Structure for constructing underwater foundation and mounting method thereof

A technology for underwater foundations and pile foundations, which is applied in infrastructure engineering, architecture, sustainable buildings, etc., and can solve the problems of single pile foundation diameter, wall thickness, penetration depth increase, complex structure and construction technology, and difficulties in offshore piling construction and other problems to achieve the effect of avoiding foundation fracture, good horizontal bearing capacity and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

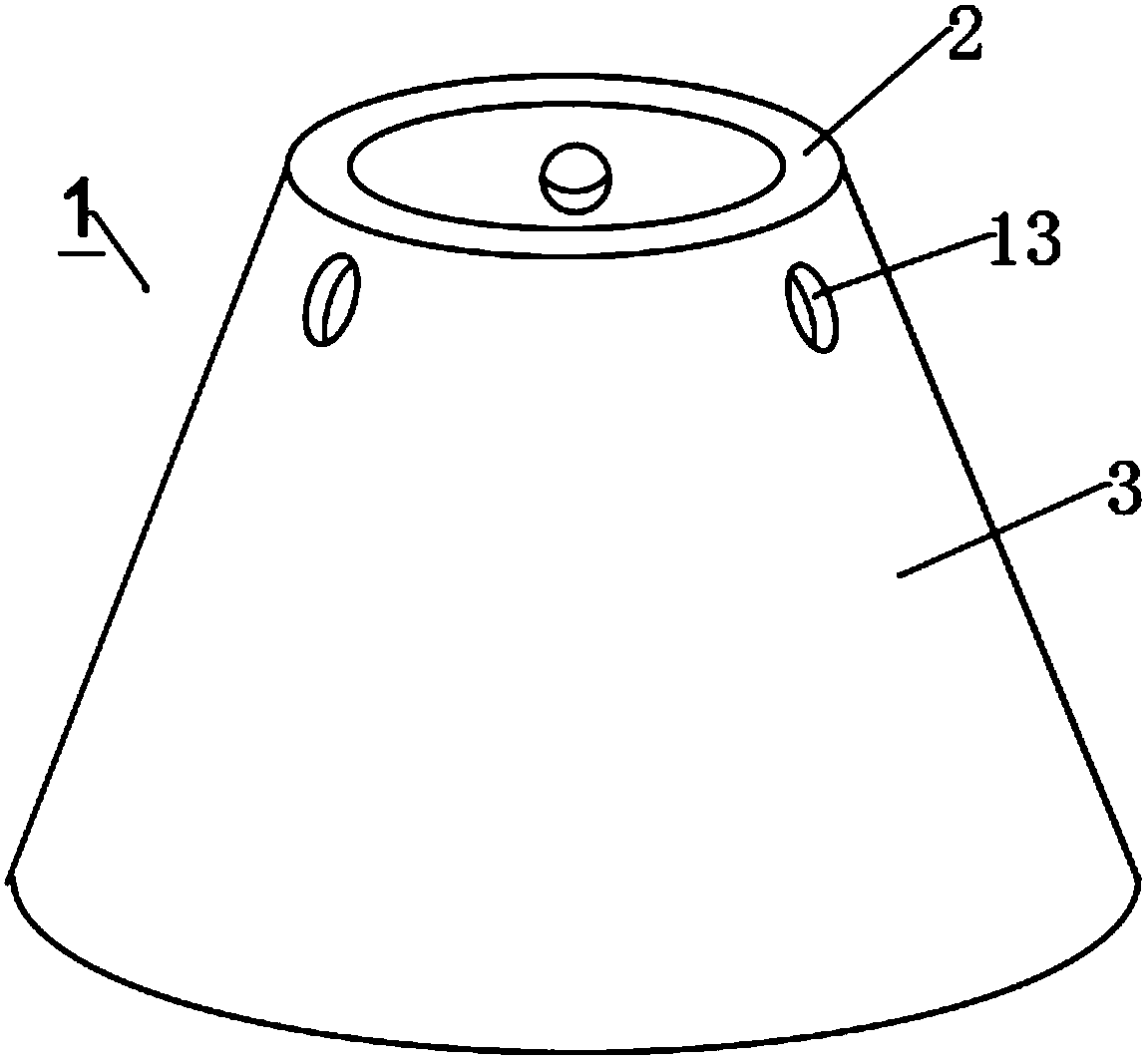

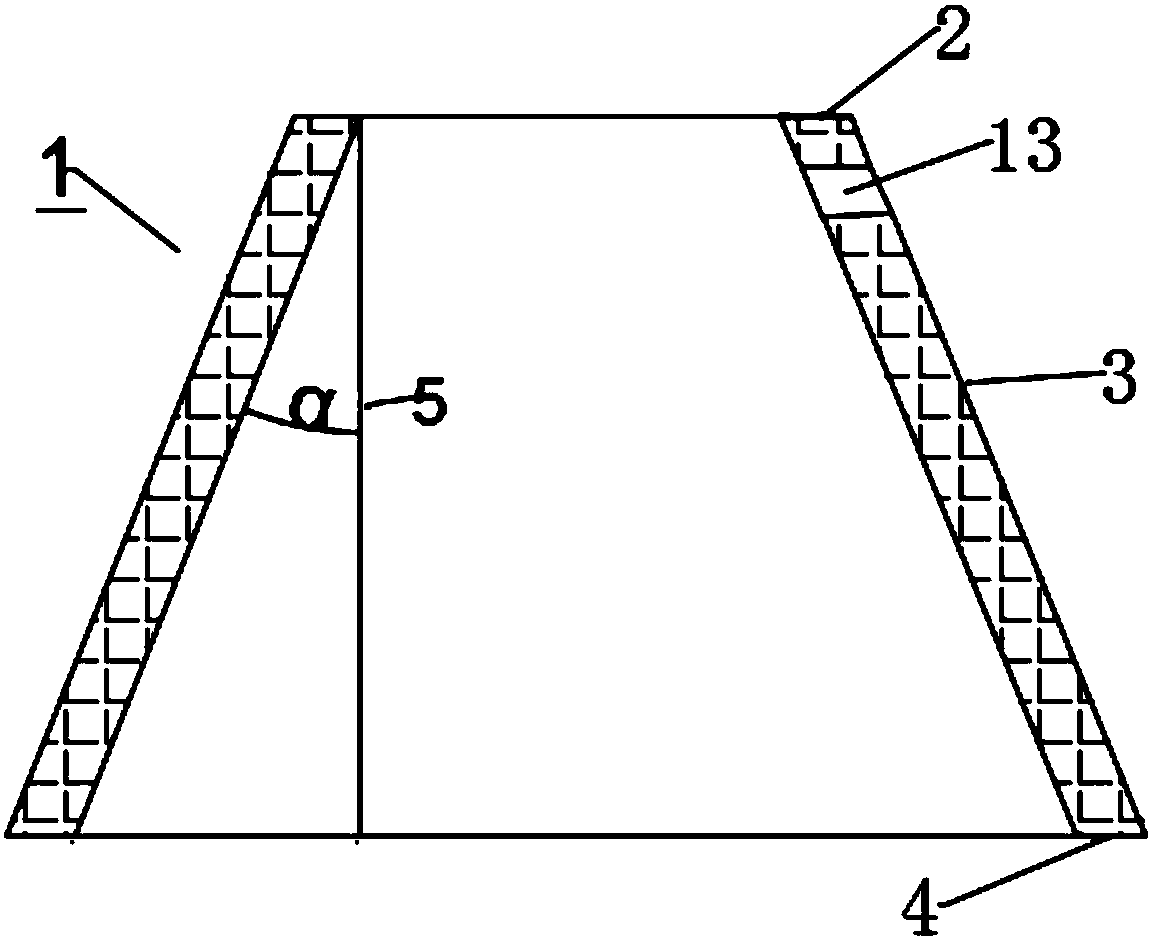

[0038] Such as Figure 1-2 As shown, the main body of the basic structure of the present invention is a hollow circular frustum structure. The hollow circular frustum structure 1 is a concrete structure with an outer diameter of the upper bottom surface 2 of 3m, an outer diameter of the lower bottom surface 4 of 21m, a wall thickness of the side surface 3 of 600mm, and a height 5 of 15m. α is 30°. When laying piles in the water, the foundation structure 1 is erected, the lower bottom surface 4 is inserted under the mud surface 8, and the upper bottom surface 2 is exposed to the water surface 7 . The outer diameters of the upper and lower bottom surfaces of the pile foundation 1 are calculated and determined depending on different soil properties and bearing capacity. The circular frustum structure of the present invention makes the side 3 form an angle with the water flow, so the impact force of the water flow on the front of the side is dispersed due to the angle, thereby pr...

Embodiment 2

[0046] Such as Figure 1-2 As shown, the main body of the basic structure of the present invention is a hollow circular frustum structure. The hollow circular frustum structure 1 is a steel circular frustum structure with an outer diameter of the upper bottom surface 2 of 10m, an outer diameter of the lower bottom surface 4 of 26m, a wall thickness of 60mm, and a height of 30m. The outer steel surfaces are all waterproofed, and α is 15°. When laying piles at sea, the foundation structure 1 is erected, the lower end is inserted into the mud surface 8, and the upper end is exposed to the water surface 7 . The outer diameters of the upper and lower bottom surfaces of the pile foundation 1 are calculated and determined depending on different soil properties and bearing capacity. The circular frustum structure of the present invention makes the side 3 form an angle with the water flow, so the impact force of the water flow on the front of the side is dispersed due to the angle, th...

Embodiment 3

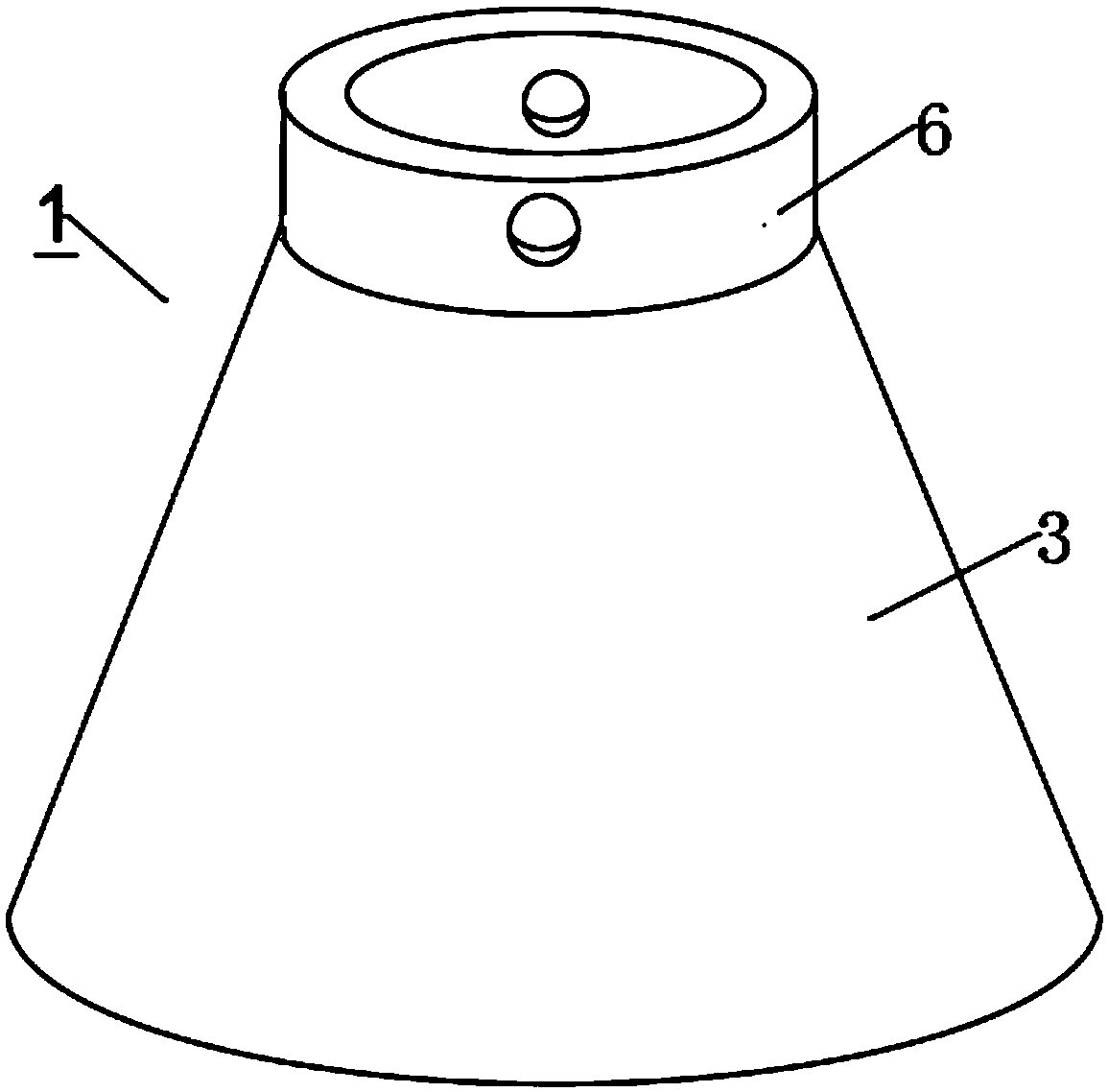

[0053] Such as Figure 3-4 As shown, the main body of the basic structure of the present invention is a hollow circular frustum structure. The hollow circular platform structure of the pile foundation 1 is a concrete structure with an outer diameter of the upper bottom surface 2 of 5m, an outer diameter of the lower bottom surface 4 of 20m, a wall thickness of 600mm, and a height 5 of 30m, and α is 20°. The upper bottom surface 2 of the pile foundation 1 is provided with a transition section 6, the transition section 6 is a cylindrical structure, the bottom of the transition section 6 is welded to the upper bottom surface 2 of the pile foundation 1, the inner and outer diameters of the transition section 6 and the upper The inner and outer diameters of the bottom surface 2 are consistent, and the height of the transition section 6 is 1M. The transition section 6 is provided with more than two hanging points 13 . When laying piles in the water, the pile foundation 1 is erected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com