High-magnesium 5-series aluminum alloy box die forging method

A technology for casting aluminum alloys and aluminum alloy ingots, applied in metal processing equipment, etc., can solve problems such as large deformation of aluminum alloy ingots, box forging failure, large processing volume, etc., to achieve excellent overall performance and avoid die forging cracks , to solve the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

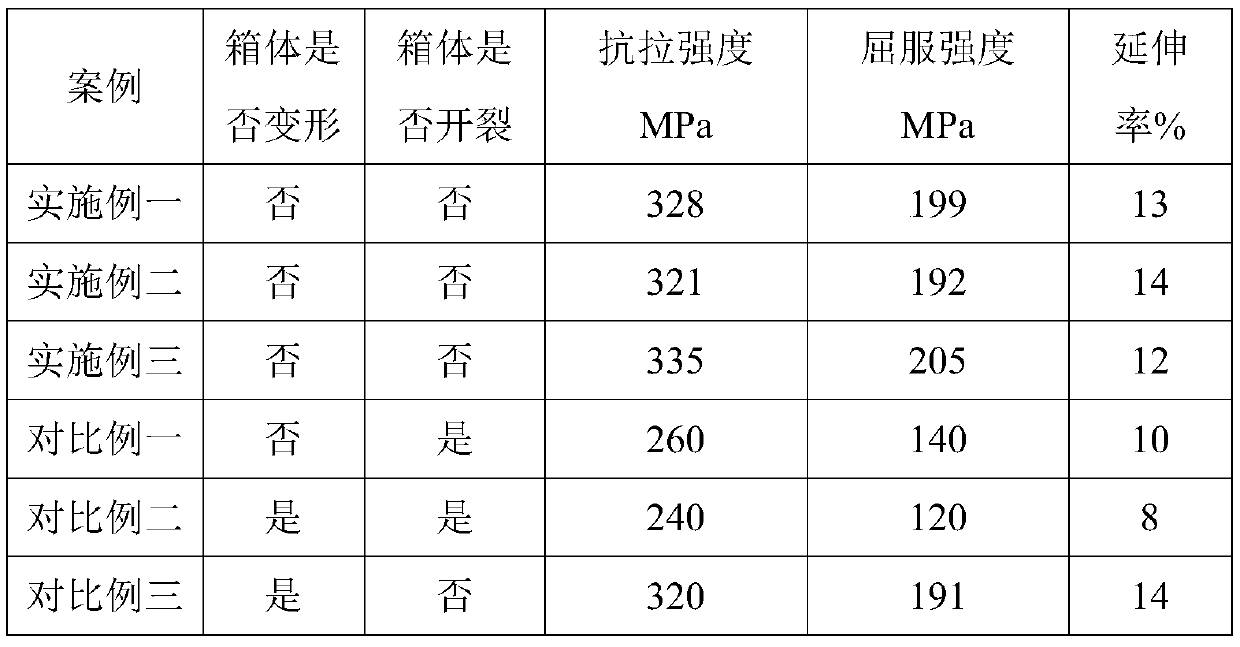

Examples

Embodiment 1

[0014] In this embodiment, the high-magnesium 5 series aluminum alloy contains the following ingredients in mass percentage: Si0.3%, Fe0.1%, Cu0.1%, Mn0.05%, Mg6.0%, Zn0.1%, single impurity 0.03 %, the total amount of impurities is 0.12%, and the balance is Al; the composite material is carried out according to the following steps in the present embodiment:

[0015] A high-magnesium 5-series aluminum alloy box die forging method specifically includes the following steps:

[0016] 1) Prepare high-magnesium 5-series aluminum alloy ingots, prepare high-magnesium-content aluminum alloy raw materials according to the following weight fraction ratios, add the prepared high-magnesium aluminum alloy raw materials into a melting furnace to melt into an aluminum alloy solution, and The molten alloy is cast into an aluminum alloy ingot. The aluminum alloy melting process is assisted by ultrasound, the frequency of the ultrasound is 0.5MHz, and the power density is 0.32W / cm 2 .

[0017...

Embodiment 2

[0022] In this embodiment, the high-magnesium 5 series aluminum alloy contains the following ingredients in mass percentage: Si0.2%, Fe0.25%, Cu0.05%, Mn0.1%, Mg5.2%, Zn0.05%, single impurity 0.04% %, the total amount of impurities is 0.13%, and the balance is Al; the composite material is carried out according to the following steps in the present embodiment:

[0023] A high-magnesium 5-series aluminum alloy box die forging method specifically includes the following steps:

[0024] 1) Prepare high-magnesium 5-series aluminum alloy ingots, prepare high-magnesium-content aluminum alloy raw materials according to the following weight fraction ratios, add the prepared high-magnesium aluminum alloy raw materials into a melting furnace to melt into an aluminum alloy solution, and The molten alloy is cast into an aluminum alloy ingot. The aluminum alloy melting process is assisted by ultrasound, the frequency of the ultrasound is 0.75MHz, and the power density is 0.31W / cm 2 .

[...

Embodiment 3

[0030] In this embodiment, the high-magnesium 5 series aluminum alloy contains the following mass percentage ingredients: Si0.1%, Fe0.4%, Cu0.02%, Mn0.2%, Mg4.5%, Zn0.02%, single impurity 0.05% %, the total amount of impurities is 0.15%, and the balance is Al; the composite material is carried out according to the following steps in the present embodiment:

[0031] A high-magnesium 5-series aluminum alloy box die forging method specifically includes the following steps:

[0032] 1) Prepare high-magnesium 5-series aluminum alloy ingots, prepare high-magnesium-content aluminum alloy raw materials according to the following weight fraction ratios, add the prepared high-magnesium aluminum alloy raw materials into a melting furnace to melt into an aluminum alloy solution, and The molten alloy is cast into an aluminum alloy ingot. The aluminum alloy melting process is assisted by ultrasound, the frequency of the ultrasound is 1MHz, and the power density is 0.3W / cm 2 .

[0033] 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com