Patents

Literature

39results about How to "Solve the yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar battery slice technology for efficient and low-cost film crystal silicon

InactiveCN101241952AExcellent electrical performanceAppearance of high qualityFinal product manufactureSemiconductor devicesSilicon solar cellSlurry

The present invention is a technique for manufacturing a crystalline silicon solar cell piece, especially a technique for manufacturing a high-efficiency, low cost and thin-sheet solar cell piece, and the invention belongs to the solar energy application field. The technique aims at the thin-sheet crystal silicon chip with thickness less than 200 mu m, by adopting innovated technique and developing the original technique, combines the domestic cell whole equipment which is independently developed, settles the contradiction between the thin sheet and the fraction ratio, finished product rate and the electrical property, and satisfies the request of the cell piece product line to the high efficiency and low cost. The technique for manufacturing crystal silicon solar cell piece is subdivided to seven steps according to the process flow: eliminating the injury and coarsen the surface, diffusing to make a knot, plasma etching for eliminating the edge, PSG eliminating, PECVD depositing Si3N4 film, printing positive back electrode slurry and back field slurry on the silk screen, and co-baking to form an ohm contact. When the technique is adopted for the size 125*125mm<2>, the efficiency of the single crystalline silicon solar cell piece is up to 16.5, and the efficiency of the polycrystalline silicon solar cell is up to 15.0%.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

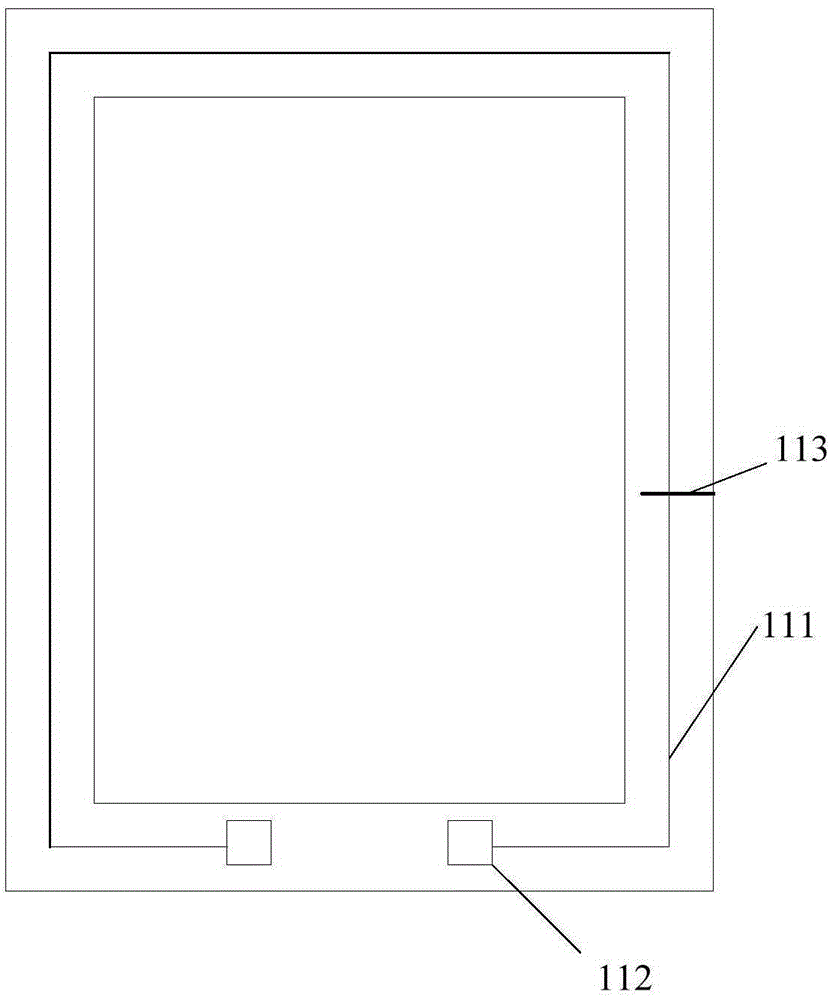

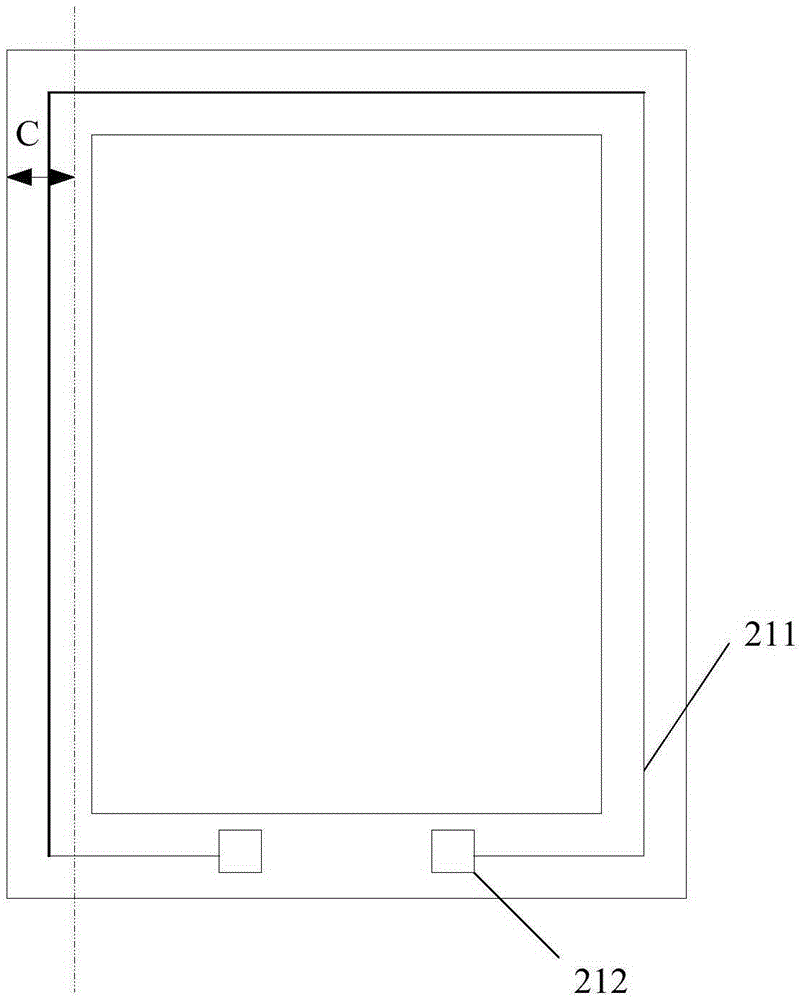

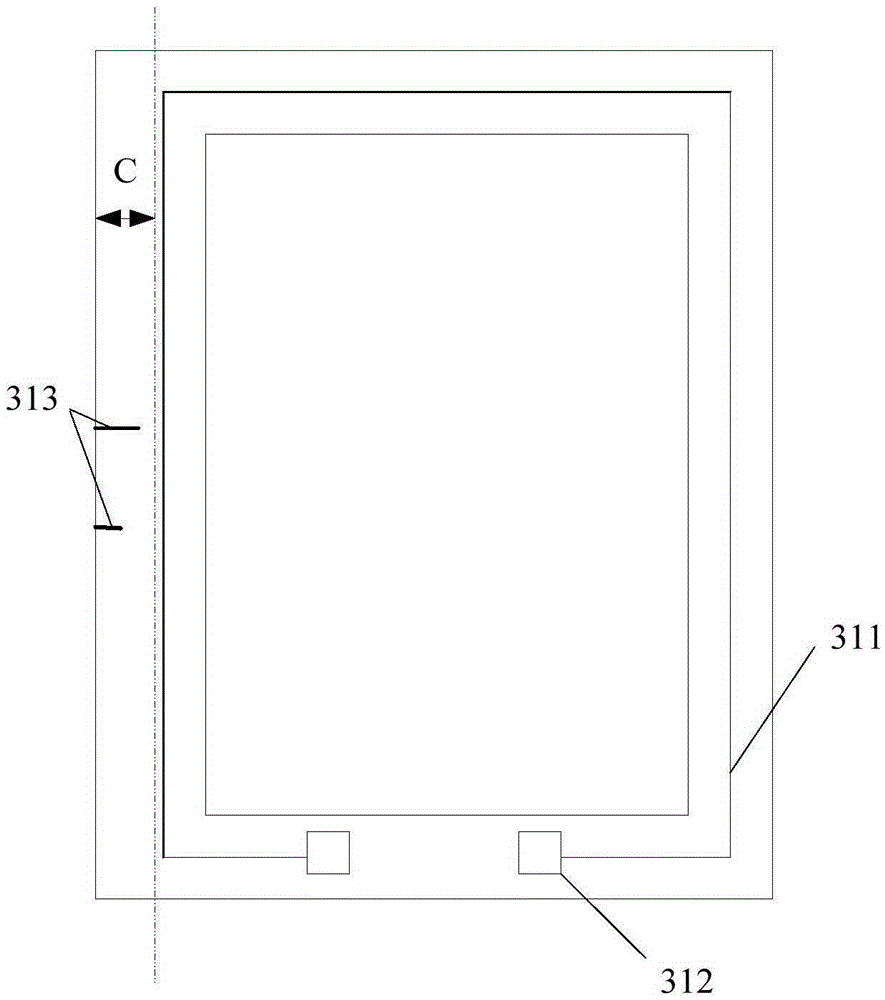

Glass substrate, liquid crystal display panel and liquid crystal display device

ActiveCN105372857ATo solve missed detection, fromSolve the yieldNon-linear opticsElectricityWire grid

The invention discloses a glass substrate, a liquid crystal display panel and a liquid crystal display device. The glass substrate comprises a display region and a non-display region, wherein a crack detection wire is arranged in the non-display region of the glass substrate and located on at least one edge of the glass substrate, the crack detection wire is divided into at least two sections in the extending direction, every two adjacent crack detection wire sections in the extending direction are electrically connected, each crack detection wire section is composed of at least two wire units connected in parallel, and at least one wire unit of each crack detection wire section is located on the outer side of the maximum cutting deviation. In the embodiment, through arranging crack detection wire grids, the purpose that edge cracks of the glass substrate and the length range, on the plane where the glass substrate is located, of the cracks are effectively detected is achieved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Hot spraying aluminium-zinc alloy wire rod and method for making same

The invention relates to a heat spraying aluminium zinc alloy wire rod composition and its preparing process, wherein the constituents (by weight percentage) of the wire rod include Al 54-56%, 0.004%<=M<=1.08%, impurity whose total amount is less than 1%, and balancing Zn, M is any one or the combination of RE, Mg, Ti or B.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

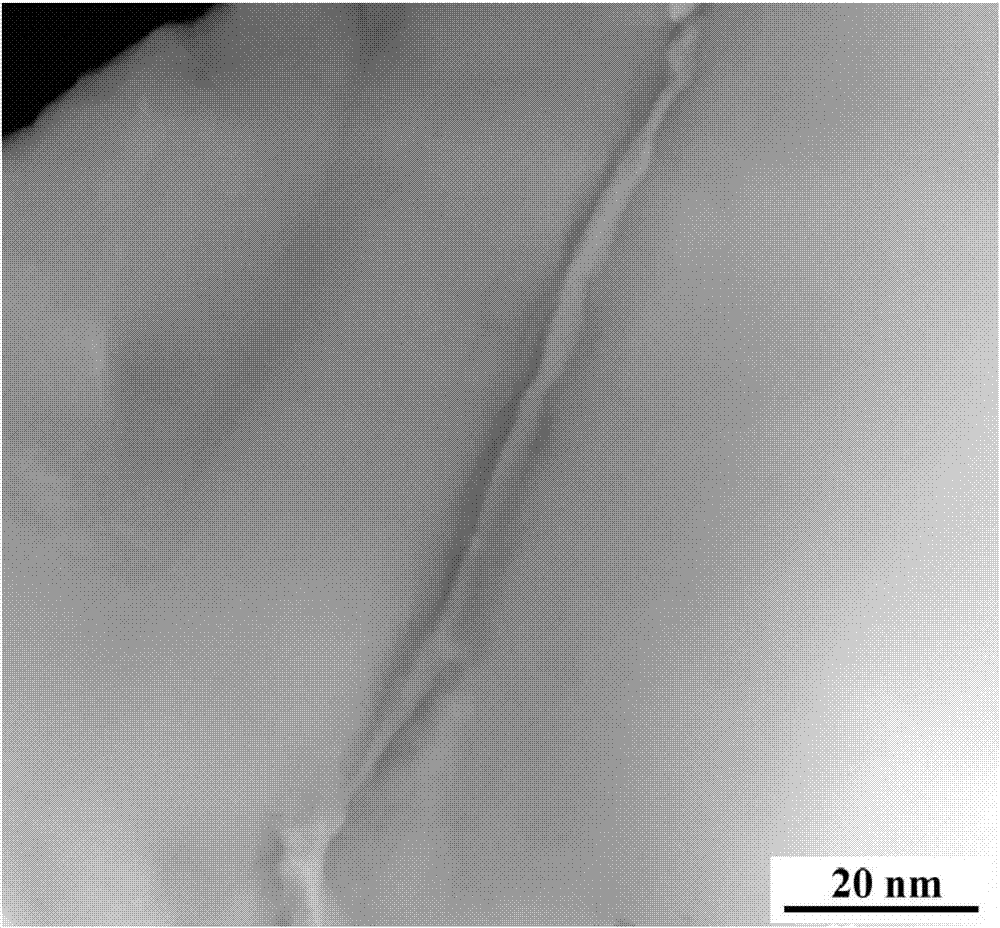

Preparation method for single-layer graphene-enhanced aluminium-based composite material

The invention discloses a preparation method for a single-layer graphene-enhanced aluminium-based composite material, relates to a preparation method for an aluminium-based composite material, and aims to solve the problems of high cost and great dispersing difficulty in the application of a single-layer graphene-enhanced aluminium-based composite material field at present. The preparation method comprises the following steps: firstly, weighing multi-layer graphene micro-flake aluminium metal powder, and weighing industrial pure aluminium block bodies, wherein the industrial pure aluminium block bodies and the multi-layer graphene micro-flake aluminium metal powder are in the weight ratio of (3-10):1; secondly, dispersing multi-layer graphene micro-flakes and moulding a precast block; thirdly, performing aluminium metal infiltration; fourthly, performing large plastic deformation; fifthly, performing high-temperature fusion treatment; sixthly, performing repeated plastic deformation and high-temperature fusion treatment. According to the preparation method for the single-layer graphene-enhanced aluminium-based composite material, the low-cost multi-layer graphene micro-flakes are taken as a raw material of an enhanced body, so that the cost is low; the content of single-layer graphene in the obtained composite material can reach 4 weight percent at most. The preparation method is applicable to preparing the single-layer graphene-enhanced aluminium-based composite material.

Owner:HARBIN INST OF TECH

Process for producing autoclaved mud bricks by using paper-making solid wastes

InactiveCN101817668AReduce weightHigh strengthSolid waste managementBuilding componentsEnvironmental resistanceBrick

The invention discloses a process for producing autoclaved mud bricks by using paper-making solid wastes. The process is characterized by comprising the following steps of: adding alkali recovery white clay into paper-making water treatment sludge to obtain modulated sludge; uniformly mixing the modulated sludge and pulverized fuel ash, crude white clay, sand, slag, lime and desulfurization gypsum in proportion in a mixer; producing unburned bricks by using the mixture with a hydraulic brick making machine; and drying the unburned bricks and sintering the dried unburned bricks at a high temperature to produce the finished products. The autoclaved mud bricks produced by the process have light weight, high strength, sound insulation, high heat preservation and anti-freezing properties and the high performance of neat appearance; and the process has the advantages of good economic, environmental-protection and social effects because the wastes of cogeneration paper-making enterprises are comprehensively treated.

Owner:岳阳华泰资源开发利用有限责任公司

Method for manufacturing miniaturized fluxgate sensor

InactiveCN101481080AEase of mass productionGood repeatabilityTelevision system detailsSemi-permeable membranesResistElectrical conductor

The invention provides a method for producing a minimized fluxgate sensor in the micro electromechanical technical field, which comprises the following steps: producing a double-sized alignment symbol; sputtering a bottom layer; flinging positive photoresists, exposing and developing; plating a drive coil and a bottom layer coil of a receiving coil, connecting a conductor with a pin of the coil; removing photosensitive resist and a bottom layer; flinging polyimide, solidifying and polishing; sputtering the bottom layer; flinging positive photoresists, exposing and developing; plating a magnetic core, connecting the conductor with a pin; removing positive photoresists and the bottom layer; flinging polyimide, solidifying and polishing; sputtering the bottom layer; flinging the positive photoresists, exposing and developing; plating the drive coil and a top layer coil of the receiving coil and a pin; removing the photosensitive resist and the bottom layer; and magnetic annealing. The invention solves the problems of the traditional fluxgate sensor of poor stability, poor repetitiveness and poor mass production, ensures that the production technique is compatible with the large-scale integrated circuit technique, can be manufactured by integrating the interface circuit, and is widely applied in a plurality of new fields.

Owner:SHANGHAI JIAO TONG UNIV

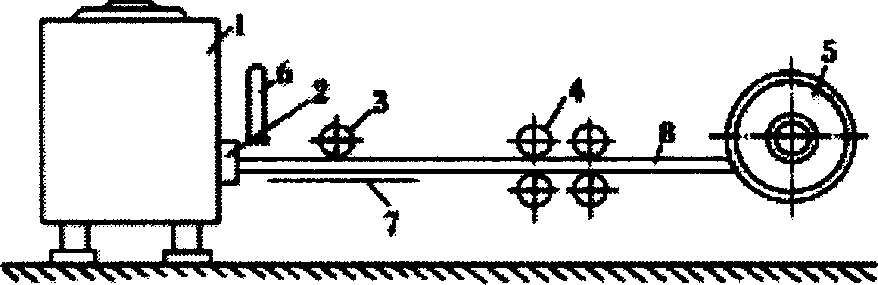

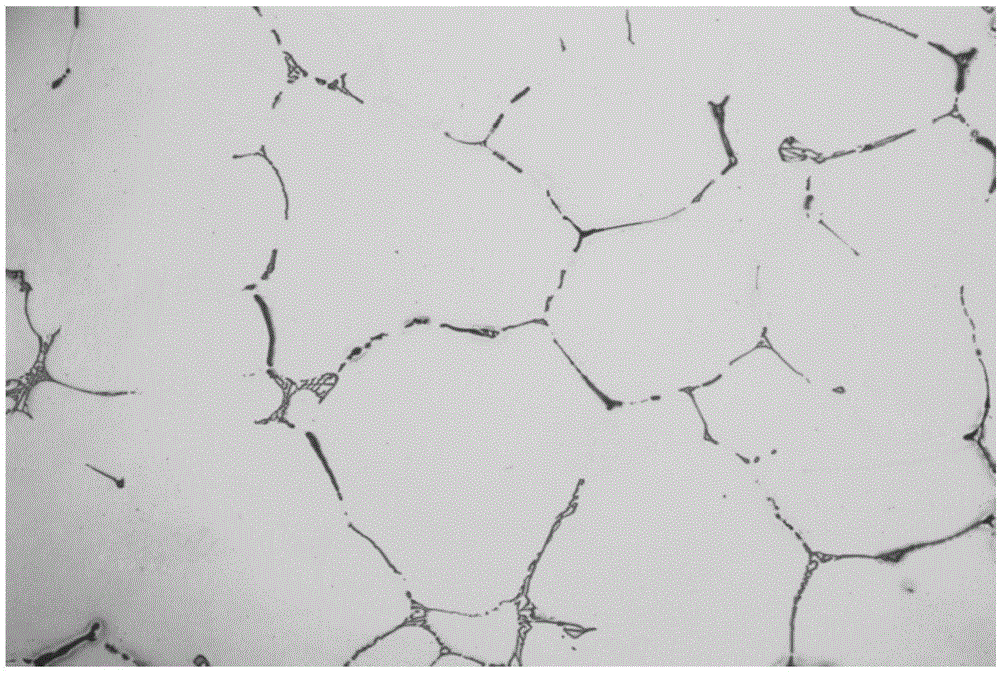

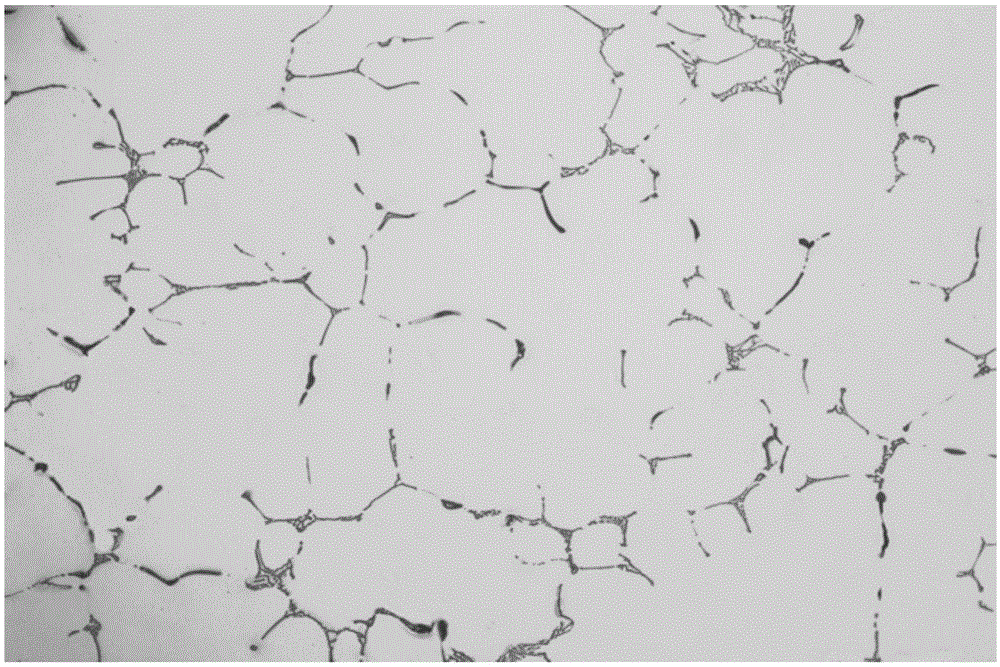

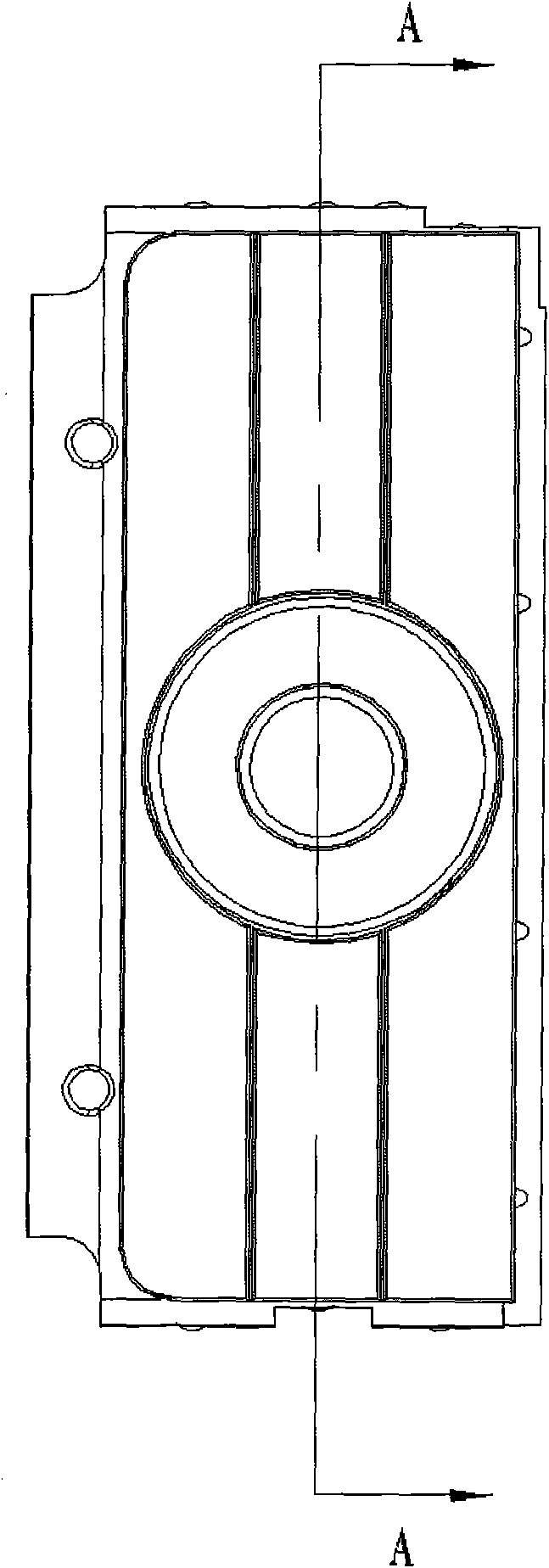

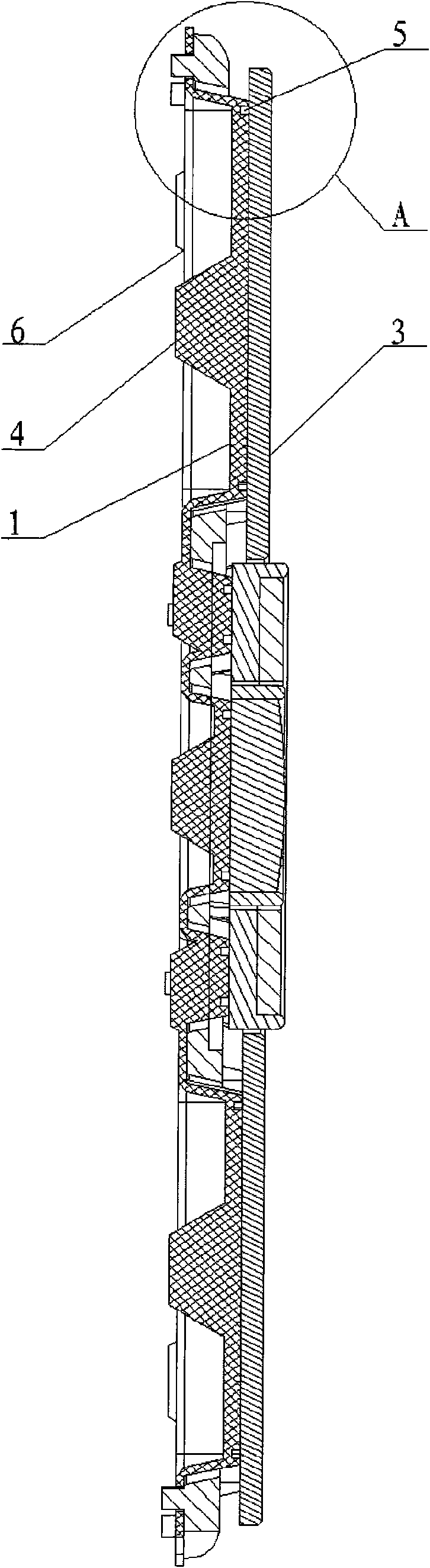

Crystal pulling method for single crystal by Czochralski pulling

ActiveCN106319620ASolve the costSolve the yieldPolycrystalline material growthBy pulling from meltSingle crystalEngineering

The invention provides a crystal pulling method for a single crystal by Czochralski pulling. The crystal pulling method is composed of seven steps of material filling, material melting, impurity extraction, stabilizing treatment, seeding, diameter enlarging, and ending. The crystal pulling method for the single crystal by Czochralski pulling provided by the invention solves the problems of high cost and low yield of single crystal pulling for polycrystalline silicon with poor quality during Czochralski pulling of the single crystal. The crystal pulling method for the single crystal by Czochralski pulling provided by the invention realizes separation and extraction of a polycrystalline raw material with a plurality of impurities and poor quality through changing of steps and parameters in the process of crystal pulling, so the quality of crystal after crystal pulling is improved; the yield of crystal pulling is increased; and the purposes of improving production efficiency and reducing production cost are achieved.

Owner:NINGXIA LONGI SILICON MATERIALS

Method for manufacturing large-size heat-treatment aluminum alloy slab ingot capable of being strengthened

The invention provides a method for manufacturing a large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, and relates to a method for manufacturing the aluminum alloy slab ingot. The method for manufacturing the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened mainly solves the problems that as for an aluminum alloy slab ingot prepared in the prior art, the casting yield is low, and wide and thick slabs with excellent properties cannot be rolled out. The method comprises the first step of material weighing, the second step of smelting, the third step of casting melt preparation and the forth step of molding, and the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened is obtained. By means of the method, according to the prepared large-size heat-treatment aluminum alloy slab ingot capable of being strengthened, the yield strength ranges from 98 N / mm<2> to 120 N / mm<2>, the tensile strength ranges from 182 N / mm<2> to 201 N / mm<2>, and the elongation percentage in a casting state ranges from 9.56% to 14.7%. By means of the method, the large-size heat-treatment aluminum alloy slab ingot capable of being strengthened can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Pure titanium seamless pipe cross rolling piercing method

ActiveCN104889163AEliminate stickingSolve the sticking problemMetal rolling arrangementsMicrometerSurface roughness

The invention discloses a pure titanium seamless pipe cross rolling piercing method which includes the steps: hot spraying a zirconium oxide coating with the thickness of 0.2-0.4mm on a working surface of a guide plate of a cross rolling piercing machine by the aid of plasma; grinding the zirconium oxide coating with surface roughness of 0.9-1.5 micrometers; smearing boron nitride lubricants on a working surface of a front guide plate of the cross rolling piercing machine; setting the ellipticity of a pure titanium seamless pipe cross rolling piercing hole pattern to be 1.09-1.2. By the method, piercing and sizing can be performed on a hot rolling mill comprising the cross rolling piercing machine, so that a high-precision pure titanium seamless pipe is directly produced on a production process line, and the problems of easiness in adhesion and low yield of guide plates of a cross rolling piercing machine in the prior art are solved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Light greenish blue matte glaze for pottery product and preparation method of light greenish blue matte glaze

The invention discloses light greenish blue matte glaze for a pottery product and a preparation method of the light greenish blue matte glaze. A process formula of the light greenish blue matte glaze is prepared from the following components in percentage by mass: 27 to 32 percent of feldspar powder, 12 to 17 percent of calcium carbonate, 6 to 8 percent of dolomite, 7 to 14 percent of talc, 6 to 8 percent of barium carbonate, 2 to 9 percent of zirconium silicate, 5 to 10 percent of frit, 0 to 4 percent of zinc oxide, 0 to 9 percent of aluminum oxide, 3 to 5 percent of carnelian cobble and 4 to 10 percent of kaolin. The preparation method comprises the following steps: weighing all the components according to the formula, then fully mixing, and adding into a grinding tank; adding water of which the weight is equivalent to 45 to 50 percent of the weight of dry powder, and grinding for 10 to 15 hours, wherein the ratio of materials to spheres to the water is 1:1.5:0.65; afterwards, deironing and sieving glaze slip subjected to ball milling, and adjusting the concentration until the true specific gravity is 50 to 54 degrees; glazing the pottery product by adopting spraying, soaking or other decoration methods, wherein the thickness of a glaze layer is 1 to 3mm; drying, then feeding into a kiln, performing oxidation firing at the temperature of 1200 to 1235DEG C, naturally cooling and then discharging from the kiln. The prepared light greenish blue matte glaze has the advantages of stable color, high rate of finished product and high artistic value.

Owner:XIAMEN EDUNUS CERAMIC IND CO LTD

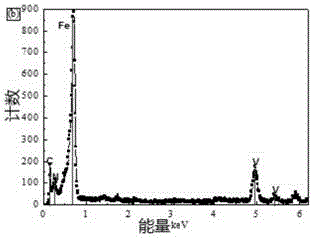

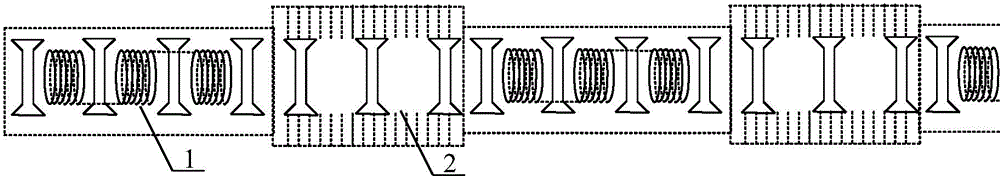

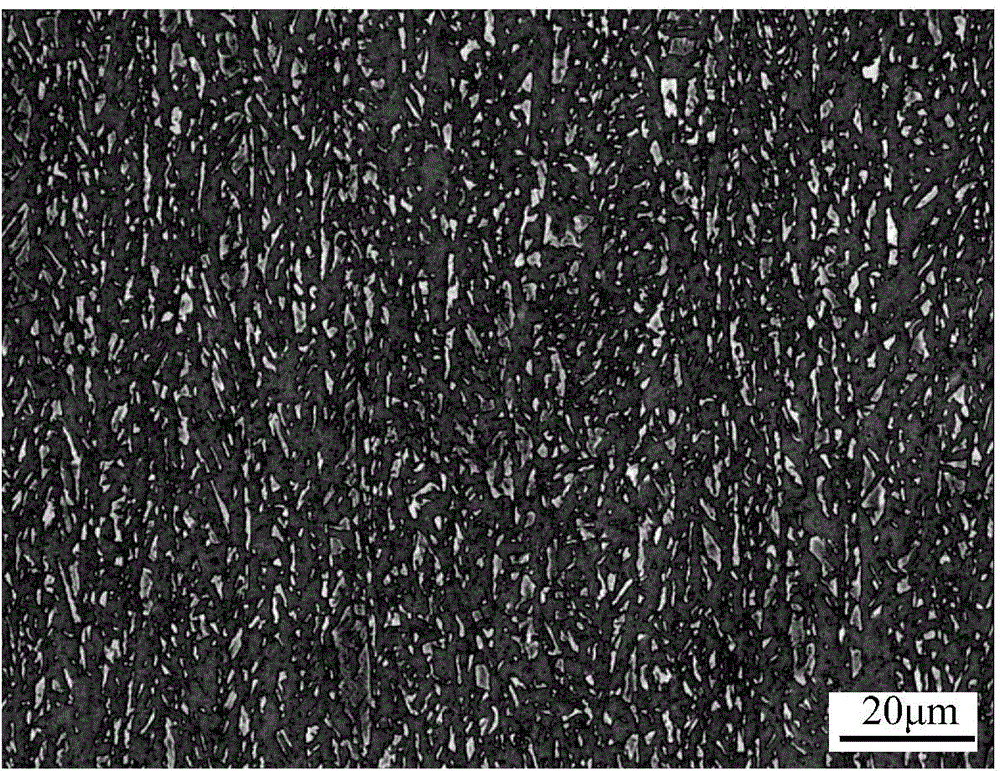

High-strength plastic vanadium microalloyed dual-phase steel seamless pipe and preparation method thereof

ActiveCN104018067AImprove mechanical propertiesHigh strengthFurnace typesIncreasing energy efficiencySolid componentHigh rate

The invention discloses a high-strength plastic vanadium microalloyed dual-phase steel seamless pipe and an on-line preparation method thereof. The seamless pipe is composed of the following chemical components in percentage by mass: 0.10-0.18% of C, 0.1-0.6% of Si, 1.1-1.6% of Mn, 0.16-0.20% of V, 0.01-0.03% of N, at most 0.006% of P, at most 0.005% of S, and the balance of Fe and other inevitable impurities. The intermediate-frequency induction heat treatment device of the thin-wall steel pipe is utilized and assisted by the vanadium microalloyed component design to produce the dual-phase steel seamless pipe with favorable comprehensive mechanical properties; the advantages of low yield-tensile ratio, high rate of work hardening, favorable strength and favorable elongation percentage of the dual-phase steel are matched and successfully applied to the field of production of steel pipes to efficiently substitute solid components with hollow components, thereby implementing light weight of the automobile; and meanwhile, the seamless pipe promotes further development of the internal high-pressure forming technique, and has wide application prospects.

Owner:LAIWU IRON & STEEL GRP

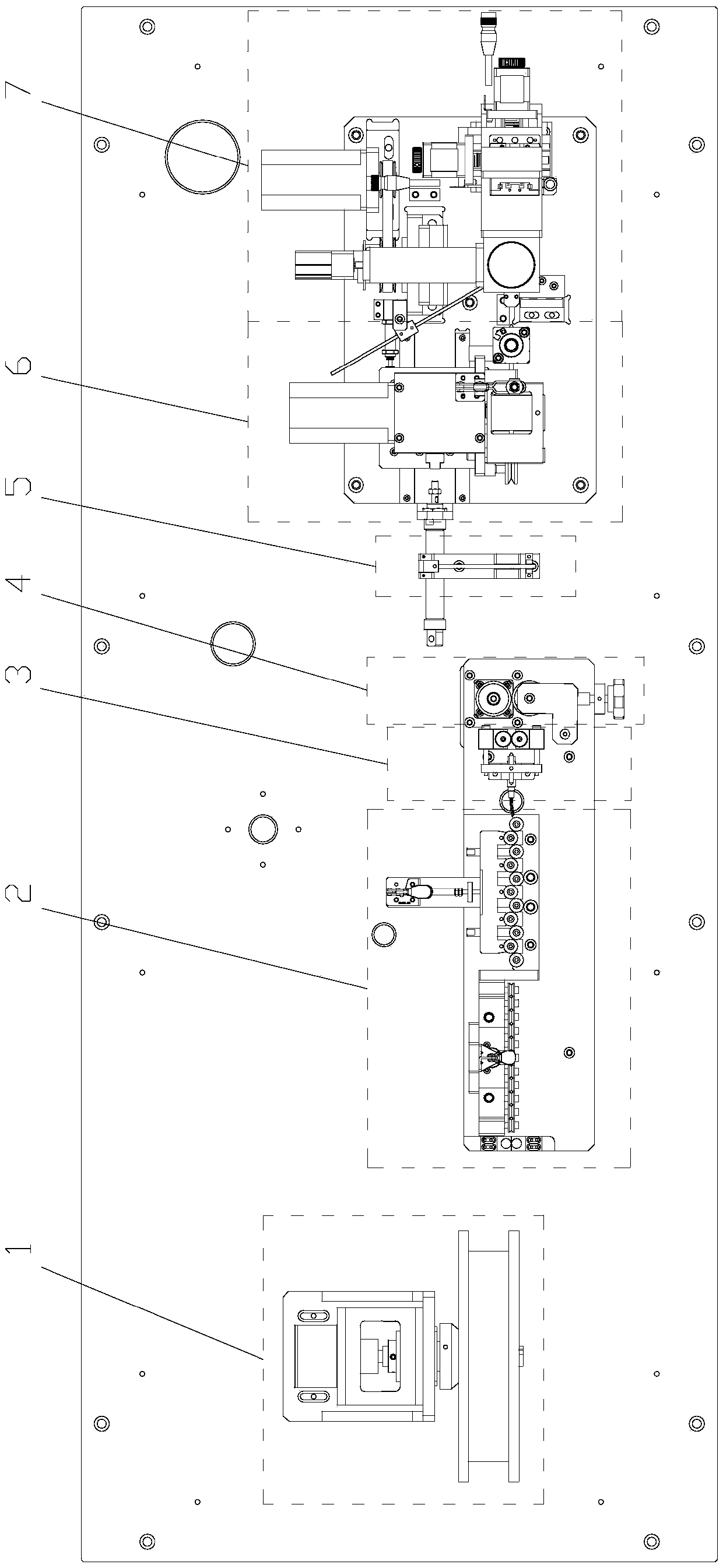

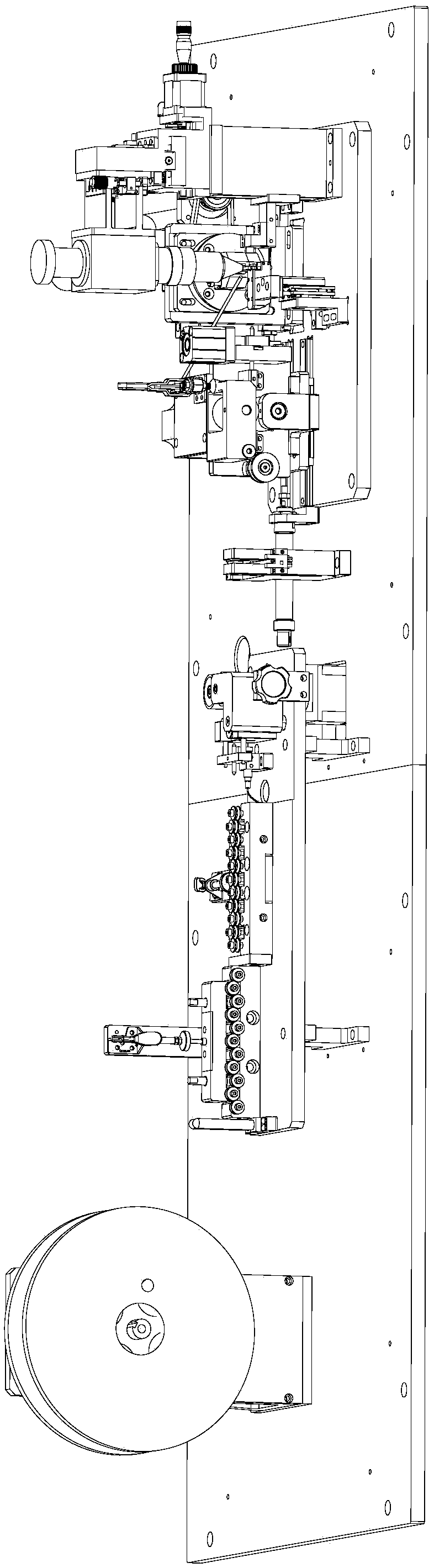

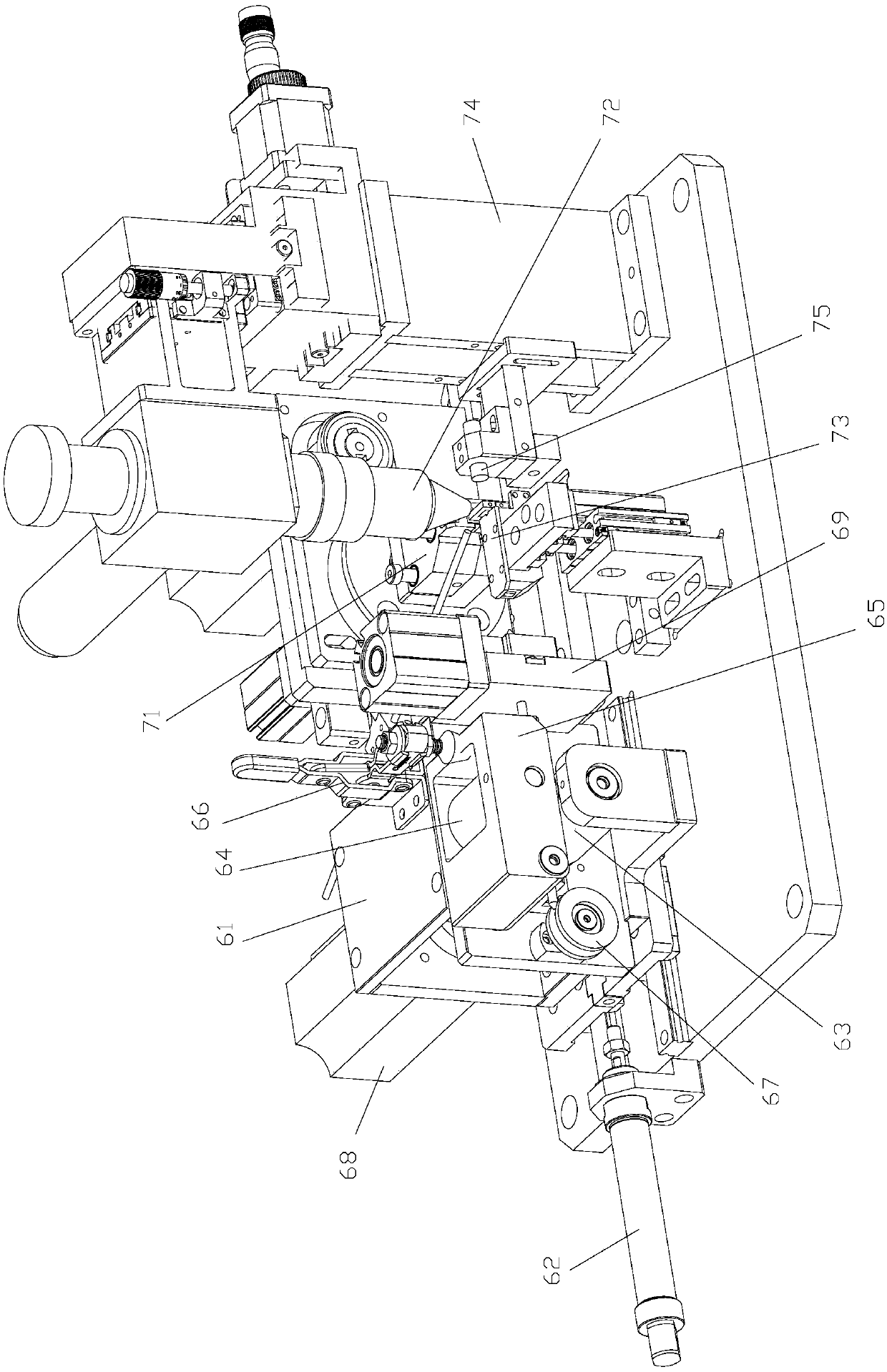

Twisted wire pin automatic cutting and welding device

ActiveCN109659790ARealize the integrated production of automatic cutting and weldingSolve outputContact member manufacturingEngineeringMechanical engineering

The invention belongs to the technical field of a twisted wire pin production devices and particularly relates to a twisted wire pin automatic cutting and welding device comprising a cutting and welding mechanism. The cutting and welding mechanism comprises a cutting mechanism and a welding mechanism. The cutting mechanism comprises a shearing module and a wire feeding mechanism for feeding a wireto the shearing module. The welding mechanism comprises a rotating clamp, a laser welding head and a lifting platform. The tabletop of the lifting platform is connected to the discharging port of theshearing module and the clamping jaw of the rotating clamp. The laser welding head rightly faces the clamping jaw of the rotating clamp.

Owner:武汉华中激光产业有限公司

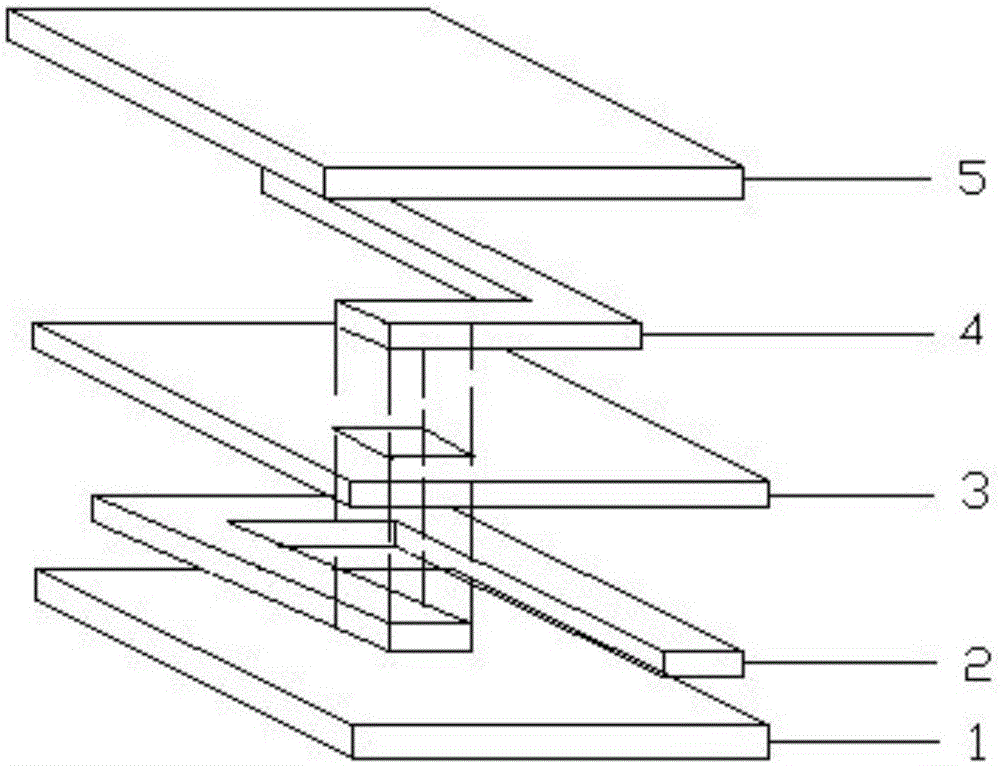

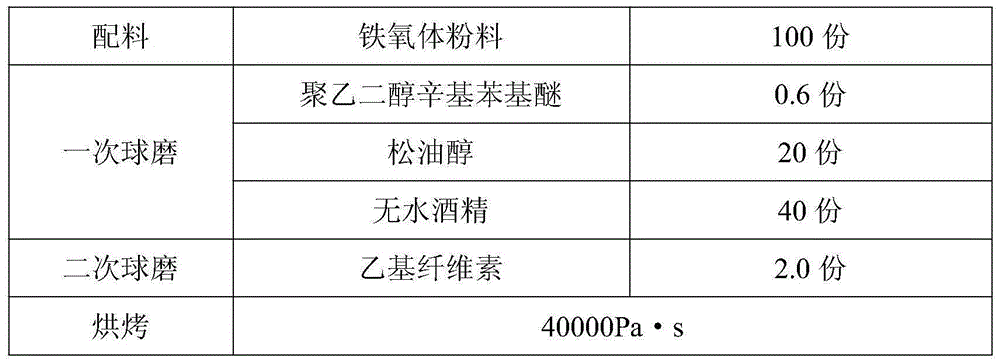

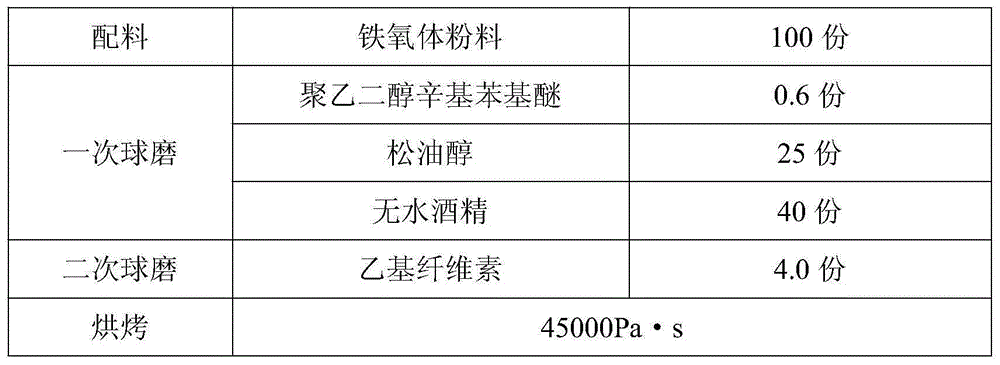

Ferrite slurry used for wet process stacked inductor printing and manufacturing method thereof

ActiveCN105000875ACause uneven sizePrevent openingInductances/transformers/magnets manufactureConductive pattern formationCombustionInductor

The invention provides ferrite slurry used for wet process stacked inductor printing and a manufacturing method thereof. The main constituent of the ferrite slurry used for the wet process stacked inductor printing is NiCuZn ferrite, Ni in the main constituent takes up 15mol%-25 mol% when being converted into NiO, copper takes up 8mol%-13mol% when being converted into CuO, Zn takes up 18mol%-25mol% when being converted into ZnO, and the balance iron takes up 46.5mol%-49.5mol% when being converted into Fe<2>O<3>; auxiliary agents comprise a combustion auxiliary agent and an addition agent, and the combustion auxiliary agent is Bi<2>O<3> and / or B<2>O<3> and takes up 1-4wt% of the main constituent; the addition agent is Co<2>O<3> and takes up 0.1-0.5wt% of the main constituent. The manufacturing method of the ferrite slurry used for the wet process stacked inductor printing comprises the steps of material compounding, first ball-milling, secondary ball-milling and baking. By means of the ferrite slurry used for the wet process stacked inductor printing, electric conduction among conductive circuit layers is good.

Owner:SHENZHEN GUDIAN ELECTRONICS

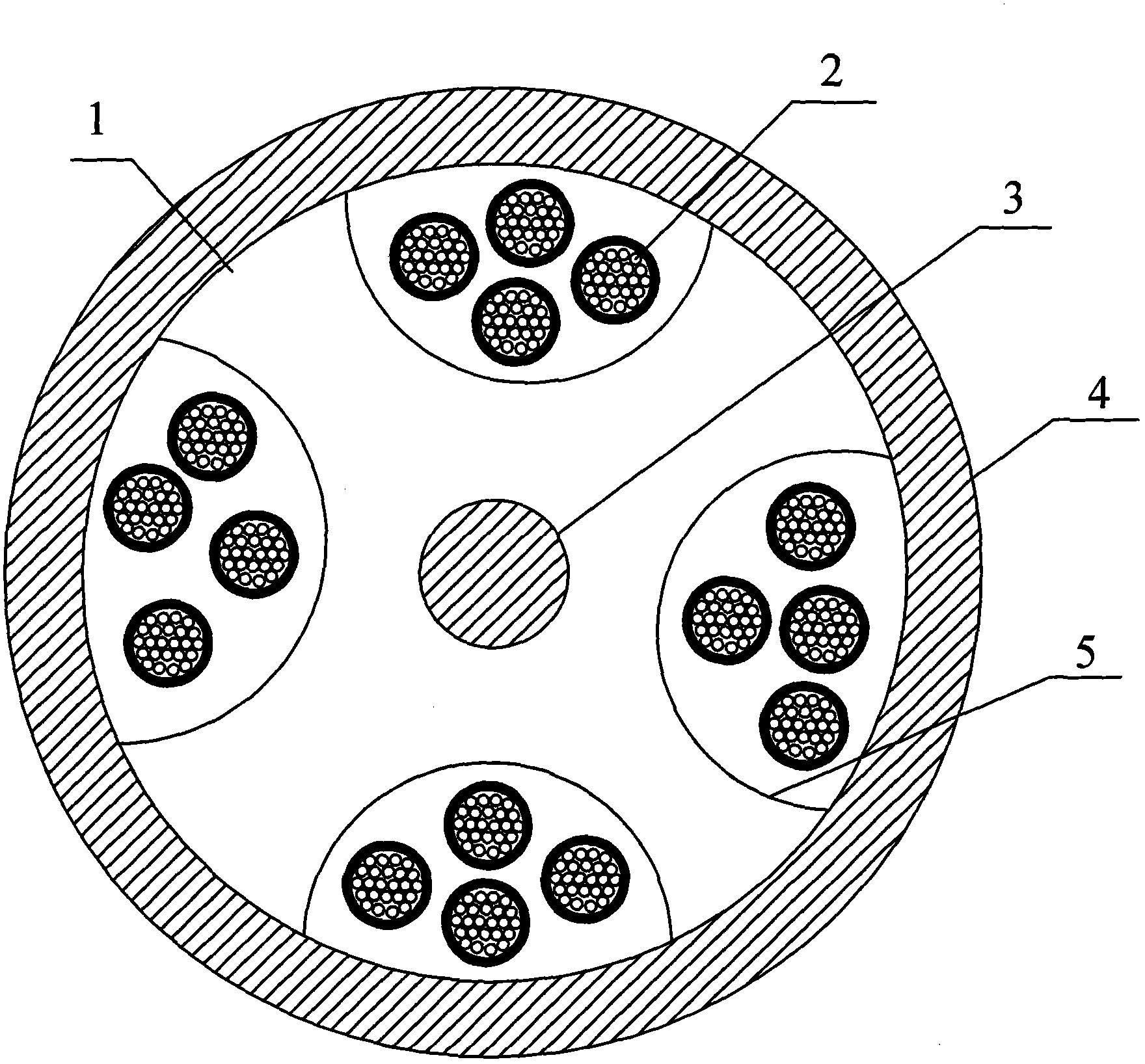

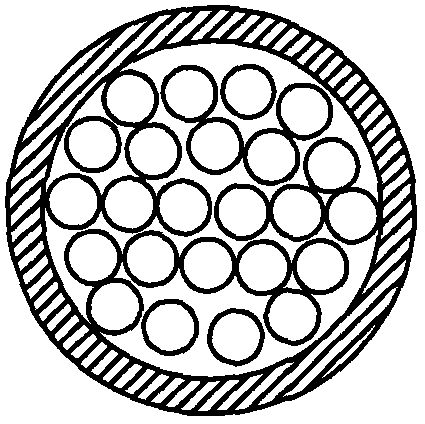

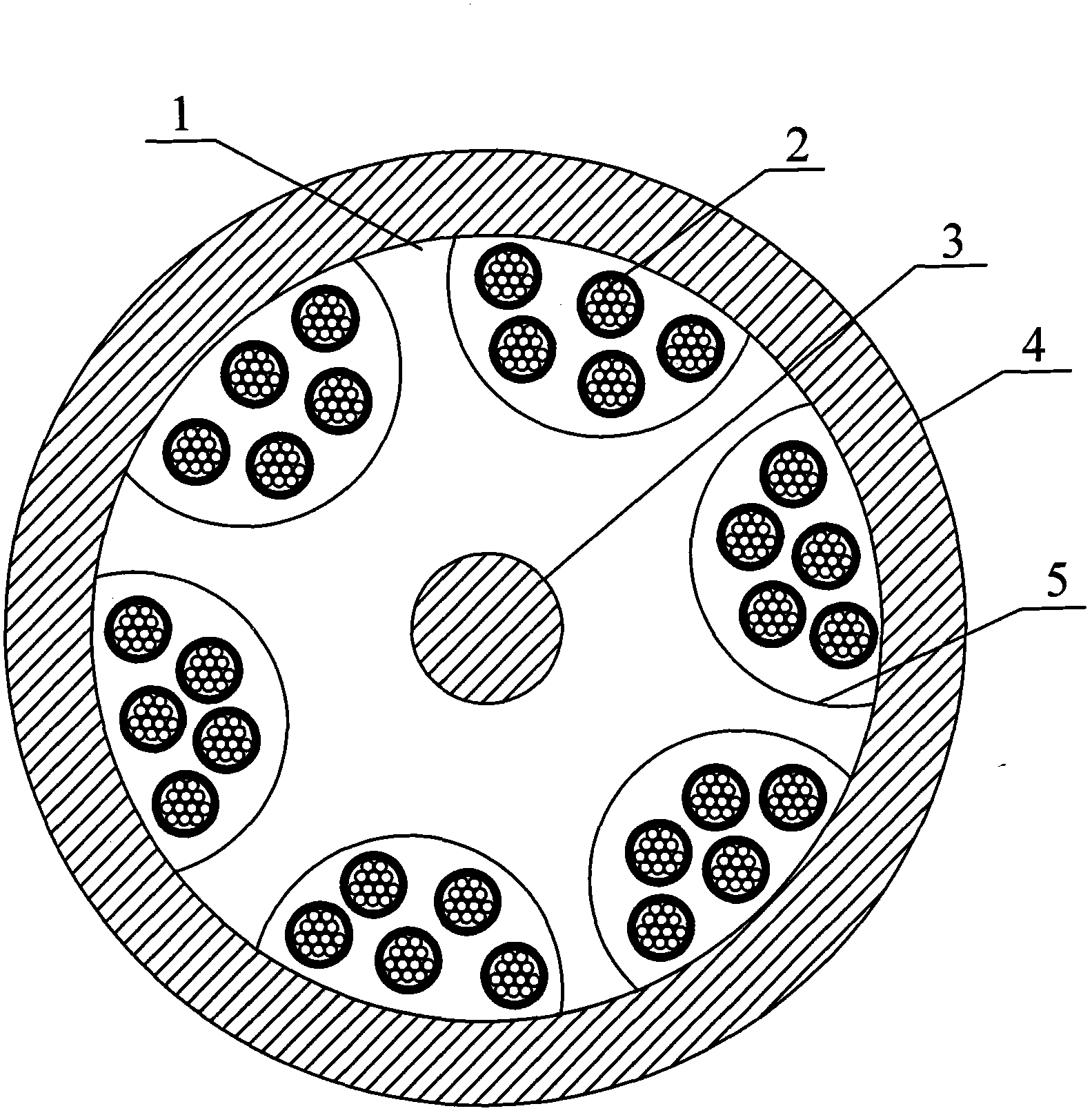

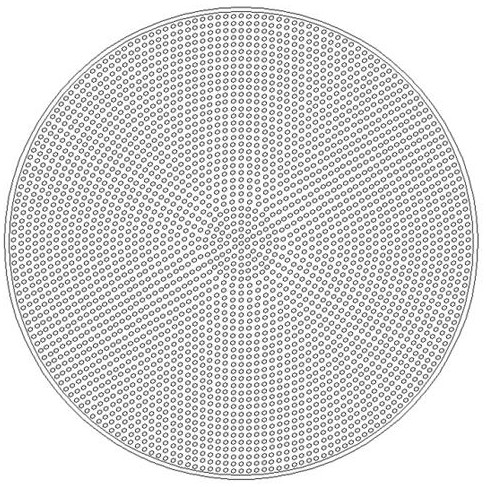

Skeleton fiber bundle optical cable with semicircular skeleton grooves

InactiveCN102692687ASolve the larger diameterSolve the yieldFibre mechanical structuresUltrasound attenuationFiber bundle

The invention discloses a skeleton fiber bundle optical cable with semicircular skeleton grooves, and relates to an optical cable applied to a communication network. The skeleton fiber bundle optical cable comprises a skeleton with a cylindrical hollow structure. A central reinforcement part is arranged in the center of the skeleton. A layer of outer sheath is extruded on the outer wall of the skeleton. The skeleton grooves are uniformly distributed along a circumferential direction on the inner wall of the skeleton, and have semicircular cross sections. A plurality of fiber bundles with circular cross sections are distributed in each semicircular skeleton groove. The fiber bundles with the circular cross sections are arranged in the skeleton grooves with the semicircular cross sections, so that the problems of great diameter, low yield, high fiber attenuation of fiber ribbons, and the like of an ordinary skeleton fiber ribbon optical cable are solved.

Owner:FENGHUO COMM SCI & TECH CO LTD

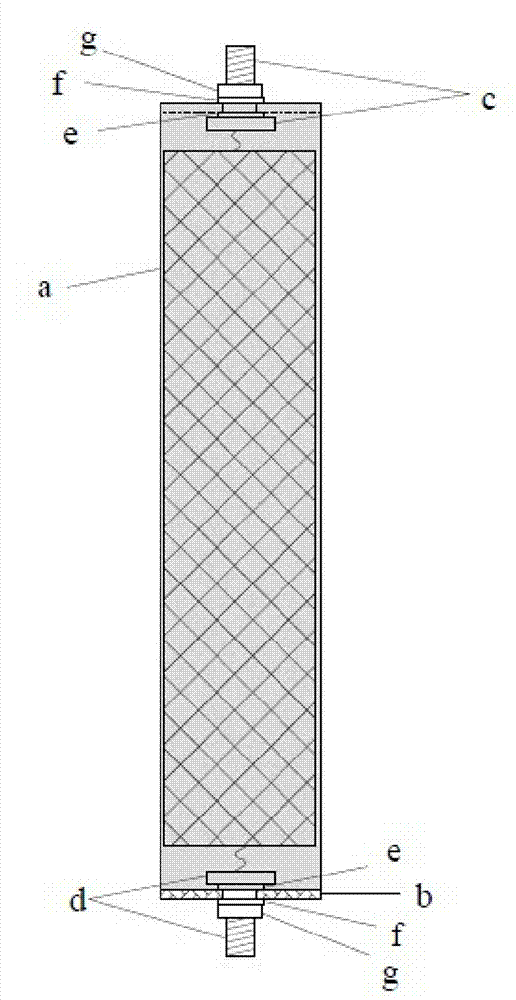

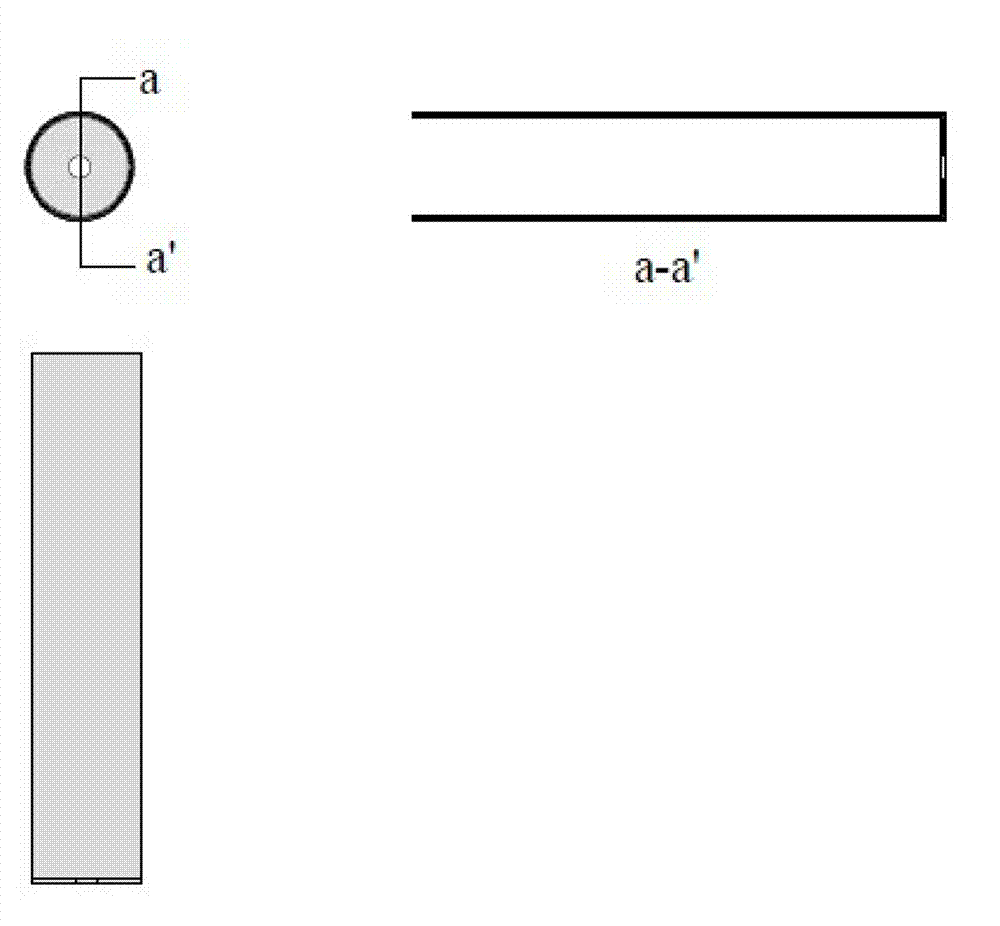

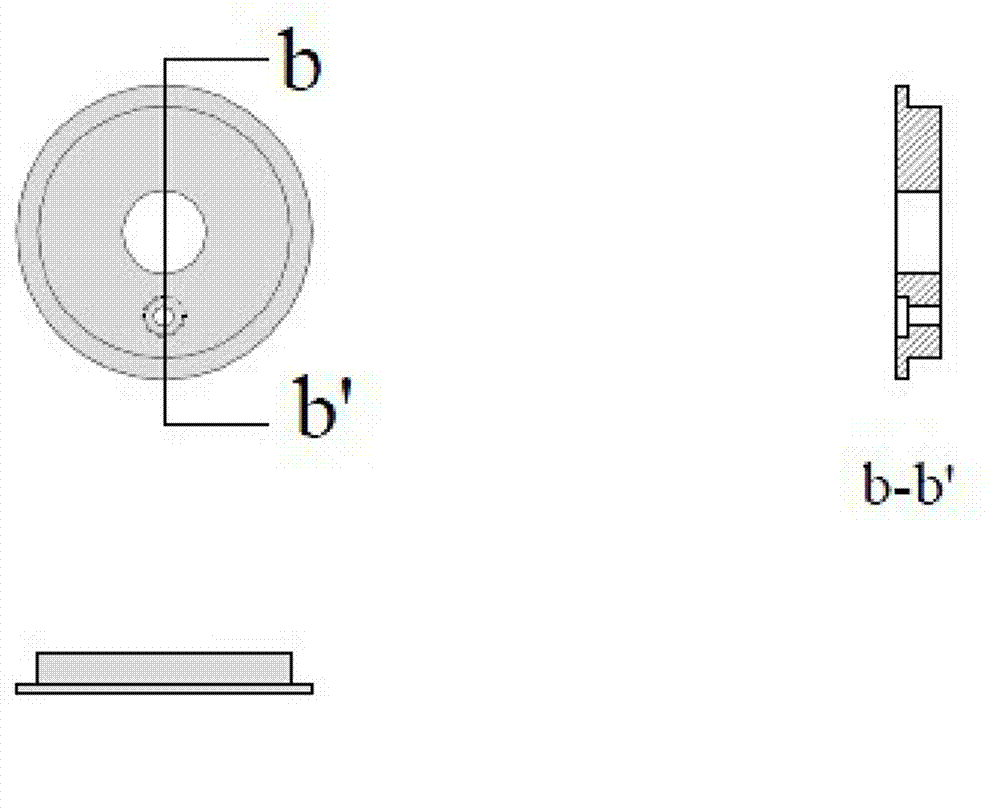

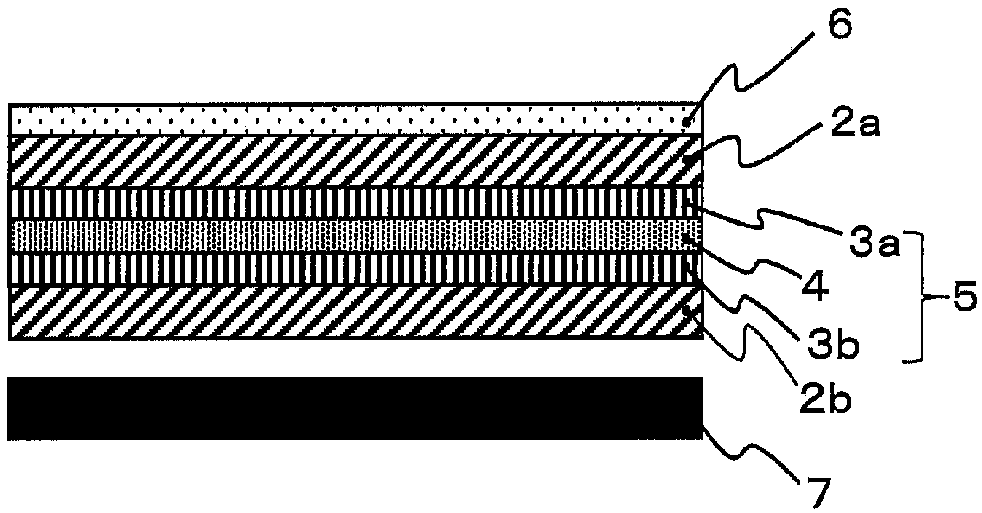

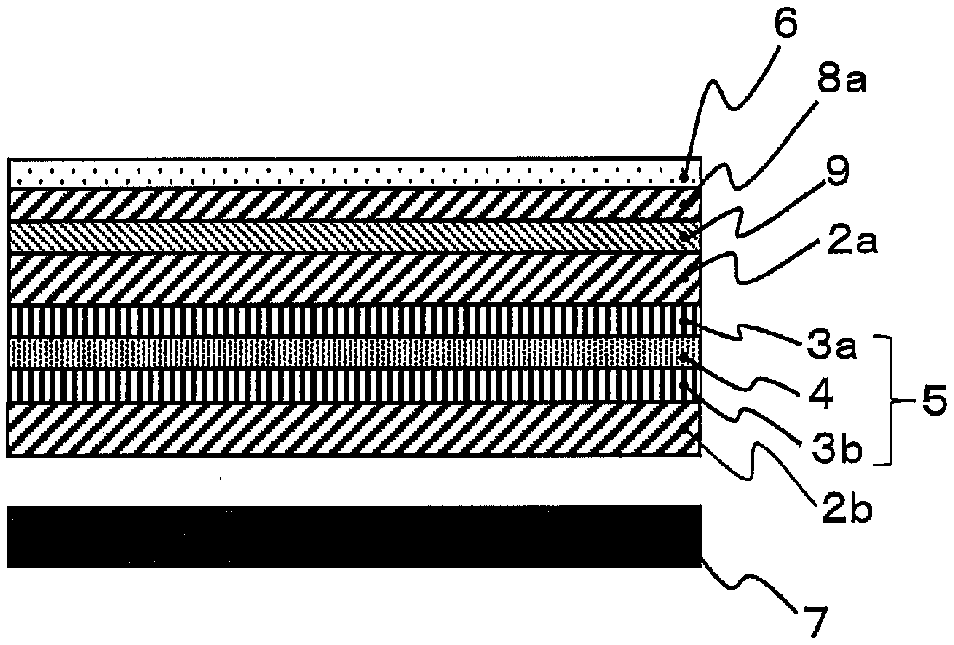

Lithium iron phosphate plastic housing cylindrical battery and preparation method thereof

ActiveCN102956848AImprove short circuit resistanceImprove pinprick resistanceFinal product manufactureCell component detailsSlurrySodium-ion battery

The present invention relates to a lithium iron phosphate plastic housing cylindrical battery and a preparation method thereof, wherein the battery is applicable for lithium ion batteries having a medium-large capacity. According to the method, a lithium iron phosphate material, an electric conduction agent, a binder and the like are mixed to obtain a positive electrode slurry; graphite, an electric conduction agent, a binder and the like are mixed to obtain a negative electrode slurry; the positive electrode slurry is coated on an aluminum foil to prepare a positive electrode sheet; the negative electrode slurry is coated on a copper foil to prepare a negative electrode sheet; the positive electrode sheet and the negative electrode sheet are added to a specially designed diaphragm to carry out rolling to obtain a cylindrical rolling core; the rolling core, a plastic housing, end caps, an upper post terminal, a lower post terminal, an inner gasket, an outer gasket and a fixation nut are assembled; and finally liquid injection formation is performed to prepare the finished battery. The present invention relates to a lithium iron phosphate plastic housing cylindrical battery and a preparation method thereof, the method has advantages of convenient assembly, high production efficiency and low cost, and battery safety performances such as short circuit resistance, needling resistance, impact resistance, extrusion resistance and the like can be improved by using the specially designed diaphragm.

Owner:SHANDONG TIANYANG NEW ENERGY

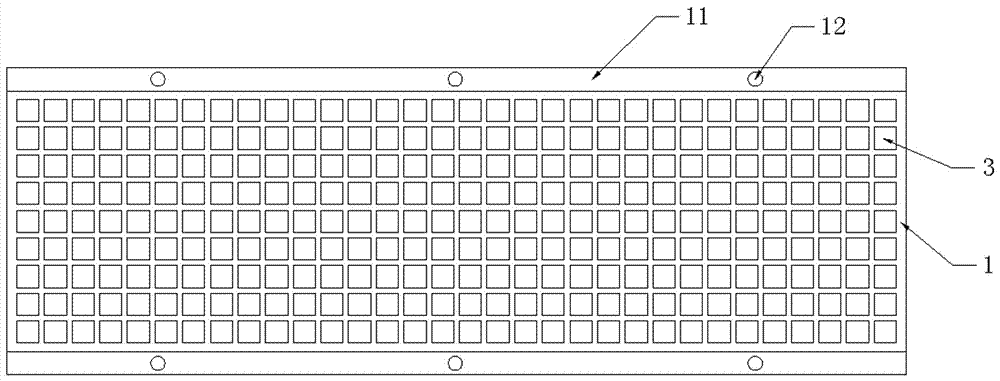

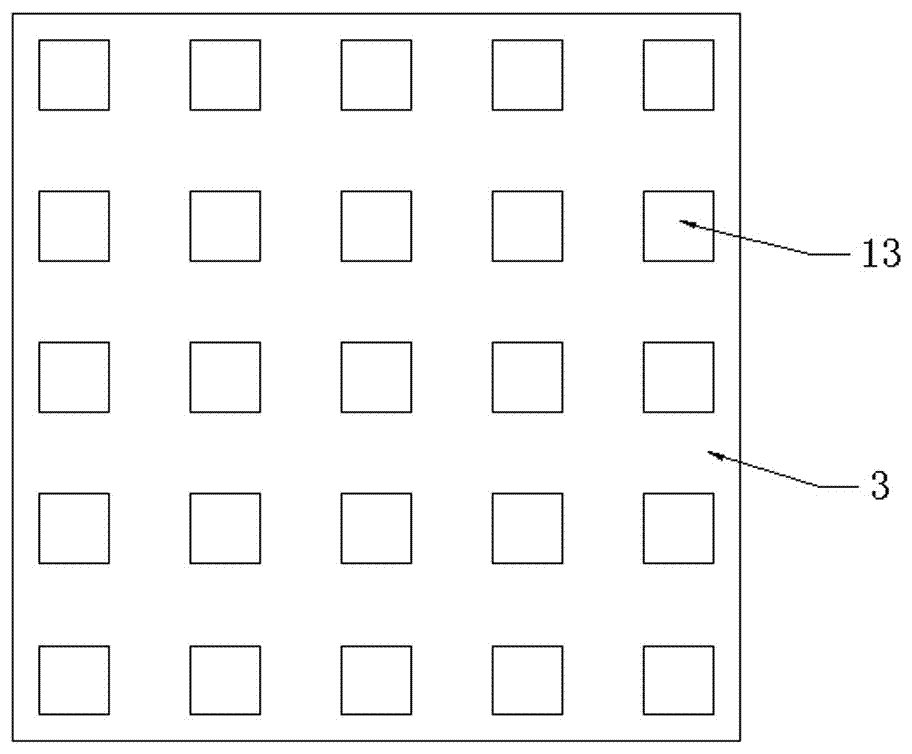

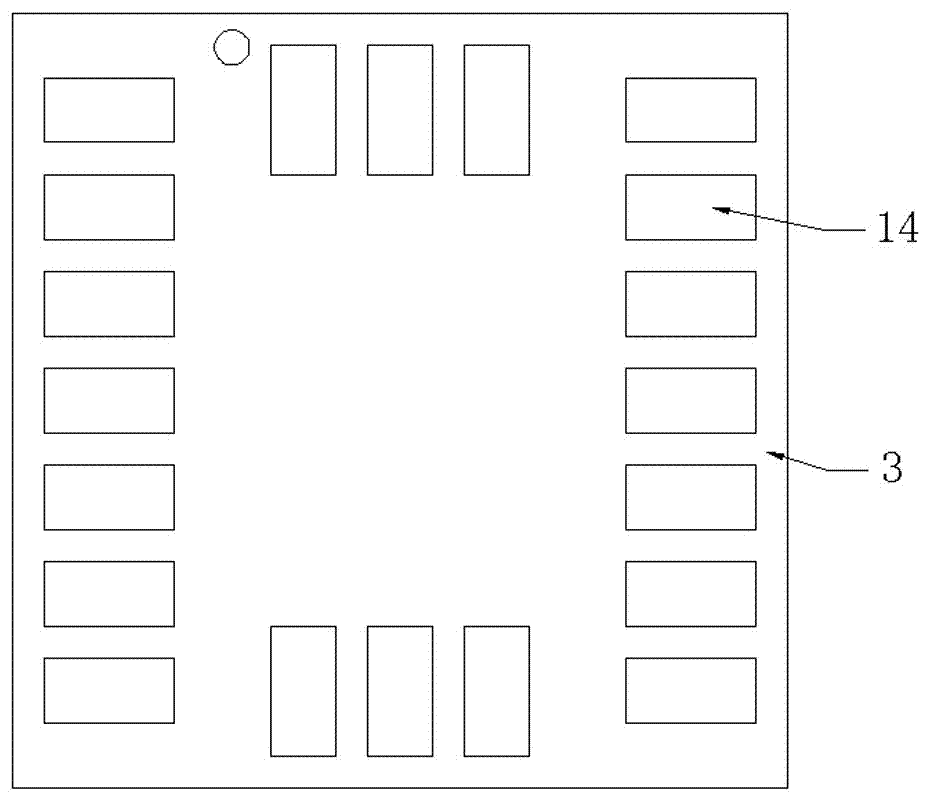

Production process of integrated surface-mounted light emitting device

ActiveCN107146787AReduce volumeHigh resolutionSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingImage resolution

The invention discloses a production process of an integrated surface-mounted light emitting device. The production process comprises the following steps of 1, enabling a plurality of light emitting point groups to be arranged and packaged on the front surface of a substrate, wherein each light emitting point group comprises at least one red light LED chip, at least one green light LED chip and at least one blue light LED chip; and all LED chips are packaged on the substrate by adopting COB; 2, cutting the substrate into a plurality of independent light emitting devices, wherein one light emitting point group is arranged in each light emitting device; 3, lightening up the red light LED chips, the green light LED chips and the blue light LED chips in each light emitting device to test wavelength and luminance values, and allocating all light emitting devices with BIN according to the test data; and 4, testing forward voltage and reverse electric leakage of each light emitting device, and picking out the unqualified devices. The production process is simple, and the produced light emitting device is high in resolution.

Owner:SHENZHEN ZIGUANG INTELLIGENT TECH CO LTD +1

Method for sealing air removal and extraction pipe of composite sheath by hydraulic tongs

The invention discloses a method for sealing an air removal and extraction pipe of a composite sheath by hydraulic tongs. The method includes the following steps: performing vacuum electron beam welding on the air removal and extraction pipe and an upper cover of the composite sheath, and then subjecting the upper cover, a lower cover and a composite sheath body to vacuum electron beam welding; mounting the welded composite sheath in an air removal furnace, connecting a vacuum set with the air removal and extraction pipe of the sheath via a vacuum rubber hose, and sealing the joint part prior to heating and air removal; after air removal is finished, baking the extraction pipe to be reddish via an oxyacetylene torch; using flat hydraulic tongs for performing tongs pressure at the position baked to be red; then using hydraulic tongs with pressure grooves to perform tongs pressure in an flattened area again; using cutting nippers to cut through the composite sheath from the position of the topmost pressure groove; performing seal welding on the cut-through part via argon arc welding. The easily-caused problems of air leakage of the sheath body and low rate of finished products in an existing tongs sealing method are solved, and the method is stable in technologic process, good in tongs sealing quality and high in rate of finished products of composite rods and wires.

Owner:西部超导材料科技股份有限公司

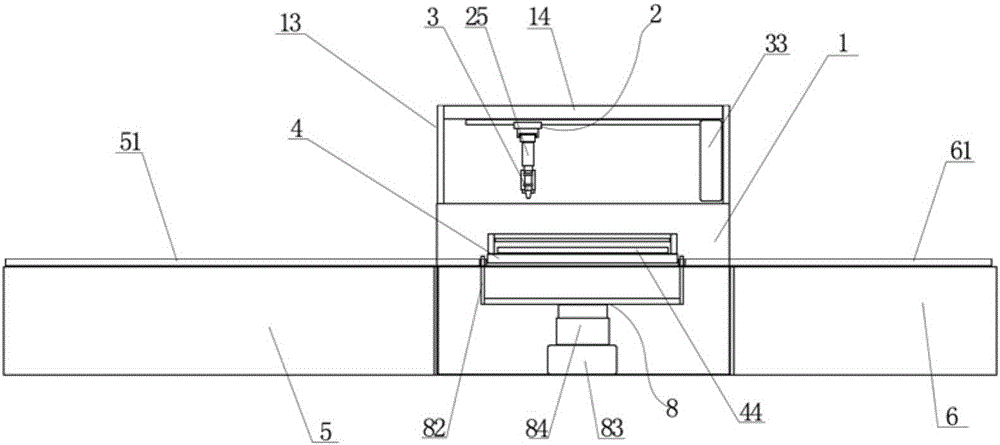

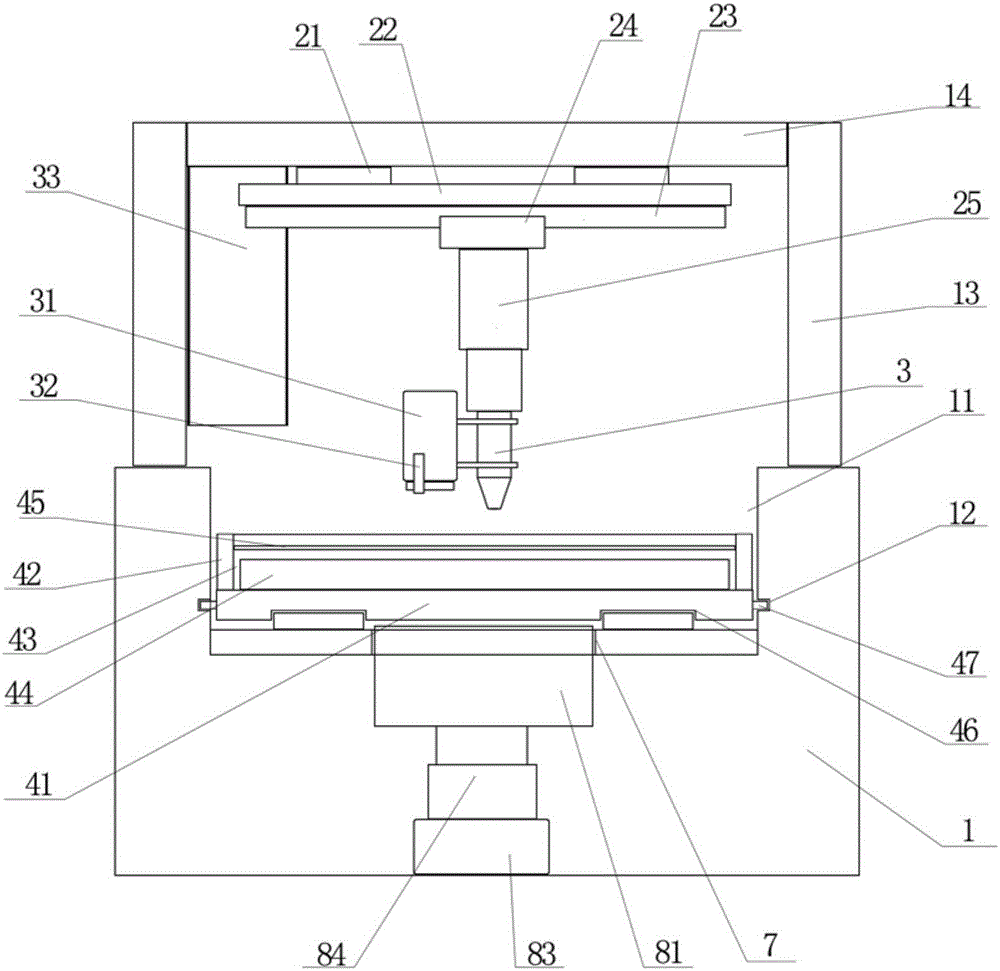

Coaxial visual cutting device used for glass cutting

InactiveCN106735870AImprove yieldSolve efficiency problemsWelding/soldering/cutting articlesLaser beam welding apparatusEngineeringSlide plate

The invention discloses a coaxial visual cutting device used for glass cutting. The coaxial visual cutting device comprises a rack as well as a first bracket and a second bracket which are separately arranged at the two ends of the rack, wherein the top of the rack is downwards equipped with a cutting station slot; the top of the first bracket is equipped with a slide path assembly; the slide path assembly extends into the cutting station slot; a cutting carrier is arranged on the slide path assembly; a supporting frame is arranged on the top of the rack; the top of the supporting frame comprises a top plate; a cutting assembly is arranged on the top plate; the cutting assembly comprises two first slide rails which are horizontally arranged on the bottom of the top plate; a movable plate is arranged on the two first slide rails; the bottom of the movable plate is horizontally equipped with a second slide rail; a slide plate is arranged on the second slide rail; the bottom of the slide plate is equipped with a telescopic pole; the bottom end of the telescopic pole is connected with a laser cutter; one side of the laser cutter is connected with a CCD camera; the side surface of the supporting frame is equipped with a main controller; and the main controller is connected with the CCD camera.

Owner:SUZHOU DADAO LASER APPL TECH CO LTD

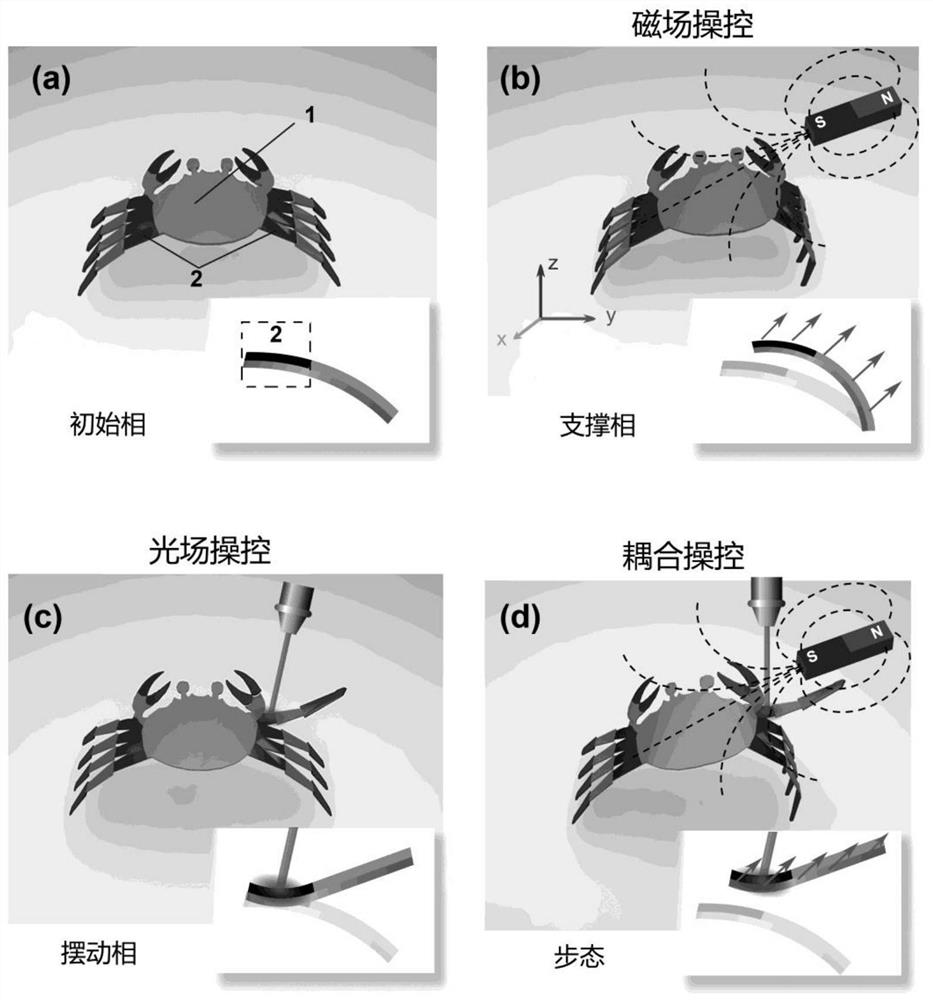

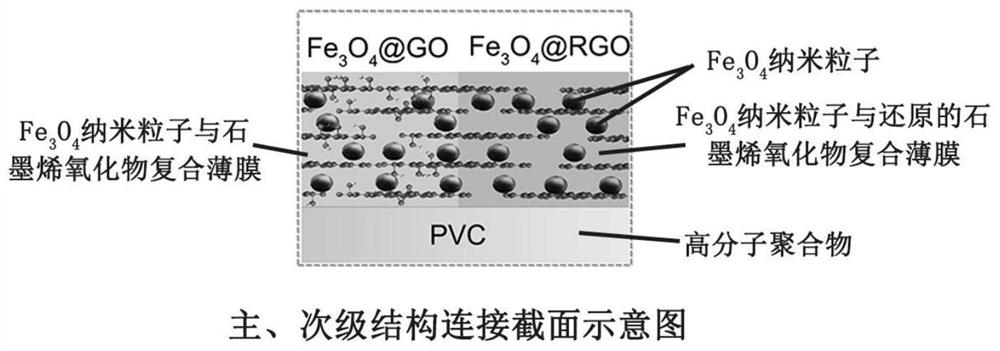

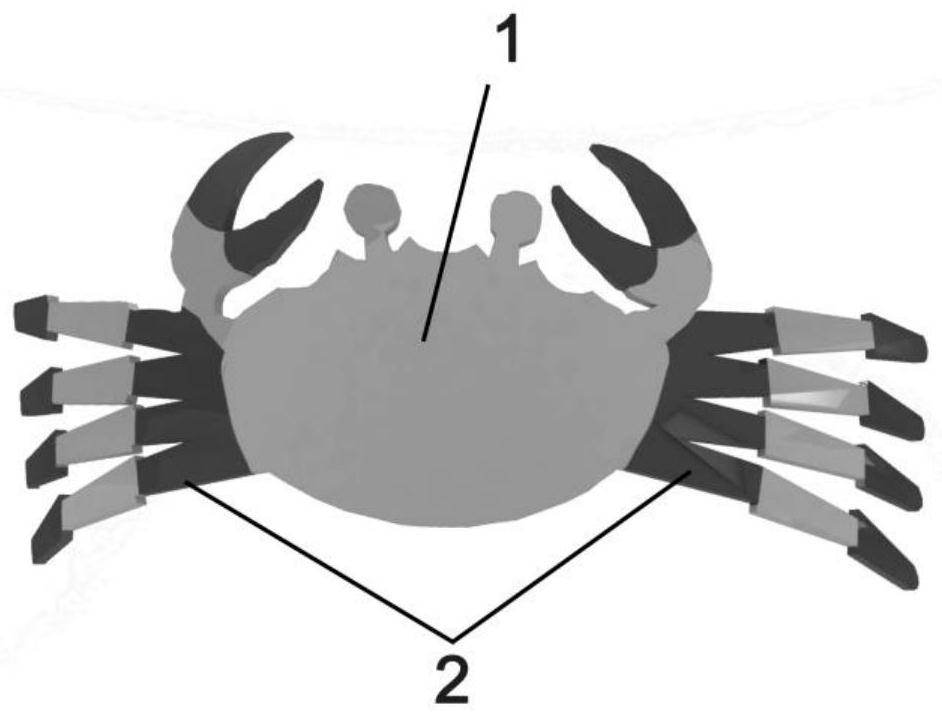

Double-field cooperative driving omni-directional motion robot and driving method thereof

ActiveCN112965483AIncreased freedom of controlSolve the cumbersome precision integrationPosition/course control in two dimensionsRoboticsMacroscopic scale

The invention discloses a double-field cooperative driving omni-directional motion robot and a driving method thereof, and belongs to the technical field of flexible robotics. The omni-directional motion robot is composed of a main body structure with magnetic response and a secondary structure with light response, wherein the main body structure is a double-layer film with the edge comprising a plurality of foot structures; the main body structure can generate macroscopic deformation under the action of an external magnetic field, internal stress is directionally accumulated, and the walking direction of the robot is determined; the secondary structure comprises a plurality of double-layer drivers arranged on the foot structure; the secondary structure can be bent under the driving of an external light field to realize a stepping process; and under cooperative driving of an external magnetic field and a light field, the robot achieves the gravity center shifting and advancing processes at the same time, and therefore the robot walks in the stress direction of the main body structure. The two energy fields are used for driving the robot at the same time, and the control process combining macroscopic overall deformation and fine local deformation of the robot is achieved.

Owner:JILIN UNIV

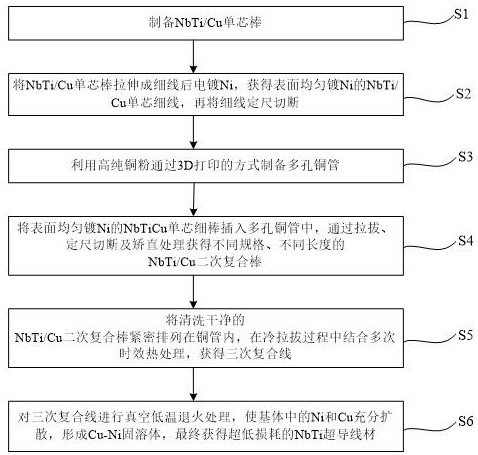

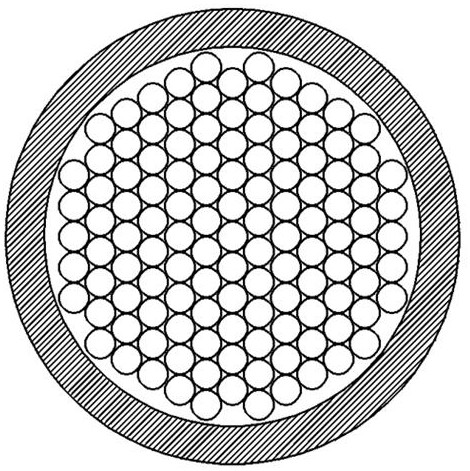

Preparation method of ultralow-loss NbTi superconducting wire

ActiveCN114783681AHigh resistivityEasy to processSuperconductors/hyperconductorsSuperconductor devicesWire rodElectric resistivity

The invention belongs to the technical field of superconducting wire preparation processes, and relates to a preparation method of an ultralow-loss NbTi superconducting wire, an NbTi / Cu single-core rod is prepared by a casting method, the single-core rod is cold-drawn into a fine wire, then the surface of the fine wire is uniformly plated with Ni, finally annealing heat treatment is carried out to improve the resistivity of a wire matrix, and the resistivity of the matrix is regulated and controlled by adjusting the thickness of a Ni plating layer, so that the ultra-low-loss NbTi superconducting wire is obtained. And the superfine core wire rod has excellent processing performance and ultralow loss. A multi-core secondary composite rod is prepared through 3D printing of a porous copper pipe, and finally, the 100,000-core-level NbTi superconducting wire with high critical current density and ultralow loss is successfully prepared through combination of pipe penetrating three-time composite and multiple times of aging heat treatment, and a traditional hot extrusion process is omitted in preparation of a single-core thin wire and the secondary composite rod. And the problems of high loss of the superfine core wire, poor deformation of the core wire, low yield and the like are thoroughly solved.

Owner:西部超导材料科技股份有限公司

Kay structure and portable mobile terminal

InactiveCN101635211ASolve the yieldSolve the technical problem of poor hand feeling when pressing buttonsElectric switchesTelephone set constructionsCushionElectrical and Electronics engineering

The embodiment of the invention discloses a key structure and a portable mobile terminal, belonging to the technical field of machinery and solving the technical problem of the prior key structure that the yield is lower and the hand touch when pressing the key is not good. The key structure comprises a cushion and a keycap glued on the cushion by glue, wherein one side of the cushion, which is far from the key cap, is provided with an electric conduction base; and an area of the cushion, which is bonded with the keycap and is close to the edge of the keycap, is provided with grooves. The portable mobile terminal comprises a shell and the key structure arranged on the shell. The invention is applied to various electronic devices provided with key structures.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Technology for manufacturing ceramic cofiring four-side lead flat package

ActiveCN102332407AImprove convenienceAddress operational complexitySemiconductor/solid-state device manufacturingMetallurgyForming processes

The invention discloses a technology for manufacturing a ceramic cofiring four-side lead flat package, comprising the following steps of: manufacturing a ceramic package main body; processing a flat lead; welding the flat lead with a ceramic part by welding fluxes; plating a layer of gold on the flat lead and the ceramic part; coating a protective material on the lead surface; cutting off connecting parts of four sides of the flat lead; bending and forming the lead; and giving the qualified products after check to a user. The technology has the beneficial effects that the steps of cutting and bending the leads by the user in the traditional technology for manufacturing a ceramic cofiring four-side lead flat package are conducted before a package-manufacturing stage, that is, the step of bending and forming the leads is carried out in the process of manufacturing the packages, thus solving the defects that the user operation is complicated, the rate of finished products is low and the leads are scrapped easily in the process of bending and forming the leads in the traditional technology, and improving the use convenience of the user.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

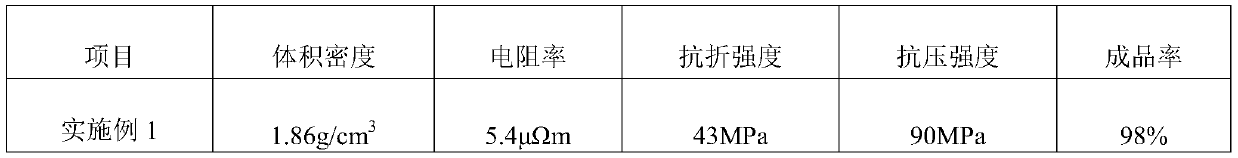

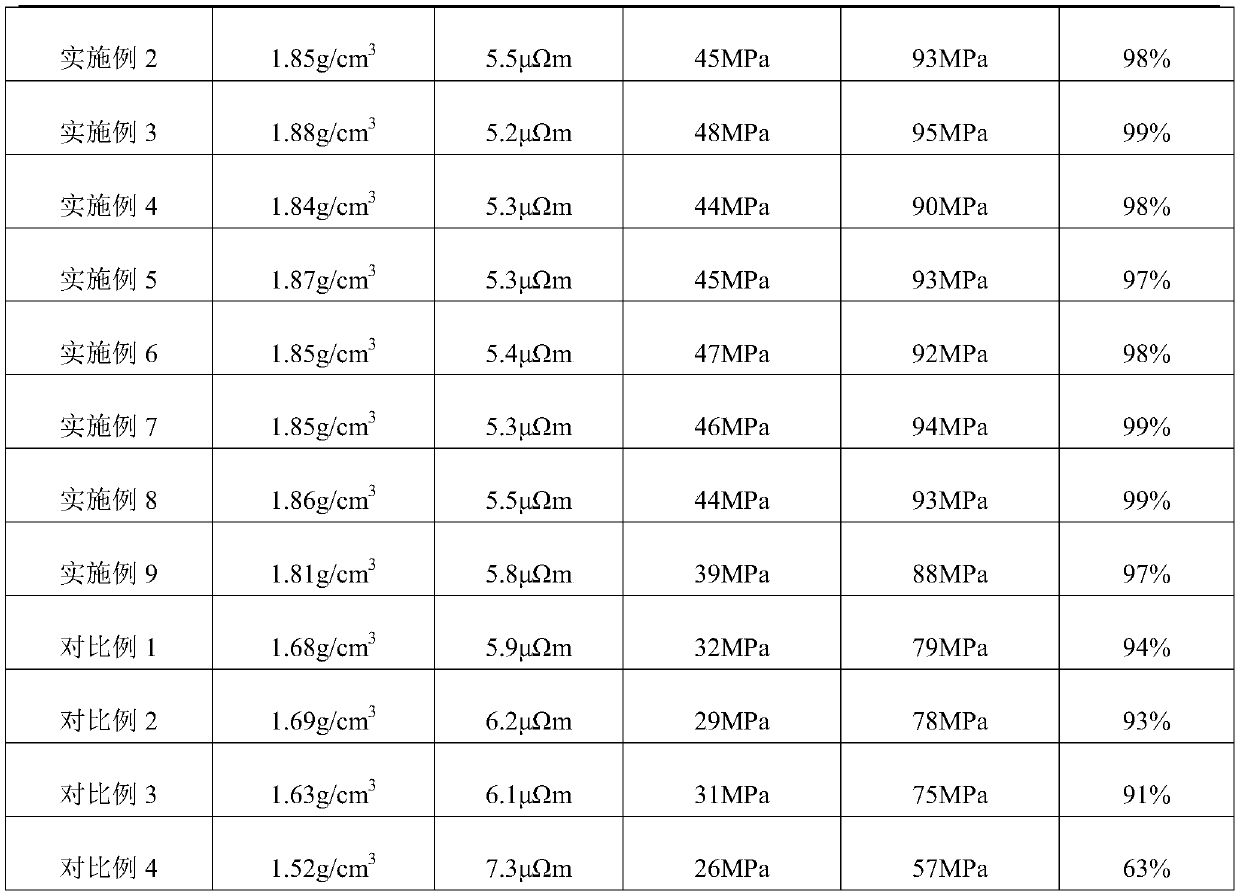

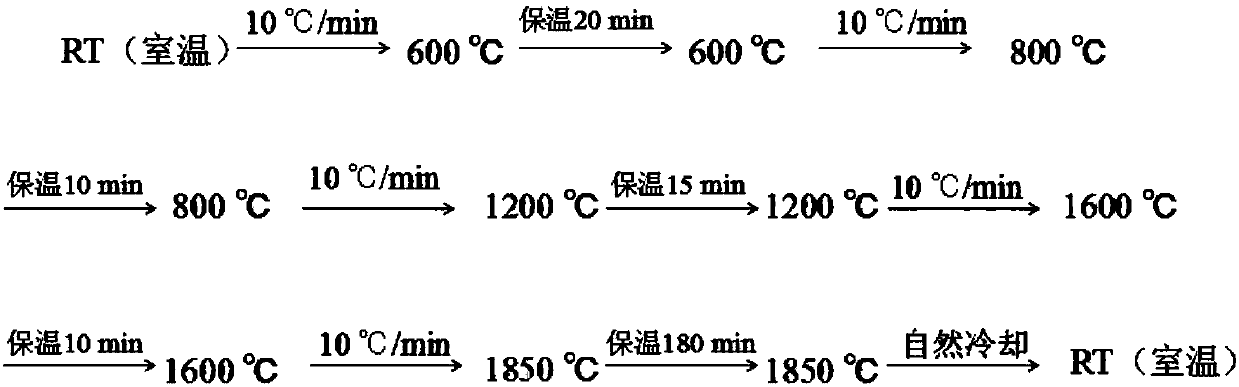

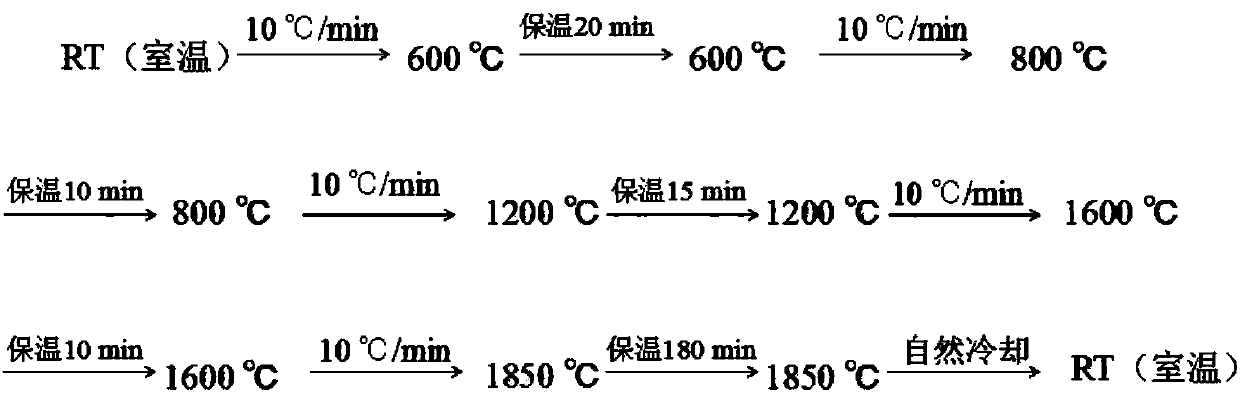

Graphite crucible for vacuum smelting of intermediate frequency furnace and preparation method thereof

InactiveCN111056843AImprove performanceImprove yieldCrucible furnacesCompression moldingPolyvinyl alcohol

The invention belongs to the technical field, and provides a graphite crucible for vacuum smelting of an intermediate frequency furnace and a preparation method thereof. The graphite crucible comprises the following components in parts by weight: 7-9 parts of needle coke with the granularity of 4-6mm, 8-10 parts of needle coke with the granularity of 2-4mm, 20-25 parts of needle coke with the granularity of 0-2mm, 26-35 parts of needle coke powder, 7-12 parts of graphite and 15-25 parts of modified asphalt. The modified asphalt is prepared from the following components in parts by weight: 60-80 parts of asphalt, 10-15 parts of nano silicon dioxide, 2-7 parts of chromic oxide, 1-5 parts of polyvinyl alcohol and 0.5-3 parts of sodium oleate. The preparation method of the graphite crucible comprises the following steps: performing dry mixing on the needle coke with the particle size of 4-6mm, the needle coke with the particle size of 2-4mm, the needle coke with the particle size of 0-2mm,needle coke powder and three-high graphite, adding modified asphalt, performing wet mixing to obtain paste, and performing crushing, compression molding, roasting, graphitization and the like on thepaste to obtain the graphite crucible. By means of the technical scheme, the problems that in the prior art, the graphite crucible is not high in strength and low in yield are solved.

Owner:JIZHOU CHANGAN ELECTRODE

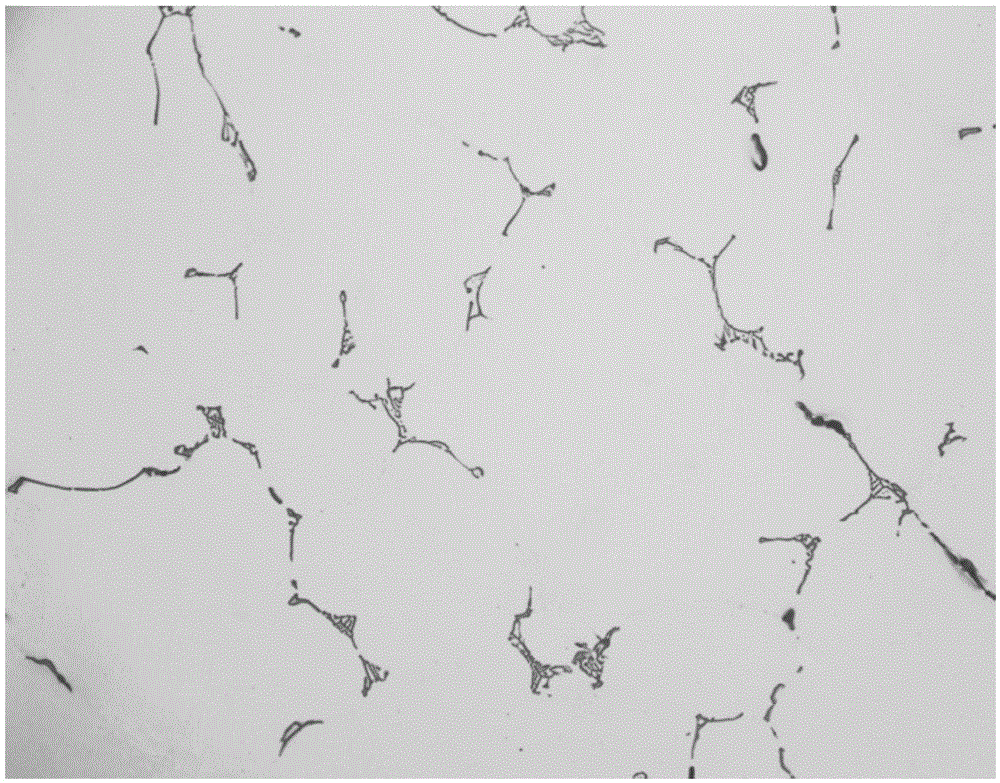

A preparing method of a polycrystalline sapphire transparent thin plate

InactiveCN107747123ASolve processabilitySolve the yieldPolycrystalline material growthSingle crystal growth detailsEmulsionOrganic solvent

An environmentally friendly tape casting method of a polycrystalline sapphire transparent thin plate is provided. High-purity submicron-order spherical aluminum oxide is adopted as a main raw material, a sintering auxiliary agent is added, and polyvinyl alcohol, waterborne acrylic resin, styrene-acrylic emulsion, and the like are adopted as main adhesives, and deionized water is adopted in place of an organic solvent. The method overcomes problems, namely difficult production and processing, a low yield and a small manufacturing dimension in present sapphire production. The dimension of a polycrystalline sapphire thin plate blank manufactured by the method can be 450*450 mm that is an ultrahigh dimension, and most monocrystal sapphire products can be replaced. The waterborne adhesives areadopted and the water is adopted to replace the organic solvent in the method, thus reducing environment pollution.

Owner:宁夏钜晶电子材料科技有限公司

Manufacturing method of micro fluxgate sensor with amorphous magnetic core

InactiveCN101885467AEase of mass productionGood repeatabilityDecorative surface effectsMagnetic field measurement using flux-gate principleCooking & bakingElectrical conductor

The invention discloses a manufacturing method of a micro fluxgate sensor with an amorphous magnetic core, belonging to the technical field of micro electronmechanical systems. The manufacturing method comprises the following steps of: sputtering a Cr / Cu bottom layer on one surface of a substrate; spinning a positive photoresist and baking to obtain bottom coils of an excitation coil and an induction coil and photoresist graph of a positioning mark; electroplating the bottom coils and the positioning mark; spinning the positive photoresist to obtain a bonding conductor and the photoresist graph of the positioning mark; electroplating the bonding conductor and the positioning mark; removing the photoresist and etching the Cr / Cu bottom layer; spinning polyimide; spinning the polyimide, adhering prefabricated amorphous magnetically soft alloy magnetic cores one by one and baking; spinning the polyimide, baking and curing; polishing the polyimide until the bonding conductor is exposed; sputtering the Cr / Cu bottom layer; spinning the positive photoresist and baking to obtain the top coils of the excitation coil and the induction coil and the photoresist graph of an electrode; electroplating the bottom coils and the electrode; and removing the photoresist and etching the Cr / Cu bottom layer to obtain the sensor which has high sensitivity and wide linear measurement range.

Owner:SHANGHAI JIAO TONG UNIV

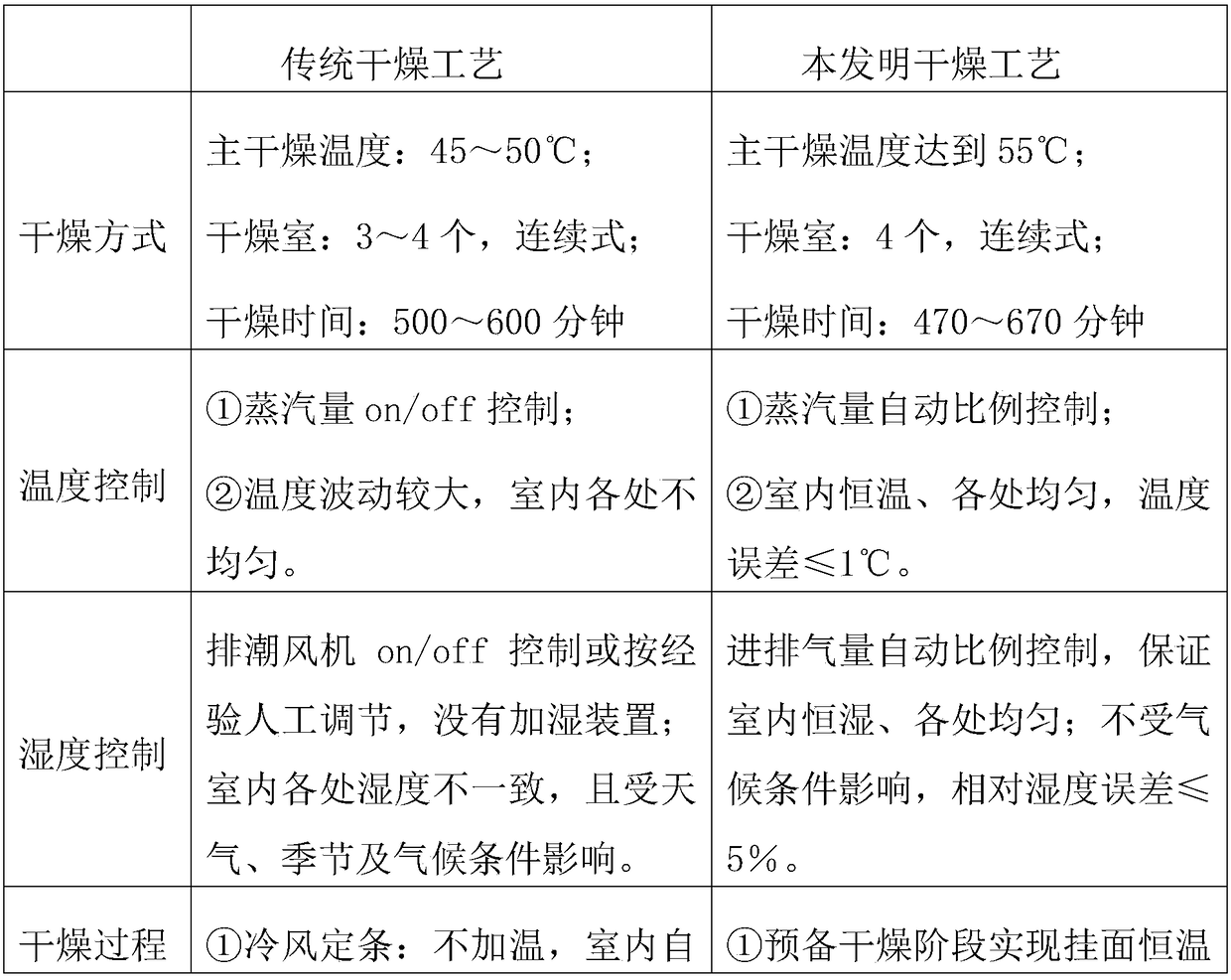

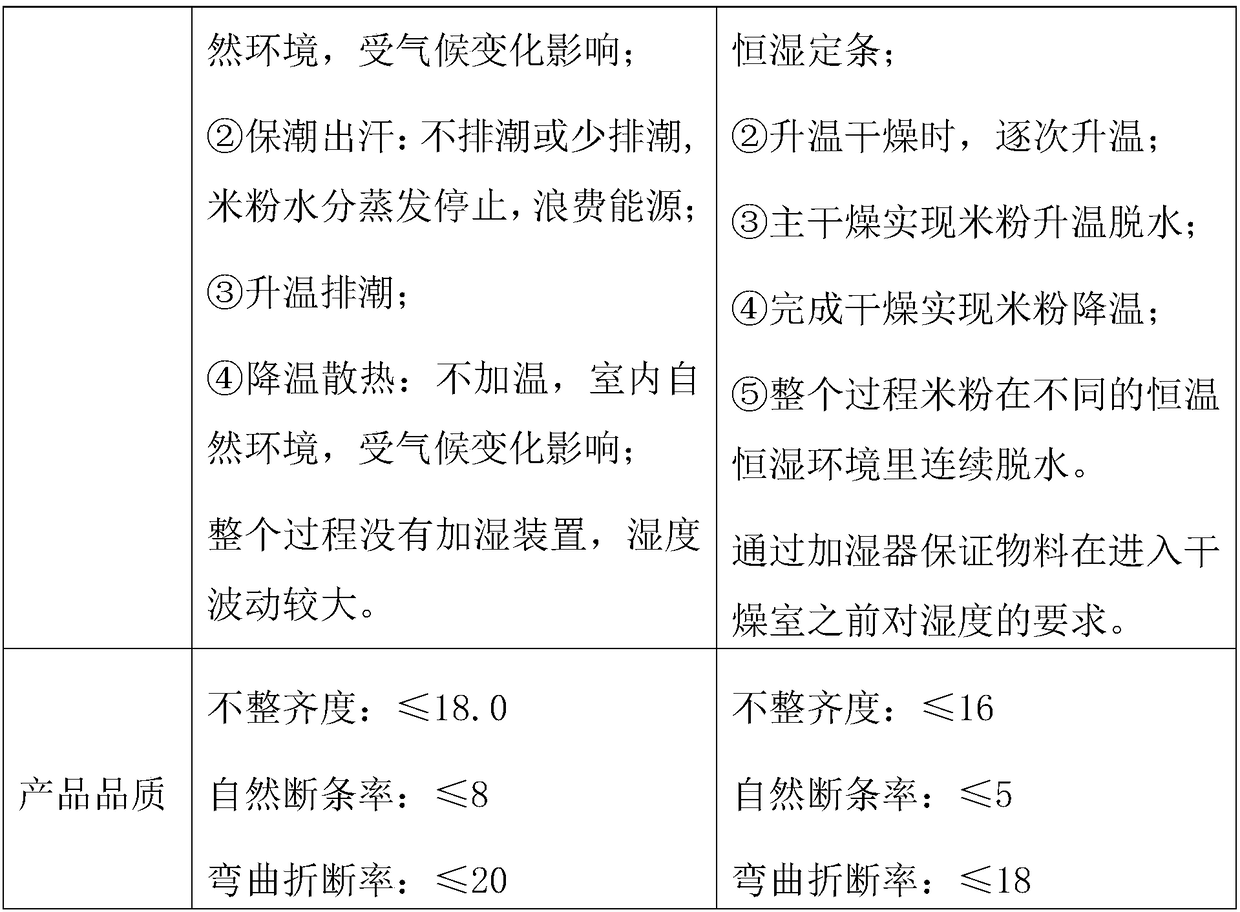

Intelligent rice noodle drying process

InactiveCN109000431ASolve the yieldSolve the problem of serious energy wasteDrying solid materials with heatDrying gas arrangementsRice flourAgricultural engineering

The invention discloses an intelligent rice noodle drying process. The prepared rice noodle sequentially pass through a constant-temperature and constant-humidity fixed-strip drying chamber, a heatingdrying chamber, a main drying chamber and an accomplishing drying chamber which are independent and closed for drying, wherein the environment temperature of the constant-temperature and constant-humidity fixed-strip drying chamber is 37 DEG C-47 DEG C, the humidity is 80%-84%, the wind speed is 2.5-3.5 m / s, and the passing through time is 55 min-70 min; the temperature of the heating drying chamber is 41 DEG C-51 DEG C, the humidity is 79%-82%, the wind speed is 2.5-3.5 m / s, and the passing through time is 90 min-110 min; the temperature of the main drying chamber is 45 DEG C-55 DEG C, the humidity is 78%-80%, the wind speed is 2.0-2.5 m / s, and the passing through time is 150 min-240 min; and the temperature of the accomplishing drying chamber is 28 DEG C-35 DEG C, the humidity is 76%-80%, the wind speed is 1.5-2.5 m / s, the passing through time is 180 min-250 min, the temperature control error in each drying chamber is less than or equal to + / -1 DEG C, and the humidity error is lessthan or equal to + / -5%. According to the intelligent rice noodle drying process, the problems of low yield and serious energy waste in the existing rice noodle drying process are solved, the constanttemperature and constant humidity in all drying chambers is achieved, so that the drying process is not affected by weather, seasons and climate conditions.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

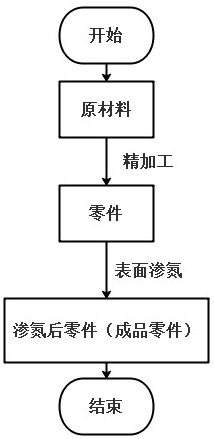

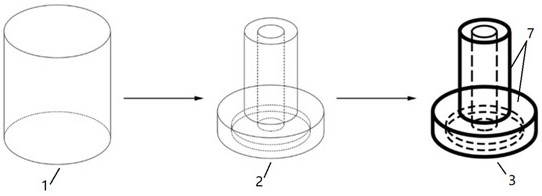

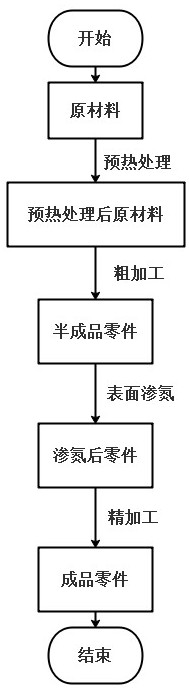

Titanium alloy part surface nitriding treatment method

ActiveCN113308664AImprove stabilityImprove yieldSolid state diffusion coatingMetallurgyThermal deformation

The invention relates to a titanium alloy part surface nitriding treatment method. The method comprises the steps of (1) preheating a titanium alloy part raw material; (2) roughly machining the preheated part raw material to obtain a semi-finished part, specifically, the semi-finished part is provided with a to-be-nitrided surface; (3) carrying out the surface nitriding treatment on the to-be-nitrided surface of the semi-finished product part to obtain a nitrided part; and (4) carrying out finish machining on the nitrided part to obtain a finished part. By means of the titanium alloy part surface nitriding treatment method, the problems that the thermal deformation is difficult to control, the quality stability is poor and the yield is low in an existing titanium alloy part surface nitriding treatment process are solved, so that the quality stability and product yield of the titanium alloy part surface nitriding treatment are remarkably improved, the titanium alloy nitriding cost is reduced, and the wide engineering application of the titanium alloy part surface nitriding treatment process is favourably and greatly promoted.

Owner:北京煜鼎增材制造研究院股份有限公司

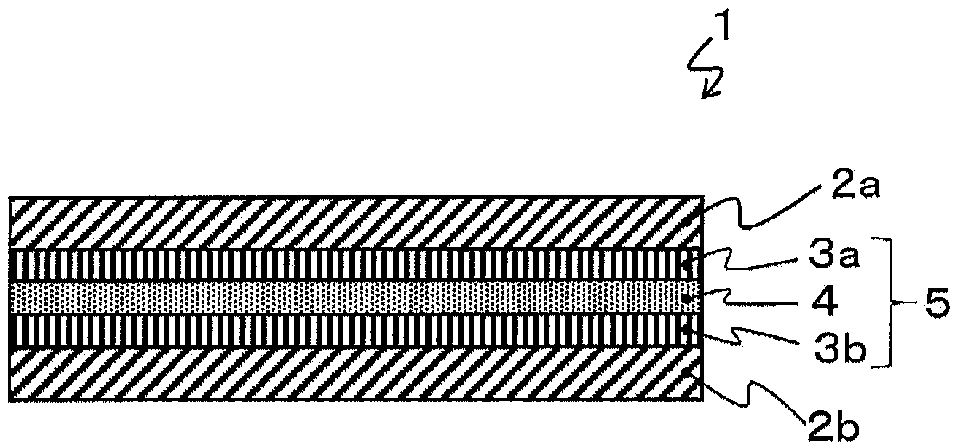

Polarizing film with pressure-sensitive adhesive layer, and image display device

ActiveCN108369305AInhibit deteriorationSolve process eliminationFilm/foil adhesivesElectroluminescent light sourcesTransmittancePolarizer

A polarizing film with a pressure-sensitive adhesive layer according to the present invention is to be used at a portion located more toward the visible side than an image display unit in an image display device. The polarizing film with a pressure-sensitive adhesive layer includes a polarizing film and a pressure-sensitive adhesive layer on both sides of the polarizing film. The polarizing film has a polarizer and a transparent protective film on both sides of the polarizer. The transparent protective film located on the visible side of the polarizer has a transmittance of less than 6% at thewavelength of 380 nm, and the pressure-sensitive adhesive layer on the visible side of the polarizing film has an ultraviolet absorption function. The present invention can solve the problem regarding a low process yield, and can provide a polarizing film with a pressure-sensitive adhesive layer capable of providing a sufficient ultraviolet protection function and inhibiting the occurrence of curling, even when the polarizing film is of a thin type.

Owner:NITTO DENKO CORP

Microwave pre-treatment method for tea tree seeds

The invention discloses a microwave pre-treatment method for tea tree seeds. The microwave pre-treatment method comprises the following steps: (1) selecting high-quality tea tree seeds and spreading the tea tree seeds in an indoor shady and cool, dried and ventilated place; removing rotted tea tree seeds; (2) immersing the tea tree seeds with warm water at 40 DEG C to 50 DEG C for 2min to 3min; adding sodium sorbate which accounts for 0.5 percent to 0.7 percent of the weight of the tea tree seeds and immersing for 8min to 10min; taking out the tea tree seeds and washing with water; (3) uniformly and flatly spreading the tea tree seeds into a container, adjusting microwave power and microwave time and carrying out microwave treatment on the tea tree seeds until the final temperature reaches 80 DEG C to 150 DEG C; (4) putting the tea tree seeds subjected to the microwave treatment into warm water at 42 DEG C and immersing for 2h to 4h; taking out the tea tree seeds and draining; uniformly spraying a gibberellin solution with the mass concentration of 0.4mg / L to 0.5mg / L, wherein the spraying amount is 7ml / Kg to 9ml / Kg; putting the tea tree seeds into a refrigerator at 3 DEG C to 4 DEG C and turning for one time every day; refrigerating for 3 to 4 days and washing the seed with clean water at 2 DEG C to 4 DEG C.

Owner:潜山县彭河幸福茶场

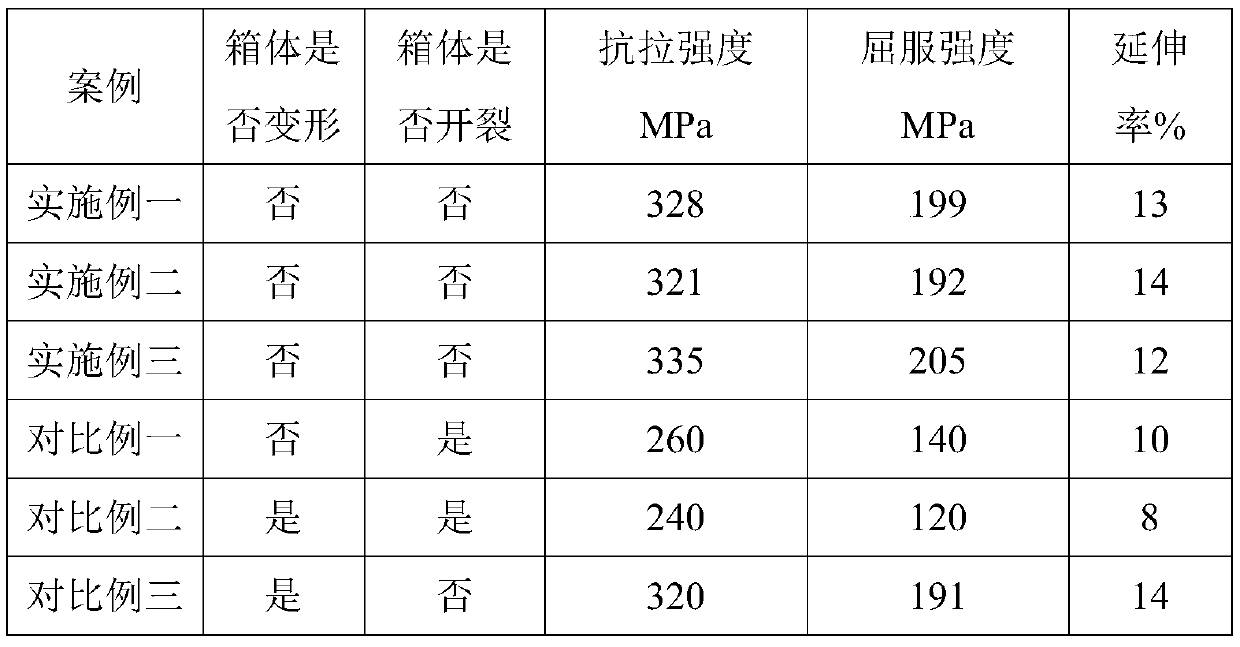

High-magnesium 5-series aluminum alloy box die forging method

ActiveCN111545695AAvoid die forging crackingSolve the yieldMetal-working apparatusMachiningAluminium alloy

The invention discloses a high-magnesium 5-series aluminum alloy box die forging method. The weight percentage of magnesium in a high-magnesium 5-series aluminum alloy is greater than that of magnesium in a 4.5% 5-series aluminum. The die forging method mainly comprises the following steps of (1) alloy casting; (2) homogenization treatment; (3) die forging; (4) stabilizing treatment; and (5) machining. Through the high-magnesium 5-series aluminum alloy box die forging method, the bottleneck of the high-magnesium 5-series aluminum alloy die forging process is overcome. A high-magnesium 5-seriesaluminum alloy box produced through the method is excellent in mechanical performance, good in surface quality, stable in size, high in rate of finished products and low in cost.

Owner:福建祥鑫股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com