A preparing method of a polycrystalline sapphire transparent thin plate

A sapphire and transparent technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of difficult to prepare thin plates, low sintering density, and long production process, and achieve low cost and high sintering density , The effect of short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

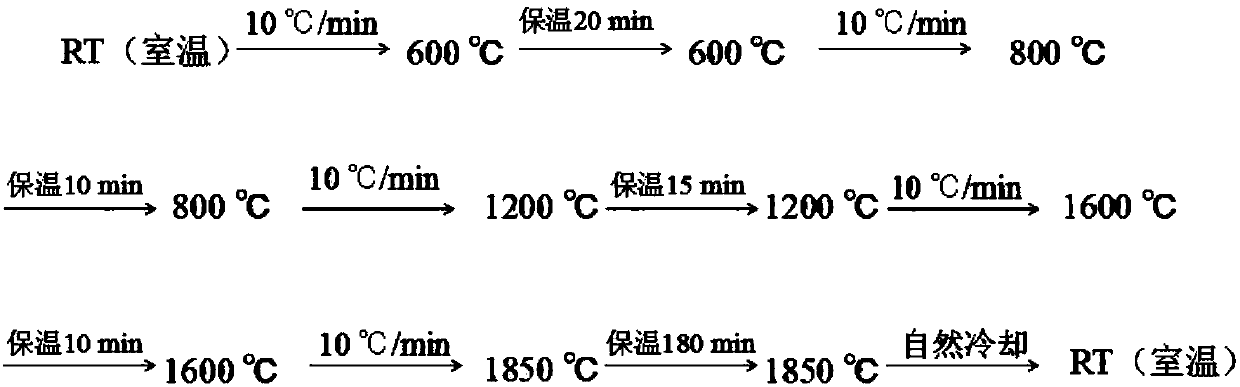

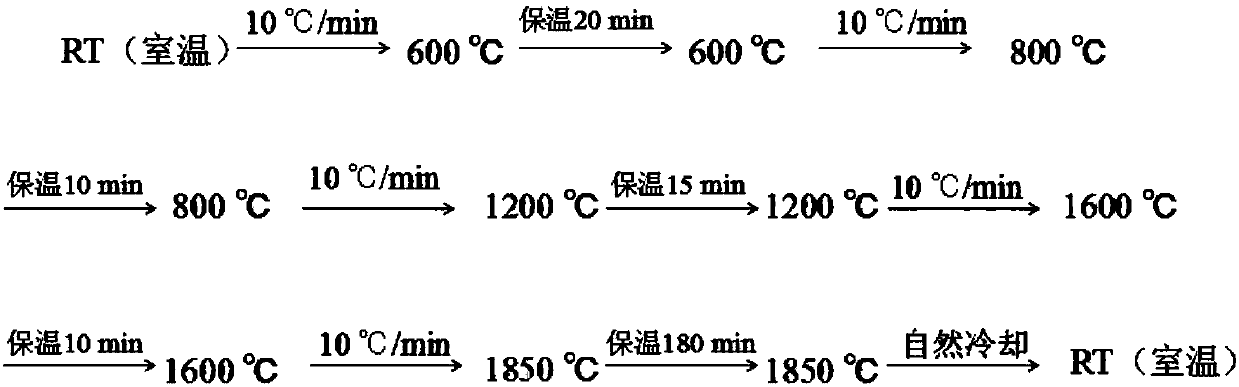

[0036] A preparation method for a polycrystalline sapphire transparent thin plate, comprising the steps of:

[0037] In the first step, clean alumina grinding balls are loaded into the nano sand mill, and the ratio of grinding balls to alumina powder is 5:1;

[0038] The second step is to weigh deionized water, dispersant, defoamer, and sintering aid in the nano sand mill according to the formula, weigh alumina powder according to the formula, and start the nano sand mill;

[0039] The third step is to add binder and plasticizer after 2 hours, continue grinding for 2 hours, and stop the nano grinder;

[0040] The fourth step is to transfer the ground slurry to a vacuum stirring and defoaming machine, vacuum defoaming for 0.5-1h, take a sample to test the viscosity, and stop defoaming when the viscosity reaches 2000-3000mPa·S;

[0041] The fifth step is to cast using a casting machine. According to the requirements of the polycrystalline sapphire green sheet, the casting thick...

Embodiment 1

[0054] Prepare polycrystalline sapphire blanks according to the following formula: 50% alumina powder, 1% dispersant DISPERBYK190, 2% polyvinyl alcohol and styrene-acrylic emulsion, 1% plasticizer Amgard TBEP, 1% defoamer tego foamex 840, 42.8% deionized water, 0.2% sintering aid nano magnesium oxide dispersion.

[0055] Prepared by the following process method:

[0056] In the first step, clean alumina grinding balls are loaded into the nano sand mill, and the ratio of grinding balls to alumina powder is 5:1;

[0057] The second step is to weigh deionized water, dispersant, defoamer, and sintering aid in the nano sand mill according to the formula, weigh alumina powder according to the formula, and start the nano sand mill;

[0058] The third step is to add binder and plasticizer after 2 hours, continue to grind for 2 hours and stop the machine;

[0059] The fourth step is to transfer the ground slurry to a vacuum stirring and defoaming machine, vacuum defoaming for 0.5-1h,...

Embodiment 2

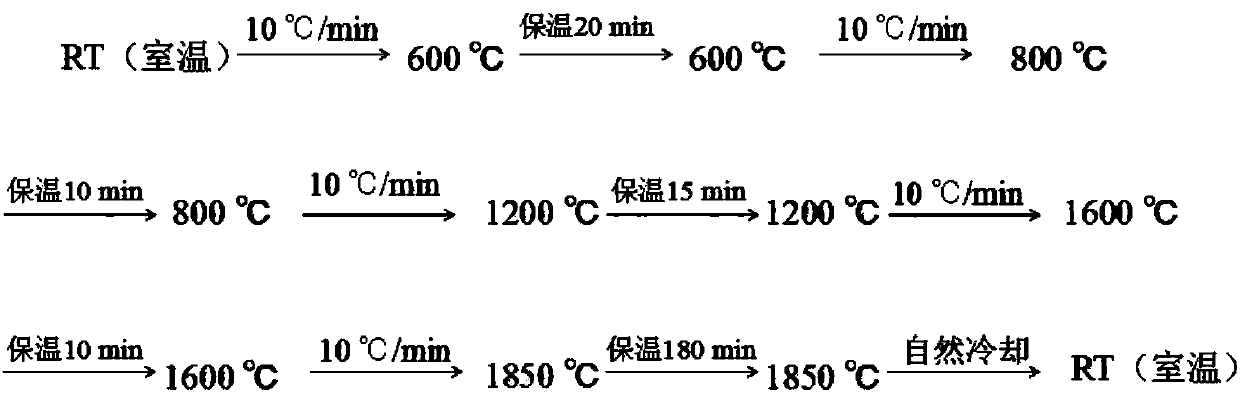

[0068] Prepare polycrystalline sapphire blanks according to the following formula: add 55% alumina powder, add 2% dispersant DISPERBYK190, add polyvinyl alcohol 2%, styrene-acrylic emulsion 1%, water-based acrylic resin 1%, plasticizer Amgard TBEP1.5 %, add 1% of defoamer tego foamex 840, add 36% of deionized water, add 0.5% of nano-magnesium oxide dispersion sintering aid.

[0069] Prepared by the following process method:

[0070] In the first step, clean alumina grinding balls are loaded into the nano sand mill, and the ratio of grinding balls to alumina powder is 5:1;

[0071] The second step is to weigh deionized water, dispersant, defoamer, and sintering aid in the nano sand mill according to the formula, weigh alumina powder according to the formula, and start the nano sand mill;

[0072] The third step is to add binder and plasticizer after 2 hours, continue to grind for 2 hours and stop the machine;

[0073] The fourth step is to transfer the ground slurry to a vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com