Device for cleaning bored pile steel protective case inner wall mud and application method thereof

A technology of bored piles and steel casings, which is applied to sheet pile walls, cleaning equipment, earthwork drilling and mining, etc., can solve the problems that there are no clearing devices and construction technical requirements, etc., and achieve simple structure, effective bonding, and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

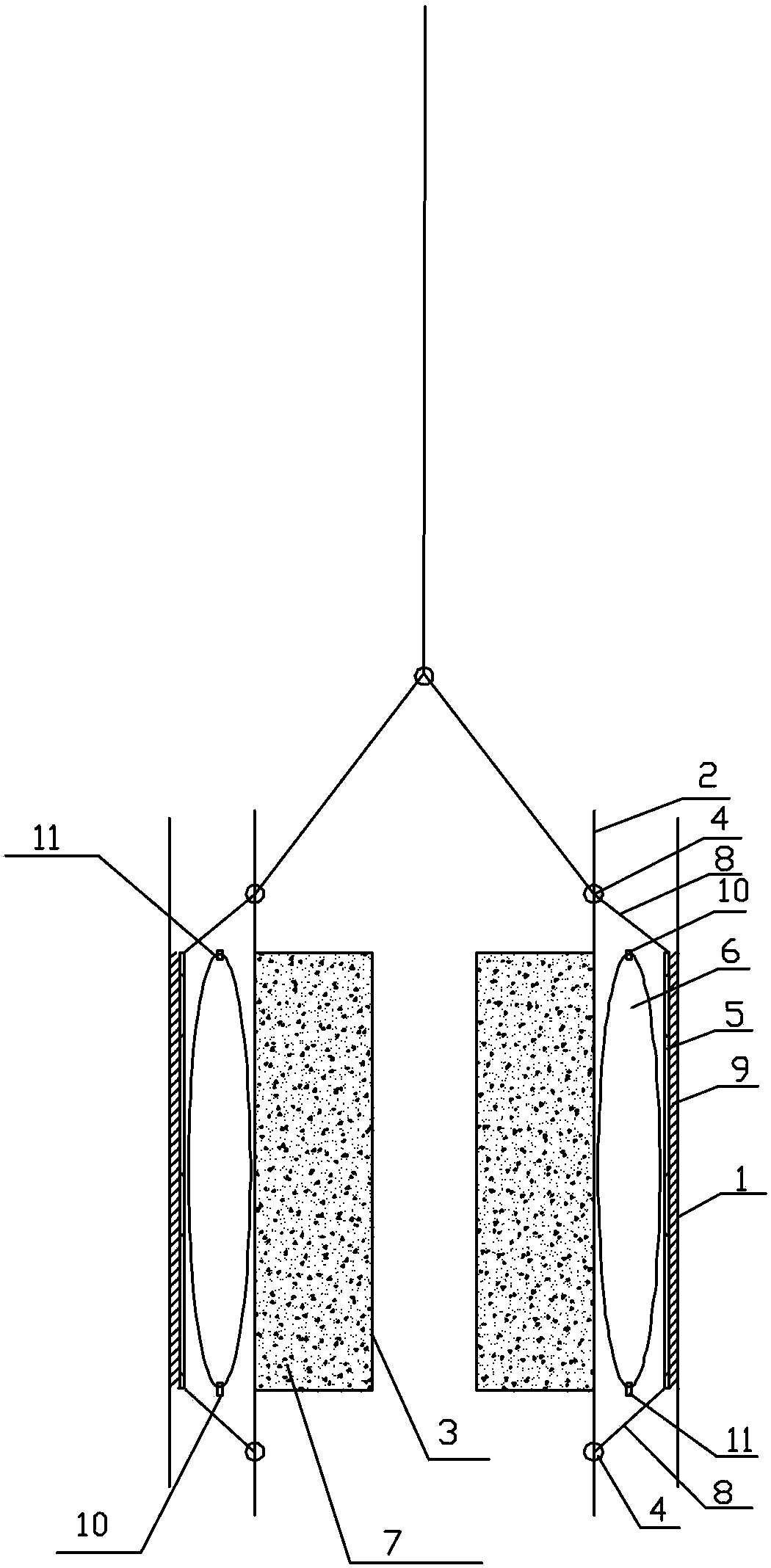

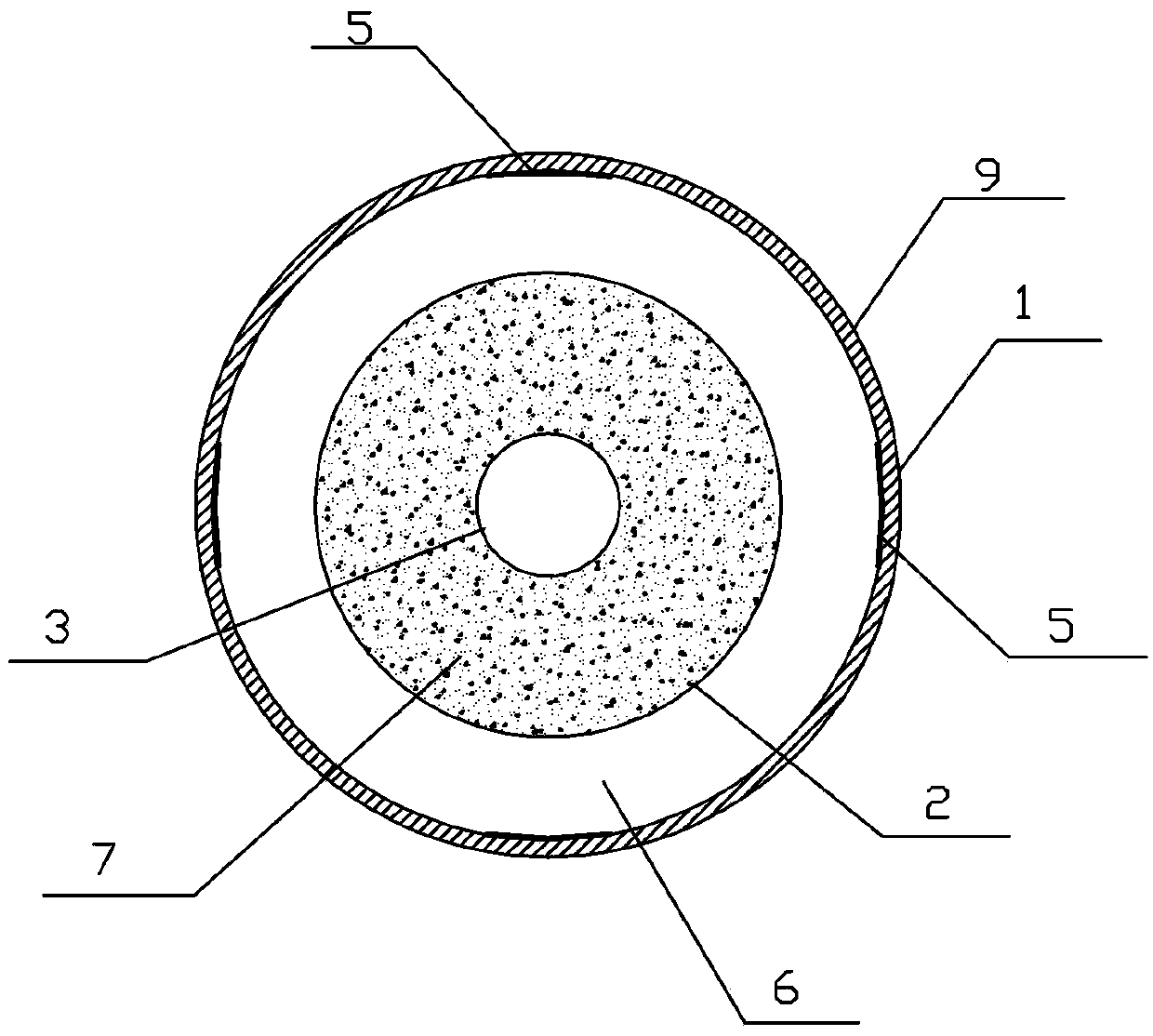

[0018] combine figure 1 and figure 2 , a device for removing the mud on the inner wall of the steel casing of the bored pile, comprising an inner cylinder 3, an outer cylinder 2 and an air-filled capsule 6. Both the inner cylinder and the outer cylinder are circular, the inner cylinder is located in the outer cylinder, the centers of the inner cylinder and the outer cylinder coincide, a concrete filling cavity is arranged between the inner cylinder and the outer cylinder, and the concrete filling cavity is filled with concrete 7 . The above-mentioned inflatable capsule is ring-shaped and surrounded by the outer cylinder; several arc-shaped steel plates 5 are arranged outside the above-mentioned inflatable capsule, and all the arc-shaped steel plates are evenly arranged along the circumferential direction. The length (height) of the above-mentioned device is about 100-300 cm, that is, the height of the outer cylinder is about 100-300 cm.

[0019] More specifically:

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com