Construction method of steel-reinforced concrete secant pile and arc-shaped protective tool

A steel-reinforced concrete and construction method technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of high price of steel cage and high engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

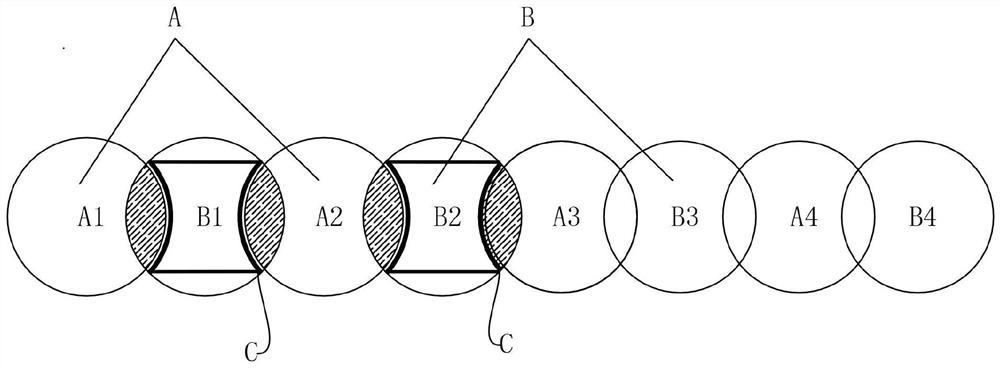

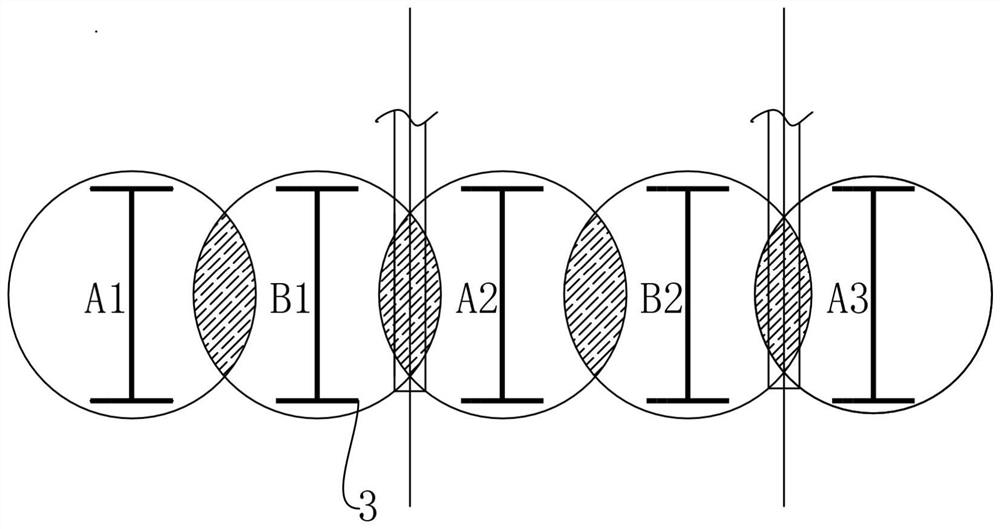

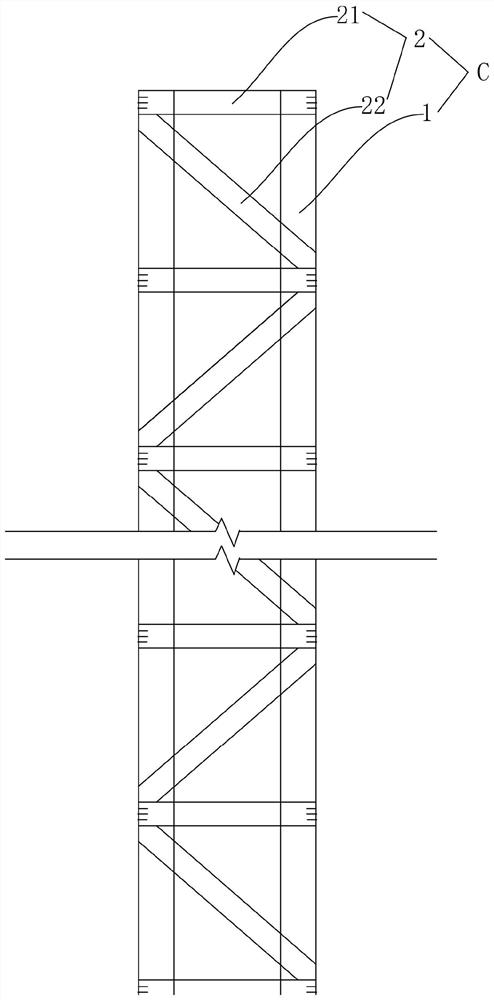

[0027] like figure 1 , figure 2 As shown, a construction method of steel-reinforced concrete occlusal piles includes an occlusal pile composed of a number of interlocking piles A and plain piles B that are alternately arranged in turn and interlocked with each other. It is completed by removing the arc-shaped protective gear C and inserting the H-shaped steel frame 3 in the pile hole of the meat pile A and the pile hole of the plain pile B. In addition, the H-shaped steel frame 3 can also be replaced with channel steel. There are two processing methods: the first one is to completely replace the reinforcement cage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com