Method for constructing steel pipe upright pile through semi-reversed-construction method

A technology of steel pipe column and construction method, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inability to meet large-scale mass production, limited number of machines, and long construction period, and achieve better economy and operation Convenient, cost-effective and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

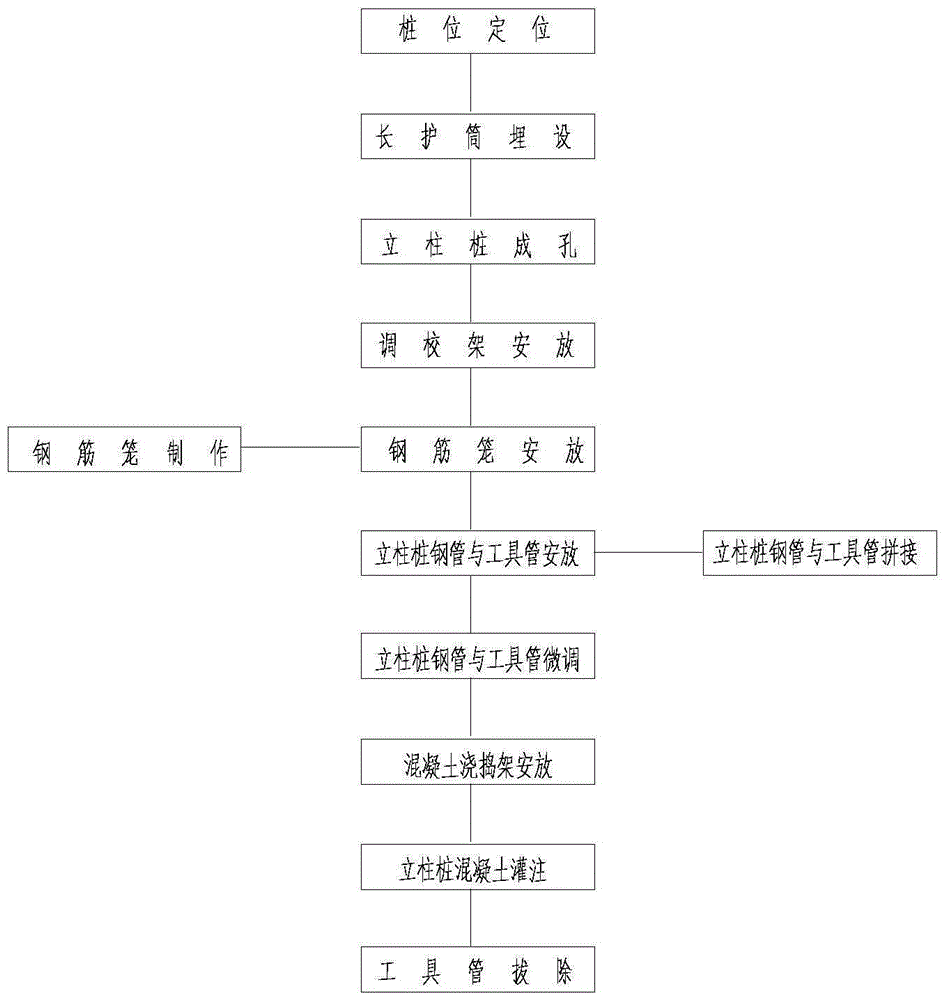

[0035] Embodiment 1: A construction method for steel pipe column piles with semi-reverse method, comprising the following construction steps:

[0036] (1) Pile position positioning, the specific process is: 1.1, calculate the coordinates of each pile position according to the design drawings, and determine the positional relationship between each pile hole and adjacent control points; 1.2, repair the site, after the pile position coordinates are checked and correct , use the total station to accurately locate in the construction site; 1.3, taking the center of the pile as the intersection point, measure 4 protective piles in the longitudinal and transverse directions and bury them;

[0037] (2) The long casing is buried, the specific process is: 2.1, according to the requirements of hole forming accuracy and the need of hydraulic jack to adjust the fulcrum, customize a 3-5m long steel casing, and the inner diameter of the casing is 20cm larger than the outer diameter of the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com