Intelligent rice noodle drying process

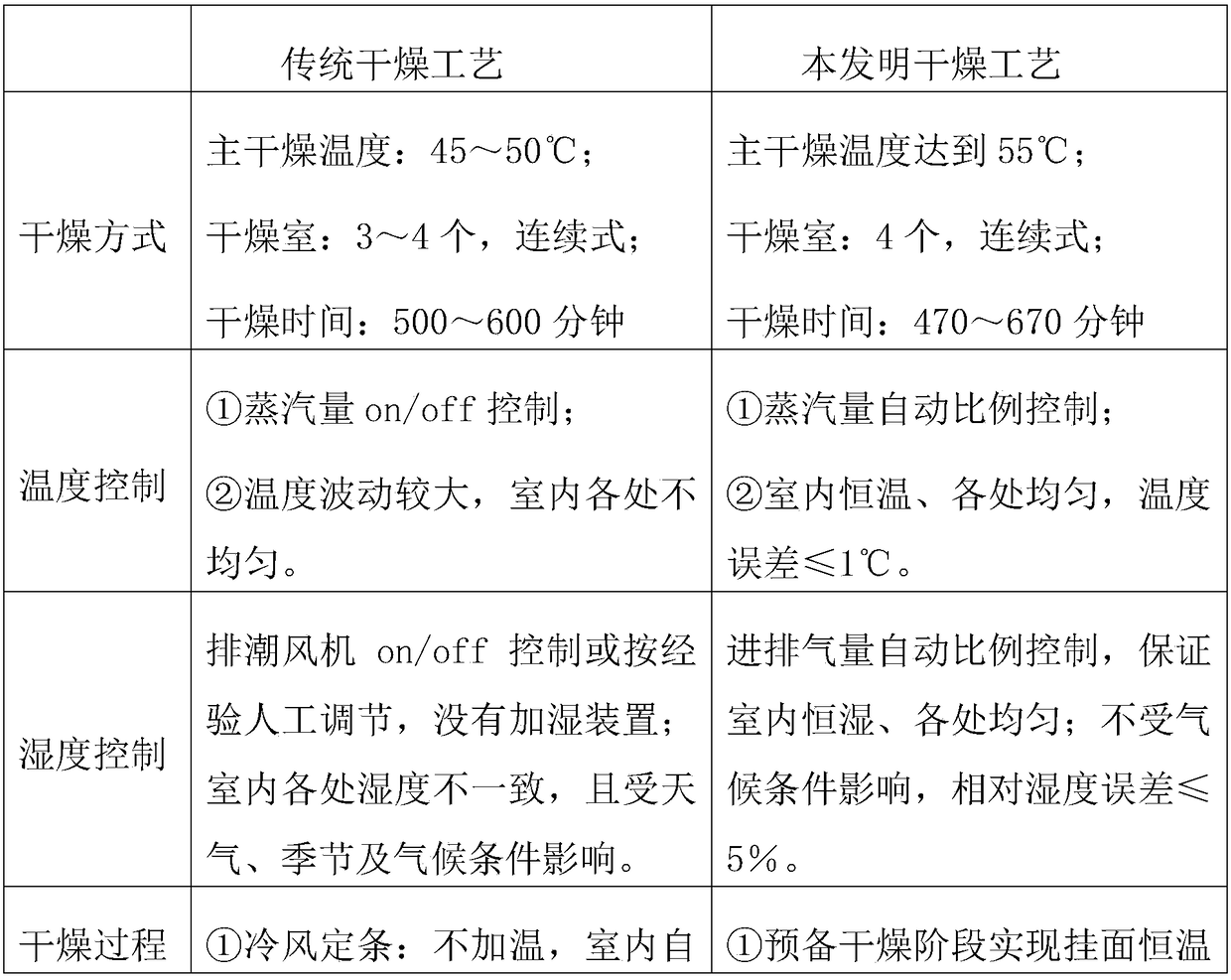

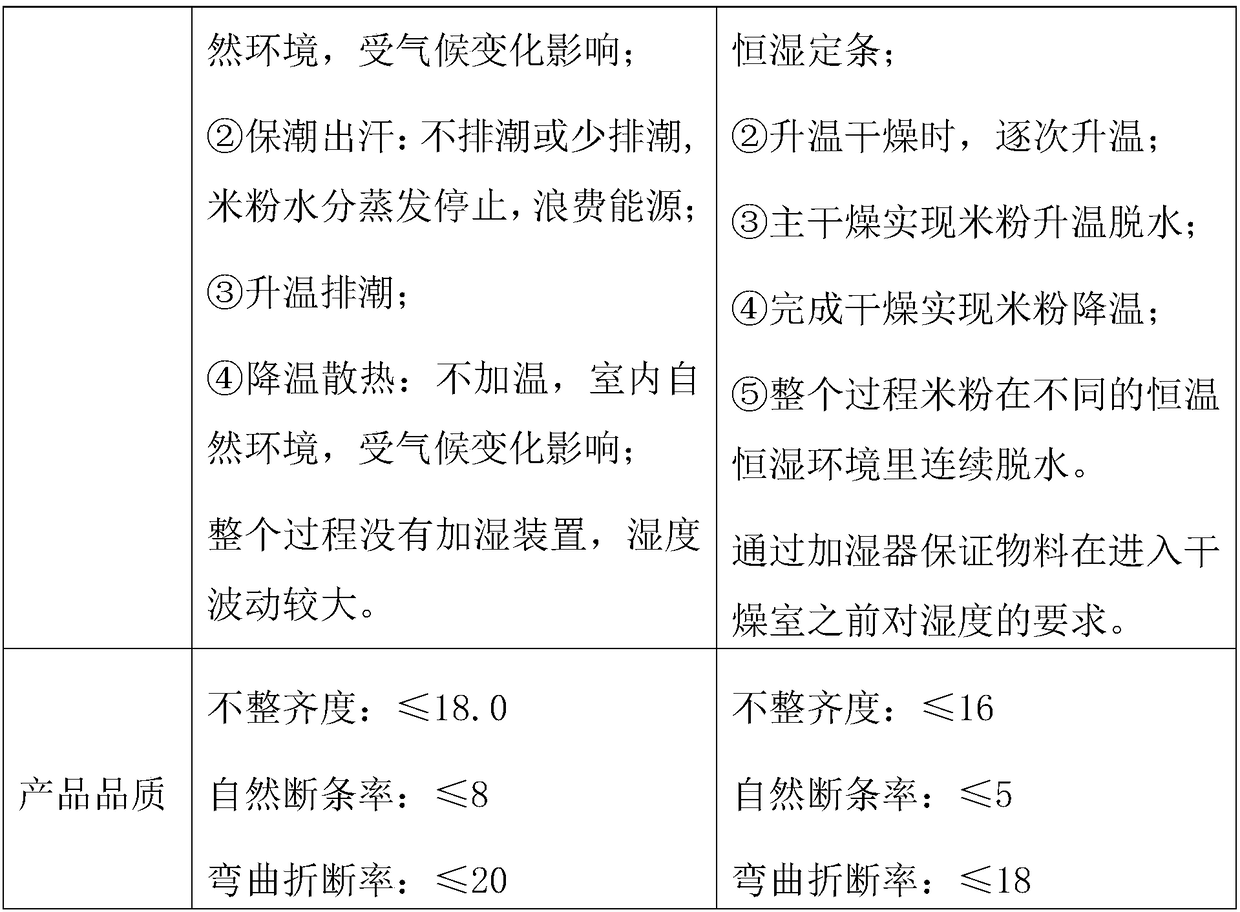

A drying process and rice flour technology, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of energy waste, low yield, poor product quality stability and consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment adopts a four-stage medium-temperature drying method. Each drying section is fully enclosed, independent of each other, and does not interfere with each other. The dry hot air is processed by the hot air centralized treatment system and distributed to each drying room through the air duct. After the air is mixed, it is in contact with the material, and the high-humidity air is returned to the centralized processing device through the air duct, and part of it is discharged to the outside. The indoor temperature, humidity, moisture removal and air intake of the four drying chambers are intelligently controlled in proportion and according to the heat demand, and the process steps are carried out in the drying chamber.

[0034] Among them, the ambient temperature in the constant temperature and humidity drying room is 47°C, the ambient humidity is 84%, the wind speed is 3.5m / s, and the time for rice noodles to run in the room is 60 minutes;

[0035] Among th...

Embodiment 2

[0040] Among them, the ambient temperature in the constant temperature and humidity drying room is 37°C, the ambient humidity is 80%, the wind speed is 2.5m / s, and the time for rice noodles to run in the room is 70 minutes;

[0041] Among them, the ambient temperature in the heating and drying chamber is 41°C, the ambient humidity is 79%, the wind speed is 2.5m / s, and the time for rice noodles to run in the chamber is 110min;

[0042]Among them, the ambient temperature in the main drying room is 45°C, the ambient humidity is 78%, the wind speed is 2.0m / s, and the time for rice noodles to pass through the room is 240min;

[0043] Among them, the ambient temperature in the drying room is 28°C, the ambient humidity is 76%, the wind speed is 1.5m / s, and the time for the rice noodles to pass through the room is 180 minutes;

[0044] The main physical and chemical indicators of the rice noodles dried by the four-stage medium-temperature drying process are as follows: the product moi...

Embodiment 3

[0046] Among them, the ambient temperature in the constant temperature and humidity drying room is 45°C, the ambient humidity is 82%, the wind speed is 3.0m / s, and the time for rice noodles to run in the room is 55 minutes;

[0047] Among them, the ambient temperature in the heating and drying room is 49°C, the ambient humidity is 81%, the wind speed is 3.0m / s, and the time for rice noodles to run in the room is 90 minutes;

[0048] Among them, the ambient temperature in the main drying room is 53°C, the ambient humidity is 80%, the wind speed is 2.5m / s, and the time for rice noodles to run in the room is 170min;

[0049] Among them, the ambient temperature in the drying room is 32°C, the ambient humidity is 79%, the wind speed is 2.0m / s, and the time for the rice noodles to pass through the room is 200 minutes;

[0050] The main physical and chemical indicators of the rice noodles dried by the four-stage medium-temperature drying process are as follows: the product moisture c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com