Cast-in-situ bored pile and expansion and compaction construction method thereof

A technology of bored piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large dispersion of pile foundation bearing capacity, and achieve the effect of reducing the number of piles or the length of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

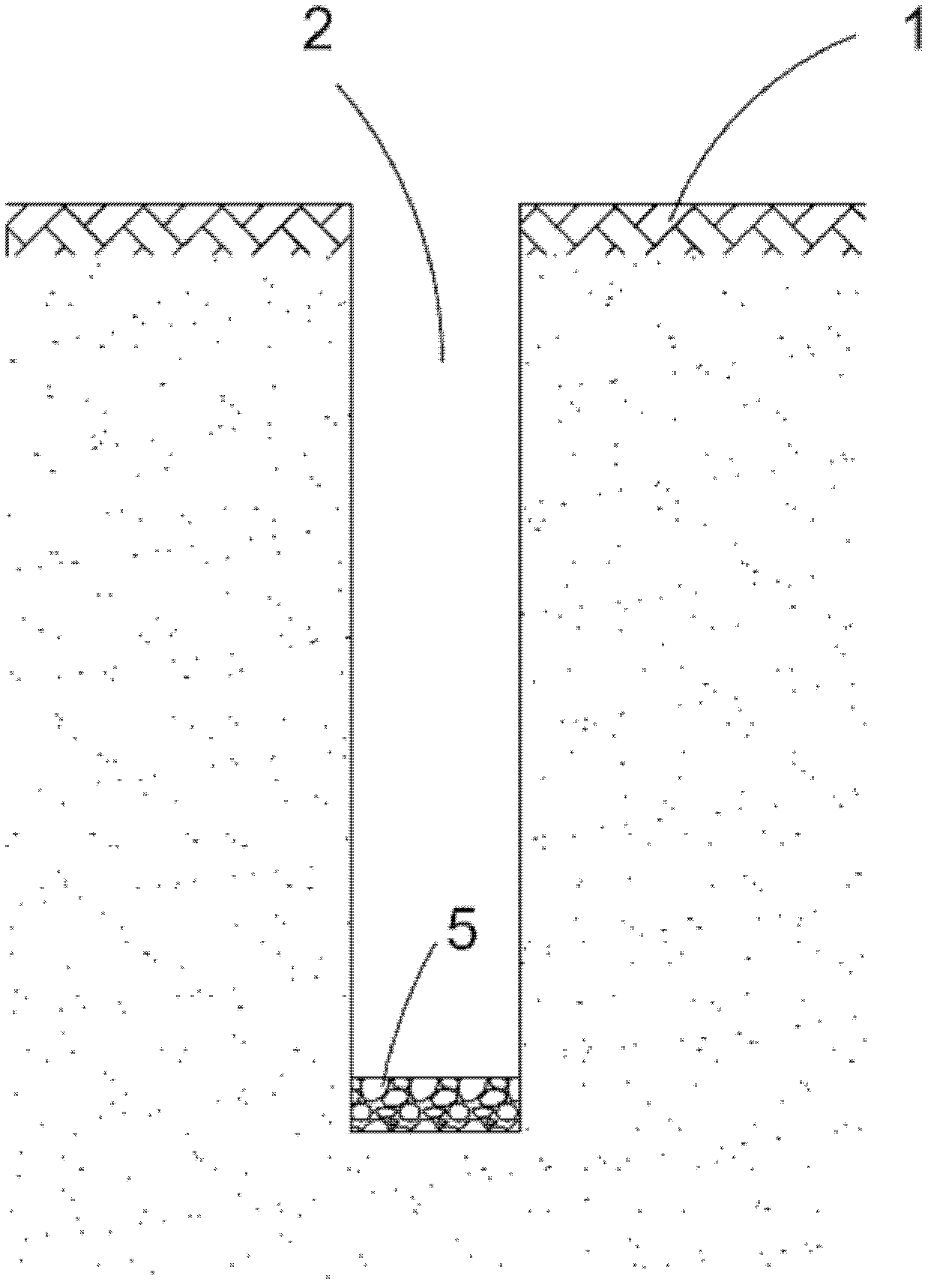

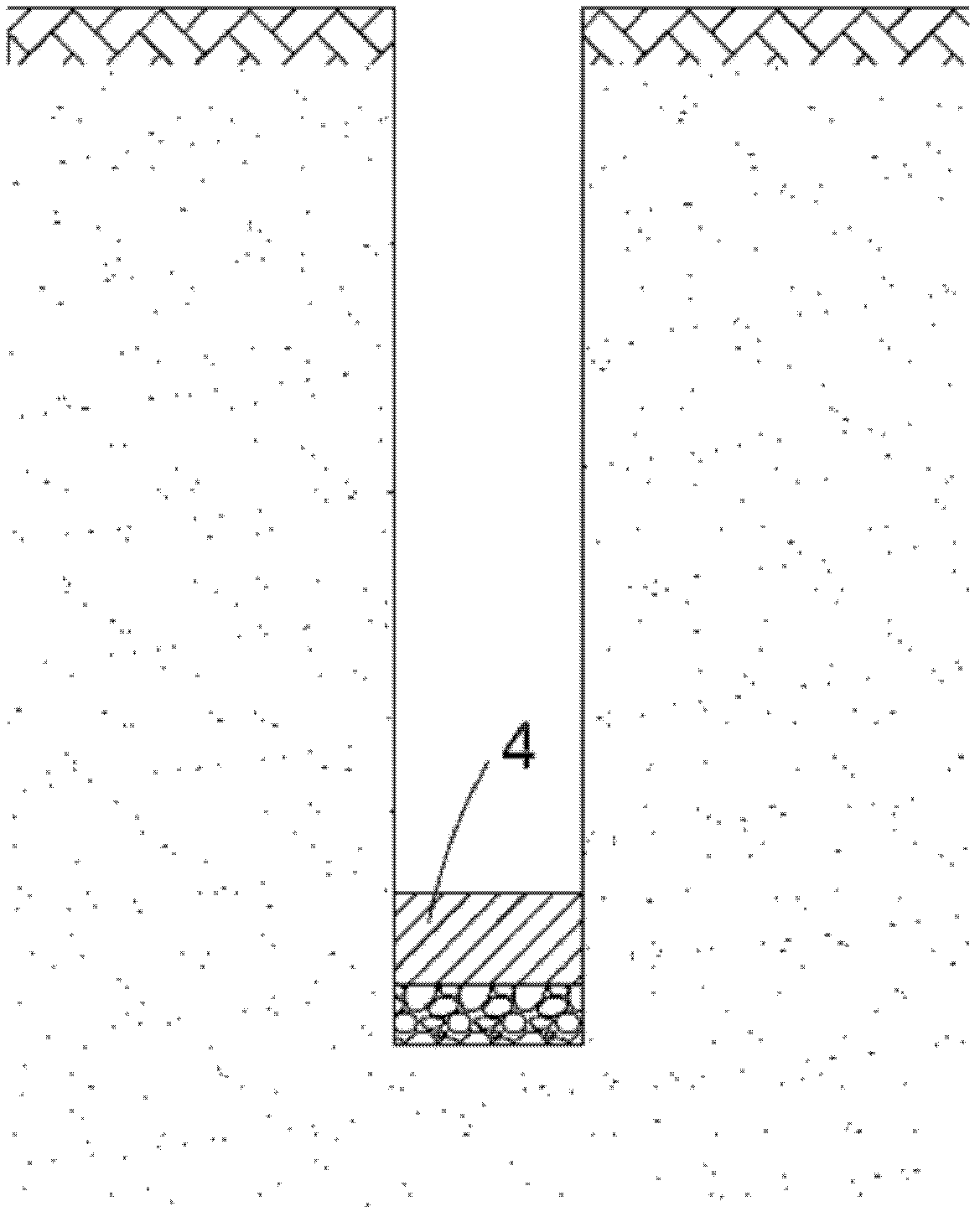

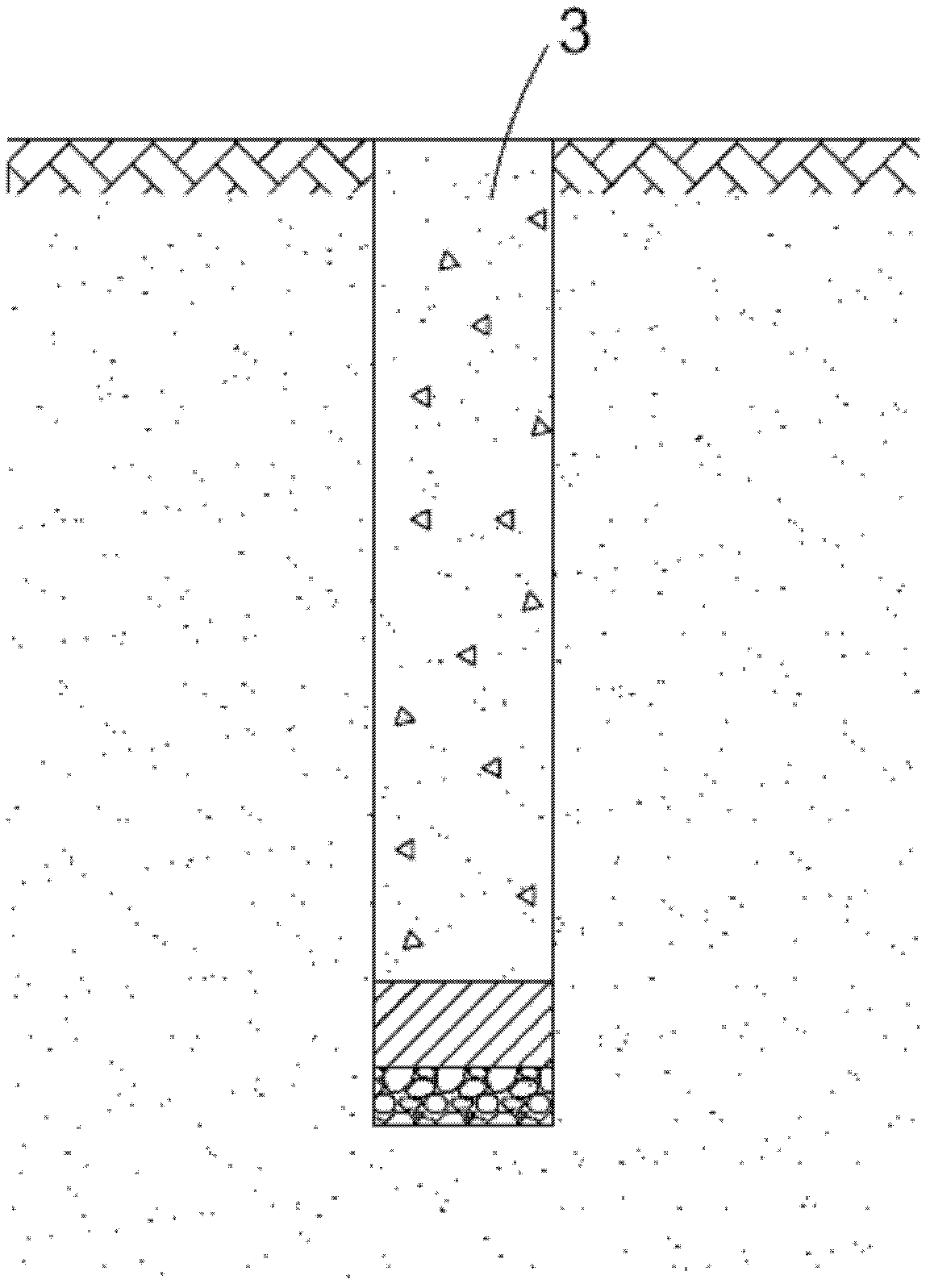

[0029] The technical content of the invention will be described in more detail below in conjunction with the accompanying drawings.

[0030] In this embodiment, taking a compression pile with a pile diameter of 600mm and a pile length of 30m as an example, the construction steps are as follows:

[0031] A) Firstly, prepare for construction: select the drilling rig, drilling tools, site layout, etc., and measure the necessary data. Before construction, the site should be leveled and debris should be removed. The position of the drilling rig should be leveled and compacted. After the drilling machine is installed, the verticality of the drilling rig should be checked. Insert a steel casing at the construction site. In order to avoid the bottom of the casing hanging in the air, causing problems such as collapse, water leakage, and slurry leakage, the lower end of the casing should be in contact with the bearing layer of the pile end during construction, such as on a natural solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com