Method for constructing long auger bored cast-with-pressure concrete uplift pile

A long-spiral drilling and concrete pouring technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of great difference in uplift resistance, lack of uplift resistance, and inability to give full play to it, and achieve social benefits Significant, low vibration, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

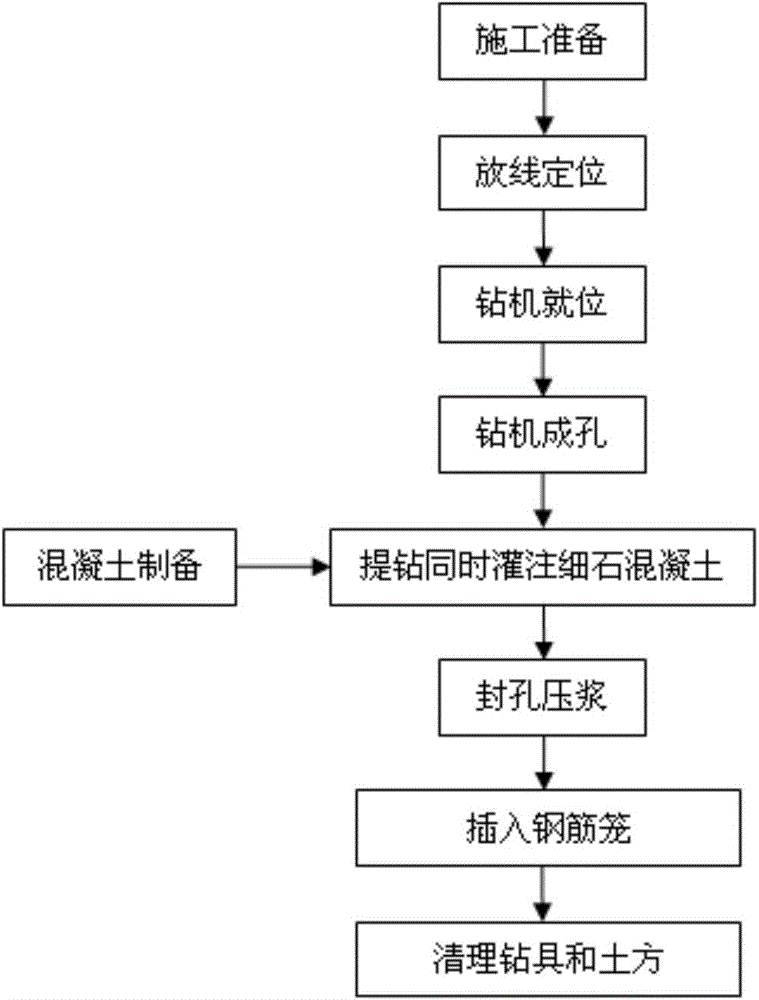

[0038] refer to figure 1 , the present invention, long auger bored pressure grouting concrete uplift pile construction method, the steps include:

[0039] (1) Construction preparation

[0040] 1. Due to the heavy weight of the long auger drilling rig, the surface that may cause subsidence should be treated before the equipment enters the site, such as laying brick slag, compacting, etc., to ensure that the site after leveling has sufficient load-bearing capacity and stability;

[0041] 2. Check whether there are underground pipelines that hinder the construction, such as water pipes, gas pipes, cables, etc., and remove them in advance if they exist;

[0042] 3. Make a quality and safety technical disclosure to the construction personnel before the start of construction.

[0043] (2) Setting out positioning

[0044] Use a total station to measure and set the axis of the pile according to the requirements of the pile design drawings, determine the pile location and mark it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com