Vibratory hammer device and shaking press type pile body construction method adopting same

A construction method and technology of vibrating hammer, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of difficult mechanical equipment, high cost of construction equipment, increased construction cost, etc., to avoid construction inconvenience and shorten construction. The effect of low cycle and construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

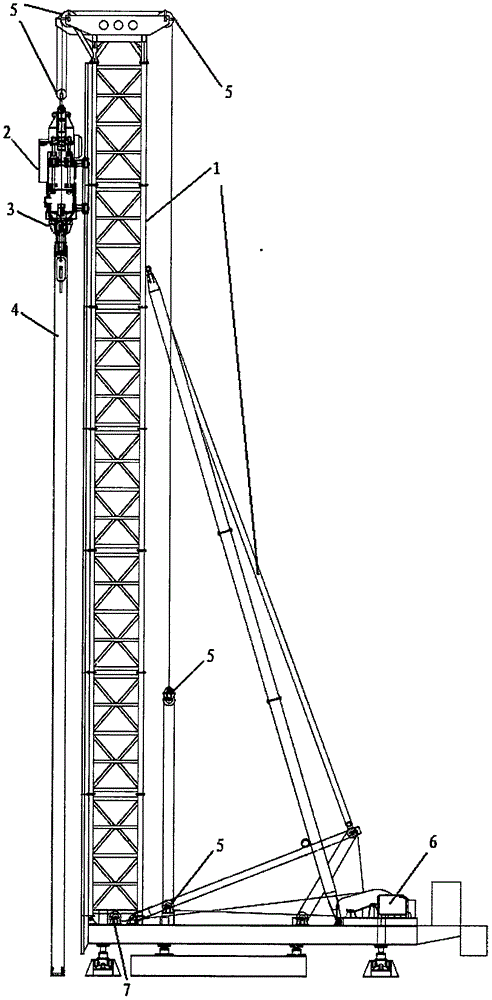

[0024] Such as figure 1 As shown, this embodiment discloses a vibratory hammer device, which includes: a bracket 1, a first pulley assembly 5 installed on the bracket 1; a vibratory hammer 2, the first end of which is connected to the first pulley assembly 5, and the second The end has a fixing structure for fixing the sleeve 4, and the sleeve includes an inner tube and an outer tube; it also includes: a second pulley assembly 7 installed on the bracket 1; a hoisting device 6 installed on the bracket 1, the hoisting device 6 is connected to the vibratory hammer 2 through the second pulley assembly 7, and is suitable for exerting a vertical downward force on the vibratory hammer 2; out), detachably connected to the vibratory hammer 2.

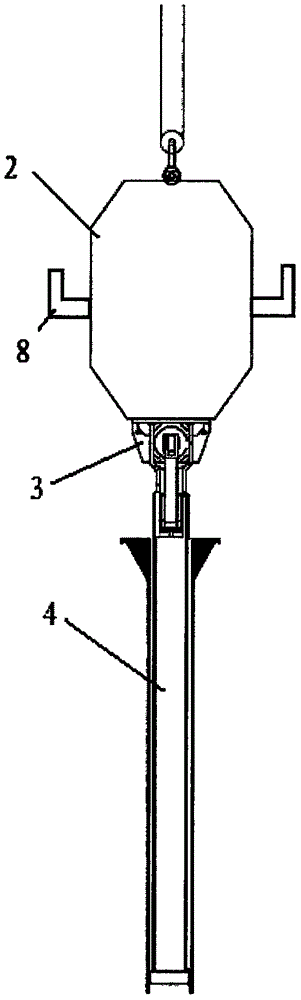

[0025] Such as figure 2 As shown, the vibratory hammer device of this embodiment preferably further includes: a counterweight installation structure 8, which is arranged on the vibratory hammer, and is used to realize the detachable connection ...

Embodiment 2

[0030] This embodiment discloses a vibratory pile construction method using the vibratory hammer device of Embodiment 1, including the following steps:

[0031] a. Adopt vibratory hammer equipment, utilize the self-weight of the hammer body of the vibratory hammer equipment, and disassemble or increase the counterweight according to the compactness of the soil to vibrate the inner tube and outer tube that are nested together, and realize sinking at the pile position pipe to form a pile hole; b. pull up the inner pipe, pour the concrete required to form the pile body into the outer pipe, and use the vibratory hammer device under predetermined working power to disassemble according to the requirements of pile formation Or increase the counterweight, vibrate and sink the inner pipe to forcibly squeeze the concrete in the outer pipe, and pull the outer pipe synchronously to form the initial pile bottom expansion for the first bottom expansion c. After the first bottom expansion, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com