Patents

Literature

58results about How to "Reduce pile diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-circulating posterior grouting bored pile construction method

ActiveCN104846810AReduced settling timeReduce pollutionBulkheads/pilesLand resourcesEconomic benefits

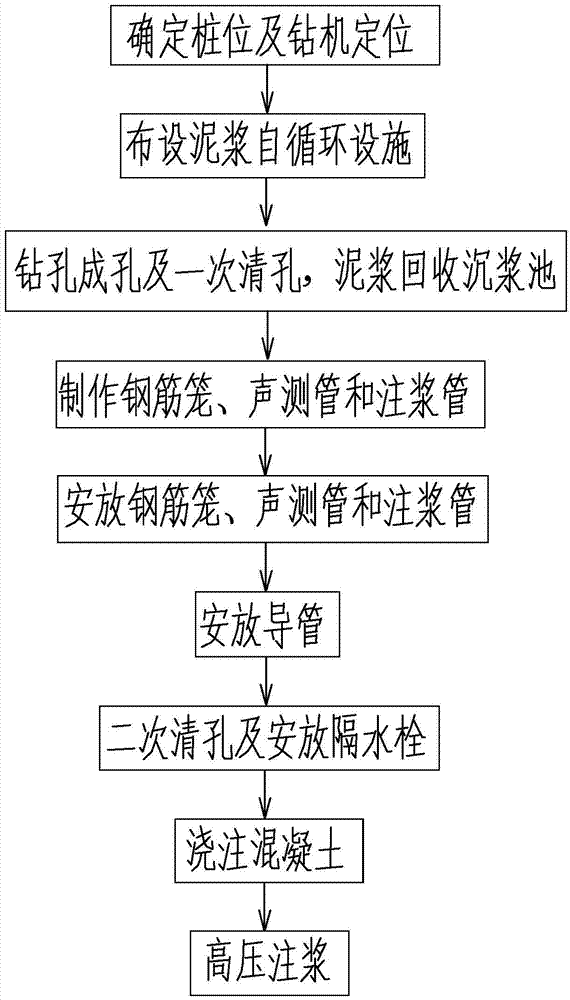

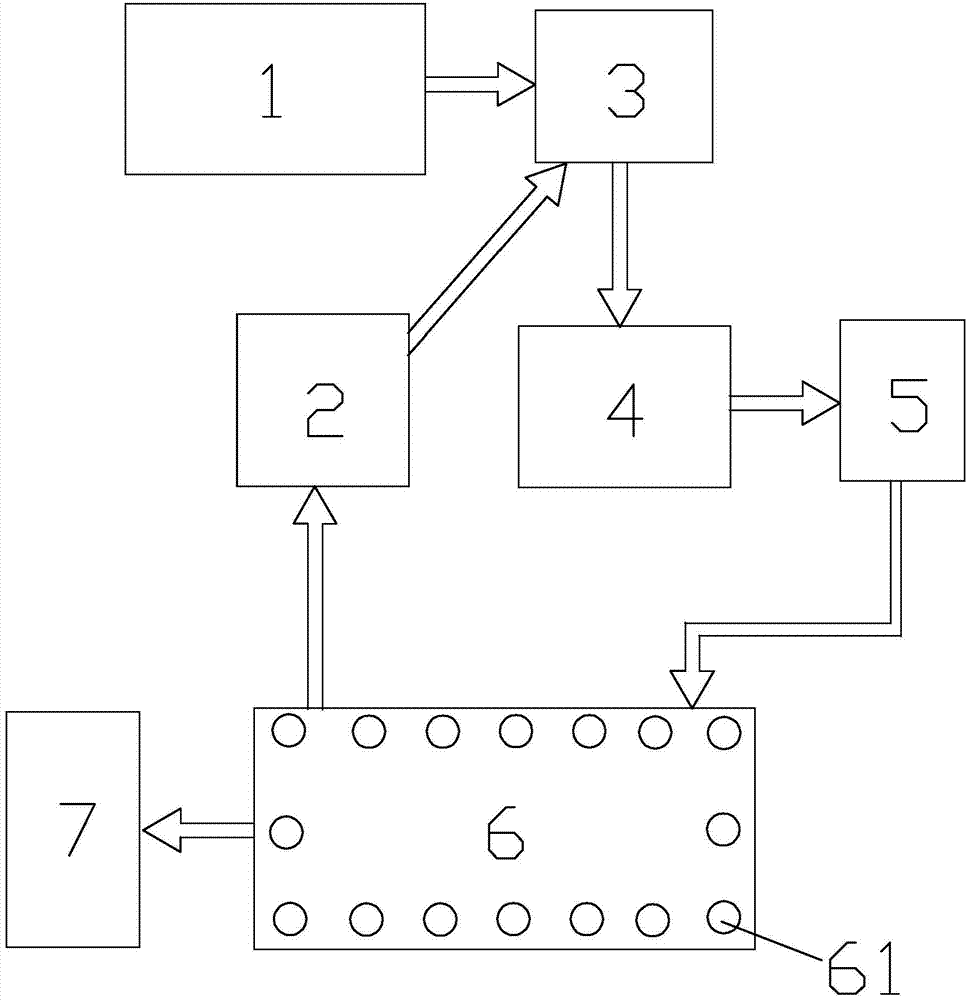

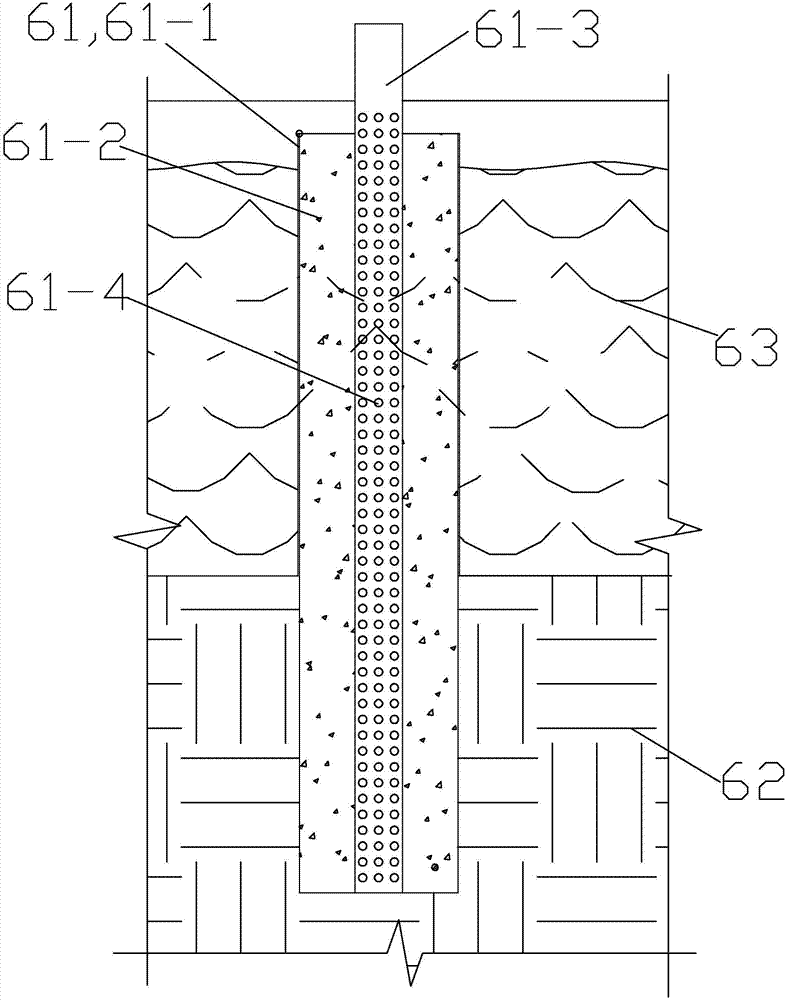

The invention provides a self-circulating posterior grouting bored pile construction method. The construction method comprises the steps of (1) determining the pile position and locating a drilling machine (5), (2) arranging a mud self-circulation facility, (3) boring and primary bore clearing, (4) fabricating a steel reinforcement cage, a sounding pipe and a grouting pipe, (4) placing the steel reinforcement cage, the sounding pipe and the grouting pipe, (5) mounting a guide pipe, (7) secondary bore clearing and mounting a waterproof hydrant, (8) pouring concrete, and (9) grouting under a high pressure. According to the self-circulating posterior grouting bored pile construction method, the supporting facilities such as a mud settling basin for recovering and recycling mud are arranged in the construction site, so that the land resources and the water resources can be effectively saved, the pollution of the mud to the environment can be greatly reduced, and the environment can be protected; meanwhile, the construction cost is reduced; furthermore, the bearing capacity of the foundation pile can be effectively improved by about 30%, and therefore, under the circumstance of the certain load of the foundation pile, the diameter of the foundation pile can be accordingly reduced, the construction investment can be saved and the economic benefit can be further increased.

Owner:CHANGZHOU NO 1 CONSTR GRP

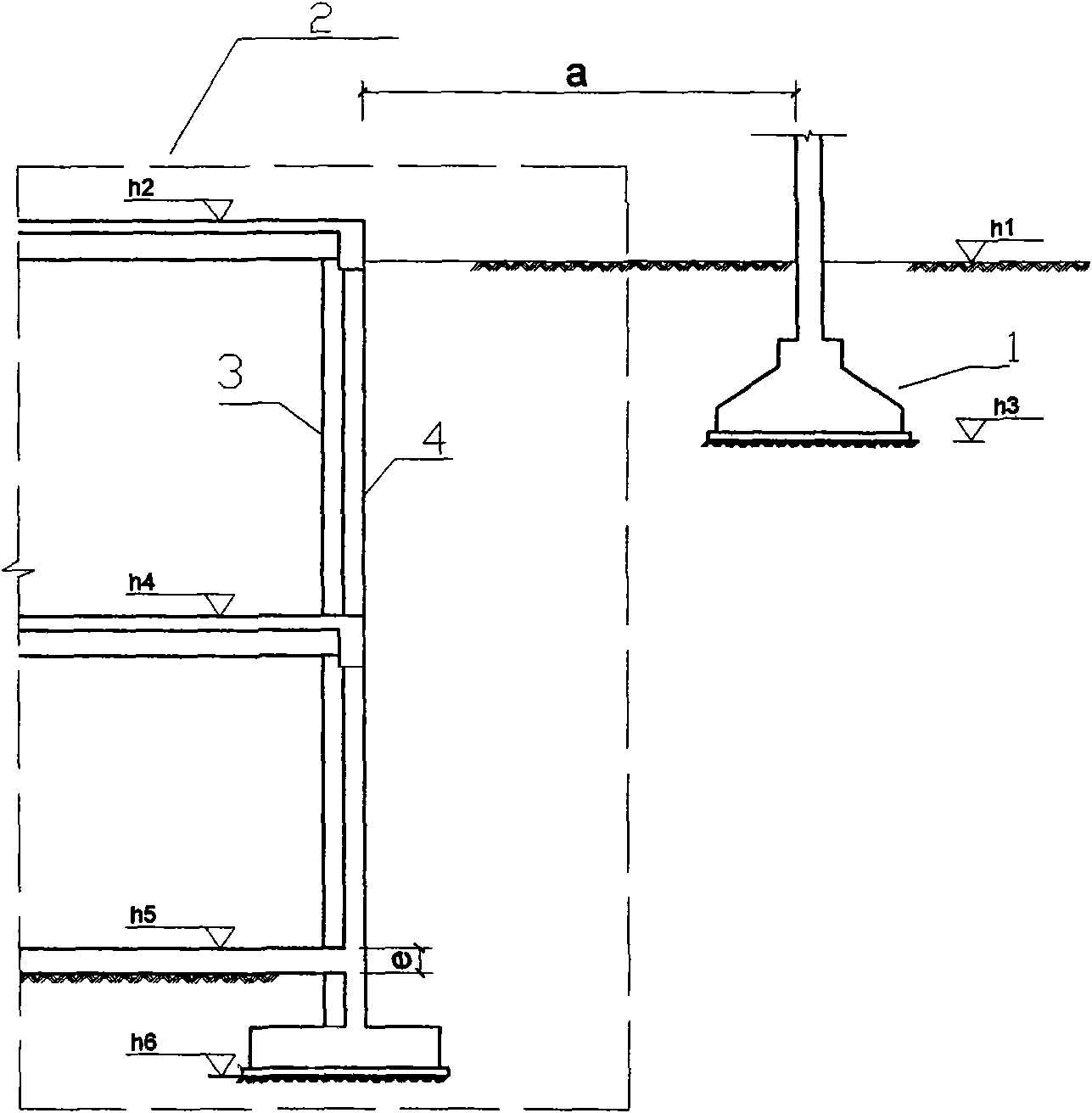

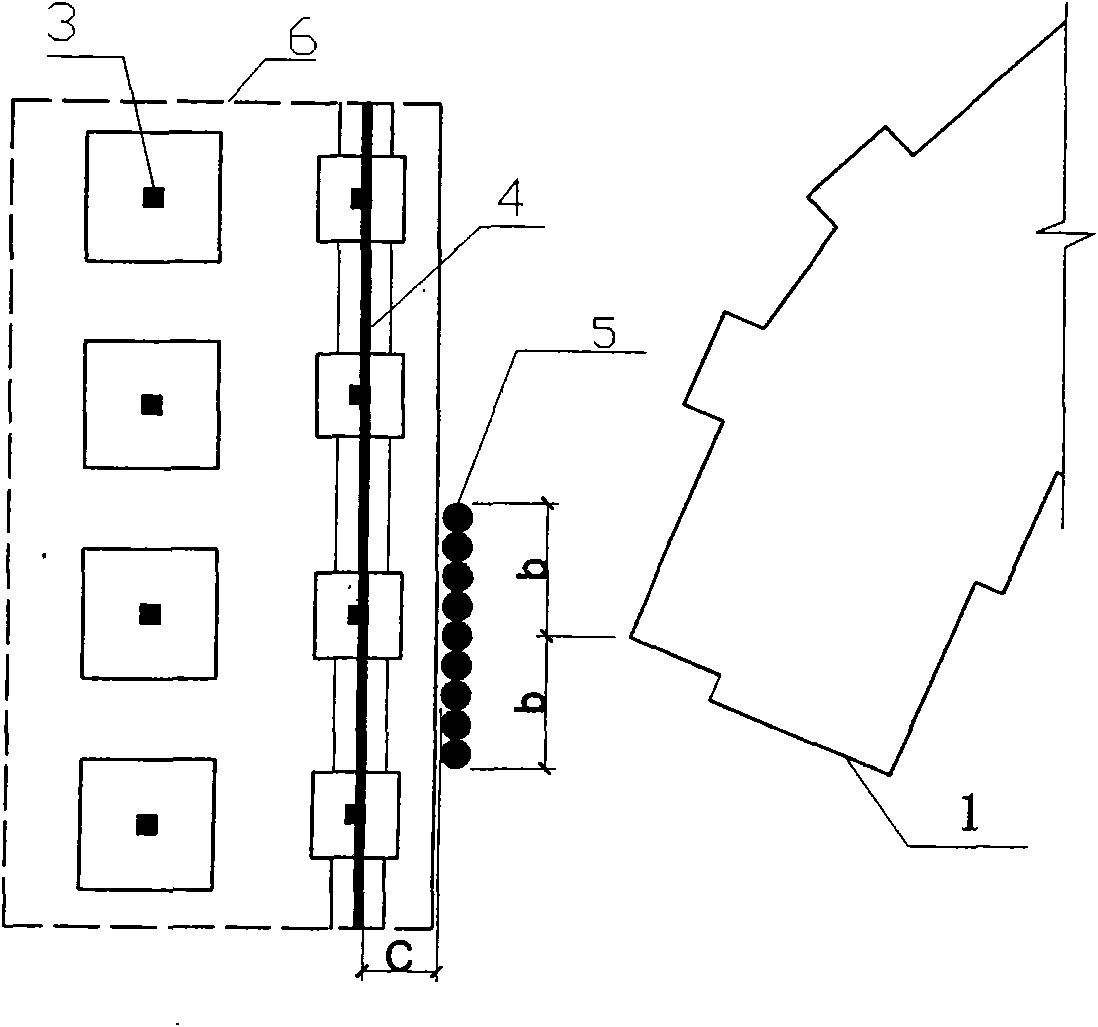

Self-supporting construction method for multilayer underground structure next to existing building

InactiveCN101614019AMinimize the bending moment effectShorten pile lengthArtificial islandsExcavationsEngineering structuresCantilever

The invention relates to a self-supporting construction method for a multilayer underground structure next to an existing building. When the distance between a proposed underground building and the existing building is within 15 meters, the construction method is adopted, and the method specifically comprises the following operation steps: 1, supporting pile construction; 2, developing and controlling an earthwork of a negative first layer; 3, controlling holes at a frame column position and setting a retaining wall; 4, carrying out the construction of frame columns of a negative second layer; 5, carrying out the construction of top beams and plates of the negative second layer and columns, beams and plates of the negative first layer; 6, mounting horizontal steel supports; 7, developing and digging the earthwork of the negative second layer; and 8, carrying out the construction of other structures of bottom plates, walls and the like of the negative second layer according to a conventional method. The method skillfully uses the rigidity of an underground engineering structure self to provide a supporting point for the supporting pile so that the supporting pile is changed into a three-span indeterminate member from a cantilever member, so the bending moment load effect of the supporting pile is greatly reduced, then the designed pile length and section area of the supporting pile can be greatly reduced, the construction cost is saved by about over 35 percent, and the integral construction progress of the underground structural engineering is accelerated.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

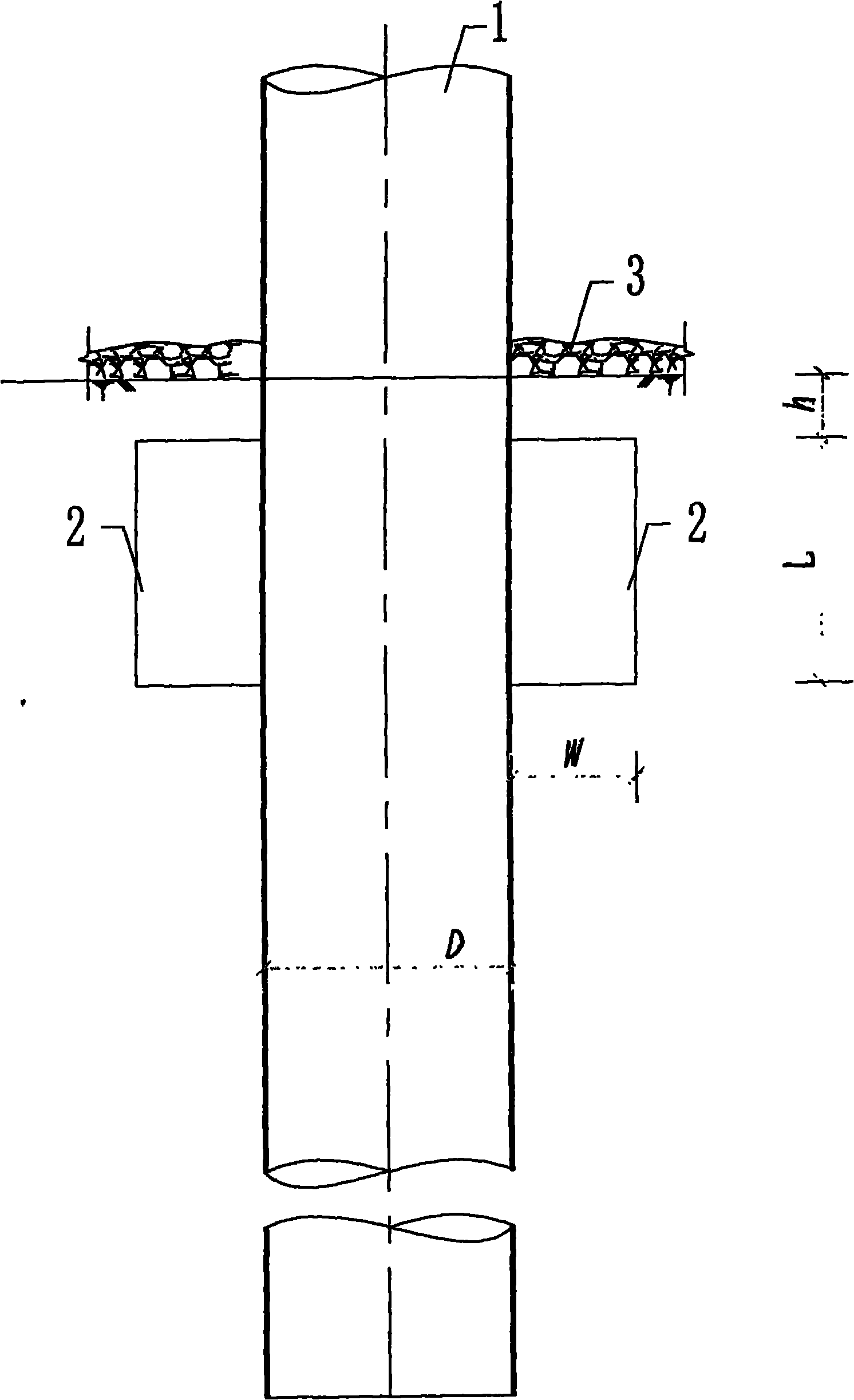

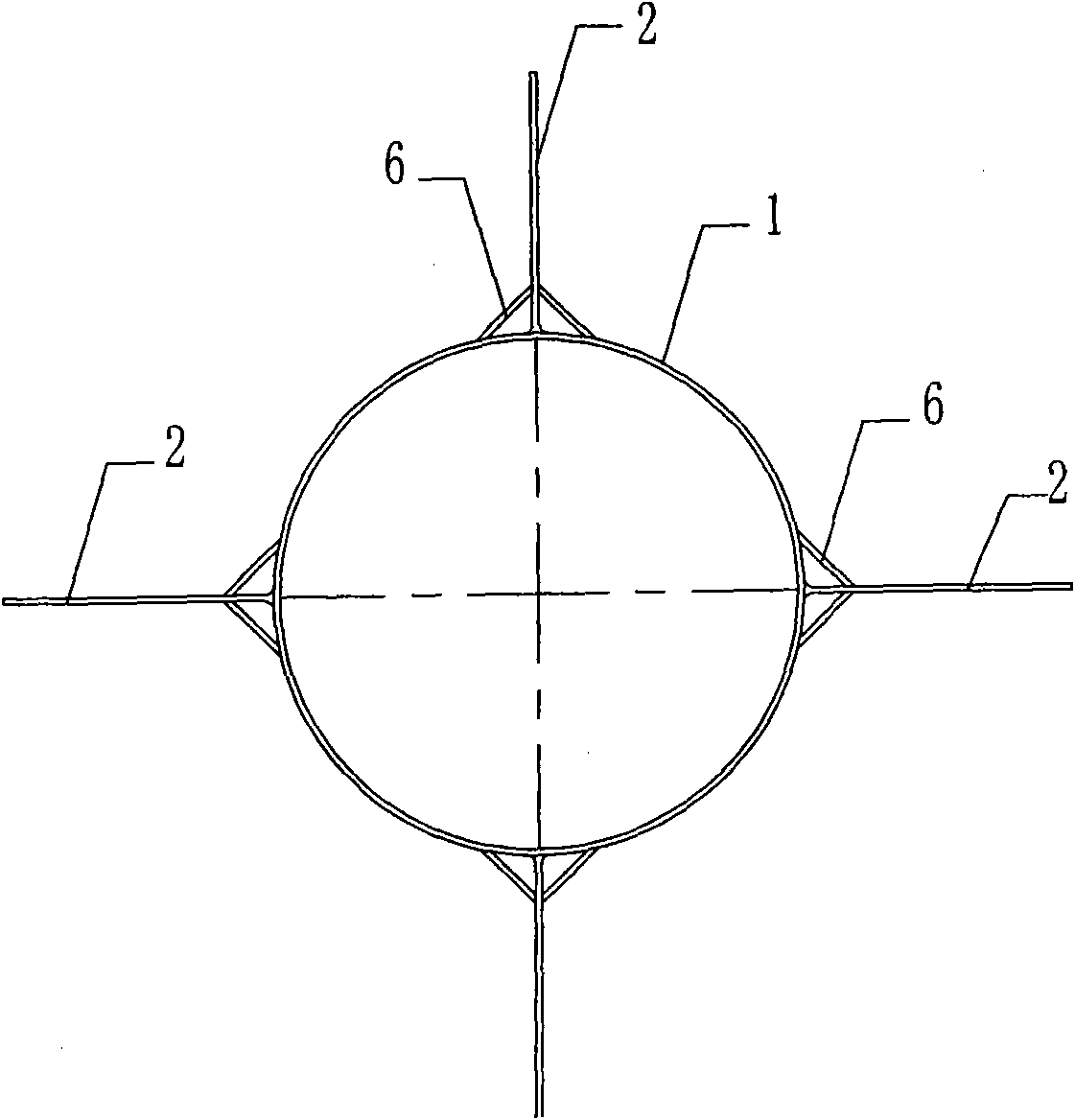

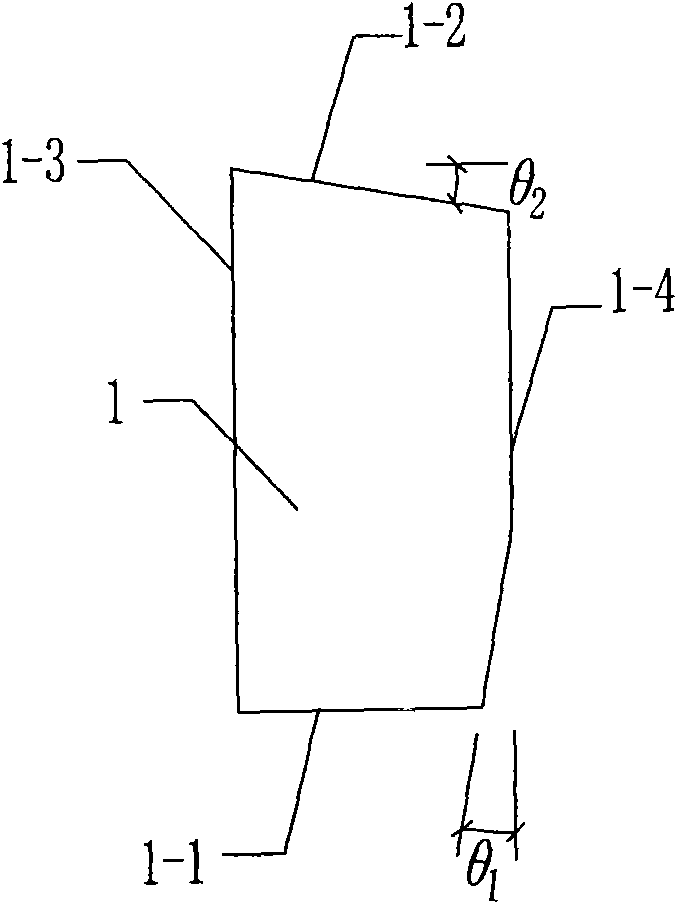

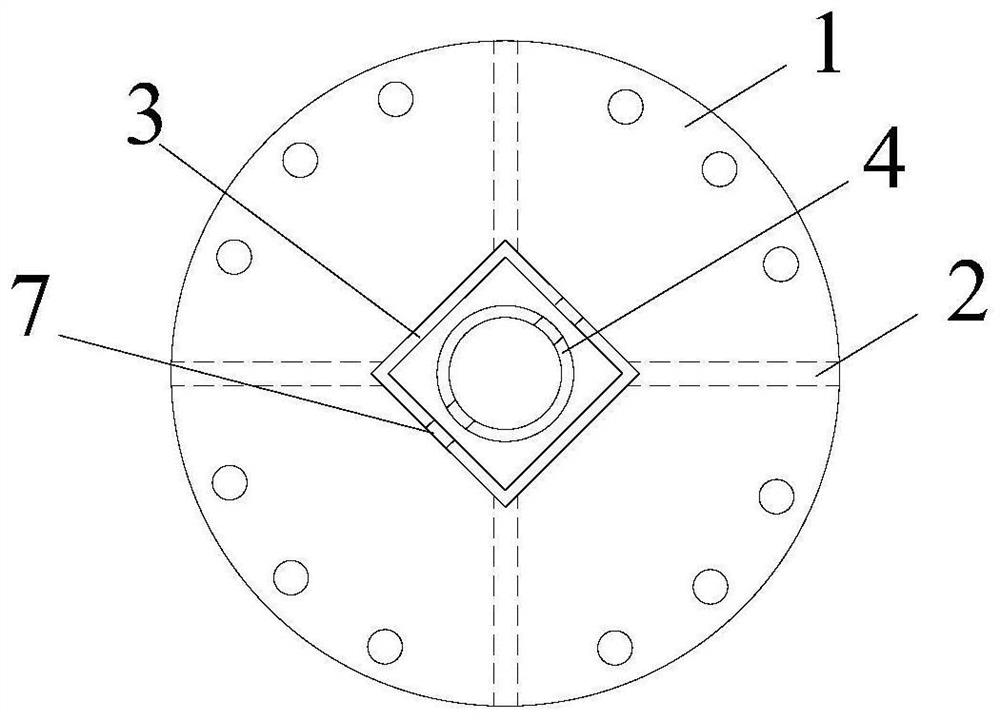

Offshore wind generator single pile base structure with stabilizer fin

ActiveCN102041813AImprove horizontal carrying capacityShorten pile lengthFoundation engineeringOffshore wind powerWind force

The invention relates to an offshore wind generator single pile base structure with a stabilizer fin, solving the technical problem of providing an offshore wind generator single pile base structure with a stabilizer fin, and aiming to improve the horizontal bearing performance of a fan base, improve the horizontal bearing force of a base pile and lower the displacement and the bending moment of the pile body. The technical scheme for solving the problem comprises: a group of stabilizer fins are additionally arranged on the elevation near the ground surface below a seabed mud surface and on the body of the base pile, the stabilizer fins are radially arranged by taking the base pile as the center, the length direction is parallel to the axial direction of the base pile, and the width direction is vertical to the axial direction of the base pile. The invention is suitable for the industry of offshore wind power generation, in particular the single pile fan base with a large pipe diameter.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

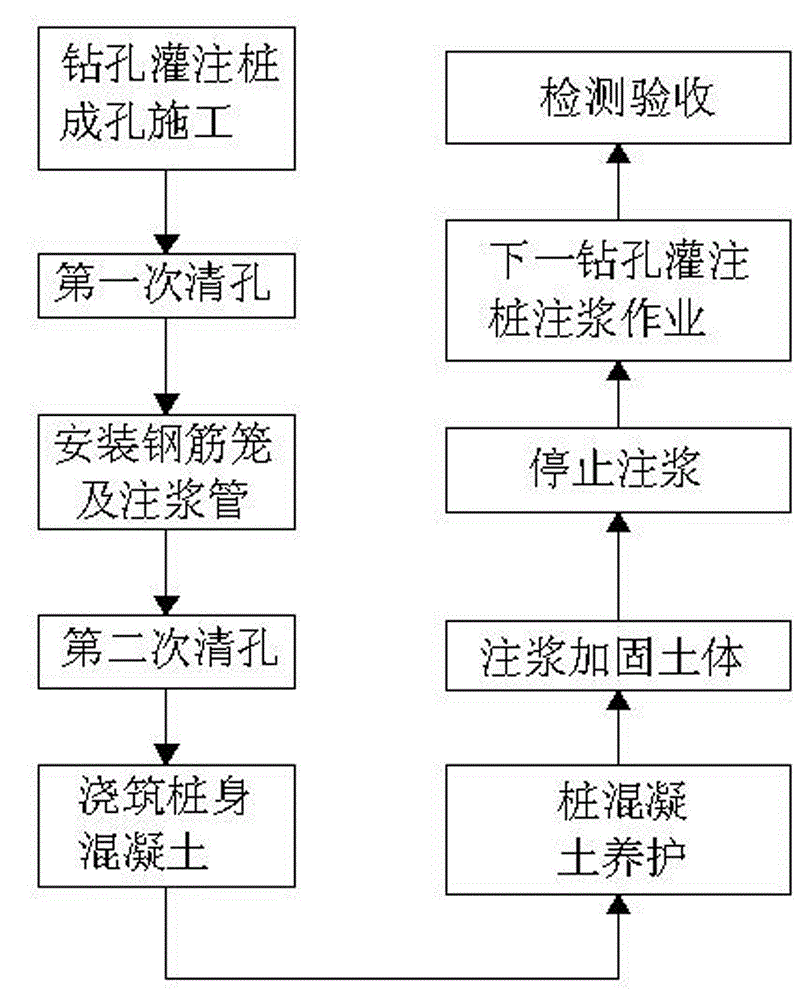

Cast-in place pile post-grouting construction method for pouring construction

The invention discloses a cast-in place pile post-grouting construction method for pouring construction. The method comprises the steps that cast-in place pile pore-forming construction is carried out; first-time hole clearing is carried out; reinforcement cage and grouting pipe mounting is carried out; second-time hole clearing is carried out; pile body concrete placing is carried out; pile concrete curing is carried out; grouting soil mass reinforcement is carried out; grouting is stopped; next cast-in place pile grouting working is carried out; and checking and accepting are carried out. After pile forming, the intensity of pile body concrete reaches a certain degree, a high-pressure generating device is used, high-pressure cement grout flow with concentrated energy is formed, grout is combined with pile body surrounding soil mass through the effects of permeating, separation, filling, compaction and the like, pile body sediment and pile side mud cakes are solidified, pile side friction resistance and pile end bearing force are enlarged, the shortcomings that due to hole bottom sediment and pile side mud cakes of a common cast-in place pile, bearing force is low, and vertical load decreasing is high are overcome, and important economic and social significance is achieved in single pile bearing force improving, pile foundation sedimentation lowering, pile foundation engineering quality guaranteeing and the like.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

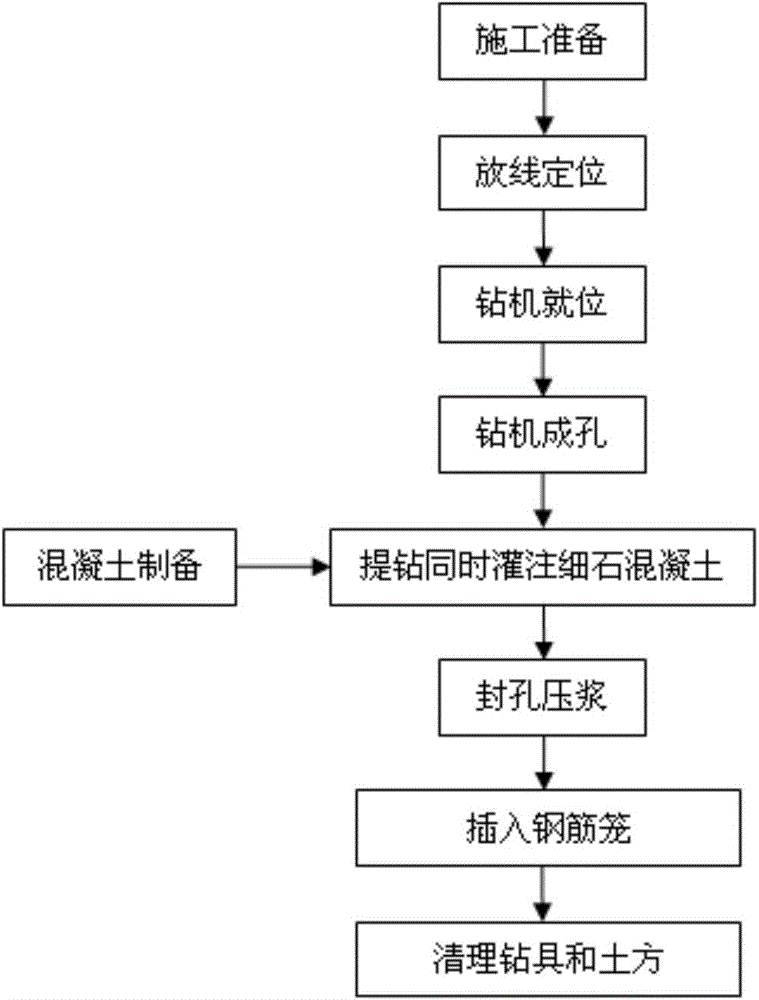

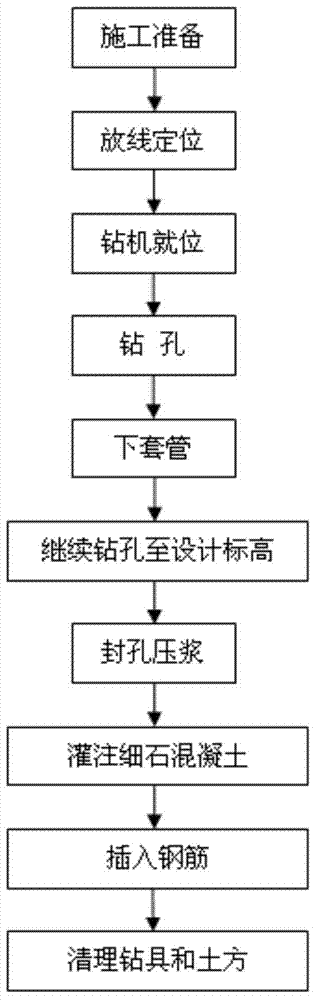

Method for constructing long auger bored cast-with-pressure concrete uplift pile

ActiveCN104631438AImprove pullout resistanceIncrease contact areaBulkheads/pilesStructural engineeringEngineering

The invention discloses a method for constructing a long auger bored cast-with-pressure concrete uplift pile. The method for constructing the long auger bored cast-with-pressure concrete uplift pile comprises the steps that the preparation for construction is made, paying-off for positioning is conducted, a drilling machine is prepared to work, a hole is formed by the drilling machine, drill lifting and fine aggregate concrete pouring are conducted at the same time, the hole is sealed and grouting is conducted, a steel reinforcement cage is inserted, and drilling tools and an earthwork are cleaned. The method for constructing the long auger bored cast-with-pressure concrete uplift pile has the advantages that concrete is pressed in a soil body and is located on the bottom and the side wall of the pile according to the specific grouting technique, the concrete and the soil body are glued into a whole, and in this way, the contact area between a pile body and the soil body is increased; compared with a traditional uplift pile, the uplift performance of the long auger bored cast-with-pressure concrete uplift pile is improved remarkably.

Owner:ANHUI TONGJI CONSTR GRP

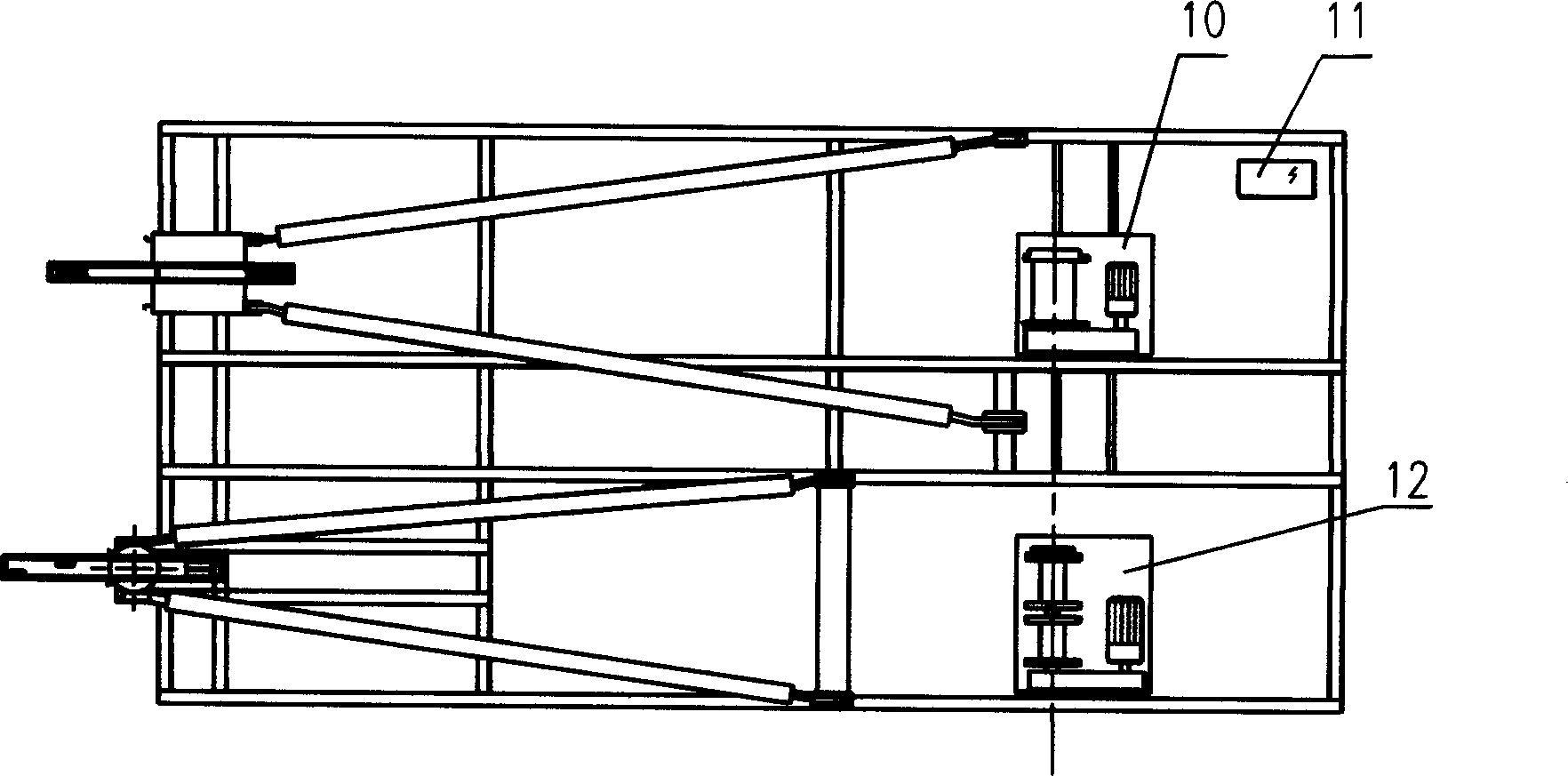

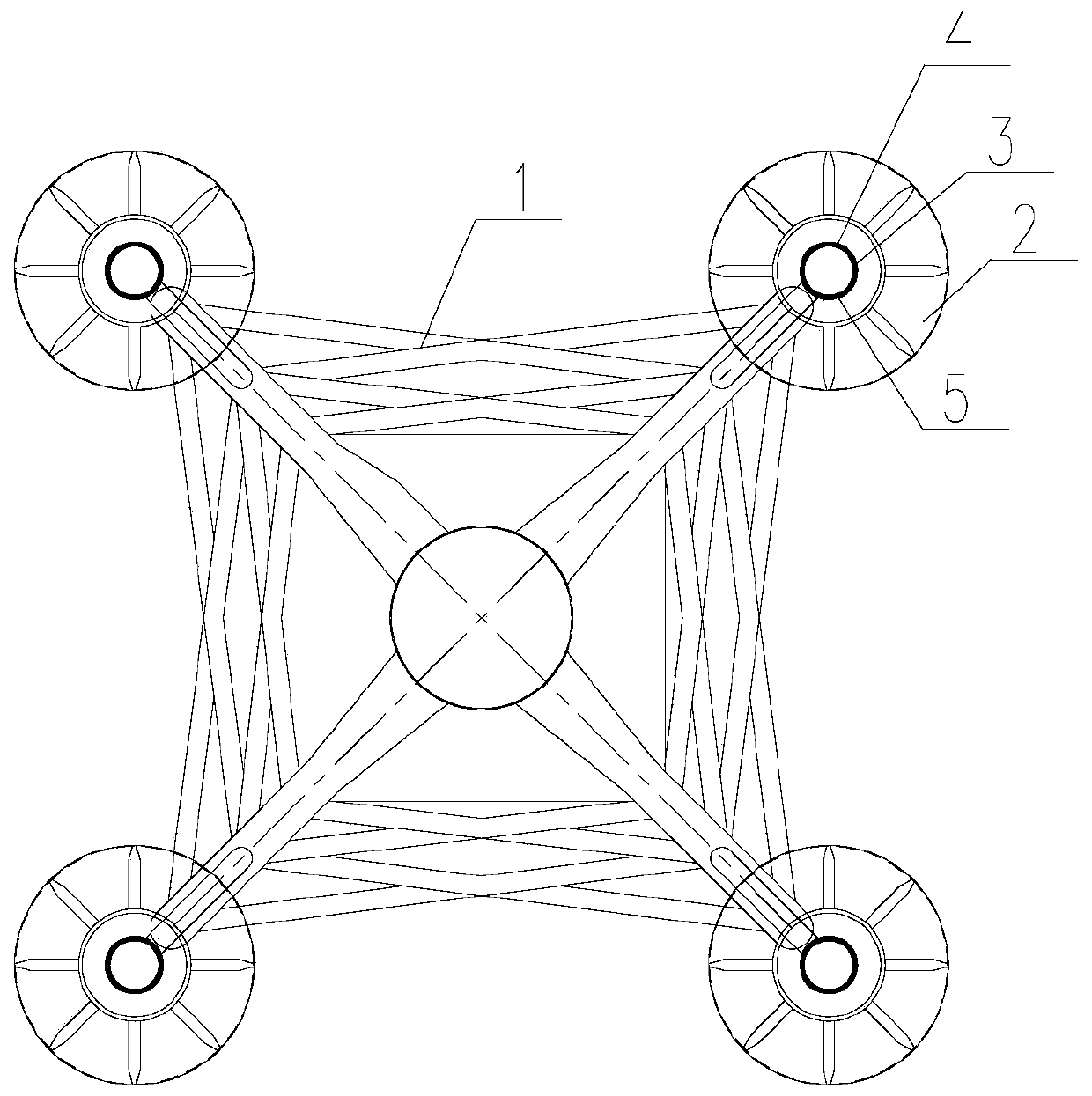

Offshore wind power and marine ranching integrated structure system

PendingCN110258611AImprove bearing capacityIncrease stiffnessClimate change adaptationAgricultural fishingElectric fieldSurface ocean

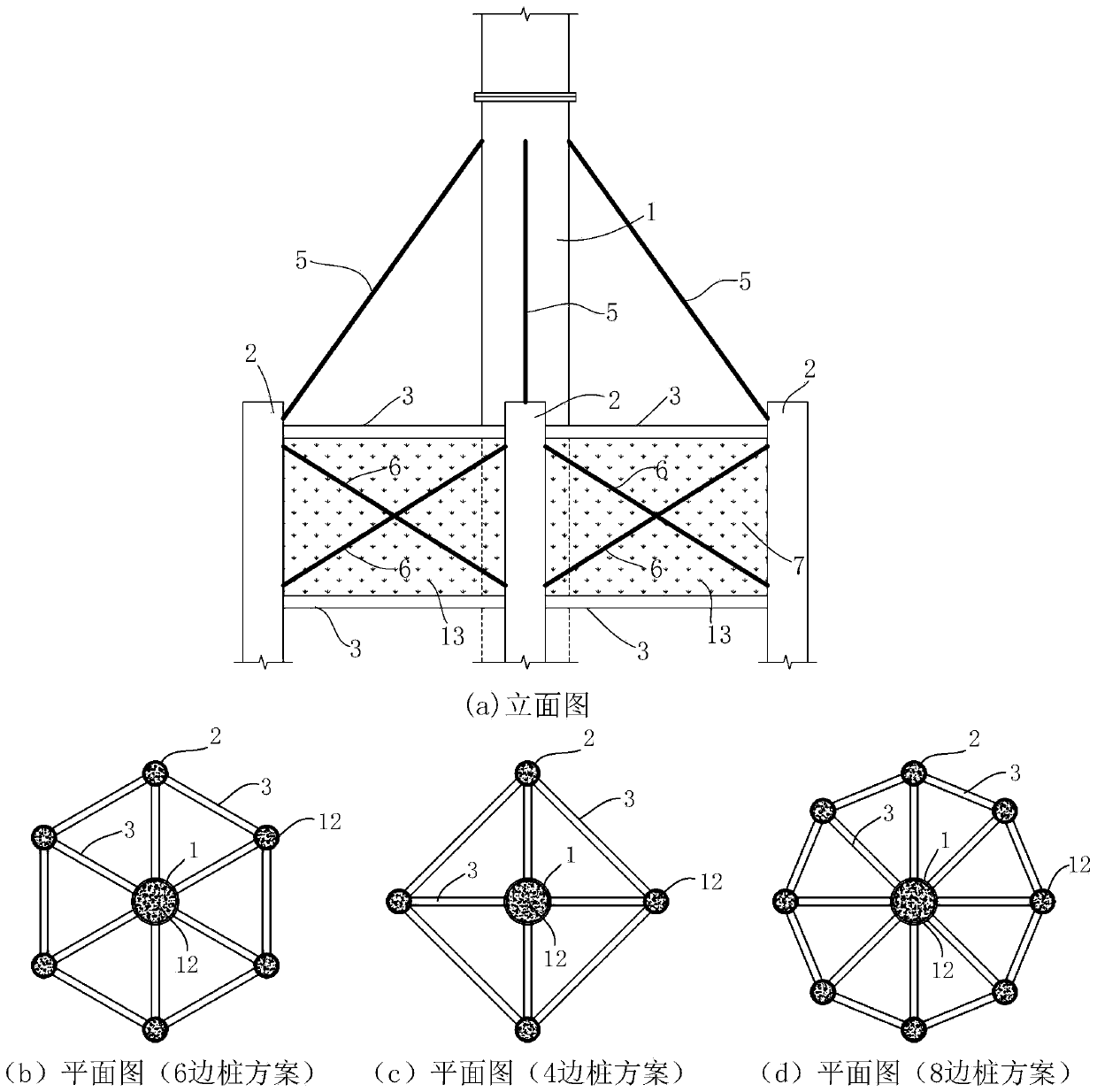

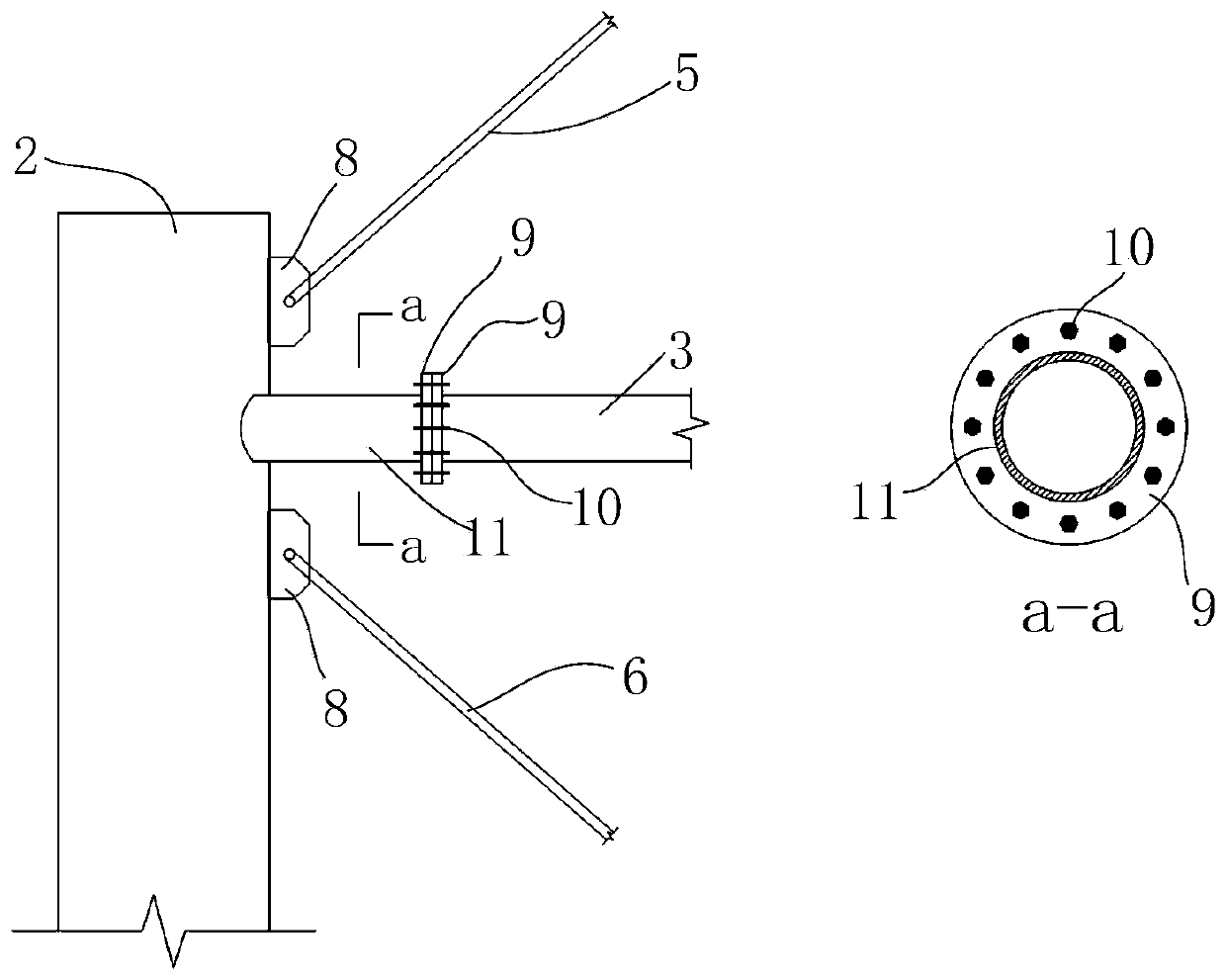

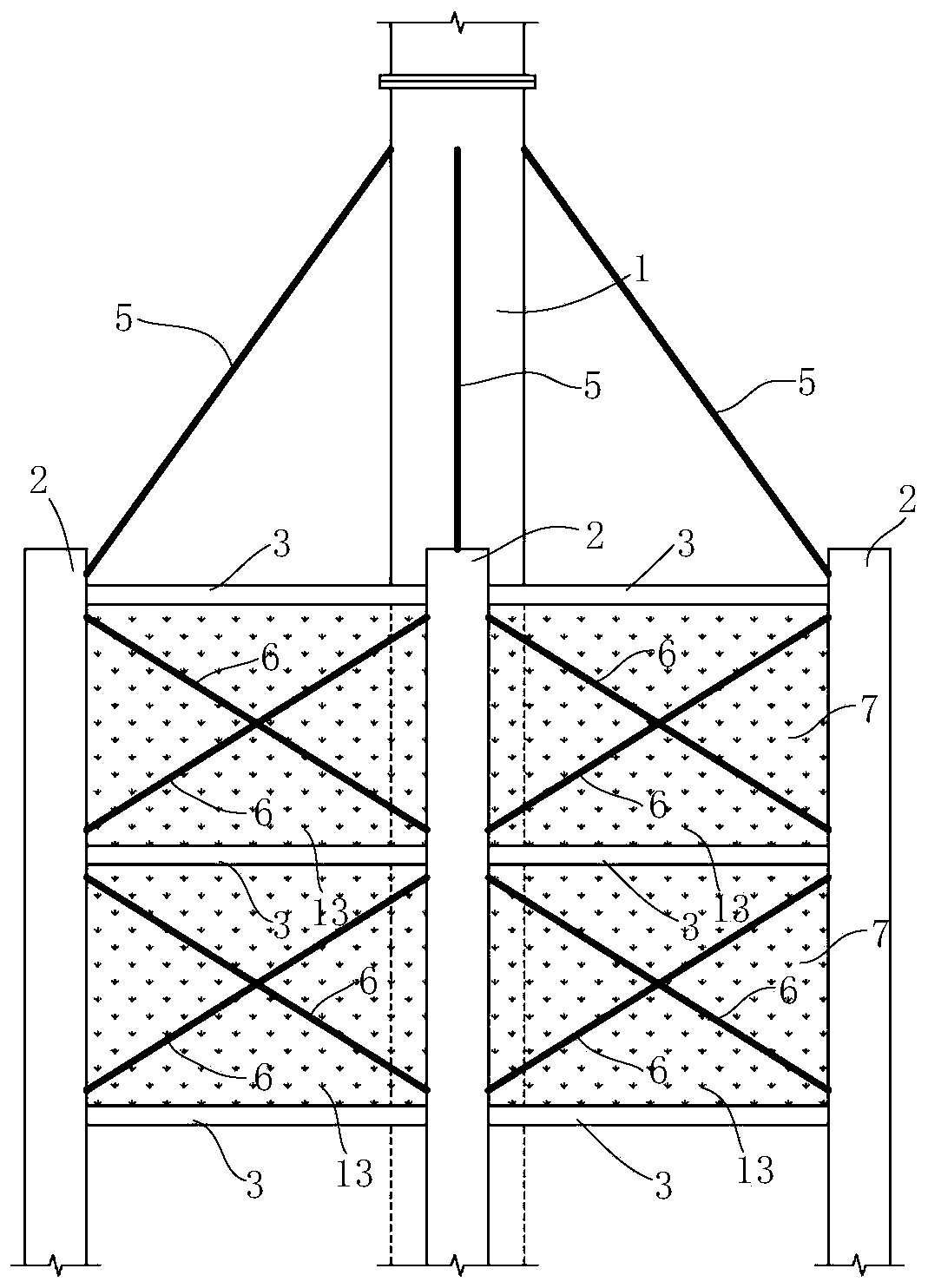

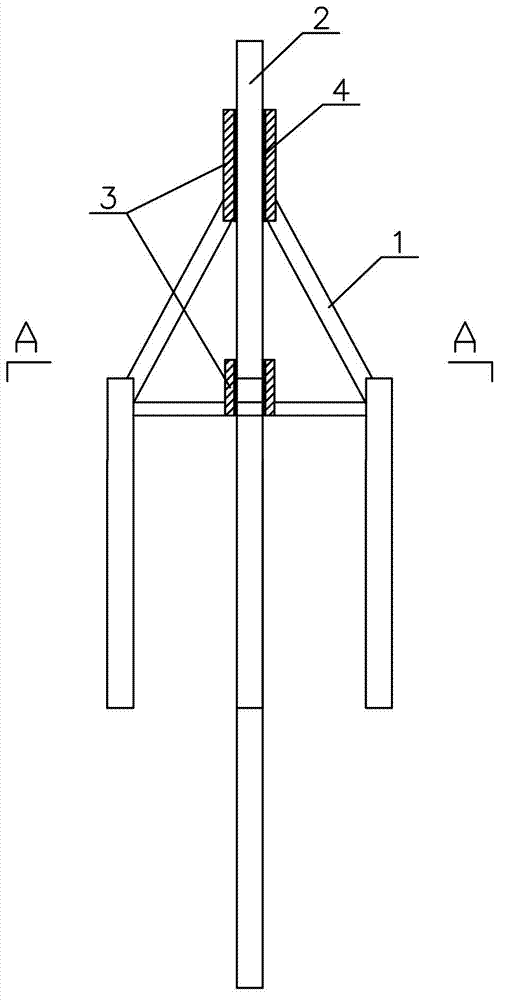

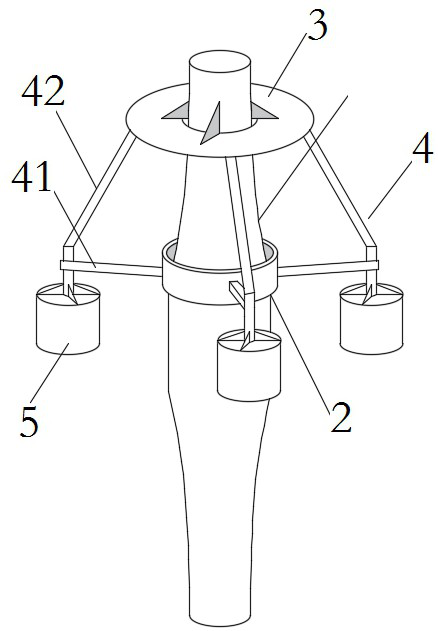

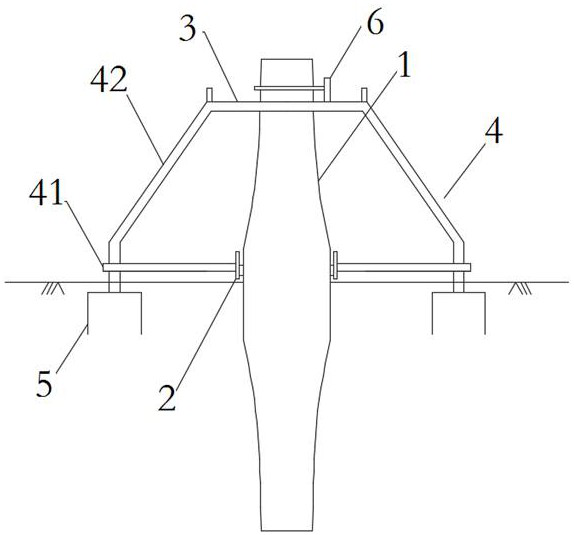

The invention discloses an offshore wind power and marine ranching integrated structure system, and relates to the field of wind power generation. The offshore wind power and marine ranching integrated structure system comprises a central pile, side piles, horizontal rods, connecting ends, upper stay cables, lower stay cables and a marine aquiculture area. The upper end of the central pile is connected with the bottom of a fan tower, and four or six or eight side piles are arranged around the central pile. The central pile and the side piles as well as the side piles are connected through the horizontal rods, the upper stay cables and the lower stay cables. The marine aquiculture area is defined by the side piles, the horizontal rods and the lower stay cables. According to the structure system, the multi-pile foundation form with good bearing capacity and overall stability is adopted, the problems of overlarge section design, difficult pile driving and insufficient rigidity of traditional single-pile foundations are solved, and on-site installation is convenient; the aquiculture area is arranged in a wind power foundation, so that offshore wind power and marine ranching are organically combined, the influence of offshore wind power plant construction on the fishery can be reduced, synchronous development of the offshore wind power industry and the marine ranching industry is promoted, and wide engineering application prospects are achieved.

Owner:CHONGQING UNIV

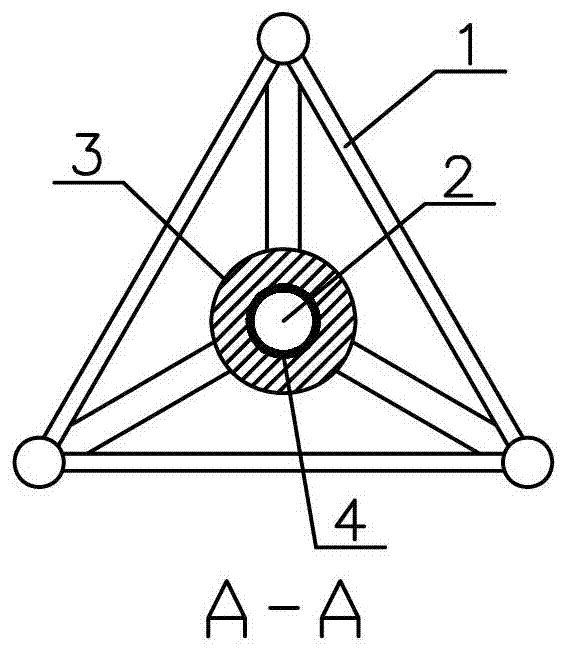

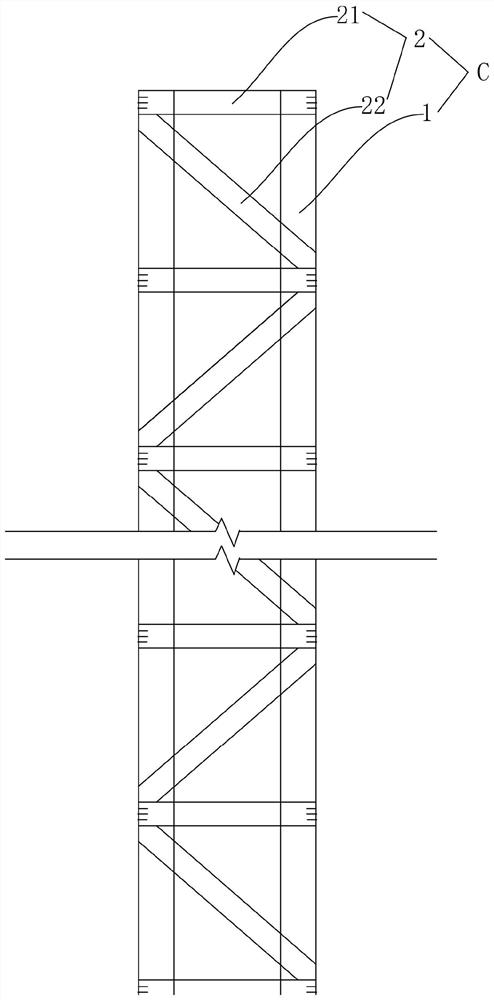

Composite pile foundation structure

InactiveCN102852156AImproved ability to resist vertical loads and bending momentsClear forceFoundation engineeringLoad resistanceBending moment

The invention discloses a composite pile foundation structure. Cylindrical connecting sections are respectively arranged in the centers of the top and the bottom of a truss on the three-pile tripod foundation; the upper and lower connecting sections are inserted into a single-pile foundation; the single-pile foundation is fixedly connected with the connecting sections; and welding, grouting connection through a shear key or elastic connection through an elastic body can be adopted. The advantages of definite stress of the single-pile foundation, high soil layer applicability, convenient construction, high horizontal bearing capacity of the three-pile tripod foundation and the like are fully utilized, compared with the independent single-pile foundation or the three-pile tripod foundation, the composite pile foundation structure has the advantages that the integral rigidity, horizontal load resistance, vertical load resistance and bending moment resistance are greatly improved, particularly the stress mode of the single-pile structure is changed, the bending moment load of the fan load on the foundation is effectively realized, and the horizontal displacement of the wind power structure is reduced, so that the pile length, the pile diameter, the wall thickness and the penetration depth of the pile foundation are reduced; and therefore, the material cost is greatly reduced, and the construction process is simple.

Owner:TIANJIN UNIV

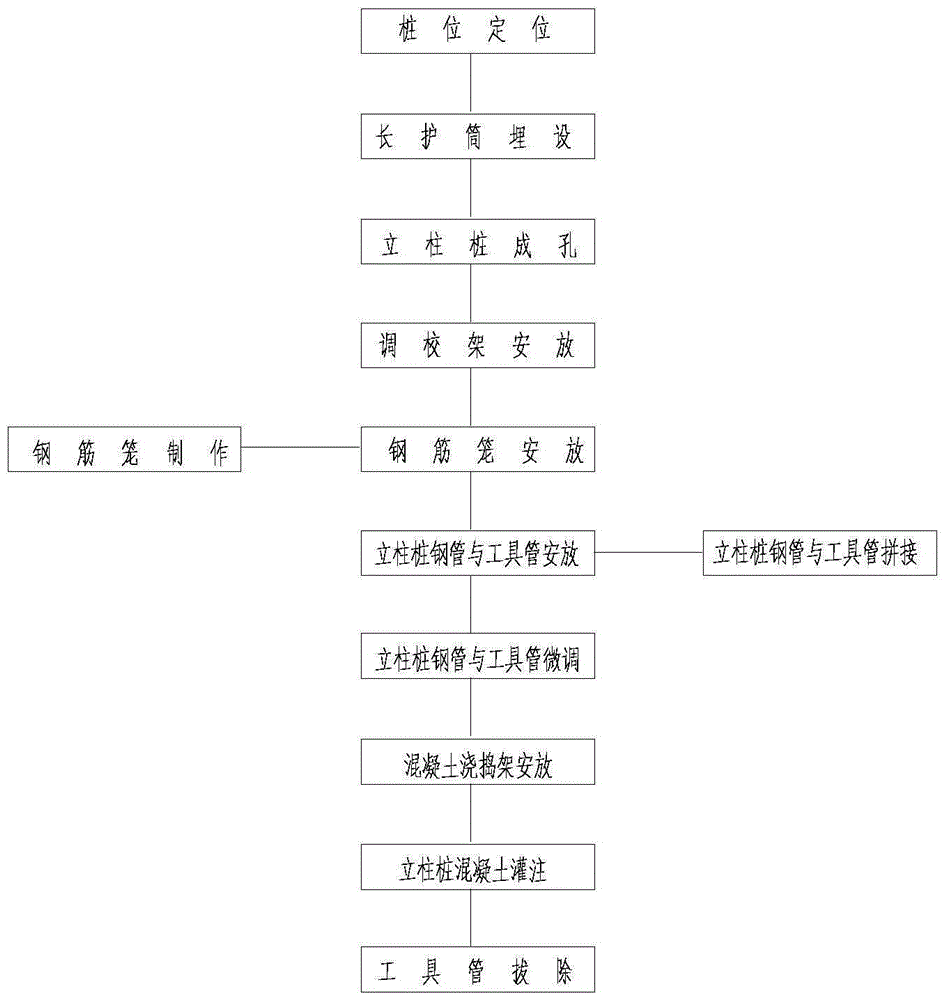

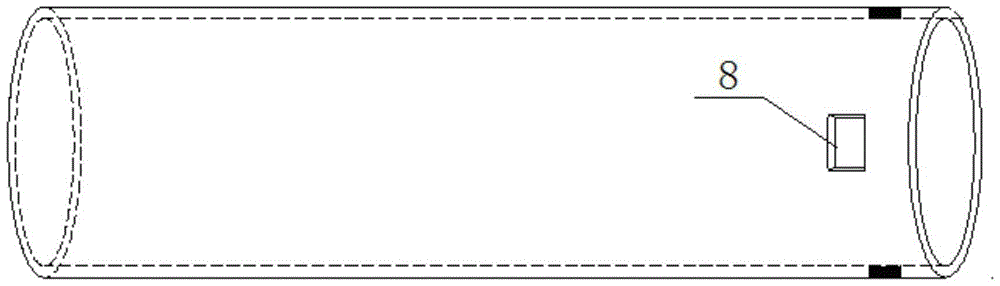

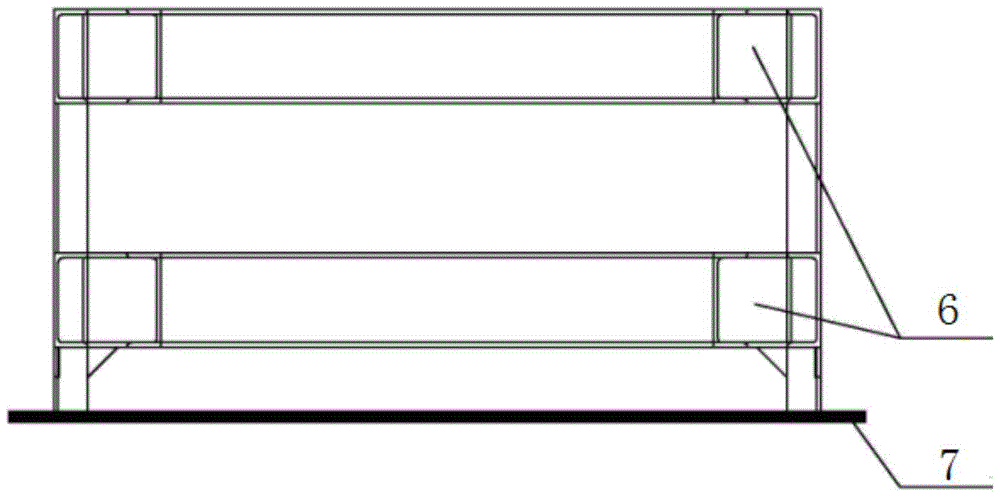

Method for constructing steel pipe upright pile through semi-reversed-construction method

ActiveCN105672314AProcess stabilityReduce pile diameterBulkheads/pilesArchitectural engineeringRebar

The invention discloses a method for constructing a steel pipe upright pile through a semi-reversed-construction method. The method includes the following steps of firstly, locating the pile position; secondly, embedding a long pile casing; thirdly, drilling the upright pile; fourthly, placing an adjusting frame; fifthly, placing a reinforcement cage; sixthly, splicing an upright pile steel pipe with a tool pipe; seventhly, placing the upright pile steel pipe and the tool pipe; eighthly, finely adjusting the upright pile steel pipe and the tool pipe; ninthly, placing a concrete pouring and tamping frame; tenthly, pouring concrete into the upright pile; and eleventhly, pulling out the tool pipe. According to the method, the independently-studied-and-created hoisting tool pipe and the whole vertical detection device are utilized, so that construction quality, the construction schedule and construction safety are guaranteed, construction cost is reduced greatly, and the method has a great significance in development of semi-reversed method construction.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

Prestressed foundation pit support bored pile

The invention provides a prestressed foundation pit support bored pile, which comprises a hollow cylindrical pile body. A cavity communicating in the axial direction of the pile body is formed in thepile body, and reinforcements are arranged in the cavity; a reinforcement cage is tightly connected with the pile body, a plurality of prestressed reinforcements are arranged on the positions, close to the excavated side of a foundation pit, on the pile body at intervals and extend in the axial direction of the pile body, and corrugated pipes coaxially sleeve the prestressed reinforcements; the top ends of the prestressed reinforcements and the top ends of the corrugated pipes are fixed to the end face of the top end of the pile body through anchorage devices; and the bottom ends of the prestressed reinforcements penetrate through the corrugated pipes and are fixed to the pile body through anchorage sections.

Owner:ZHEJIANG UNIV OF TECH

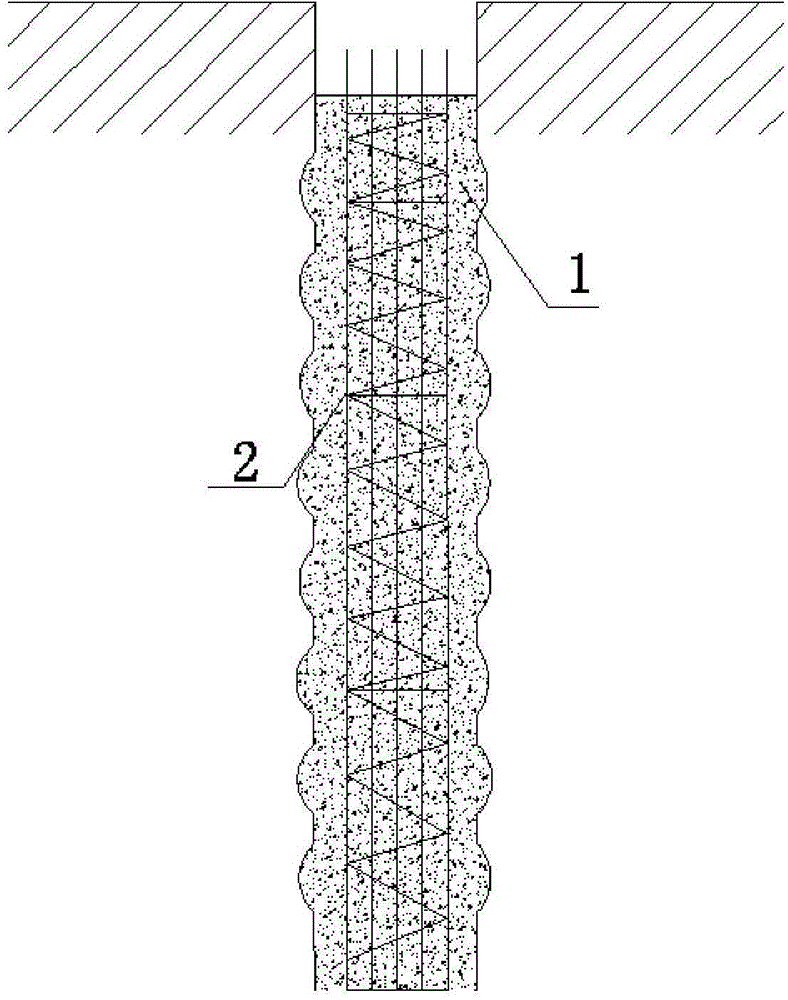

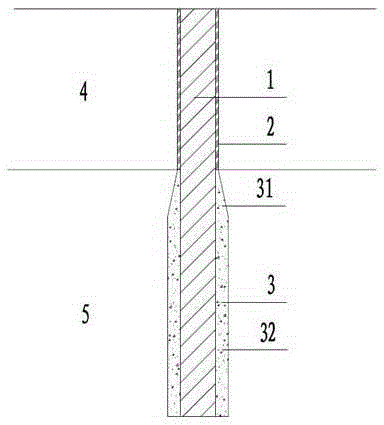

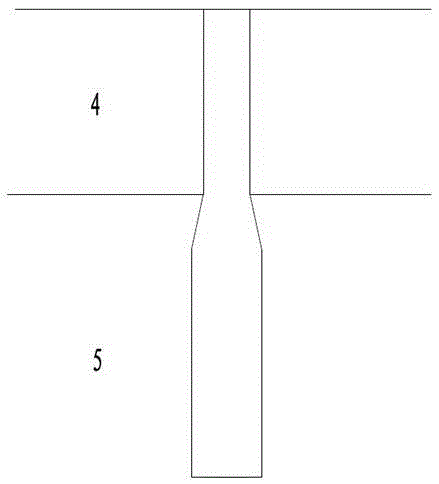

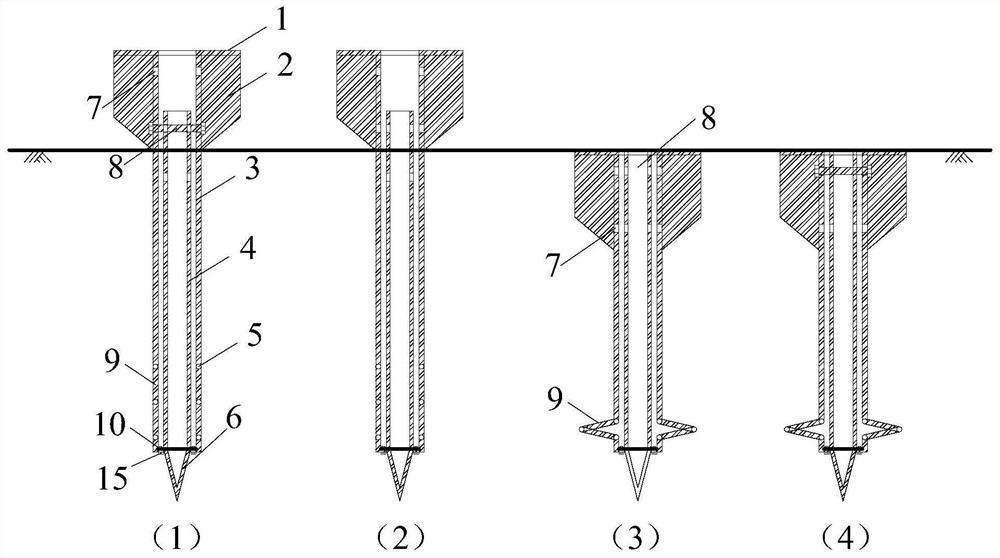

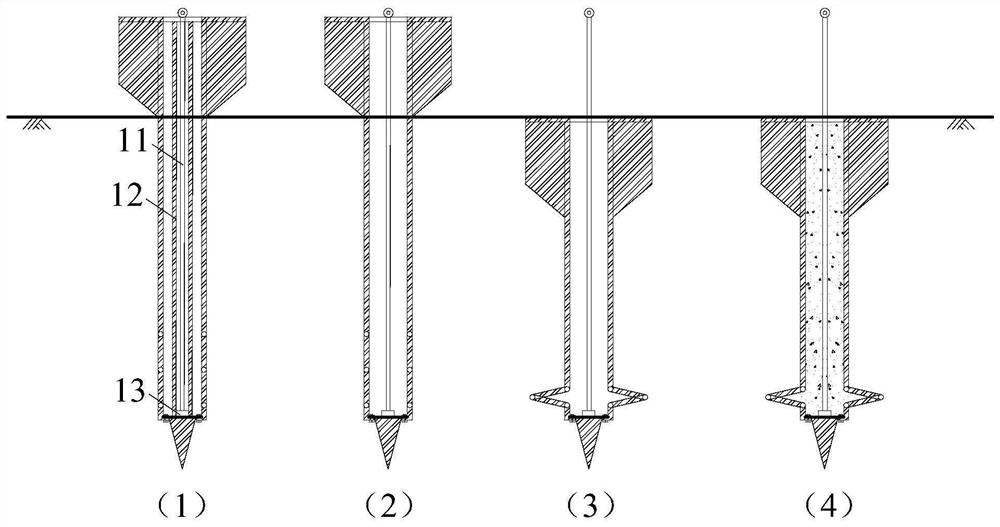

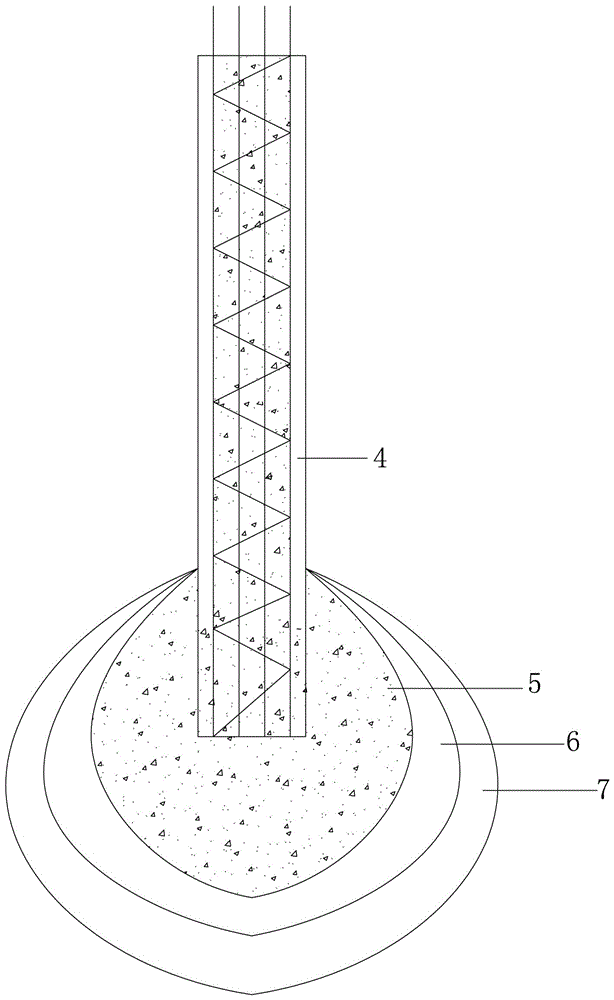

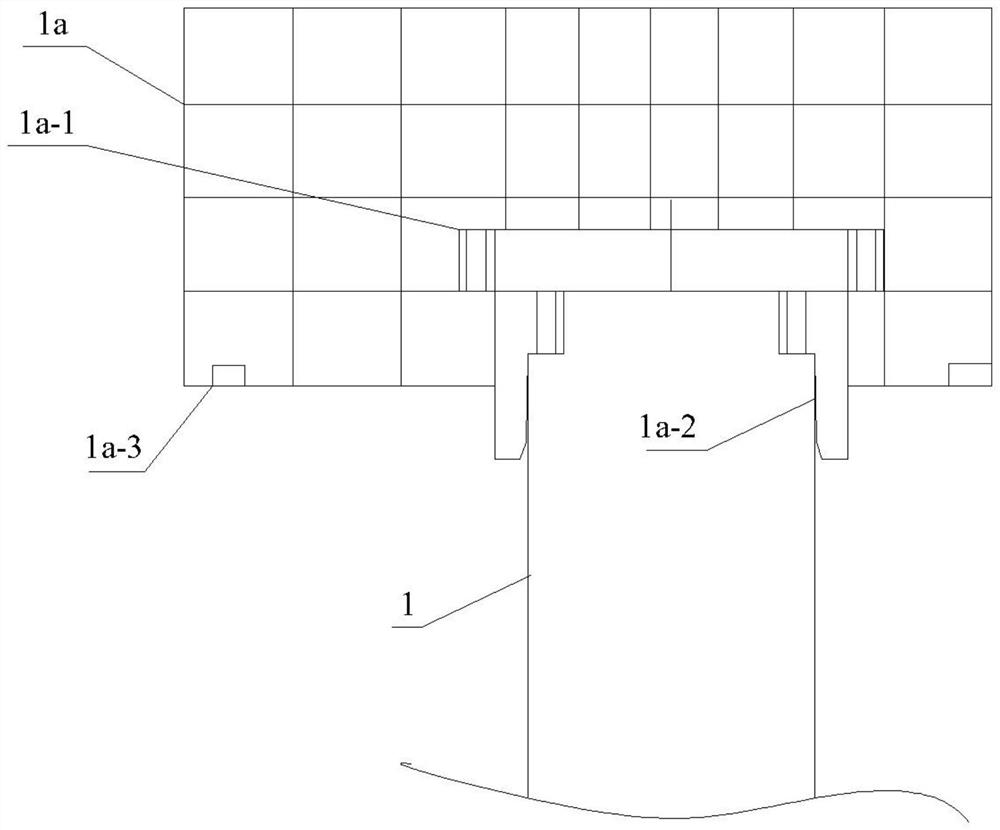

Composite foundation pile with lower portion enlarged diameter section and construction method of composite foundation pile

InactiveCN105297717AImprove pile foundation bearing capacityImprove performanceBulkheads/pilesEngineeringSoil horizon

The invention discloses a composite foundation pile with a lower portion enlarged diameter section and a construction method of the composite foundation pile. The composite foundation pile comprises a precast concrete pile body, and a cast-in-place pile is arranged on the outer side of the lower portion of the precast concrete pile body. The construction method comprises the following steps that (1) a hole is formed by a drilling machine or manually; (2) mechanical or manual chambering is conducted on a soil layer below a soft soil layer; (3) cured materials are poured into the hole; and (4) the precast concrete pile body is implanted into the hole. Compared with a pile body of a single diameter and the same length, the bearing capacity of the composite foundation pile with the lower portion enlarged diameter section is greatly improved, the pile is shorter on the premise of meeting the requirement of designed bearing capacity, and the playing capacity of side resistance and tip resistance of a pile foundation is improved.

Owner:周同和

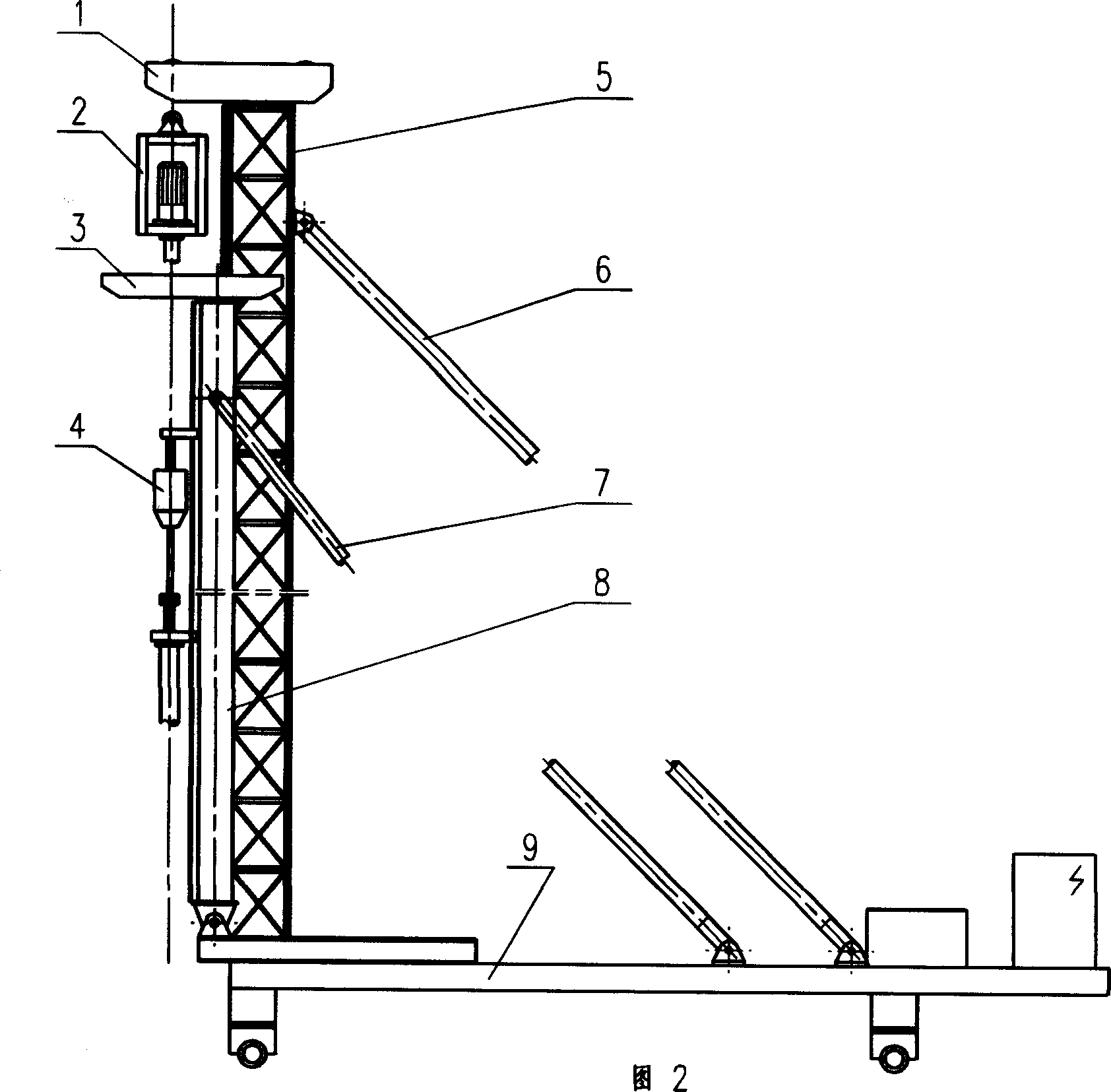

Original soil strengthen pile sinking method and its construction apparatus

The invention discloses a method of crude soil solidifying pile sinking used in building operation and its construction device. The method of pile sinking is that cut moving is stirred into stirred cut crude soil as pre-selected at pre-calculated position of the ground base; prepared curing agent is pressed into the stirred cut crude soil and stirred uniformly into solidified soil; the prefabricated pile is sunk into the solidified soil, the ground base is formed into crude soil solidified pile base. The construction device includes bottom head, stirring machine upright equipped on the bottom head, deep lift stirring machine equipped on the stirring machine upright, pile driver upright equipped on the bottom head, pile driver equipped on the pile diver upright. The advantage of the ground base formed by this method is high intension, strong bearing capacity, and low cost.

Owner:江苏东达集团股份公司

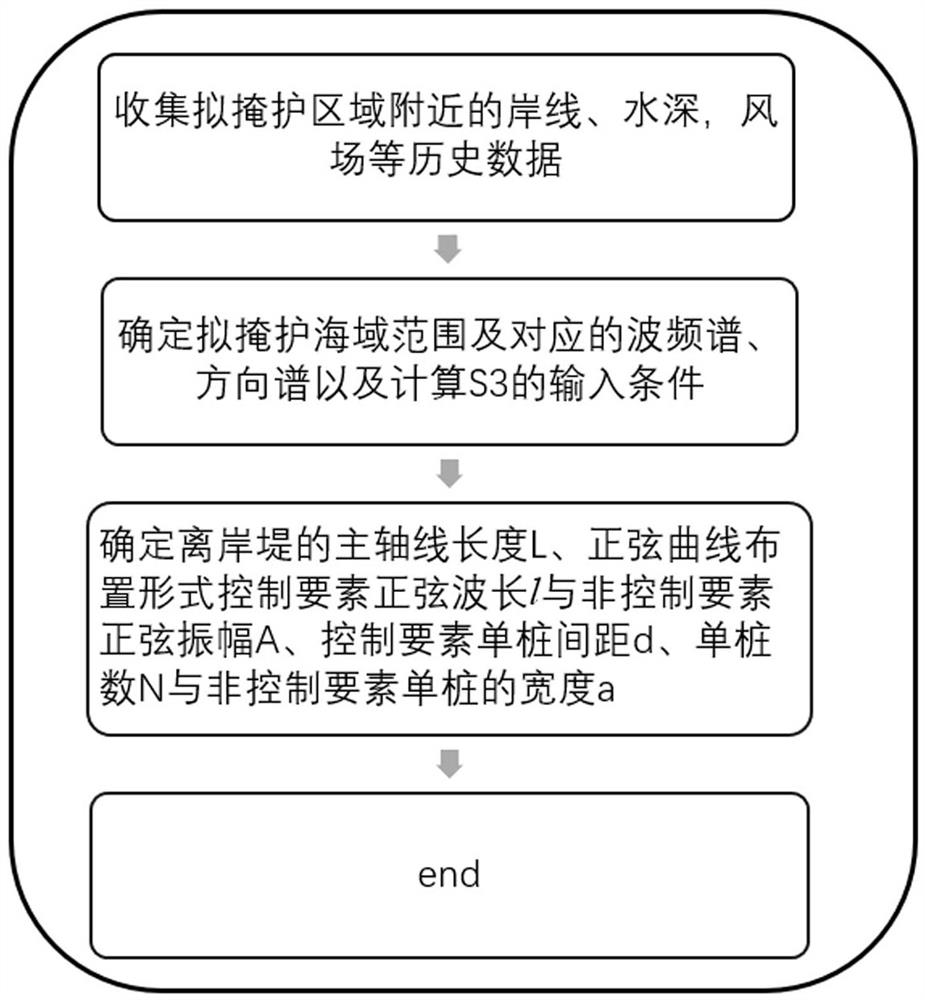

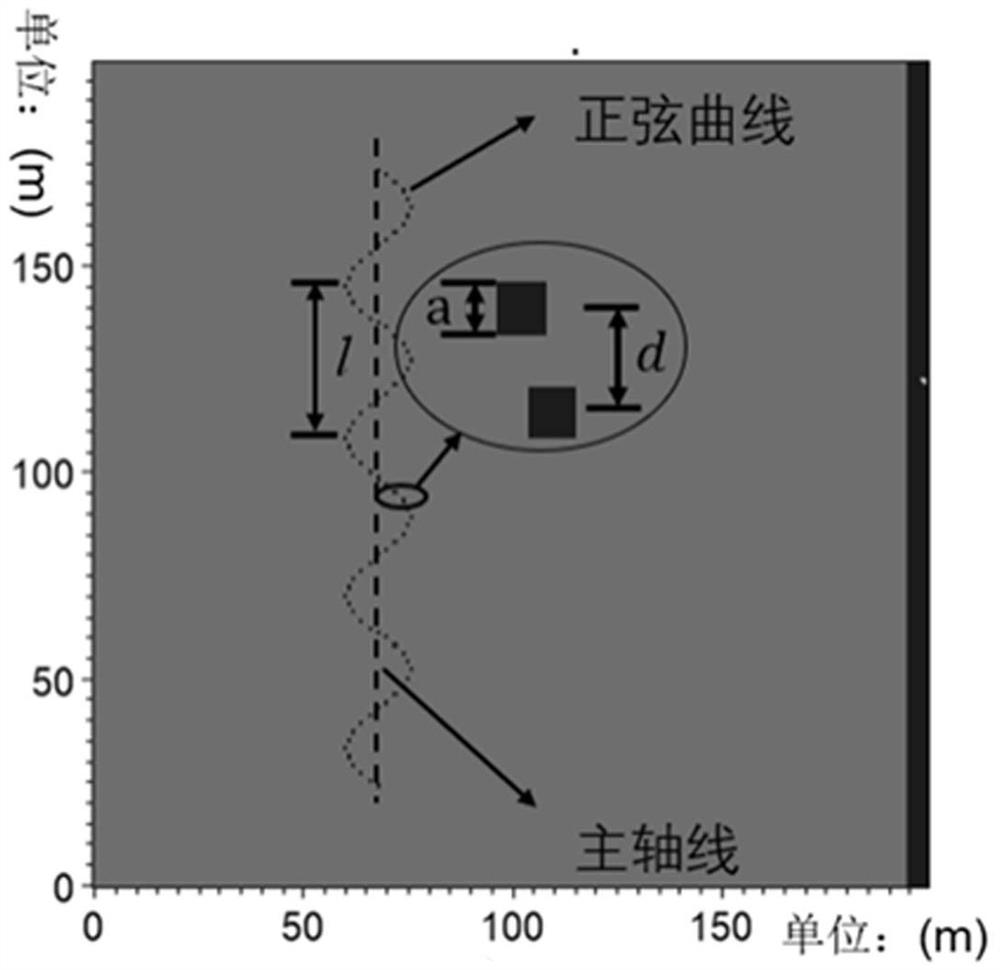

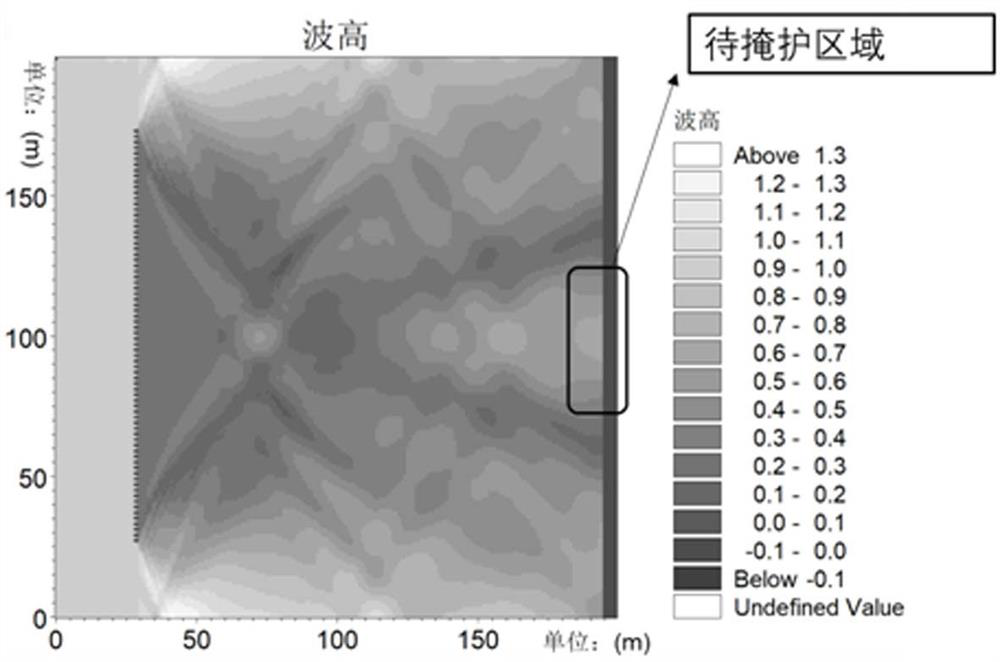

Pile type offshore embankment, design method and application

ActiveCN113255050ASimple structural designSolving resonance problemsGeometric CADDesign optimisation/simulationFrequency spectrumStructural engineering

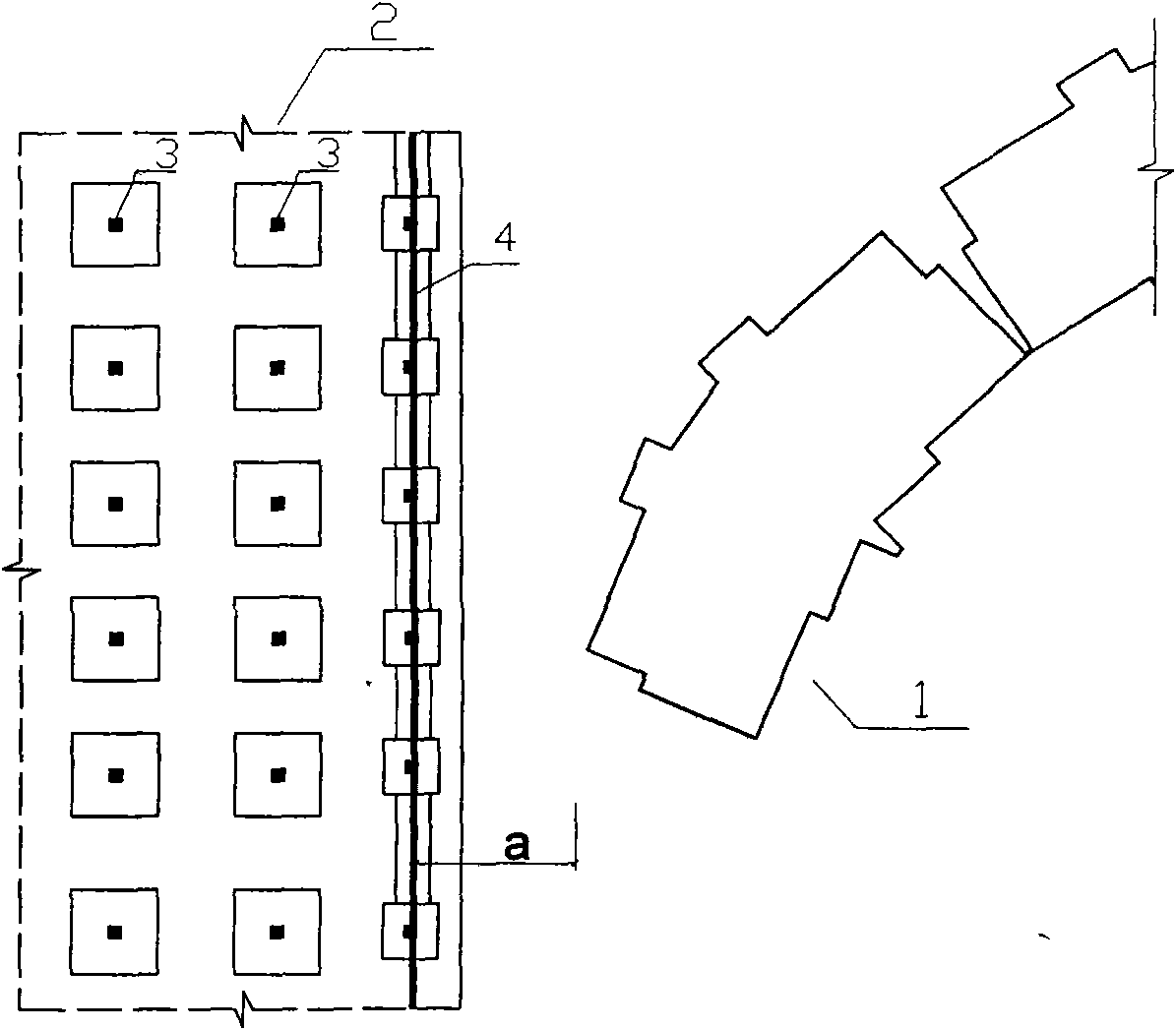

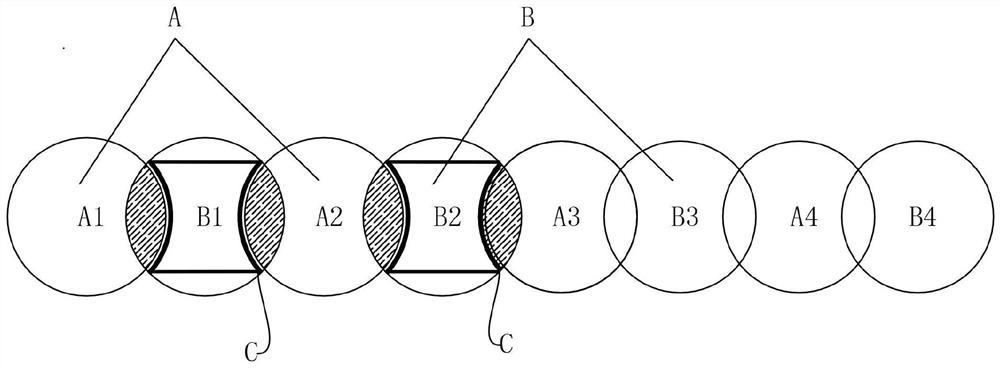

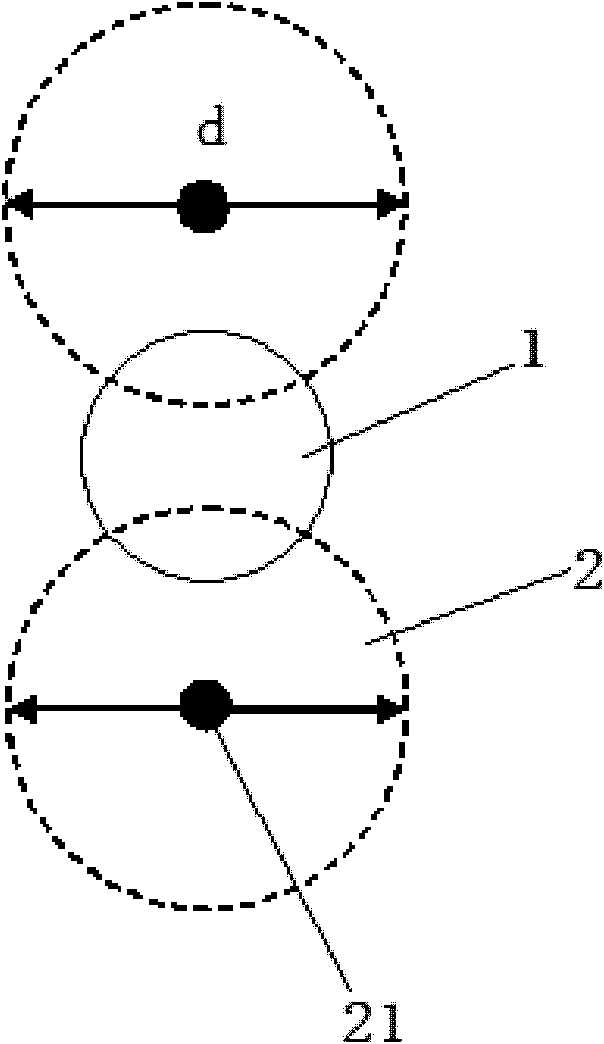

The invention discloses a pile type offshore embankment, a design method and application, and belongs to the technical field of coast engineering. The arrangement structure of the pile type offshore embankment is in a sine curve form. The design method comprises: collecting historical data such as a shoreline, water depth and a wind field near a to-be-shielded area; determining a to-be-shielded sea area range, a corresponding wave frequency spectrum and a direction spectrum, and calculating an input condition of S3; and determining the length L of the main axis of the offshore embankment, the sine wave length (m) of a control element in a sine curve arrangement form, the sine amplitude A of a non-control element, the spacing d of single piles of the control element, the number N of the single piles and the width a of the single piles of the non-control element. The interference of long-period waves can be effectively blocked through sinusoidal array arrangement, wave resonance of a to-be-shielded area is avoided, meanwhile, the interference of short waves can be effectively blocked through the single piles arranged in an array mode, the wave dissipation frequency is expanded from the narrow bandwidth to the wide bandwidth, and then the wave blocking efficiency of the pile type offshore embankment is improved.

Owner:OCEAN UNIV OF CHINA

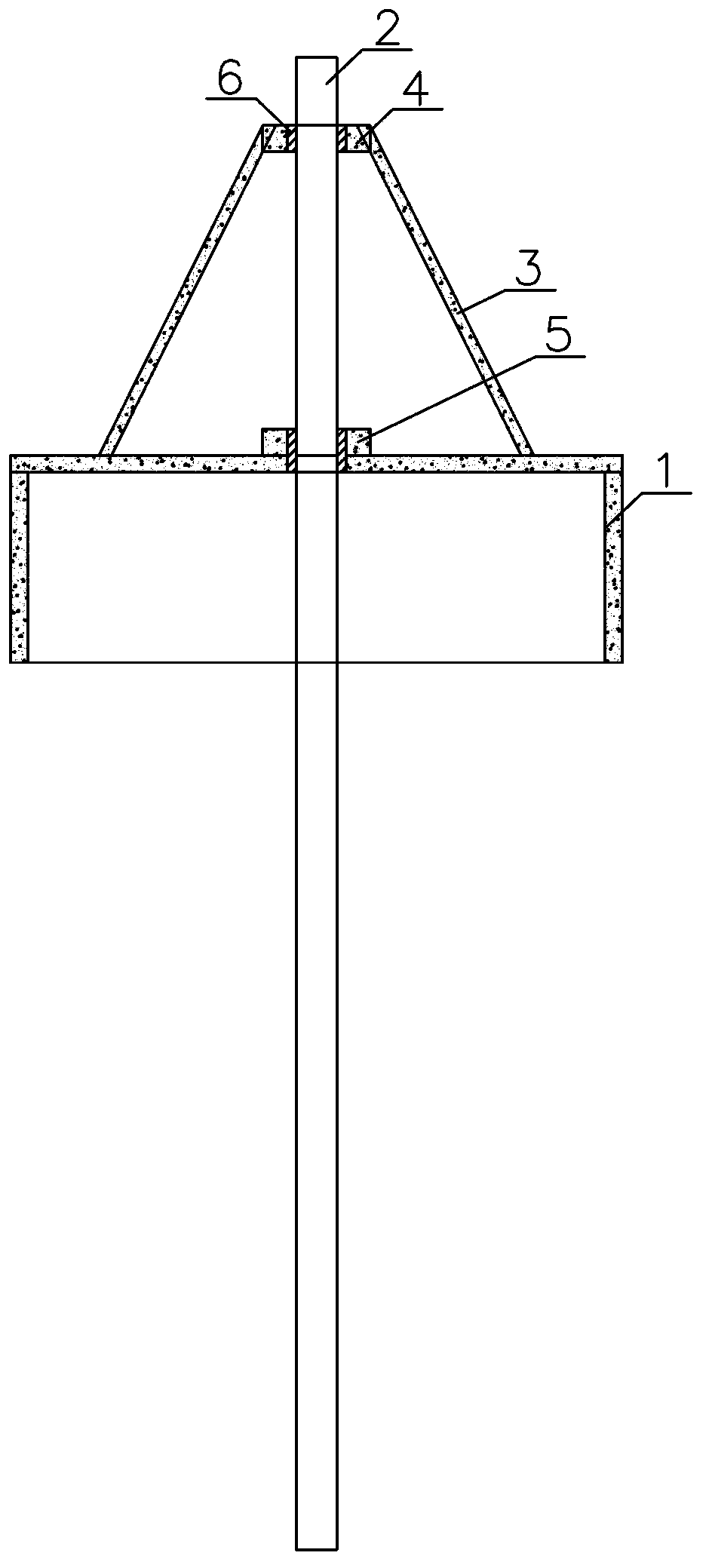

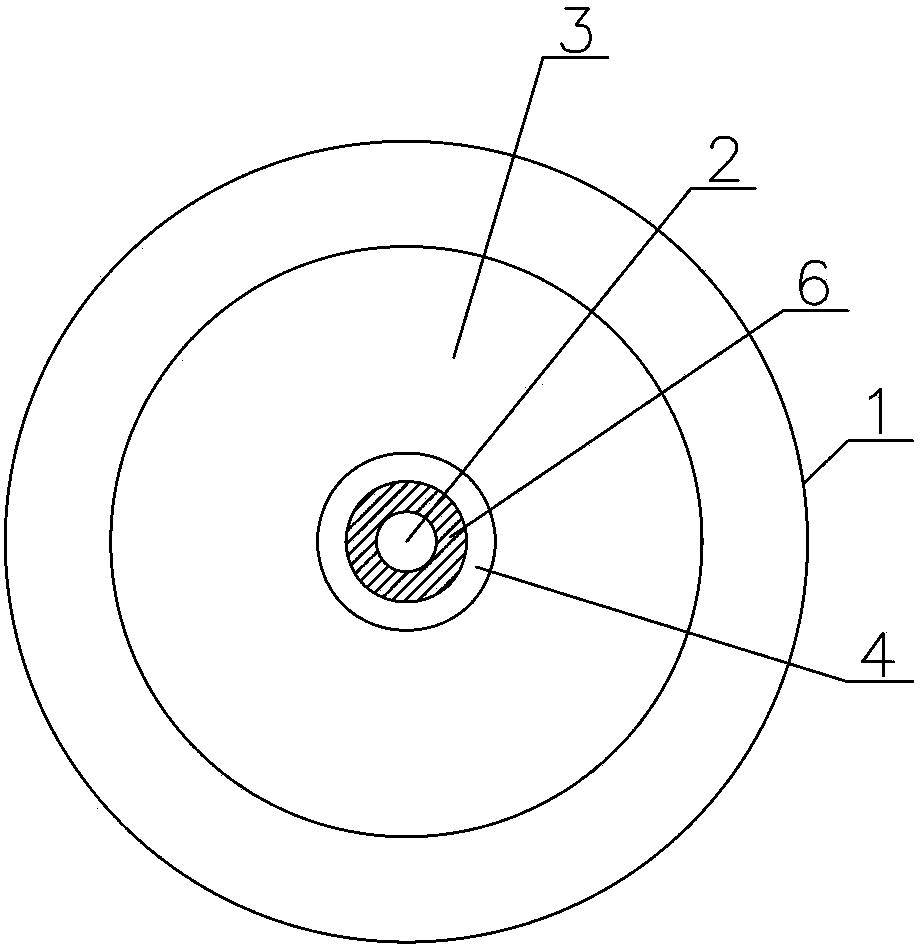

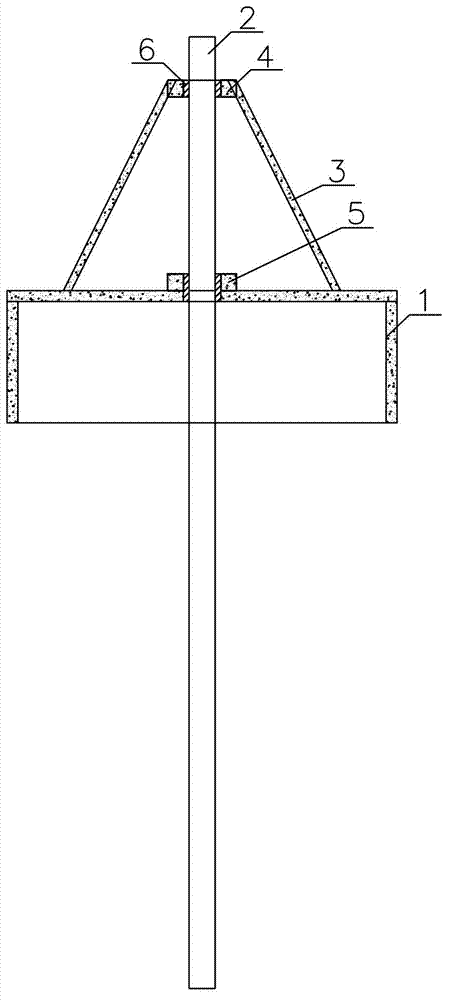

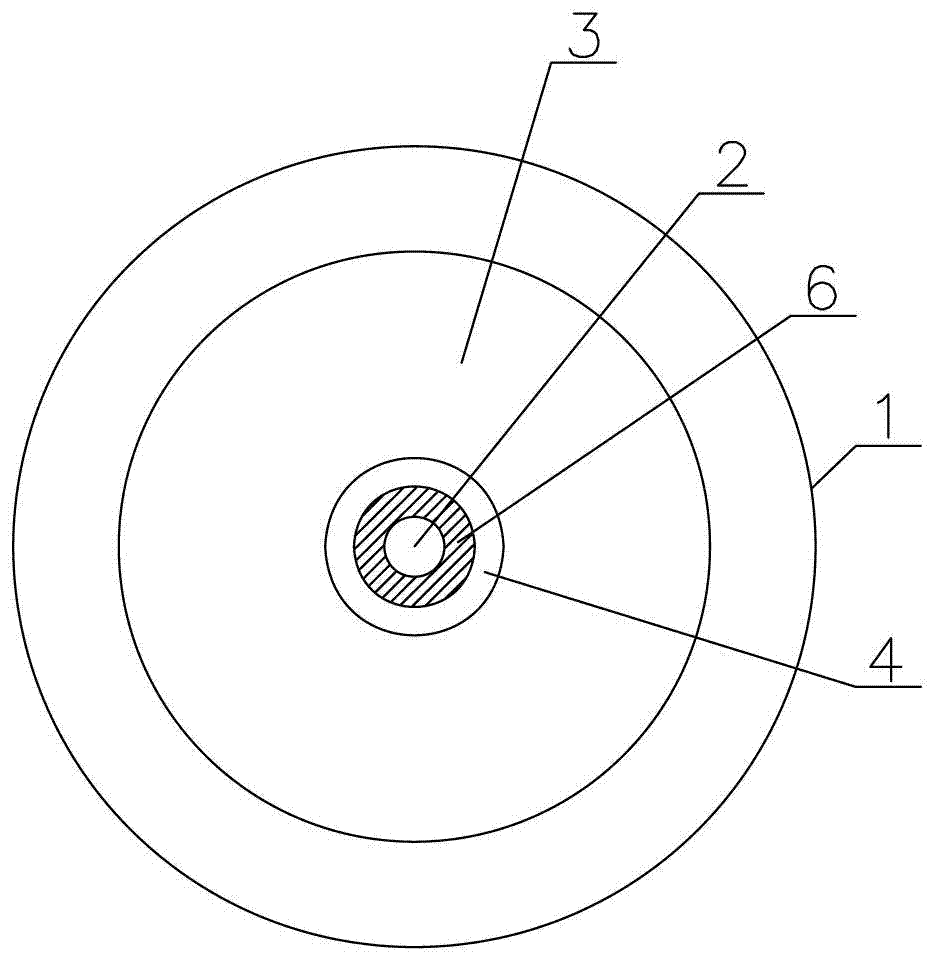

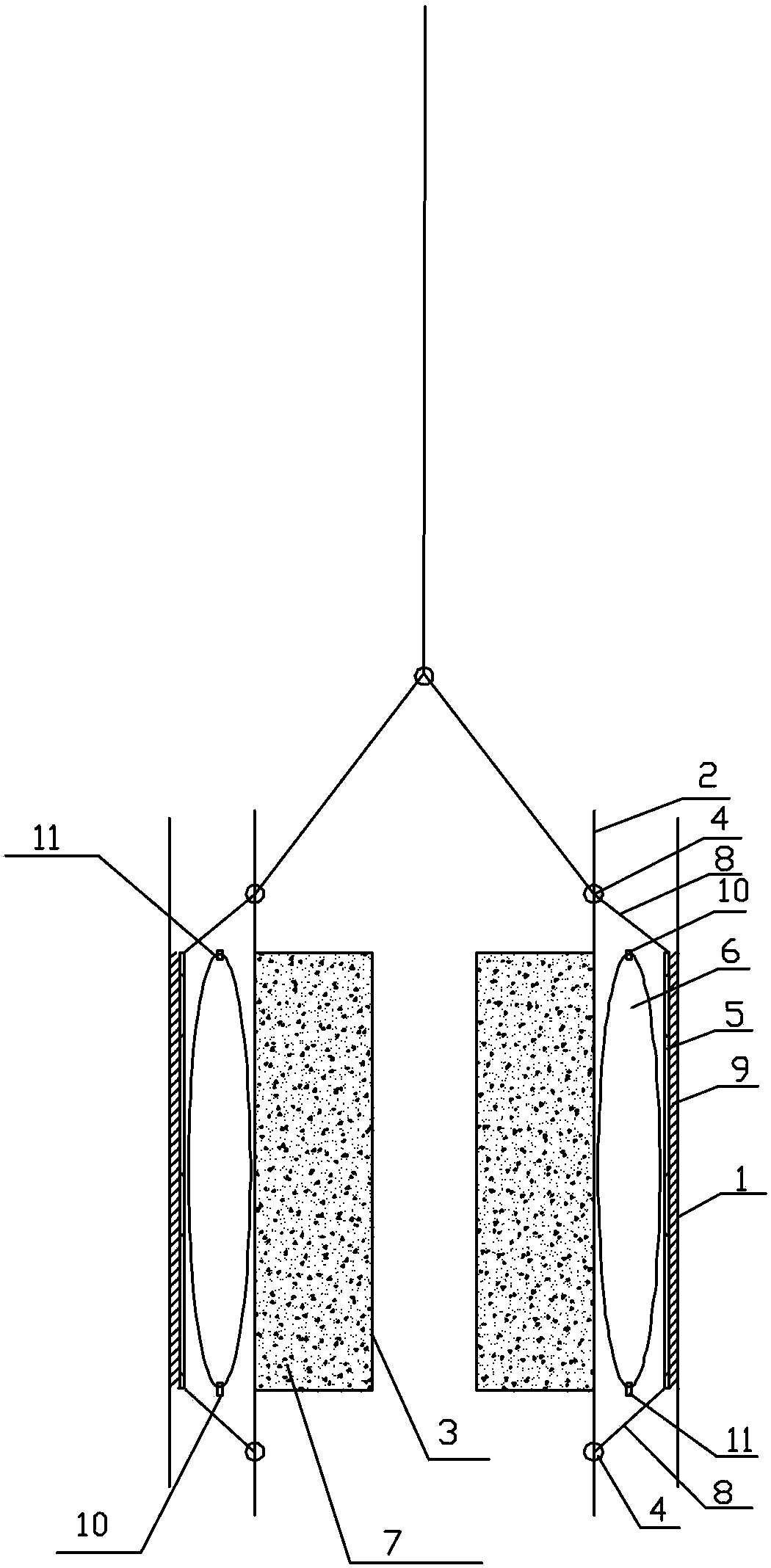

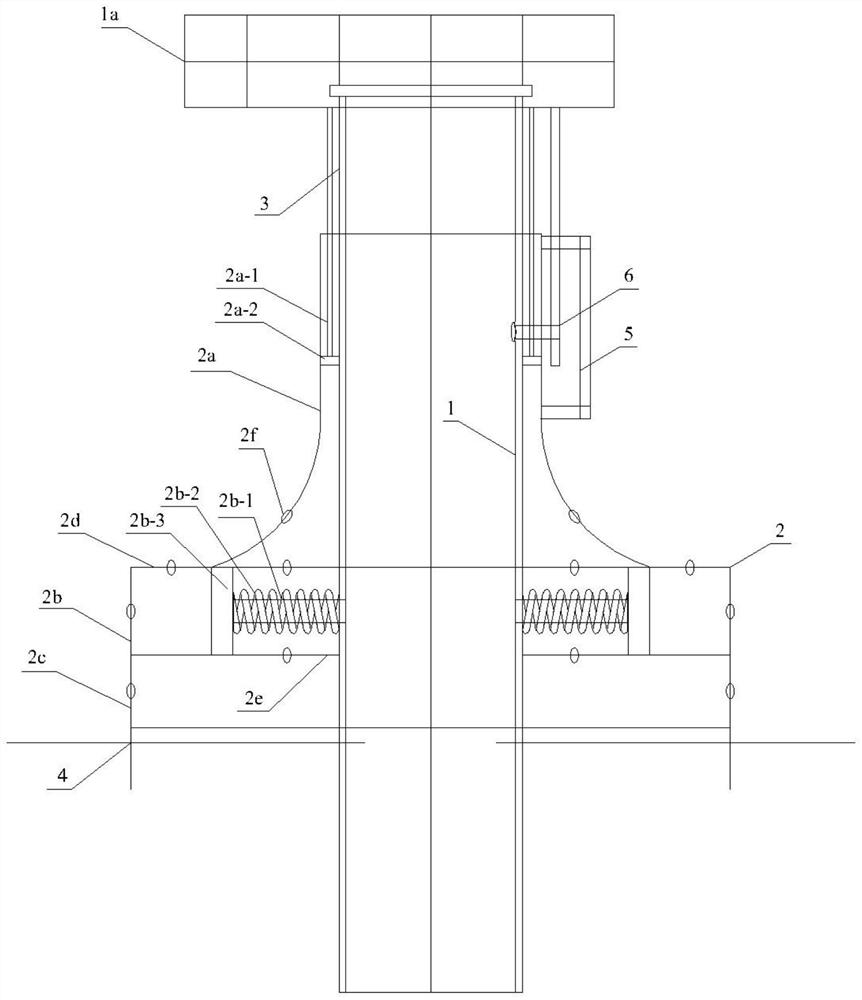

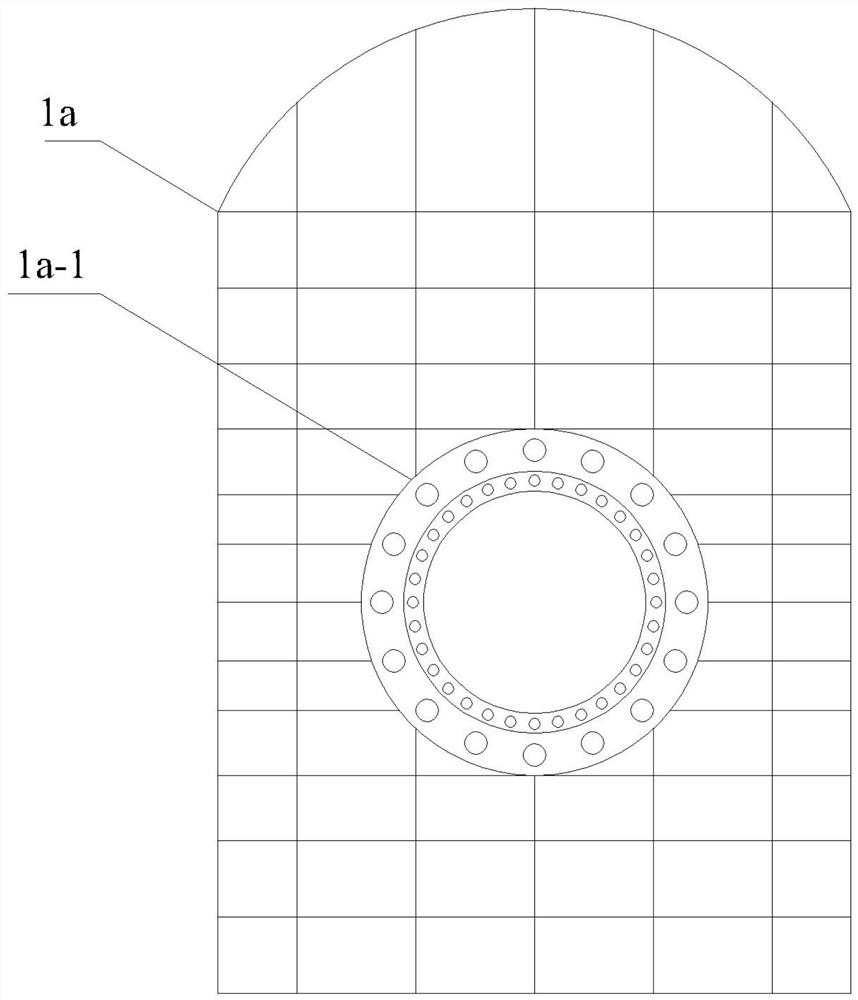

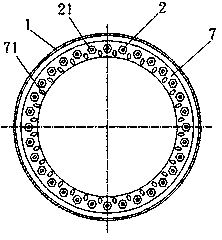

Combined pile foundation structure

ActiveCN102808419BIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityCarrying capacity

The invention discloses a combined pile foundation structure. A hollow cone structure coaxial to a barrel-shaped foundation is arranged on the top of the barrel-shaped foundation; the centre of the top surface of the hollow cone structure is provided with a first connecting section ring girder structure; the centre of the top cover of the barrel-shaped foundation is provided with a second connecting section ring girder structure; a single-pile foundation is inserted in the first connecting section ring girder structure at the upper part and the second connecting section ring girder structure at the lower part; and the single-pile foundation is respectively fixedly connected with the first connecting section ring girder structure and the second connecting section ring girder structure. According to the combined pile foundation structure, the advantages of clear stress, strong applicability to soil layers, convenience in construction and good horizontal carrying capacity of the barrel-shaped foundation of the single-pile foundation are sufficiently utilized; the integral rigidness, horizontal load resistance, vertical load resistance and bending moment capacity are greatly improved, the bending moment load of a blower load to the foundation is effectively reduced and the horizontal displacement of a wind power structure is reduced, so that the pile length, pile diameter, wall thickness and penetrating depth of the pile foundation are reduced, the cost of materials is greatly reduced and the construction process is simpler.

Owner:TIANJIN UNIV

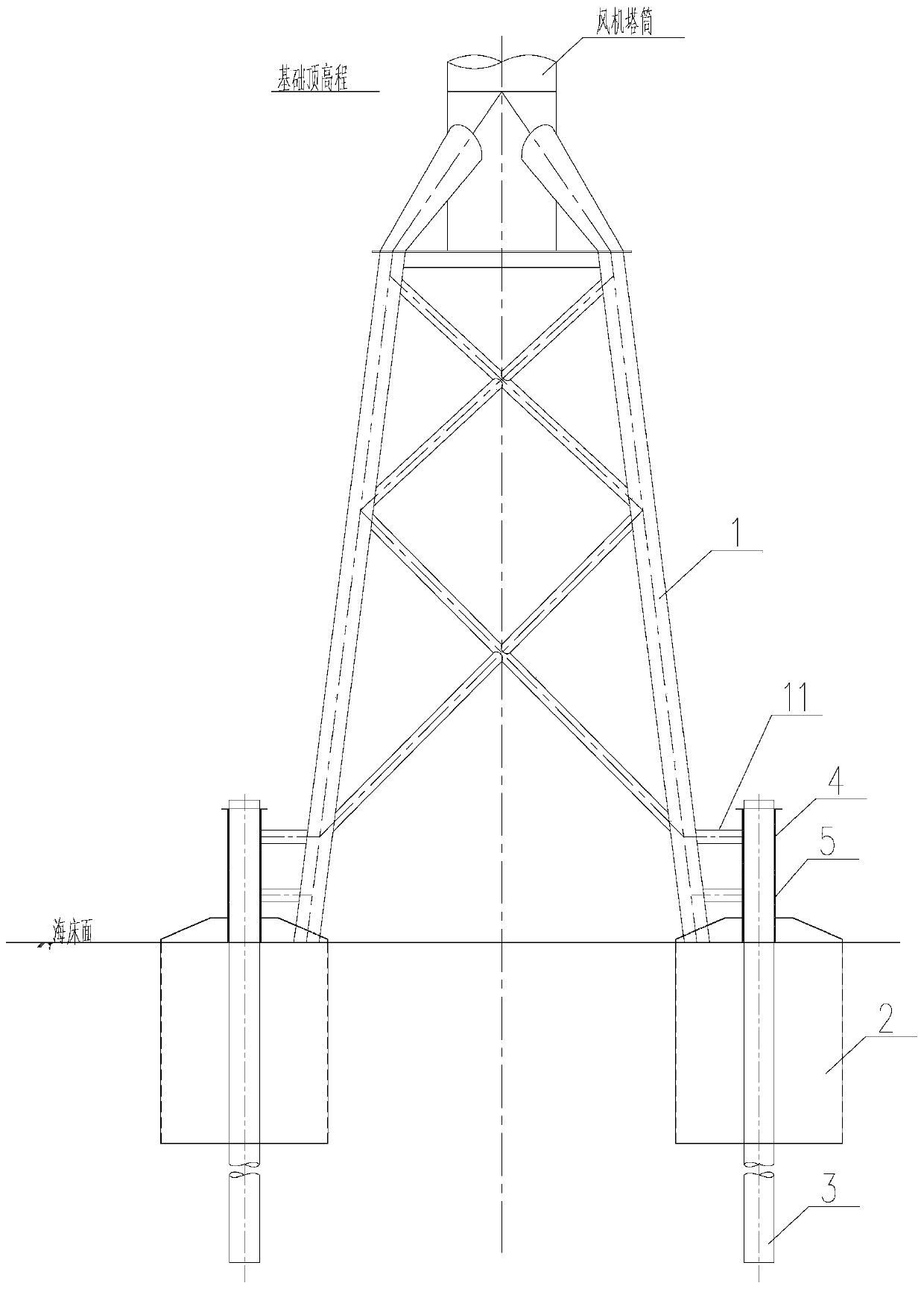

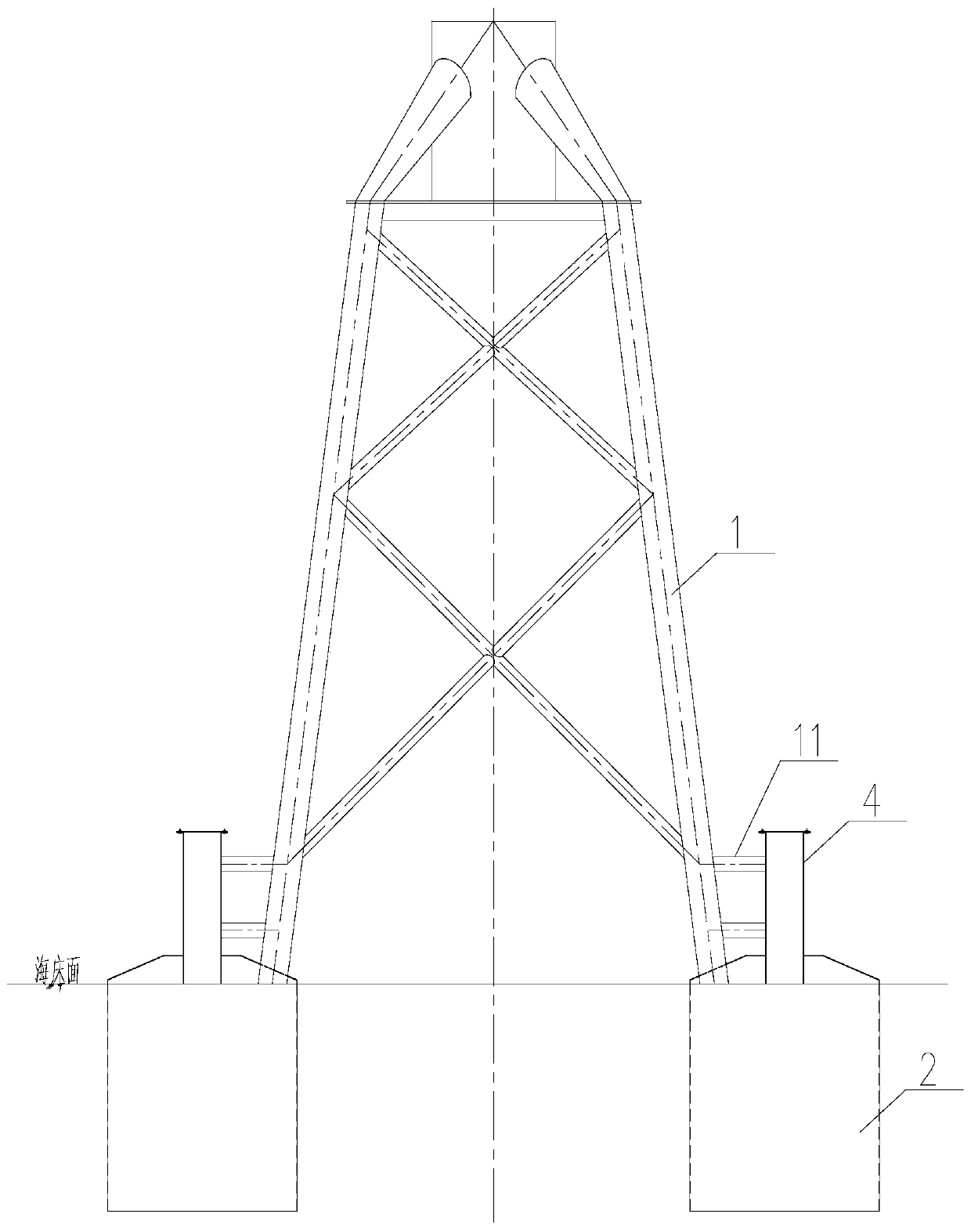

Offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and construction method thereof

PendingCN111101535AExpand the scope of actionImprove bearing capacityFoundation engineeringSuction forceOffshore wind power

The invention relates to an offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and a construction method thereof. The offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and the construction method thereof are simple in structure, convenient to construct, low in cost, safe and stable. According to the technical scheme, the offshorewind-driven generator multi-pile-suction barrel-jacket foundation structure is characterized in that a plurality of suction barrels are uniformly arranged at the bottom of a jacket, wherein guide sleeves communicating with the interiors of the suction barrels are arranged in the centers of the tops of the suction barrels; the jacket is supported on a seabed through the suction barrels and fixed to the seabed through steel pipe piles inserted into the guide sleeves and driven into the seabed; and high-strength grouting materials are poured into gaps between the guide sleeves and the steel pipepiles. The offshore wind-driven generator multi-pile-suction barrel-jacket foundation structure and the construction method thereof are suitable for the technical field of ocean engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Combined pile foundation structure

ActiveCN102808419AIncrease stiffnessIncreased resistance to horizontal loadsFoundation engineeringElectricityCarrying capacity

The invention discloses a combined pile foundation structure. A hollow cone structure coaxial to a barrel-shaped foundation is arranged on the top of the barrel-shaped foundation; the centre of the top surface of the hollow cone structure is provided with a first connecting section ring girder structure; the centre of the top cover of the barrel-shaped foundation is provided with a second connecting section ring girder structure; a single-pile foundation is inserted in the first connecting section ring girder structure at the upper part and the second connecting section ring girder structure at the lower part; and the single-pile foundation is respectively fixedly connected with the first connecting section ring girder structure and the second connecting section ring girder structure. According to the combined pile foundation structure, the advantages of clear stress, strong applicability to soil layers, convenience in construction and good horizontal carrying capacity of the barrel-shaped foundation of the single-pile foundation are sufficiently utilized; the integral rigidness, horizontal load resistance, vertical load resistance and bending moment capacity are greatly improved, the bending moment load of a blower load to the foundation is effectively reduced and the horizontal displacement of a wind power structure is reduced, so that the pile length, pile diameter, wall thickness and penetrating depth of the pile foundation are reduced, the cost of materials is greatly reduced and the construction process is simpler.

Owner:TIANJIN UNIV

Static pressure type rear support spiral pile based on bionics and construction method thereof

The invention discloses a static pressure type rear support screw pile based on bionics, which comprises a pile tip, an outer sleeve, a flange and an empennage, the empennage is arranged at the upperend of the outer sleeve, the flange is arranged at the top ends of the empennage and the outer sleeve, an outer support blade is arranged at the lower part of the outer sleeve, and when the outer support blade is pressed at the top of the outer sleeve, the outer supporting blades are unfolded outwards. A built-in steel pipe or a flexible anchor rod is arranged in the outer sleeve, and the pile tipis fixedly connected with the built-in steel pipe or the flexible anchor rod. By optimally designing the pile body, the side resistance is small during static pressure pile sinking penetration, the outer supporting blades are unfolded through secondary sinking of the outer sleeve, the vertical uplift and compression resistance bearing capacity of the outer supporting blades is improved, the horizontal bearing capacity of the outer supporting blades is improved through the arrangement of the empennage, and the uplift bearing capacity of the pile side and the blades is improved by utilizing thecharacteristics of compression shrinkage and tension expansion of negative poisson ratio materials. The method has the advantages of small soil disturbance, low construction noise and environmental friendliness.

Owner:HOHAI UNIV +3

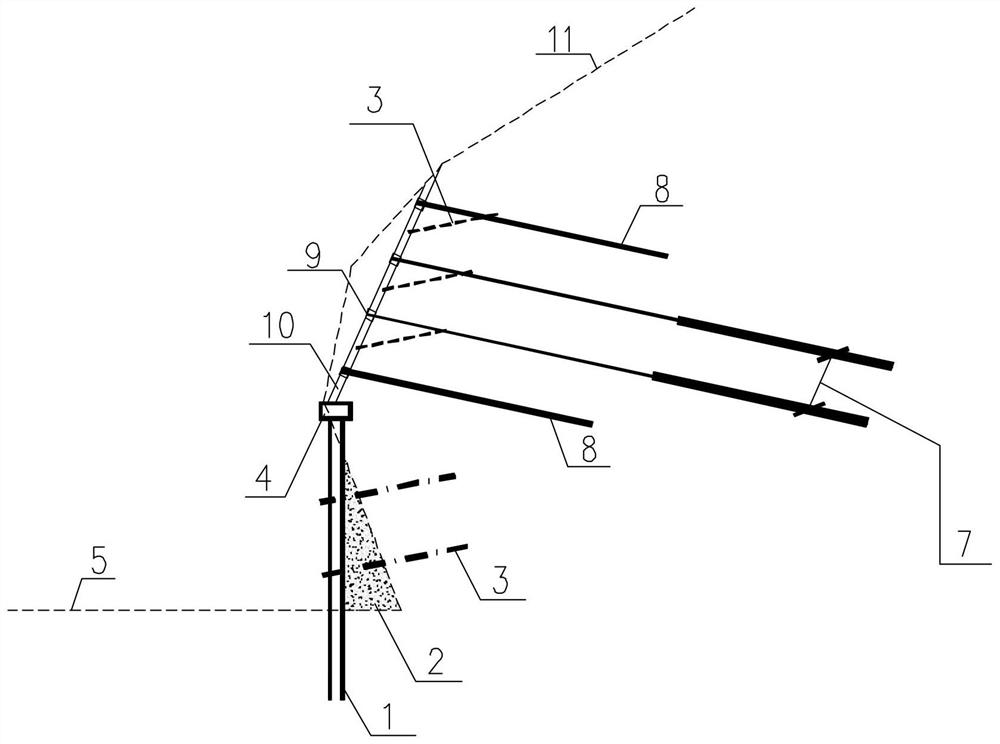

Combined supporting structure for treating dangerous rock mass and construction method thereof

PendingCN112681347APermanent reinforcementEnsure safety and stabilityExcavationsPre stressArchitectural engineering

The invention discloses a combined supporting structure for treating dangerous rock mass and a construction method thereof. The combined supporting structure comprises micro steel pipe piles arranged in two rows on the lower dangerous rock mass, wherein pile top crown beams are arranged at the tops of the micro steel pipe piles; prefabricated concrete baffles are arranged between the micro steel pipe piles, the prefabricated concrete baffles are covered with meshes in a net hanging and spraying mixing mode, and PVC drainage pipes are arranged in the micro steel pipe piles; backfill concrete is adopted between the micro steel pipe piles and the dangerous rock mass for backfill treatment; and frame beams are arranged on the upper slope surface of the dangerous rock mass, prestressed anchor cables or anchor rods are arranged at the joints of the frame beams, the bottoms of the frame beams extend to the pile top crown beams, backfill soil is arranged in the frame beams, and grass seeds are planted in the backfill soil to play a greening role. Due to the fact that the construction speed of the micro piles is high, the development of deformation of the dangerous rock mass can be preliminarily controlled within a short time, and high efficiency is achieved; and meanwhile, the pile diameter of the micro steel pipe piles is small, the design composition is simple, the requirement for driving equipment is not high, and good economic efficiency is achieved.

Owner:中国水电顾问集团贵阳勘测设计研究院岩土工程有限公司 +1

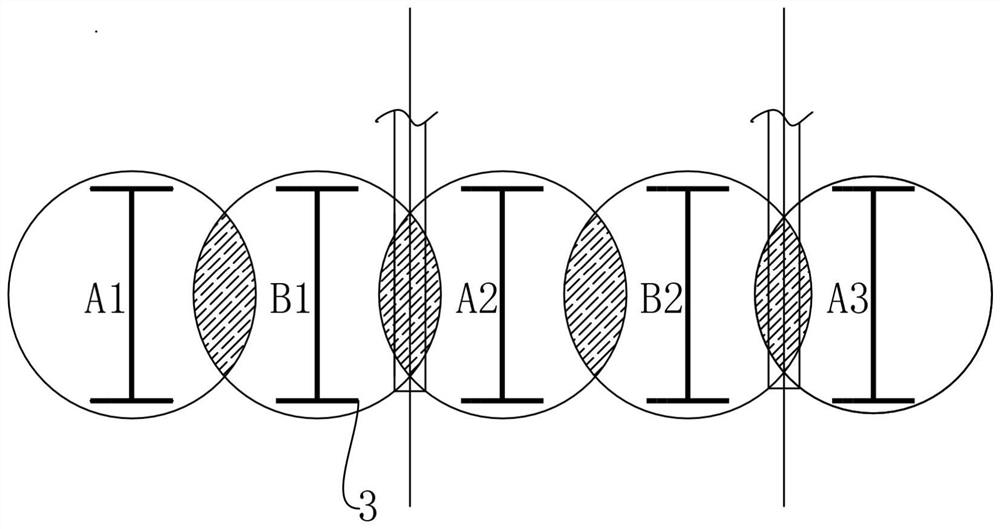

Construction method of steel-reinforced concrete secant pile and arc-shaped protective tool

PendingCN112049123AIncrease stiffnessHigh strengthExcavationsBulkheads/pilesReinforced concreteUltimate tensile strength

The invention relates to the technical field of foundation pit supporting in engineering construction, and particularly relates to a construction method of a steel-reinforced concrete secant pile andan arc-shaped protective tool. The steel-reinforced concrete secant pile comprises a secant pile body composed of a plurality of meat piles and plain piles, wherein the meat piles and the plain pilesare sequentially and alternately arranged and engaged with one another. The secant pile body is completed by repeatedly mounting and dismounting the arc-shaped protective tool in pile holes of the plain piles and inserting H-shaped steel ribs into pile holes of the meat piles and pile holes of the plain piles. By the adoption of the method of inserting the H-shaped steel ribs, the rigidity and strength of the secant pile body can be improved, the pile diameter of a supporting pile is reduced, and the excavation amount and the concrete pouring amount are reduced; the H-shaped steel ribs can bepulled out to be recycled, so that the material cost is reduced, the construction period is shortened, and meanwhile environmental protection is facilitated; and the arc-shaped protective tool is placed before plain pile concrete pouring, then in-mold concrete pouring is conducted, and thus materials can be further saved.

Owner:SHENZHEN SOFORE GEOTECHNICAL ENG CO LTD

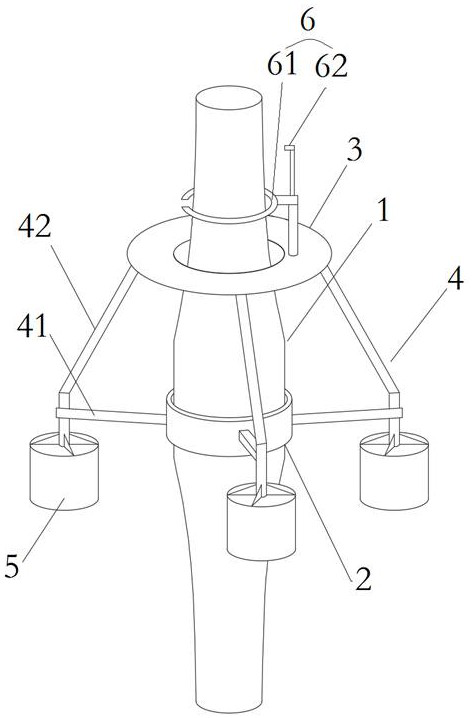

Integrated offshore wind power foundation

InactiveCN114108686AImprove bearing capacityIncrease stiffnessFoundation testingWind motor supports/mountsSuction forceMarine engineering

The invention relates to the technical field of wind power generation, in particular to an integrated offshore wind power foundation which comprises a steel pipe pile, a guide ring, a platform, a supporting frame, a suction barrel and a pile embracing structure, and the guide ring is of an annular structure arranged outside the steel pipe pile in a sleeving mode and is suitable for being fixedly connected with the steel pipe pile after pile sinking; the platform is of an annular structure arranged outside the steel pipe pile in a sleeving mode, located above the guide ring and suitable for being fixedly connected with the steel pipe pile after pile sinking. One end of the support frame is connected with the guide ring, and the other end of the support frame is connected with the platform; the suction barrel is connected to the bottom of the supporting frame. The pile embracing structure is suitable for being arranged on the platform and is suitable for embracing the steel pipe pile in the installation process of the steel pipe pile. The integrated offshore wind power foundation provided by the invention is convenient to transport and construct in various sea areas.

Owner:CHINA THREE GORGES CORPORATION

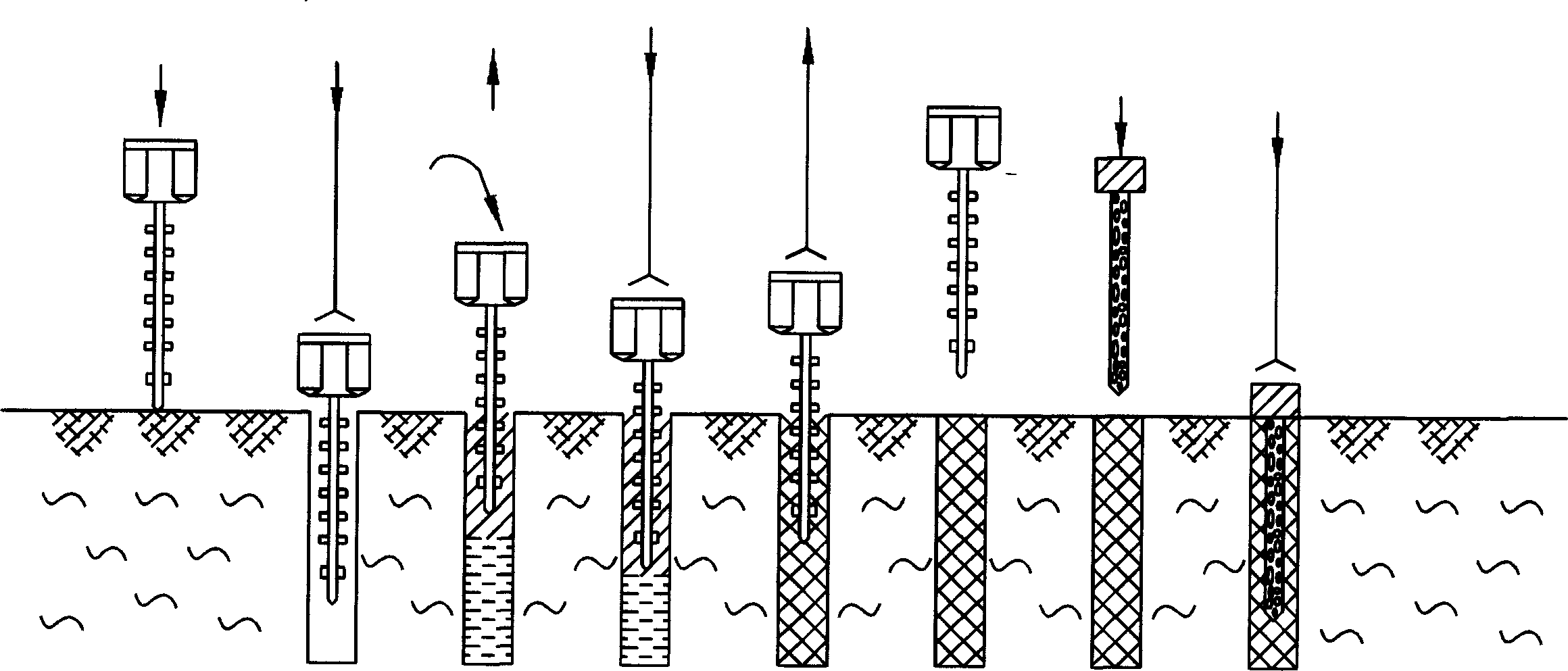

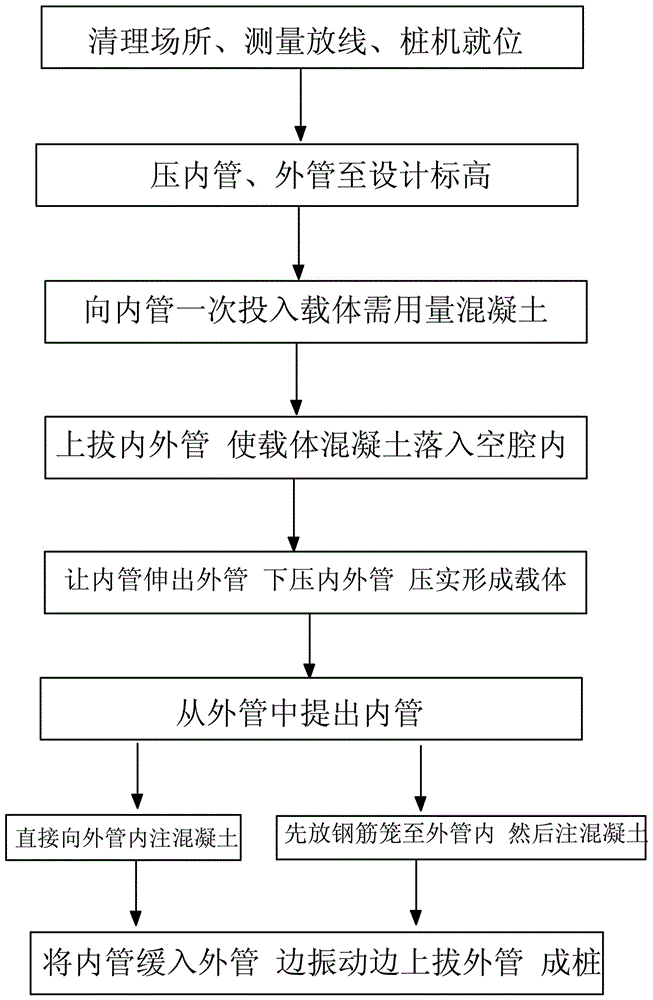

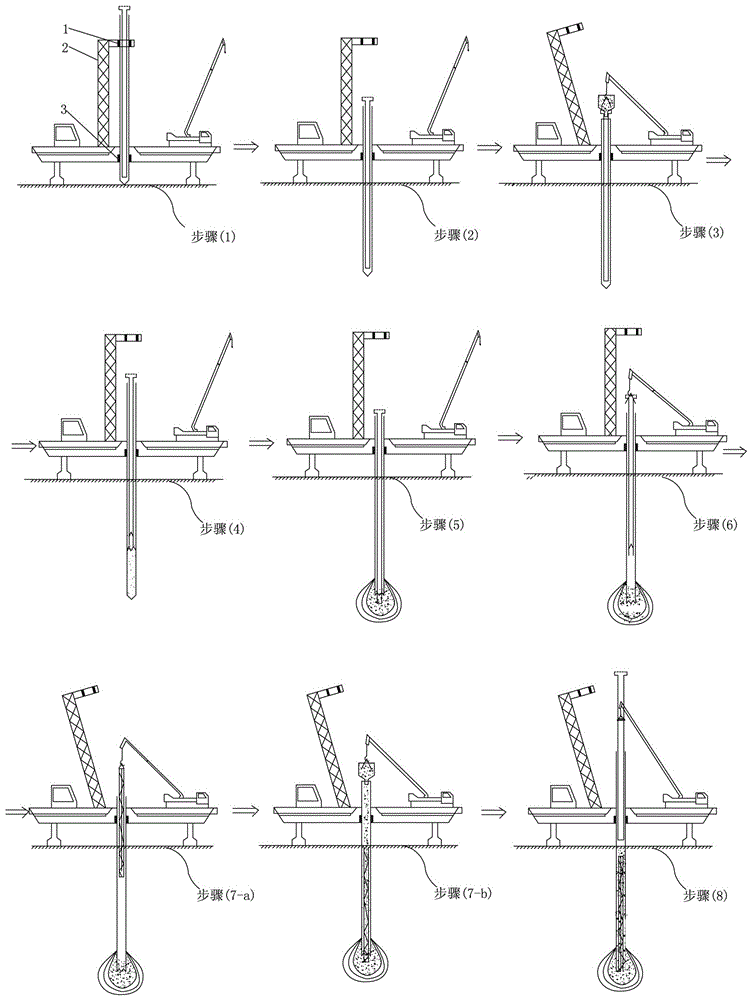

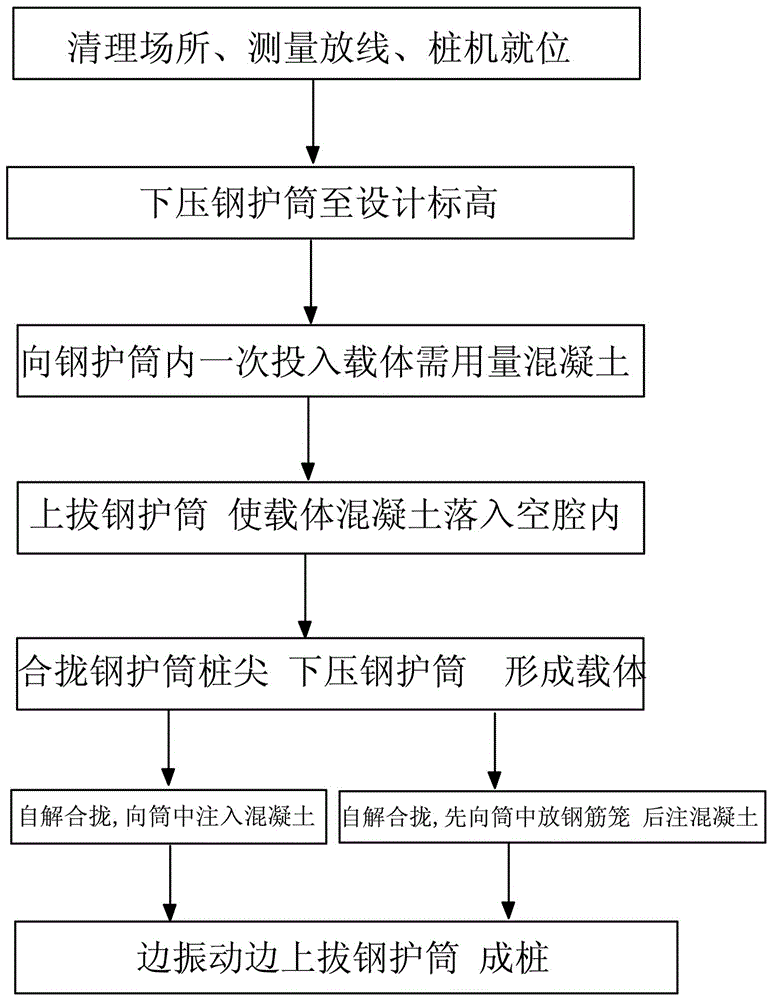

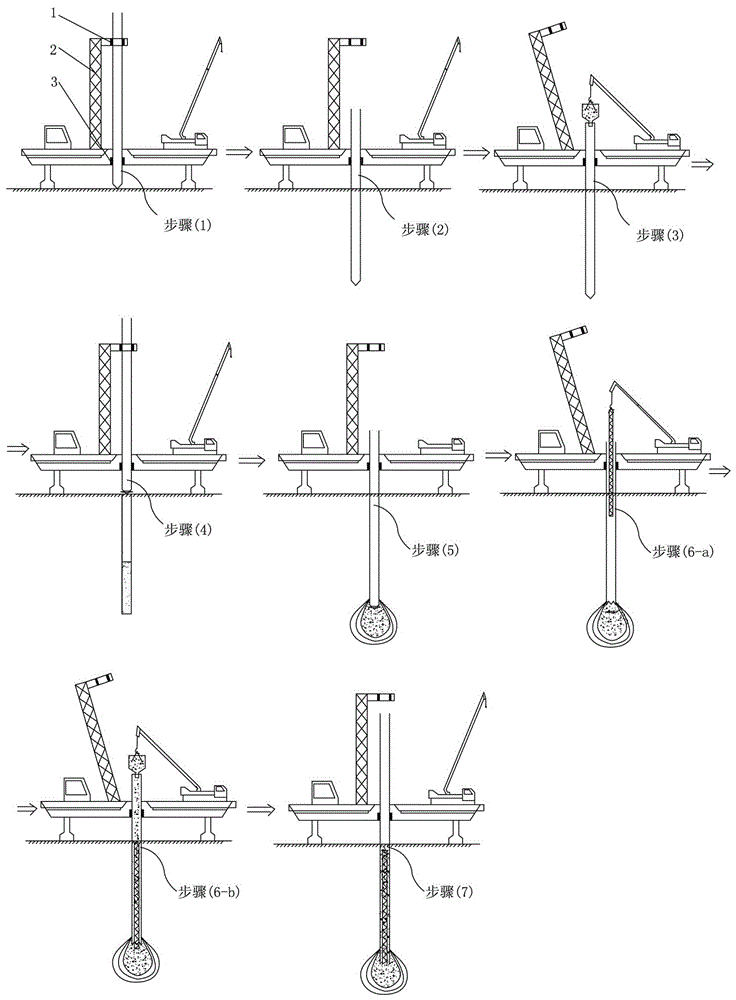

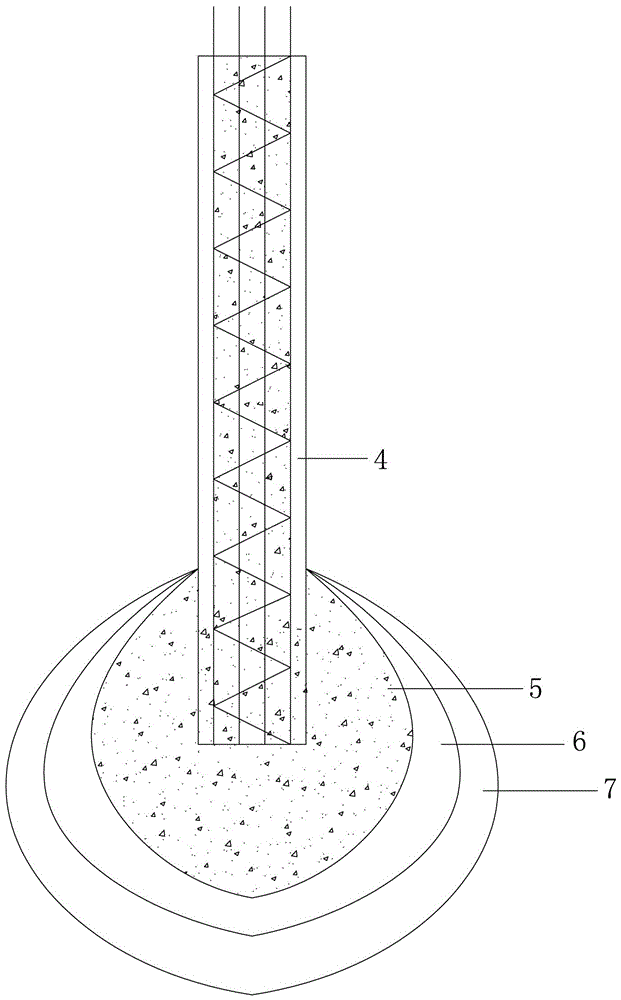

Double-pipe construction method for static pressure pipe-sinking carrier cast-in-place pile

InactiveCN105926594AImprove bearing capacityOvercome the defects of pile forming processBulkheads/pilesDouble tubeArchitectural engineering

The invention provides a double-pipe construction method for a static pressure pipe-sinking carrier cast-in-place pile. The carrier pile is manufactured through a static pile driver, an inner pipe and an outer pipe. Throwing of a carrier concrete material is completed at a time, the pile-forming period is shortened, energy is saved, and the environment is protected; and the pull resistance of the manufactured pile is improved remarkably. The double-pipe construction method includes the following steps that firstly, a site is cleaned, surveying and setting-out are conducted, and the pile driver is moved to a station; secondly, the inner pipe and the outer pipe are pressed to the designed elevation; thirdly, concrete required by a carrier is thrown into the inner pipe at a time; fourthly, the inner pipe and the outer pipe are up-pulled to the set height together, and a space formed when the inner pipe and the outer pipe are up-pulled can be filled with the carrier concrete automatically; fifthly, the inner pipe is lowered, the bottom end of the inner pipe extends out of the bottom end of the outer pipe, the inner pipe and the outer pipe are pressed downwards, the downward pressing force and the elevation reach the preset numerical value, and the expanded carrier is formed; sixthly, the inner pipe is lifted out of the outer pipe; seventhly, concrete is poured into the outer pipe, or a reinforcement cage is placed in the outer pipe firstly, and pile body concrete is poured; and eighthly, the inner pipe is put into the outer pipe, the outer pipe is up-pulled while vibrating, and the pile is formed.

Owner:朱龙

Precast perforated pipe pile and preparation method

InactiveCN101768962AImprove bearing capacityFlexible adjustment of bearing capacityBulkheads/pilesDistribution characteristicSteel tube

The invention provides a precast perforated pipe pile. A perforated pipe and concrete arranged in and out the perforated pipe form a pipe body, and the outer wall of the pipe body is provided with a self-tapping screw which is a spiral bump arranged on the outer wall of the pipe body. The bottom end of the pipe body is a flat head or a tip head, and the top end of the pipe body is a multi-face column and is externally sheathed with a side limited ring. The side limited ring is in a horn shape, and foundation soil is arranged between the pipe body and the side limited ring. The preparation method of the precast perforated pipe pile comprises the following steps: the perforated pipe is manufactured by steel pipes with different specifications, and the thickness is larger than 2 mm; the aperture of perforated holes in the perforated pipe is manufactured by a cutting mode and is determined according to the grain diameter of stone in the concrete, and the distribution of the perforated holes from the pile top to the pile end is determined according to the distribution characteristics of additional stress of the pile; the spiral bump of the outer pipe of the perforated pipe is determined according to the bearing capacity of single pile and the rotational torque; and a variety of parameters of the perforated pipe precast pile are determined according to shared building load, final foundation deformation, foundation soil conditions and conditions for affecting pile sinking.

Owner:吴保全

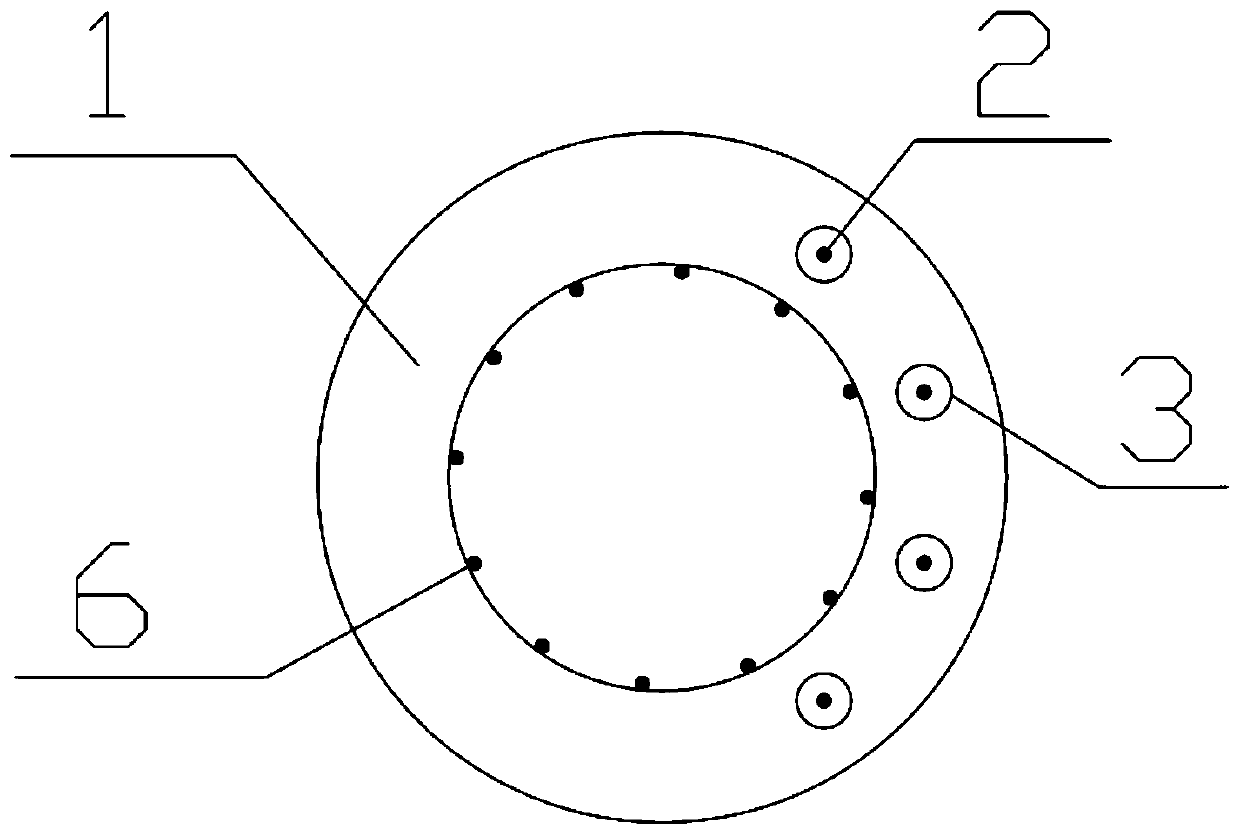

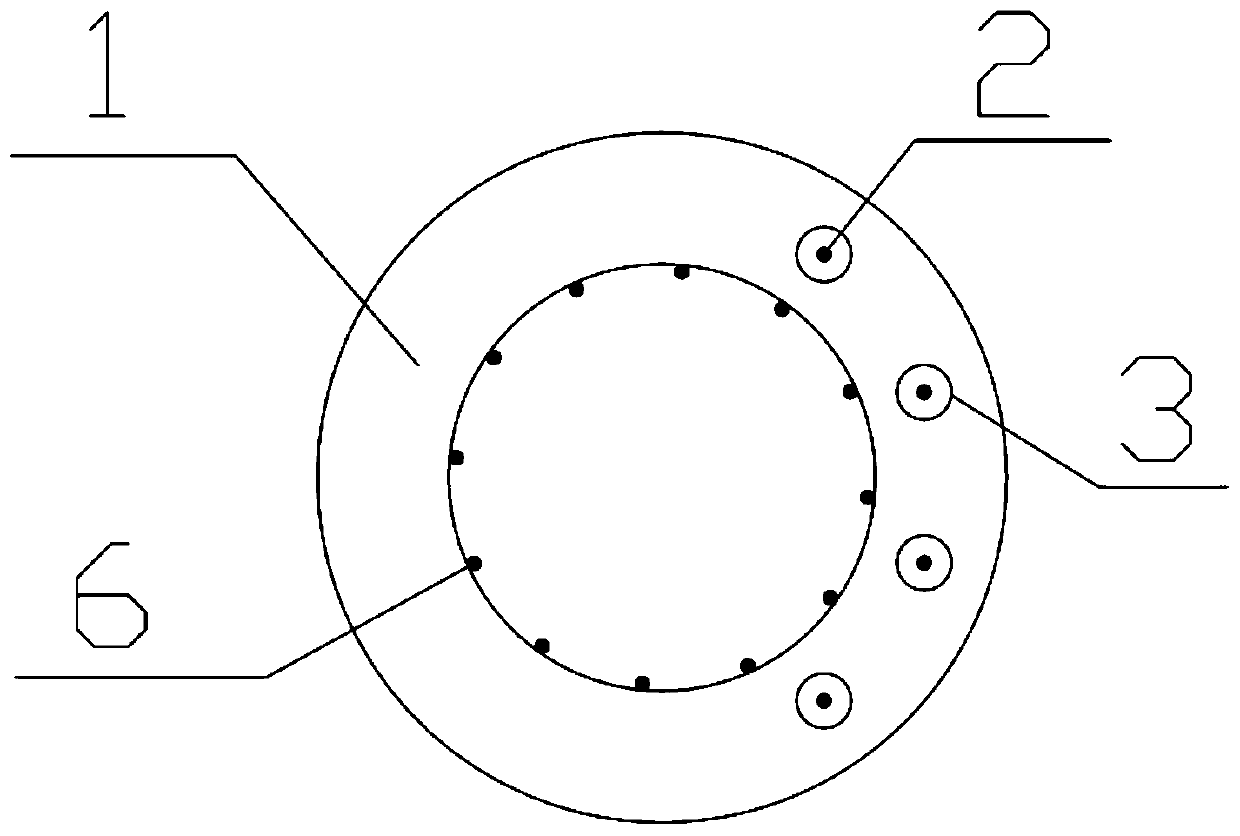

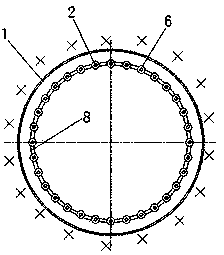

Device for cleaning bored pile steel protective case inner wall mud and application method thereof

InactiveCN103114590BEasy to cleanImprove mechanical propertiesCleaning apparatusBulkheads/pilesStructural engineeringMechanical property

The invention discloses a device for cleaning bored pile steel protective case inner wall mud and an application method thereof. The device comprises an inner barrel, an outer barrel and a pneumatic capsule, wherein the inner barrel and the outer barrel are both in circular shapes, the inner barrel is located in the outer barrel, the circle centers of the inner barrel and the outer barrel coincide, a concrete-filled cavity is arranged between the inner barrel and the outer barrel, and the concrete-filled cavity is filled with concrete. The pneumatic capsule is in a ring shape and is blanketed on the outer barrel. A plurality of arc-shaped steel plates are arranged outside the pneumatic capsule, and all the arc-shaped steel plates are evenly distributed along the circumference direction. The device for cleaning the bored pile steel protective case inner wall mud and the application method thereof are simple in structure, easy in spot operation and capable of being reused. The cleaning effect of the bored pile steel protective case inner wall mud can be improved greatly, the effective bonding of the steel protective case and the pile foundation concrete is further guaranteed, the development of the mechanical property of the steel protective case is improved, and the reinforcement ratio of the pile foundation or the pile diameter can be reduced.

Owner:山东畅通路桥科技股份有限公司 +2

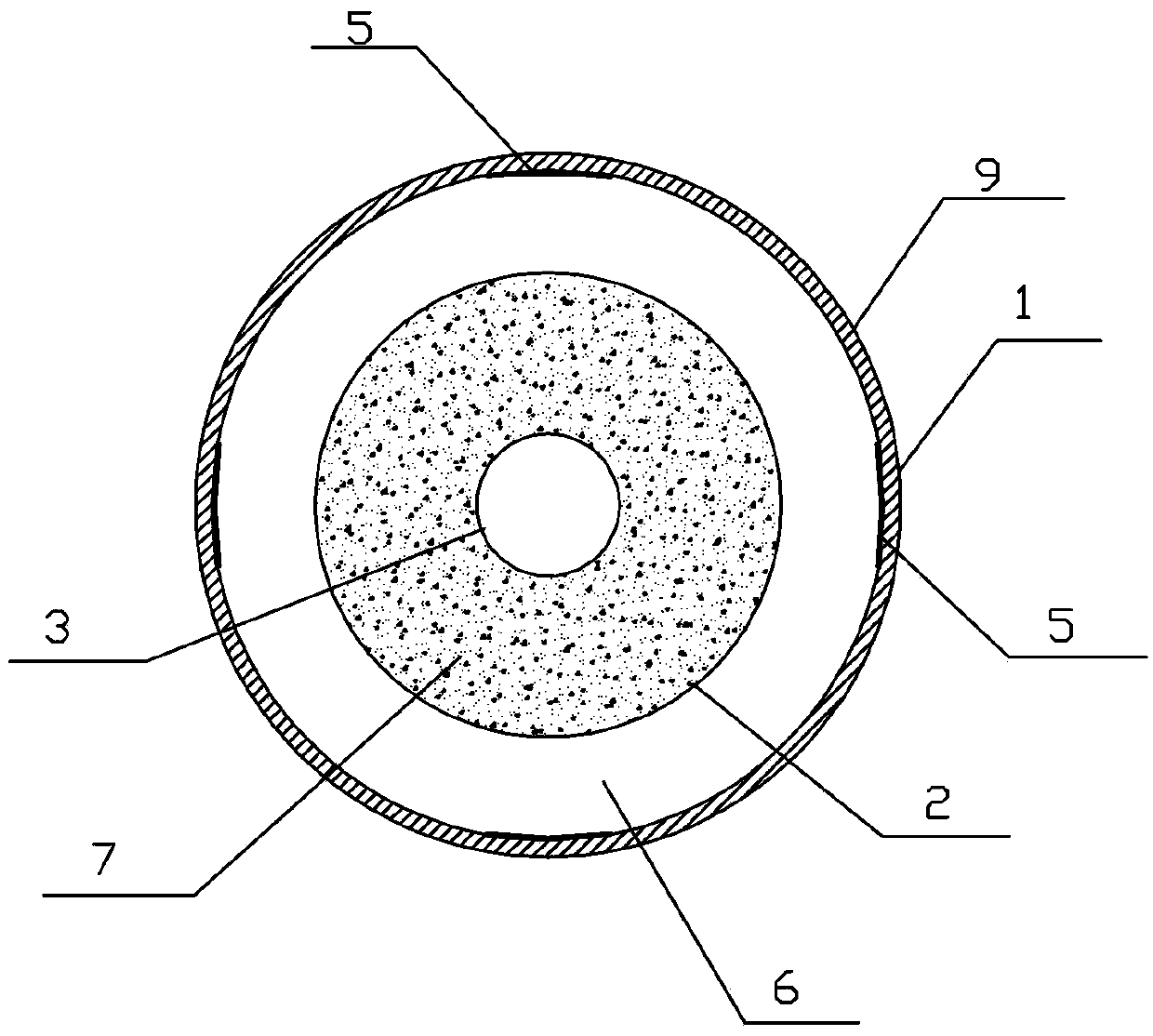

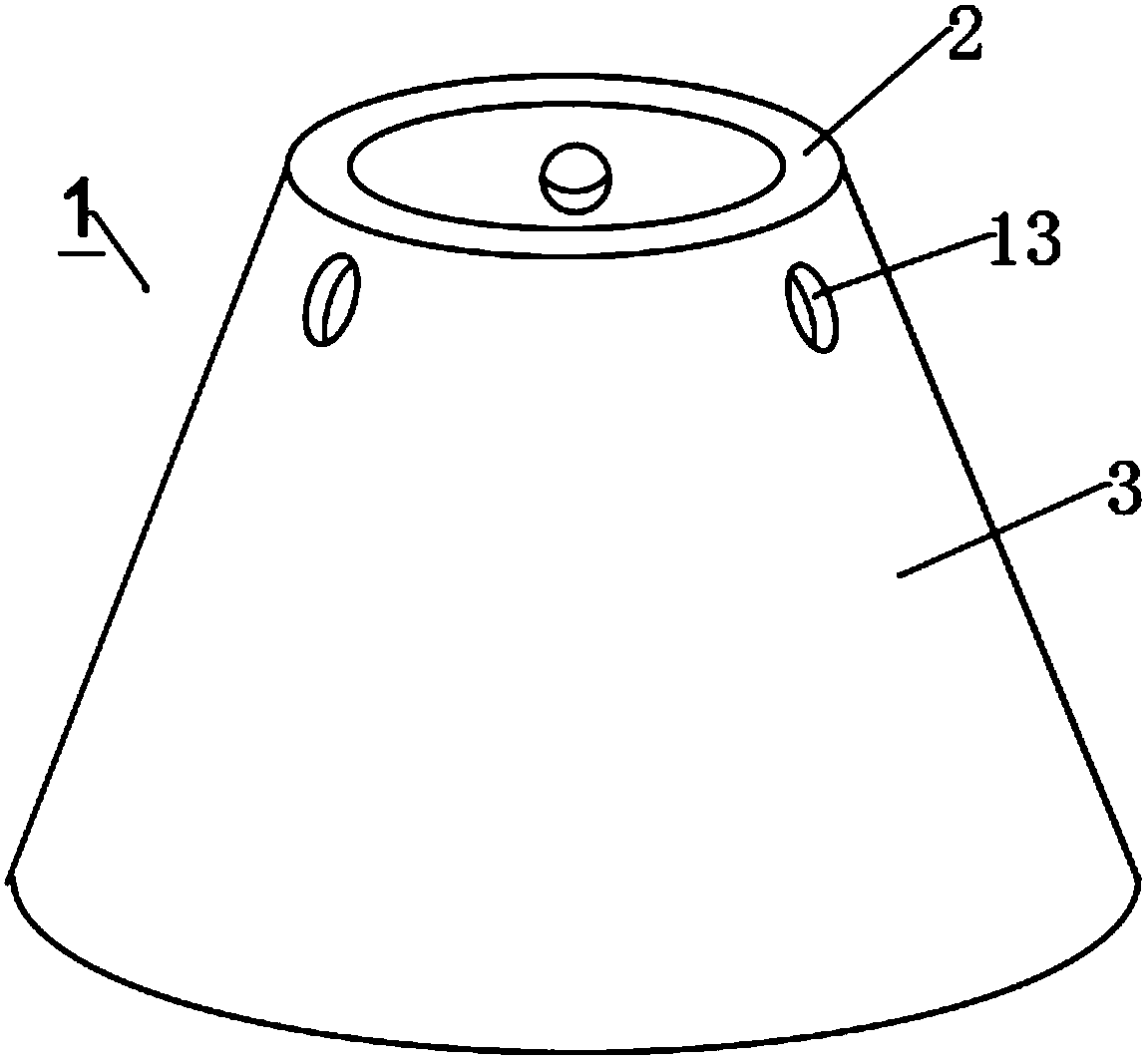

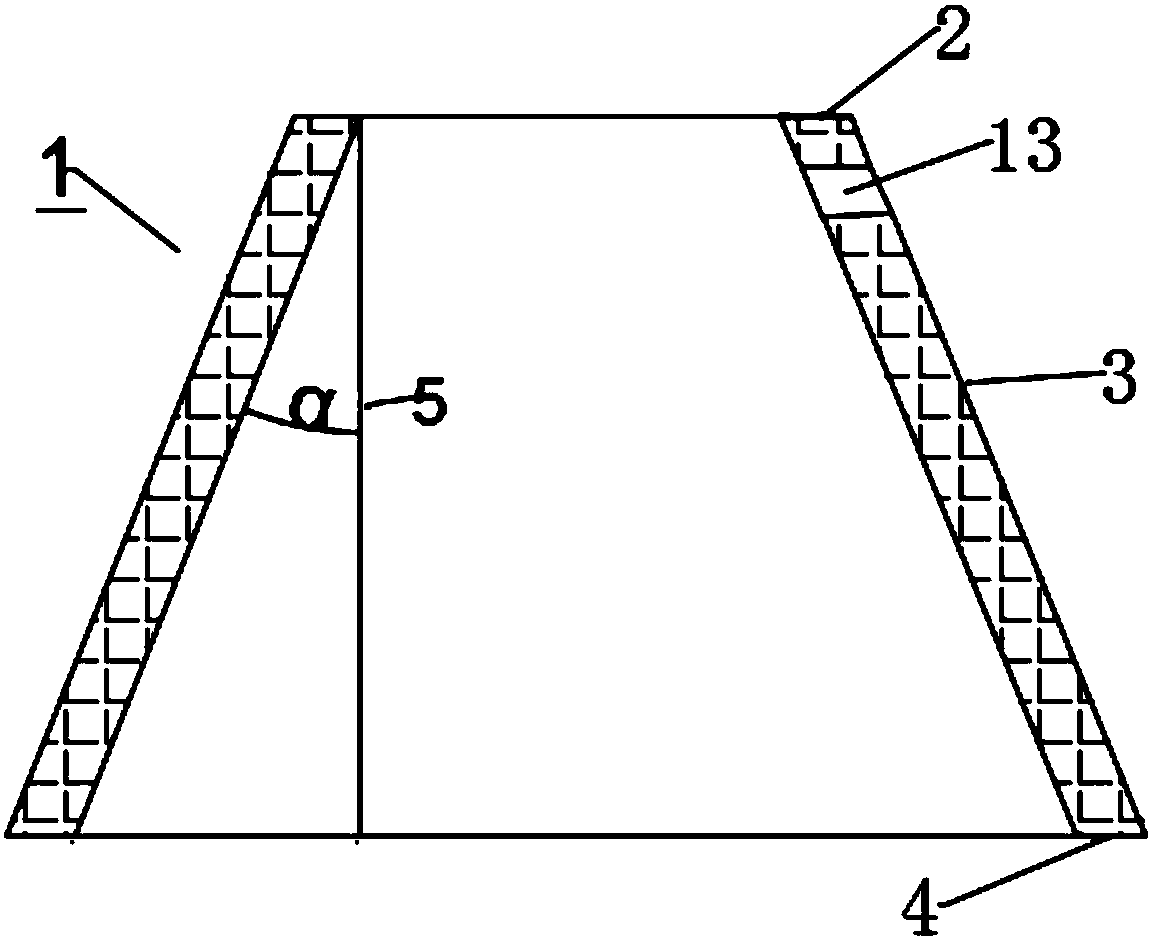

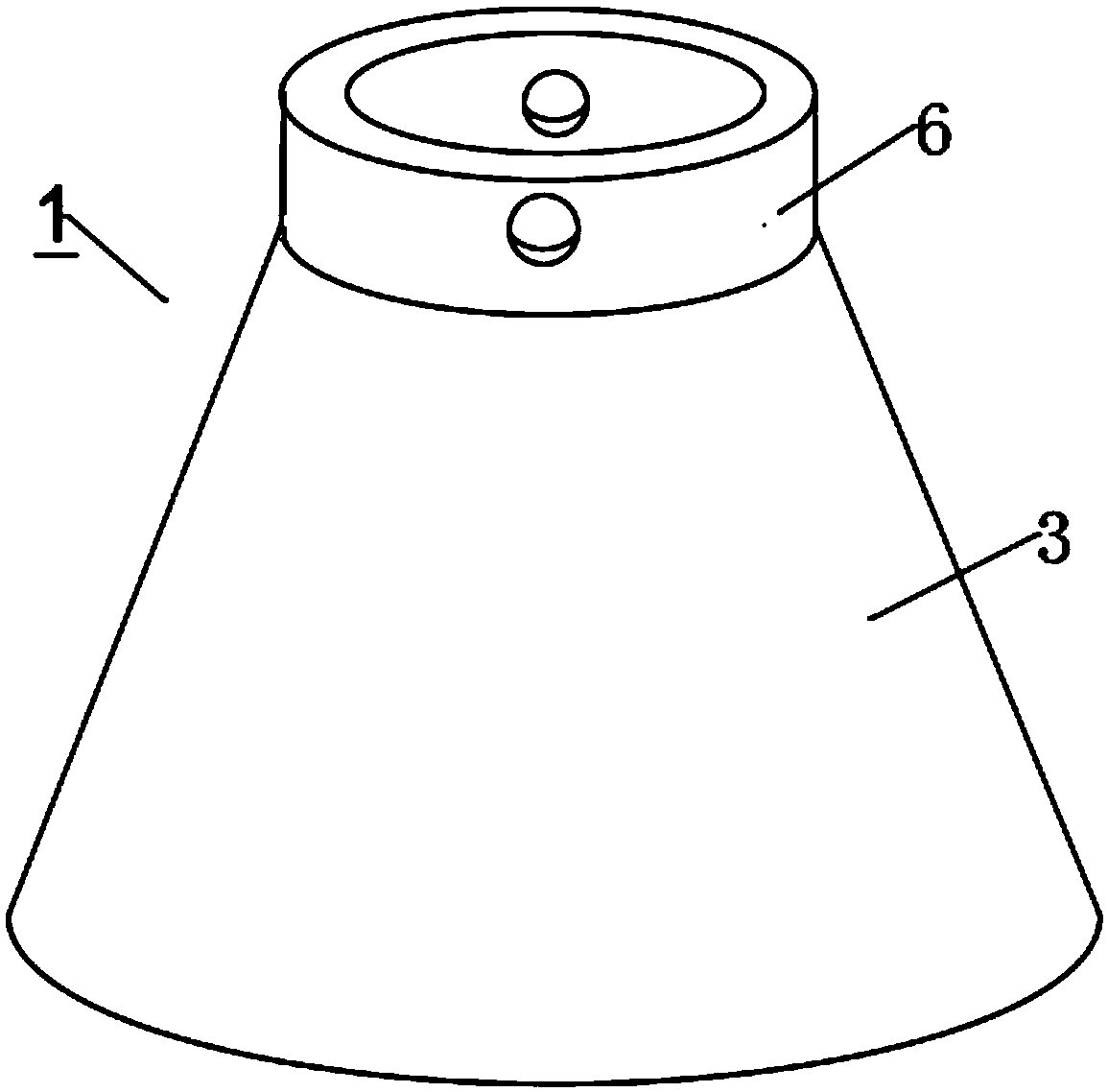

Structure for constructing underwater foundation and mounting method thereof

InactiveCN107724416AEasy constructionReduce erosionBulkheads/pilesRenewable energy source integrationElectricityRound table

The invention discloses an underwater building foundation structure which is a hollow round-table-shaped structure. The structure is characterized in that the advantages, such as clear force-bearing state, high soil applicability, convenient construction and high horizontal bearing capacity of the round table structure, of a single-pile foundation, are fully utilized; the overall rigidity, the horizontal load resistance, the vertical load resistance and the anti-bending capacity of the structure are greatly improved; the bending load caused by wind turbine load to the foundation can be effectively reduced; the horizontal displacement of a wind-powered generations structure is reduced; the sedimentation value is decreased. Therefore, the pile length, the pile diameter, the wall thickness and the extending depth of the pile foundation can be reduced; the material cost is greatly decreased; the construction technology is simple. The structure also has the characteristics of being resistant to corrosion, and long service life in water. The invention also discloses a method for mounting the underwater building foundation structure. The underwater building foundation structure can be mounted in an area with complex underwater condition through the method.

Owner:CHINA METALLURGICAL CONSTR HIGH TECH ENG TECH CO LTD

Drilling and high-pressure grouting construction method for uplift pile

ActiveCN104727305AReduce consumptionImprove pullout resistanceBulkheads/pilesSocial benefitsHigh pressure

The invention discloses a drilling and high-pressure grouting construction method for an uplift pile. The drilling and high-pressure grouting construction method includes the steps that step1, construction preparation is performed; step2, paying-off positioning is performed; step3, a drilling machine is in place; step4, drilling is performed; step5, casing running is performed; step6, drilling is continued to a designed elevation; step7, hole sealing grouting is performed; step8, concrete pouring is performed; step9, steel bars are inserted; step10, drilling tool and earthwork clearing is performed. The drilling and high-pressure grouting construction method has the advantages that in the drilling process, noise is low, vibration is small, the construction period is short, influences on surrounding traffic and social activities are small, and the construction method is a green construction method; while the uplift bearing capacity of a foundation is improved, the construction method saves a lot of resources and energy, and has remarkable social benefits.

Owner:ANHUI TONGJI CONSTR GRP

Multifunctional comprehensive fan single-pile type foundation and dynamic damping adjusting method thereof

ActiveCN112761177ARealize dynamic adjustmentReduced installation depthClimate change adaptationWind motor supports/mountsArchitectural engineeringWater flow

The invention discloses a multifunctional comprehensive fan single-pile type foundation and a dynamic damping adjusting method thereof. The multifunctional comprehensive fan single-pile type foundation comprises a single-pile type foundation body with an operation platform, a hydraulic damper, a fixing frame and a fixing pile; the hydraulic damper is provided with a mounting position allowing the single-pile type foundation body to penetrate through; the single-pile type foundation body penetrates through the mounting position of the hydraulic damper and is fixedly connected to the hydraulic damper through the fixing frame; one end of the fixing pile is installed at the bottom of the hydraulic damper, the other end of the fixing pile is driven into a seabed to be fixed, and the fixing pile is used for fixing the hydraulic damper to the seabed; a plurality of one-way valves are arranged on the hydraulic damper, in the process of changing the internal volume of the hydraulic damper, external water can be injected into the hydraulic damper or existing water in the hydraulic damper can be discharged through the one-way valves; and meanwhile, water flow is adjusted, so that dynamic adjustment of damping is achieved, the structural stability of the single-pile type foundation is improved, and economical efficiency is improved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

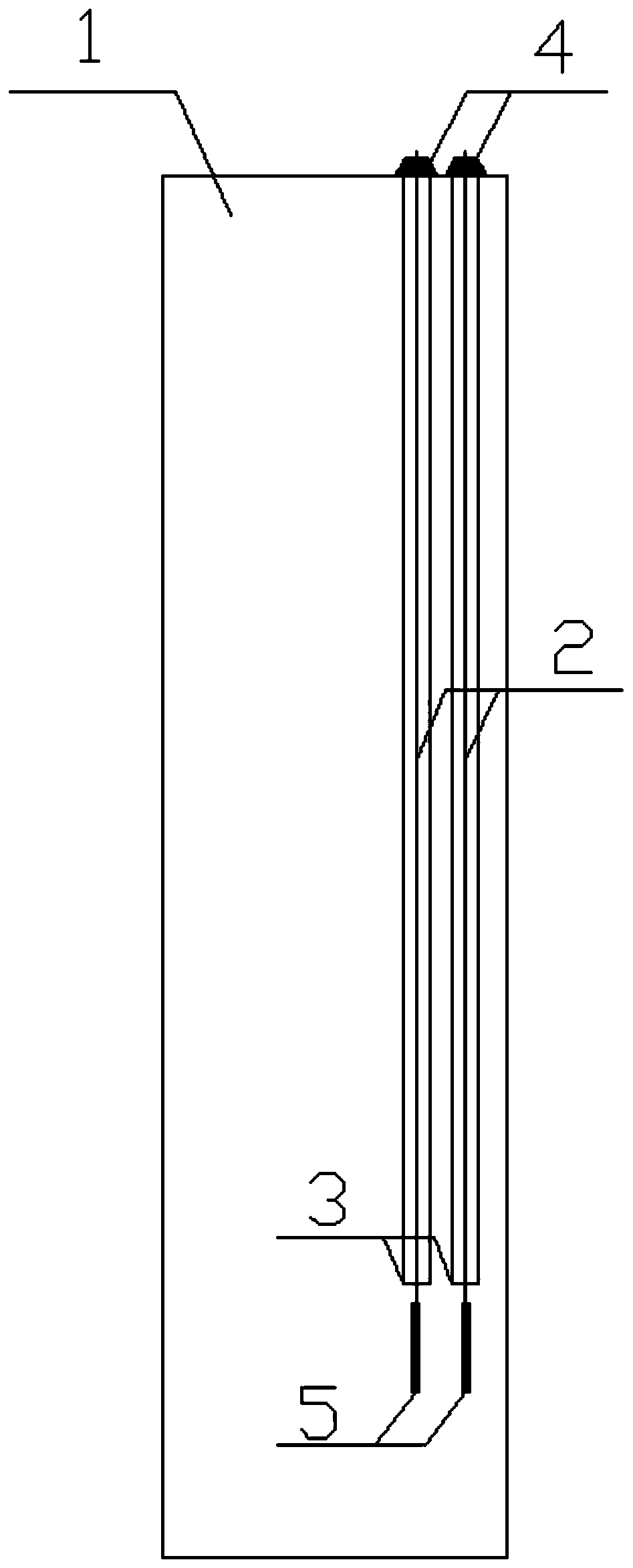

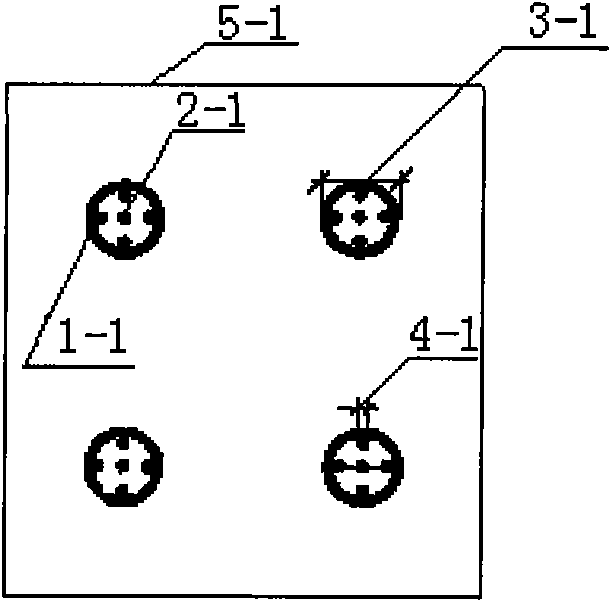

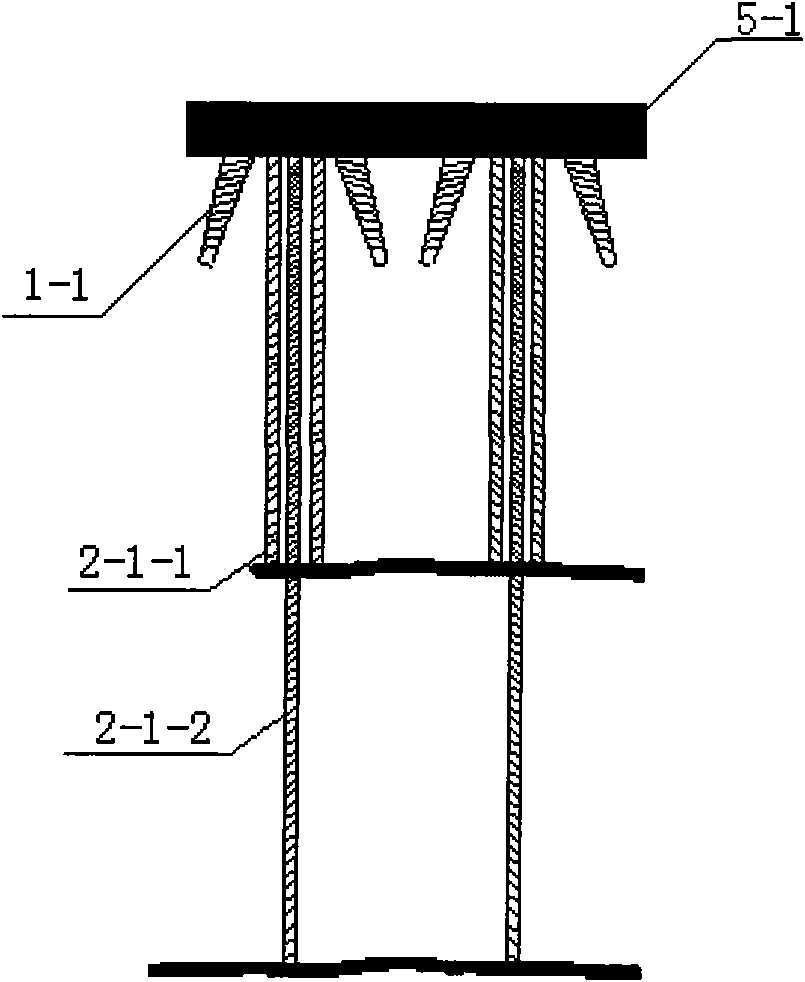

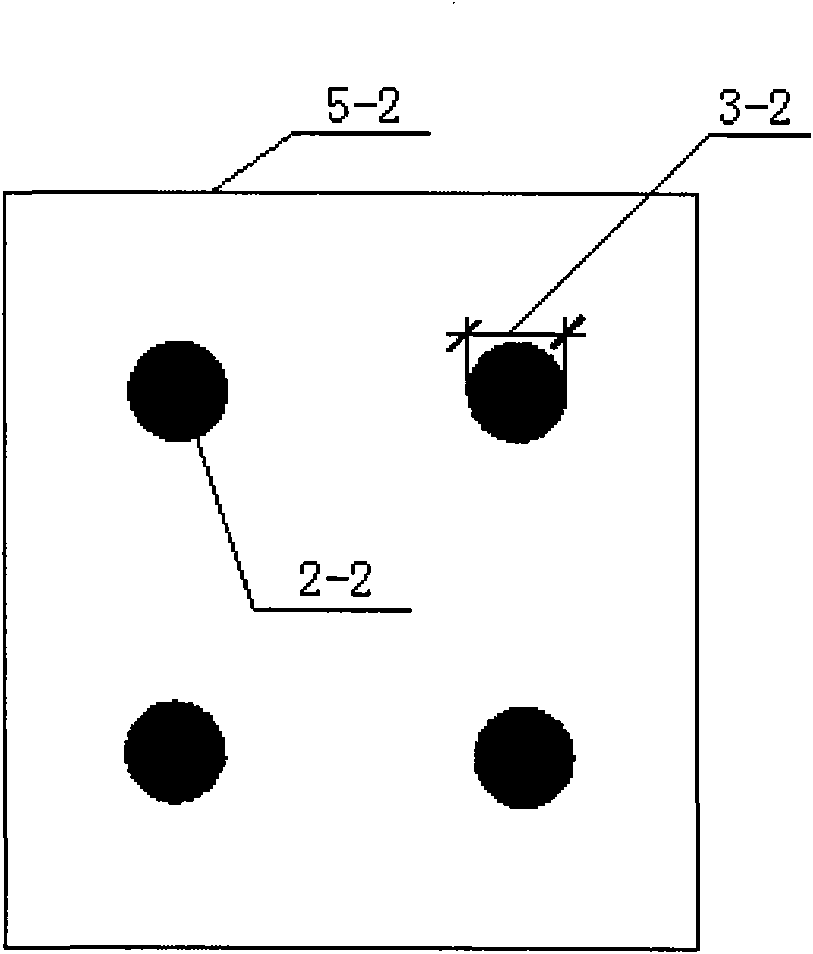

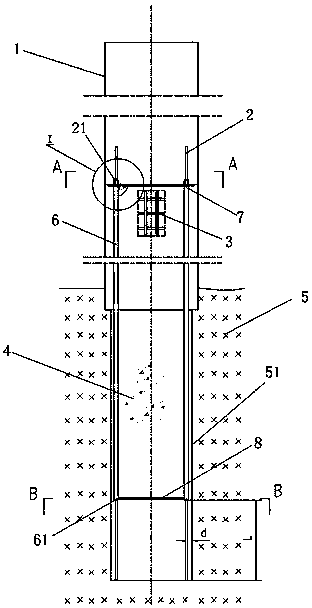

Prestressed reinforcement rock-socketed cast-in-place pile and construction method thereof

InactiveCN103410144AReduce pile diameterImprove bending abilityBulkheads/pilesPre stressHigh intensity

The invention discloses a prestressed reinforcement rock-socketed cast-in-place pile which comprises a steel casing of the cast-in-place pile and a plurality of reinforcing steel bars, wherein the plurality of reinforcing steel bars are respectively sleeved in a steel sleeve; the lower ends of the reinforcing steel bars extend out of a closure plate; the upper ends of the reinforcing steel bars are fixedly connected with the lower side of an anchoring plate respectively; a plurality of transverse connecting pipes are communicated with the lower ends of the reinforcing steel bars respectively; the plurality of reinforcing steel bars extending out of the anchoring plate respectively are stretched one by one to form prestressed reinforcements, and the steel sleeve is fully filled with cement paste. The invention also discloses a construction method of the prestressed reinforcement rock-socketed cast-in-place pile. The method comprises the following steps of 1, preparation before embedding of the reinforcing steel bars; 2, embedding of the reinforcing steel bars; 3, concrete pouring; 4, stretching of the prestressed reinforcements; 5, filling of the steel sleeve 6 by the cement paste; 6, concrete pouring and sealing. Due to the adoption of the prestressed reinforcement rock-socketed cast-in-place pile construction method, the bending resistance of the rock-socketed cast-in-place pile can be greatly enhanced by applying prestress to the high-tensile reinforcing steel bars, the diameter of the rock-socketed cast-in-place pile is reduced, and the construction cost is lowered.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 3RD ENG

Construction method for reinforcing foundation of soft soil area

InactiveCN102162245AMeet the construction qualityEasy to operateBulkheads/pilesOperabilityBuilding construction

The invention discloses a construction method for reinforcing the foundation of a soft soil area. The construction method comprises the following steps of: preparing a construction facility; preparing a construction plant; measuring and lofting and the like. The construction method is a safe, economic and efficient construction method for reinforcing the foundation of the soft soil area. The method is high in on-site operability, and can be popularized easily; moreover, by the method, the construction safety and the construction quality of foundation reinforcement of a filling area beside an operation line of the soft soil area are guaranteed.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

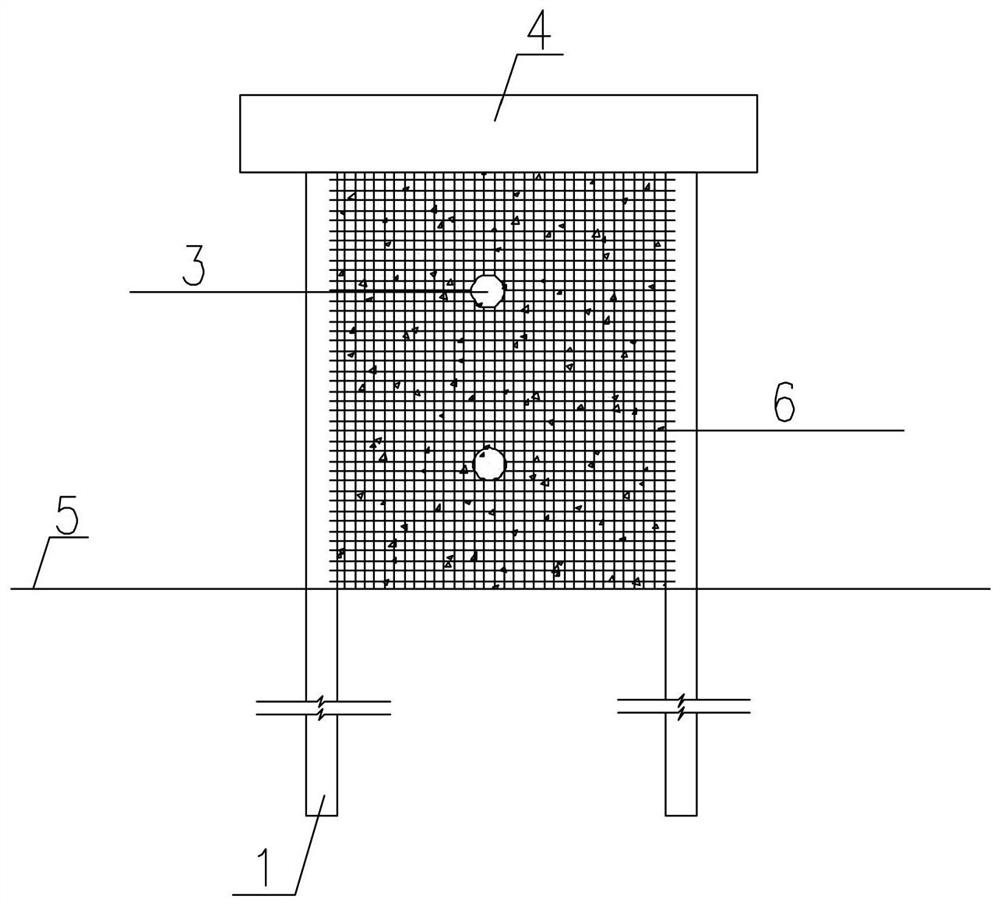

Composite pile structure for iron tower of electric transmission line

The invention relates to a composite pile structure for an iron tower of an electric transmission line. The composite pile structure comprises a pile body and pile body fastening pieces. The pile body fastening pieces are arranged on two sides of the pile body. Compared with the prior art, the composite pile structure has the advantages of shortening length of the pile body, effectively reducing horizontal displacement, saving concrete dosages, and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Single-pile-casing construction method for static pressure sinking pipe carrier cast-in-place pile

The invention discloses a single-pile-casing construction method for a static pressure sinking pipe carrier cast-in-place pile. A static pile driver and a single pile casing can be used for manufacturing the carrier pile; carrier concrete materials are put in at a time, the construction speed is obviously increased, and energy conservation and environment friendliness are achieved; and the pulling resistance of the carrier pile manufactured through the static pile driver and the single pile casing is obviously improved. The method includes the following steps that firstly, a field is cleaned, surveying and setting out are conducted, and the static pile driver is moved to a station; secondly, the steel pile casing provided with a conical valve pile tip is pressed to the designed elevation; thirdly, concrete with the amount needed by a carrier is put into the steel pile casing at a time; fourthly, the steel pile casing is pulled upwards to be exposed out of the ground, and the space formed by upward pulling of the steel pile casing is automatically filled with the put-in carrier concrete ; fifthly, the pile tip is closed, the steel pile casing is pressed downwards, the downward pressing force and the elevation reach preset values, and the carrier concrete is compacted to form an expanded carrier; sixthly, closing is automatically relieved, pile body concrete is poured, or a reinforcement cage is firstly placed, and then concrete is poured; and seventhly, the steel pile casing is pulled out of the ground while vibration is conducted, and the pile is formed.

Owner:朱龙

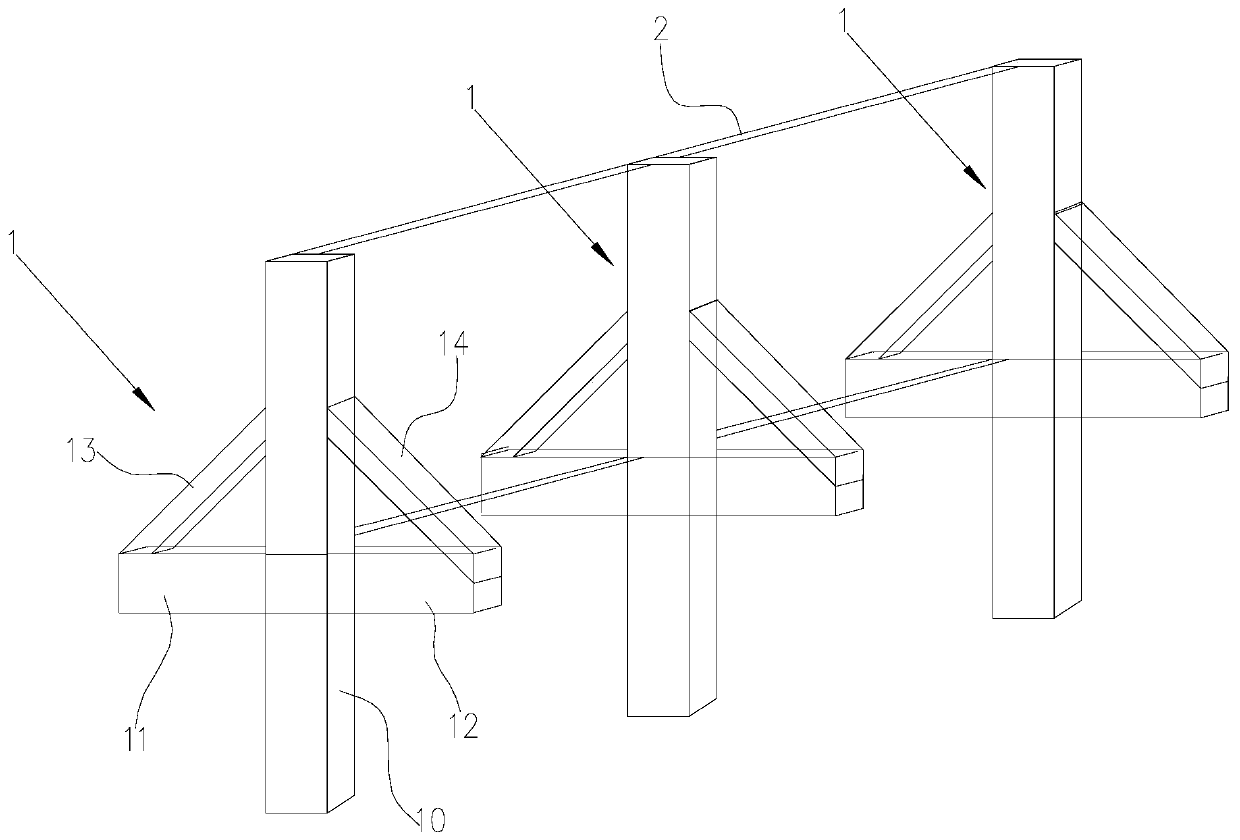

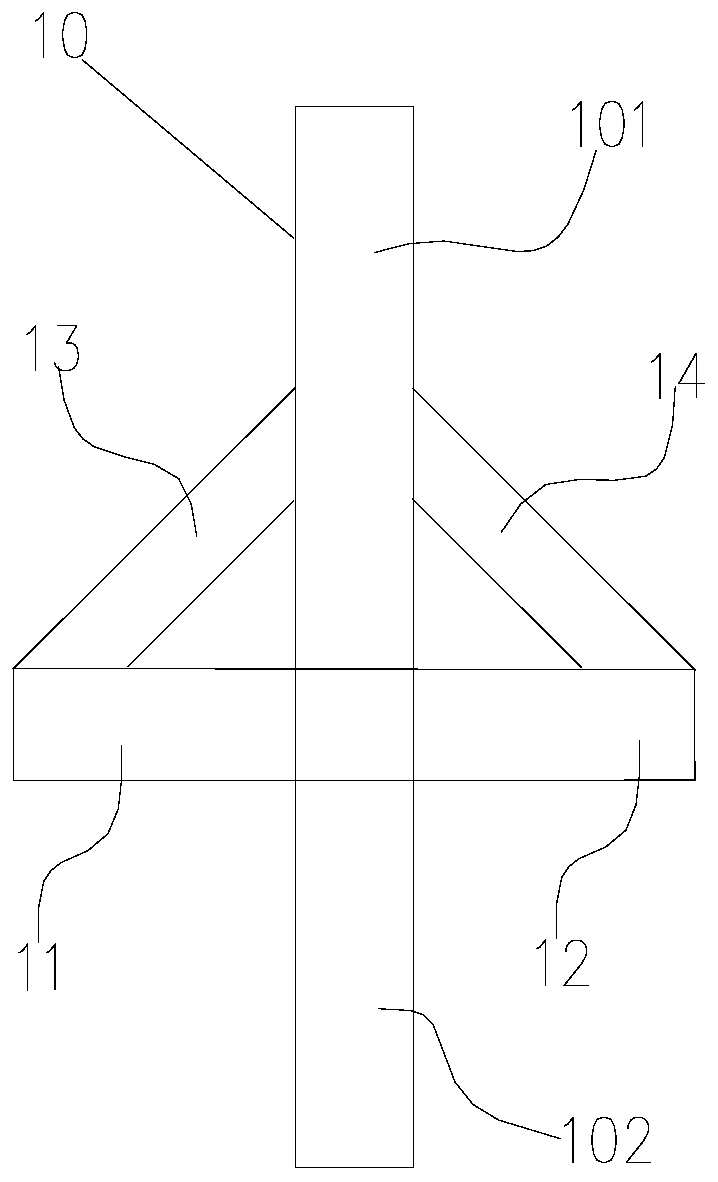

Umbrella-type supporting structure for slope prevention and control and construction method thereof

PendingCN111576455AReduce side loadEffective supportExcavationsBulkheads/pilesArchitectural engineeringInternal forces

The invention discloses an umbrella-type supporting structure for slope prevention and control and a construction method thereof. The umbrella-type supporting structure comprises a plurality of supporting units which are arranged at intervals and soil baffles arranged between the adjacent supporting units; the supporting units comprise vertical piles, toe beams, heel beams, bracing beams and diagonal beams, wherein the toe beams and the heel beams are vertically and rigidly connected to the two side faces of the vertical piles, the bracing beams are rigidly connected between the toe beams andthe vertical piles, and the diagonal beams are rigidly connected between the heel beams and the vertical piles; and the soil baffles are arranged between the adjacent vertical piles, and included angles are formed between the bracing beams and the vertical piles as well as between the diagonal beams and the vertical piles correspondingly. The umbrella-type supporting structure can resist the larger lateral load of a soil body, and is high in deformation-resisting capacity, good in supporting effect, small in structural internal force, safe and economic.

Owner:CCTEG CHONGQING ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com