Self-supporting construction method for multilayer underground structure next to existing building

A technology for existing buildings and underground structures, applied to underwater structures, foundation structure engineering, construction, etc., to achieve the effect of reducing engineering volume, shortening pile length and pile diameter, and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

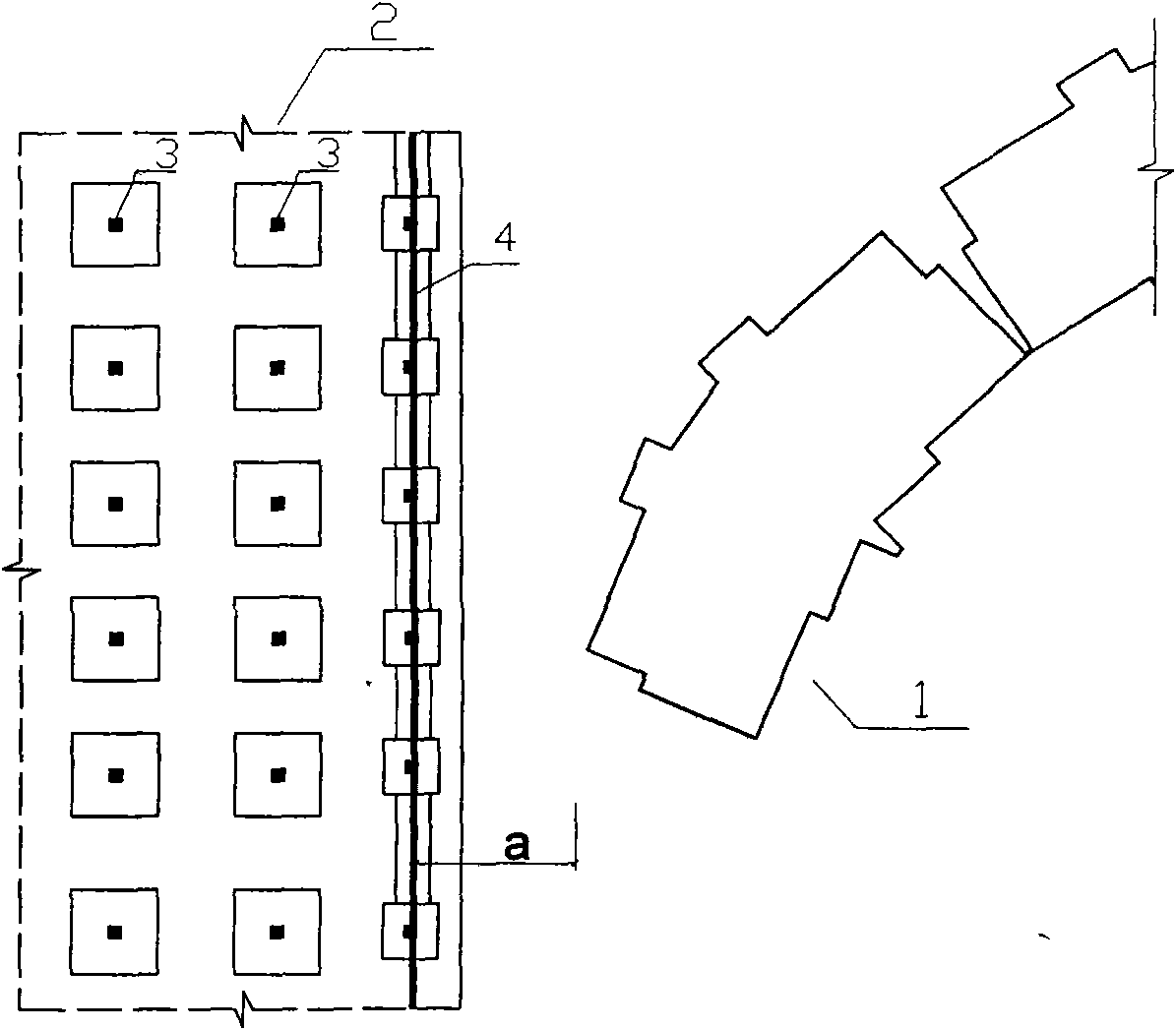

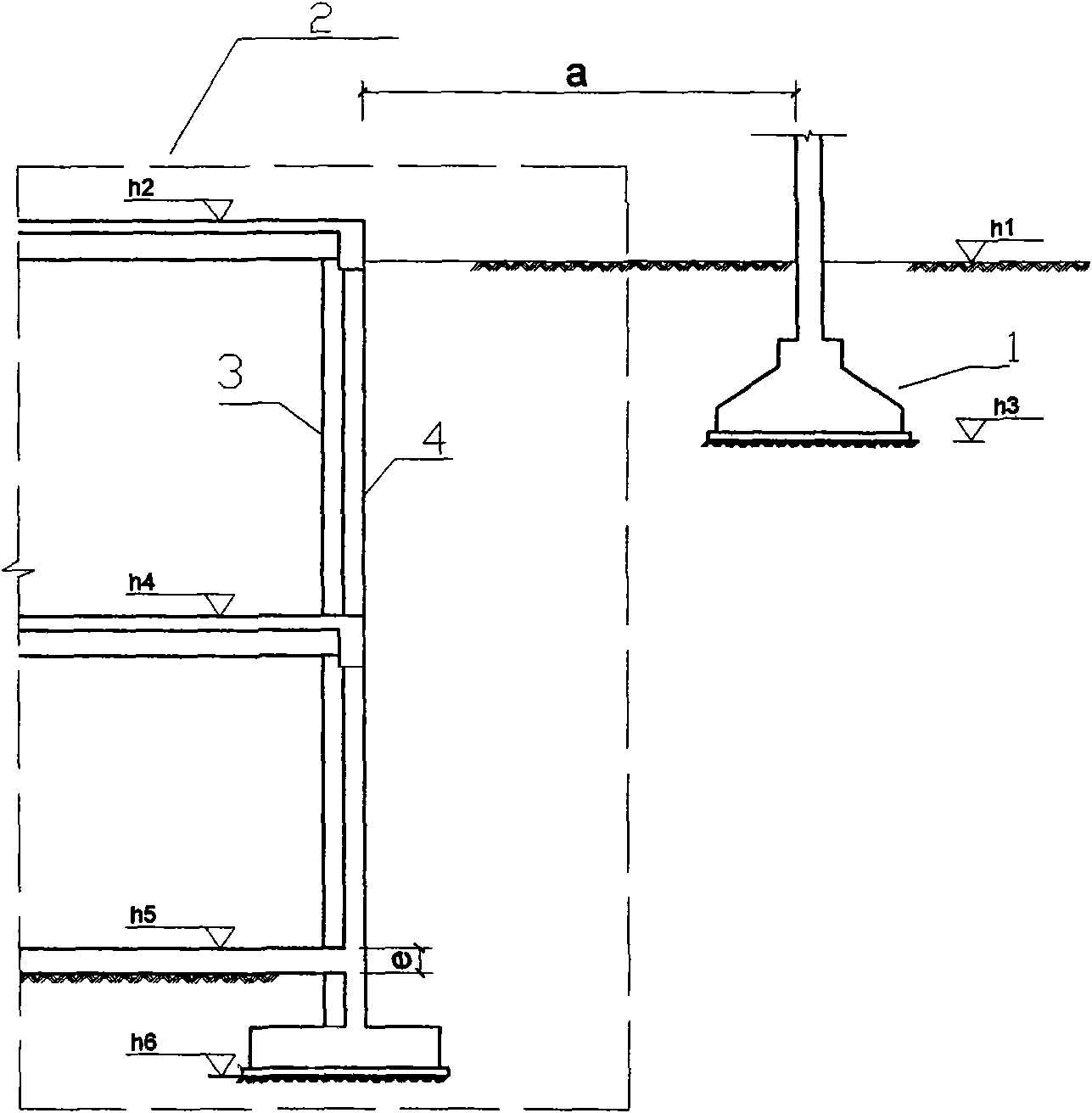

[0071] Example 1: Anqing Xiangzhangli. Nashui’an Residential Community is located at Huxin North Road, Anqing City, Anhui Province. The underground garage 2 of the community is designed to have two floors, and the building area of each floor is 4232m2 2 . Among them, the basement floor is an ordinary basement, which is used for bicycle storage, garages and equipment rooms in normal times. The east side of the proposed underground garage and the existing 11 # The residential building 1 is next to, and the shortest distance is only about 5m. If the earthwork excavation is directly carried out on the underground garage 2, it will certainly endanger the existing 11 # The main structure of residential building 1 is safe (see the relative position for details figure 1 , figure 2 ). Adopting the inventive method to carry out garage 2 constructions in construction process has guaranteed existing 11 # The safety of the residential building 1 speeds up the construction progress,...

Embodiment 2

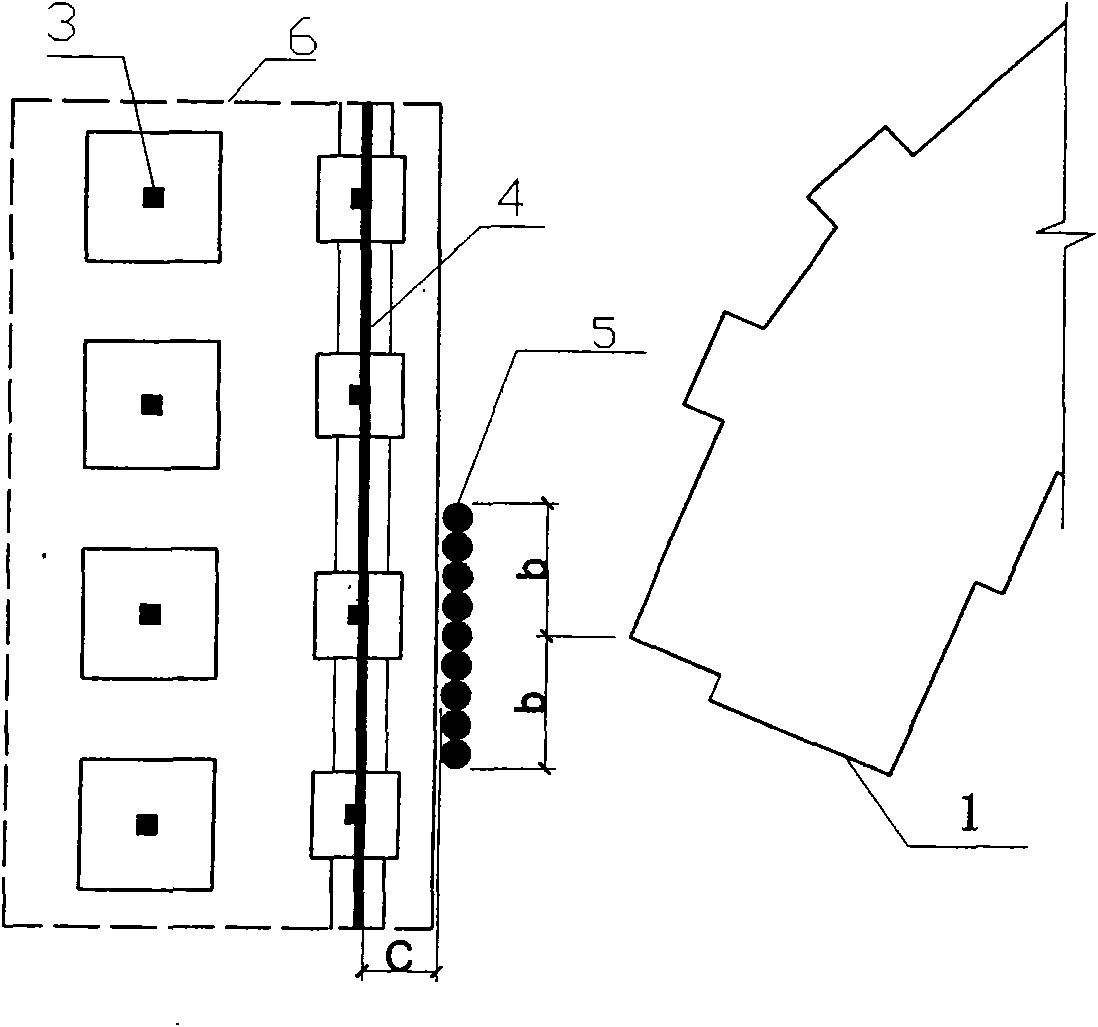

[0090] The steel support 12 can also be directly supported on the cast-in-place slab, and the planar rigidity of the slab is large, which meets the support requirements. The channel steel used for the steel support 12 can be selected in the range of 250mm-300mm in width and 2m-3m in length according to actual conditions.

[0091] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com