Patents

Literature

67results about How to "Solve the inconvenience of construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

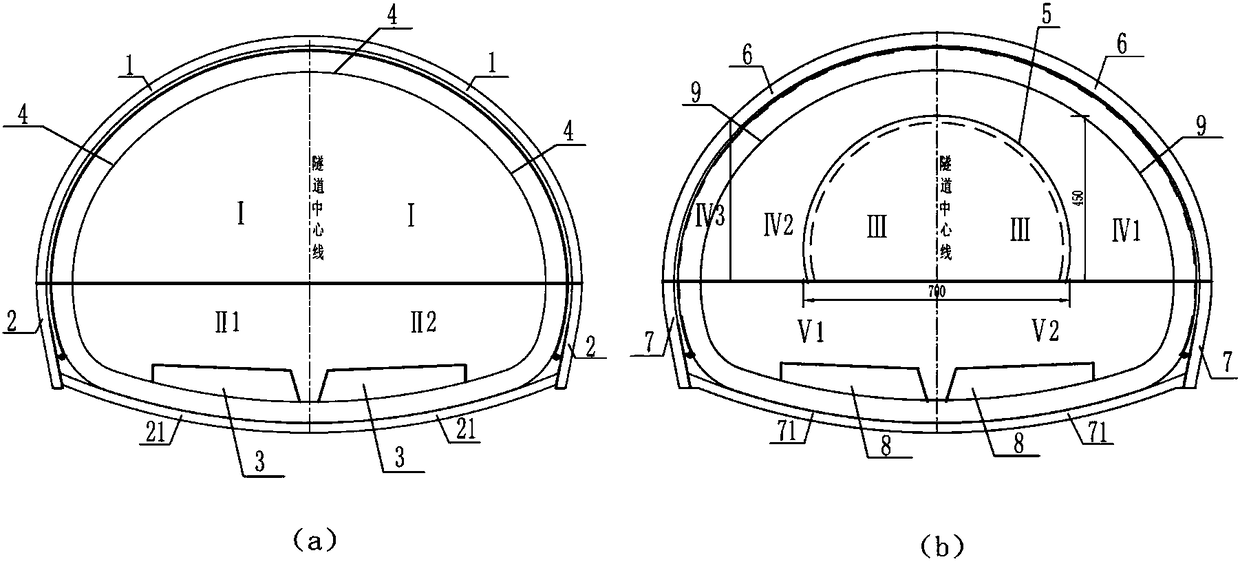

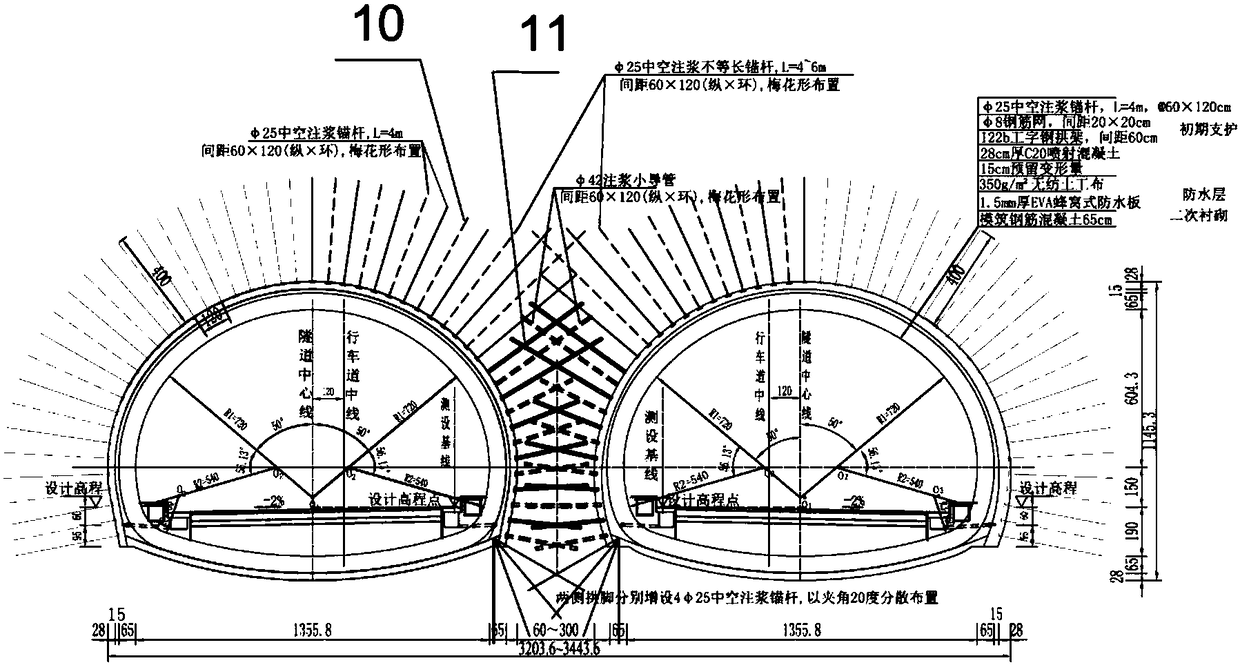

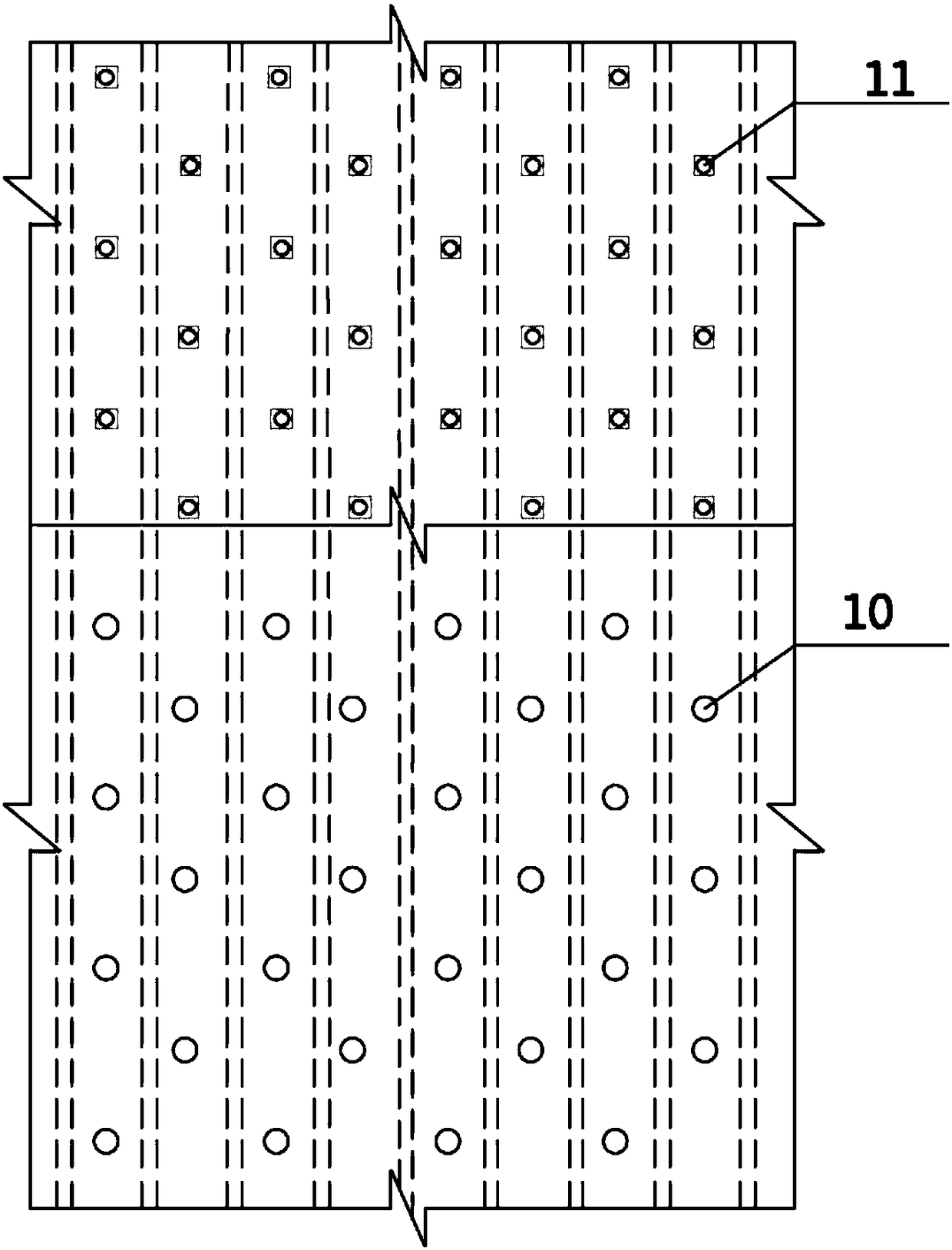

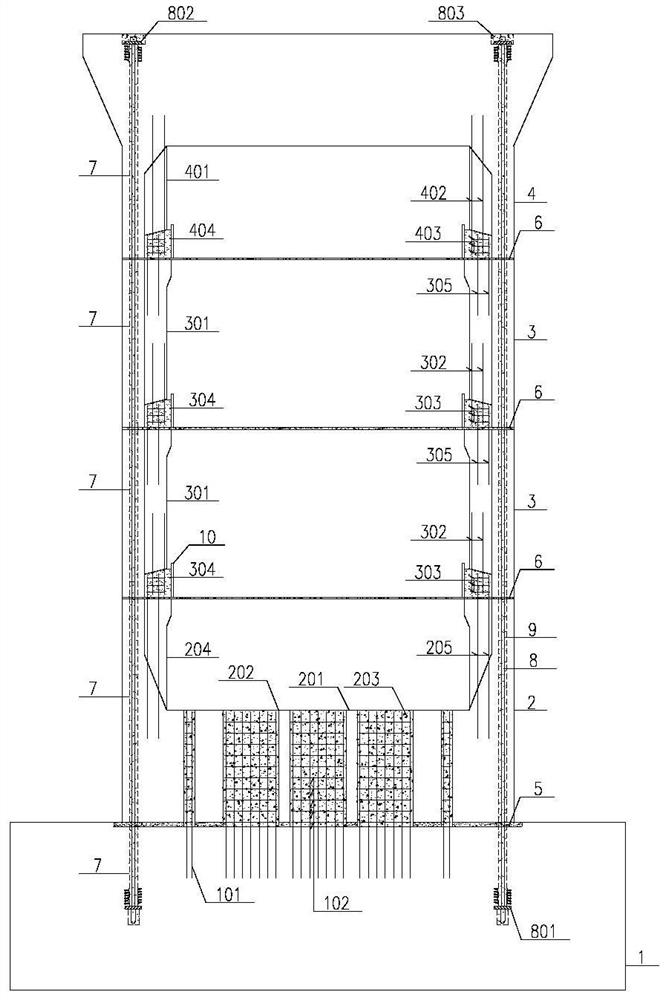

Out-of-pit tunneling construction method for minimum spacing tunnel

ActiveCN108533272ASolve the inconvenience of constructionReduce disturbanceUnderground chambersBlastingIndustrial engineeringTunnel construction

The invention provides an out-of-pit tunneling construction method for a minimum spacing tunnel, and belongs to the technical field of out-of-pit tunneling construction of small spacing tunnels. The out-of-pit tunneling construction method comprises the following steps that a left line upper step section is excavated, and a left line lower step left section and a left line lower step right sectionare excavated separately; a left line inverted arch and a left line filling layer are constructed, and a left line secondary lining is piled in a staggered mode; a right line small guide hole sectionis excavated, a right line upper step right section, a right line upper step left middle section and a right line upper step left edge section are excavated in an expanded mode, and a right line upper step primary support is constructed; a small guide hole primary support is removed, a right line lower step left section and a right line lower step right section are excavated, and a right line lower end face primary support is constructed; and a right line inverted arch and a right line filling layer are constructed, and a right line secondary lining is subjected to overall model-building. According to the out-of-pit tunneling construction method, an advanced tunnel is subjected to one-way out-of-pit tunneling, so that the problem that cliff construction of the exit section is inconvenientis solved; after a left tunnel is excavated, a middle rocky column is reinforced, the left line secondary lining is piled in the staggered mode, a right tunnel adopts an advanced small guide hole forout-of-pit tunneling, the section is excavated in an expanded mode, the construction risk is reduced, and tunnel construction safety is ensured.

Owner:GUIZHOU HIGHWAY ENG GRP +1

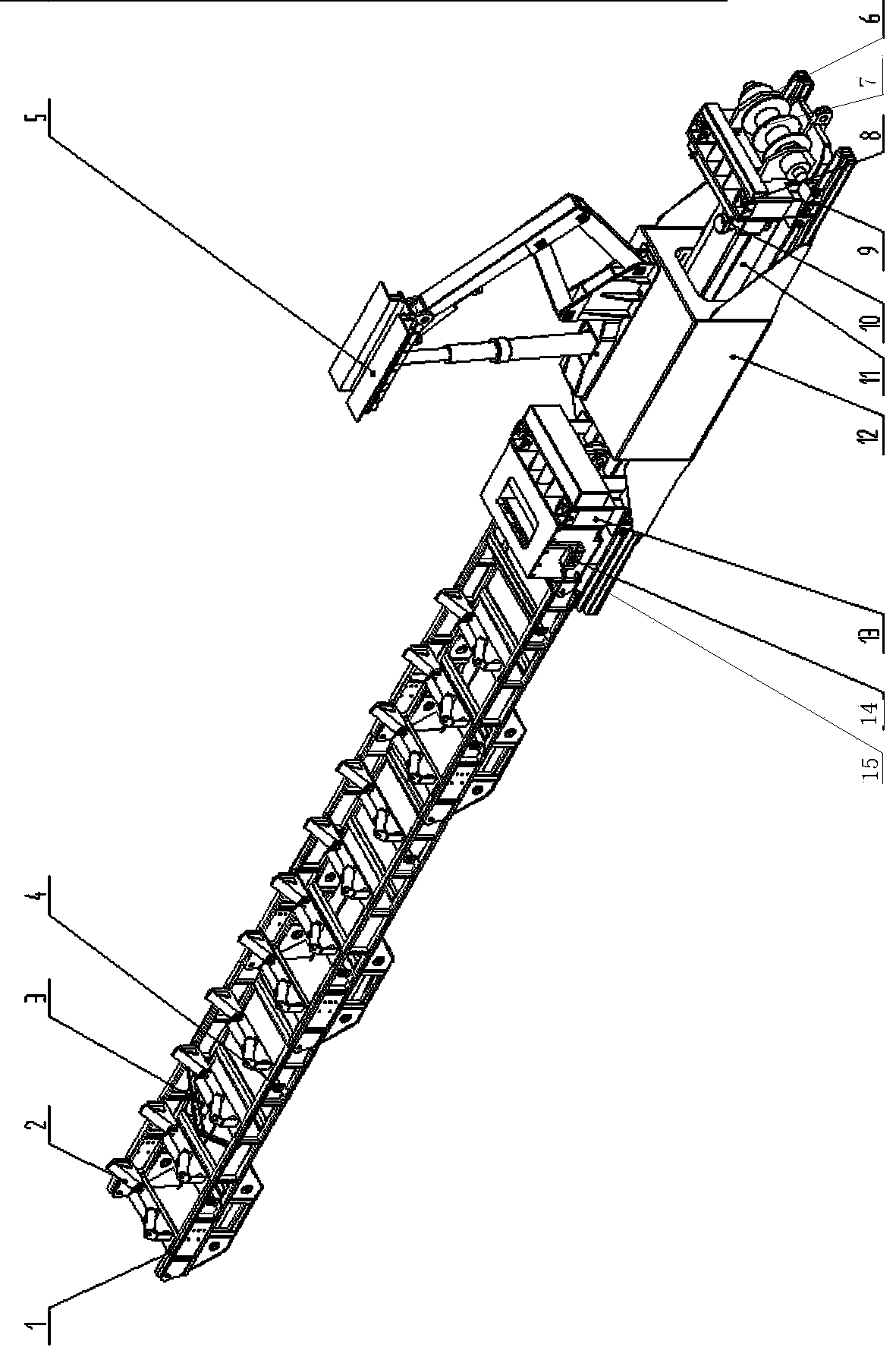

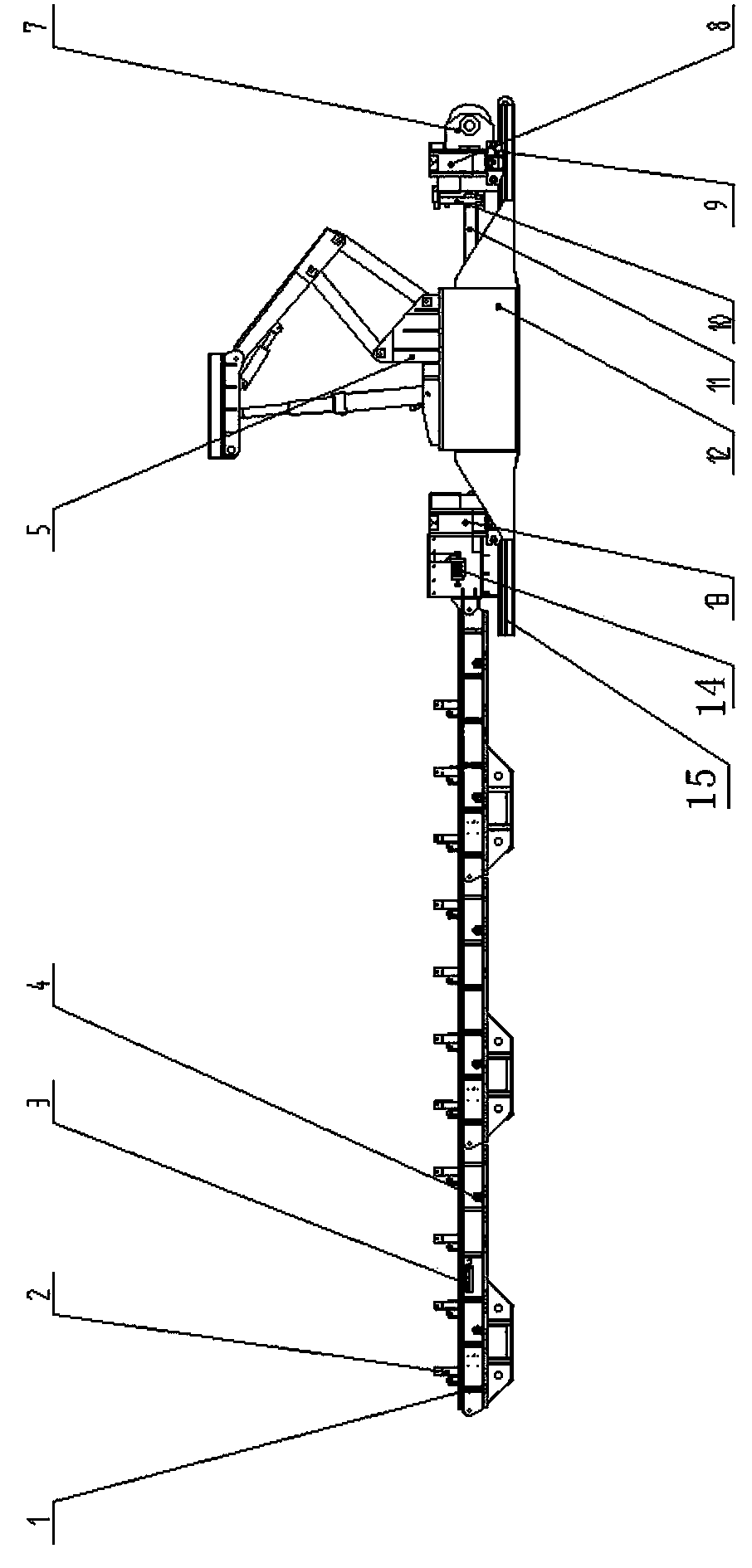

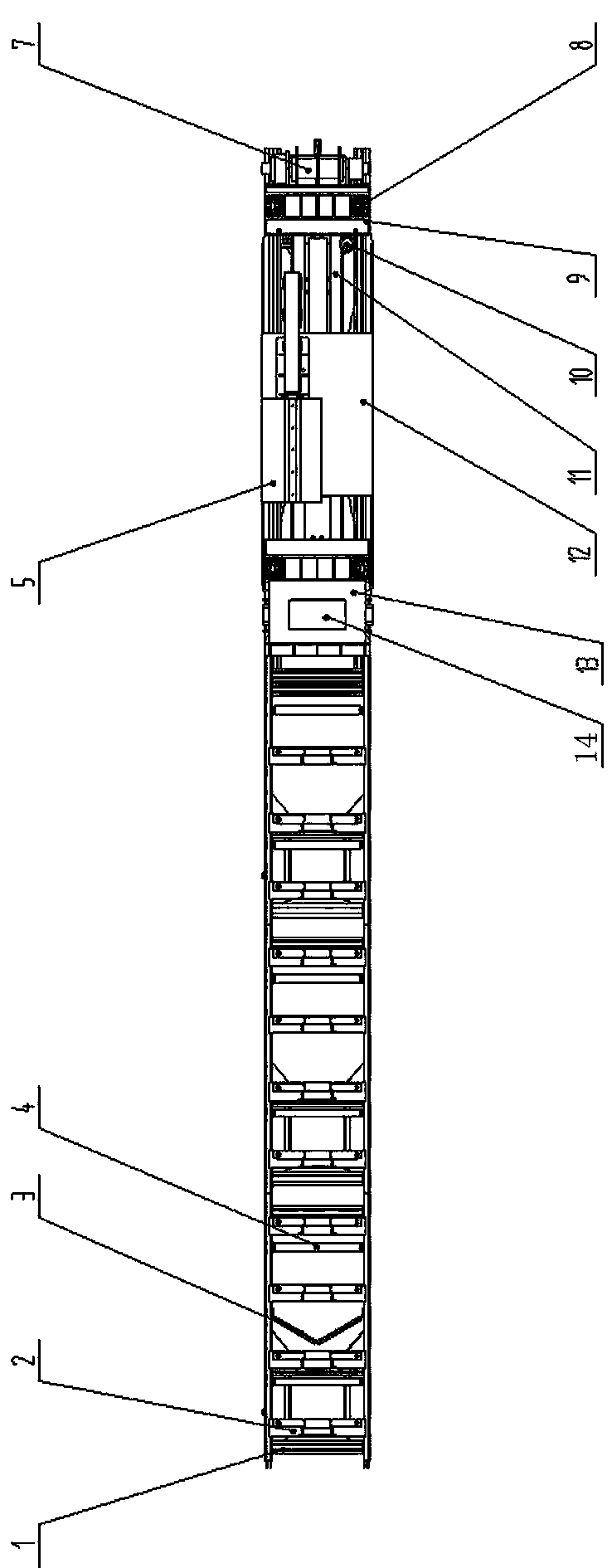

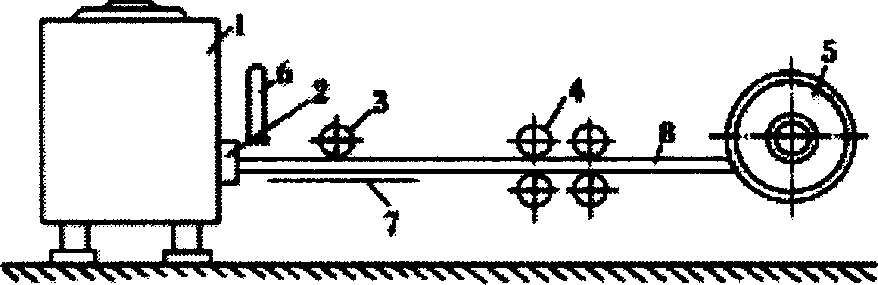

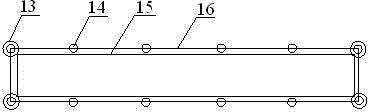

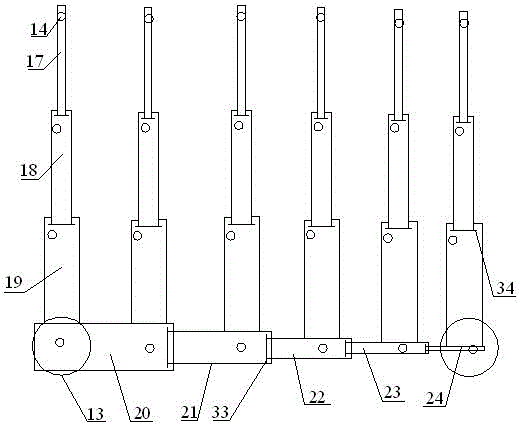

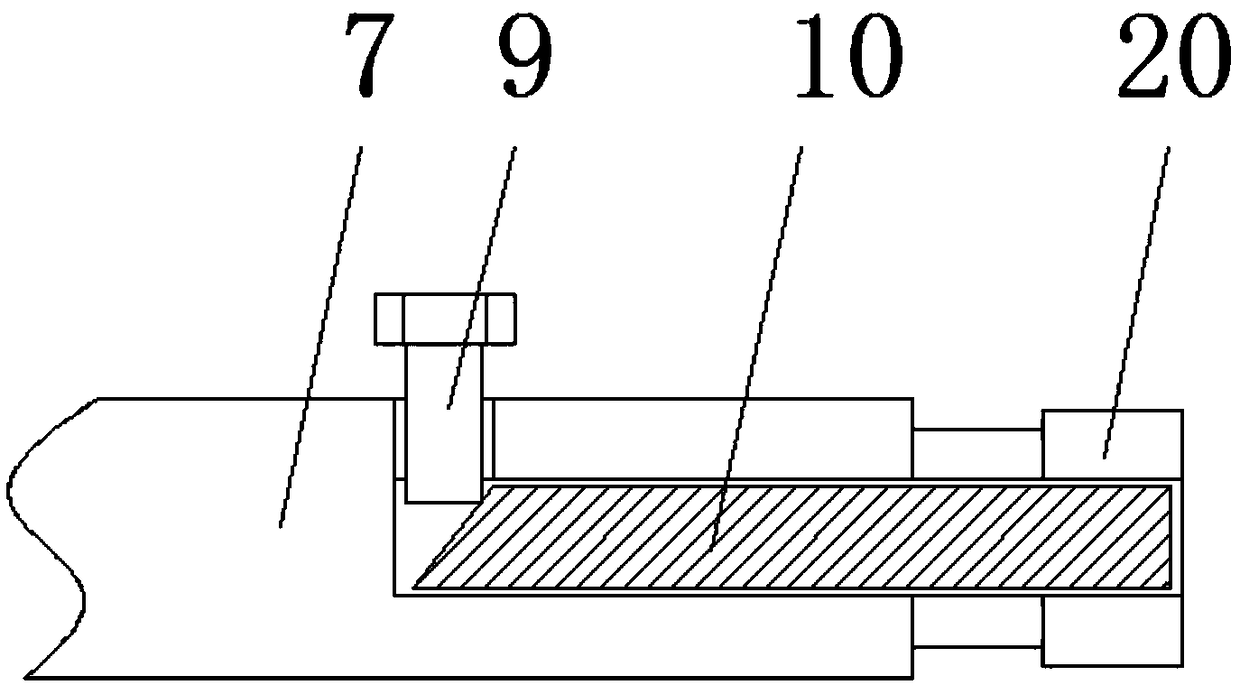

Stepping self-moving rubber belt conveyor tail used for fast driving

The invention belongs to the technical field of designing and manufacturing of driving working face devices in a coal mine and particularly relates to a stepping self-moving rubber belt conveyor tail used for fast driving. The problems existing in the moving mode of an existing driving working face belt conveyor tail are solved. The stepping self-moving rubber belt conveyor comprises a rigid frame, a roller and a rack. The rack comprises a front rack and a back rack, a beam is connected between the front rack and the back rack, a base is arranged between the front rack and the back rack, and guide rails are connected with the bottom of the base. A push moving oil cylinder is arranged on the beam, and a stand column mechanism and a four-bar mechanism are arranged at the top of the base. Roller boxes are arranged on the two sides of the front rack and the two sides of the back rack. The roller boxes are matched with the guide rails in a sliding mode, and lifting oil cylinders are connected inside the roller boxes and arranged in the vertical direction. The stepping mode is unique, and a set of device combines a hydraulic support and the belt conveyor tail to achieve stepping self moving, so that the requirement for fast moving of the device under different working conditions is met. The stepping self-moving rubber belt conveyor tail is simple in structure, convenient to install and flexible in operation.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

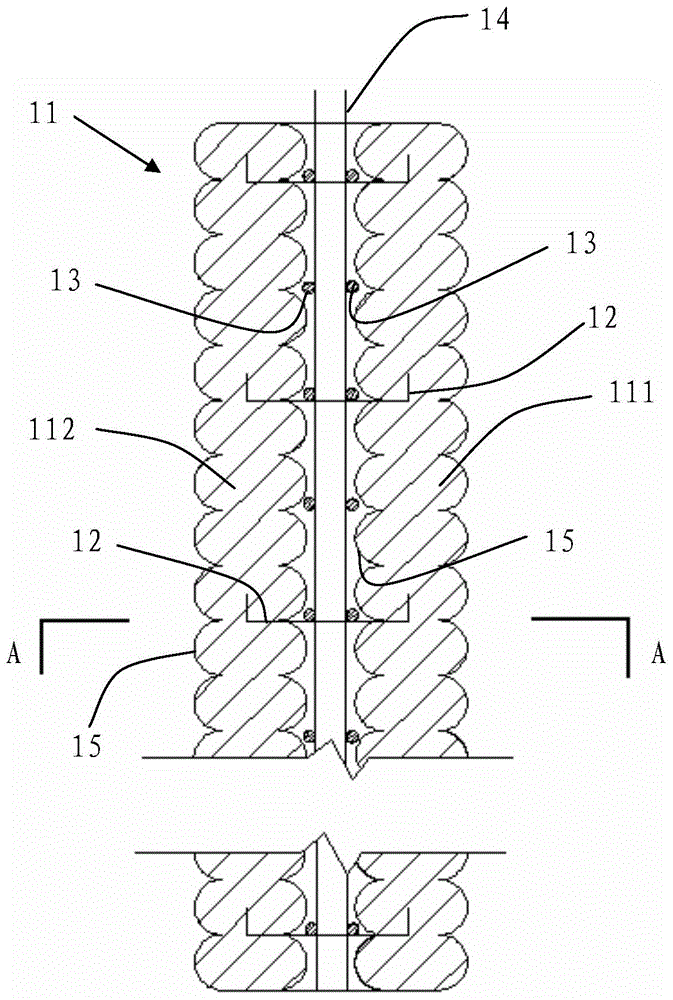

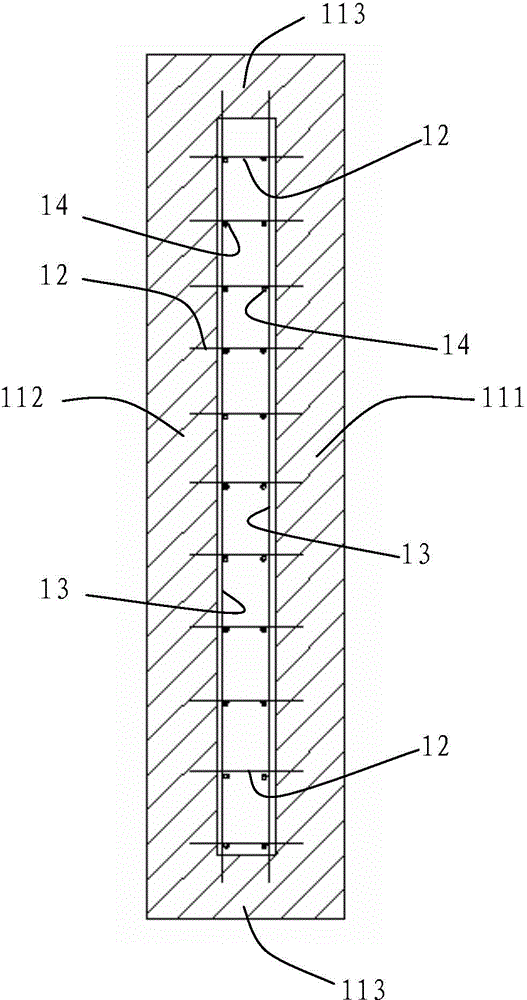

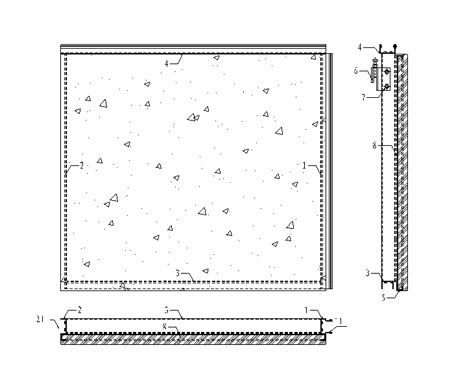

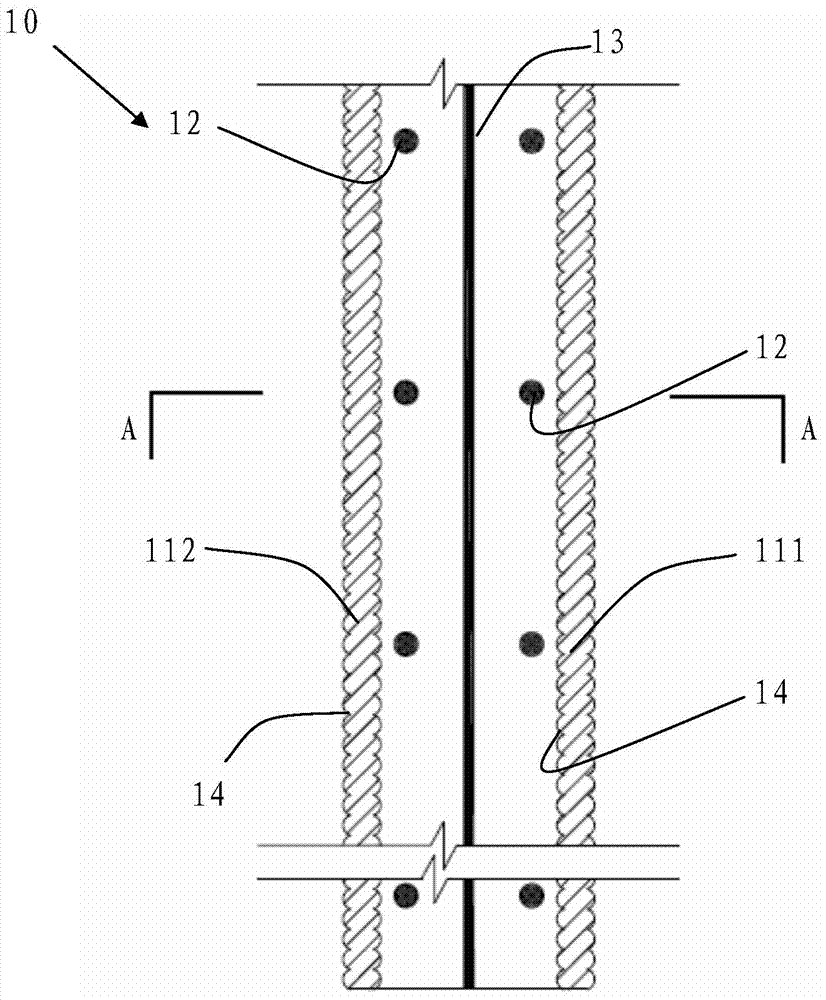

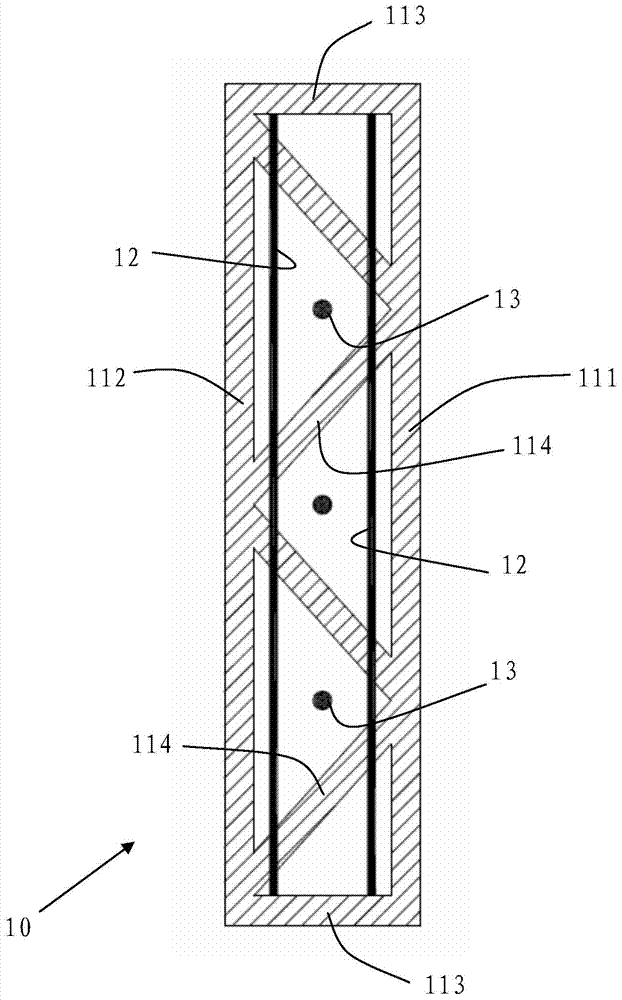

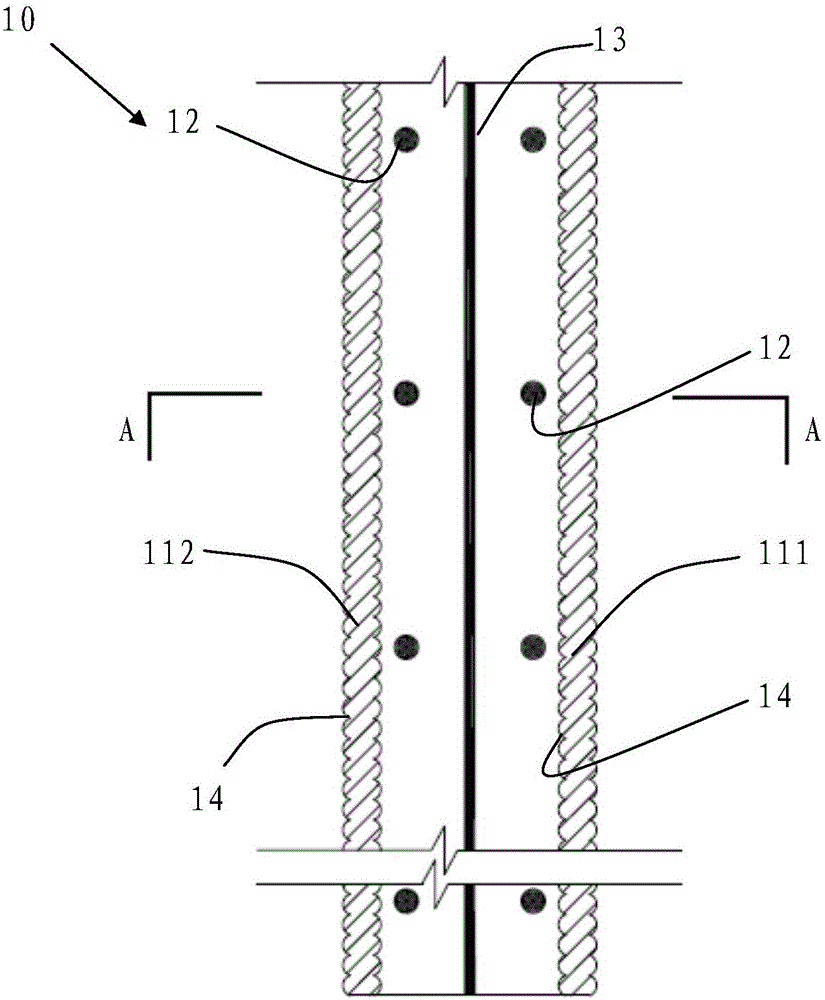

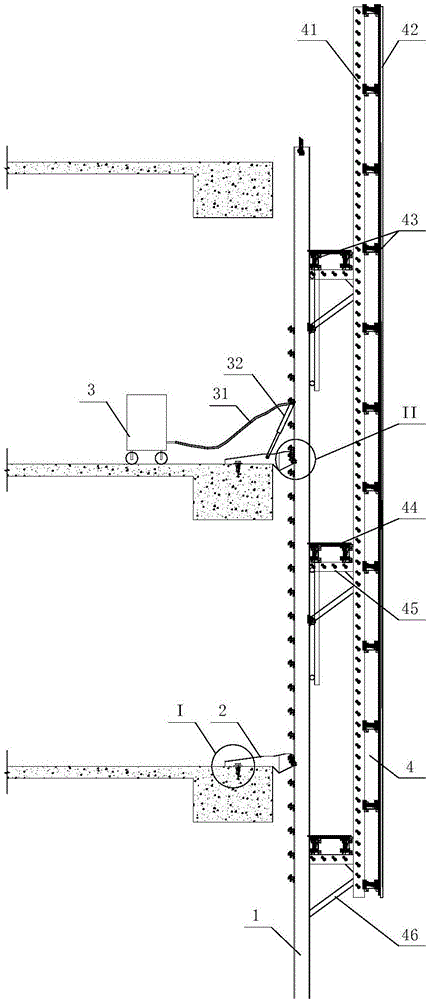

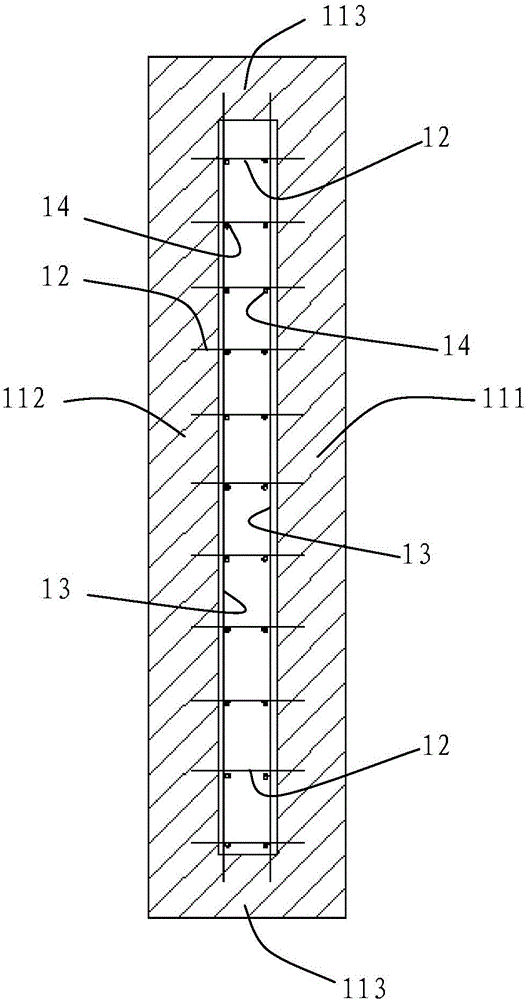

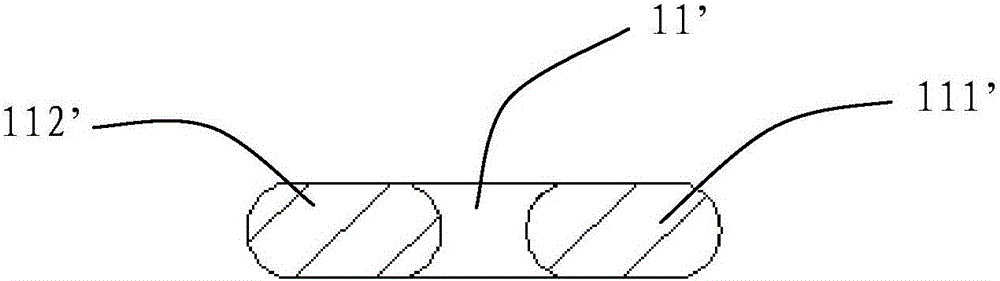

Concrete shear wall structure based on 3D printing and construction method of concrete shear wall structure

ActiveCN104153493AAvoid constructionAvoid demolitionAdditive manufacturing apparatusWallsEngineeringHorizontal bar

The invention discloses a concrete shear wall structure based on 3D printing and a construction method of the concrete shear wall structure. The construction method comprises the following steps that (a) a first layer of prefabricated concrete shell is manufactured by adopting 3D printing; (b) a first layer of tie bars and / or horizontal bars are arranged on the top of the first layer of prefabricated concrete shell; (c) a second layer of prefabricated concrete shell is manufactured on the top of the first layer of prefabricated concrete shell, and the two ends of the tie bars and / or the horizontal bars are embedded into the prefabricated concrete shells respectively; (d) a second layer of tie bars and / or horizontal bars are arranged on the top of the second layer of prefabricated concrete shell, the step (c) is repeated until the prefabricated concrete shells are completed to reach designed elevation, and concrete is poured. The tie bars are prefabricated between an inner wall faces and an outer wall faces of the prefabricated concrete shells to prevent formwork expansion, the horizontal bars of a shear wall are also embedded between the prefabricated concrete shells, construction inconvenience brought by the horizontal bars in the later mounting process is avoided, and construction is simplified.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Hot spraying aluminium-zinc alloy wire rod and method for making same

The invention relates to a heat spraying aluminium zinc alloy wire rod composition and its preparing process, wherein the constituents (by weight percentage) of the wire rod include Al 54-56%, 0.004%<=M<=1.08%, impurity whose total amount is less than 1%, and balancing Zn, M is any one or the combination of RE, Mg, Ti or B.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

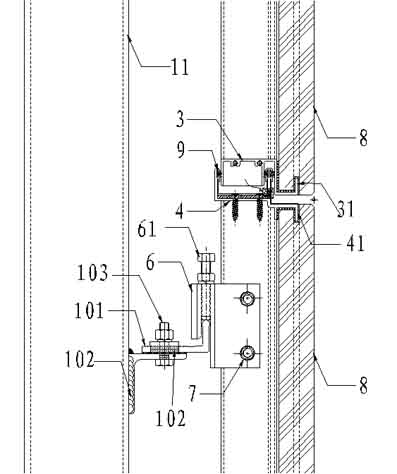

Cell-type hollow joint stone curtain wall

ActiveCN101956439AAvoid causing inconvenience to constructionHigh degree of factoryCovering/liningsWallsEngineeringRelationship - Father

The invention provides a cell-type hollow joint stone curtain wall which comprises a stone unit, connecting members and a support system, wherein the stone unit is formed by splicing a father material, a mother material, a bottom material, a top material and stone together; the connecting members are respectively arranged on the father material and the mother material; the stone unit is hanged onthe support system through the connecting members; an adjusting screw rod is arranged on each connecting member; a long hole is arranged on the support system; and the stone unit can be horizontally and longitudinally adjusted through the adjusting screw rod and the long hole. The stone curtain wall has the advantages of good security, convenient replacement, high industrial degree as well as time-saving and labor-saving installation.

Owner:SUZHOU KELIDA BUILDING & DECORATION CO LTD

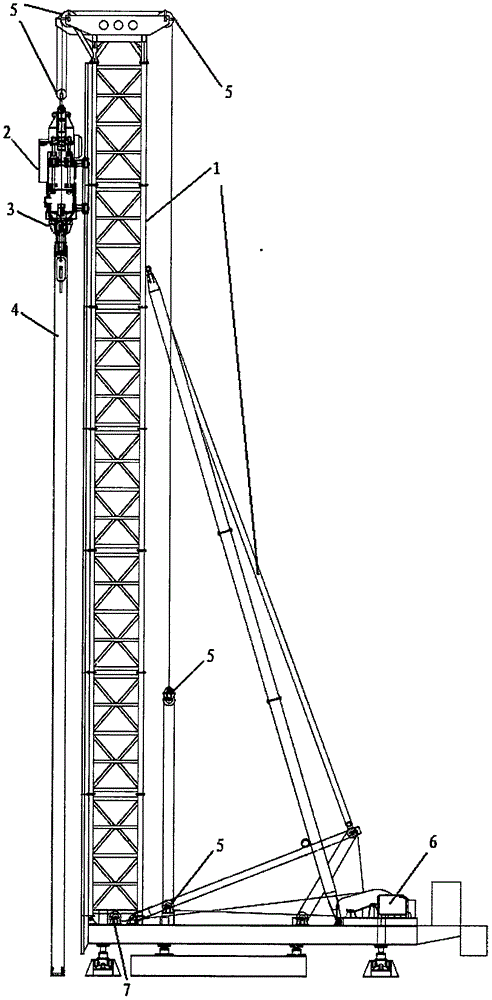

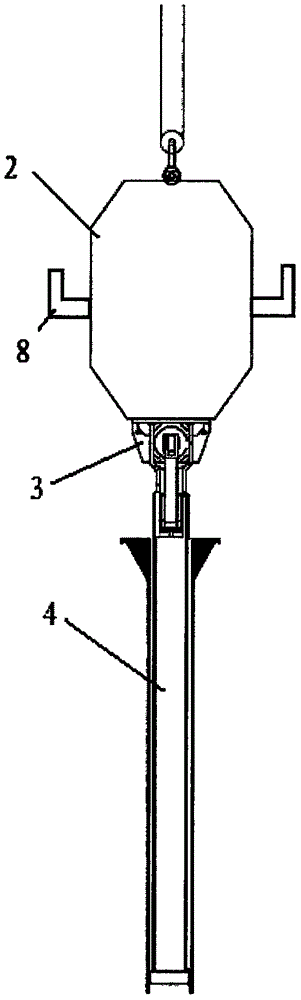

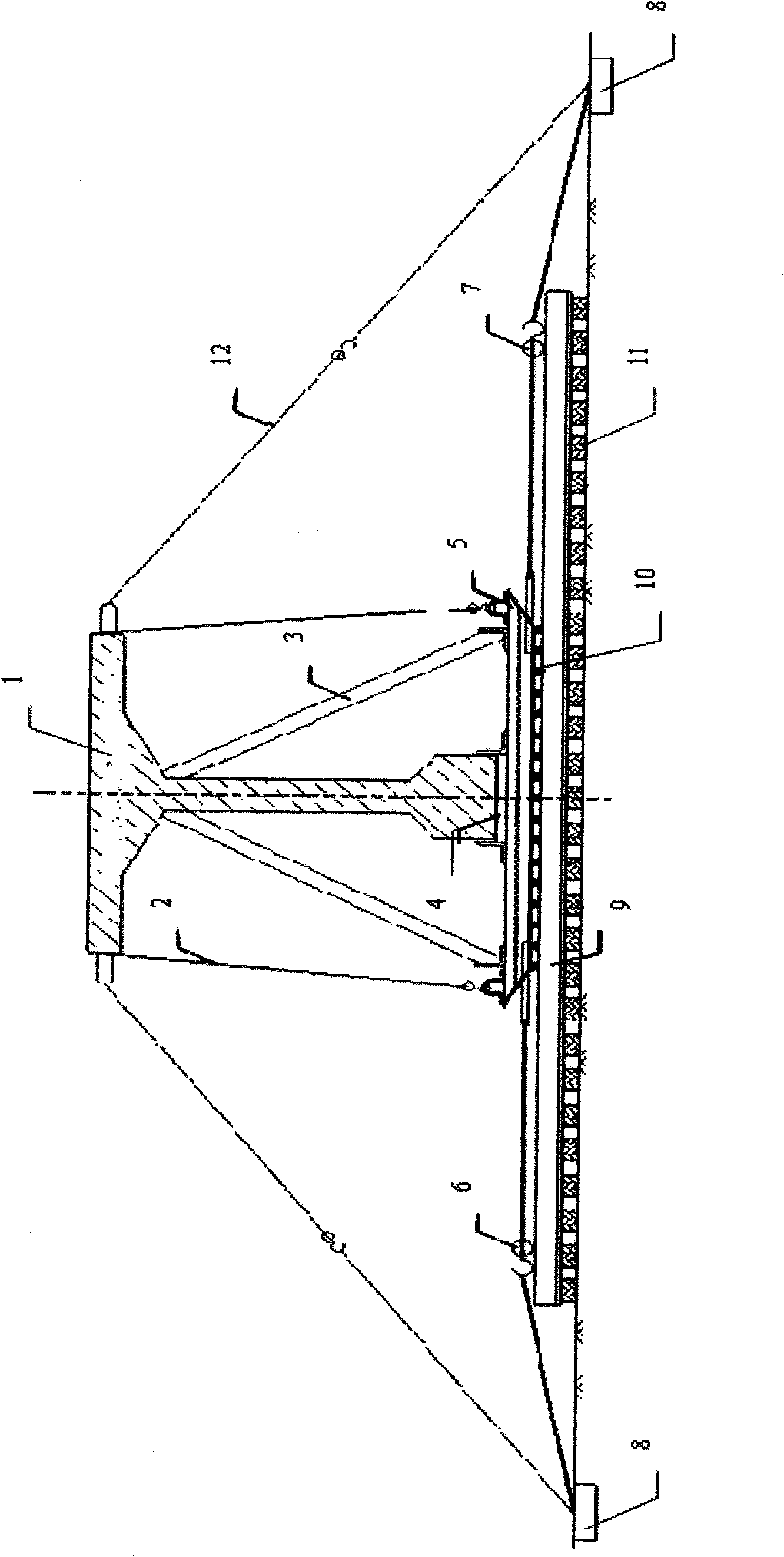

Vibratory hammer device and shaking press type pile body construction method adopting same

InactiveCN106168027AVibration pressure increasedFlexible adjustment of self-weightBulkheads/pilesArchitectural engineeringPulley

The invention discloses a vibratory hammer device. The device comprises a support, a vibratory hammer, a second pulley component, a winding plant and a balancing weight, wherein a first pulley component is installed on the support, the first end of the vibratory hammer is connected with the first pulley component, and the second end of the vibratory hammer is provided with a fixing structure used for fixing an inner pipe and an outer pipe; the second pulley component is installed on the support, the winding plant is installed on the support and connected with the vibratory hammer through the second pulley component and can apply a vertically downward force to the vibratory hammer, and the balancing weight is detachably connected to the vibratory hammer. In this way, construction noise is low, construction efficiency is high, and the dead weight of a hammer body can be adjusted flexibly to meet the requirement for pile forming. The invention further discloses a shaking press type pile body construction method adopting the vibratory hammer device.

Owner:刘献刚

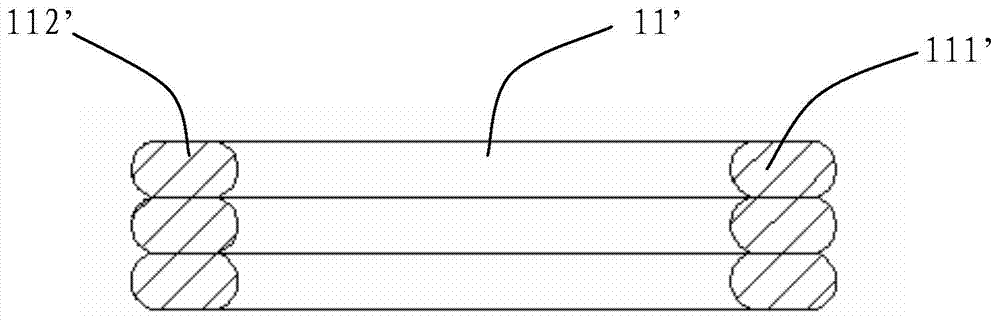

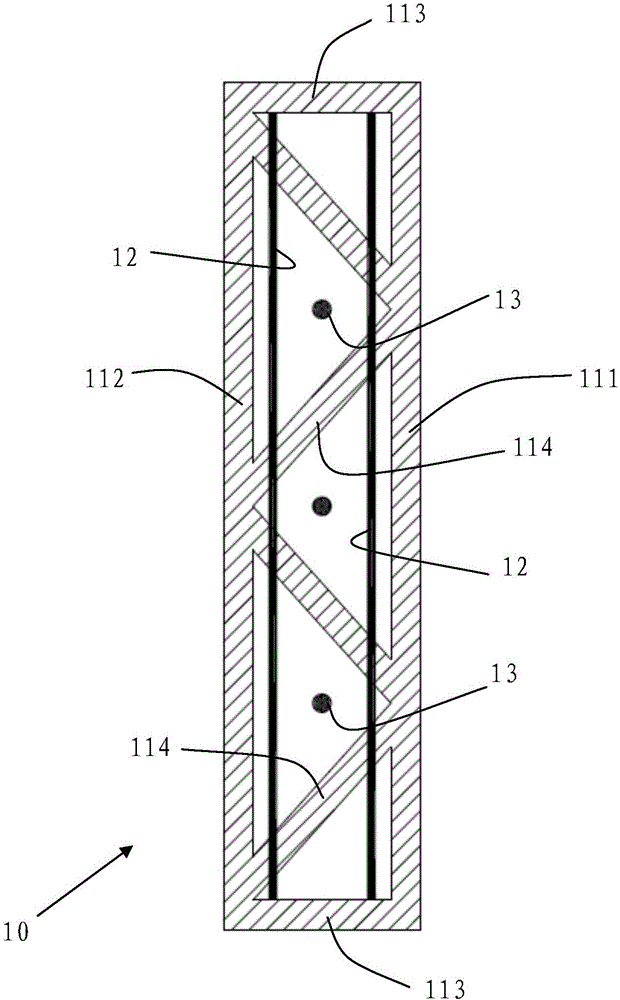

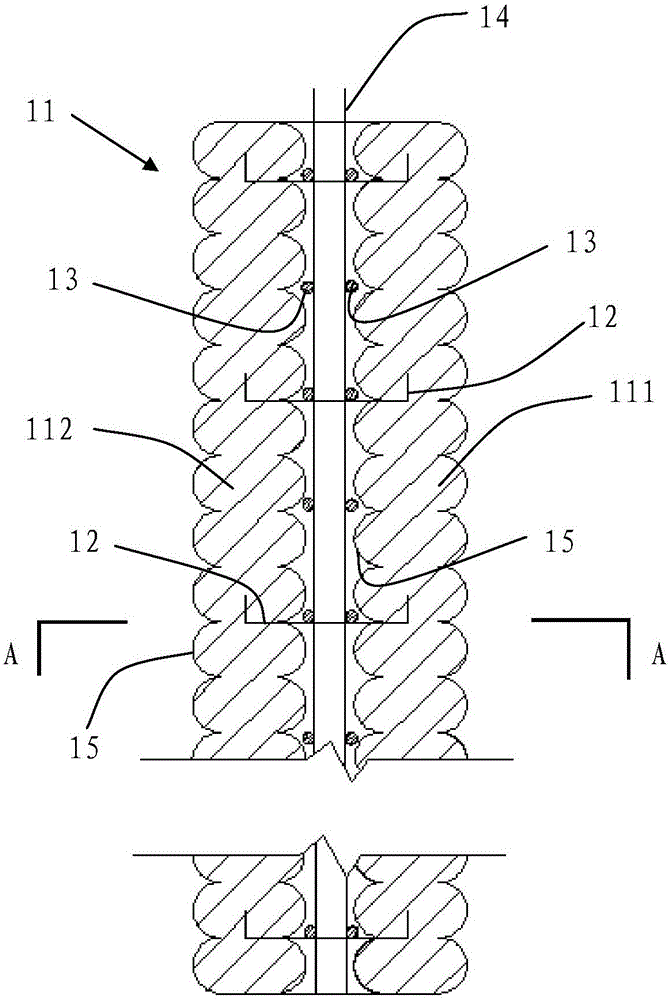

3D printing reinforcement masonry shear wall structure and construction method thereof

ActiveCN104264862ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebarTransverse reinforcement

The invention discloses a 3D printing reinforcement masonry shear wall structure and a construction method thereof. The construction method includes the following steps that a, the 3D printing technology is used for manufacturing a first layer of masonry outer shell to the pre-buried elevation position of transverse reinforcement; b, the transverse reinforcement is arranged on the top of the first layer of masonry outer shell; c, the 3D printing technology is used for manufacturing a second layer of masonry outer shell on the top of the first layer of masonry outer shell, and thus the transverse reinforcement can be laid in the masonry outer shell; d, the step b and the step c are executed repeatedly, so that the masonry outer shell is obtained; e, the step a and the step d are executed repeatedly, so that a plurality of masonry outer shells are obtained, and the masonry outer shells are stacked to the designed elevation of a shear wall; f, vertical reinforcement is mounted in each masonry outer shell; g, concrete is poured, and accordingly the shear wall can be constructed. By the adoption of the 3D printing technology, the masonry outer shells of reinforcement masonry can be integrally formed, original concrete small hollow blocks are replaced, the site construction labor force is greatly reduced, the construction procedures are omitted, the building quality is guaranteed, and thus building industrialization can be facilitated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

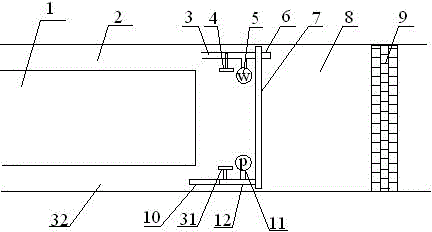

Precast beam artificial sliding boat translation system

InactiveCN101914896ASolve the inconvenience of constructionSave electricityBridge erection/assemblyGantry craneEngineering

The invention discloses a precast beam artificial sliding boat translation system, which comprises a sliding boat, a track, a round steel roll, a sleeper support, a chain block, a square wood diagonal bracing, a beam bundling rope and a wind resistant rope, wherein the sliding boat is used for conveying precast beams; the square wood diagonal bracing and the beam bundling rope are used for reinforcing the precast beams; the round steel roll is arranged between the sliding boat and the track and used for making the sliding boat slide on the track; and the sleeper support is arranged below the track and used for supporting the track. Compared gantry crane, the precast beam artificial sliding boat translation system is more advantageous; the gantry crane cannot be used for installation in a limited space in a narrow field, and the beam transfer cost of the gantry carne is high; and the artificial sliding boat translation system can avoid construction inconvenience brought by the narrow field and at the same time, save power and reduce construction cost.

Owner:RAILWAY NO 10 ENG GRP CO LTD

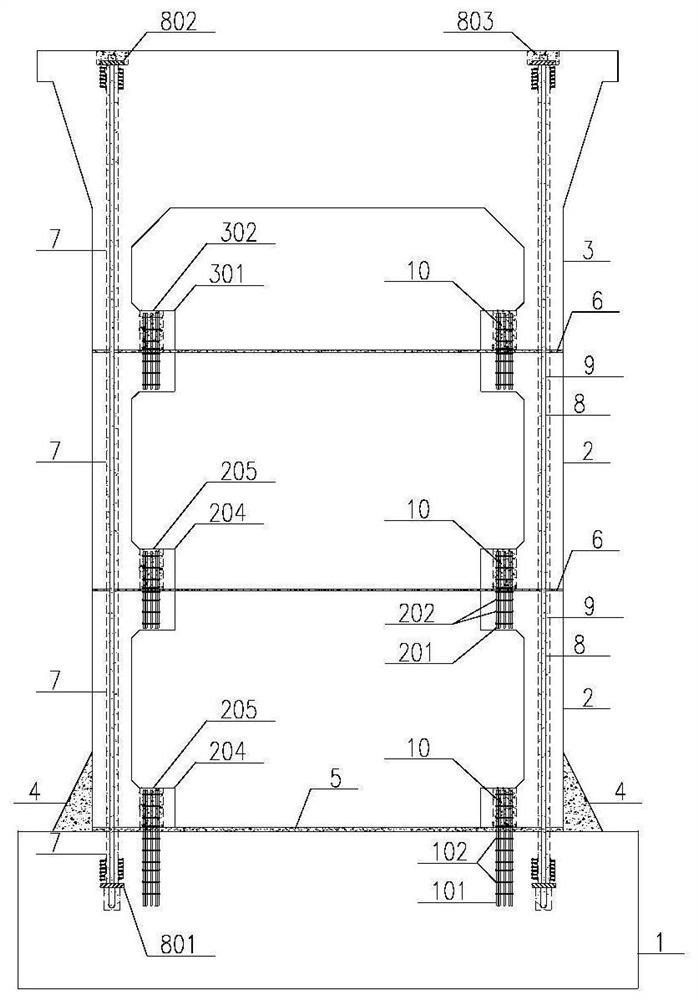

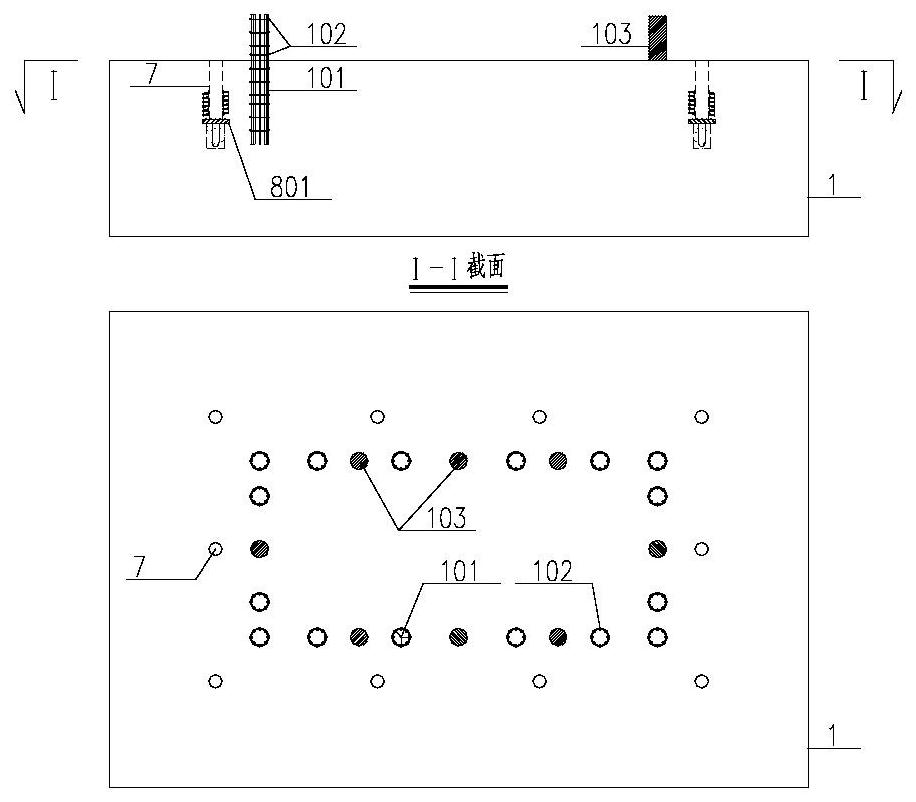

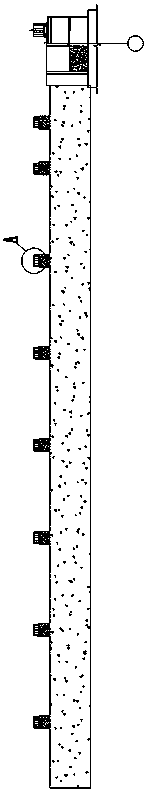

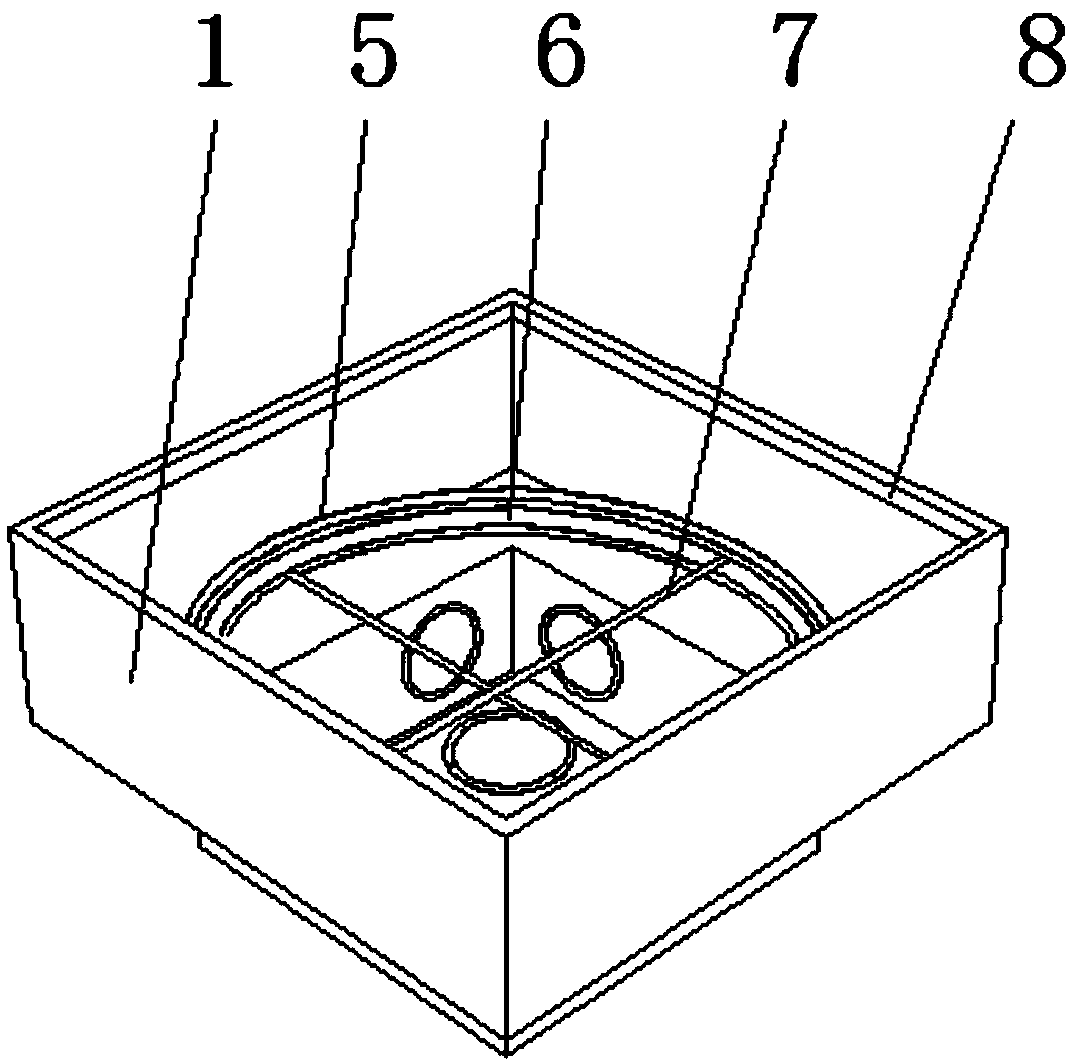

Prefabricated assembled hollow pier with transverse partition plates and construction method

PendingCN111827092ASuitable for erosive environmentFlexible layoutBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention provides a prefabricated assembled hollow pier with transverse partition plates and a construction method, and relates to the technical field of bridge construction. The hollow pier sequentially comprises a foundation, a general section and a top cap section from bottom to top, and foundation connecting steel bars and foundation connecting columns are arranged at the top of the foundation; general section transverse partition plates are arranged at the top and the bottom of the general section, a general section reserved groove is arranged in the general section transverse partition plate located at the bottom, and a general section connecting steel bar is arranged on the general section transverse partition plate located at the top; a top cap section transverse partition plate is arranged at the bottom of the top cap section, and a top cap section reserved groove is formed in the top cap section transverse partition plate at the bottom; during splicing, the connecting steel bars and the connecting columns located on a lower portion extend into the corresponding reserved grooves located on the upper portion, and a high-strength slurry is poured into the reserved grooves; and prestressed pipelines are pre-buried in the foundation, the general section and the top cap section, and connection is performed by penetrating through full-length prestressed tendons. By theadoption of the scheme, a prestress on a pier wall can be flexibly arranged, and manufacturing is easy and convenient.

Owner:CHINA RAILWAYS CORPORATION +1

Reinforcing structure of 3D printing reinforced masonry shear wall

ActiveCN105908860ASimplify on-site construction laborReduce construction proceduresAdditive manufacturing apparatusWallsRebar3d printed

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Mobile type goaf gas quick blocking and extraction device and technology

InactiveCN104405431ASolving Governance ChallengesReduce aggregationSurveyMining devicesProcess engineeringCoal

The invention discloses a mobile type goaf gas quick blocking and extraction device and a mobile type goaf gas quick blocking and extraction technology. The device and the technology are easy and convenient to operate; furthermore, gas in a goaf can be quickly blocked, and the blocked gas can be quickly extracted, so that the difficulty in treating the gas in the goaf can be effectively solved, the gas content of the goaf is fundamentally reduced, the goaf gas gathering amount and the gas gush amount to a stopping working surface are reduced, the influence of the gas in the goaf on the concentration of the gas on the stopping working surface is reduced to the maximum extent, and great significance in reducing the mine ventilating difficulty and realizing safe and high-efficiency production of a coal mine is realized. Multiple stages of fixing devices are convenient for flexible gas pocket forming, and overlarge deformation of a local area of a flexible gas pocket can be avoided; the operation and the use are convenient and quick; the requirement on an underground narrow space can be met, and quick moving is facilitated; meanwhile, the device can be recycled, multi-frequency utilization is realized, and the treatment cost is lowered.

Owner:HENAN POLYTECHNIC UNIV

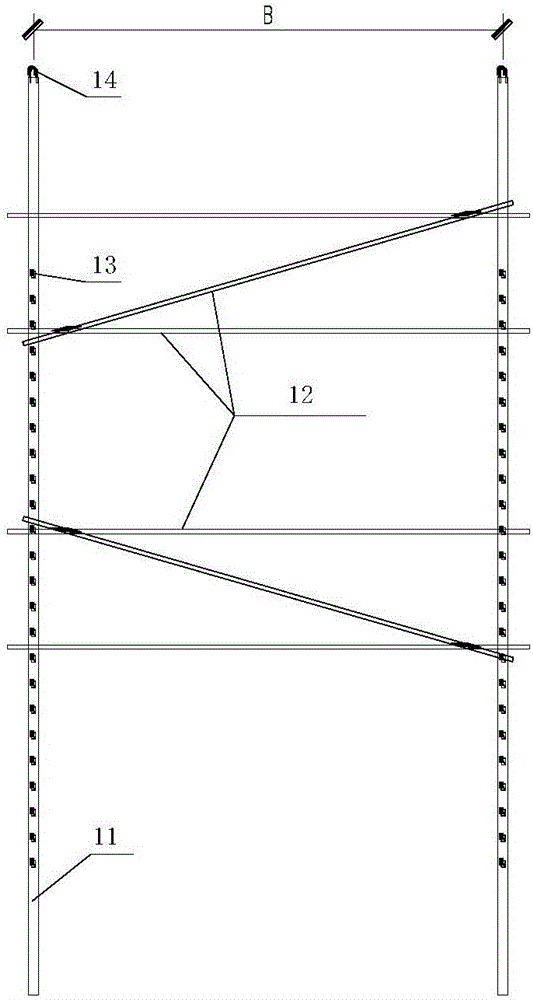

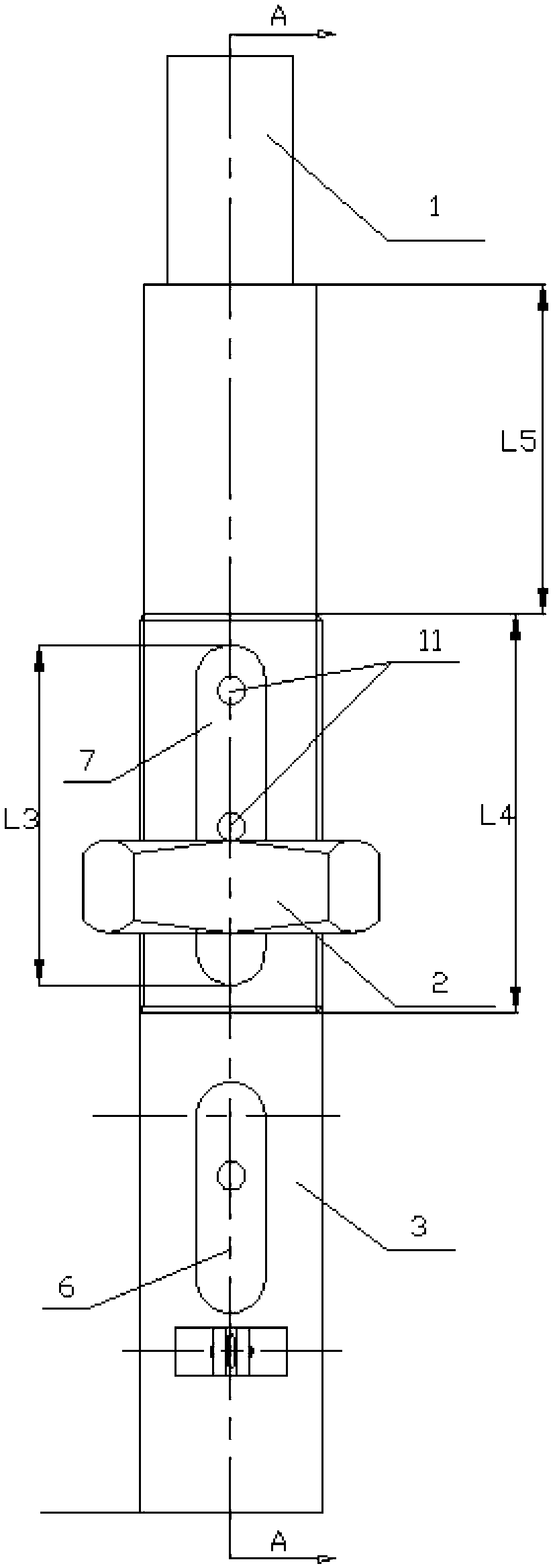

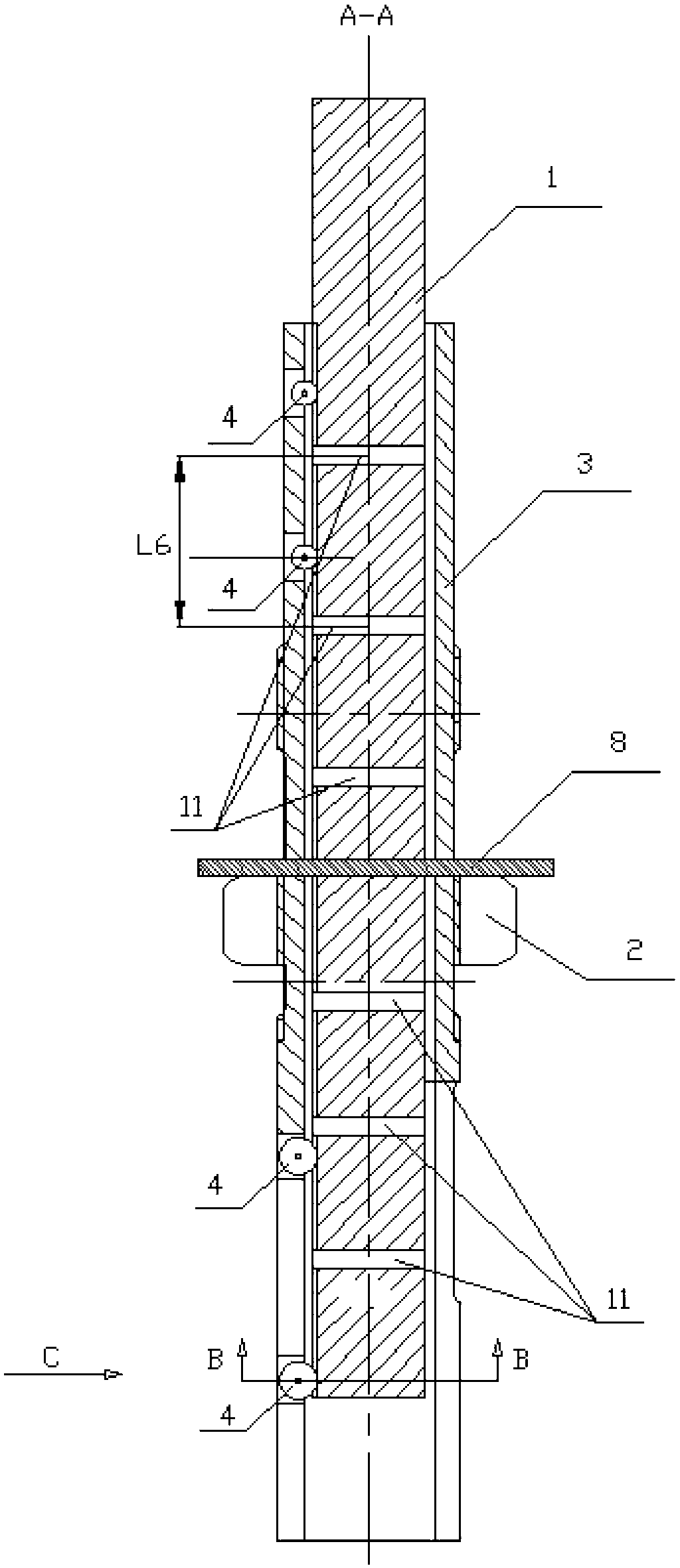

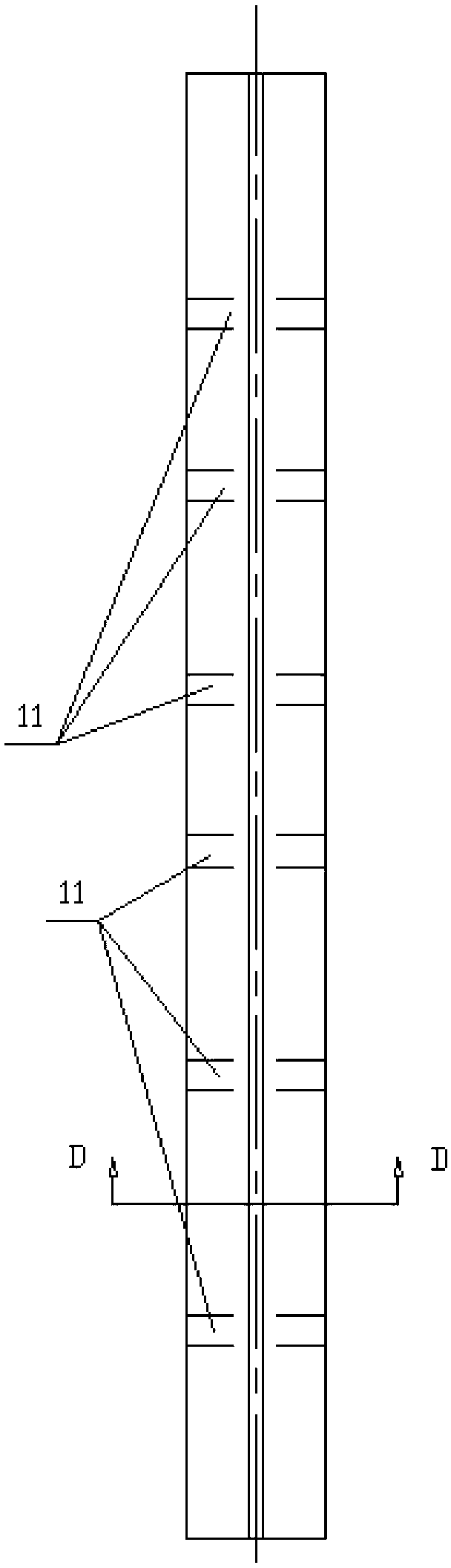

Split type hydraulic lifting and climbing frame

ActiveCN106150057ASolve the inconvenience of constructionSolve the costScaffold accessoriesBuilding support scaffoldsControl engineeringBuilding construction

Owner:CHINA THIRD METALLURGICAL GRP

Novel height-adjustable building bracket

Owner:TIANJIN UNIV

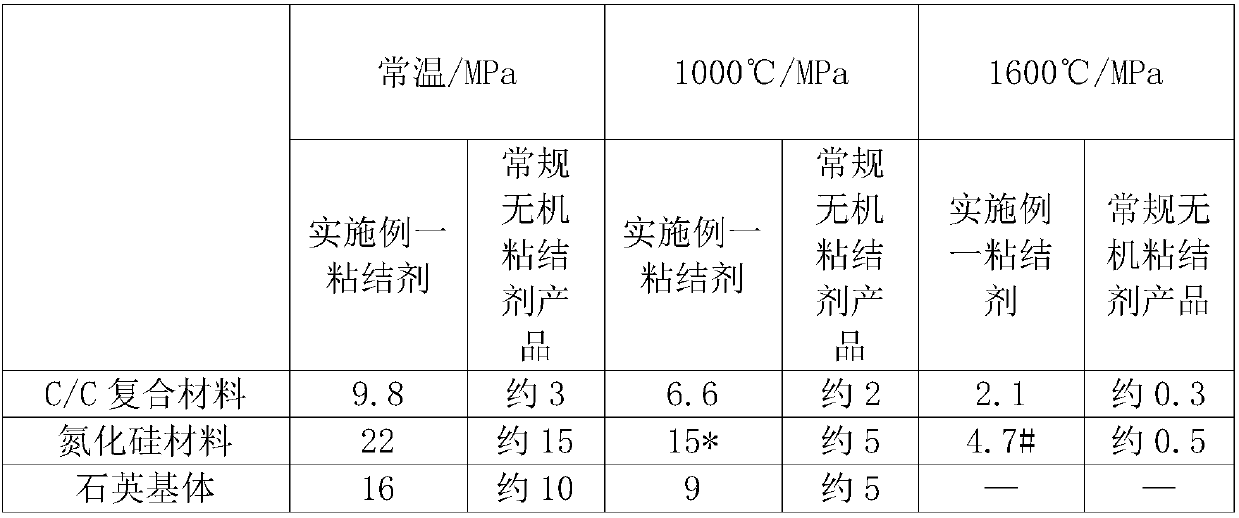

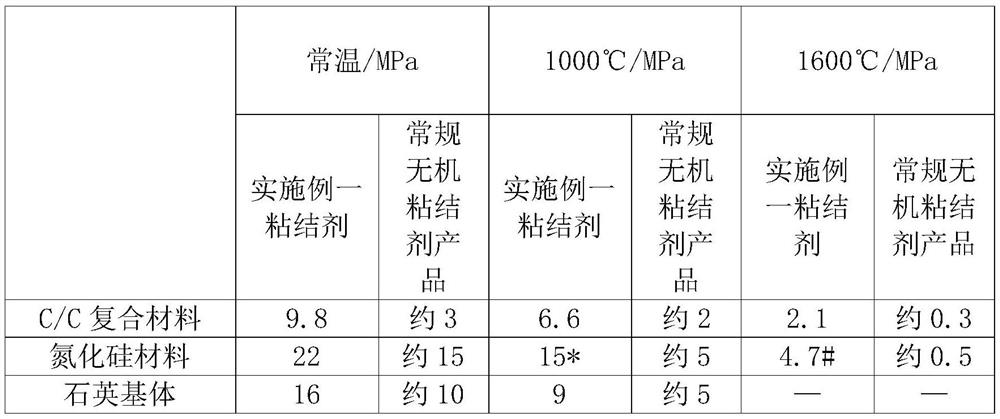

Normal-temperature curing silicate high-temperature resistant binder and preparation method thereof

ActiveCN109749633AHigh strengthImprove high temperature resistanceNon-macromolecular adhesive additivesInorganic adhesivesFiberTemperature resistance

The invention discloses a normal-temperature curing silicate high-temperature resistant binder and a preparation method thereof. The binder comprises 2-10% by weight of chopped fibers, and is preparedfrom the following raw materials in parts by weight: 40-70 parts of water glass, 20-52 parts of alumina powder, 2-10 parts of chopped fibers, 2-6 parts of silicon nitride, 2-5 parts of lanthanum oxide and 2-5 parts of zirconium diboride. The chopped fibers are toughened to enhance the strength of the normal-temperature curing silicate high-temperature resistant binder and improve the high-temperature resistance of the binder; the binder is resistant to high temperature of 1600 DEG C, at 1600 DEG C, the shear strength of the binder is multiple times of the strength of the conventional inorganic binder under the same conditions, and the high-temperature resistance is far superior to the conventional inorganic binder.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

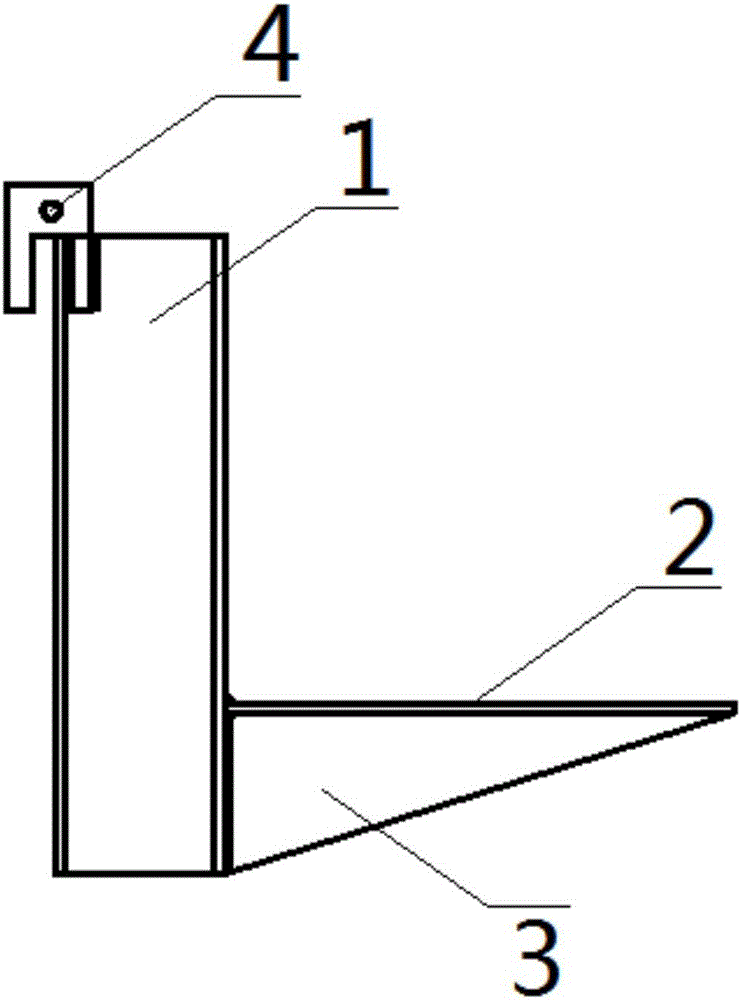

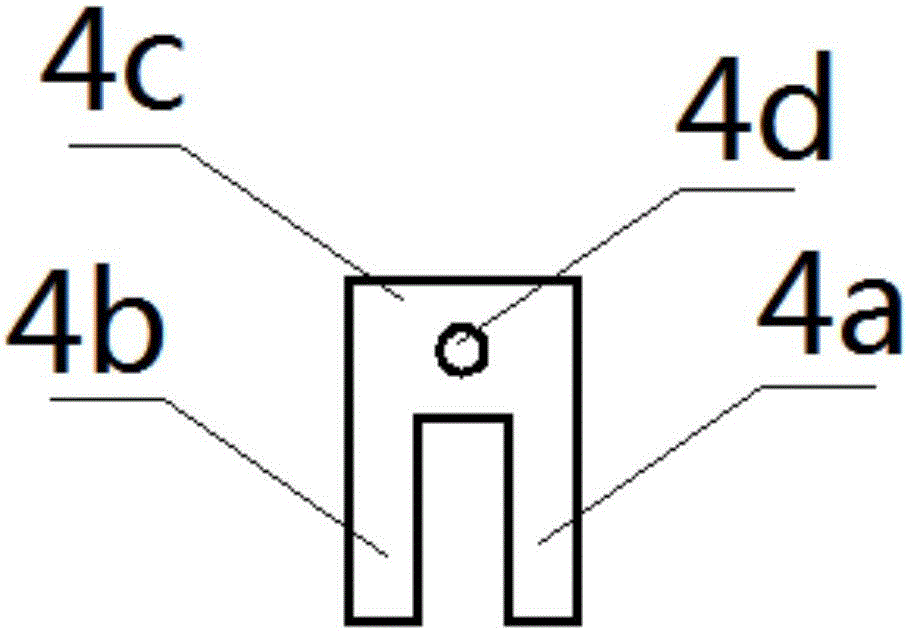

Bracket and construction method of deep trench support

The invention provides a bracket and a construction method of a deep trench support so as to solve the problem that the bracket is inconvenient to mount and cannot be repeatedly utilized in the construction process of the deep trench support. Due to the arrangement of a suspending device at the upper part of the left flange of an I steel, when the bracket is mounted, the mounting of the bracket can be finished as long as the bracket is fixed at the top of a steel sheet pile wall through the suspending device, so that unnecessary construction steps, such as welding, are avoided, and the problem of construction inconvenience caused by welding necessity during the mounting of the bracket is solved. As the bracket can be conveniently disassembled after the construction of the deep trench support is finished, the bracket can be cyclically used, and the problem that the existing bracket cannot be repeatedly utilized is solved.

Owner:SHANGHAI NO 7 CONSTR

Making method of prefabricated concrete casting structure of 3D printing concrete shear wall

ActiveCN105937276AAvoid constructionAvoid demolitionAdditive manufacturing apparatusWallsHorizontal barPrecast concrete

The invention discloses a making method of a prefabricated concrete casting structure of a 3D printing concrete shear wall. The making method comprises the steps that (a) a first layer of prefabricated concrete casting is made by adopting 3D printing; (b) a first layer of binding bars and / or horizontal bars is arranged at the top of the first layer of prefabricated concrete casting; (c) a 3D printing technology is adopted to make a second layer of prefabricated concrete casting at the top of the first layer of prefabricated concrete casting to make two ends of the first layer of binding bars and / or horizontal bars embedded at the connecting position of the first layer of prefabricated concrete casting and the second layer of prefabricated concrete casting; (d) the steps (b) and (c) are repeated till all layer of prefabricated concrete casting are made to reach designed elevation. The formwork swelling is prevented by prefabricating the binding bars between the inner wall face and the outer wall face of the prefabricated concrete casting, the horizontal bars of the shear wall are also embedded in the prefabricated concrete casting, inconvenient construction brought during post-installation of the horizontal bars is avoided, and the construction is simplified.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

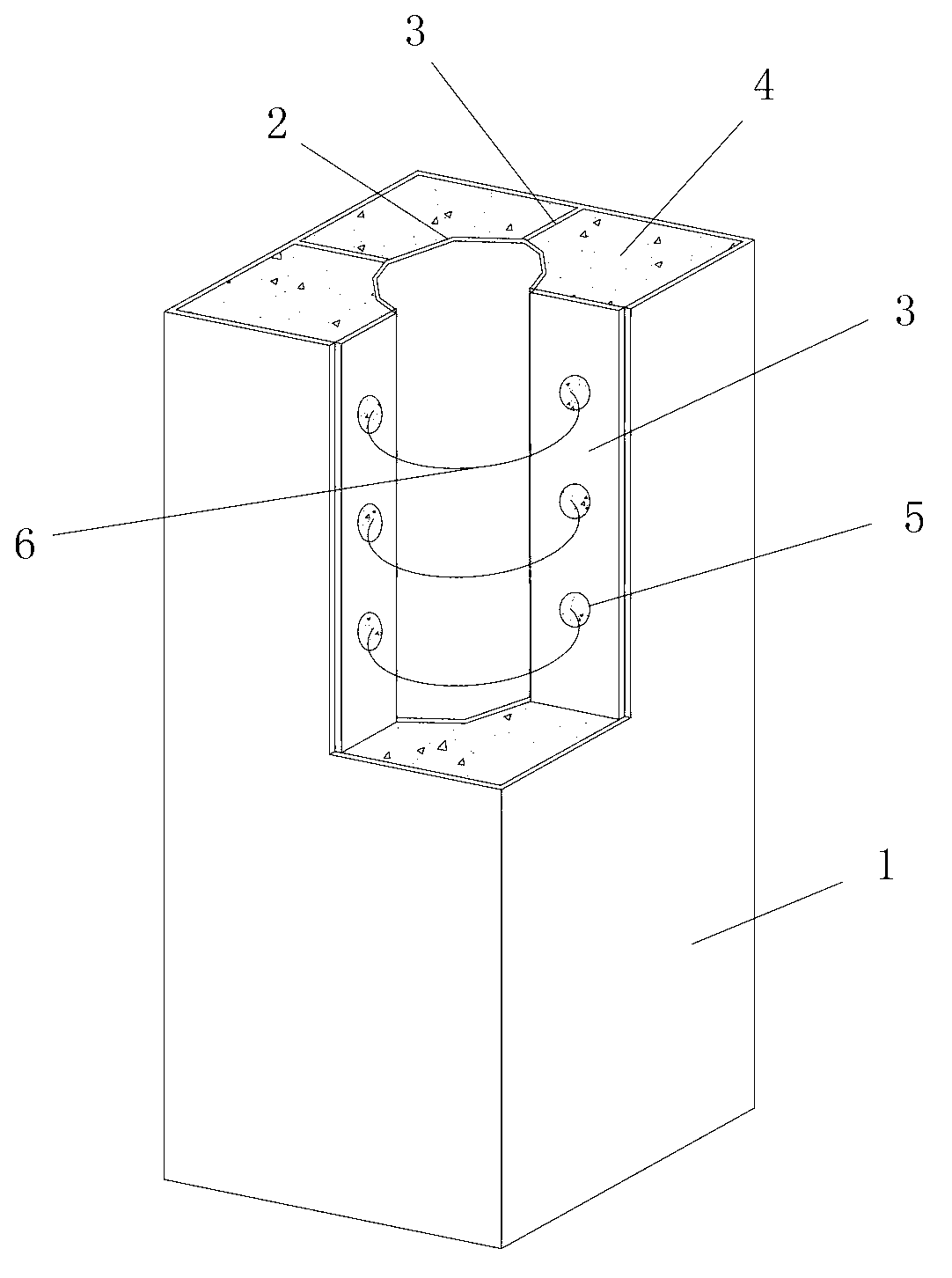

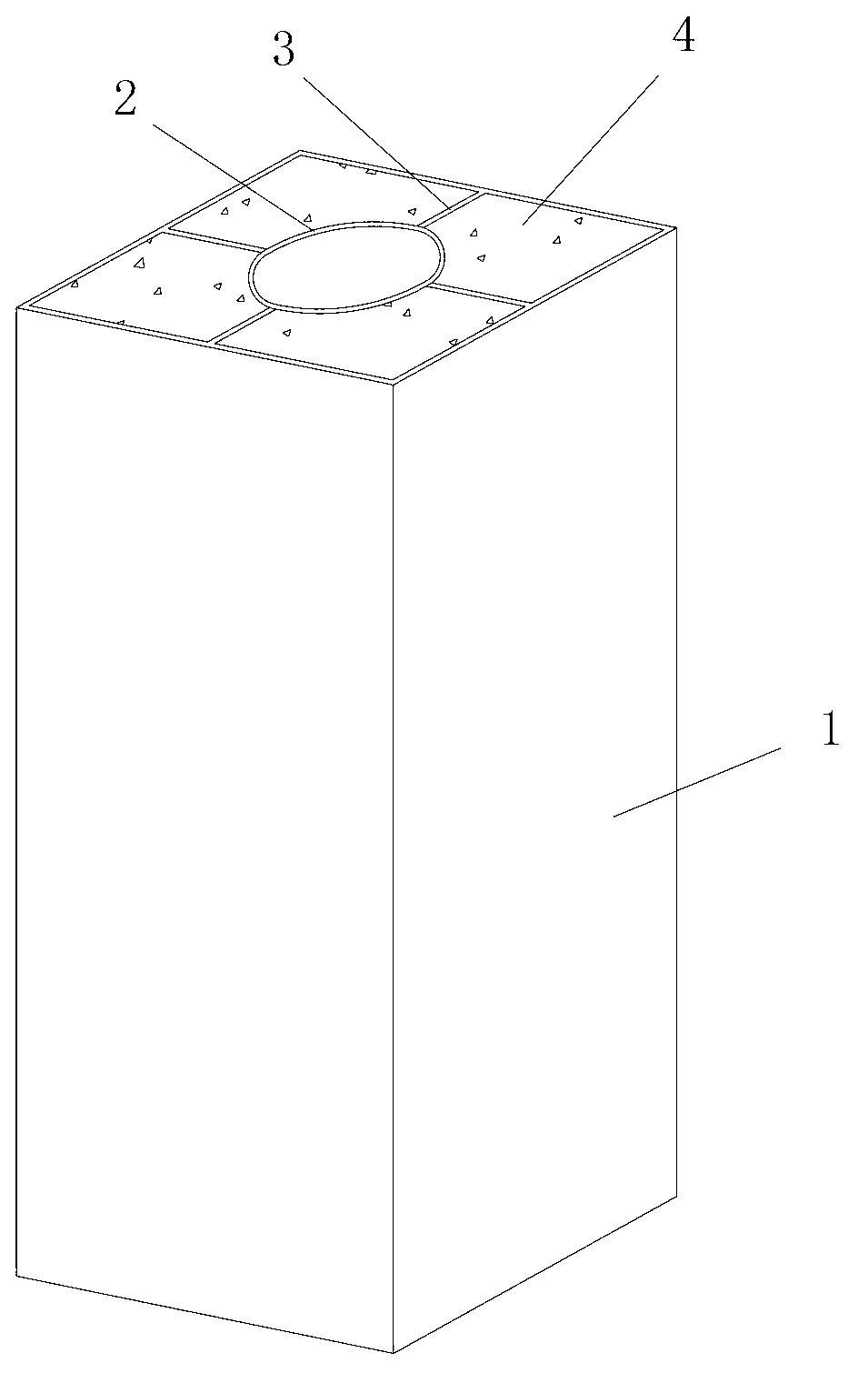

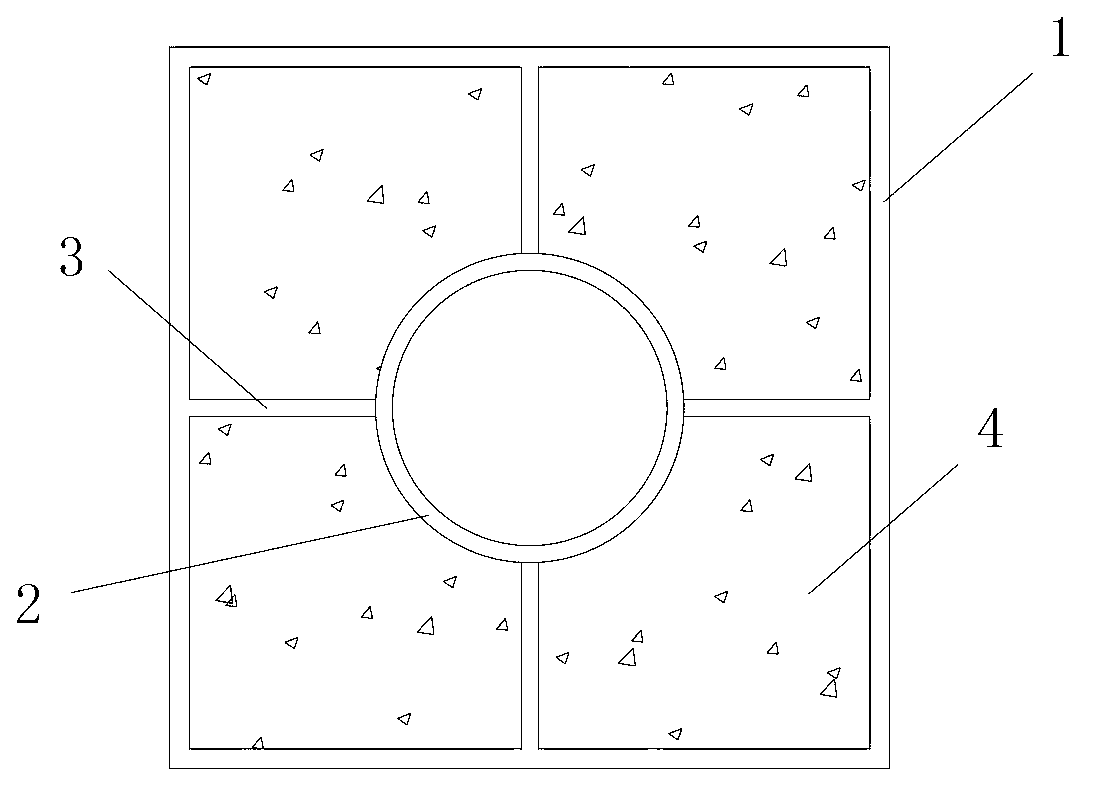

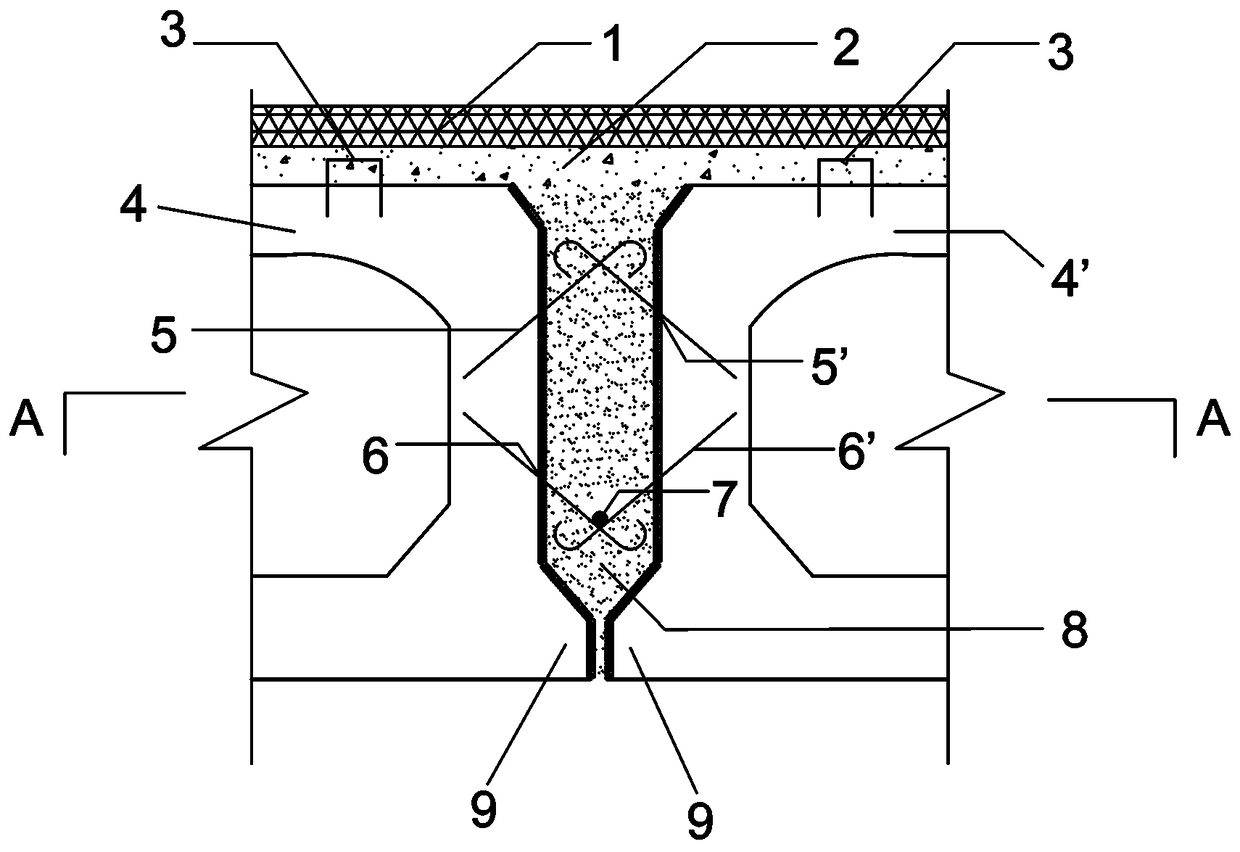

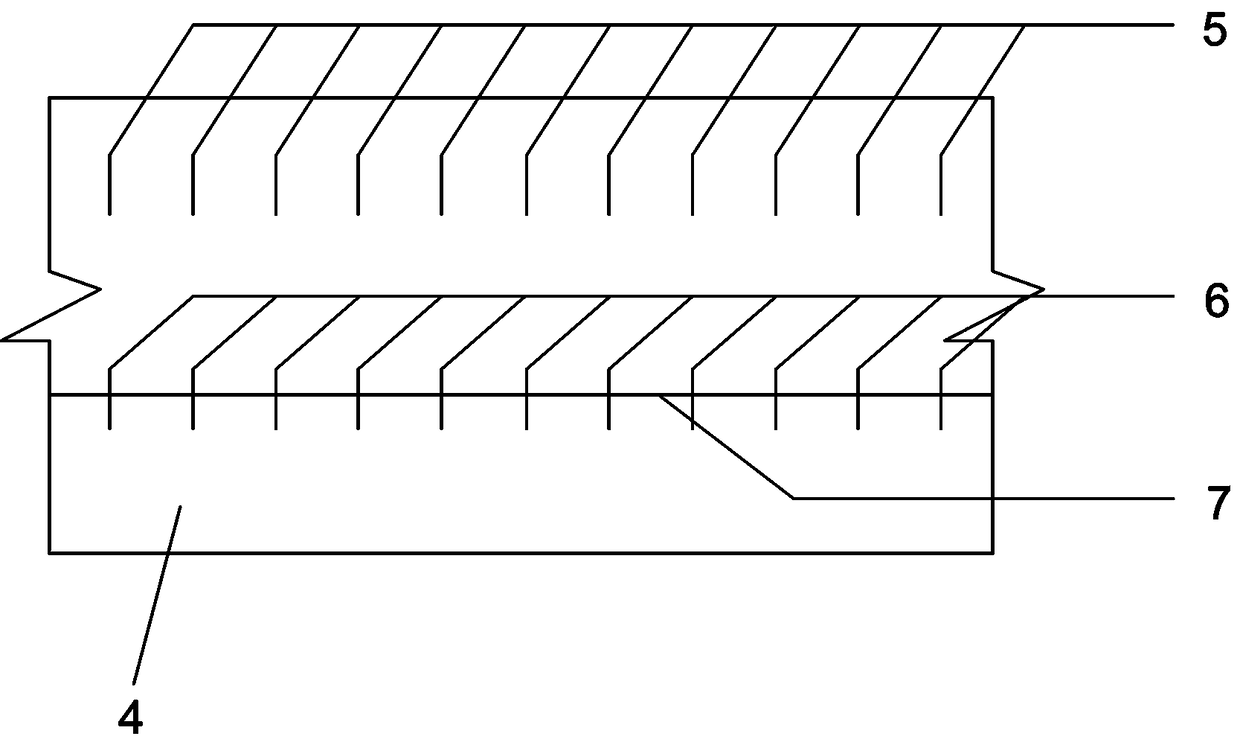

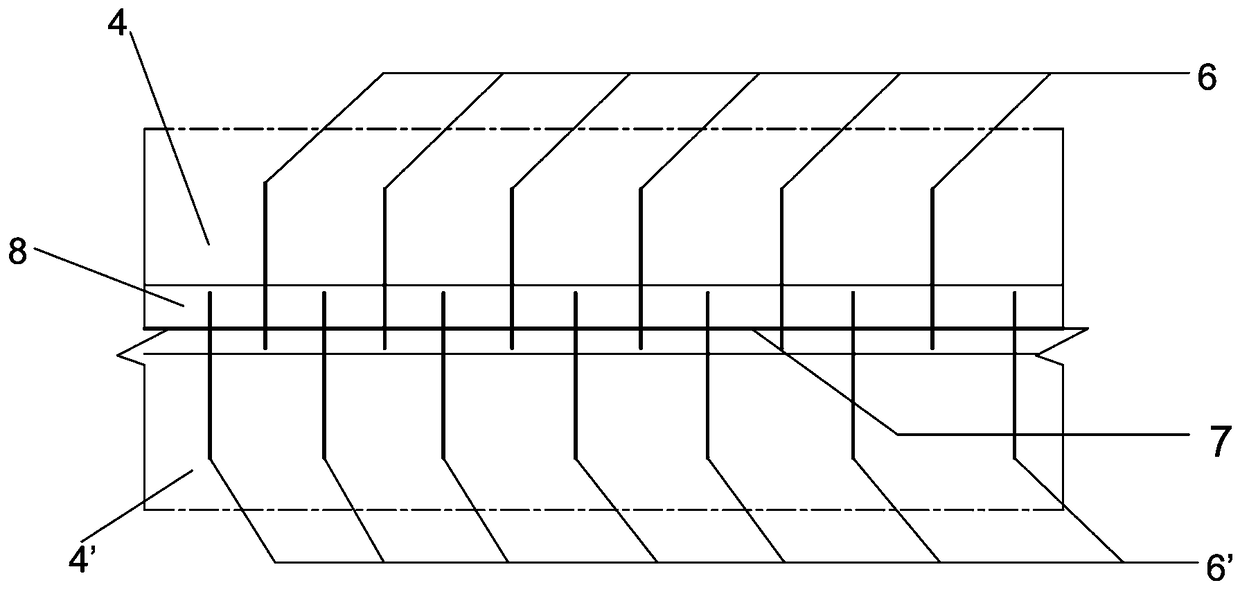

A double stiffened SCS square steel tube concrete structure based on stirrups and stiffening ribs

InactiveCN103061449ASimple structureReasonable designArched girdersStrutsMechanical propertyStructure based

The present invention discloses a double stiffened SCS square steel tube concrete structure based on stirrups and stiffening ribs, including a square steel pipe, a round steel pipe sleeved inside the square steel pipe, a plurality of PBL stiffening ribs laid between the square and round steel tube, a plurality of stirrups laid in the plurality of PBL stiffening ribs from top to bottom, and a concrete structure pouring formed by concrete filled in the cavity between the square steel tube and the round steel pipe, and the square steel pipe and the round steel pipe laid around the same axis. The layout directions of the plurality of PBL stiffening ribs are all the same with the central axis direction of the round steel pipe; the longitudinal lengths of the square steel pipe, the round steel pipe and the plurality of PBL stiffening ribs are the same; the plurality of PBL stiffening ribs are laid along the circumferential direction; and the plurality of stirrups are laid in parallel. The concrete structure of the invention has simple structure, reasonable design, easy construction and low construction cost, excellent mechanical properties and good use effect, and can solve many problems existing in current square steel concrete structures.

Owner:XIAN HIGHWAY INST +1

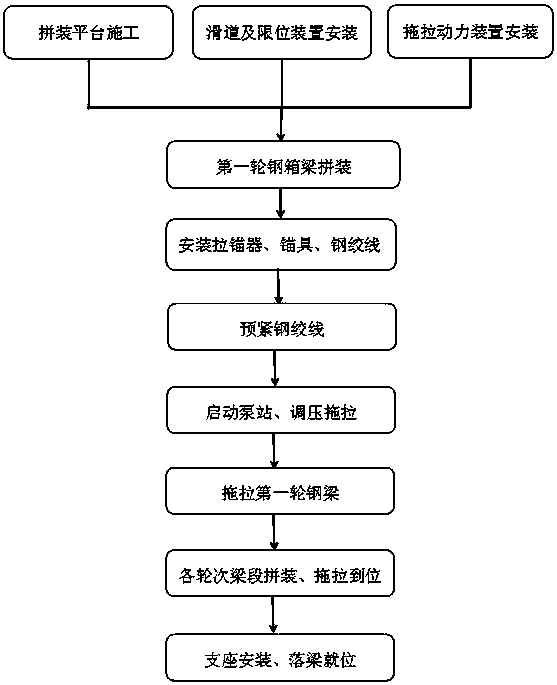

Long-distance incremental launching construction method for deck type arch bridge steel-concrete composite girder span arch ring

ActiveCN108385539ASolve the inconvenience of constructionEasy constructionBridge erection/assemblyCable stayedSpandrel

The invention relates to a long-distance incremental launching construction method for a deck type arch bridge steel-concrete composite girder span arch ring. The long-distance incremental launching construction method for the deck type arch bridge steel-concrete composite girder span arch ring comprises the steps of mounting a steel girder assembly platform and a gantry crane; mounting a slide way girder and a limiter on a spandrel column, placing a sliding, deviation rectifying and lifting device and a mounting a drag type incremental launching power device; connecting a steel strand to thespandrel column in series and applying a pretension force; enabling cable-stayed steel strands at the roots of No. 2, No. 4, No. 8 and No.10 uprights to be connected with the top of a junction pier and applying a pretension force; assembling a composite girder on the the assembly platform and mounting a front launching nose; towing the assembled girder segments forwards by using a horizontal jack;after a space is available on the site, continuing to assemble a rear boundary beam body; alternately carrying out towing and assembling; connecting the head part of a rear link with the tail part ofa front link by using a pin shaft and integrally pushing the rear link and the front link; dismantling the front launching nose mounting the last one pier on the steel girder; after the steel girderis integrally pushed in place, releasing the connection between the steel girders; and dismantling a rear launching nose and carrying out enabling the girders to fall in sections. According to the long-distance incremental launching construction method for the deck type arch bridge steel-concrete composite girder span arch ring, the construction quality can be improved, the construction efficiencycan be enhanced, the working period can be reduced and the construction cost can be reduced.

Owner:中铁十八局集团第二工程有限公司 +1

Large-opening inverse trenching technology

InactiveCN1978794AReduce underground transfer volumeImprove efficiencyBuilding constructionsExcavationsCaveBuilding construction

The invention supplies big opening backward practicing excavating technique. It includes the following steps: selecting unearthed cave mouth on the structure top plate; excavating. Its features are that the distance of the adjacent two borrow cave mouths is 20-40m; and their area is 600-700m2. The technique can increase excavating efficiency and speed, avoid earthwork transportation inconvenience caused by dark excavating plane, and shorten structure construction time for each construction block.

Owner:SHANGHAI NO 7 CONSTR

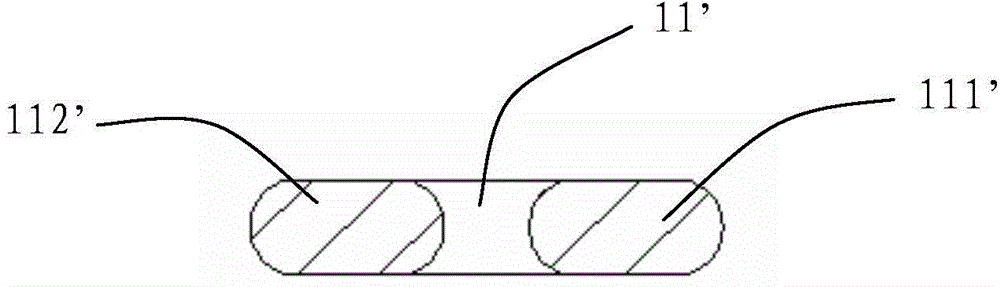

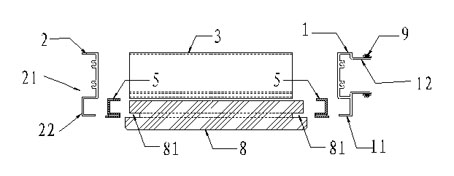

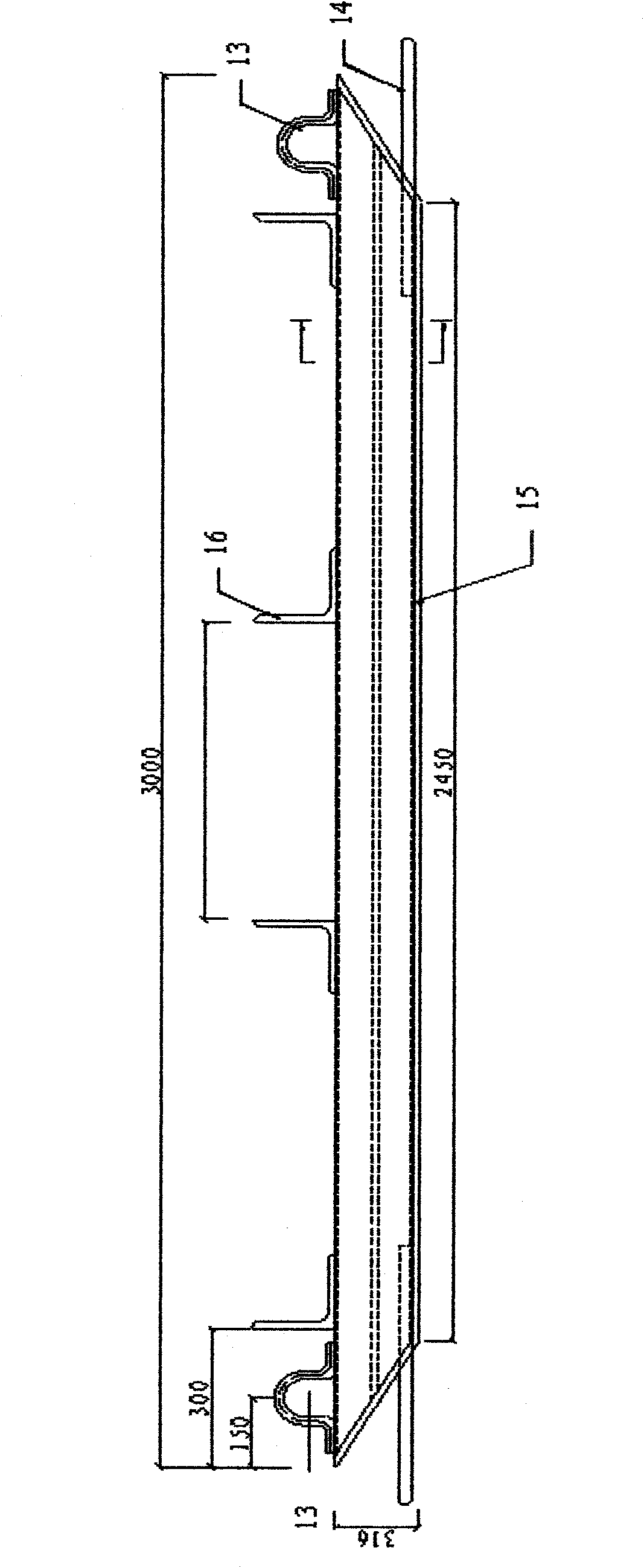

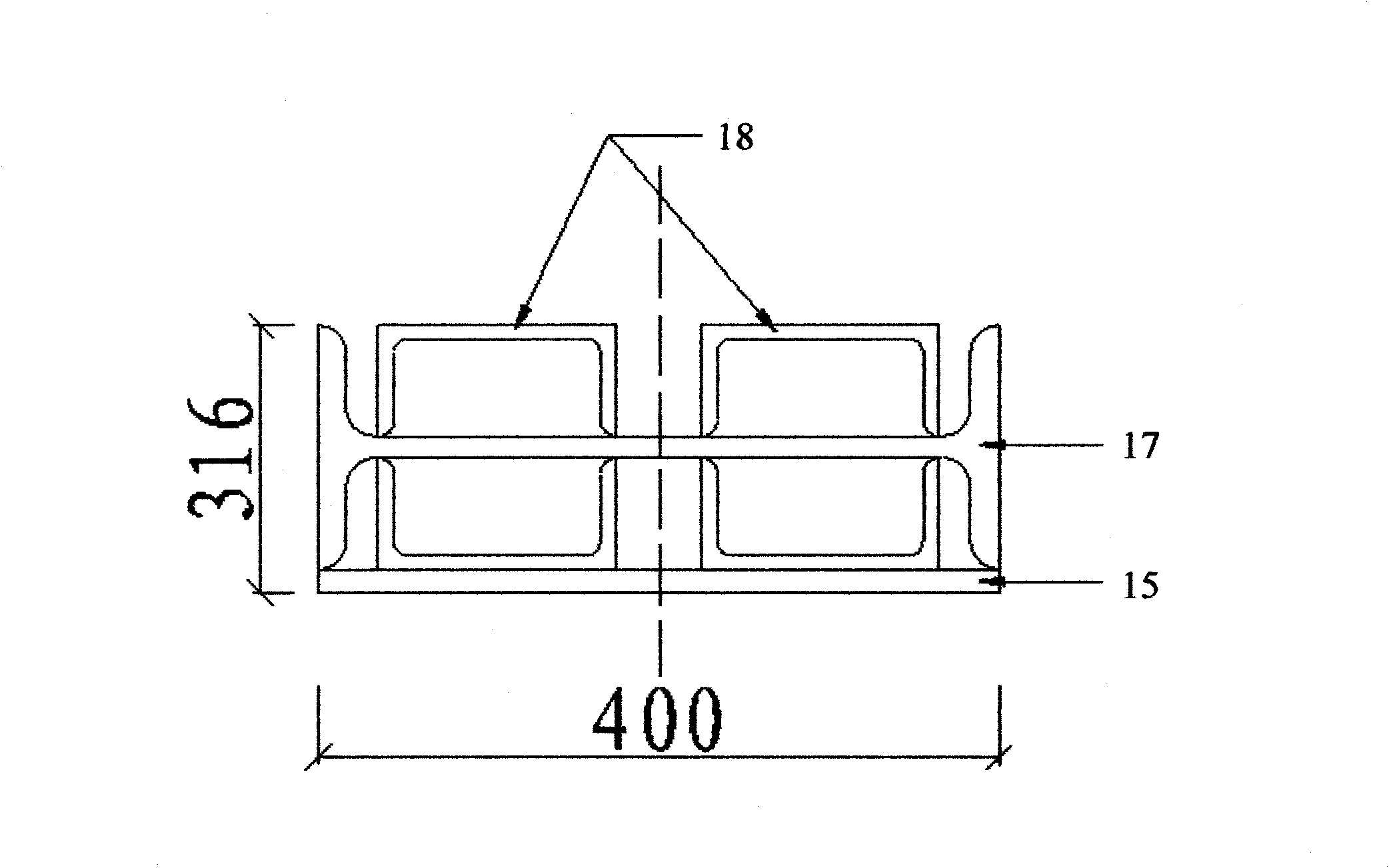

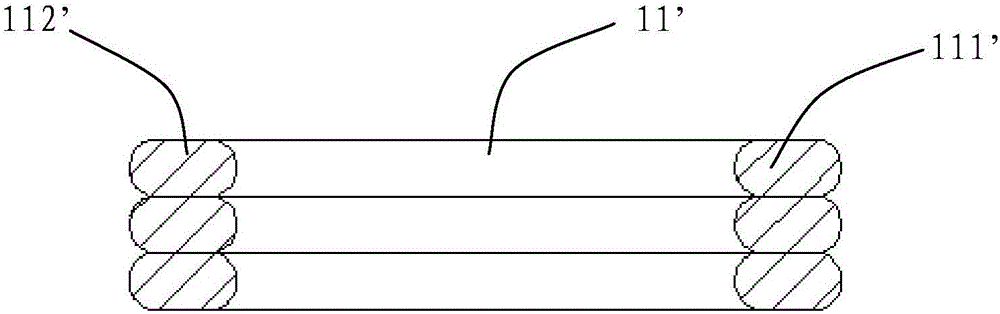

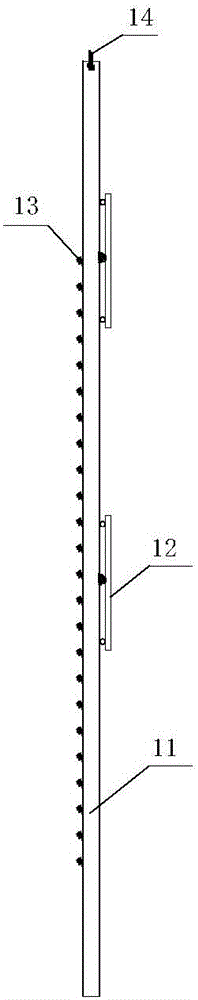

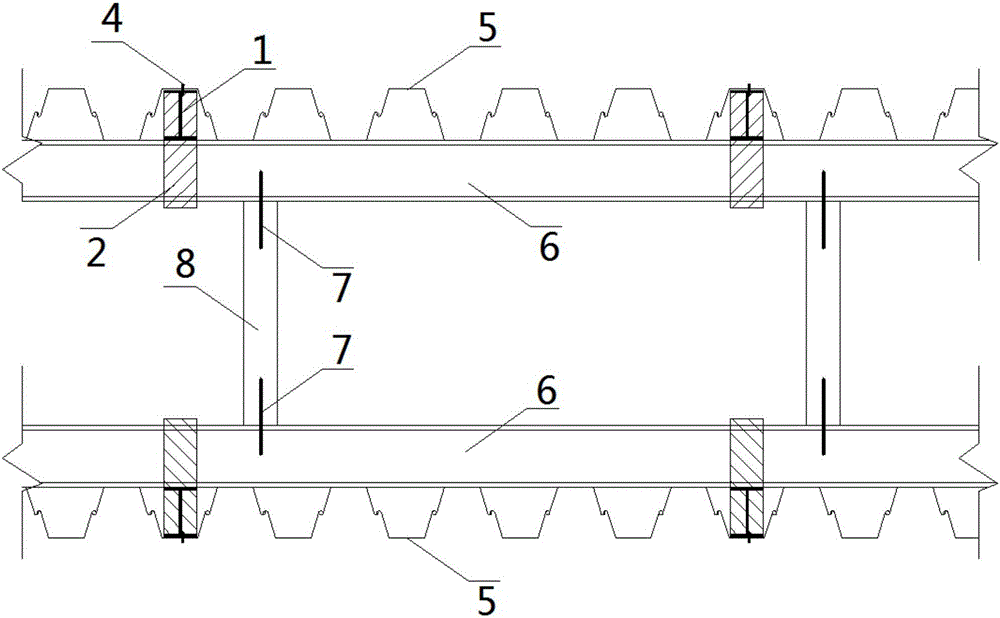

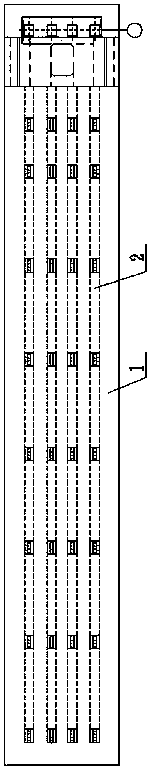

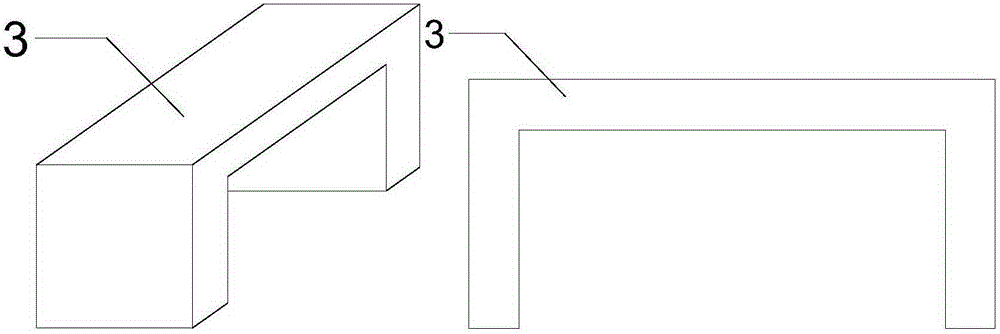

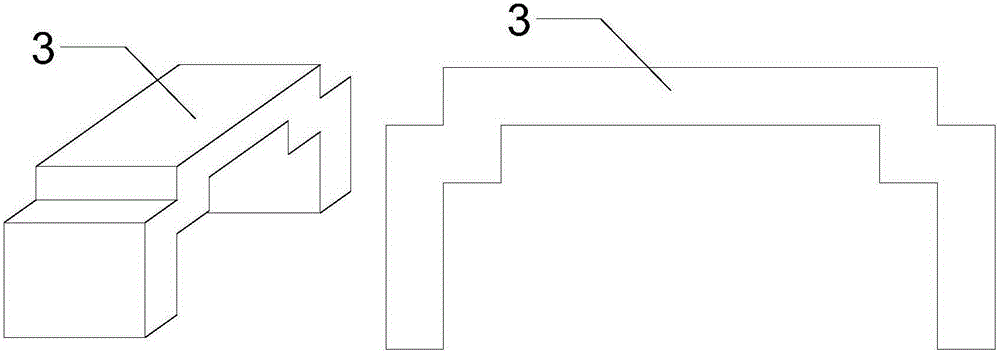

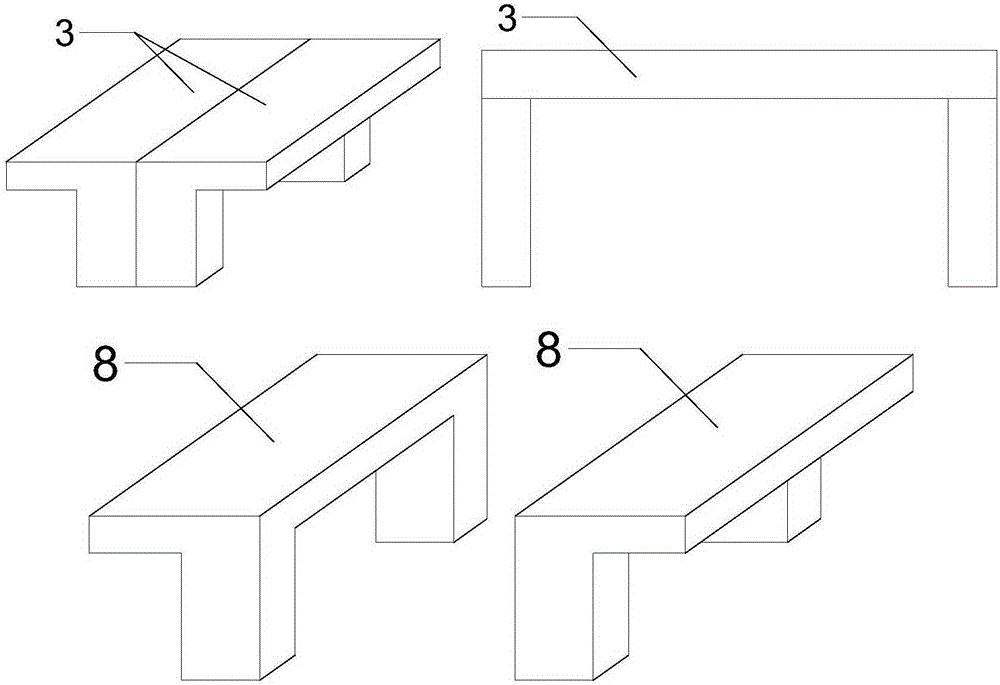

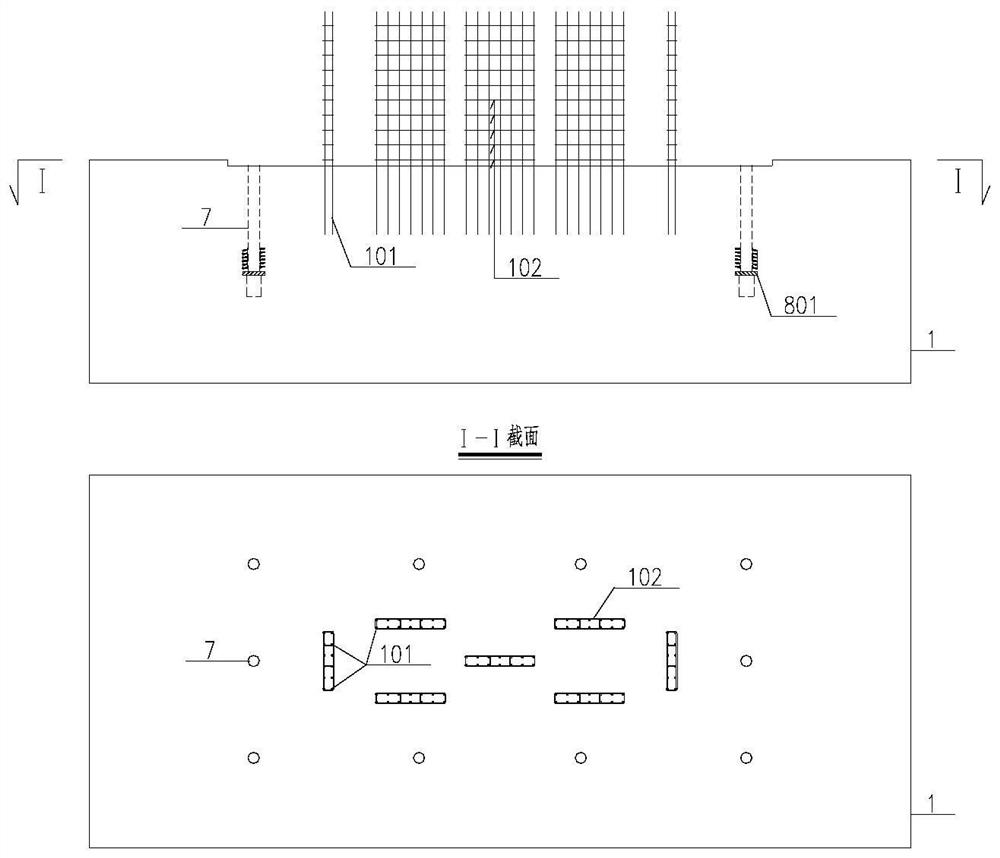

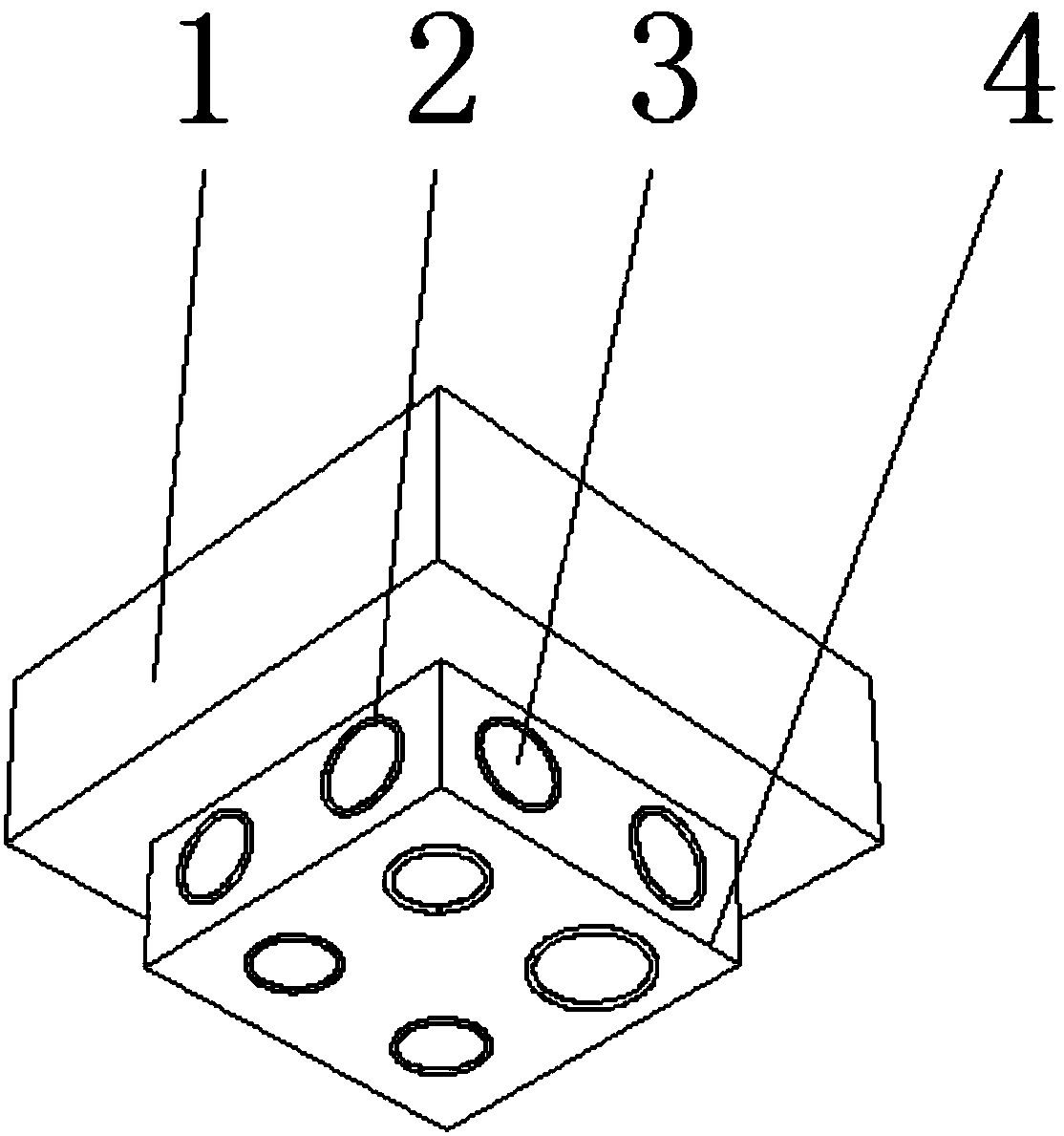

Ribbed prestressed reinforced concrete prefabricated member plate

A ribbed prestressed reinforced concrete prefabricated member plate comprises a reinforced concrete bottom plate 1, reinforced concrete longitudinal ribs 2 and prestressed rebars 4. The ribbed prestressed reinforced concrete prefabricated member plate is characterized in that the reinforced concrete longitudinal ribs 2 are provided with hole prefabricated members 3. In the ribbed prestressed reinforced concrete prefabricated member plate, the hole prefabricated members 3 form holes in the reinforced concrete longitudinal ribs, placing of filler or form supporting plates at the longitudinal ribs is not required, and manufacturing is facilitated; similarly, rebars can be placed below the holes to connect multiple reinforced concrete prefabricated members, thereby forming an assembled floor. The ribbed prestressed reinforced concrete prefabricated member plate has the advantages of ease of construction, process simplicity, and low time and labor consumption.

Owner:吴方伯

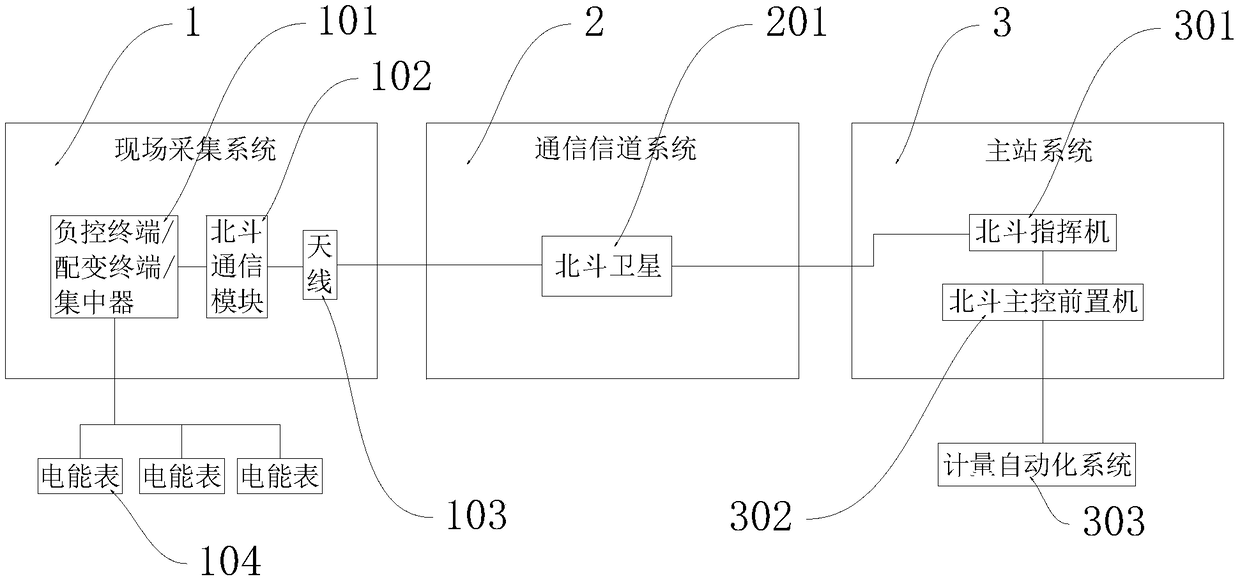

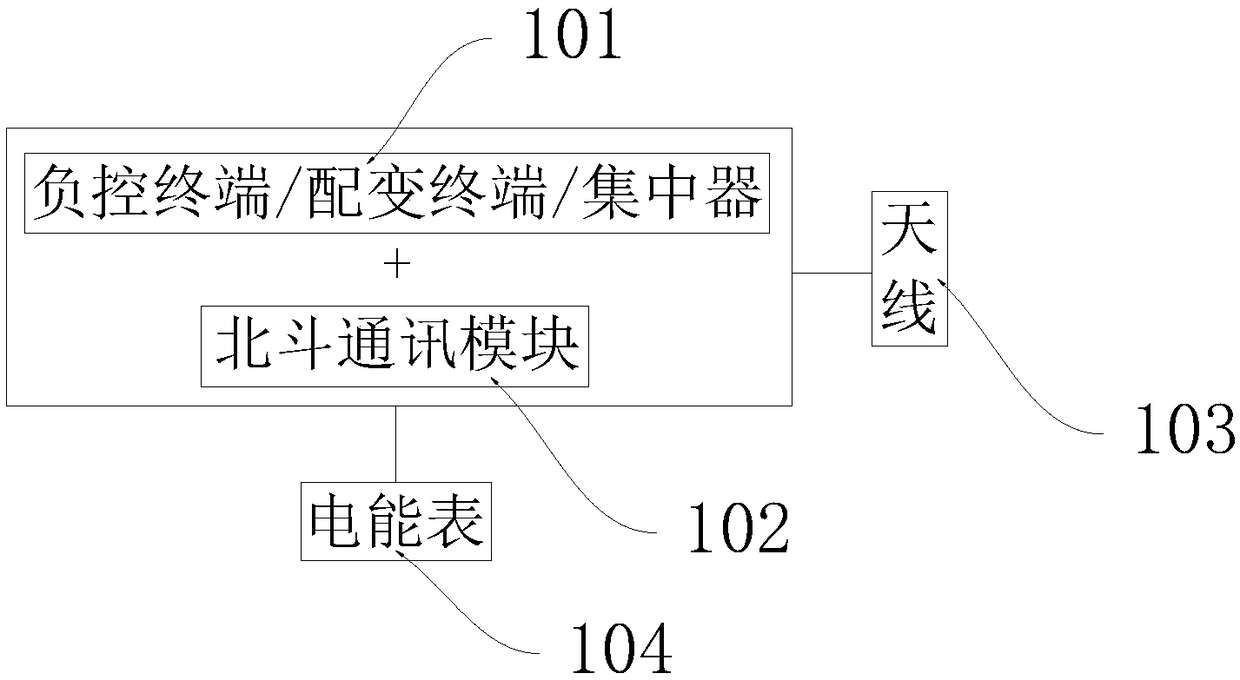

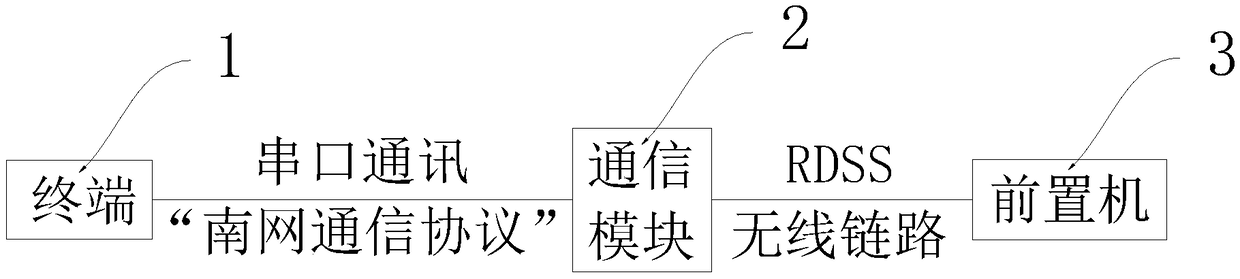

Grid communication system based on Beidou system

InactiveCN109462432ASolve the inconvenience of constructionImprove confidentialityTransmission systemsRadio transmissionCommunications systemMaster station

The invention discloses a grid communication system based on a Beidou system, which comprises a field acquisition system, a communication channel system and a master station system. The field acquisition system comprises a terminal module, a communication module, and an antenna. The terminal module is connected with an electric energy meter; the terminal module is in communication connection withthe communication module through a serial port; the communication module shields a connection wire through multiple wires so as to supply power for the antenna and perform data interaction; the antenna achieves data transmission with the communication channel system through a RDSS wireless link; the communication channel system comprises the Beidou satellite; the Beidou satellite communicates witha Beidou director in the master station system through the RDSS wireless link; the master station system comprises the Beidou director and the Beidou master control front-end processor; and the Beidou director is connected with the Beidou master control front-end processor through a communication cable. The system in the invention has the beneficial effects that a Beidou communication module anda Beidou antenna are added in the field acquisition system so that the system can better adapt to various use scenes and the problem of inconvenience of construction of communication wires in remote mountainous areas is solved.

Owner:GUANGZHOU YUNYI INTELLIGENT TECH CO LTD

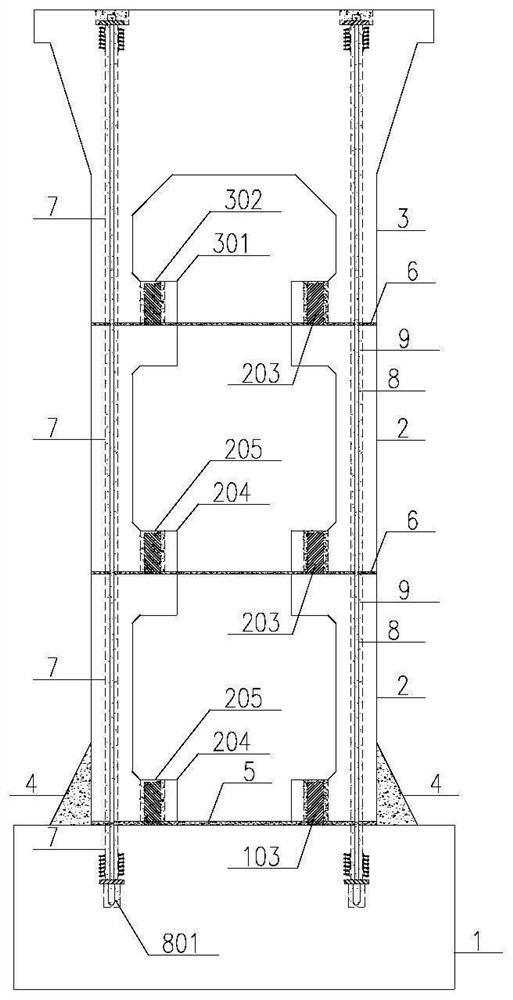

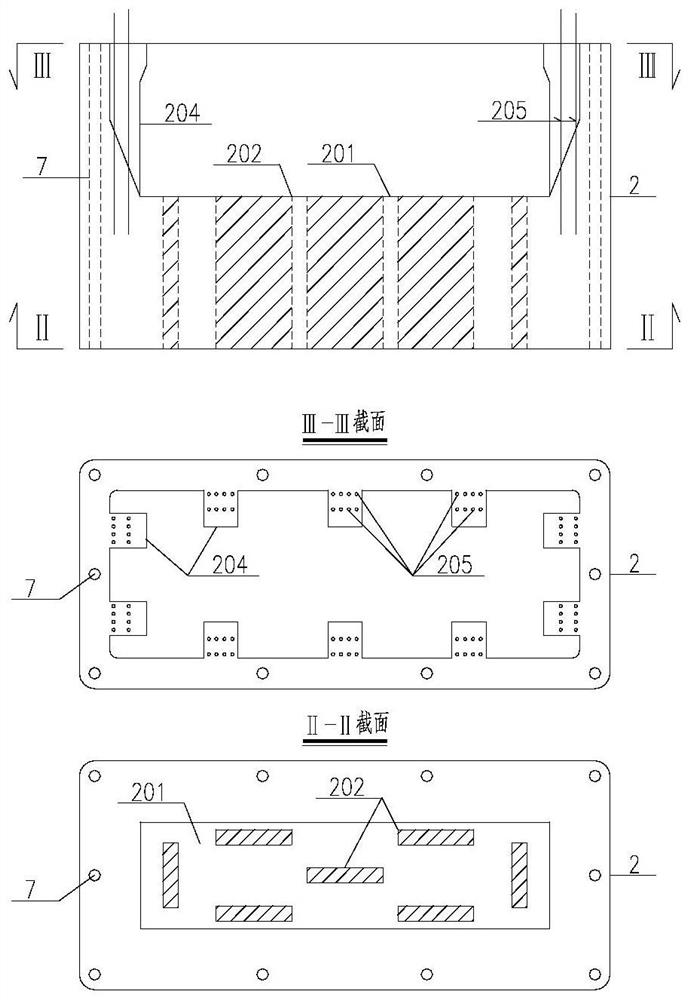

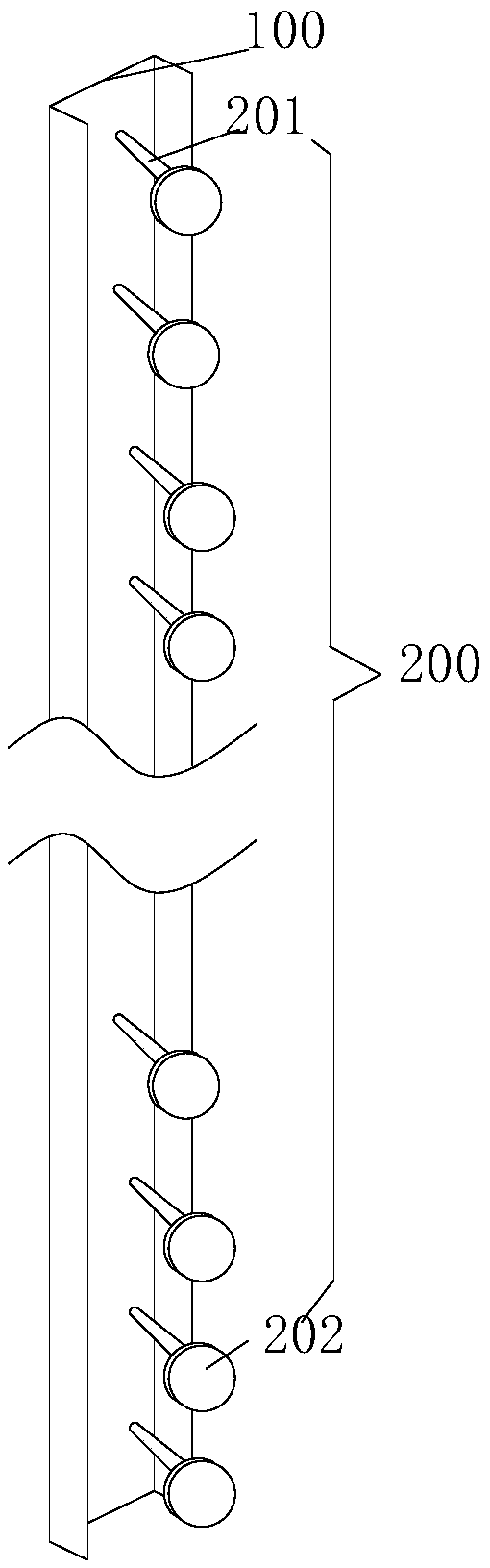

Prefabricated assembled hollow pier with built-in rib plates and construction method

PendingCN111827095ASuitable for erosive environmentFlexible layoutBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention provides a prefabricated assembled hollow pier with built-in rib plates and a construction method, and relates to the technical field of bridge construction. The hollow pier sequentiallycomprises a foundation, a bottom section, a middle section and a top cap section from bottom to top. Embedded steel bars are arranged at the top of the foundation, and stirrups are arranged on the embedded steel bars; a solid section is arranged below the bottom section, the bottom section and the solid section are prefabricated together, a connecting steel bar hole channel is reserved in the solid section, and a diameter of the connecting steel bar hole channel is 5 cm larger than that of each side of the embedded steel bar at the top of the foundation; post-cast concrete is filled in pore channels of the embedded steel bars; the rib plates are arranged on the bottom section, the middle section and the top cap section, each rib plate is provided with a connecting reinforcing steel bar, each connecting reinforcing steel bar extends out of the corresponding rib plate, and the connecting reinforcing steel bars between the sections are in lap joint with one another by more than 10 timesof the diameter of the reinforcing steel bars; and prestressed pipelines are pre-buried in the foundation, the bottom section, the middle section and the top cap section and are connected by penetrating through full-length prestressed tendons. By adopting the scheme, defects of insufficient energy consumption and low ductility of prestressed assembled piers can be overcome.

Owner:CHINA RAILWAYS CORPORATION +1

Multi-directional correction wire box

PendingCN108666945ASolve the inconvenience of constructionAvoid the problem of secondary picking and correcting the wire boxElectrical apparatusFixed frameMulti directional

The invention discloses a multi-directional correction wire box. The box comprises a box body part, a connecting part and a plugging part, wherein the box body part comprises an upper box body, a threading hole, a stopper, a lower box body and a ring; the connecting part comprises a telescopic pole, bolts, a moving pole, a panel, a support leg, a sliding block, a lug and a T-shaped fixture block;the plugging part comprises a plugging plate, a tie rod and an annular fixed frame. The position of the panel of a product can be adjusted in four directions: up, down, left and right, and the panel can be rotated at a certain angle, thereby effectively solving the problem of construction inconvenience caused by the pre-buried position deviation of a wire box, avoiding the problem of correcting the wire box during the secondary chiseling, improving the construction efficiency and achieving a good fixing effect; the sliding block in the product can slide in an arc sliding chute, so that the position of a screw hole formed in the sliding block can also be adjusted, thus facilitaitng the installation of a switch and a socket panel, reducing the difficulty of using the device and improving thepracticability of the device.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

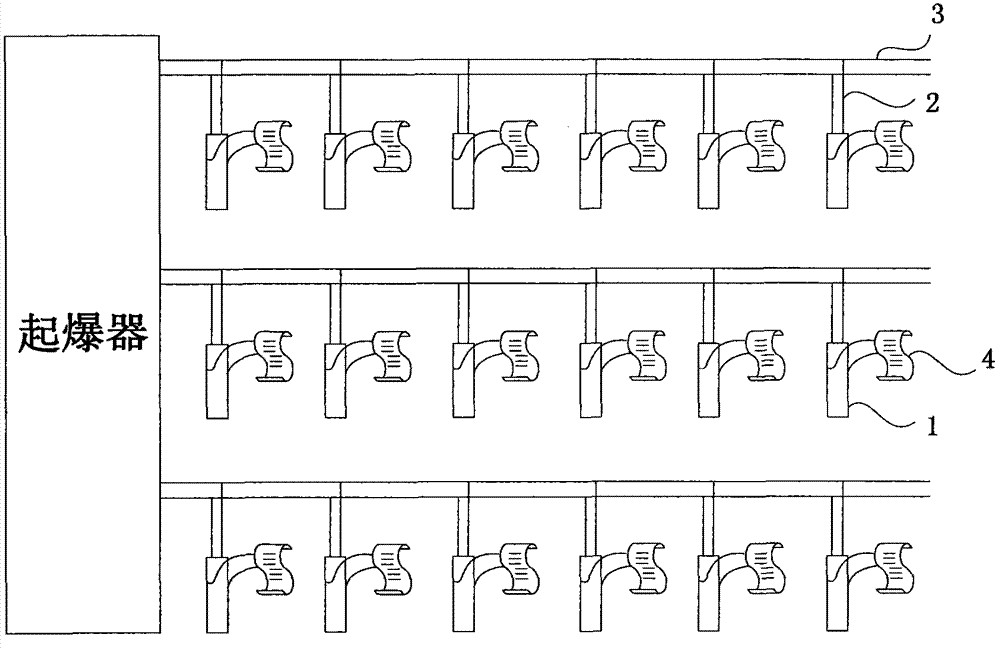

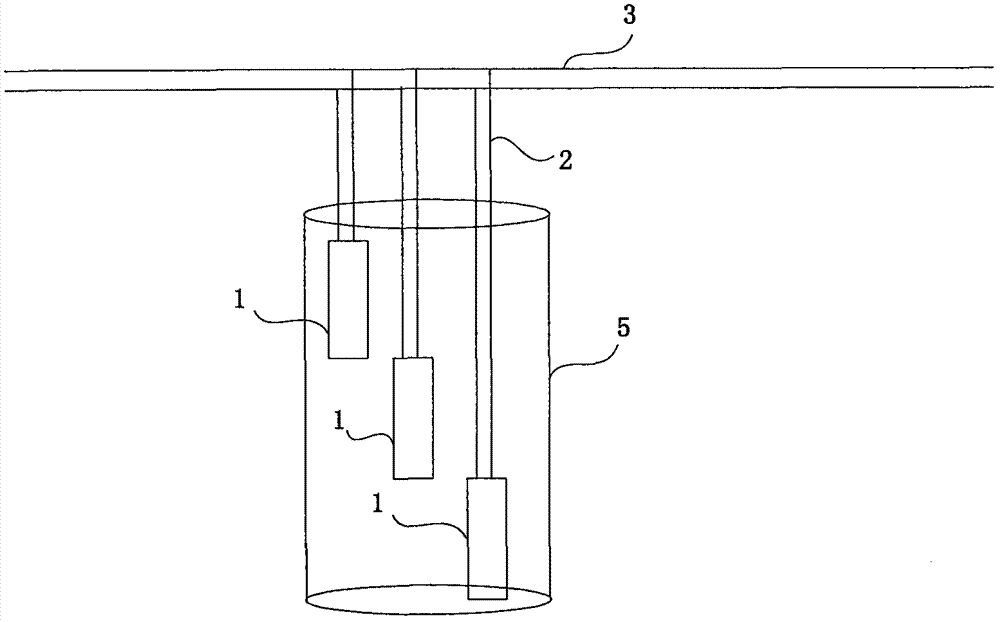

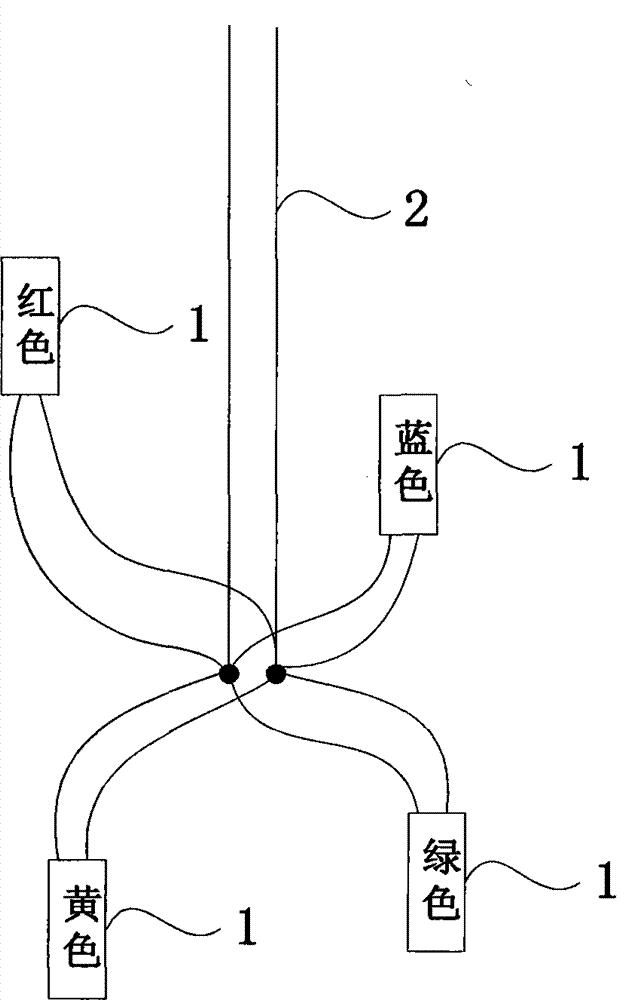

Communication method for multiple electronic detonators with shared leg wire

InactiveCN103884245AAvoid the construction processImprove reliabilityAmmunition fuzesCommunication designDetonation

The invention discloses a communication method for multiple electronic detonators with a shared leg wire in the technical field of connection and communication design of electronic detonators. The method comprises the following steps: connecting multiple electronic detonators with different types of preset codes in parallel in the same leg wire; connecting the leg wire with an electronic detonator characteristic reader; respectively transmitting the type codes and characteristic information to the multiple electronic detonators connected to the leg wire in parallel by the electronic detonator characteristic reader; after the electronic detonators connected to the leg wire in parallel receive the type codes and characteristic information, storing the characteristic information and transmitting response information when the type codes transmitted by the electronic detonator characteristic reader are judged to be consistent with preset type codes; disconnecting connection between the leg wire and the electronic detonator characteristic reader after the characteristic information is stored in each electronic detonator which is connected in parallel with the leg wire, and connecting the leg wire into a detonation branch. The communication and recognition problems in the process of sharing the same leg wire among the multiple electronic detonators are solved, the construction convenience is improved, and the miss-fire rate of the electronic detonators is reduced.

Owner:徐宁涛

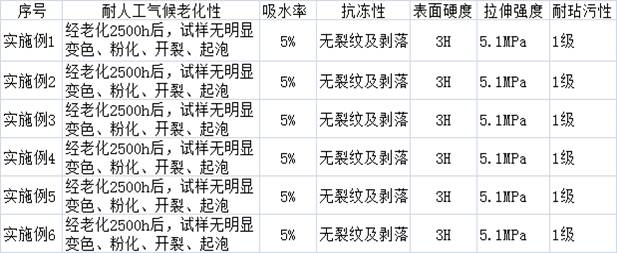

Ultrathin crystal stone and manufacturing method thereof

PendingCN114591037ASolve self-importanceSolve the inconvenience of constructionSolid waste managementMouldsFiberKaolin clay

The invention discloses an ultrathin crystal stone and a manufacturing method thereof, and the ultrathin crystal stone is prepared from the following components in percentage by weight: 20%-26.6% of cement, 21%-34% of fly ash, 20%-30% of water, 0.6%-1.5% of inorganic resin, 10%-20% of a high-molecular polymer, 0.15%-0.5% of metakaolin, 5%-10% of magnesium hydroxide, 0.1%-0.2% of inorganic fiber, 0.1%-0.3% of an alkali-resistant glass fiber mesh, 0.2%-0.8% of a water reducing agent, 0.1%-0.5% of a defoaming agent and 0.5%-1% of a rapid hardening agent. According to the ultrathin crystal stone and the manufacturing method thereof, the problems that a traditional material is large in dead weight, inconvenient to construct, poor in weather resistance and not environmentally friendly can be solved, and therefore the purposes of being vivid in effect, ultrathin, light in dead weight, soft, bendable, convenient to construct, large in hardness, resistant to impact, high in weather resistance, long in service life, environmentally friendly, good in water resistance and resistant to cracking are achieved.

Owner:江门市科能建材有限公司

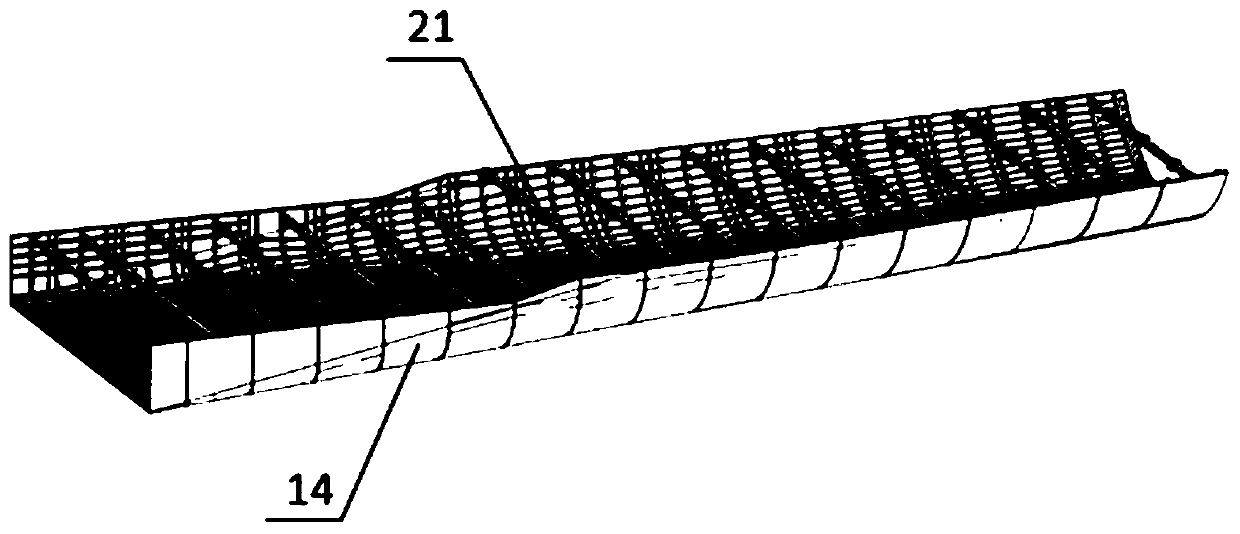

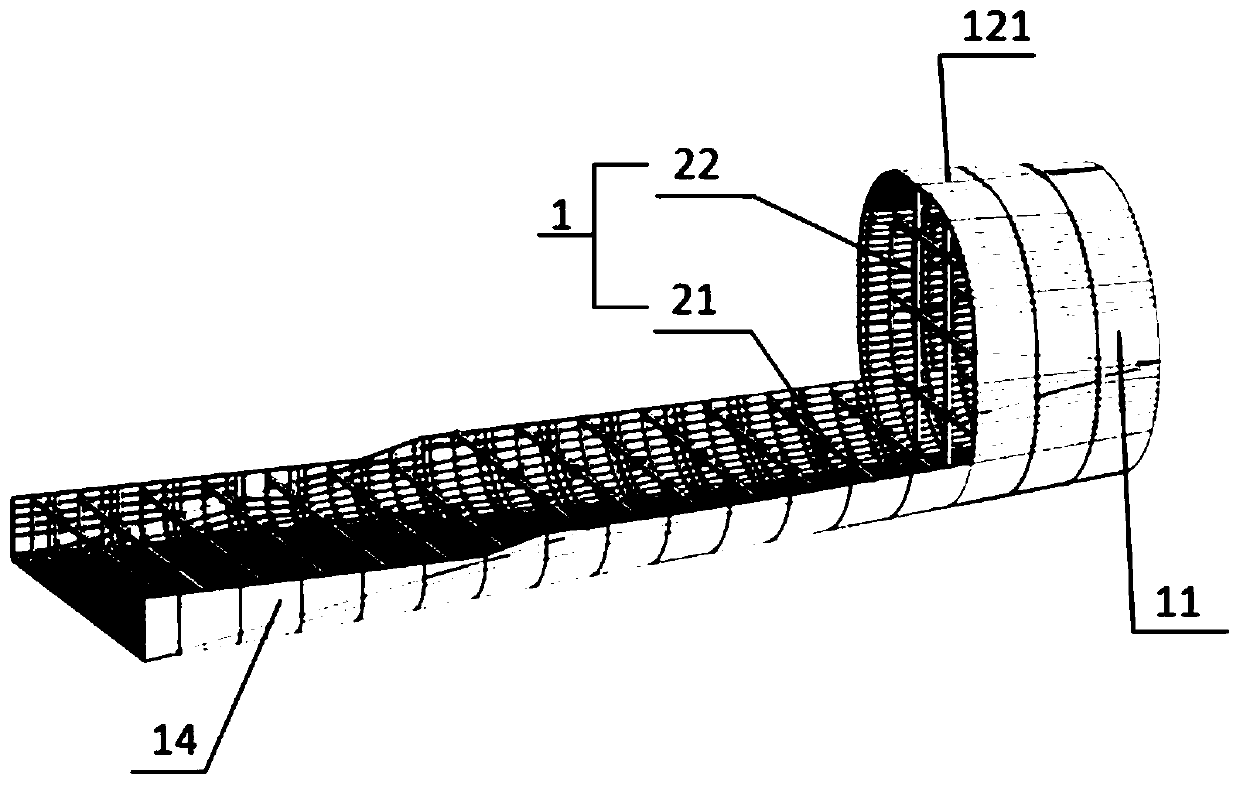

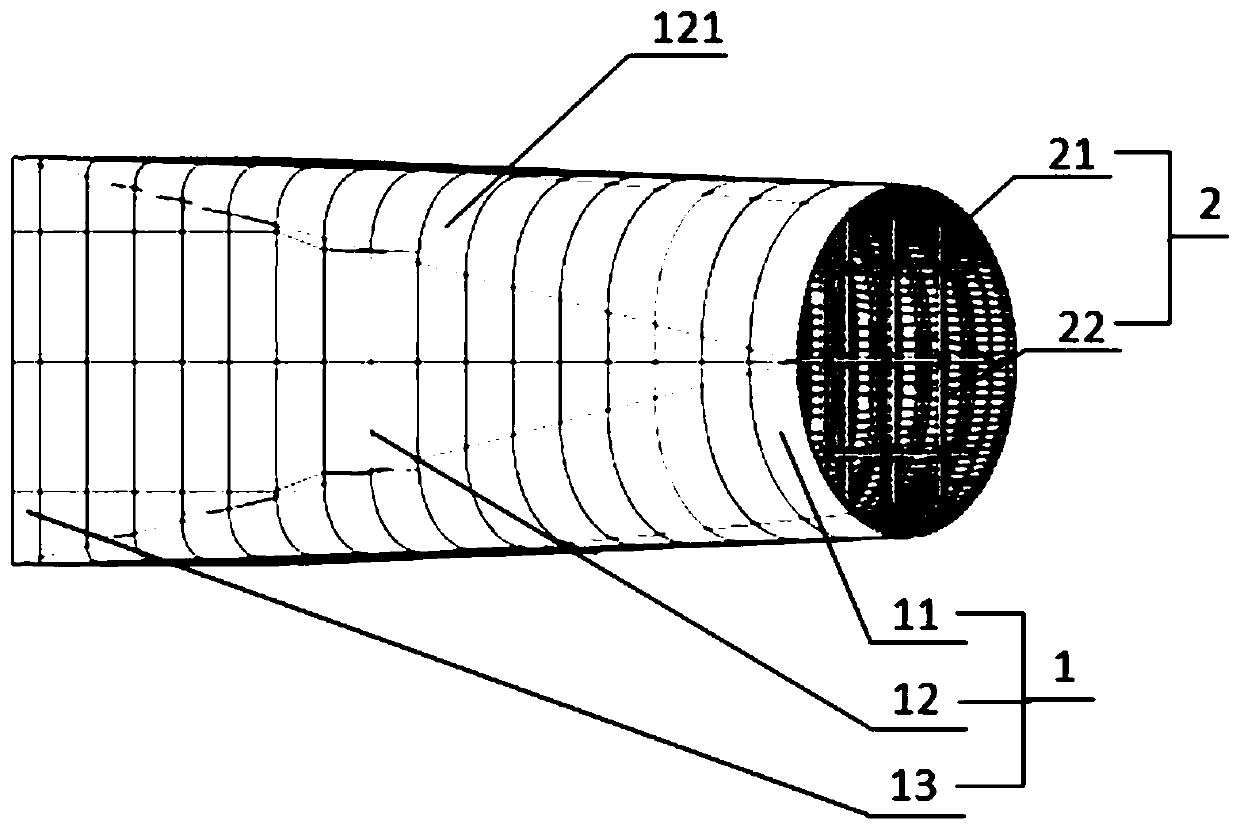

Construction method of inner mold support system for super large wind tunnel diffusion section

ActiveCN110284706AAvoid construction inconvenienceSimplify the construction processForms/shuttering/falseworksBuilding material handlingSteel cylinderMachining

The invention belongs to the technical field of wind tunnel construction methods, andparticularly relates to a construction method of an inner mold support system for a super large wind tunnel diffusion section.Theconstruction method of the inner mold support system for the super large wind tunnel diffusion sectioncomprises the following steps that A, an inner steel cylinder formwork and a profile steel structure support frameare structurally designed and subjected to consigned machining; B, the inner steel cylinder formwork and the profile steel structure support frame are machined, pass an examination, and are transported to a construction site, a project department organizes material acceptance, and data such as the size,flatness, curvature, and chord length of each formwork are rechecked one by one according to two-dimensional code data to ensure that the design requirements are met; C, on-site positioning and line dropping of each cross section of the inner steel cylinder formwork are conducted; and D, positioning and mounting of the inner steel cylinder formwork and the profile steel structure support frame are conducted.According to the construction method of the inner mold support system for the super large wind tunnel diffusion section, the construction problem of the super large wind tunnel circular-to-square diffusion section iseffectively solved,with the method, the internal mold support system which meets the construction accuracy requirements can be built, and smooth completion of the construction is ensured.

Owner:CONSTR DEV OF CHINA CONSTR SIXTH ENG DIV +1

A kind of normal temperature curing silicate high temperature resistant adhesive and preparation method thereof

ActiveCN109749633BHigh strengthImprove high temperature resistanceNon-macromolecular adhesive additivesInorganic adhesivesFiberAdhesive

The invention discloses a normal-temperature curing silicate high-temperature resistant binder and a preparation method thereof. The binder comprises 2-10% by weight of chopped fibers, and is preparedfrom the following raw materials in parts by weight: 40-70 parts of water glass, 20-52 parts of alumina powder, 2-10 parts of chopped fibers, 2-6 parts of silicon nitride, 2-5 parts of lanthanum oxide and 2-5 parts of zirconium diboride. The chopped fibers are toughened to enhance the strength of the normal-temperature curing silicate high-temperature resistant binder and improve the high-temperature resistance of the binder; the binder is resistant to high temperature of 1600 DEG C, at 1600 DEG C, the shear strength of the binder is multiple times of the strength of the conventional inorganic binder under the same conditions, and the high-temperature resistance is far superior to the conventional inorganic binder.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

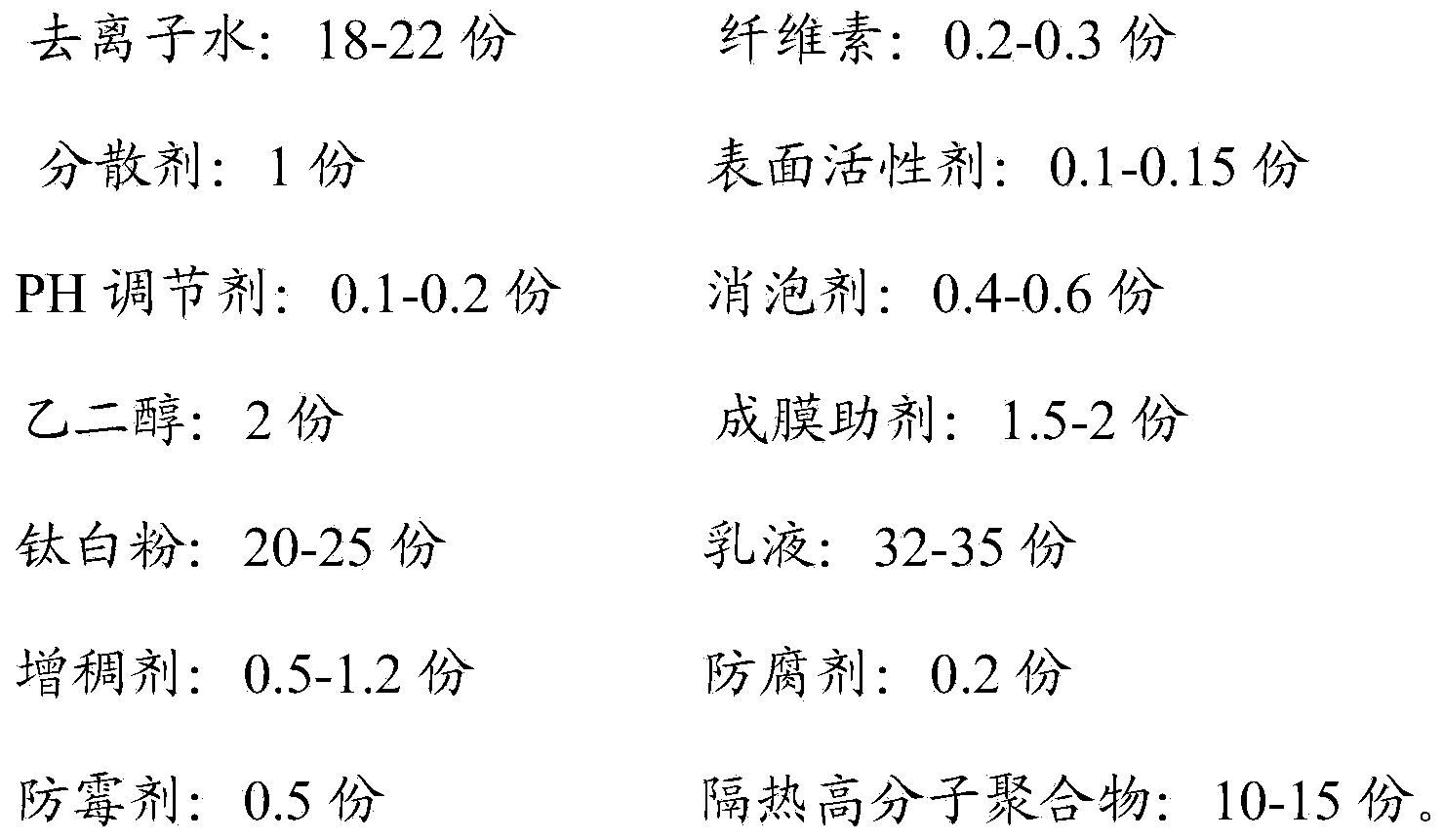

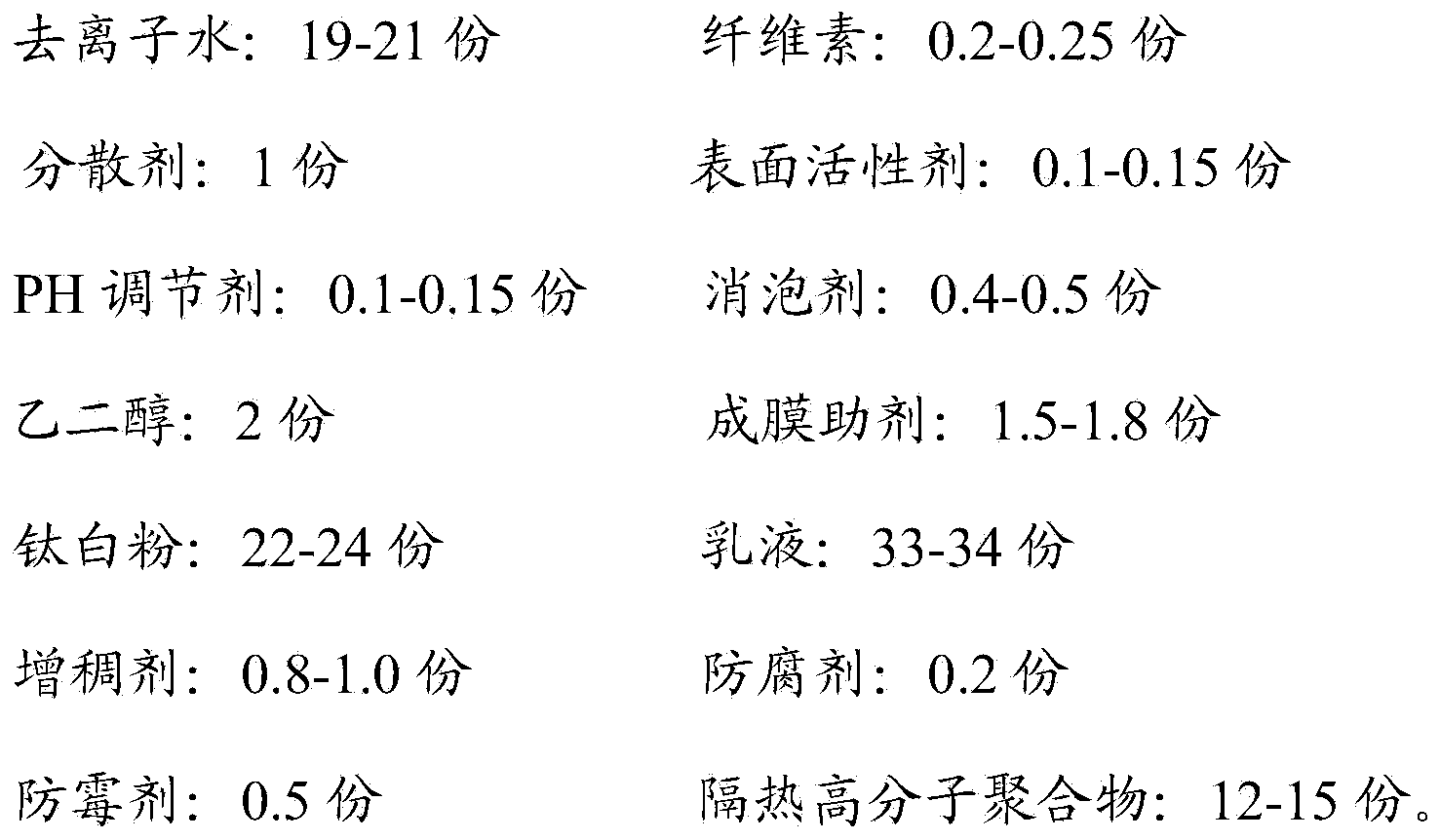

Ultra-thin smooth-type heat-insulation coating

InactiveCN104327646AGood compatibilitySolve Adhesion ProblemsAntifouling/underwater paintsPaints with biocidesCelluloseWeather resistance

The invention discloses an ultra-thin smooth-type heat-insulation coating and belongs to the technical field of building external wall coating. The heat-insulation coating is prepared from the following components in parts by weight: 18-21 parts of deionized water, 0.2-0.3 part of cellulose, 1 part of a dispersant, 0.1-0.15 part of a surfactant, 0.1-0.2 part of a regulator, 0.4-0.6 part of a defoaming agent, 2 parts of ethylene glycol, 1.5-2 parts of a coalescing agent, 20-25 parts of titanium dioxide powder, 32-35 parts of emulsion, 0.5-1.2 parts of a thickener, 0.2 part of an anti-corrosion agent, 0.5 part of a mildew preventive and 10-15 parts of a heat-insulation high-molecular polymer, wherein the heat-insulation high-molecular polymer is an SOLARPROOF SP-105 reflective heat-insulation polymer. The production process of the heat-insulation coating is simple and feasible, the heat-insulation coating has super-efficient heat reflectivity, the surface of the coating film is smooth, not rough, and the coating film has a high dirt resistance rate, excellent weather resistance and high storage stability.

Owner:GUANGDONG VALSPAR CHEM IND

Concrete hinge joint structure provided with intersecting shearing-resistant reinforcing steel bars and construction method of concrete hinge joint structure

InactiveCN109403215AImprove mechanical performanceExcellent shear resistanceBridge structural detailsBridge erection/assemblyShear capacityEngineering

A concrete hinge joint structure provided with intersecting shearing-resistant reinforcing steel bars comprises a hinge joint body formed by connecting the bottoms of a first hollow slab girder and asecond hollow slab girder, wherein protruding blocks are arranged on the two sides of the bottoms of the first hollow slab girder and the second hollow slab girder. The multiple first upper high-strength reinforcing steel bars inclining upwards at a certain angle relative to the horizontal direction are evenly arranged on the upper portion of the first hollow slab girder in the extension directionof the hinge joint body. The multiple second upper high-strength reinforcing steel bars inclining upwards at a certain angle relative to the horizontal direction are evenly arranged on the upper portion of the second hollow slab girder in the extension direction of the hinge joint body. The multiple first lower high-strength reinforcing steel bars are evenly arranged on the lower portion of the first hollow slab girder in the extension direction of the hinge joint body. The multiple second lower high-strength reinforcing steel bars are evenly arranged on the lower portion of the second hollowslab girder in the extension direction of the hinge joint body. By the adoption of the provided concrete hinge joint structure provided with the intersecting shearing-resistant reinforcing steel barsand a construction method of the concrete hinge joint structure, the problems that the shear performance is poor and construction is inconvenient can be solved, the shear capacity of a hinge joint isimproved, and construction is greatly simplified.

Owner:CHINA THREE GORGES UNIV

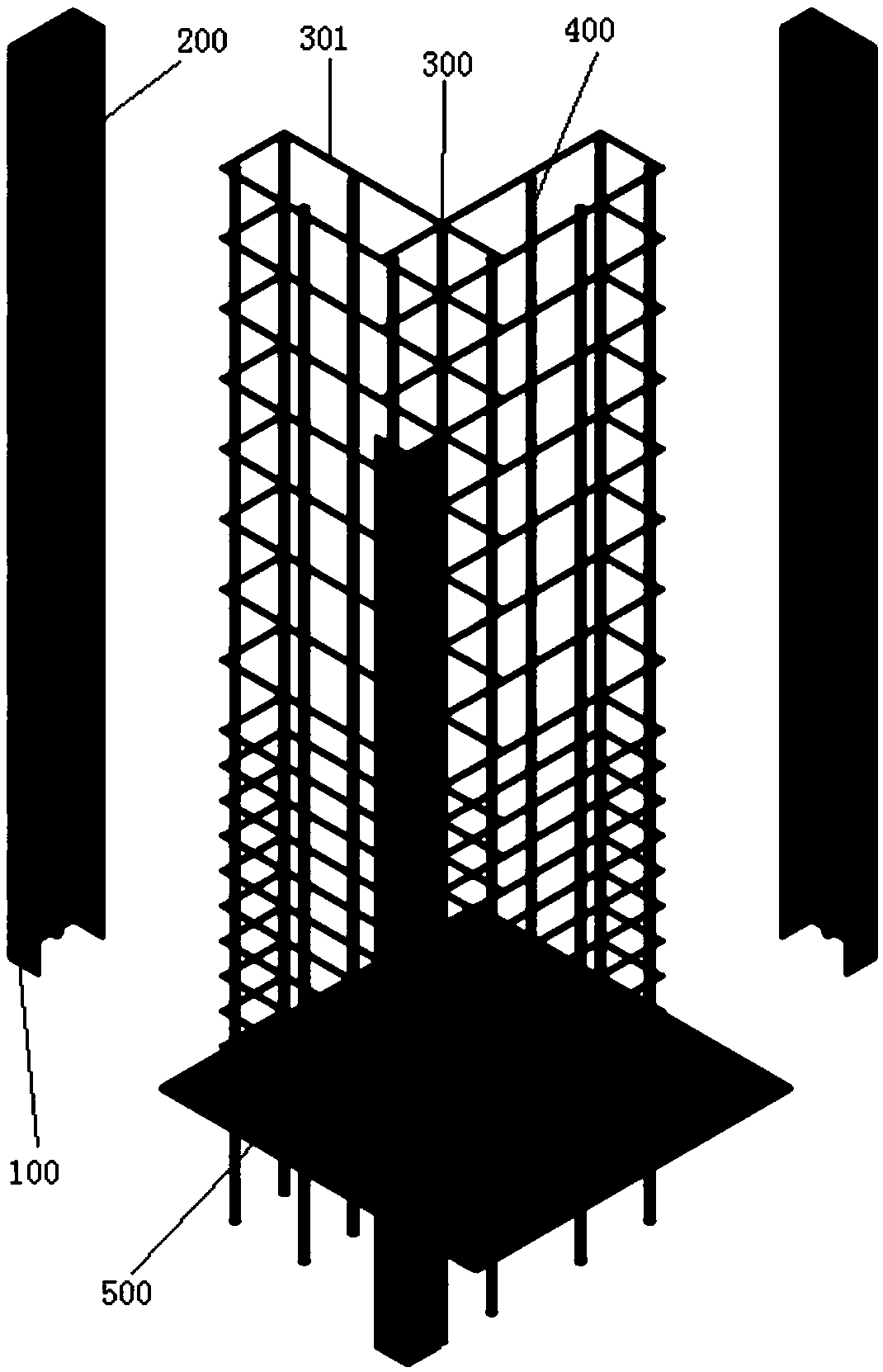

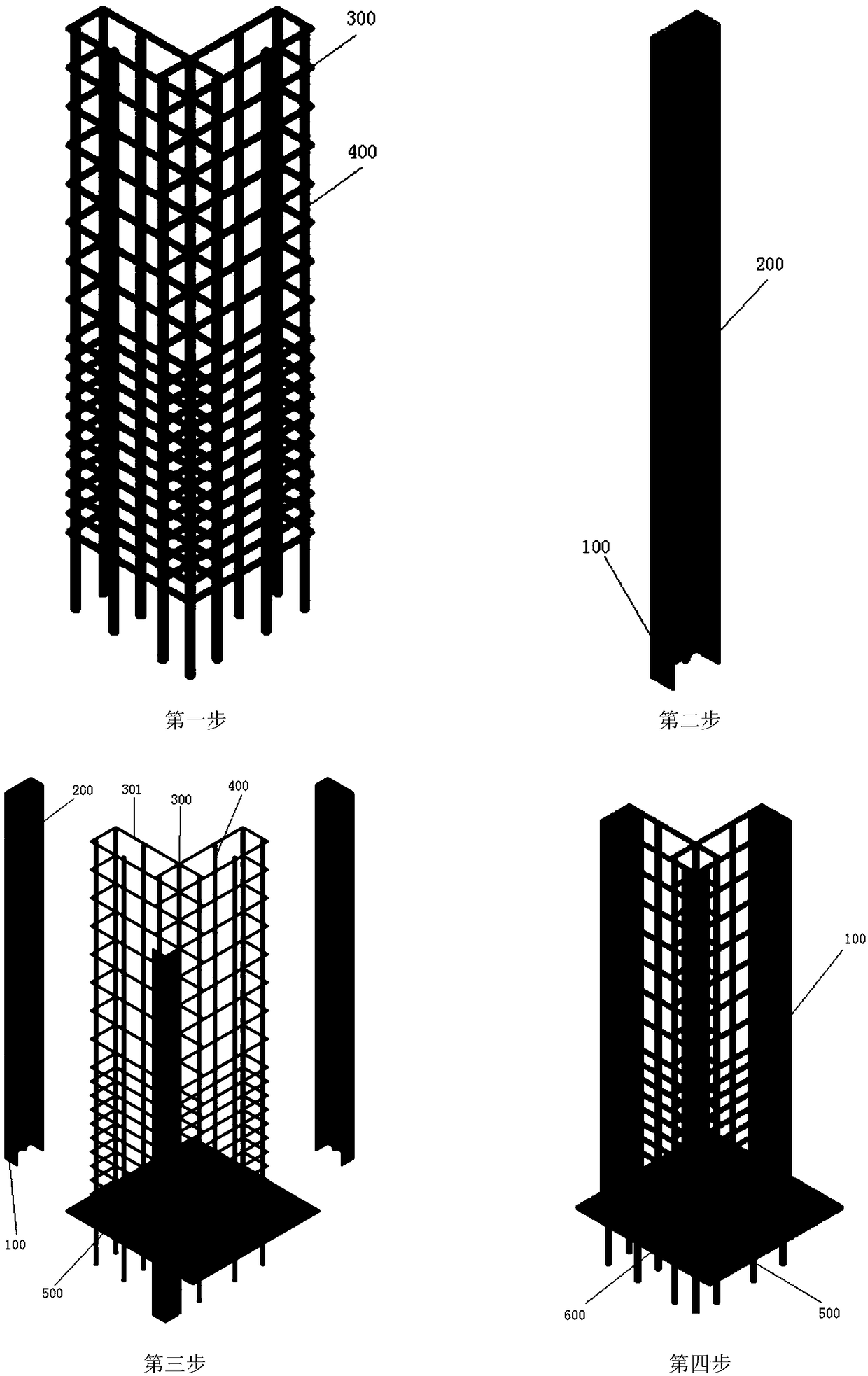

L-shaped section branch end external wrapped box iron-concrete composite special-shaped column and construction method thereof

InactiveCN109281437AWill not hinder passingEasy constructionStrutsBuilding material handlingReinforced concreteRebar

The invention discloses an L-shaped section branch end external wrapped box iron-concrete composite special-shaped column and a construction method thereof, and belongs to the field of construction. The L-shaped section end external wrapped box iron-concrete composite special-shaped column comprises a base and an L-shaped special-shaped column vertically mounted on the base, the L-shaped special-shaped column forms two branch ends, the two branch ends are provided with groove-shaped steel correspondingly, and the exterior of the two branch ends are sleeved with the groove-shaped steel; and notches of the groove-shaped steel face toward the center of the L-shaped special-shaped column, concave backs of the groove-shaped steel are exposed outside the two branch ends of the L-shaped special-shaped column, corners of the L-shaped special-shaped column are provided with angle steel, the angle steel is arranged outside the corners of the L-shaped special-shaped column in a sleeving mode, andnotches of the angle steel face toward the turning position of the L-shaped special-shaped column. The construction method of the L-shaped section branch end external wrapped box iron-concrete composite special-shaped column includes the steps of rebar bone binding, composite L-shaped steel skeleton assembling, template erecting, and moulding by casting. According to the L-shaped section branch end external wrapped box iron-concrete composite special-shaped column and the construction method thereof, the problem that steel skeletons of profile steel concrete special-shaped columns are complexand consequently construction is inconvenience is effectively solved, and the construction time and cost are saved; and anti-seismic performance of reinforced concrete special-shaped column structures is effectively improved, and the bearing capacity of the reinforced concrete special-shaped column structures is effectively improved.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com