Patents

Literature

81results about How to "Shorten pile length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

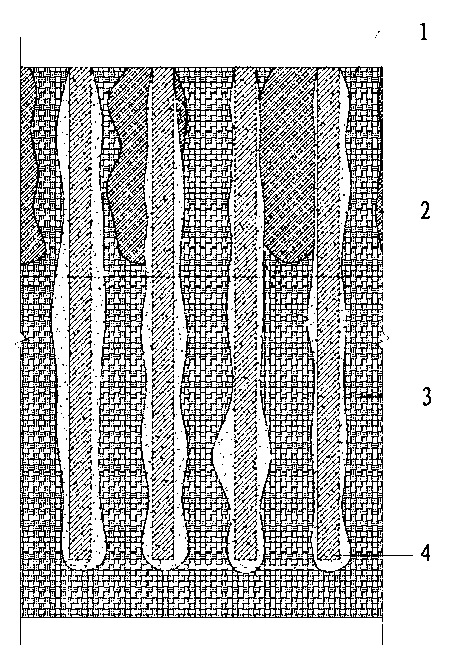

A construction method of collapsible loess foundation

InactiveCN102277867ASolve the carrying capacitySettlementFoundation testingIn situ soil foundationHigh riseSoil compaction

The invention discloses a construction method for a collapsible loess foundation. The construction method comprises the following steps of: firstly, performing foundation treatment on a loess field with collapsibility by using a super downhole dynamic consolidation (SDDC) pile; secondly, collecting undisturbed soil on site, normally performing an indoor experiment to measure an inter-pile soil compaction coefficient and an SDDC pile body compaction coefficient, evaluating the collapsibility, and if any one of the three indexes cannot meet a design requirement, performing pile compensation construction on the SDDC pile until the design requirement is met; and finally, pouring the pile and mudjacking. The method has the advantages of economy, environment friendliness, high treatment depth, good treatment effect, large bearing potential, high complicated load resistance and the like. By application of the method, various side effects caused by the collapsibility of the deep collapsible loess field can be eliminated, and requirements of upper-part high rise buildings on the bearing capability and settlement of the foundation can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Construction method for collapsible loess foundation

InactiveCN102277867BShorten pile lengthFoundation testingIn situ soil foundationHigh riseSoil compaction

The invention discloses a construction method for a collapsible loess foundation. The construction method comprises the following steps of: firstly, performing foundation treatment on a loess field with collapsibility by using a super downhole dynamic consolidation (SDDC) pile; secondly, collecting undisturbed soil on site, normally performing an indoor experiment to measure an inter-pile soil compaction coefficient and an SDDC pile body compaction coefficient, evaluating the collapsibility, and if any one of the three indexes cannot meet a design requirement, performing pile compensation construction on the SDDC pile until the design requirement is met; and finally, pouring the pile and mudjacking. The method has the advantages of economy, environment friendliness, high treatment depth, good treatment effect, large bearing potential, high complicated load resistance and the like. By application of the method, various side effects caused by the collapsibility of the deep collapsible loess field can be eliminated, and requirements of upper-part high rise buildings on the bearing capability and settlement of the foundation can be met.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

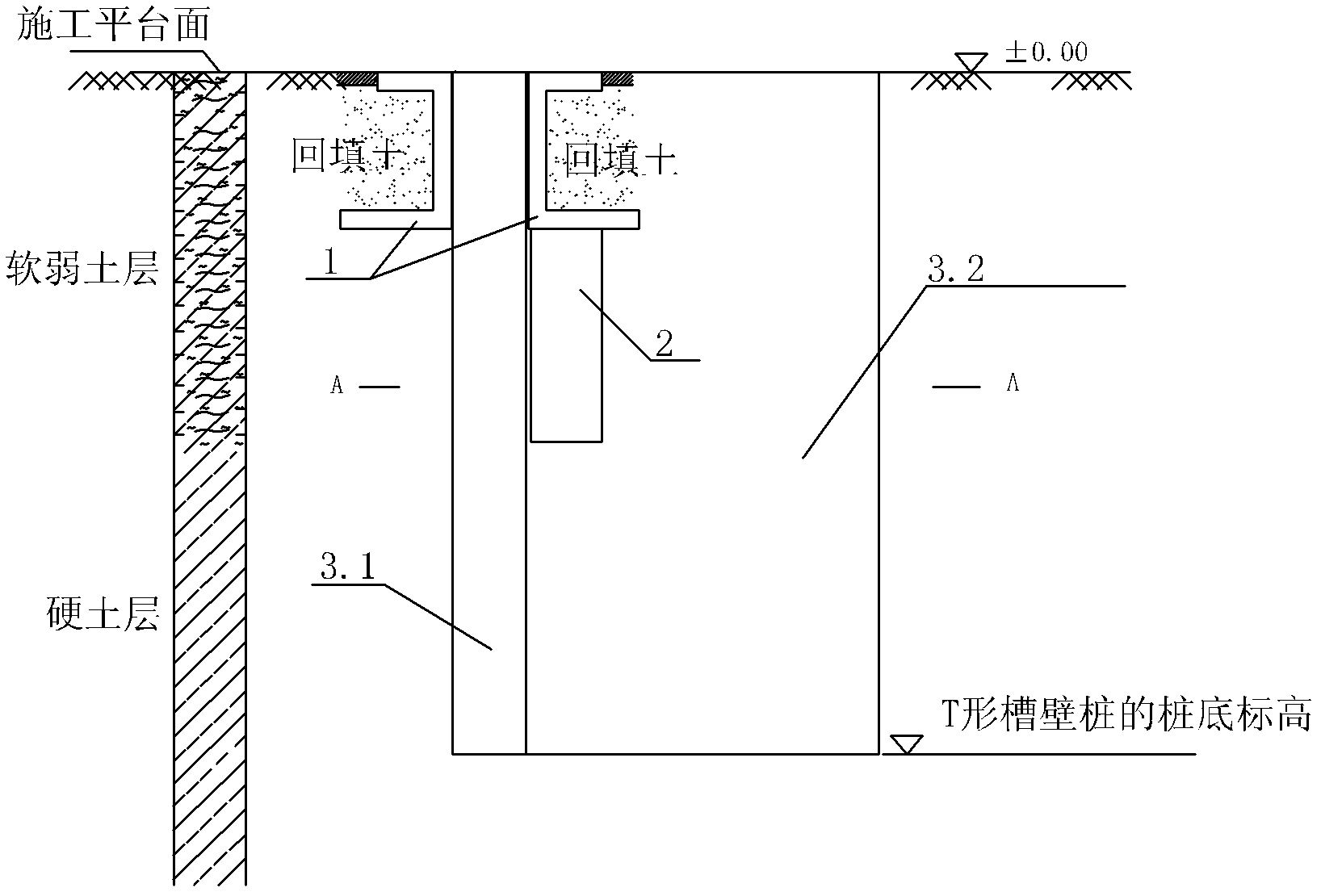

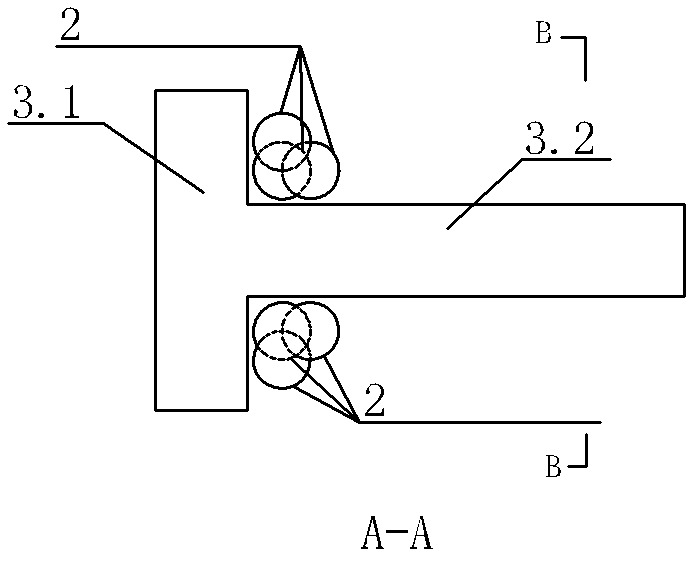

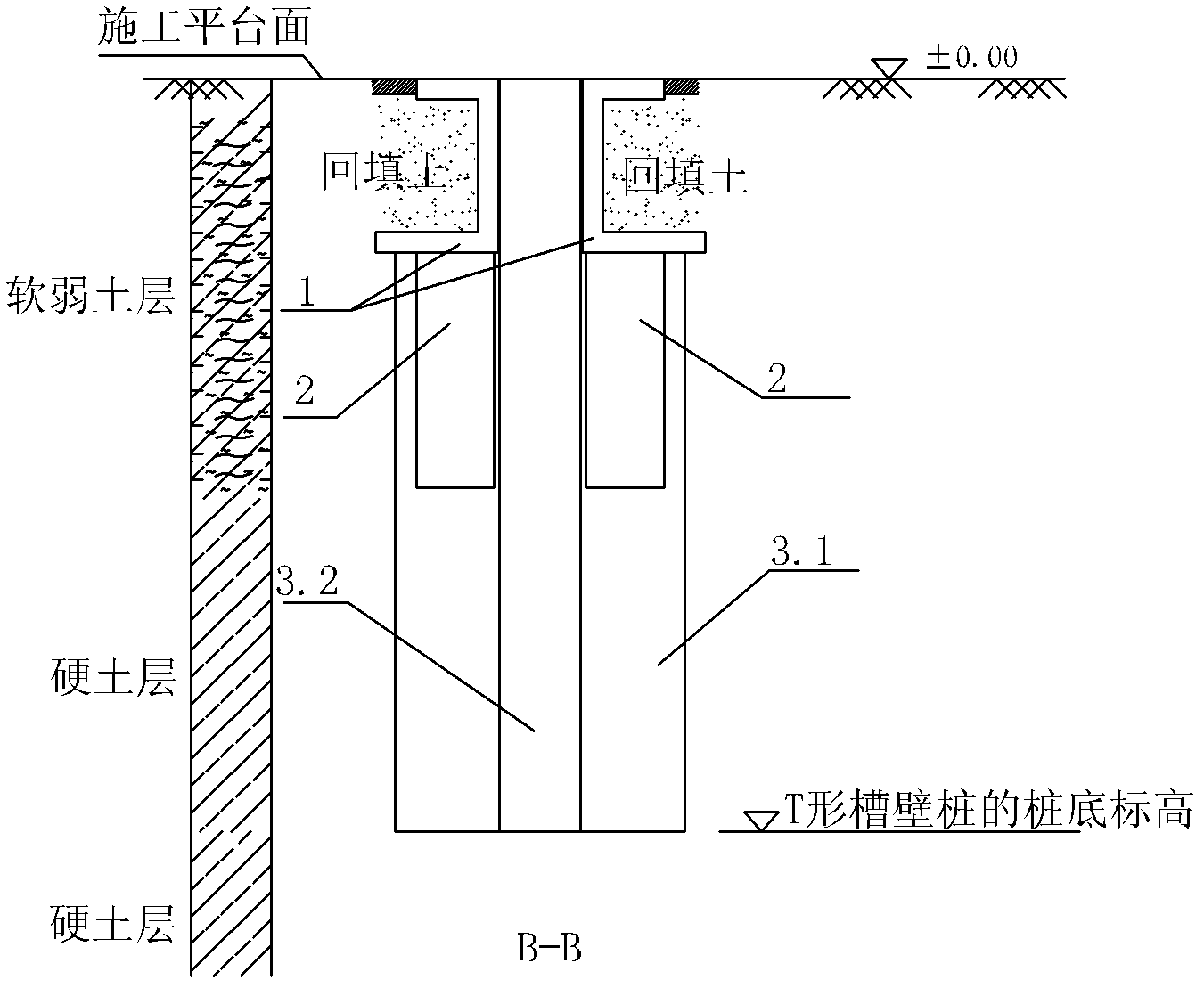

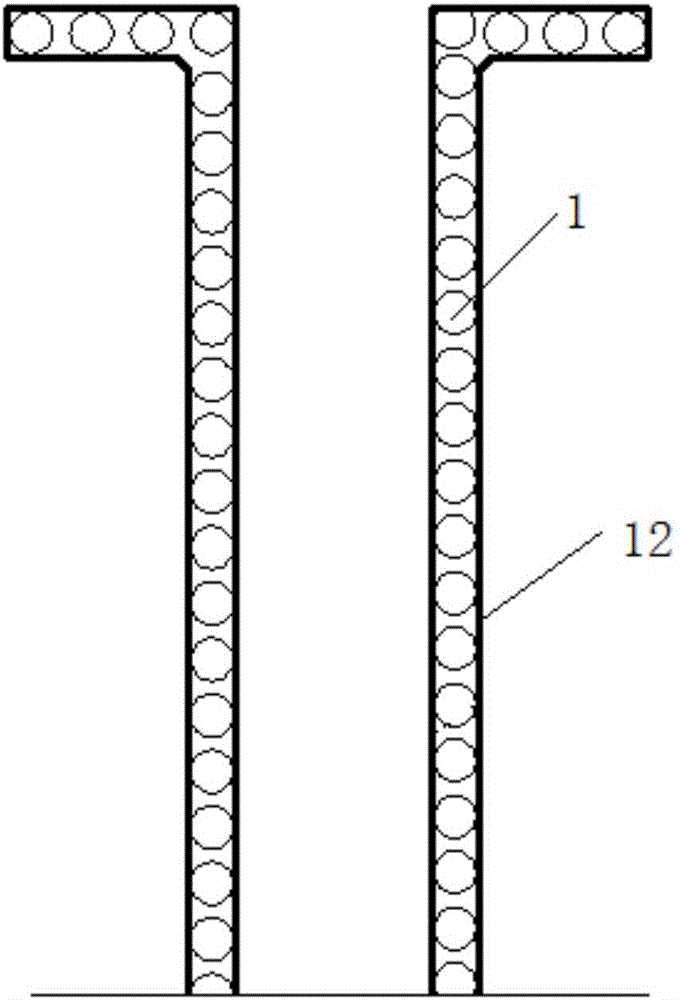

Ultra-deep T-shaped trench-wall pile in soft-toped hard-bottomed soil layer and trench forming method

InactiveCN102561361AReduce post-construction settlementReduce horizontal displacementSoil-shifting machines/dredgersExcavationsEngineeringSoil horizon

The invention discloses an ultra-deep T-shaped trench-wall pile in a soft-toped hard-bottomed soil layer and a trench forming method. The trench forming method includes the steps: firstly, pre-reinforcing soft soil at each external corner of a T-shaped trench wall; secondly, digging a guide wall foundation pit, treating the extremely soft soil layer at the bottom area of a guide wall to lead the bearing capacity of the foundation bottom of the guide wall to be larger than or equal to 100kPa; and thirdly using the trench forming way of 'drilling and gripping'. By the method, trench forming efficiency can be improved greatly, cost is lowered, and evident economy is achieved.

Owner:CCCC FOURTH HARBOR ENG CO LTD +1

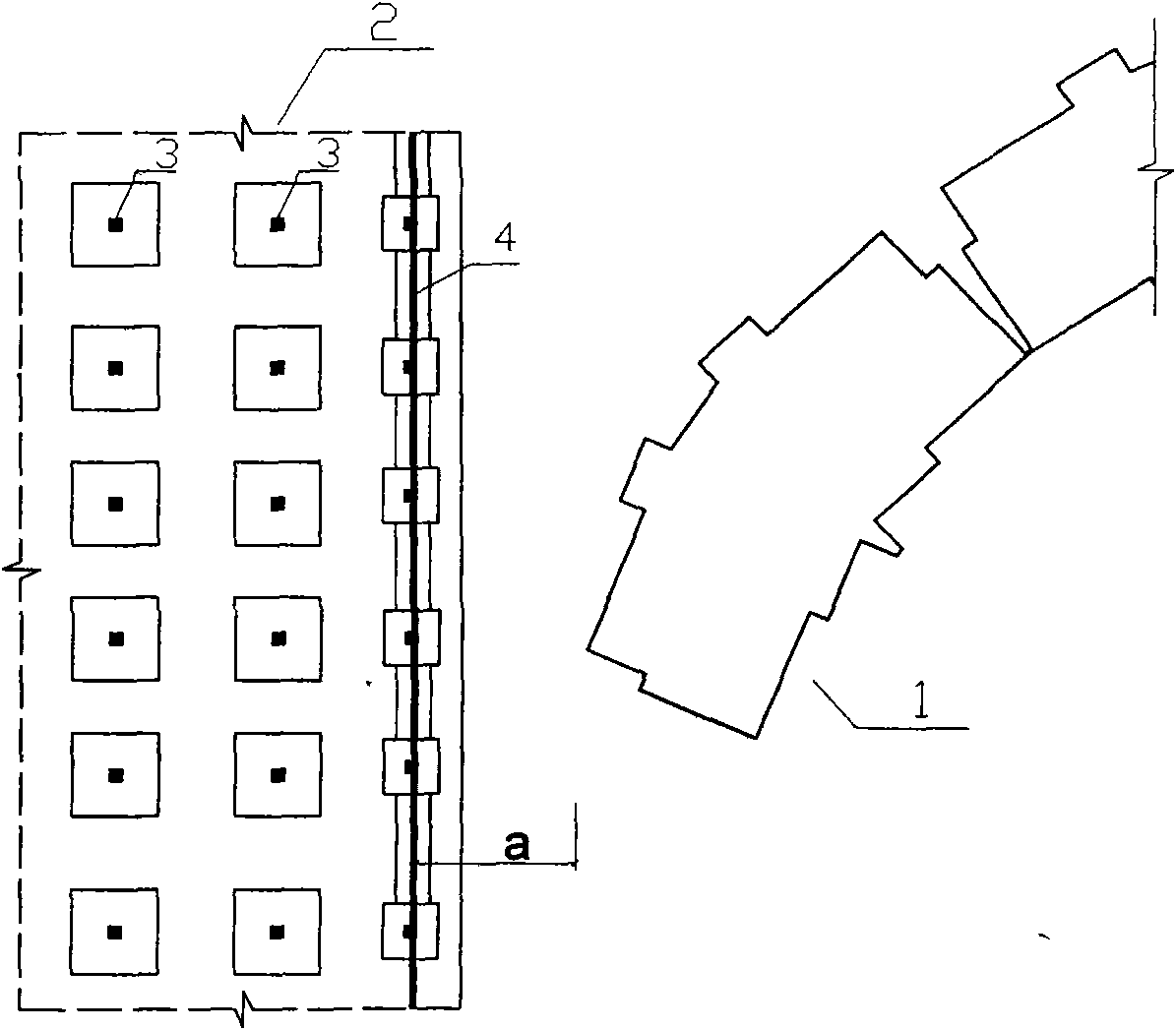

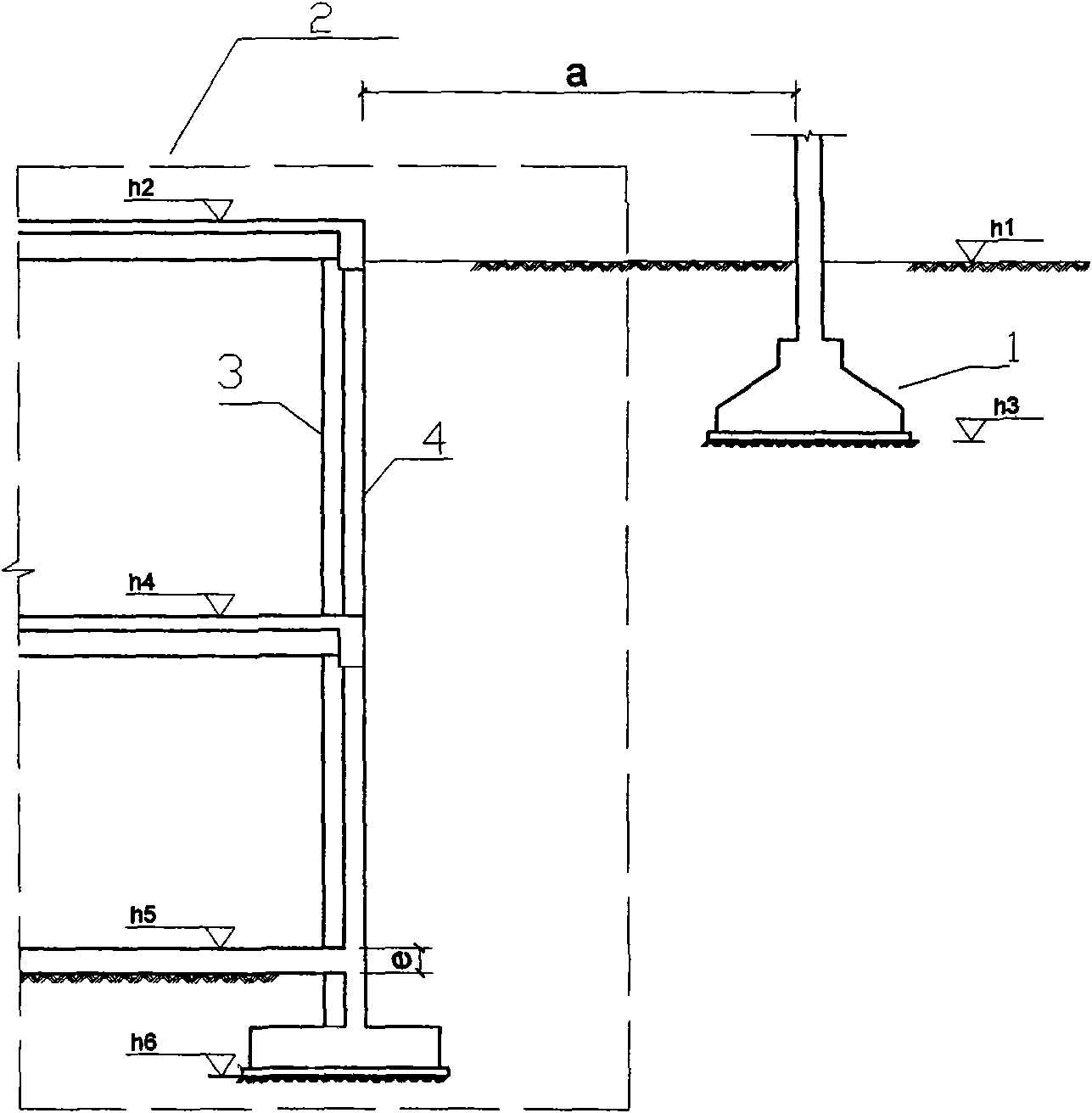

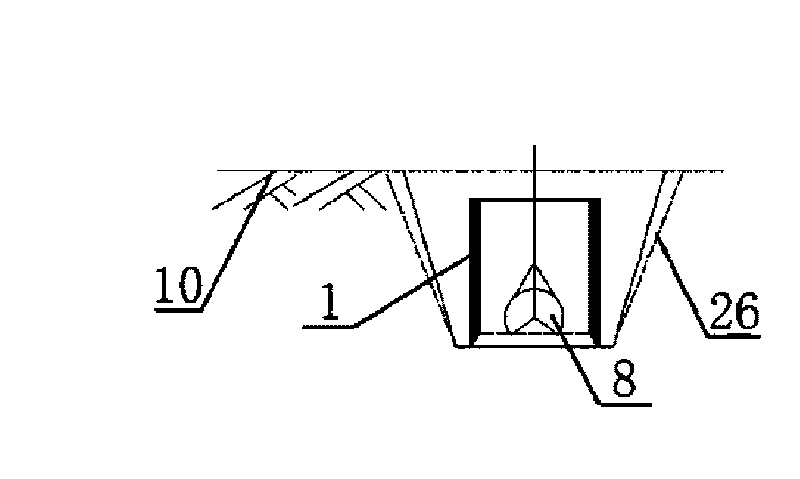

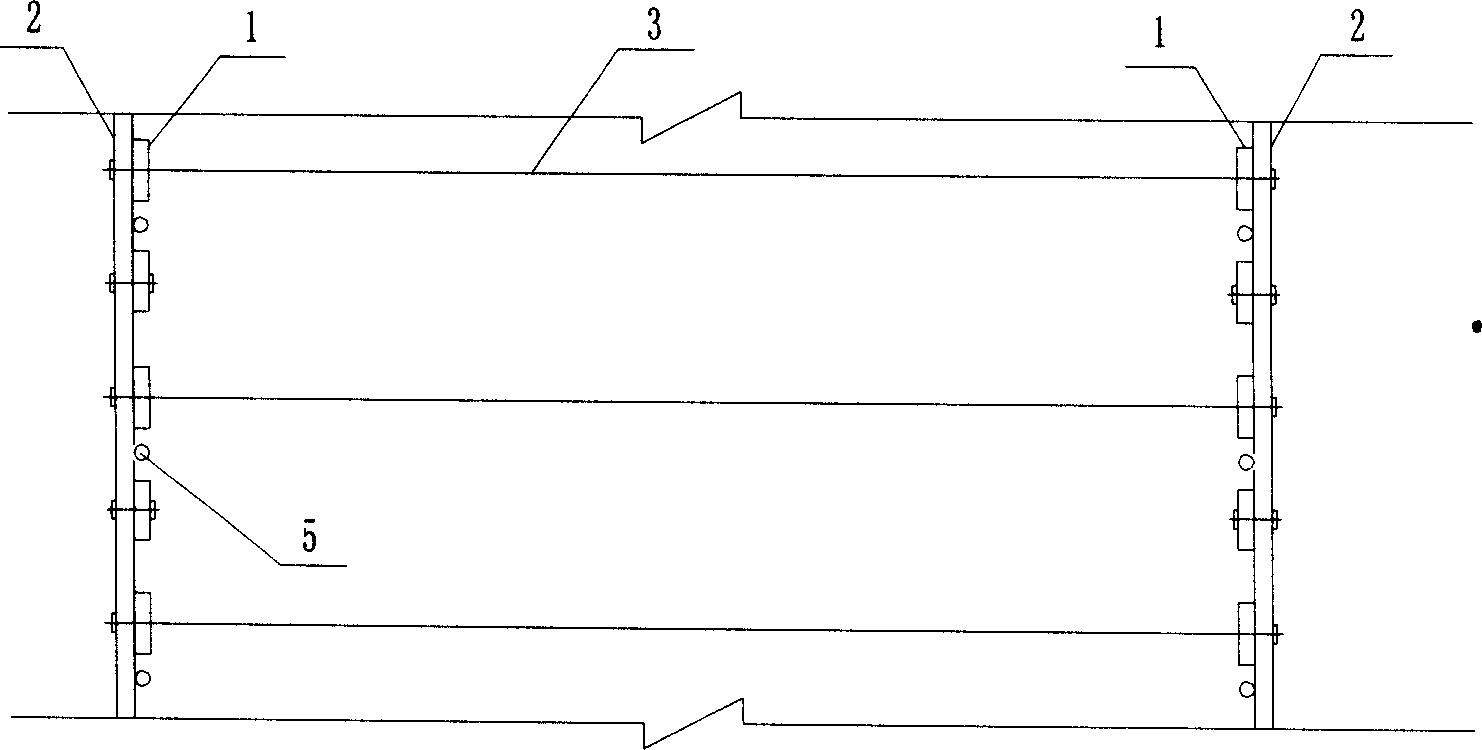

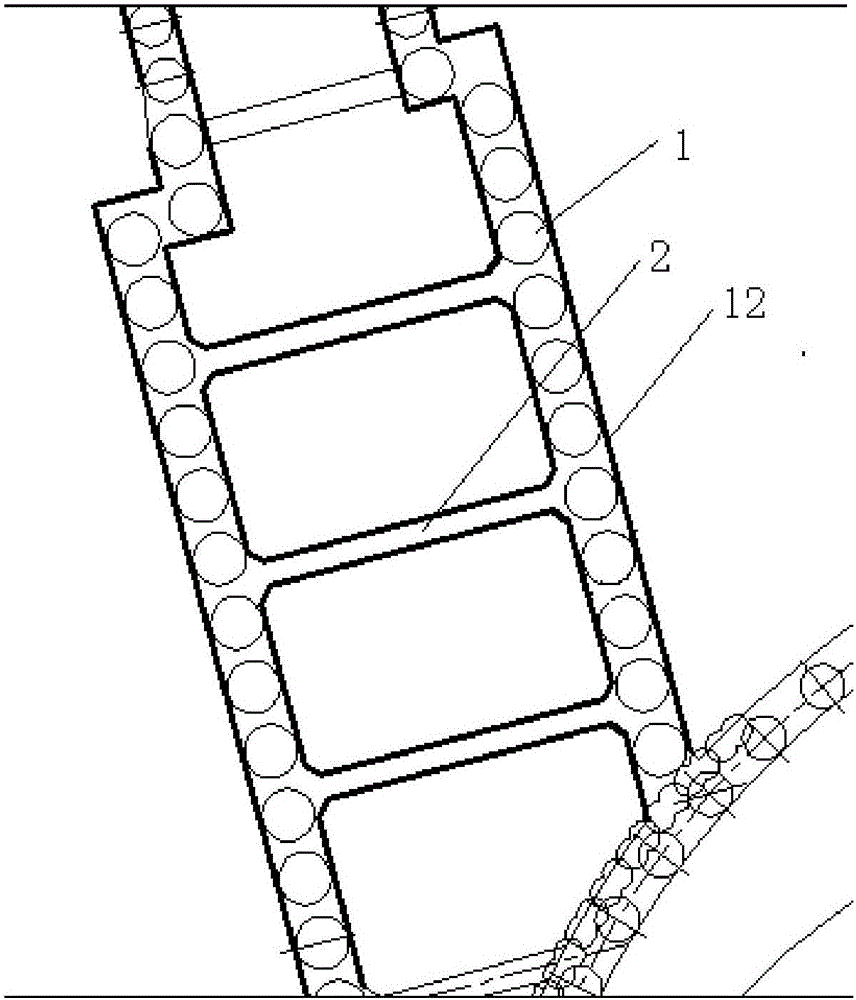

Self-supporting construction method for multilayer underground structure next to existing building

InactiveCN101614019AMinimize the bending moment effectShorten pile lengthArtificial islandsExcavationsEngineering structuresCantilever

The invention relates to a self-supporting construction method for a multilayer underground structure next to an existing building. When the distance between a proposed underground building and the existing building is within 15 meters, the construction method is adopted, and the method specifically comprises the following operation steps: 1, supporting pile construction; 2, developing and controlling an earthwork of a negative first layer; 3, controlling holes at a frame column position and setting a retaining wall; 4, carrying out the construction of frame columns of a negative second layer; 5, carrying out the construction of top beams and plates of the negative second layer and columns, beams and plates of the negative first layer; 6, mounting horizontal steel supports; 7, developing and digging the earthwork of the negative second layer; and 8, carrying out the construction of other structures of bottom plates, walls and the like of the negative second layer according to a conventional method. The method skillfully uses the rigidity of an underground engineering structure self to provide a supporting point for the supporting pile so that the supporting pile is changed into a three-span indeterminate member from a cantilever member, so the bending moment load effect of the supporting pile is greatly reduced, then the designed pile length and section area of the supporting pile can be greatly reduced, the construction cost is saved by about over 35 percent, and the integral construction progress of the underground structural engineering is accelerated.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

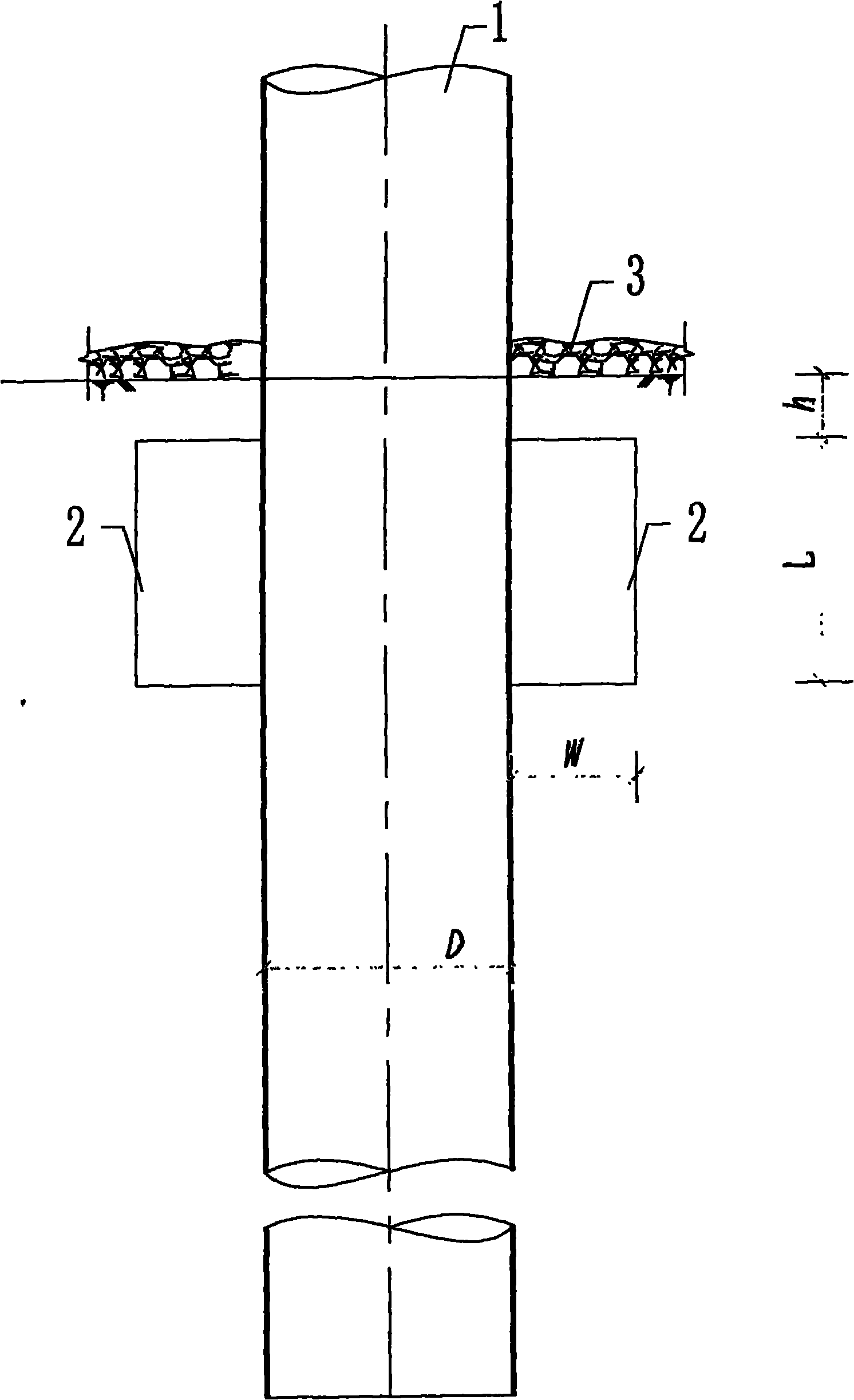

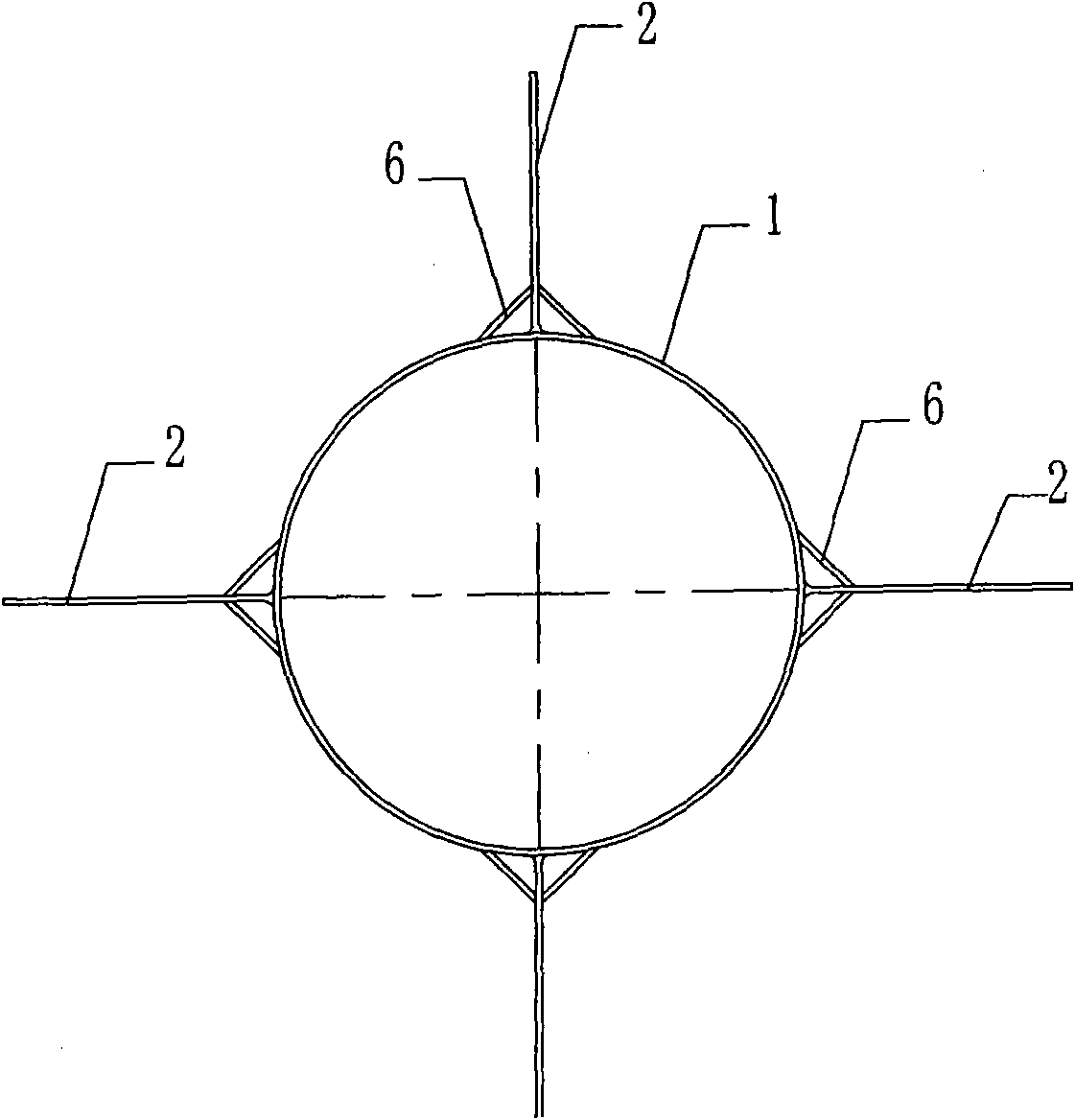

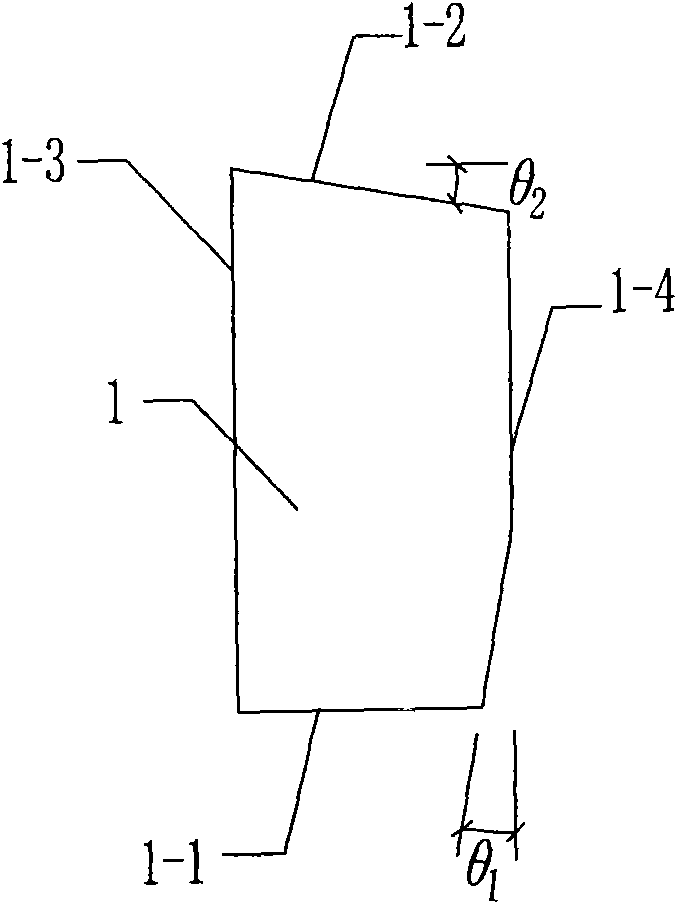

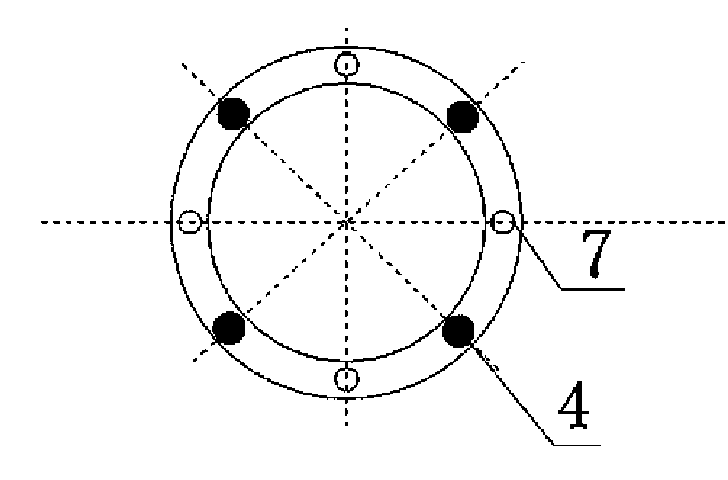

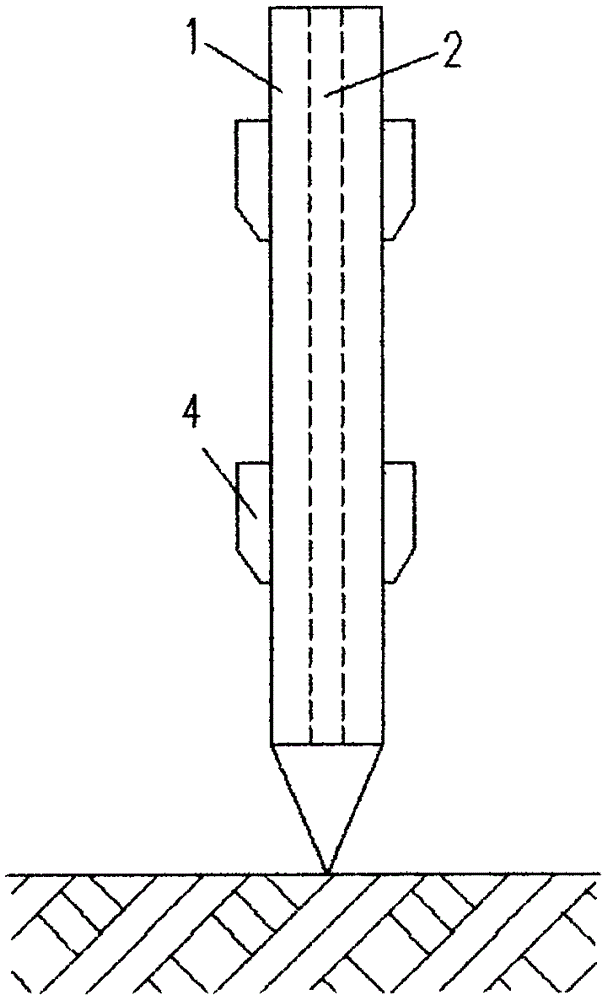

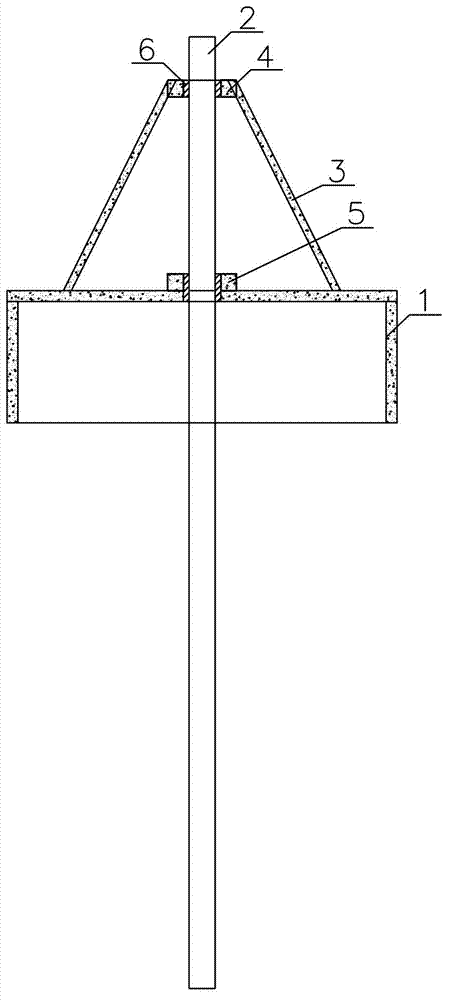

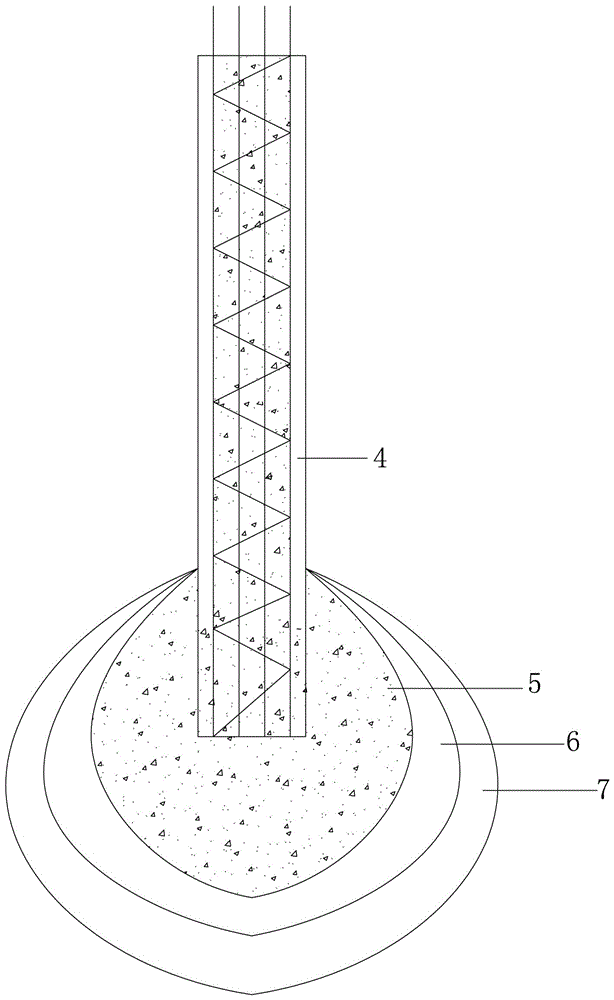

Offshore wind generator single pile base structure with stabilizer fin

ActiveCN102041813AImprove horizontal carrying capacityShorten pile lengthFoundation engineeringOffshore wind powerWind force

The invention relates to an offshore wind generator single pile base structure with a stabilizer fin, solving the technical problem of providing an offshore wind generator single pile base structure with a stabilizer fin, and aiming to improve the horizontal bearing performance of a fan base, improve the horizontal bearing force of a base pile and lower the displacement and the bending moment of the pile body. The technical scheme for solving the problem comprises: a group of stabilizer fins are additionally arranged on the elevation near the ground surface below a seabed mud surface and on the body of the base pile, the stabilizer fins are radially arranged by taking the base pile as the center, the length direction is parallel to the axial direction of the base pile, and the width direction is vertical to the axial direction of the base pile. The invention is suitable for the industry of offshore wind power generation, in particular the single pile fan base with a large pipe diameter.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

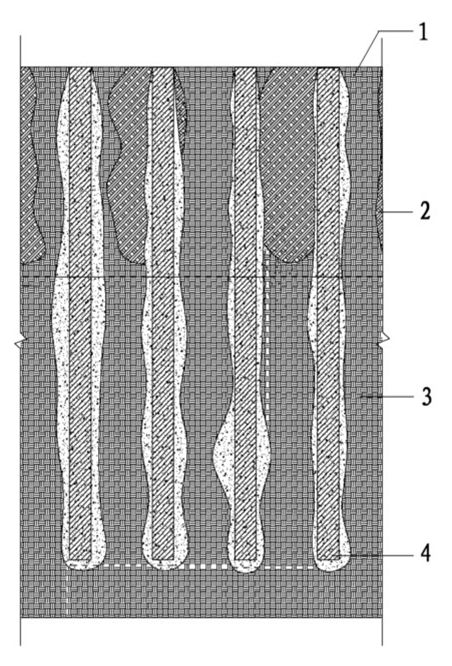

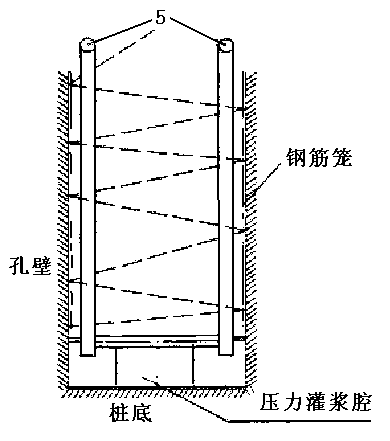

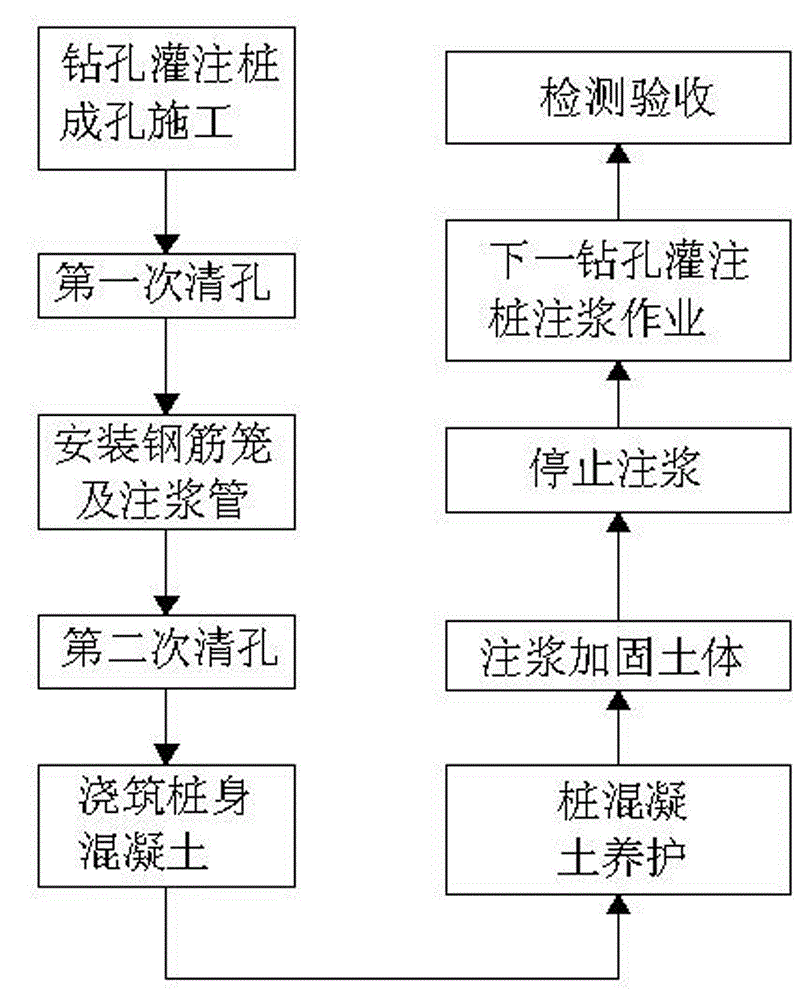

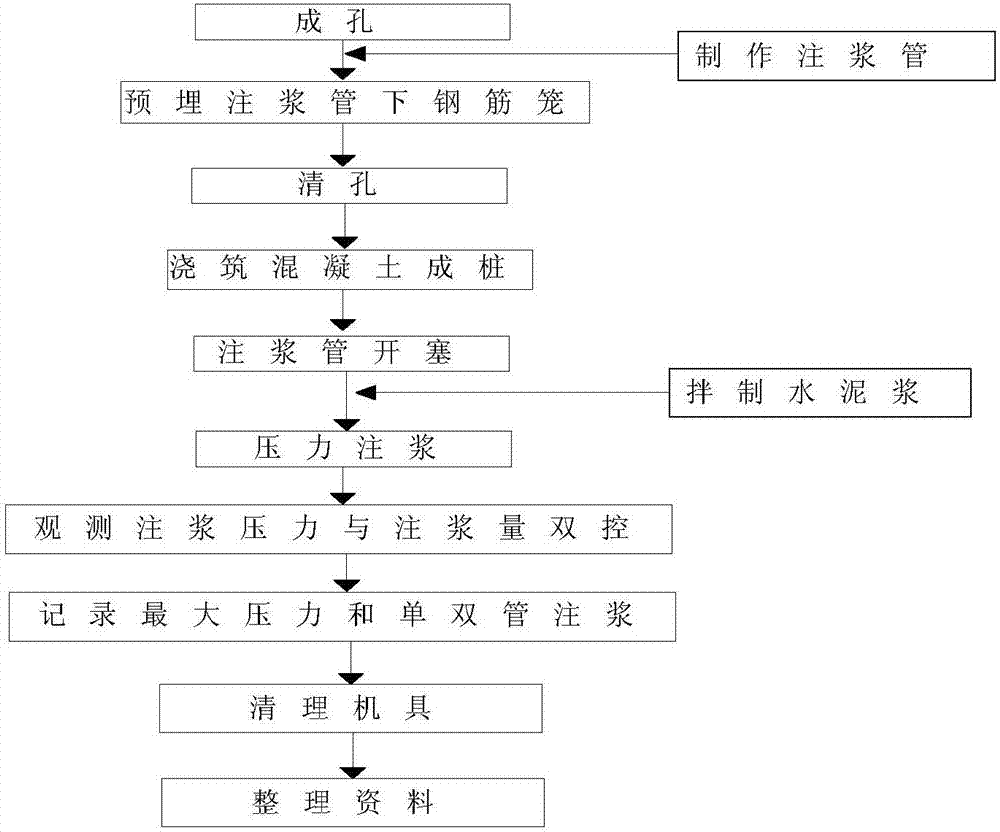

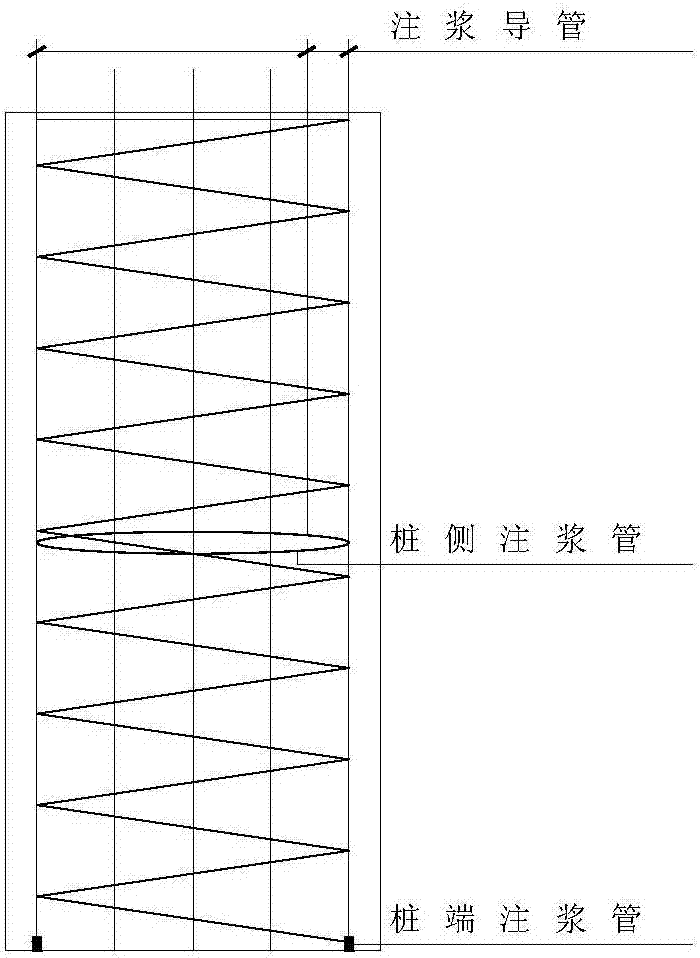

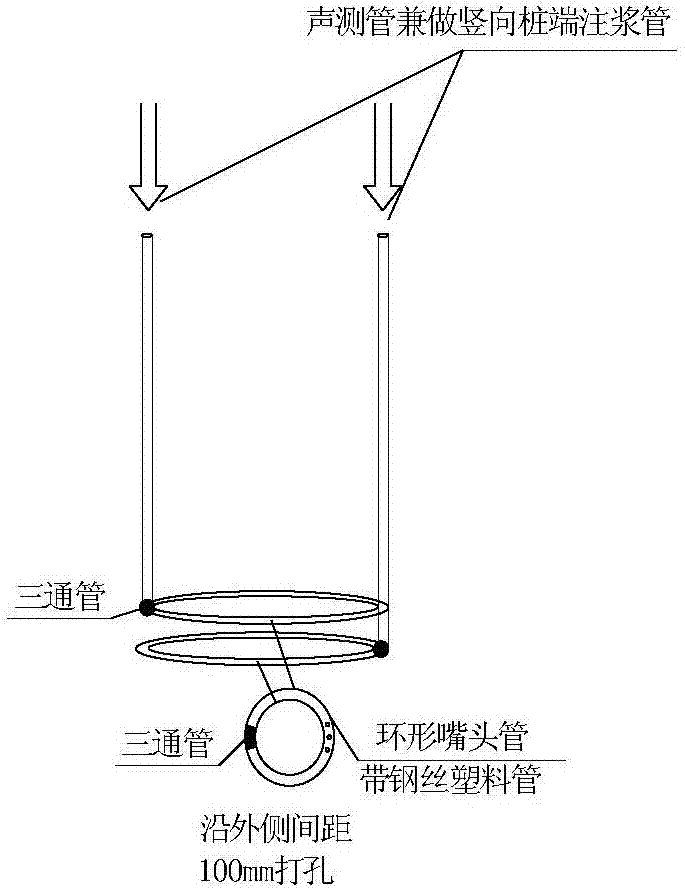

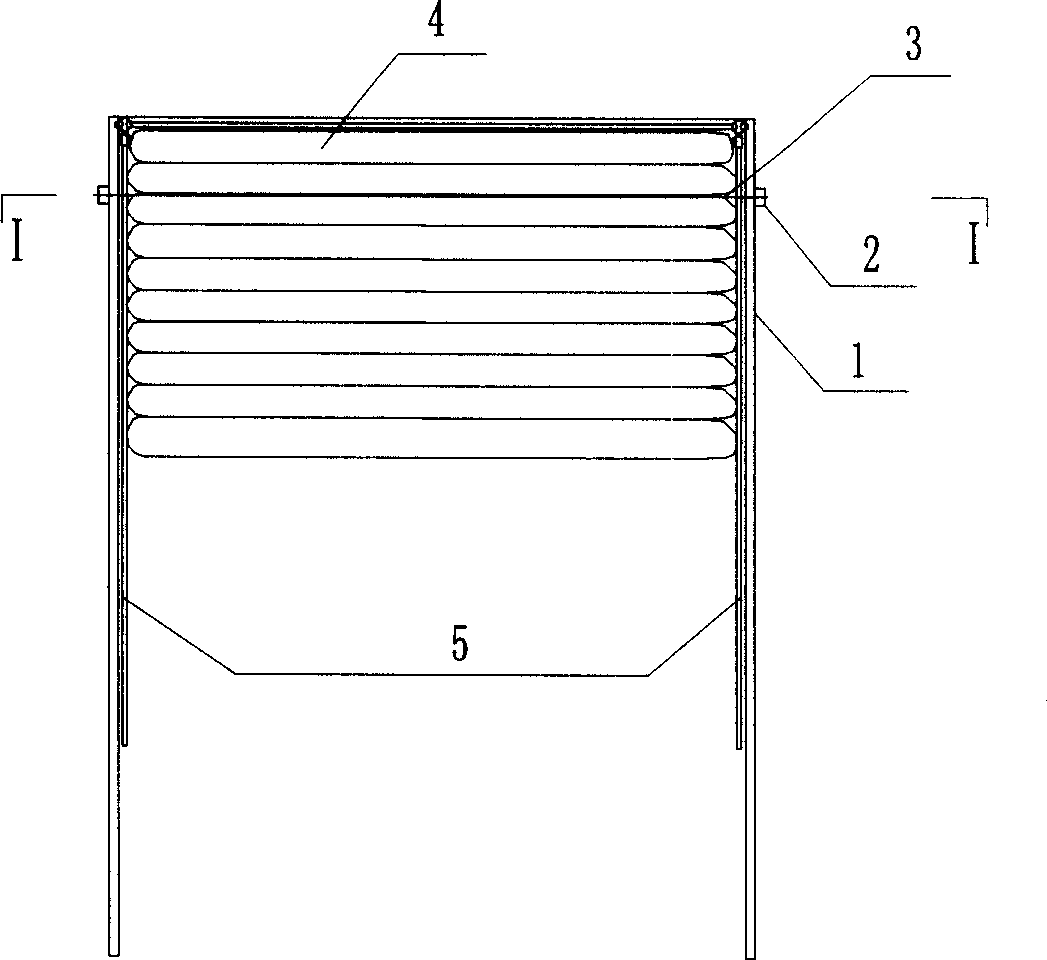

Cast-in place pile post-grouting construction method for pouring construction

The invention discloses a cast-in place pile post-grouting construction method for pouring construction. The method comprises the steps that cast-in place pile pore-forming construction is carried out; first-time hole clearing is carried out; reinforcement cage and grouting pipe mounting is carried out; second-time hole clearing is carried out; pile body concrete placing is carried out; pile concrete curing is carried out; grouting soil mass reinforcement is carried out; grouting is stopped; next cast-in place pile grouting working is carried out; and checking and accepting are carried out. After pile forming, the intensity of pile body concrete reaches a certain degree, a high-pressure generating device is used, high-pressure cement grout flow with concentrated energy is formed, grout is combined with pile body surrounding soil mass through the effects of permeating, separation, filling, compaction and the like, pile body sediment and pile side mud cakes are solidified, pile side friction resistance and pile end bearing force are enlarged, the shortcomings that due to hole bottom sediment and pile side mud cakes of a common cast-in place pile, bearing force is low, and vertical load decreasing is high are overcome, and important economic and social significance is achieved in single pile bearing force improving, pile foundation sedimentation lowering, pile foundation engineering quality guaranteeing and the like.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

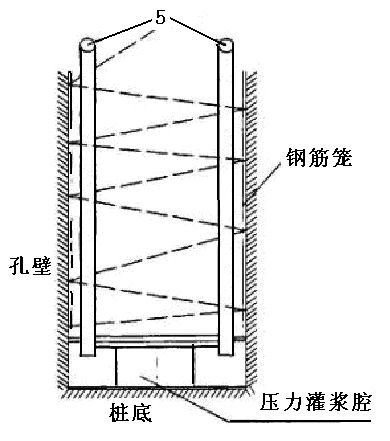

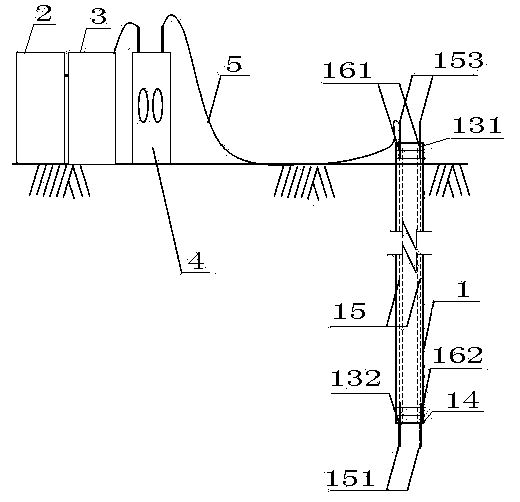

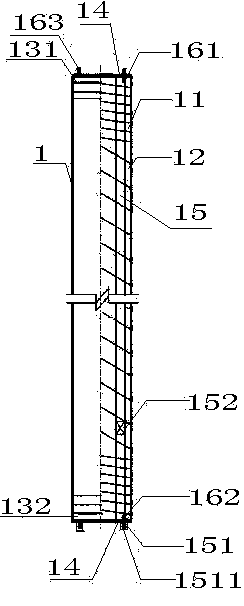

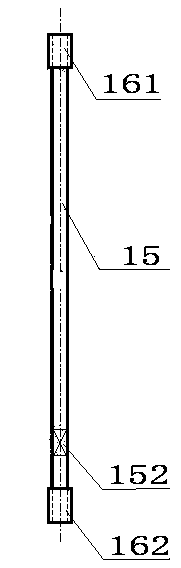

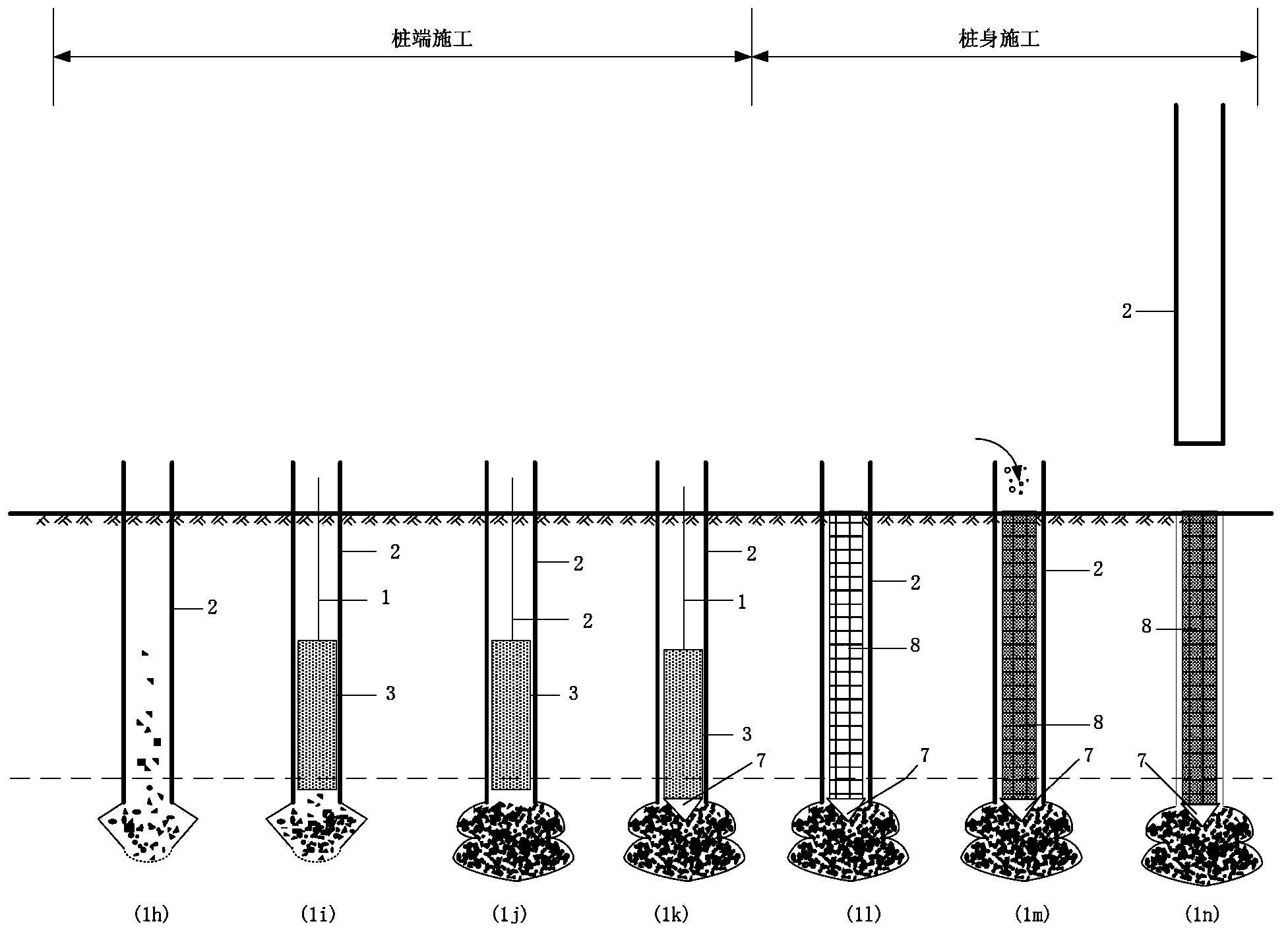

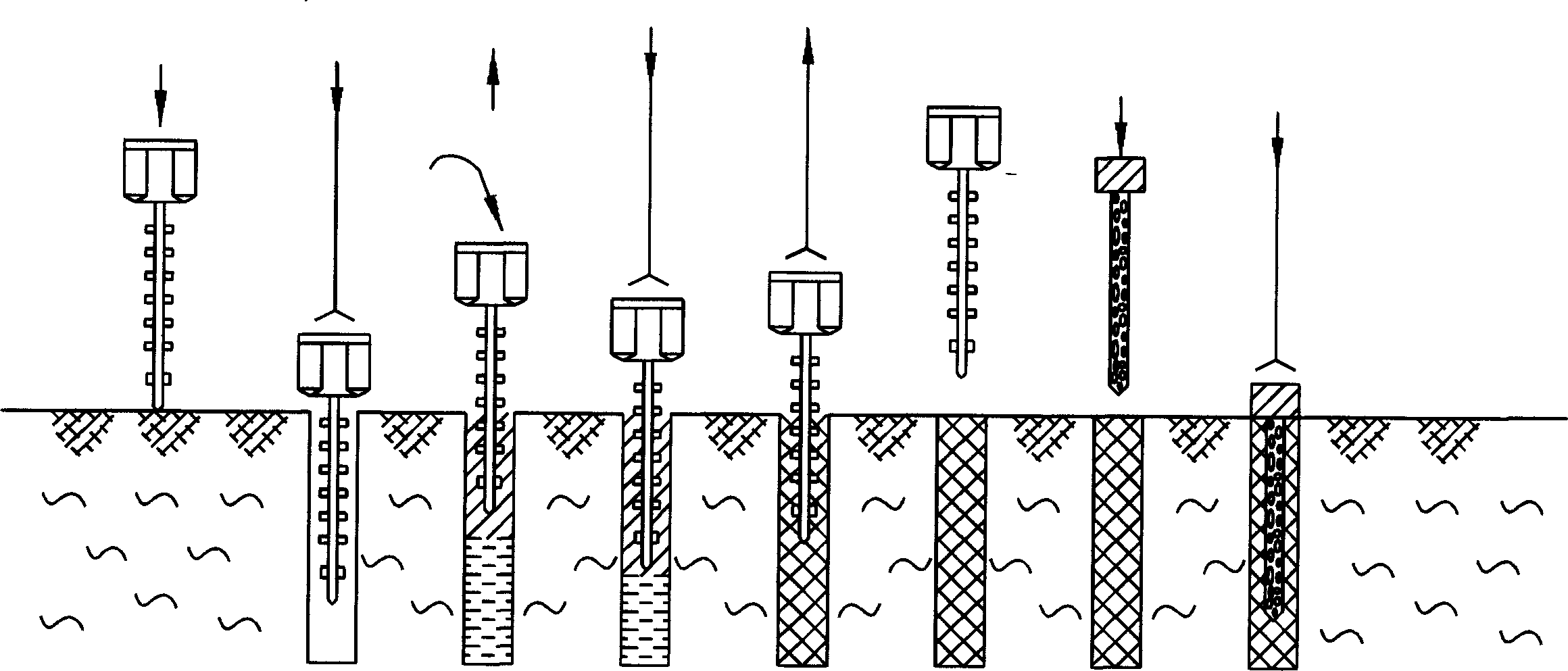

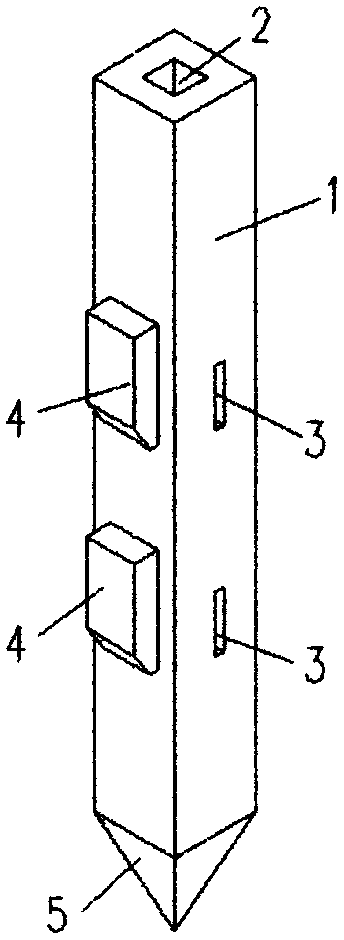

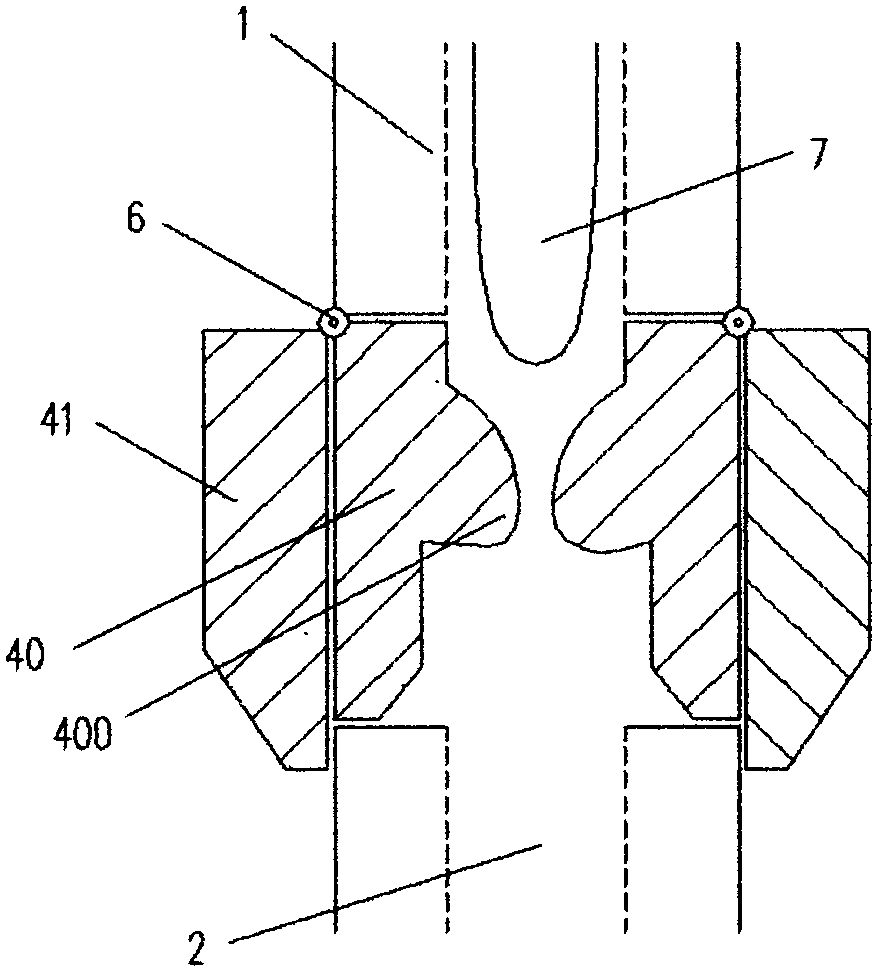

Precast pile post-grouting device and precast pile post-grouting process

InactiveCN104234055AGrouting construction method after solutionImprove pile sinking efficiencyBulkheads/pilesPre stressSlurry

The invention relates to the technical field of foundation stabilization, in particular to a precast pile post-grouting device and a precast pile post-grouting process. The technical scheme adopted by the invention is that the precast pile post-grouting device comprises a precast pile, a stirrer, a slurry tank, a grouting pump and a grouting hose; a pile body of the precast pile is provided with a prestressed reinforcement, a spiral bar, an upper end plate and a lower end plate. The precast pile post-grouting device is characterized in that grouting holes are also formed in the precast pile, and the precast pile is also provided with grouting pipes, an upper transition pipe and a lower transition plate. Compared with the prior art, the precast pile post-grouting device and the precast pile post-grouting process have the beneficial effects that a construction process of pile tip and pile tip peripheral grouting and the arrangement form of the grouting pipes can be realized on piles with various pile diameters (large diameters and small diameters), various pile types (square piles, round piles, hollow piles and solid piles) and various pile lengths (short piles and long piles), and the problems of a post-grouting construction method of all precast pile types are solved.

Owner:顾孙平

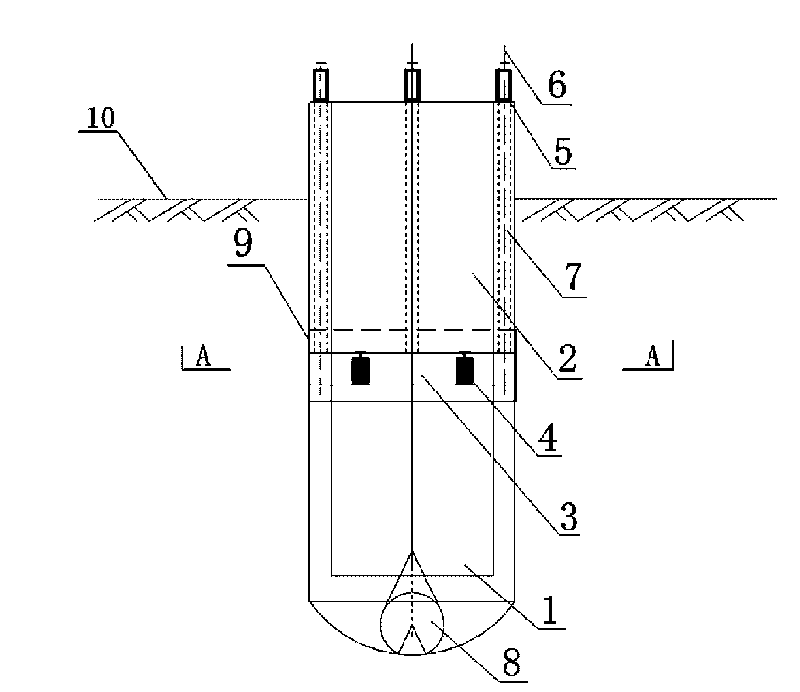

Self-balancing sinking large-diameter tubular pile and construction method thereof

ActiveCN101736744AReduce the amount of masonryBasic engineering cost reductionBulkheads/pilesStructural engineeringBuilding construction

The invention discloses a self-balancing sinking large-diameter tubular pile and a construction method thereof. A tubular pile body comprises at least two sections of tubular piles, the diameter of the tubular pile body is phi3 to phi5 meters, a relay chamber is arranged between the upper and lower adjacent two sections of tubular piles, a group of relay jacks are arranged uniformly in the relay chamber at intervals, a base of the relay jack is arranged on the lower end face of the upper tubular pile, a telescopic rod of the relay jack is propped against the upper end face of the lower tubular pile, reserved pore canals are staggered in the tubular pile body between the adjacent two relay jacks at intervals, a pull rod passes through each reserved pore canal, the tubular piles are connected linearly by a group of pull rods, the lower end part of each pull rod is connected with an anchoring element on the lower end face of the lowest tubular pile, and the upper end part of each pull rod is provided with a through jack on the upper end face of the uppermost tubular pile. The relay chamber and the reserved pore canals are closed by concrete after the tubular pile reaches the bottom and the relay jacks are taken out. An external force such as hammering, strong vibration and the like does not need to work in the construction, so the construction cost is reduced, and the efficiency is improved.

Owner:张子良

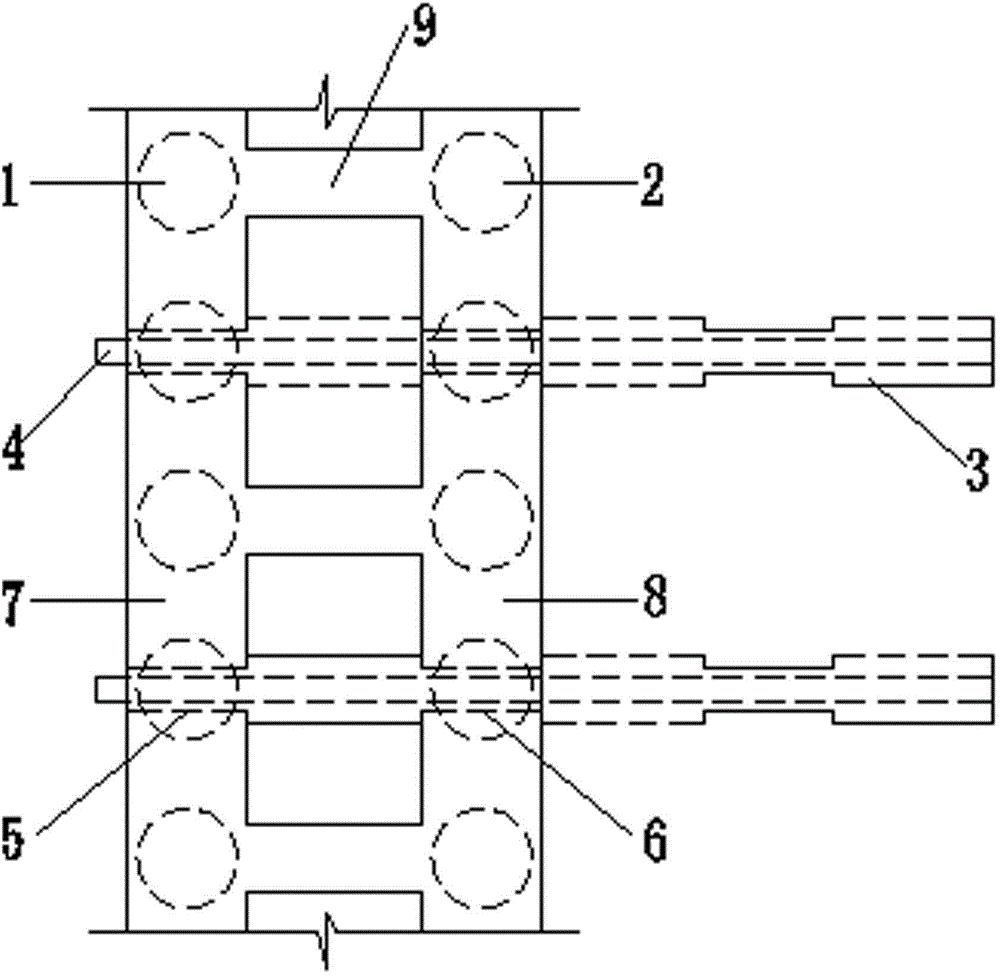

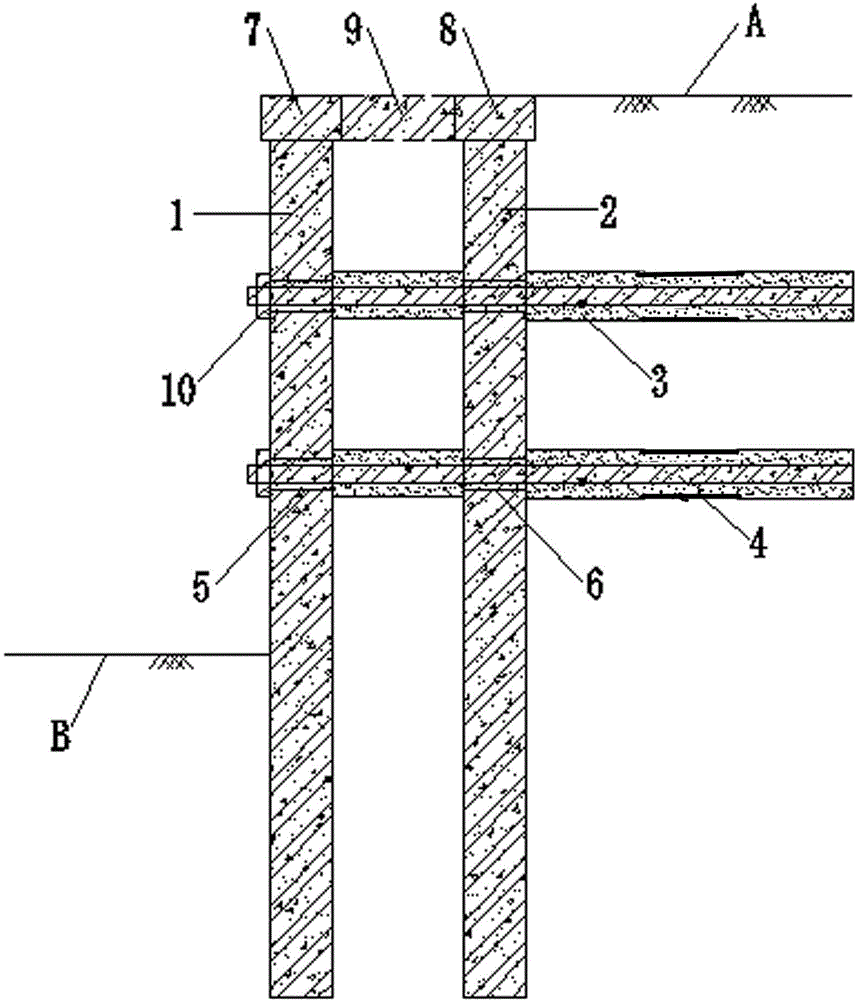

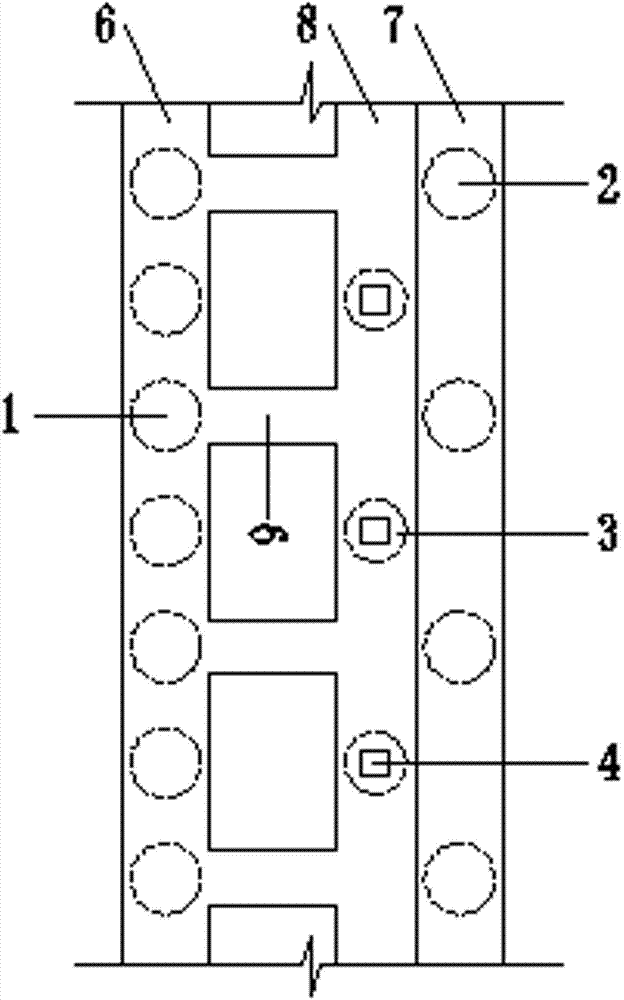

Double-row pile structure with cored horizontal rotary jet grouting pile on pile body

ActiveCN104563129AImprove anti-overturn performanceIncrease stiffnessExcavationsBulkheads/pilesReinforced concreteRebar

The invention discloses a double-row pile structure with a cored horizontal rotary jet grouting pile on the pile body, and belongs to the field of building foundation pit engineering. A first crown beam and a second crown beam are respectively arranged at the top ends of the front-row pile and the rear-row pile, and are connected by a connecting beam. During the construction process of the front-row pile and the rear-row pile, first embedded pipes with the same diameters are respectively embedded at the positions with the same depths in the reinforcement cages; after the pile-forming construction is completed, when the foundation pit is excavated to the depth position of the embedded pipes, the horizontal rotary jet grouting pile is constructed along the embedded pipes in the front-row pile body and the rear-row pile body. The rotary jet grouting pile is constructed by rotary jet grouting segment by segment, the positions between the front-row pile and the rear-row pile completely subjected to rotary jet grouting and solidified, and the rotary jet grouting diameter of the tail position is correspondingly increased to form an anchor body with an enlarged head. After the construction of the rotary jet grouting pile completed, before the pile body quality is stable, a prefabricated reinforced concrete square pile is inserted into the pile body, and thereby the double-row pile structure with the cored horizontal rotary jet grouting pile on the pile bodies is formed.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

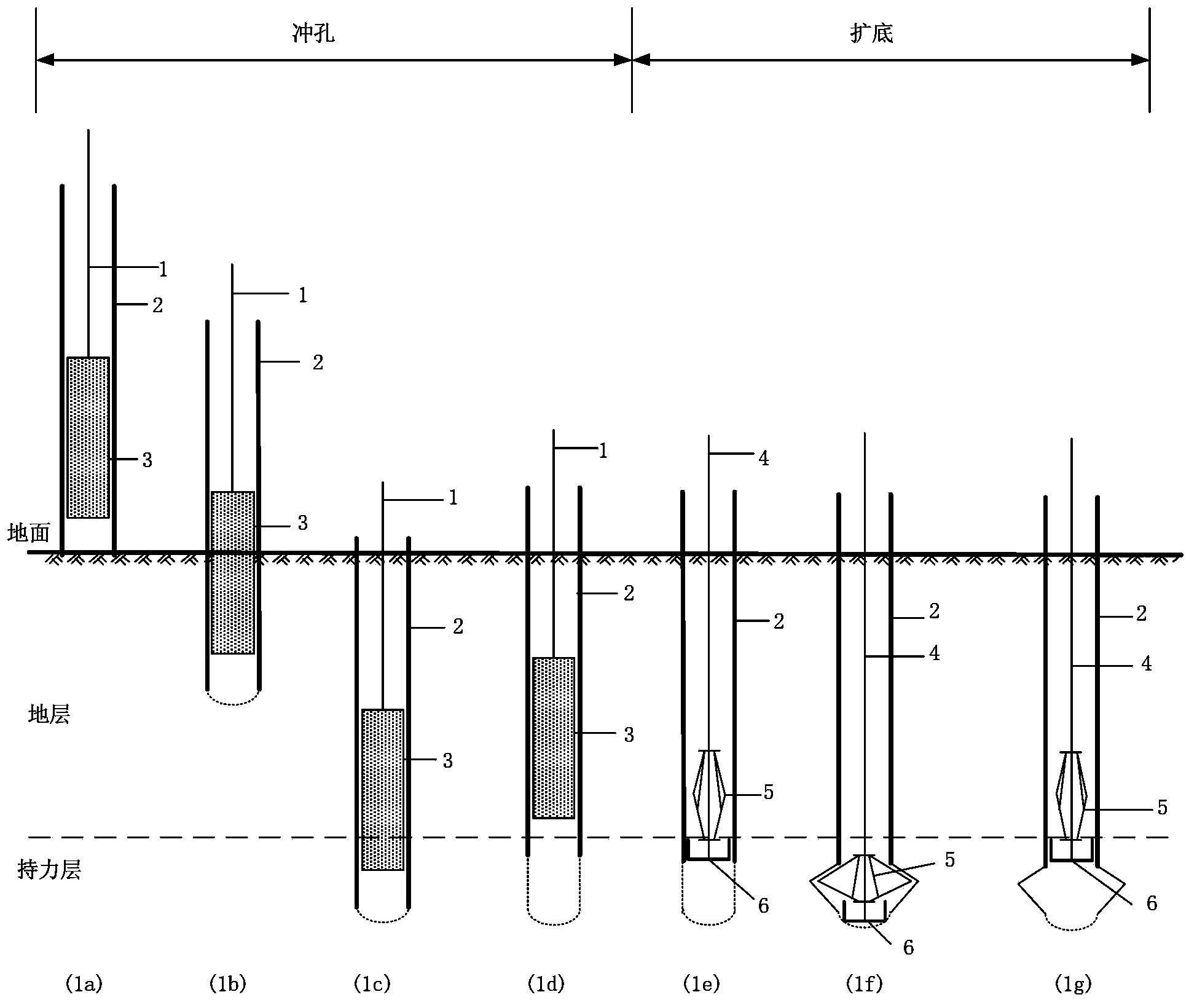

Construction method for cast-in-place pile through punching and base expanding and base expanding device

ActiveCN103410142AImprove bearing capacityReduce settlementBulkheads/pilesDrilling machines and methodsPunchingSlag

The invention discloses a construction method for a cast-in-place pile through punching and base expanding and a base expanding device. The method includes the steps of 1) punching which includes reserving the pile position and pressing a protection drum into soil by utilizing hydraulic pressure; 2) base expanding which includes connecting a drill rod and the base expanding device and placing the drill rod and the base expanding device into the protection drum; 3) pile end construction which includes pouring a hard bulk material into a hole, utilizing a heavy punch to conduct tamping repeatedly till the material is compacted and pressing a conical pile head into the pile end through the heavy punch; 4) pile body construction which includes that a connection pipe is connected with the drill rod through threads, the connection pipe is welded with a first rod piece, two ends of the first rod piece are connected with a second rod piece through bolts, the second rod piece is arranged in a guide groove through a bolt, the first rod piece is fixed on the second rod piece through a bolt, a baffle is arranged on the connection rod, the connection rod is connected with the bolts, and the connection rod is welded at the bottom of a slag clearing drum. The construction method is easy to implement, simple to operate, convenient to construct, reliable in piling quality, low in construction cost, high in bearing capability, simple in structure and convenient to use. Functions of a conventional base expanding device can be achieved, and the problem that a conventional base expanding drill bit can not effectively clear slag at the bottom of the pile is solved.

Owner:WUHAN ZHONGLI GEOTECHN ENG

Post-grouting construction method of bridge cast-in-place pile

InactiveCN107513995AHigh structural reliabilityElimination of hidden dangers of mud skinBulkheads/pilesStructural reliabilityPipe water

The invention discloses a post-grouting construction method of a bridge cast-in-place pile. The method comprises the following steps of (1) grouting nozzle manufacturing, (2) grouting pipe installing, (3) grouting pipe water testing and (4) pump-in test and pump-in plug opening. The method has the advantages that the structural reliability of the pile bearing capacity is improved, the method can be used as an effective remedial measure for a cast-in-place pile with quality defect, a grouting pipe can be piled in the pile-forming side for grouting to improve the single-pile bearing capacity, the single-pile bearing capacity of the drilled grouting pile can be improved, and the settlement of pile foundation can be controlled effectively.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

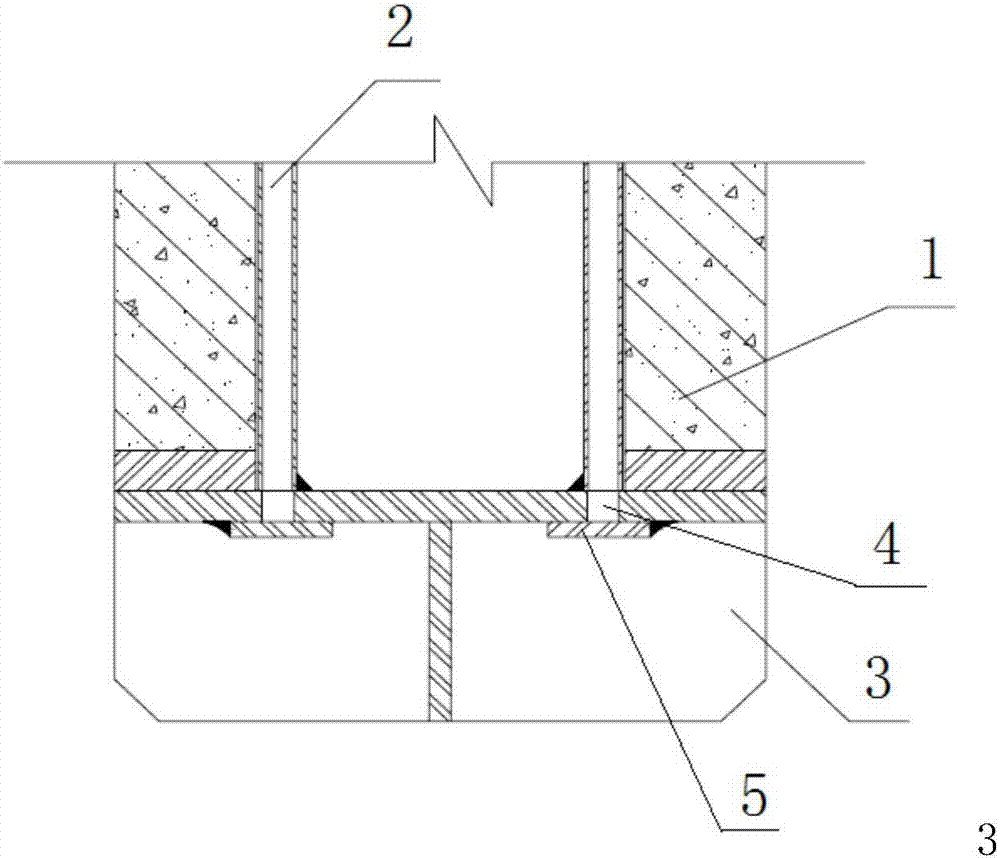

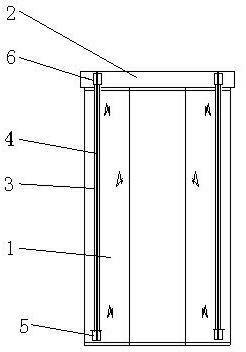

Water-retaining cofferdam structure and construction method thereof

ActiveCN1876968ASimple construction methodReduce difficultyFoundation engineeringCofferdamEngineering

The invention relates to a water retaining coffer structure, which comprises two rows of posts; at least two coffers connected to each transverse direction of one row of posts; at least one row of upper steel drawing rod connected between two rows of posts. Wherein, said posts, coffers, and upper steel drawing rods form the solid frame; and the long blow stuff is filled with soil to be fixed into the frame. The invention has easy application.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

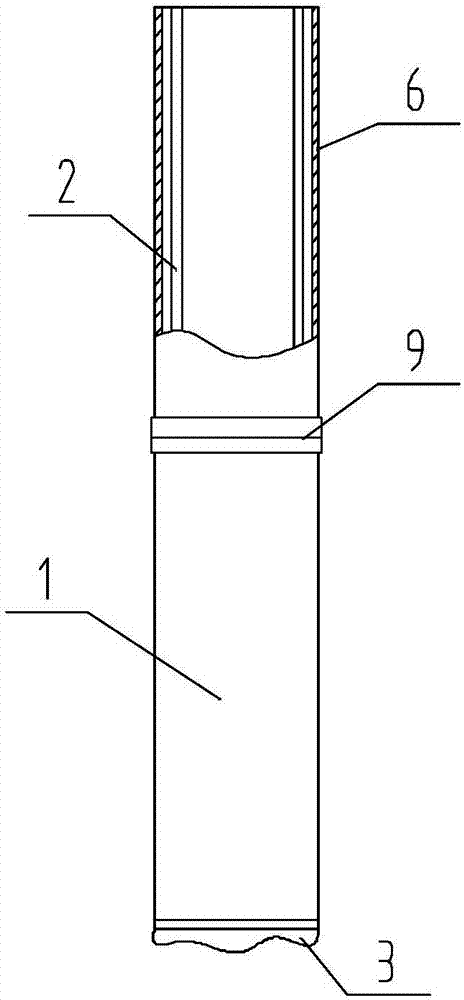

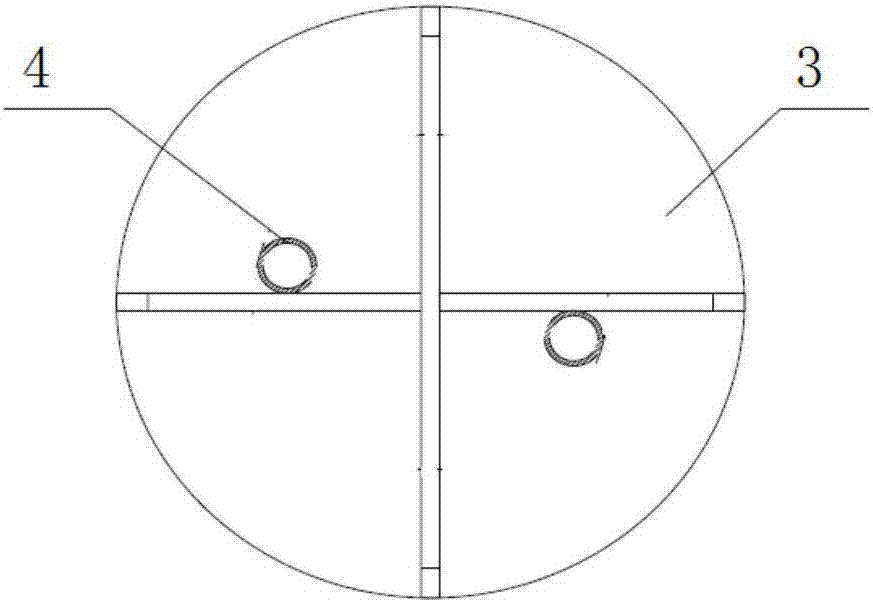

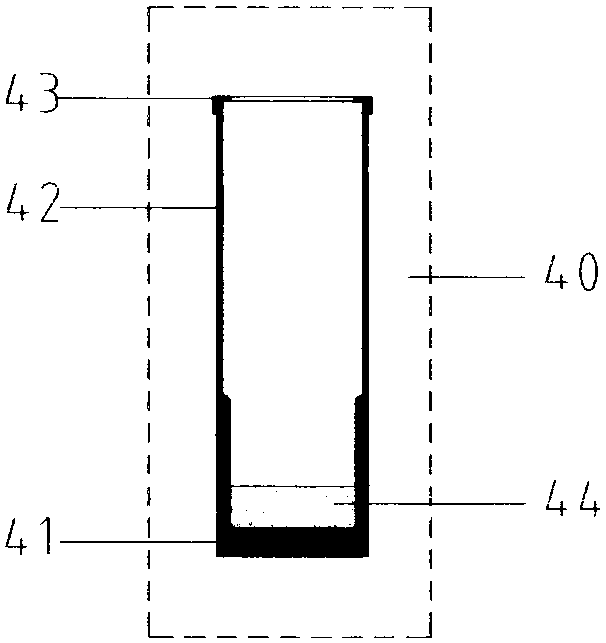

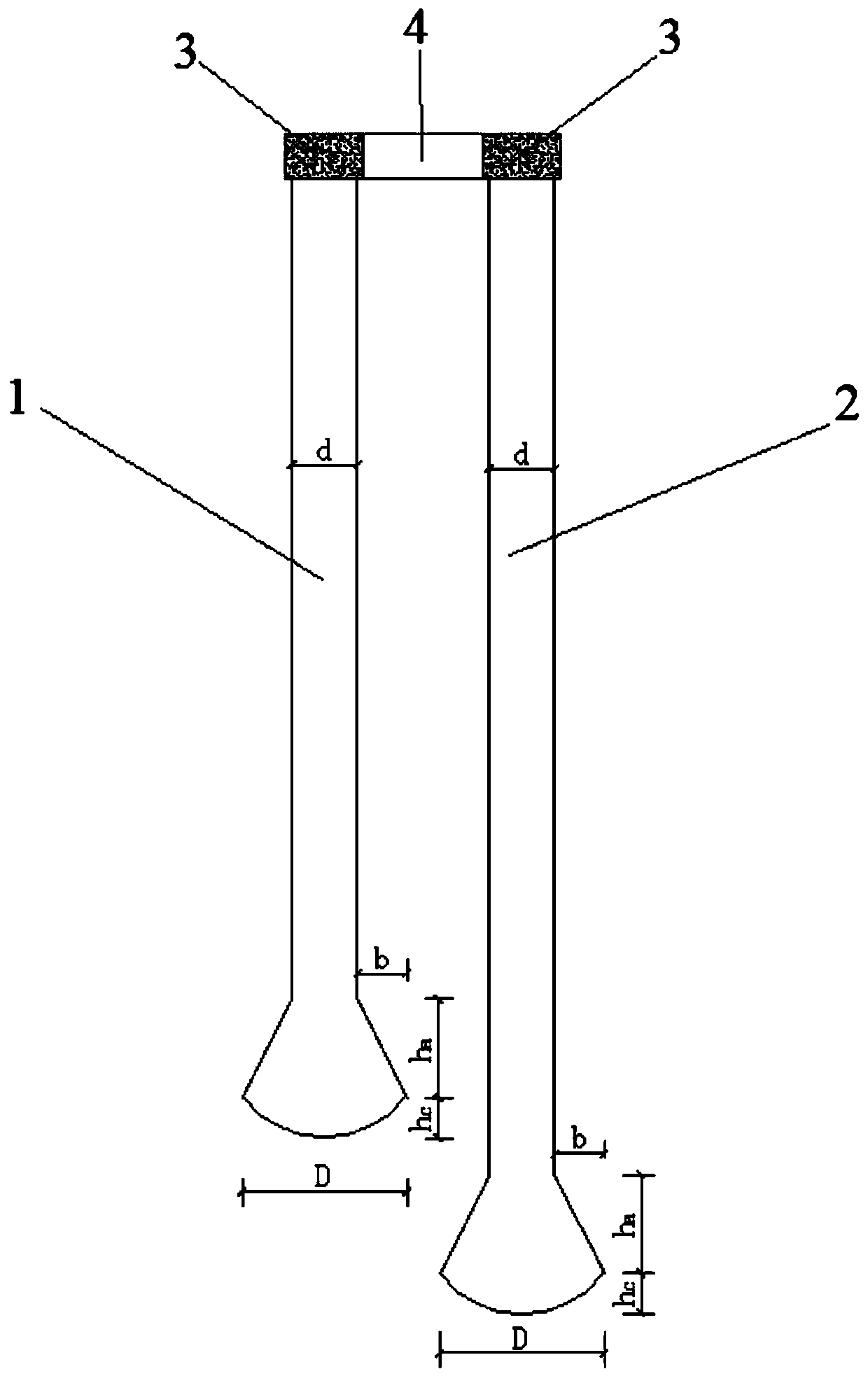

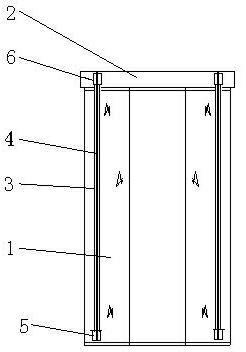

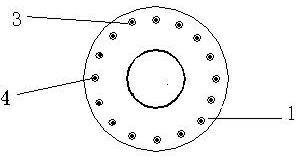

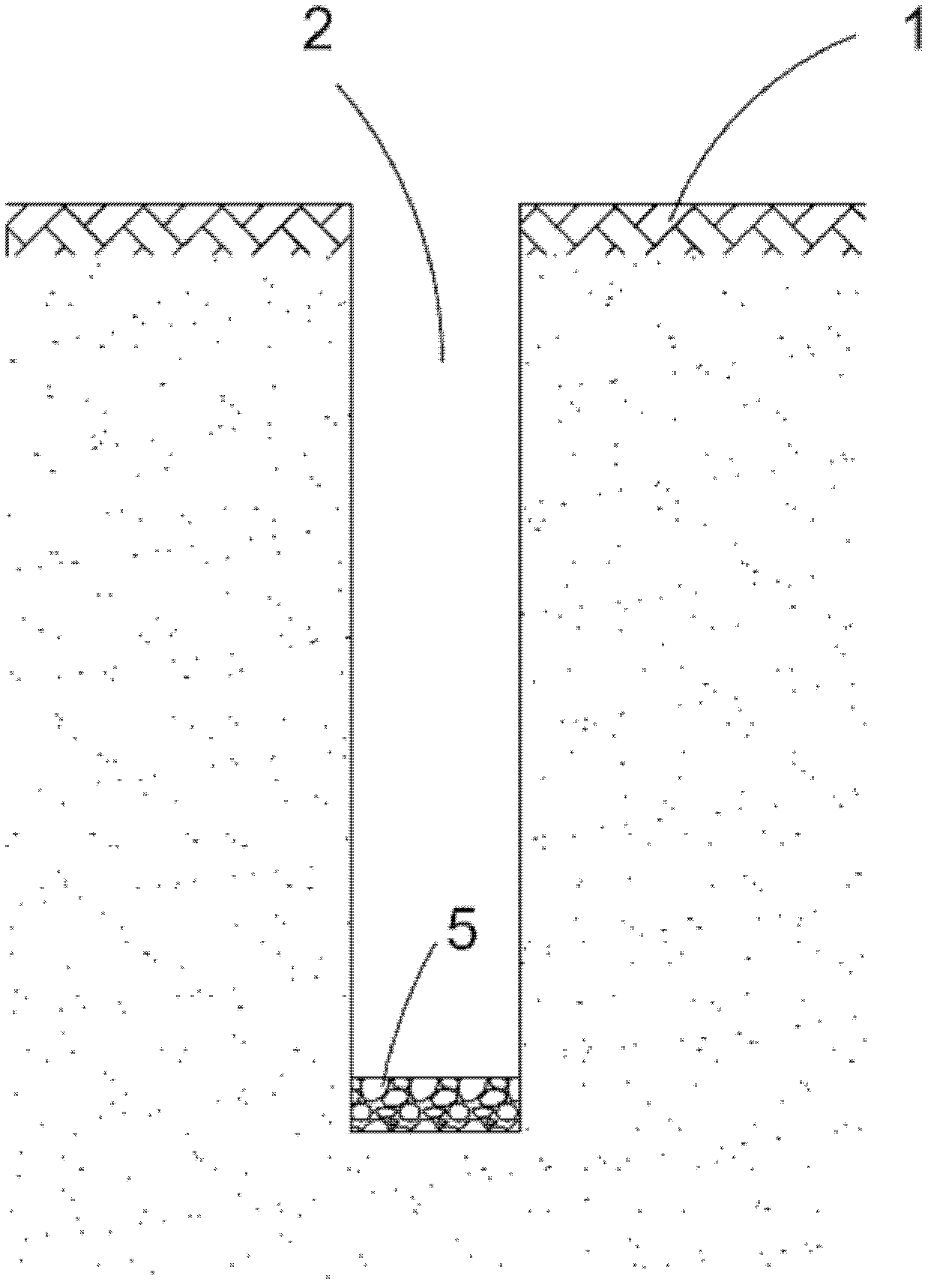

Pipe pile with post-pressure-grouting grouting pipes and construction method of pipe pile

ActiveCN107237319AImprove bearing capacityImprove the modulus of compressionBulkheads/pilesSlurrySpot welding

The invention provides a pipe pile with post-pressure-grouting grouting pipes. The pipe pile comprises a pipe pile body, the grouting pipes which are arranged in the pipe pile body and symmetrically arranged with the axis of the pipe pile body as the center and a steel pile point arranged at the lower end of the pipe pile body. Slurry discharge holes are formed in the positions, corresponding to the pouring pipes, on the steel pile point. Blocking plates which are used for covering the slurry discharge holes and can be jacked up by the grouting pressure are welded to the positions corresponding to the slurry discharge holes in a spot welding manner. The two grouting pipes are vertically arranged. The pipe pile body is formed by the multiple-joint butt joint. Each grouting pipe comprises multiple sections matched with the sections, corresponding to the grouting pipe, of the pipe pile in length. The portions, close to the joints of the pipe pile body, of the sections of the grouting pipes are connected through pipe joints. By the adoption of the pipe pile with the post-pressure-grouting grouting pipes, the single-pile bearing force of the prefabricated concrete pipe pile is improved effectively, the modulus of compression of foundation soil is increased, the settlement of a building is reduced, the pile length is reduced, the number of piles is reduced, the stability of the building is guaranteed, and the building cost is saved.

Owner:MCC TIANGONG GROUP

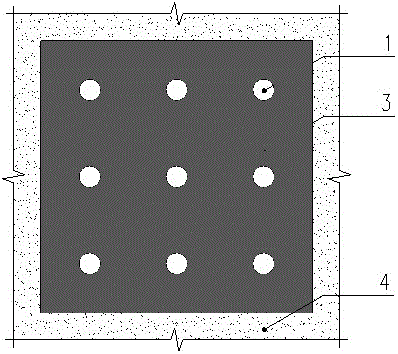

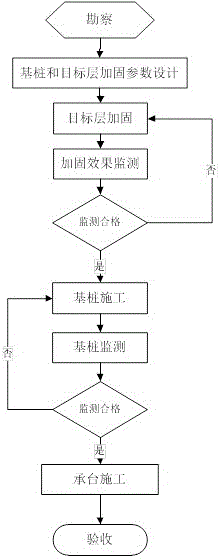

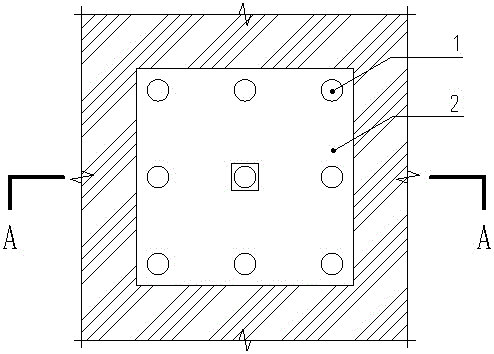

Pile space oil continuous reinforced pile group system and construction method thereof

PendingCN106759424AReduce settlementImprove bearing capacityFoundation engineeringHigh intensityGroup system

The invention provides a pile space oil continuous reinforced pile group system and a construction method thereof. The pile space oil continuous reinforced pile group system comprises two and more foundation piles, a bearing platform, target layer pile space oil and non-target layer pile space oil; and the upper ends of the foundation piles are embedded in the bearing platform by a certain length, and are fixedly connected with the bearing platform, and the rest parts are buried in a pile space oil layer. The system adopts a foundation treatment technology to continuously reinforce the target layer pile space soil; and the reinforced target layer pile space soil forms a continuous high-strength whole in the horizontal direction to supply an excellent manual supporting layer to a pile group. The system can solve the problem of high or ultrahigh bearing force demand of a pile group foundation in a limited range by a lower manufacturing cost, such as large or superlarge foundations as bridges, wind power and petroleum platforms. The invention further provides the construction method of the pile space oil continuous reinforced pile group system.

Owner:SHANDONG UNIV OF SCI & TECH

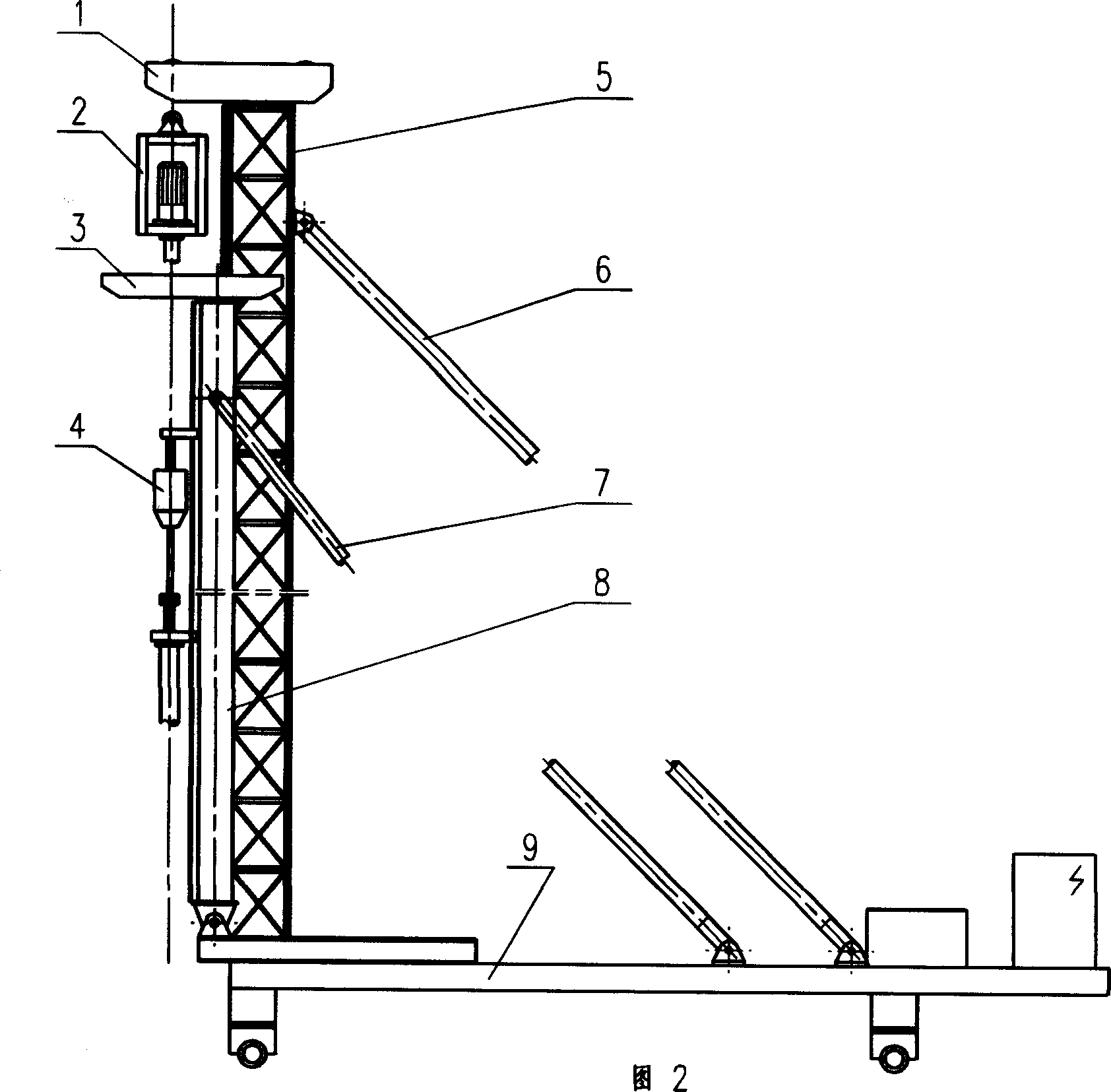

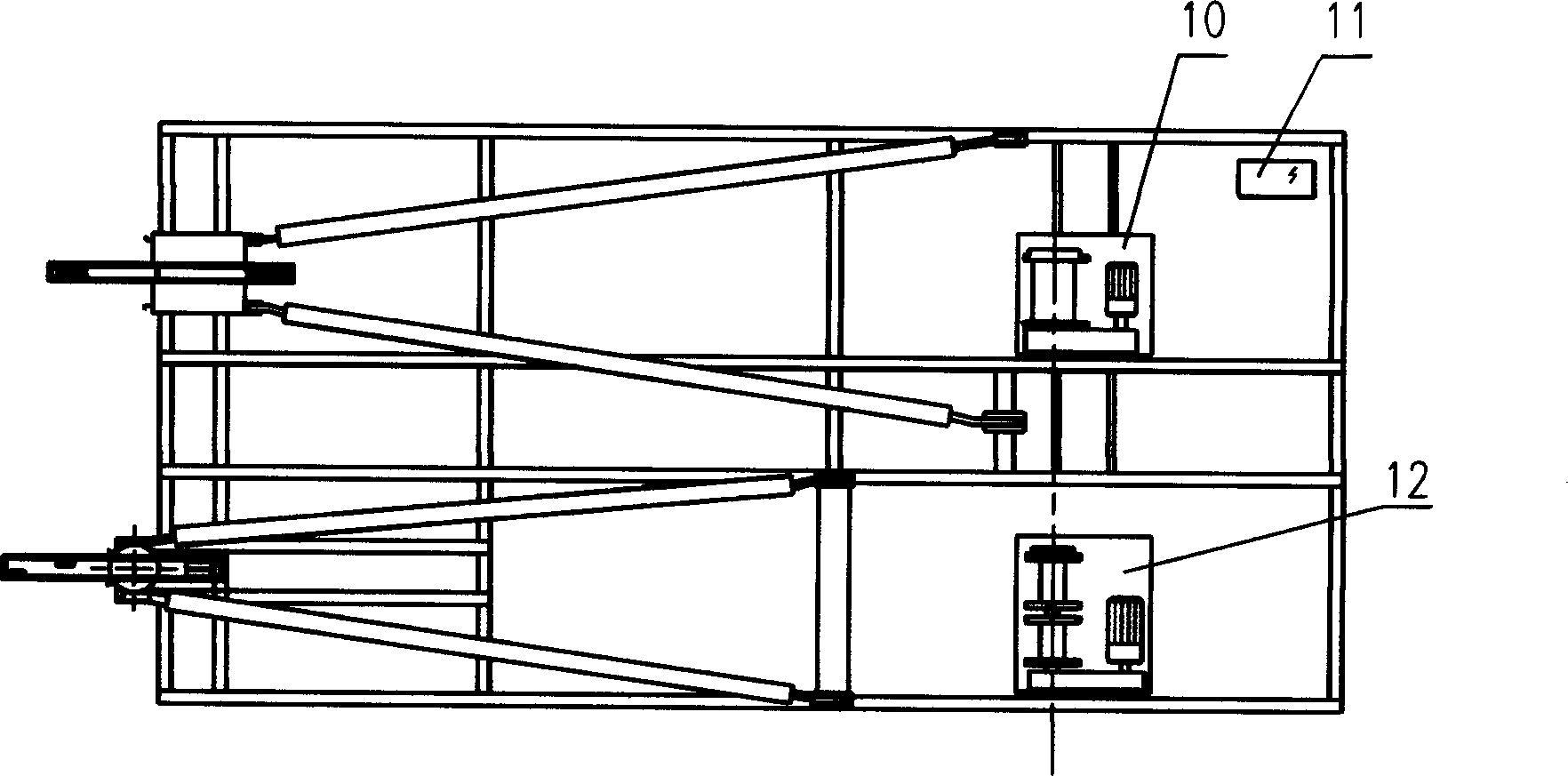

Original soil strengthen pile sinking method and its construction apparatus

The invention discloses a method of crude soil solidifying pile sinking used in building operation and its construction device. The method of pile sinking is that cut moving is stirred into stirred cut crude soil as pre-selected at pre-calculated position of the ground base; prepared curing agent is pressed into the stirred cut crude soil and stirred uniformly into solidified soil; the prefabricated pile is sunk into the solidified soil, the ground base is formed into crude soil solidified pile base. The construction device includes bottom head, stirring machine upright equipped on the bottom head, deep lift stirring machine equipped on the stirring machine upright, pile driver upright equipped on the bottom head, pile driver equipped on the pile diver upright. The advantage of the ground base formed by this method is high intension, strong bearing capacity, and low cost.

Owner:江苏东达集团股份公司

Tubular pile with unfolding blades and construction method of tubular pile

The invention discloses a tubular pile with unfolding blades. The tubular pile comprises a prefabricated tubular pile, wherein the prefabricated tubular pile is pressed into a soil layer through hammering or static pressure and comprises a mother pile and a pile tip; a cavity extending from the pile tail to the pile tip is formed in the pile body of the mother pile; a layer or a plurality of layers of blade jacking holes communicated with the cavity are formed in the pile wall of the mother pile in the length direction of the pile body; blades which can rotate around rotating devices and rotate towards the direction far away from the cavity are arranged at the upper edge far away from the cavity of each blade jacking hole; and a force applying part used for jacking the blades out of the blade jacking holes is arranged in the cavity. The construction method of the prefabricated tubular pile can be referred in an instruction book; and compared with a conventional prefabricated pile, the pile body is provided with unfoldable blades, so that the end-bearing effect of the pile is greatly improved, the bearing capacity of the pile is increased by multiple times or even tens of times, the number of used piles and the pile length can be greatly reduced, and the comprehensive benefits are extremely remarkable.

Owner:陈明

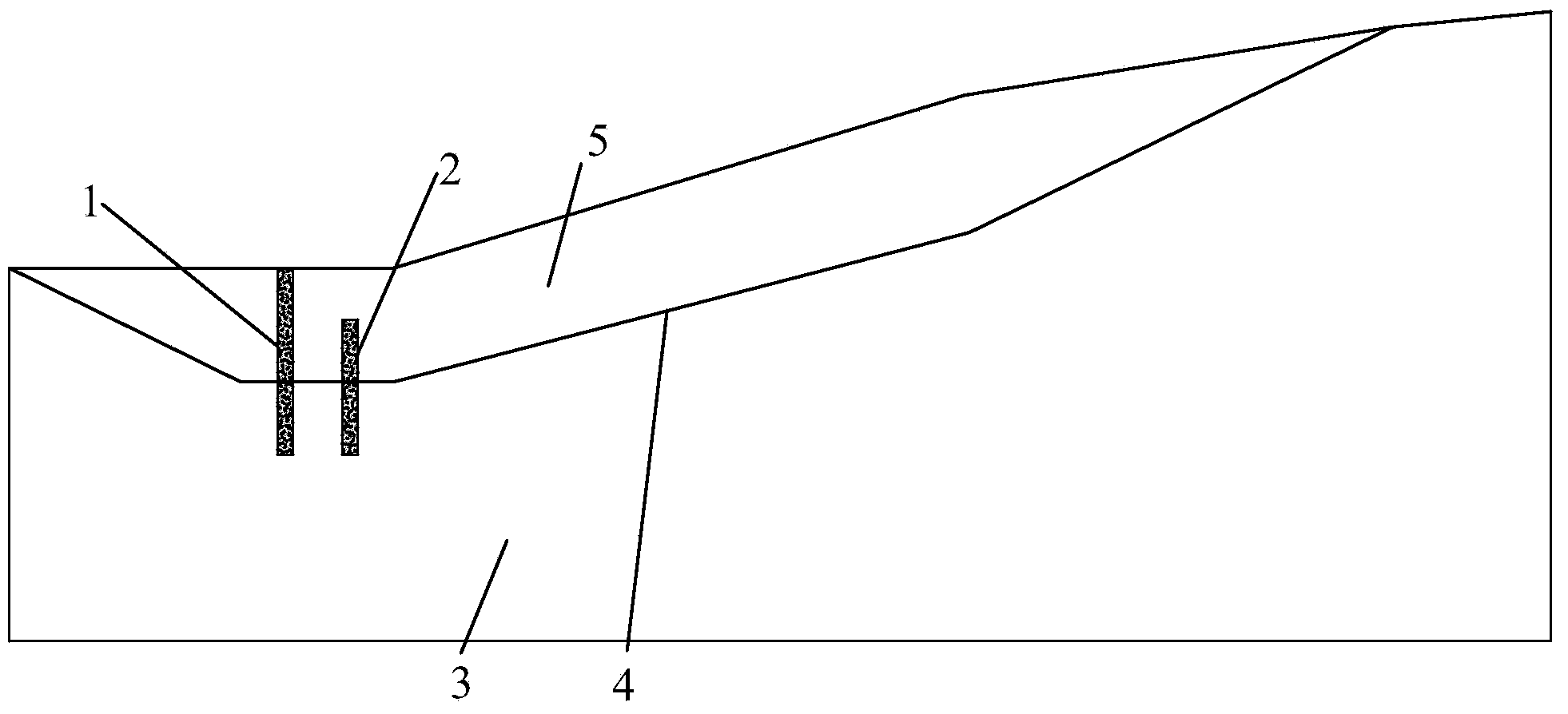

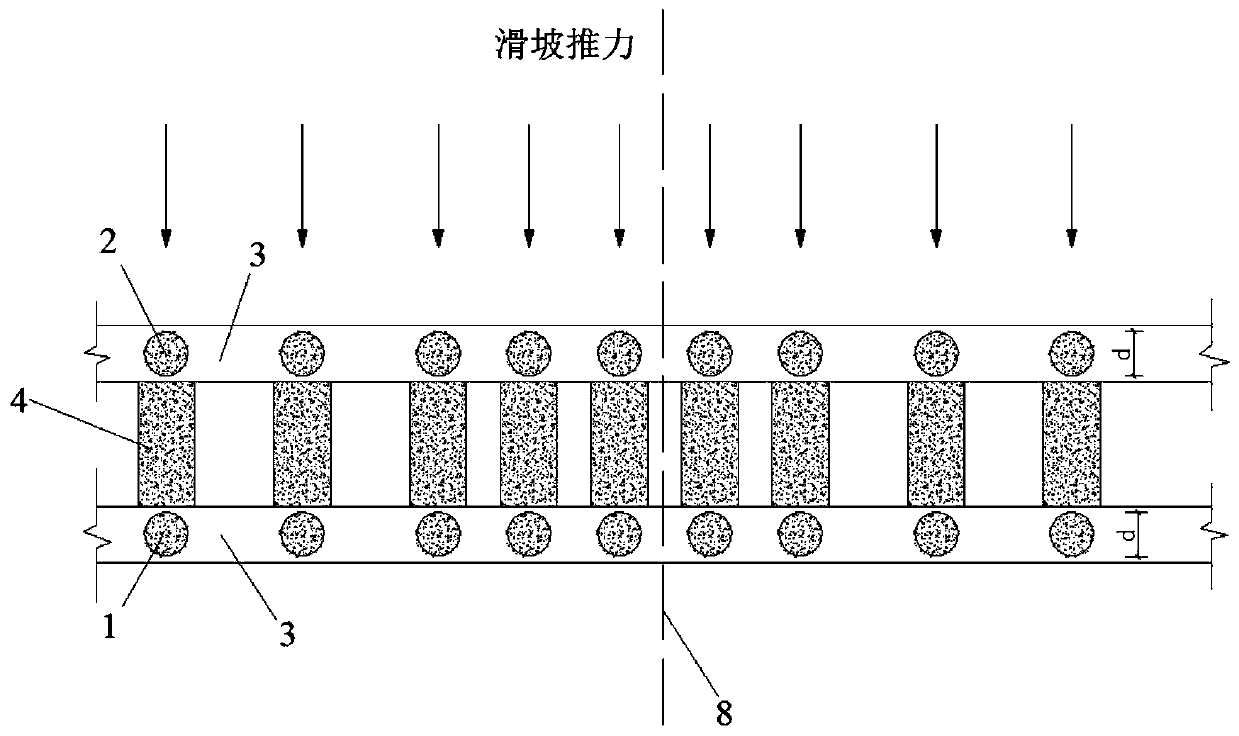

Double-row long-short combined landslide-resistant pile

ActiveCN104179187AReduce landslide thrustLandslide thrust increaseExcavationsBulkheads/pilesThrust bearingLandslide

A double-row long-short combined landslide-resistant pile comprises a front-row landslide-resistant pile body and a rear-row landslide-resistant pile body and is characterized in that the front-row landslide-resistant pile body is a full-length type landslide-resistant pile, the rear-row landslide-resistant pile body is a buried landslide-resistant pile, the length of the load-bearing section of the rear-row pile body is reduced to reduce the landslide thrust borne by the rear-row landslide-resistant pile body, and the landslide thrust borne by the front-row landslide-resistant pile body is increased. Stress and deformation of the front-row landslide-resistant pile body and the rear-row landslide-resistant pile body are adjusted, the problem of uneven stress and deformation of the front-row landslide-resistant pile body and the rear-row landslide-resistant pile body is solved, and landslide-resistant effects of the landslide-resistant can be brought into play. In addition, the arrangement form of dense middle and sparse two sides allows the landslide-resistant piles on two sides a landslide mass are well brought into play.

Owner:CENT SOUTH UNIV

High-bearing-force thin-wall steel tube concrete pile construction method and device and application thereof

InactiveCN108385674AImprove construction efficiencyPracticalBulkheads/pilesMechanical propertySteel tube

The invention provides a high-bearing-force thin-wall steel tube concrete pile construction method and device and application thereof. An inward-beating method is used for achieving high bearing force, the technology of weakening the pile hole soil is used for solving the problem about the construction efficiency of the inward-beating method, the device is used for solving the problem about buffering and corrosion prevention, and therefore high-bearing-force thin-wall steel tube concrete pile construction has feasibility, the pile forming quality is good, the use amount of steel is small, operation is easy, control is easy, construction efficiency is high, reliable corrosion prevention is formed, durability and the mechanical property are good, and cost performance is high.

Owner:毕建宏

Slag trough structure and construction method for same

The invention discloses a slag ditch structure and a construction method thereof, belonging to the field of foundation pit construction. It includes support beams and slag ditch walls. Support piles are arranged outside the slag ditch walls, and support beams are arranged between the support piles. The supporting piles include water-stop piles and water-stop curtain piles, and the water-stop curtain piles are arranged between two adjacent water-stop piles. The supporting piles are bored cast-in-place piles, which are drilled with a drilling rig, then the steel cage is lowered into the hole, and concrete is poured. During the construction of the supporting piles, the pile position, the elevation of the top and bottom of the pile, the specific gravity of the mud, and the quality of the underwater concrete are strictly controlled. The number of water-stop piles is set to more than two rows, which is to strengthen the water-stop effect, and the water-stop piles can also play a role in resisting the lateral pressure of the soil. It can prevent water from entering the slag ditch, and can also bear the side pressure of the soil. The high-pressure rotating nozzle sprays the cement slurry into the soil layer and mixes with the soil to form a continuous lapped cement reinforcement. The construction occupies less land, has less vibration and less noise. Low.

Owner:马钢集团设计研究院有限责任公司

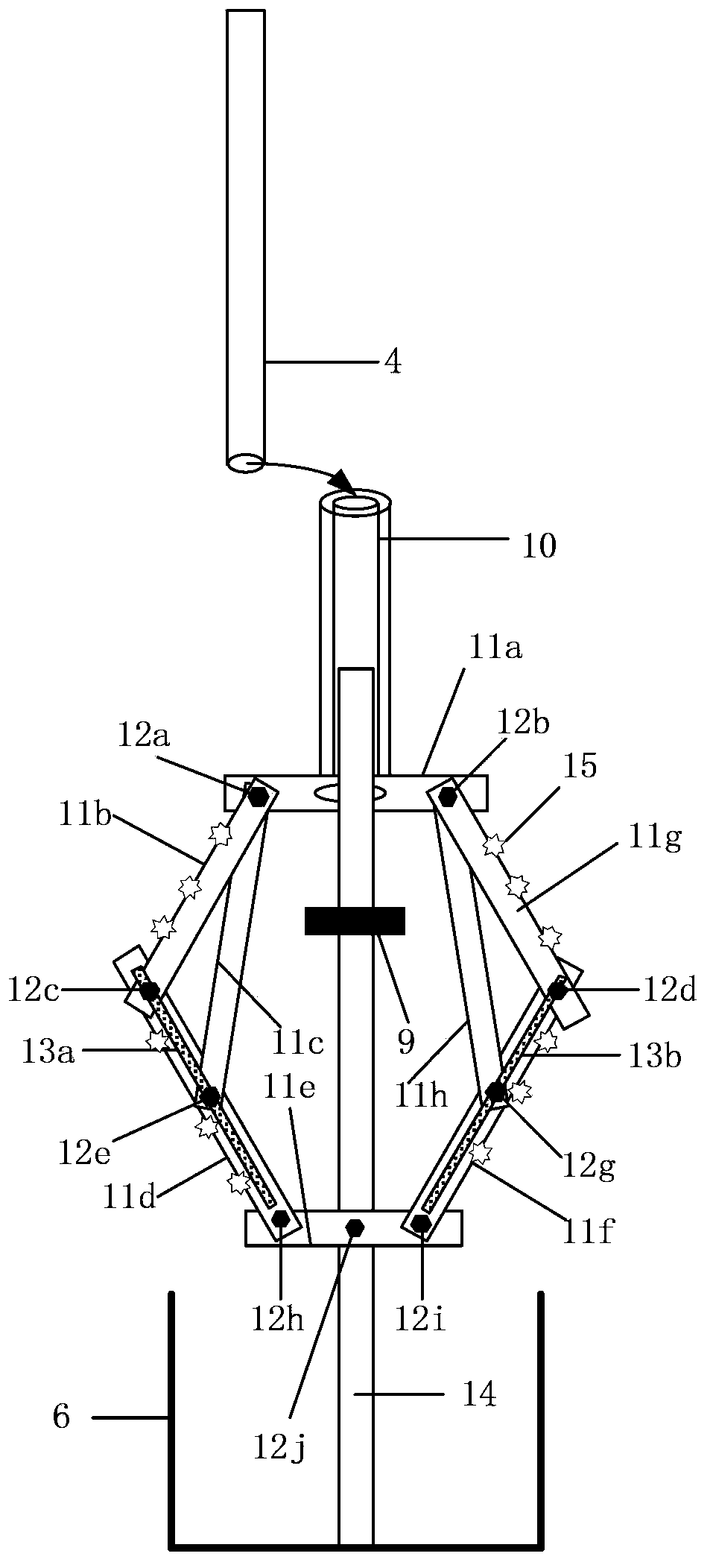

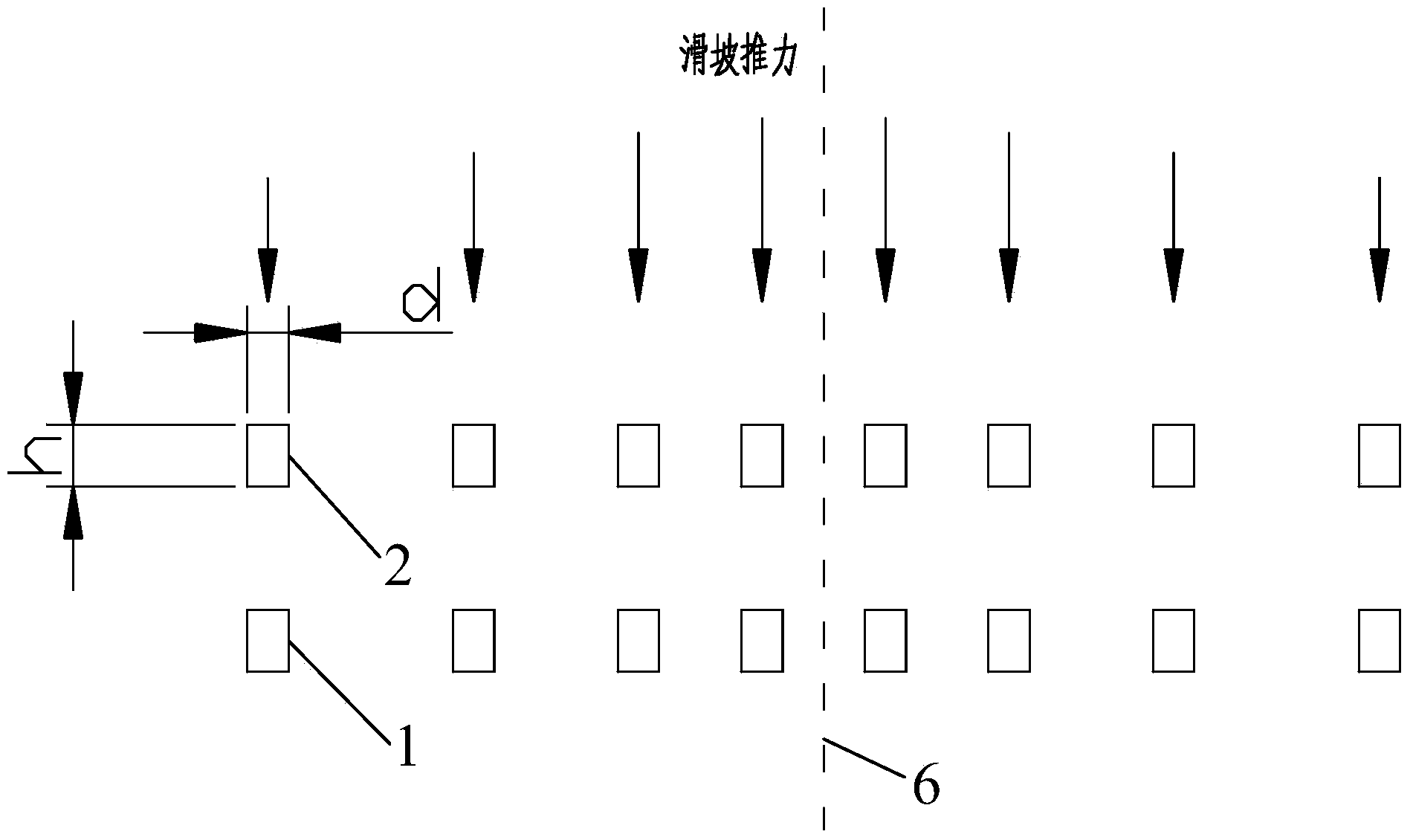

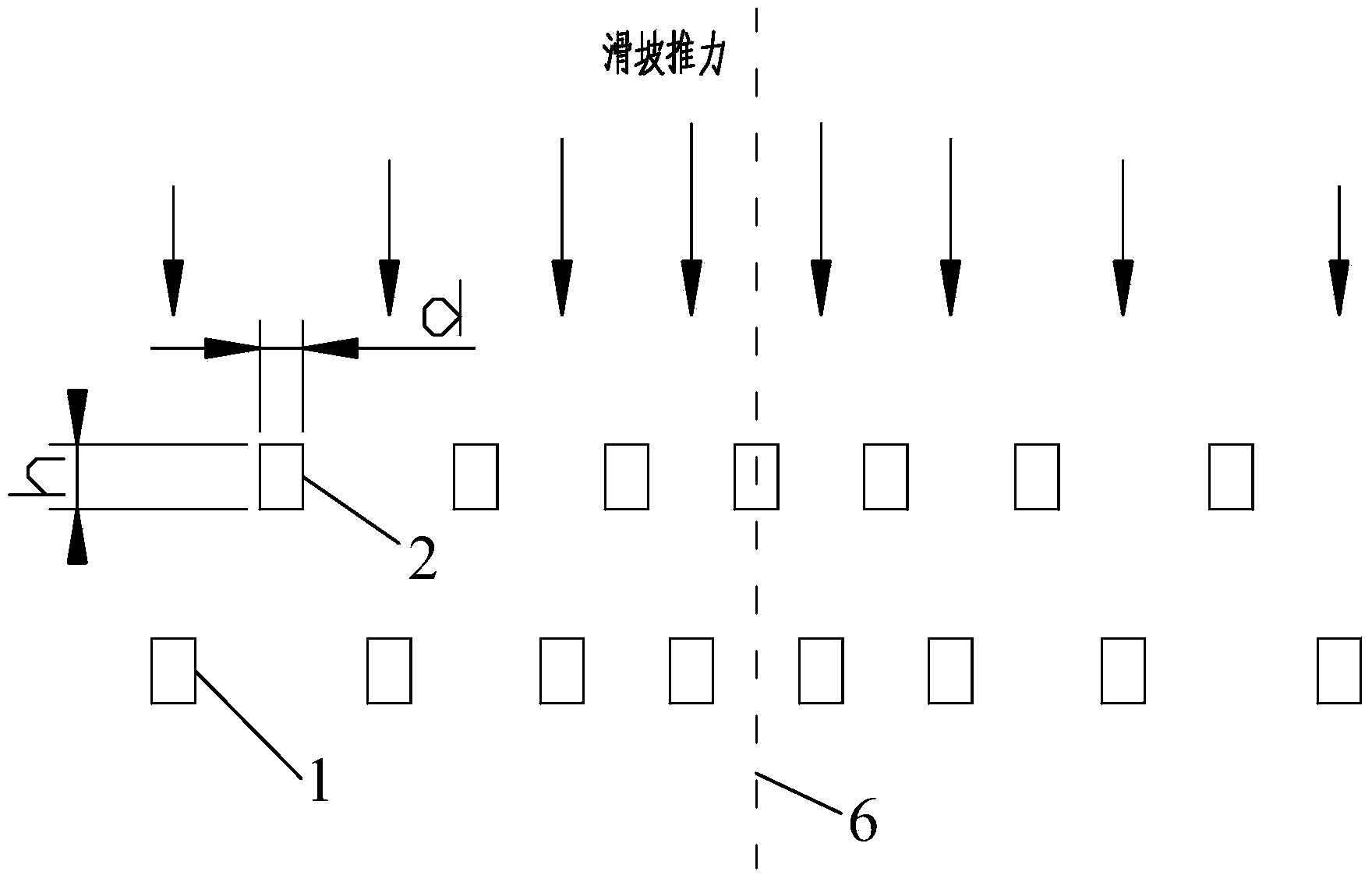

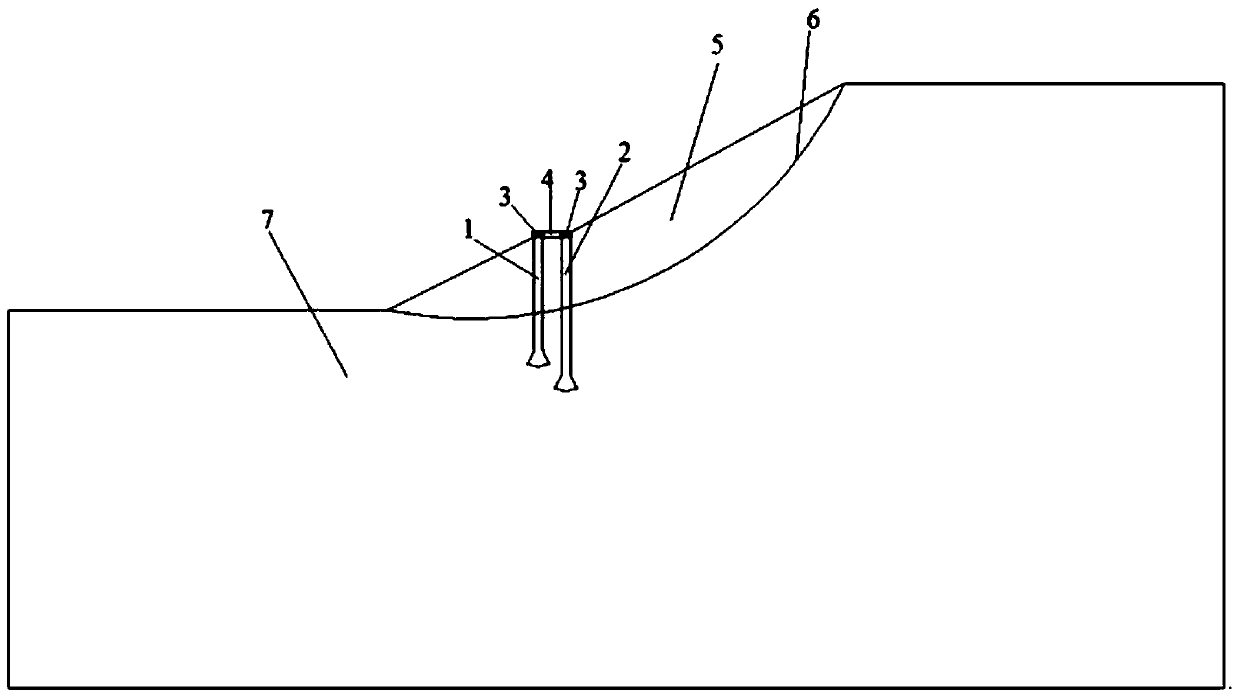

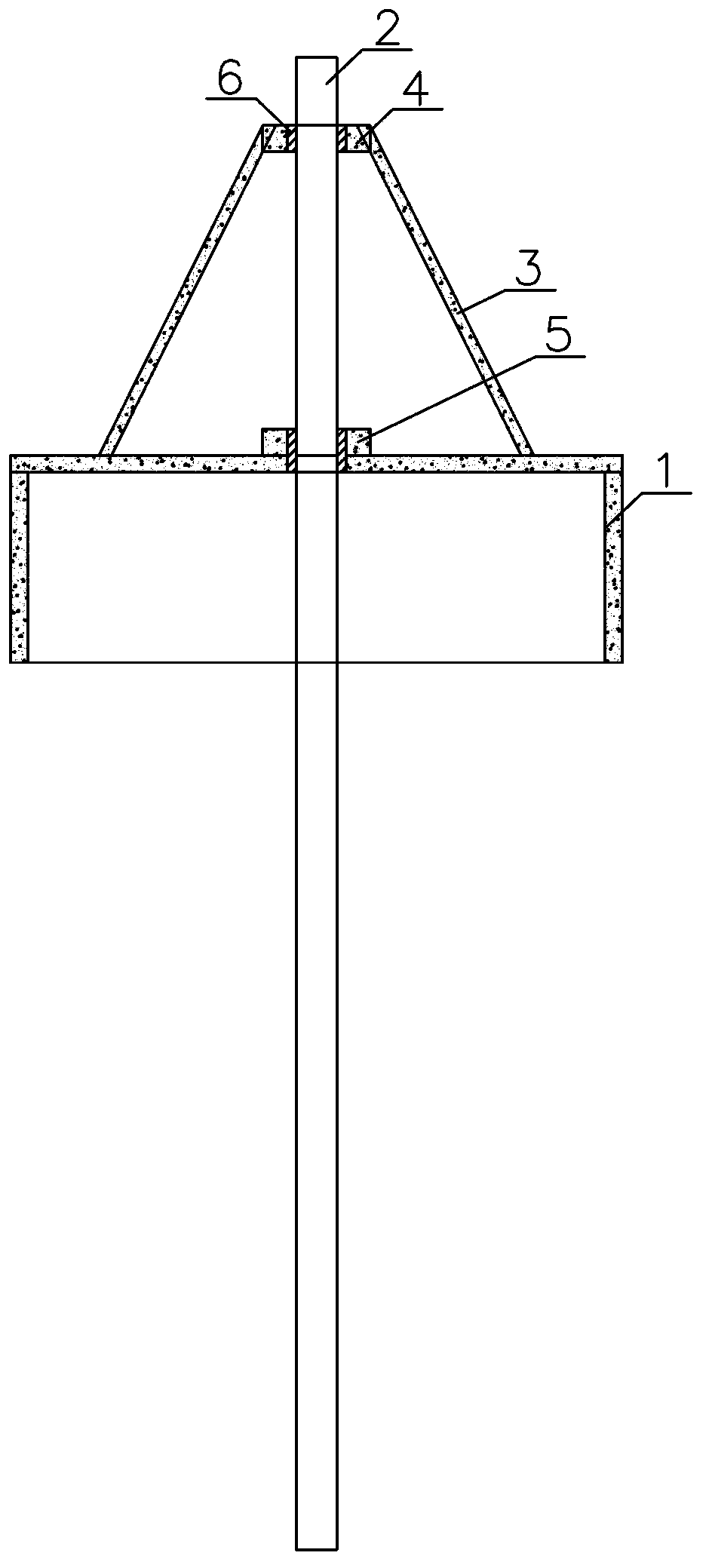

Double-row bottom-expanded long and short combined anti-slide pile for slope supporting

InactiveCN110565658AReduce dosageEffectively regulate internal forceExcavationsBulkheads/pilesThrust bearingLandslide

The invention discloses a double-row bottom-expanded long and short combined anti-slide pile for slope supporting. The double-row bottom-expanded long and short combined anti-slide pile comprises front-row bottom-expanded anti-slide pile bodies, rear-row bottom-expanded anti-slide pile bodies, pile top crown beams and connecting beams, both the front-row anti-slide pile bodies and the rear-row anti-slide pile bodies adopt bottom-expanded piles, and the pile length of the front-row bottom-expanded anti-slide pile bodies is less than that of the rear-row anti-slide pile bodies. Through the bottom expanding effect of the front-row anti-slide pile bodies and the rear-row anti-slide pile bodies, landslide thrust borne by the combined anti-slide pile is increased, force bearing and deformation between the front-row pile bodies and the rear-row pile bodies are regulated, and thus the anti-slide ability of the front-row pile bodies and the rear-row pile bodies can be given to full play; and meanwhile, the arrangement form that the position near a central line of landslide is dense and the two sides of the central line of the landslide are sparse is adopted so that the anti-slide pile bodies on the two sides of a landslide body can play a better role, and the landslide treatment cost is lowered.

Owner:江苏省地质矿产局第三地质大队 +1

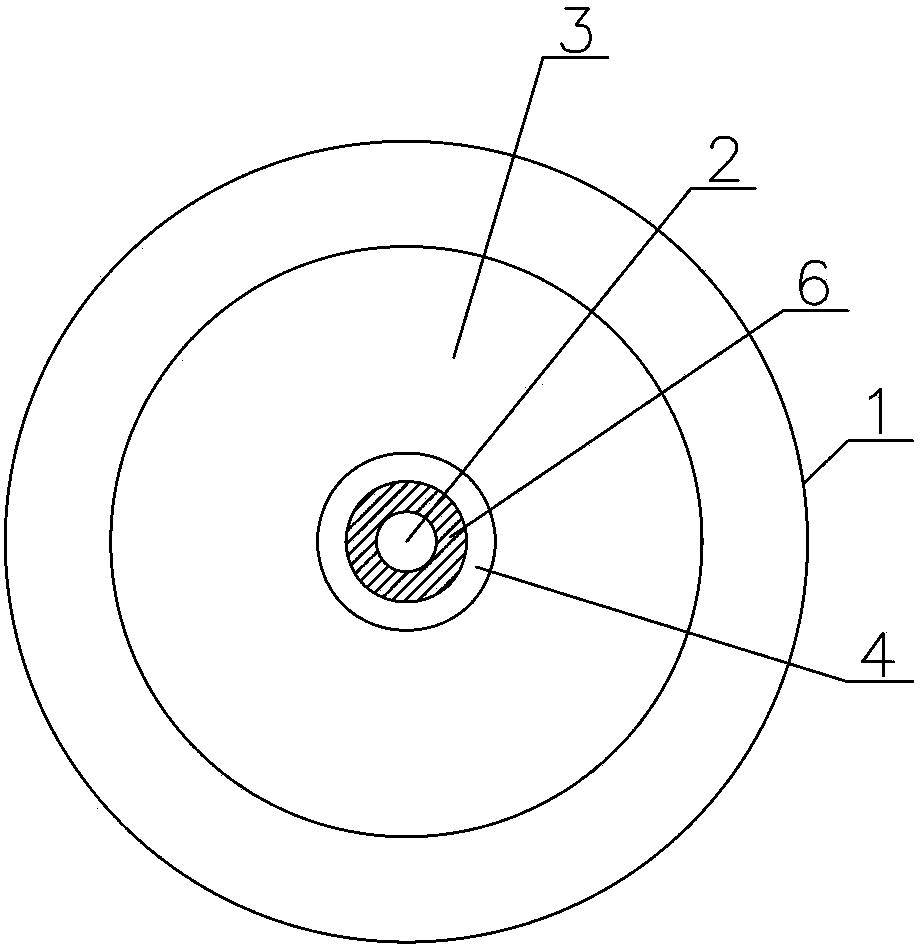

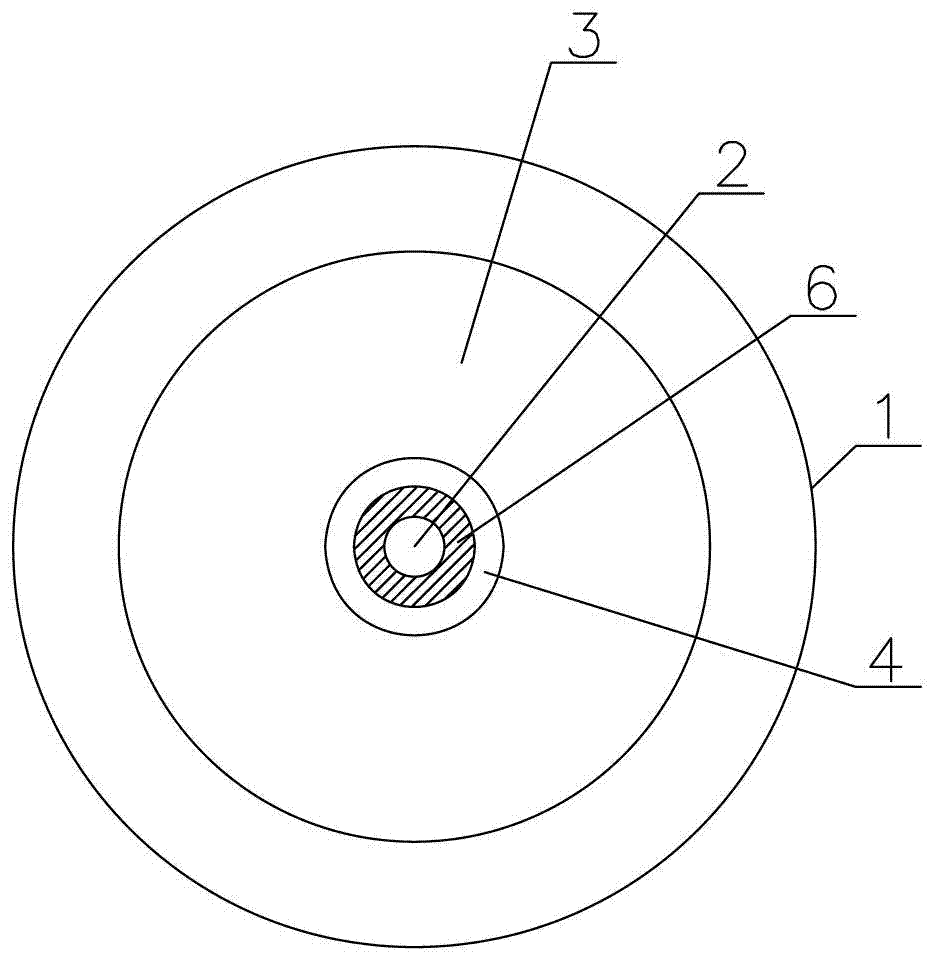

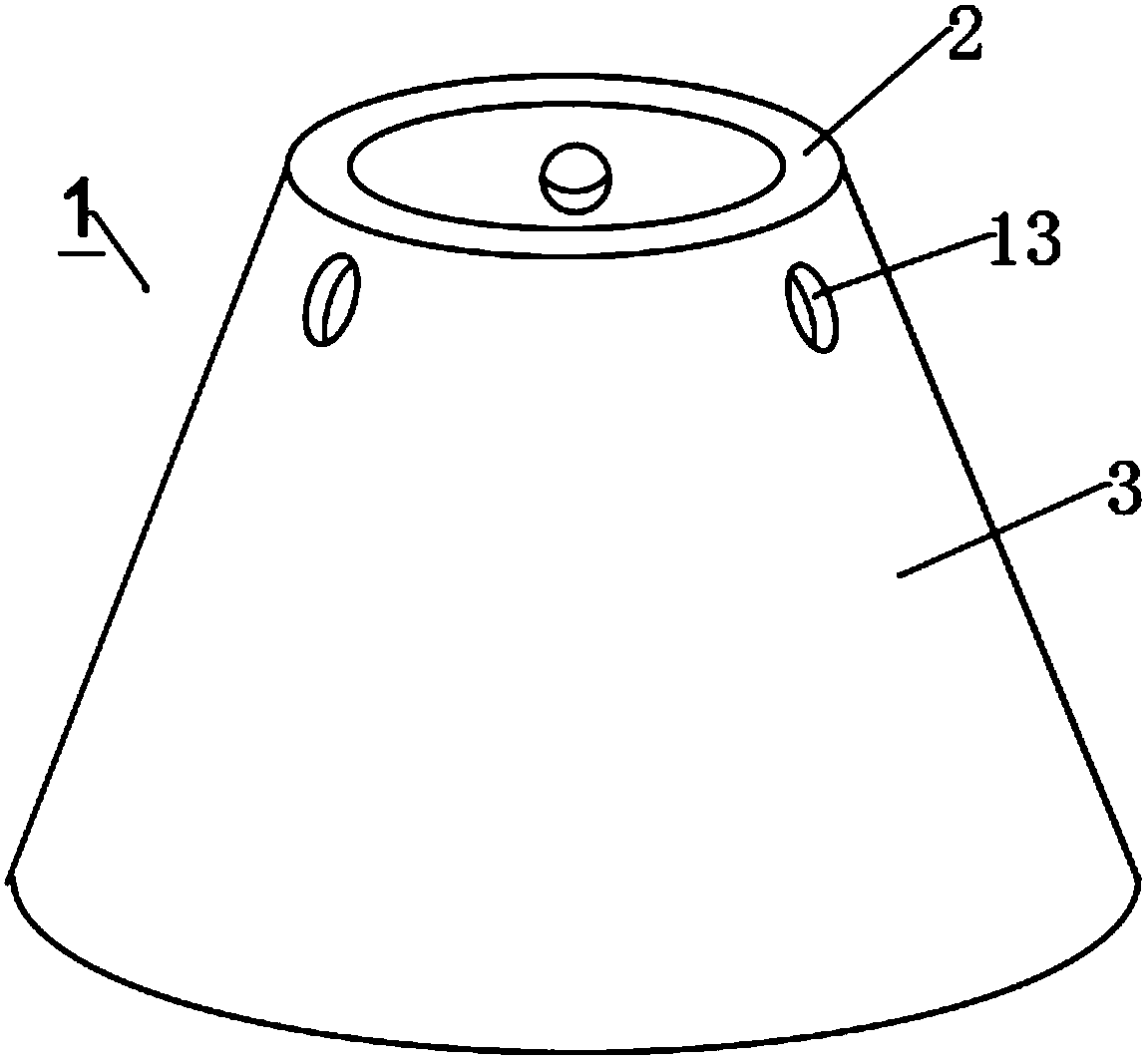

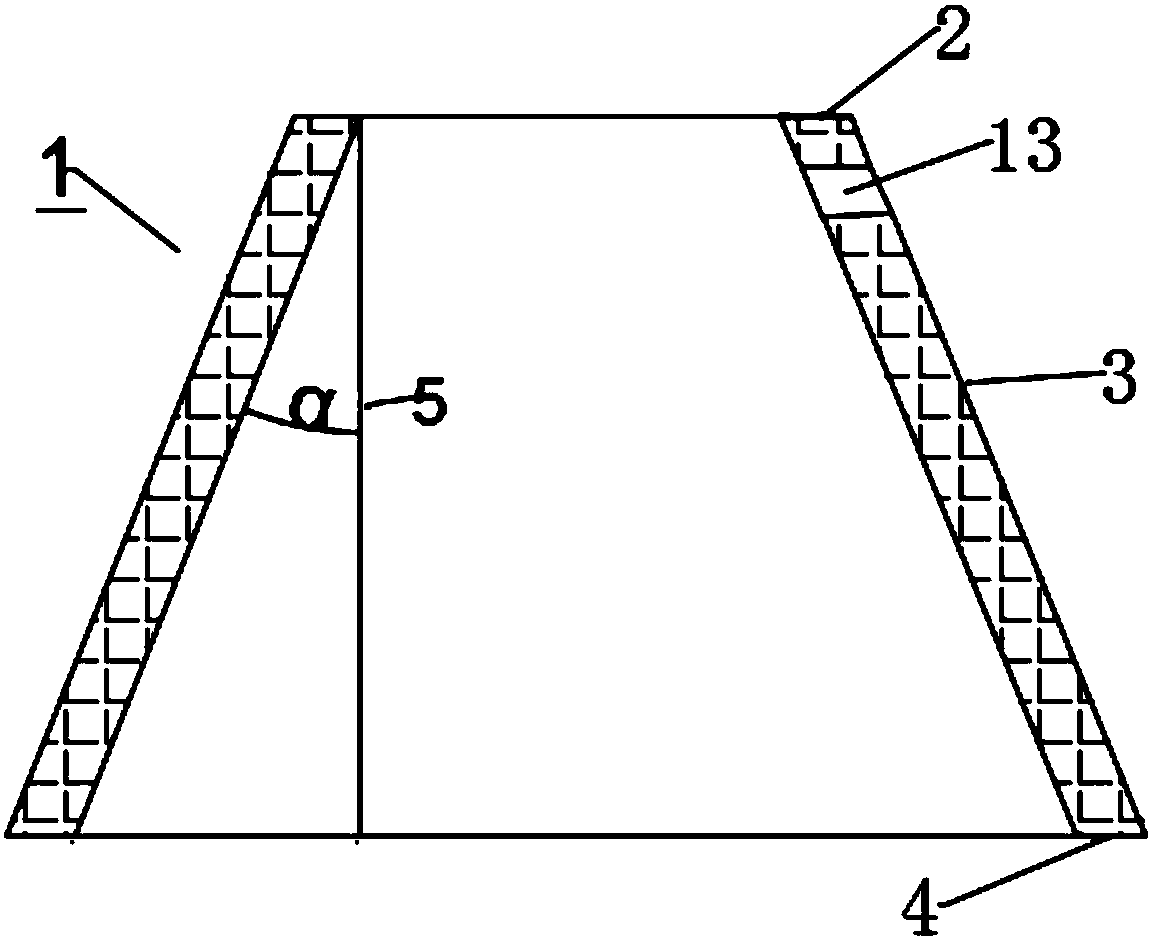

Combined pile foundation structure

ActiveCN102808419BIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityCarrying capacity

The invention discloses a combined pile foundation structure. A hollow cone structure coaxial to a barrel-shaped foundation is arranged on the top of the barrel-shaped foundation; the centre of the top surface of the hollow cone structure is provided with a first connecting section ring girder structure; the centre of the top cover of the barrel-shaped foundation is provided with a second connecting section ring girder structure; a single-pile foundation is inserted in the first connecting section ring girder structure at the upper part and the second connecting section ring girder structure at the lower part; and the single-pile foundation is respectively fixedly connected with the first connecting section ring girder structure and the second connecting section ring girder structure. According to the combined pile foundation structure, the advantages of clear stress, strong applicability to soil layers, convenience in construction and good horizontal carrying capacity of the barrel-shaped foundation of the single-pile foundation are sufficiently utilized; the integral rigidness, horizontal load resistance, vertical load resistance and bending moment capacity are greatly improved, the bending moment load of a blower load to the foundation is effectively reduced and the horizontal displacement of a wind power structure is reduced, so that the pile length, pile diameter, wall thickness and penetrating depth of the pile foundation are reduced, the cost of materials is greatly reduced and the construction process is simpler.

Owner:TIANJIN UNIV

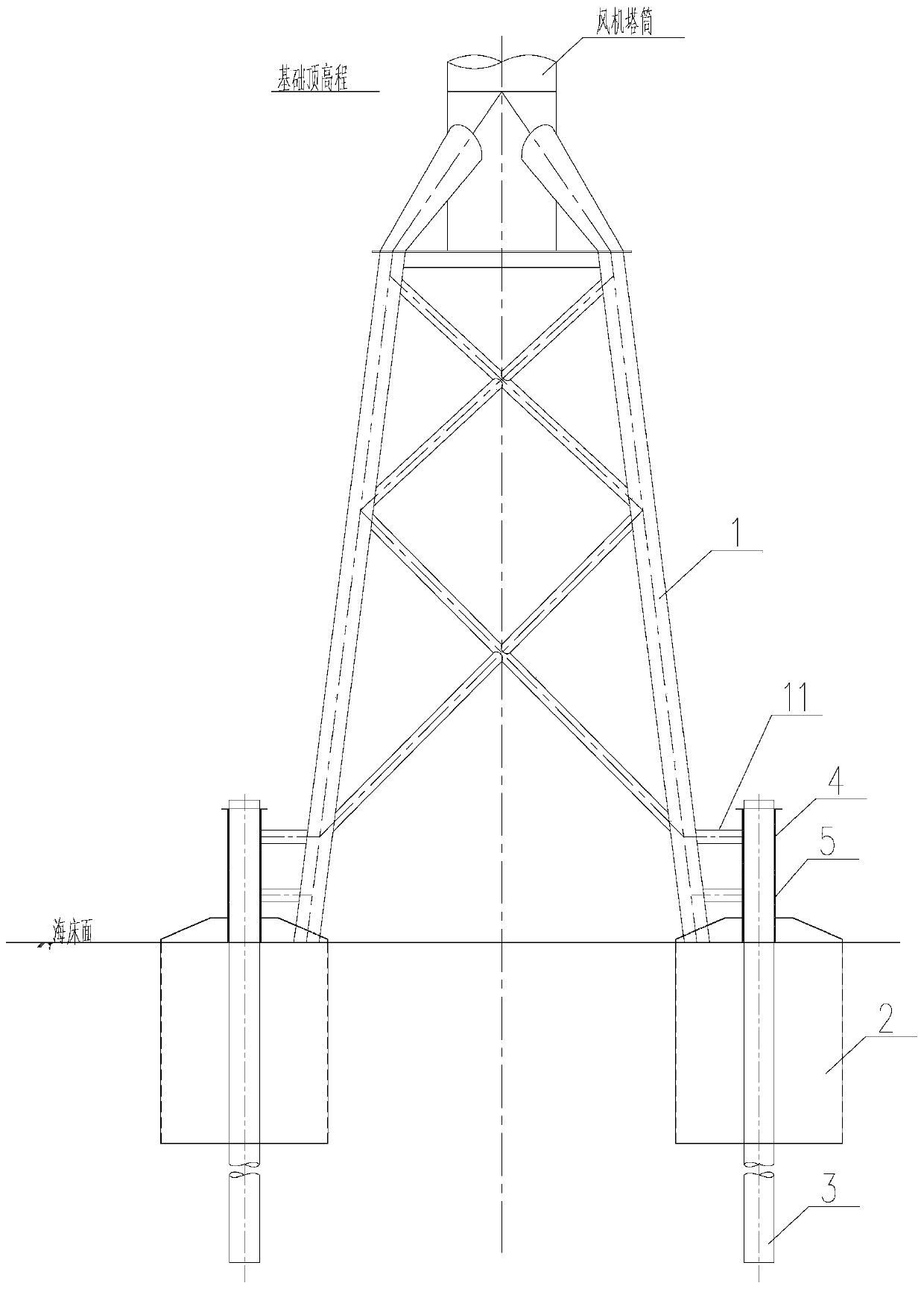

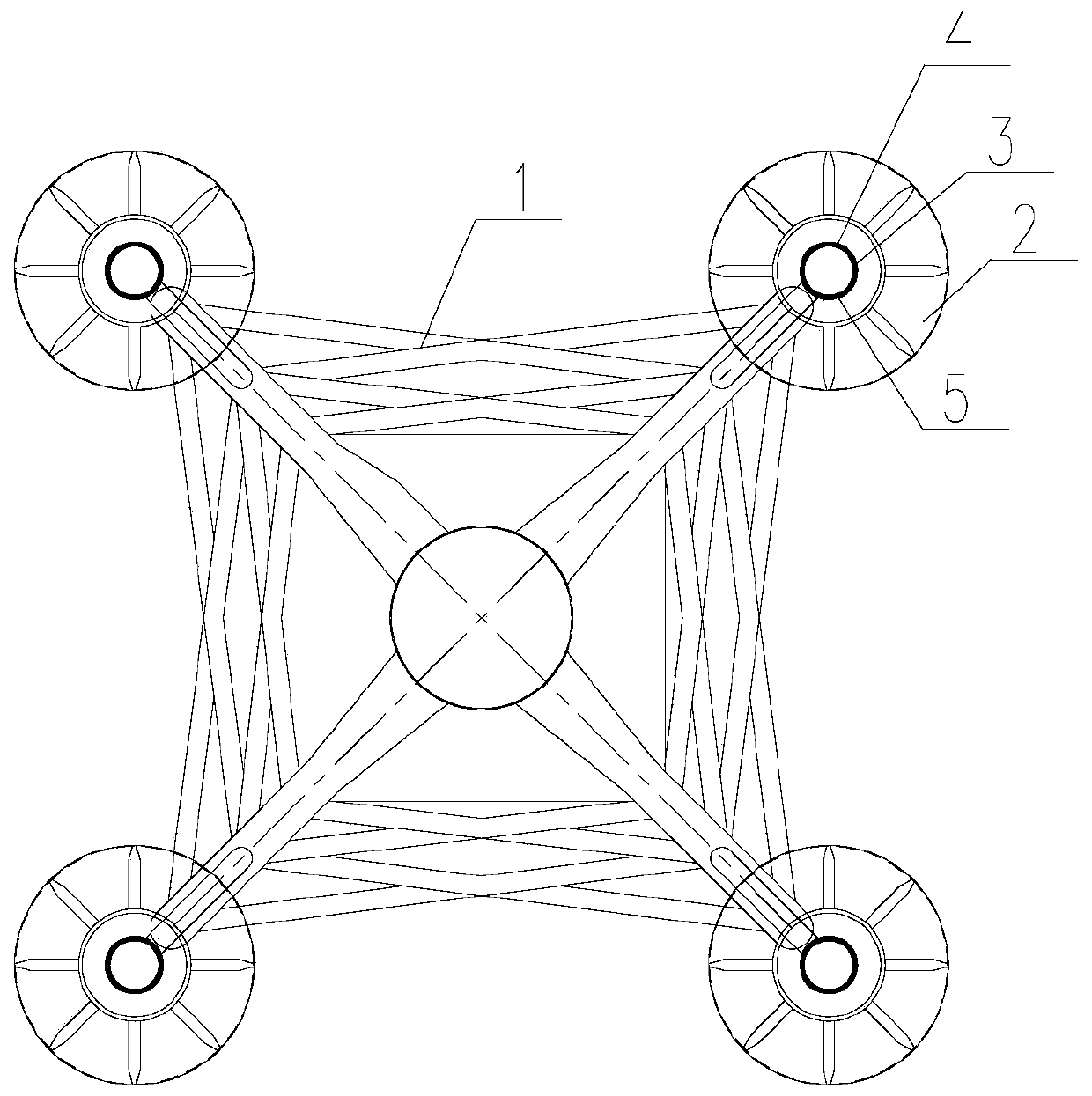

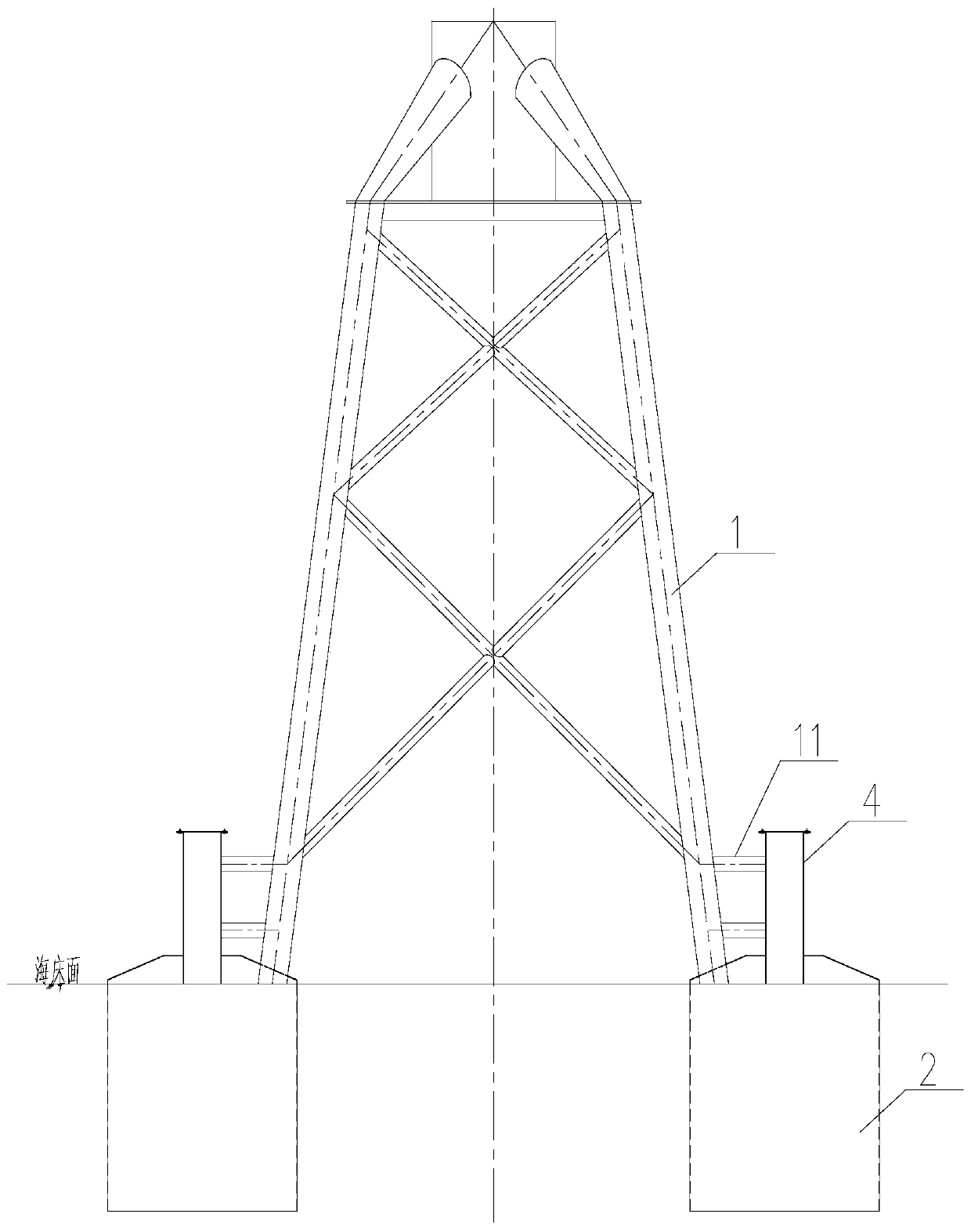

Offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and construction method thereof

PendingCN111101535AExpand the scope of actionImprove bearing capacityFoundation engineeringSuction forceOffshore wind power

The invention relates to an offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and a construction method thereof. The offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and the construction method thereof are simple in structure, convenient to construct, low in cost, safe and stable. According to the technical scheme, the offshorewind-driven generator multi-pile-suction barrel-jacket foundation structure is characterized in that a plurality of suction barrels are uniformly arranged at the bottom of a jacket, wherein guide sleeves communicating with the interiors of the suction barrels are arranged in the centers of the tops of the suction barrels; the jacket is supported on a seabed through the suction barrels and fixed to the seabed through steel pipe piles inserted into the guide sleeves and driven into the seabed; and high-strength grouting materials are poured into gaps between the guide sleeves and the steel pipepiles. The offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and the construction method thereof are suitable for the technical field of ocean engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Tube pile provided with posttensioned prestressing steel noose hole and posttensioned prestressing pulling tube pile

InactiveCN102409672AIncrease stiffnessAvoid crackingBulkheads/pilesPre stressArchitectural engineering

The invention discloses a tube pile provided with a posttensioned prestressing steel noose and a posttensioned prestressing pulling tube pile, comprising a tube pile body and a bearing platform board at the upper end of the pile body, a hole is arranged at a circle of coaxial line in the pile body, the lower end of the posttensioned prestressing steel noose is provided with the expanded head, the upper end penetrates through the hole arranged on the pile body, is tensioned and is connected and fixed by virtue of a connecting piece, and the upper end of the steel noose and the connecting piece thereof are arranged in the bearing platform board. By adopting the invention, application range of the tube pile is expanded, posttensioned prestressing is adopted, rigidity of the pile body is greatly improved, the pile body is extruded under the prestressing longitudinal action and is radially enlarged, soil body is extruded, and uplift resistance is improved, thus pile length can be shortened; and meanwhile cracking phenomenon as the pile body is tensioned is overcome.

Owner:从卫民

Combined pile foundation structure

ActiveCN102808419AIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityCarrying capacity

The invention discloses a combined pile foundation structure. A hollow cone structure coaxial to a barrel-shaped foundation is arranged on the top of the barrel-shaped foundation; the centre of the top surface of the hollow cone structure is provided with a first connecting section ring girder structure; the centre of the top cover of the barrel-shaped foundation is provided with a second connecting section ring girder structure; a single-pile foundation is inserted in the first connecting section ring girder structure at the upper part and the second connecting section ring girder structure at the lower part; and the single-pile foundation is respectively fixedly connected with the first connecting section ring girder structure and the second connecting section ring girder structure. According to the combined pile foundation structure, the advantages of clear stress, strong applicability to soil layers, convenience in construction and good horizontal carrying capacity of the barrel-shaped foundation of the single-pile foundation are sufficiently utilized; the integral rigidness, horizontal load resistance, vertical load resistance and bending moment capacity are greatly improved, the bending moment load of a blower load to the foundation is effectively reduced and the horizontal displacement of a wind power structure is reduced, so that the pile length, pile diameter, wall thickness and penetrating depth of the pile foundation are reduced, the cost of materials is greatly reduced and the construction process is simpler.

Owner:TIANJIN UNIV

Cast-in-situ bored pile and expansion and compaction construction method thereof

InactiveCN102409668AImprove bearing capacityReduce the number of rootsBulkheads/pilesHardnessSediment

The invention relates to a cast-in-situ bored pile and a construction method thereof. The construction method comprises the following steps of: A) embedding a pile casing on a construction site; B) drilling a hole; C) cleaning the hole; D) putting a dry powder expansion material into the bottom of the hole, and arranging a reinforcement cage in the hole; and E) concreting, absorbing water to expand the expansion material so as to compact sediment at the bottom of the pile, wherein the expansion material comprises 85 to 90 weight percent of cement and 10 to 15 weight percent of UEA expansive agent. The sediment at the bottom of the pile is compacted by the expansion material under the condition that construction processes are not increased, so that the sediment has the same hardness as a bearing layer at the end of the pile. Compared with the traditional grouting process at the end of the pile, the construction method is simple and applicable; therefore, in the construction method, the number or length of piles can be reduced under the condition that the bearing capacity of the pile is improved.

Owner:SHANGHAI CONSTRUCTION GROUP

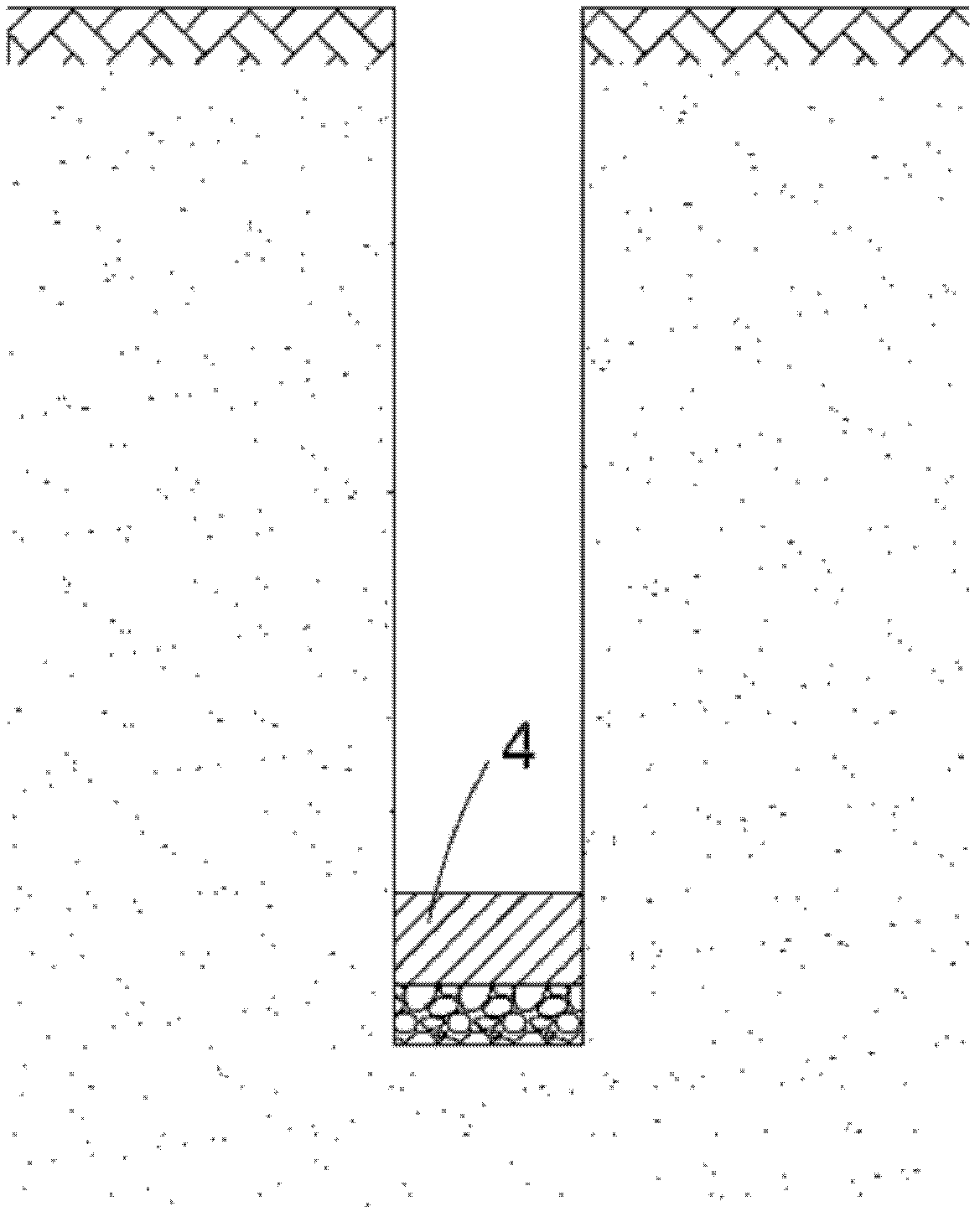

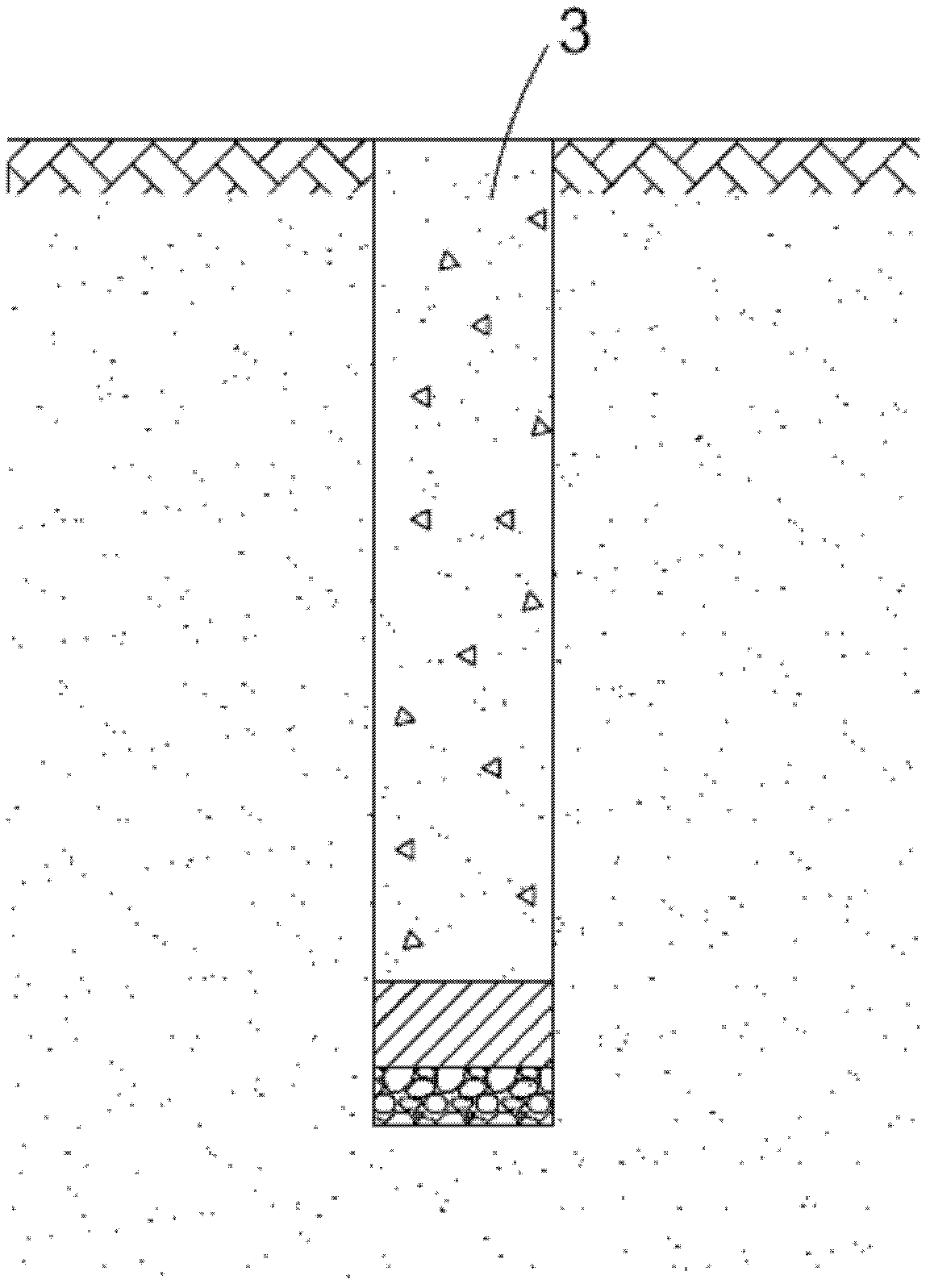

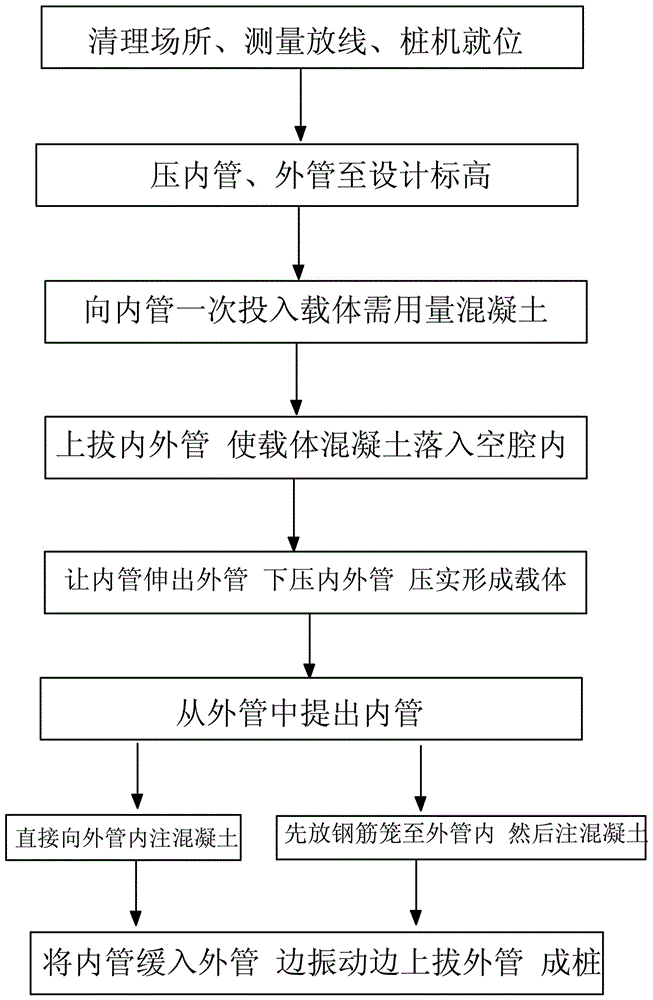

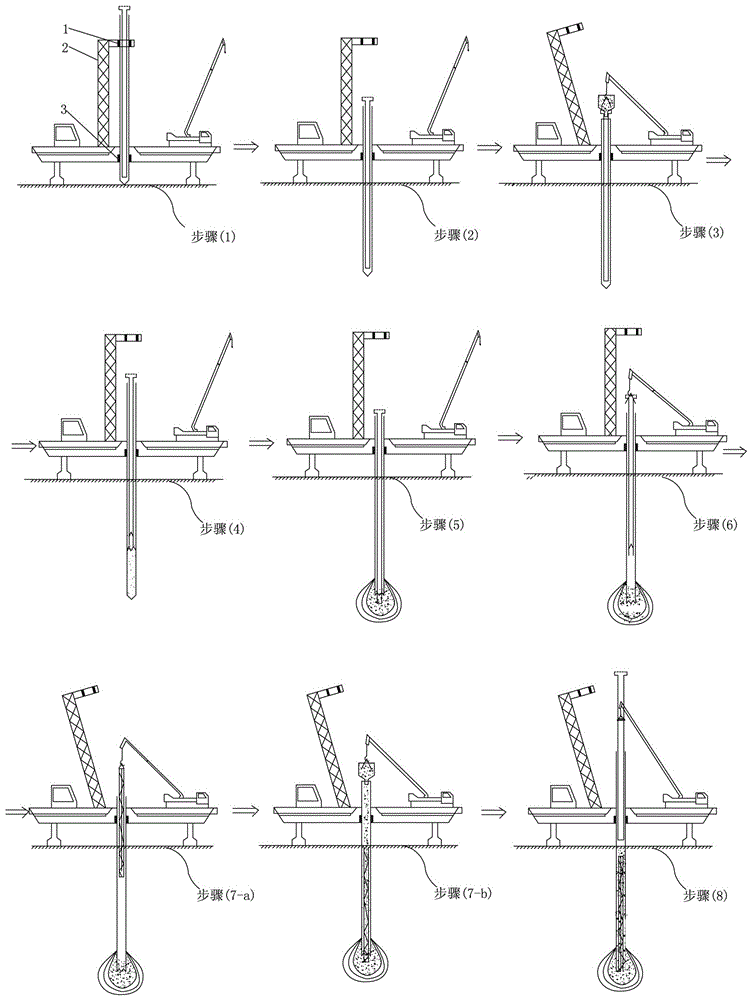

Double-pipe construction method for static pressure pipe-sinking carrier cast-in-place pile

InactiveCN105926594AImprove bearing capacityOvercome the defects of pile forming processBulkheads/pilesDouble tubeArchitectural engineering

The invention provides a double-pipe construction method for a static pressure pipe-sinking carrier cast-in-place pile. The carrier pile is manufactured through a static pile driver, an inner pipe and an outer pipe. Throwing of a carrier concrete material is completed at a time, the pile-forming period is shortened, energy is saved, and the environment is protected; and the pull resistance of the manufactured pile is improved remarkably. The double-pipe construction method includes the following steps that firstly, a site is cleaned, surveying and setting-out are conducted, and the pile driver is moved to a station; secondly, the inner pipe and the outer pipe are pressed to the designed elevation; thirdly, concrete required by a carrier is thrown into the inner pipe at a time; fourthly, the inner pipe and the outer pipe are up-pulled to the set height together, and a space formed when the inner pipe and the outer pipe are up-pulled can be filled with the carrier concrete automatically; fifthly, the inner pipe is lowered, the bottom end of the inner pipe extends out of the bottom end of the outer pipe, the inner pipe and the outer pipe are pressed downwards, the downward pressing force and the elevation reach the preset numerical value, and the expanded carrier is formed; sixthly, the inner pipe is lifted out of the outer pipe; seventhly, concrete is poured into the outer pipe, or a reinforcement cage is placed in the outer pipe firstly, and pile body concrete is poured; and eighthly, the inner pipe is put into the outer pipe, the outer pipe is up-pulled while vibrating, and the pile is formed.

Owner:朱龙

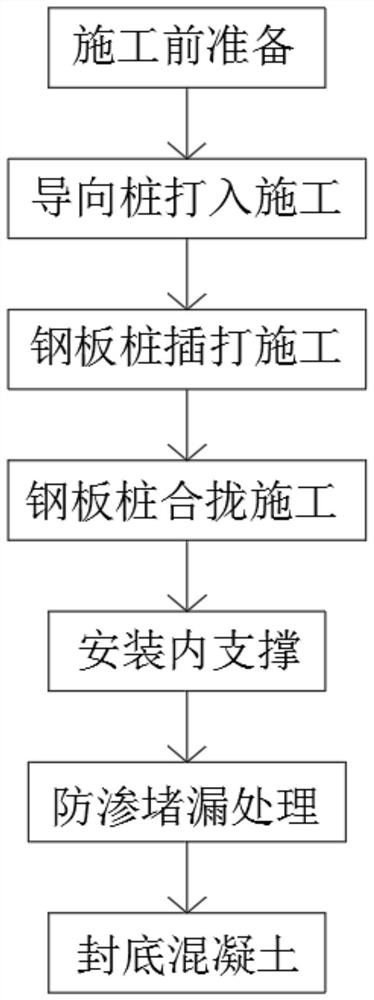

Steel sheet pile cofferdam construction process

InactiveCN113026782AReduce side pressureReduce dosageBulkheads/pilesArchitectural engineeringCofferdam

The invention discloses a steel sheet pile cofferdam construction process. The steel sheet pile cofferdam construction process comprises the steps of preparation before construction, guide pile driving construction, steel sheet pile inserting and driving construction, steel sheet pile folding construction, inner support installation, seepage-proofing and leakage-stopping treatment and bottom sealing concrete. The steel sheet pile cofferdam construction process has the beneficial effects that the side pressure of a soil body in a cofferdam to steel sheet piles is reduced through the steel sheet pile cofferdam mode, the pile length is properly decreased, and compared with a traditional cofferdam structure, the steel sheet pile consumption is greatly reduced; due to the fact that the steel sheet piles are located on the water side of the cofferdam, overwater driving and pulling are convenient, the construction difficulty of cofferdam engineering is effectively lowered, the cofferdam construction quality is improved, the construction progress is accelerated, and the construction period is shortened; and the steel sheet piles have a good seepage-proofing effect and good anti-scouring performance, compared with a traditional earth-rock cofferdam, the cofferdam upstream face protection and seepage-proofing workload can be greatly reduced, and the steel sheet pile cofferdam structure has better adaptability and feasibility.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

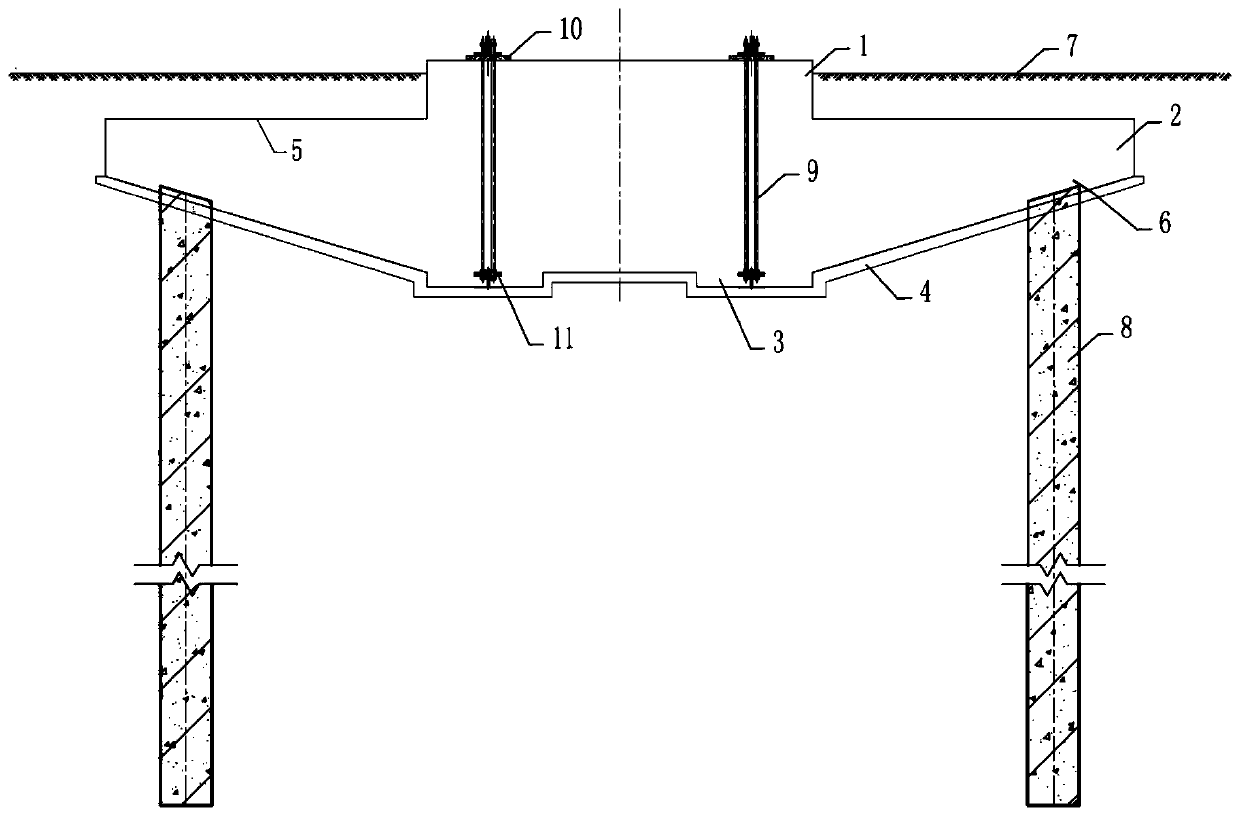

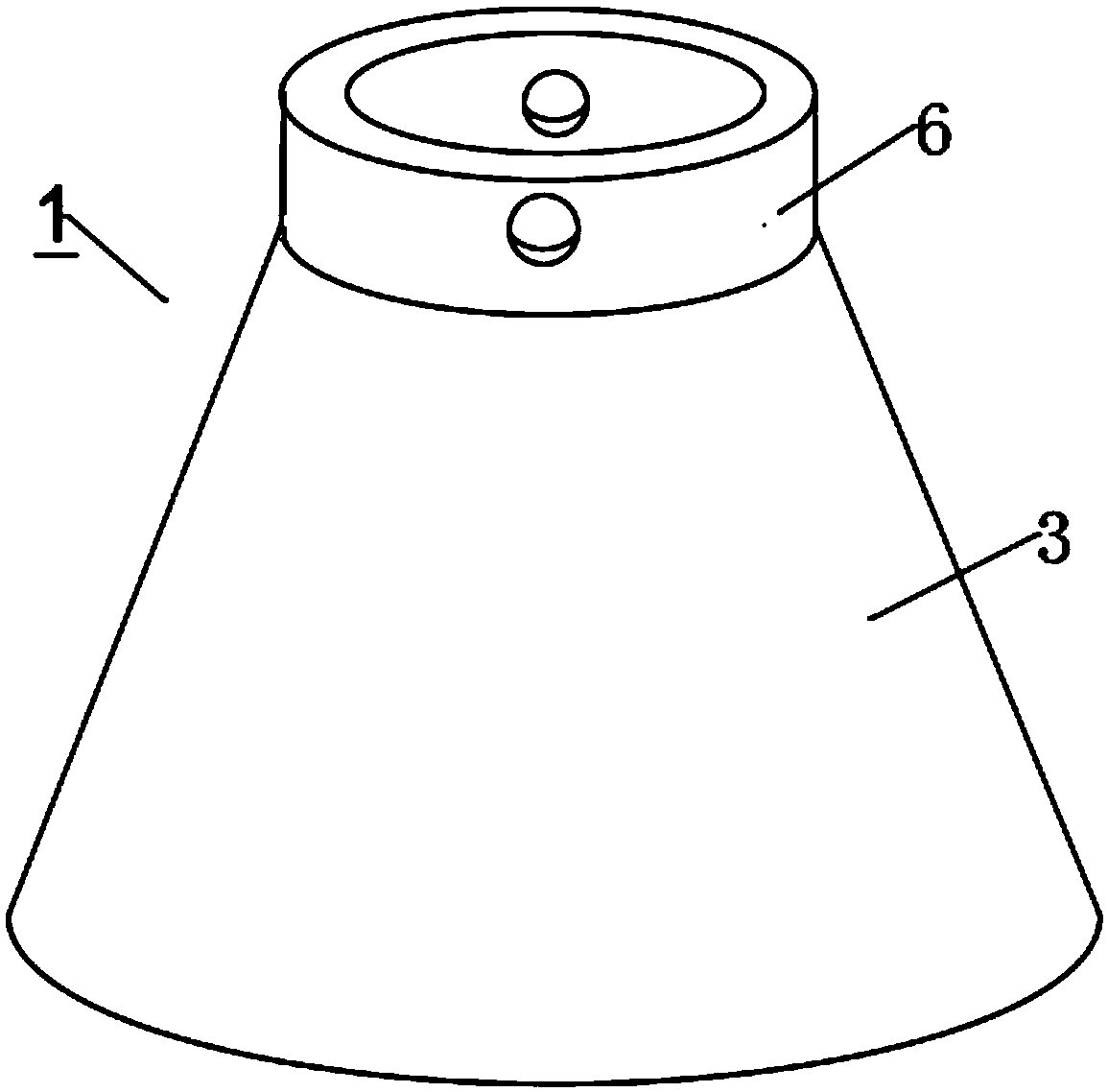

Fan bearing platform assembly improving pile uplift bearing capacity

PendingCN110607801AReduce thicknessReduce excavationWind motor supports/mountsFoundation engineeringCushionEngineering

The invention discloses a fan bearing platform assembly improving pile uplift bearing capacity. The fan bearing platform assembly comprises a bearing platform and foundation piles supporting the bearing platform; the bearing platform comprises a cylindrical upper platform column, a middle cylindrical middle platform column, a lower inverted circular truncated cone and an annular bottom convex platform which are concentrically connected in the axial direction; the diameter of the upper platform column is smaller than that of the cylindrical middle platform column, the large diameter of the upper portion of the lower inverted circular truncated cone is equal to the diameter of the cylindrical middle platform column, and the outer diameter of the bottom convex platform is equal to the small diameter of the lower portion of the lower inverted circular truncated cone; an anchor bolt cage connected with a fan tower barrel stretches into the bottom of the bearing platform; a lower anchor plate of the anchor bolt cage is located in the bottom convex platform, and an upper anchor plate of the anchor bolt cage is located above the upper platform column; the conical surface of the inverted circular truncated cone and the surface of the bottom convex platform are coated with cushion layers; and the bottom of the bearing platform is vertically provided with one or more circles of cylindrical foundation piles. By inverting a traditional bearing platform type structure, the thickness of a soil covering body is decreased, the excavation quantity and the backfill quantity of bearing platform soil are substantially reduced, the vertical pressure of the piles is reduced, the uplift force of the piles is increased, and the construction difficulty is lowered.

Owner:POWERCHINA BEIJING ENG

Structure for constructing underwater foundation and mounting method thereof

InactiveCN107724416AEasy constructionReduce erosionBulkheads/pilesRenewable energy source integrationElectricityRound table

The invention discloses an underwater building foundation structure which is a hollow round-table-shaped structure. The structure is characterized in that the advantages, such as clear force-bearing state, high soil applicability, convenient construction and high horizontal bearing capacity of the round table structure, of a single-pile foundation, are fully utilized; the overall rigidity, the horizontal load resistance, the vertical load resistance and the anti-bending capacity of the structure are greatly improved; the bending load caused by wind turbine load to the foundation can be effectively reduced; the horizontal displacement of a wind-powered generations structure is reduced; the sedimentation value is decreased. Therefore, the pile length, the pile diameter, the wall thickness and the extending depth of the pile foundation can be reduced; the material cost is greatly decreased; the construction technology is simple. The structure also has the characteristics of being resistant to corrosion, and long service life in water. The invention also discloses a method for mounting the underwater building foundation structure. The underwater building foundation structure can be mounted in an area with complex underwater condition through the method.

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

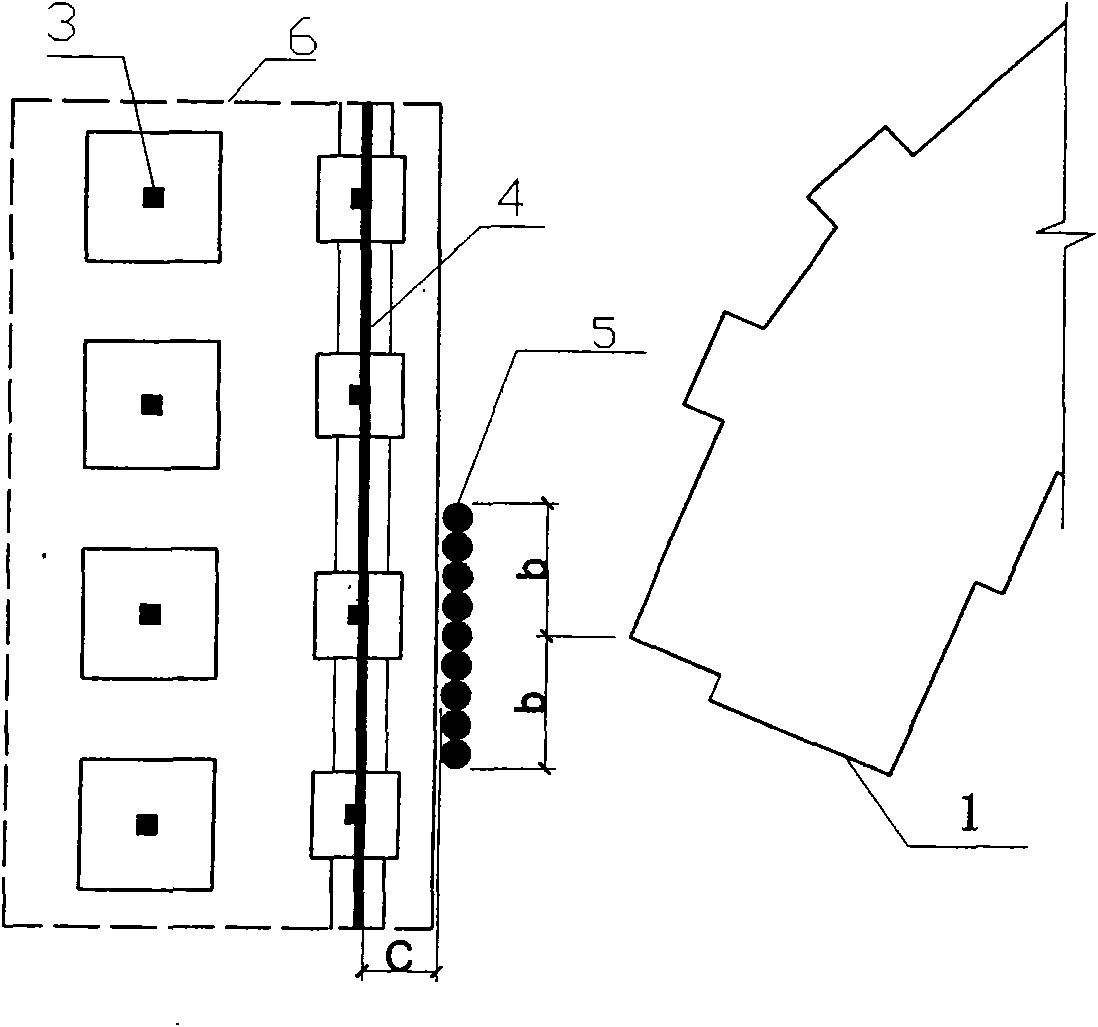

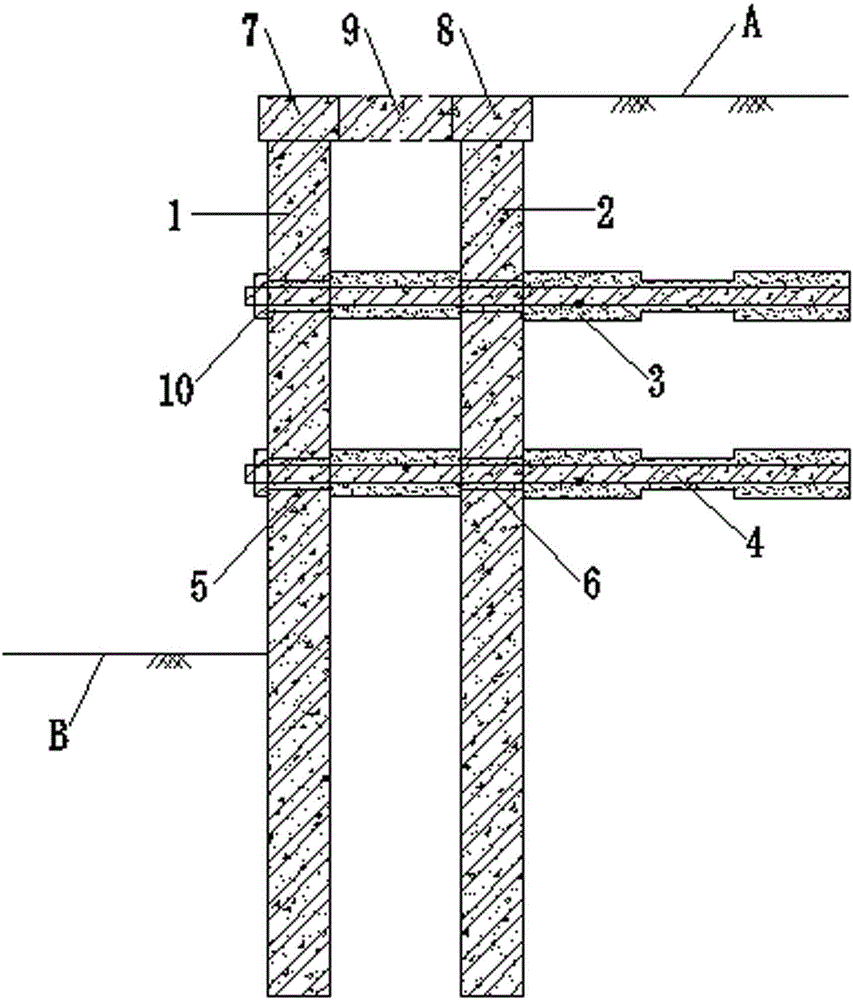

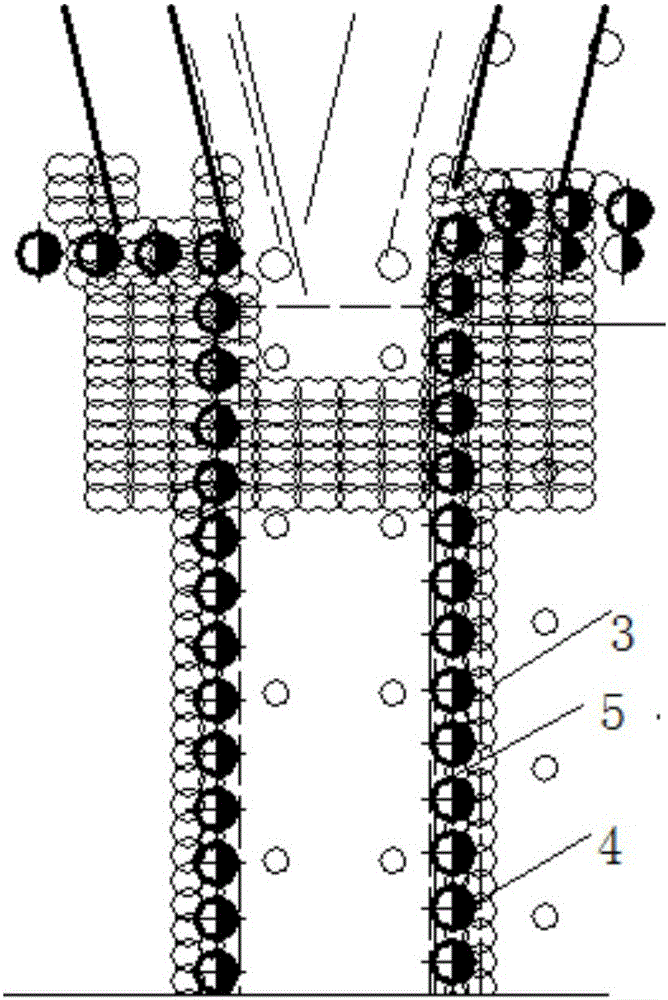

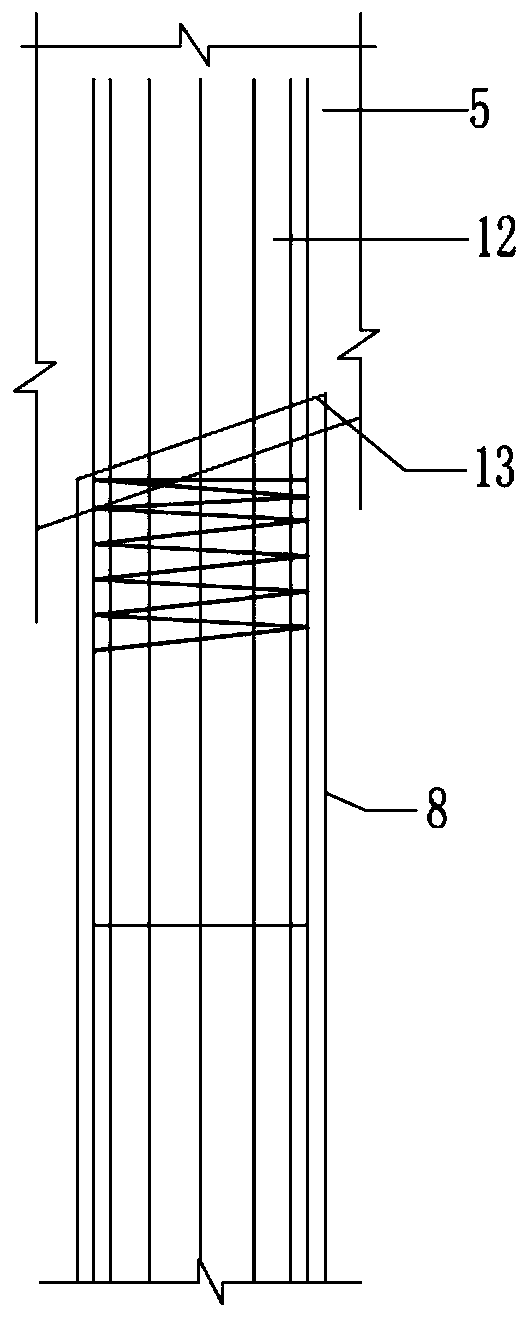

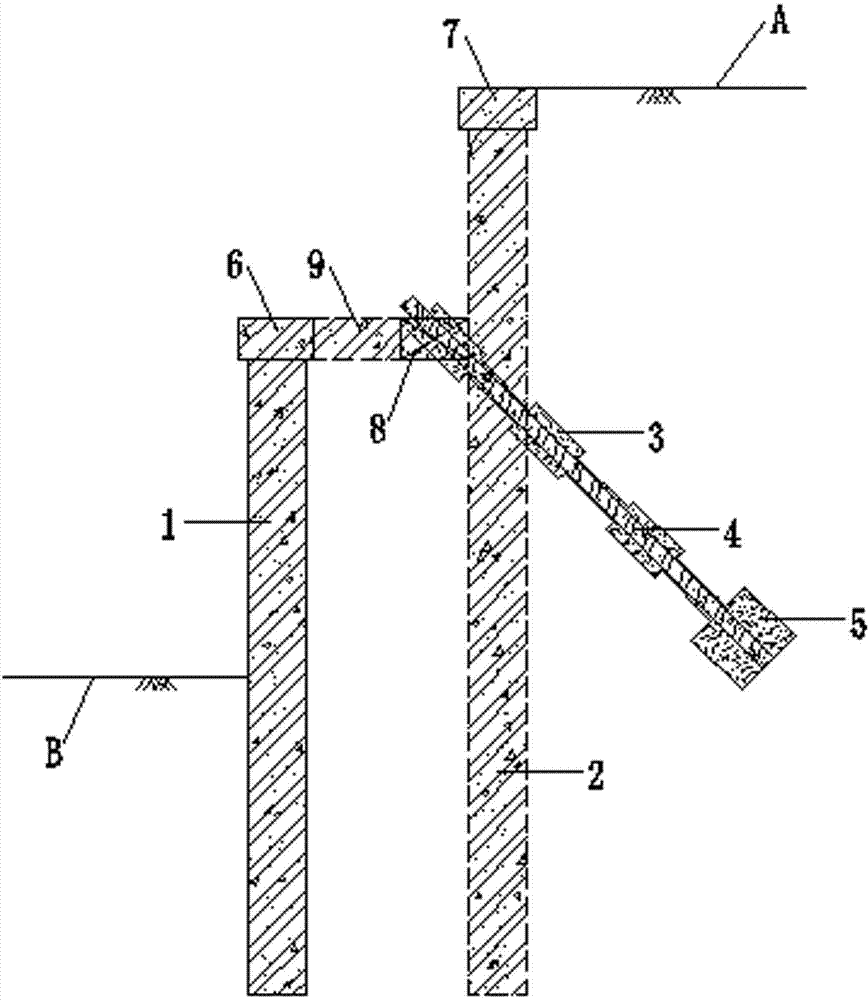

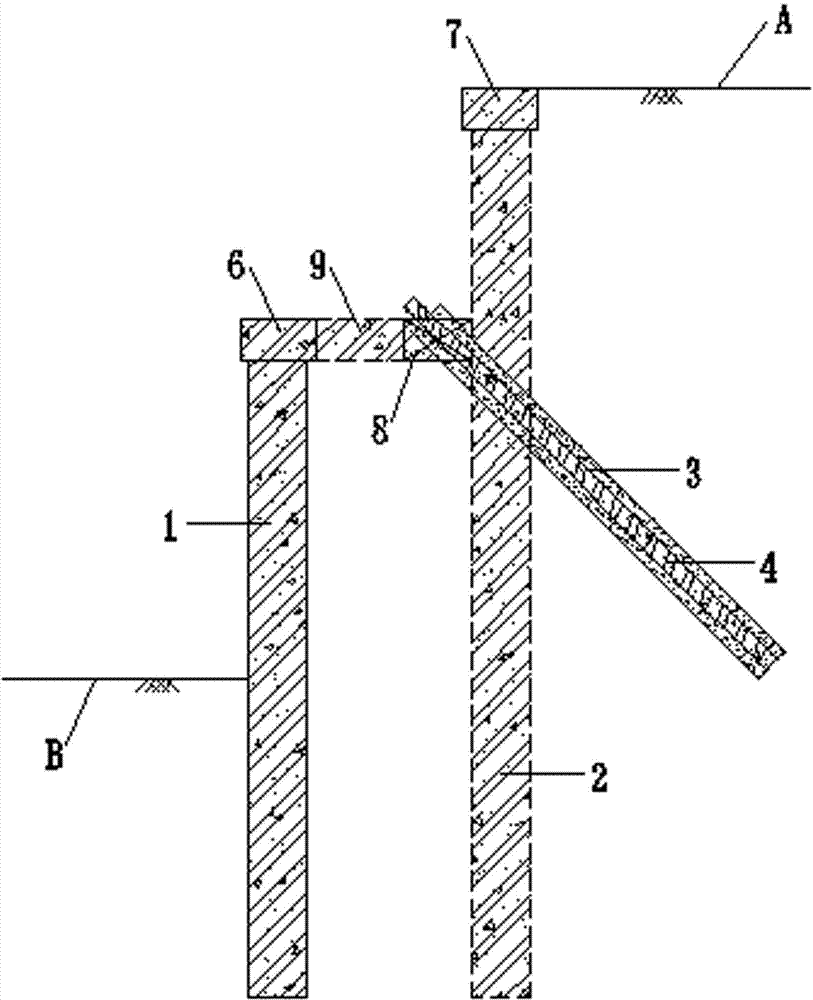

H-shaped double-row pile structure provided with core-entraining jet grouting pile

ActiveCN104762975AShorten pile lengthImprove stabilityExcavationsBulkheads/pilesReinforced concreteArchitectural engineering

The invention discloses an h-shaped double-row pile structure provided with a core-entraining jet grouting pile, and belongs to the field of building foundation pit engineering. The h-shaped double-row pile structure comprises a plurality of front rows of piles, a plurality of rear rows of piles, the jet grouting pile, a precast reinforced concrete square pile, an expanded-head anchoring body, a top beam I, a top beam II, a top beam III and a connecting beam, wherein the front rows of piles and the rear rows of piles are arranged in parallel and form an h shape; the top beam I, the top beam I and the top beam III are respectively arranged on each front row of pile, each rear row of pile and the jet grouting pile; the top beam I and the top beam II are connected through the connecting beam; the jet grouting pile with a large inclination angle is arranged between the piles in each group of rear rows from the inner side of a pile top platform of each front row of piles; the jet grouting pile is constructed by a sectional jet grouting manner, and the jet grouting diameter of the tail end is correspondingly increased to form the expanded-head anchoring body; after the construction of the jet grouting pile, the precast reinforced concrete square pile is inserted into the jet grouting pile before the mass is stabilized; the jet grouting solidifying body in sectional construction can be closely matched with the earth at the back of the pile and integrally connected with the earth at the back of the pile through a precast reinforced concrete pile.

Owner:YUNNAN JIANTOU FOUND ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com