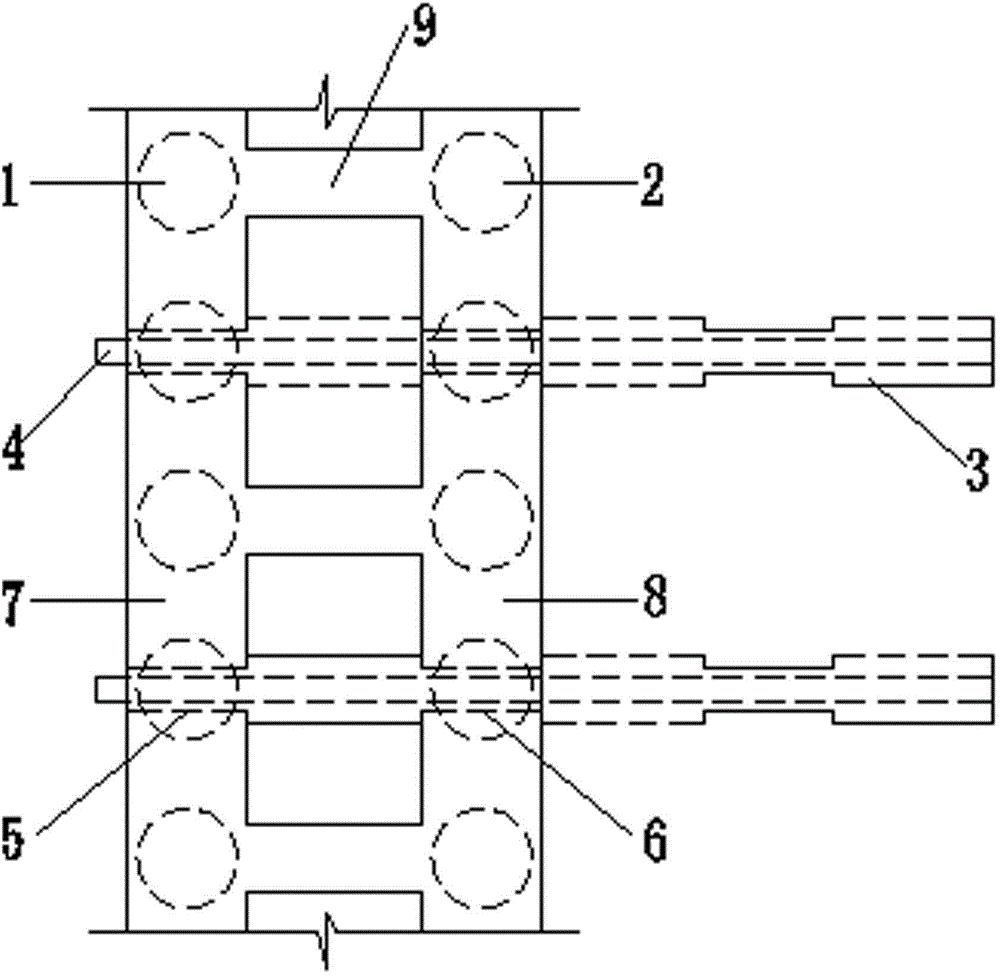

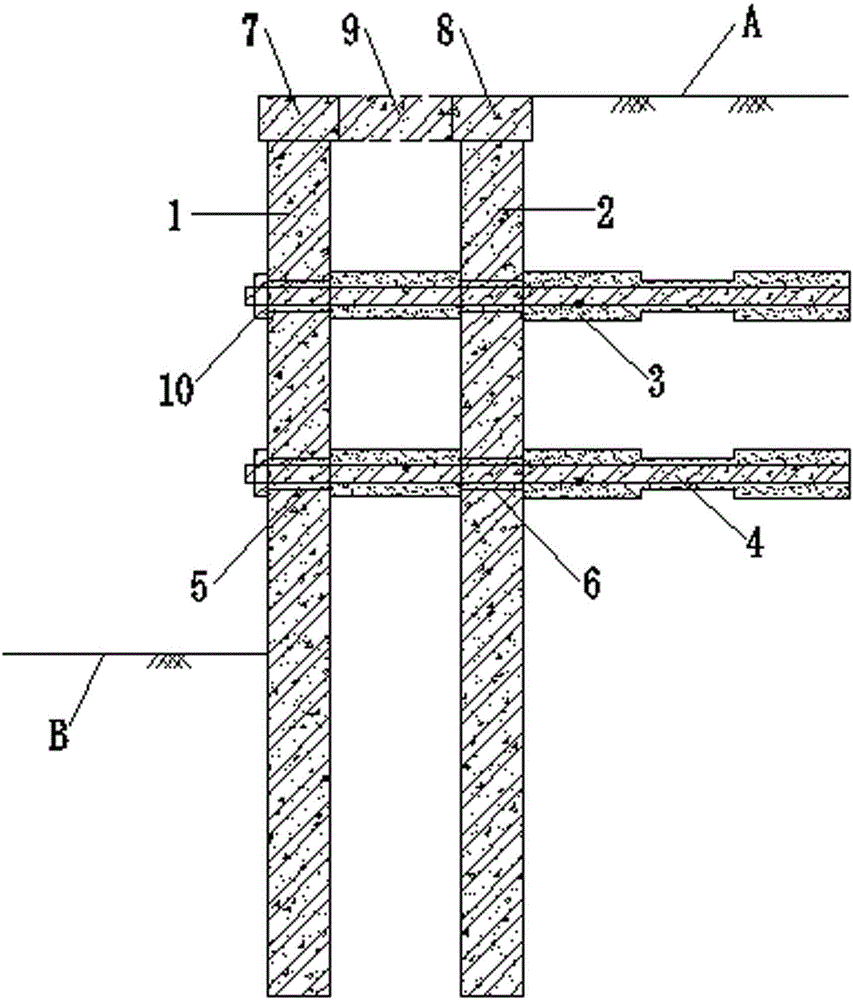

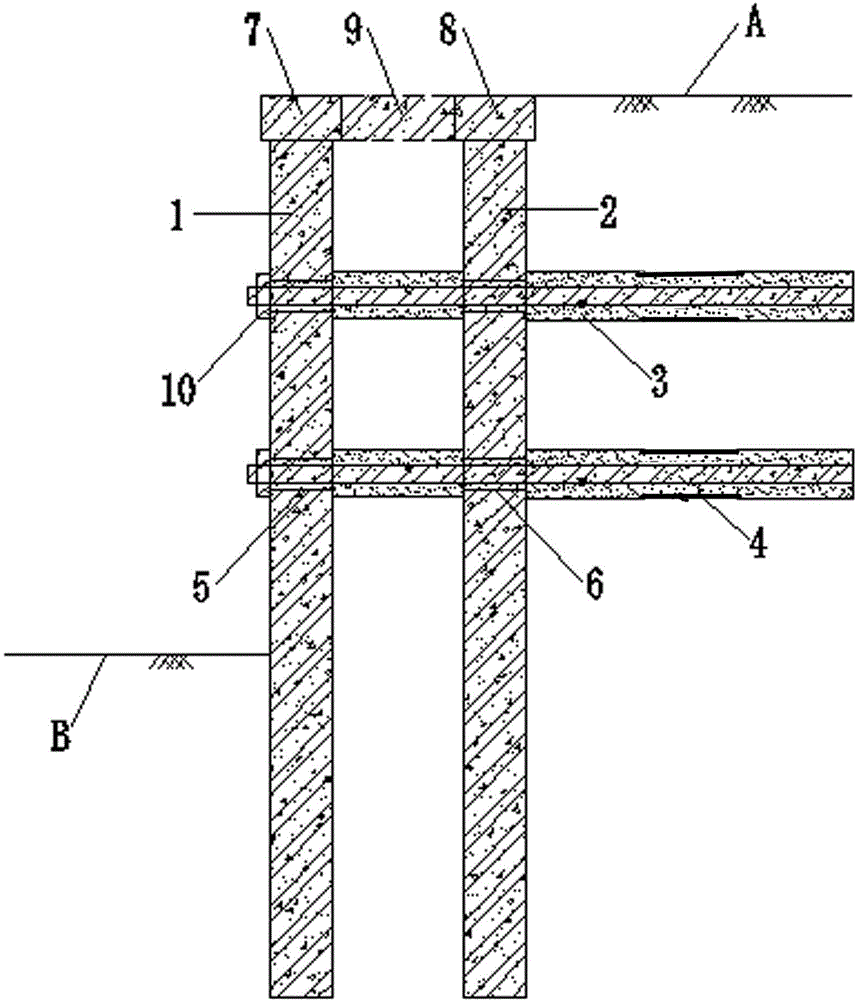

[0031] Example 1: if figure 1 , 2 As shown, a pile body is equipped with a double-row pile structure with cored horizontal jet grouting piles, which consists of front row piles 1, rear row piles 2, jet jet piles 3, prefabricated reinforced concrete square piles 4, pre-embedded pipe I5, prefabricated piles Buried pipe Ⅱ6, crown beam Ⅰ7, crown beam Ⅱ8, connecting beam 9, expansion head anchor 10 and waist beam 11. During the construction of the front row of piles 1 and the rear row of piles 2, pre-embedded pipes I5 and I6 of the same diameter were pre-embedded at the same depth on the steel cage respectively. To the depth position of the embedded pipe, construct the horizontal jet grouting pile 3 along the embedded pipe in the pile body of the front and rear row piles. The rotary grouting pile (3) adopts segmental rotary grouting construction, and the positions between the front and rear rows of piles are all consolidated by rotary grouting, and the diameter of the rotary gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com