H-shaped double-row pile structure provided with core-entraining jet grouting pile

A technology of jet grouting piles and double-row piles, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of excessive displacement of pile bodies and weak anti-overturning ability, so as to reduce pile length, save engineering cost, Effect of increasing stability and stiffness against overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

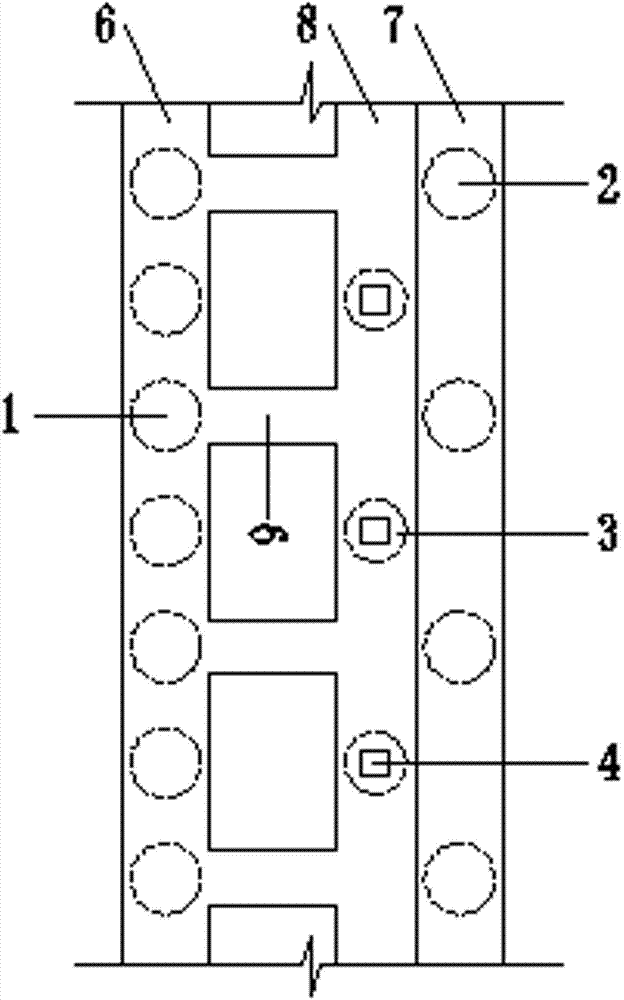

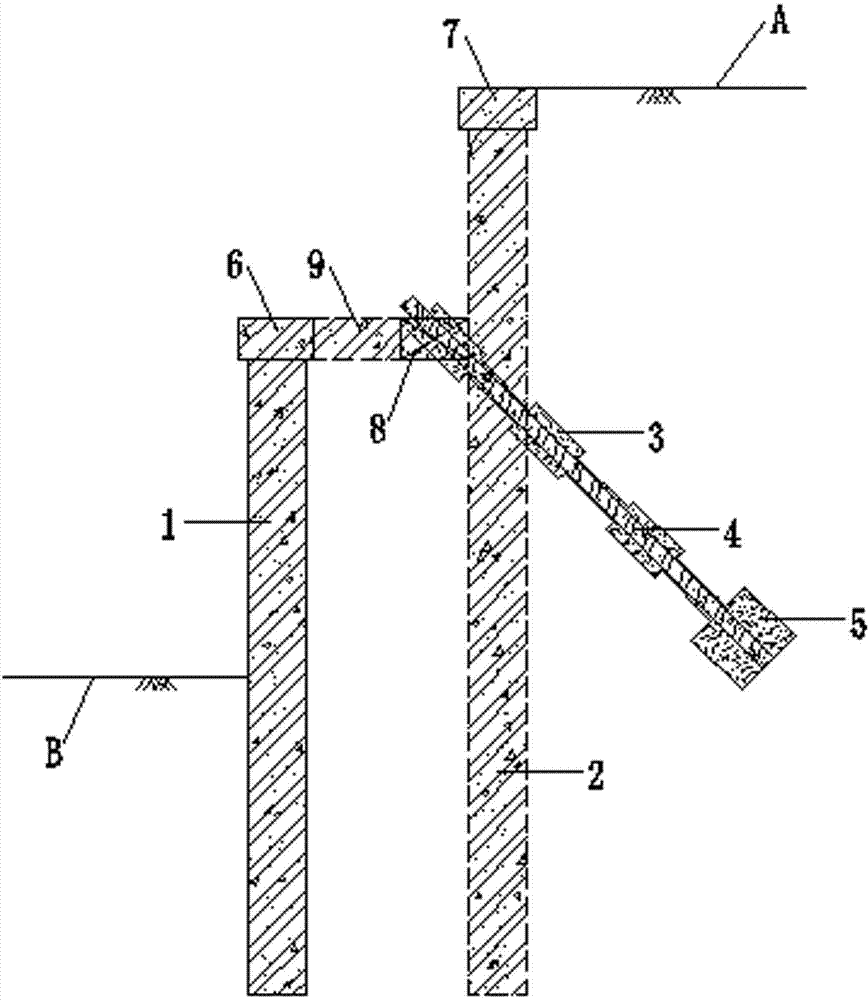

[0033] Example 1 :Such as figure 1 , 2 As shown, a h-shaped double-row pile structure with cored rotary grouting piles consists of front row piles 1, rear row piles 2, rotary grouting piles 3, prefabricated reinforced concrete square piles 4, enlarged head anchors 5, crowns It consists of beam Ⅰ6, crown beam Ⅱ7, crown beam Ⅲ8 and connecting beam 9. From the inner side of the pile top platform of the front row of piles 1, the jet grouting piles 3 with a large inclination angle are arranged between the piles of the rear row of piles 2 in each group. The rotary grouting pile 3 adopts segmental rotary grouting construction, and the diameter of the rotary grouting at the end position increases correspondingly to form an enlarged head anchor body 5 . After the construction of the rotary grouting pile 3 is completed, the prefabricated reinforced concrete square pile 4 is inserted thereinto before its quality becomes stable. The front row of piles 1 and the rear row of piles 2 ar...

Embodiment 2

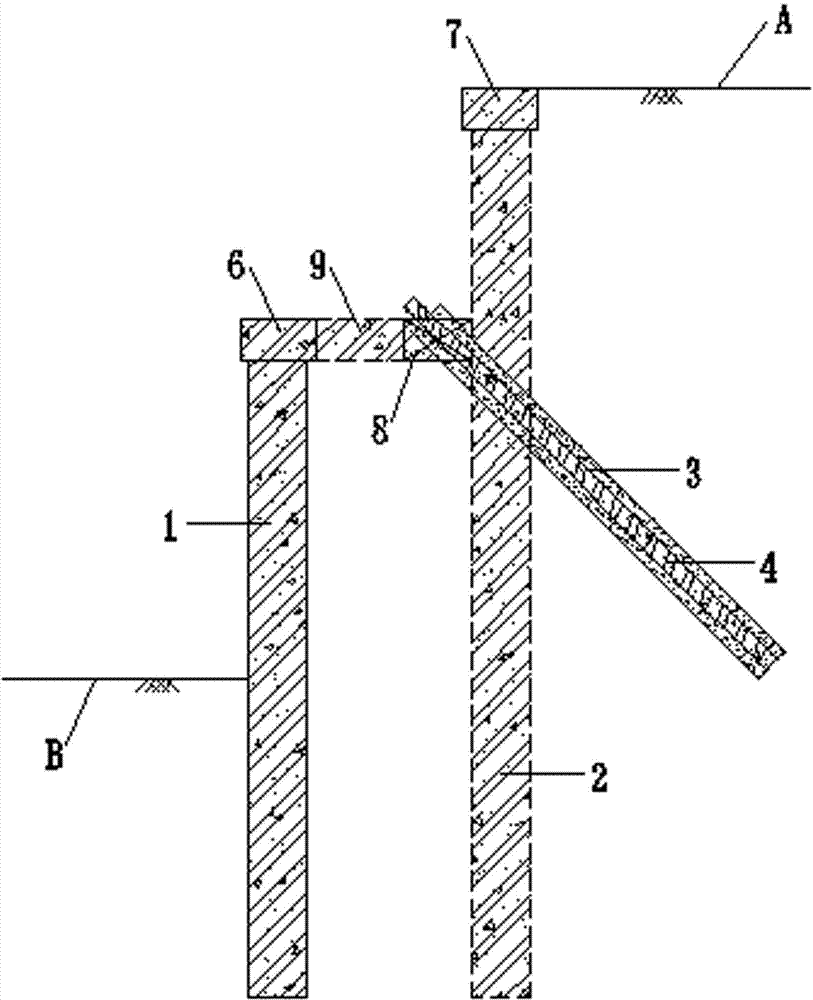

[0034] Example 2: Such as figure 1 , 3 As shown, an h-shaped double-row pile structure with cored jet grouting piles consists of front row piles 1, rear row piles 2, jet grouting piles 3, prefabricated reinforced concrete square piles 4, crown beam Ⅰ 6, and crown beam Ⅱ 7 , crown beam III8 and connecting beam 9. From the inner side of the pile top platform of the front row of piles 1, the jet grouting piles 3 with a large inclination angle are arranged between the piles of the rear row of piles 2 in each group. The rotary grouting pile 3 adopts continuous rotary grouting construction, and after the construction is completed, the prefabricated reinforced concrete square pile 4 is inserted into it before its quality becomes stable. The front row of piles 1 and the rear row of piles 2 are bored cast-in-situ piles, arranged in parallel and in an h-shape. The rotary grouting pile 3 adopts the double pipe method for segmental rotary grouting construction, the diameter is 0.6~1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com