Preparation method of ultralow-loss NbTi superconducting wire

A superconducting wire, ultra-low technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of increasing the hardness of the wire, increasing the resistivity of the matrix, and breaking the thin stretched wire, etc. problems, achieve excellent processing performance, solve the effect of high loss and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

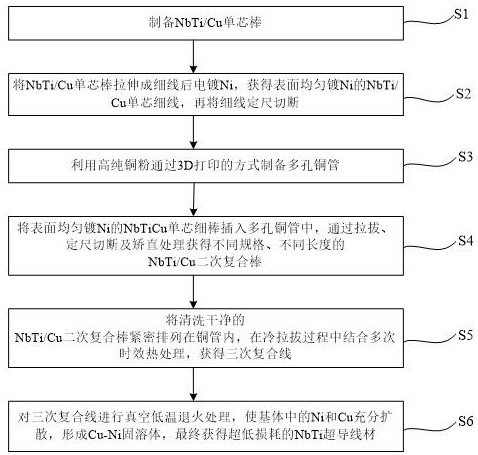

[0050] The present embodiment provides a method for preparing an ultra-low loss NbTi superconducting wire, which is specifically implemented according to the following steps:

[0051] Step 1. Heat the mold with an outer diameter of Φ101mm to 150°C, keep the temperature for 1 hour, then place a NbTi rod with a diameter of Φ78mm in the center of the mold, and then pour the molten copper water into the mold, the casting temperature is 1150°C, and the casting speed is is 250mm / min, and the mold cooling water flow is 1m 3 / h, and finally obtain NbTi / Cu single core rod by demoulding;

[0052] Step 2. Use a roller die to draw a single mandrel with a diameter of Φ100mm to Φ70mm, and the processing rate per pass does not exceed 5%, then use a conventional peeling die and a drawing die to draw to Φ0.985mm, and the thickness of electroplated Ni is 5μm. Cut the Ni-plated single-core thin wire with a diameter of Φ1.0mm to a fixed length of 2000mm;

[0053] Step 3. Insert the single-core ...

Embodiment 2

[0058] The present embodiment provides another method for preparing an ultra-low loss NbTi superconducting wire, which is specifically implemented according to the following steps:

[0059] Step 1. Heat the mold with an outer diameter of Φ76mm to 100°C, keep the temperature for 1 hour, then place a NbTi rod with a diameter of Φ58mm in the center of the mold, and then pour the molten copper water into the mold, the casting temperature is 1150°C, and the casting speed is is 150mm / min, and the mold cooling water flow is 0.5m 3 / h, and finally obtain NbTi / Cu single core rod by demoulding;

[0060] Step 2. The diameter Φ75mm single-core rod is drawn to Φ1.990mm by conventional peeling die and drawing die, the thickness of Ni-plated Ni is 10μm, and finally the Ni-plated single-core thin wire with diameter Φ2.0mm is cut to a fixed length to a length of 2000mm;

[0061] Step 3. Insert the single-core thin wire neatly into the porous copper tube, the outer diameter of the copper tube ...

Embodiment 3

[0066] The present embodiment provides a method for preparing an ultra-low loss NbTi superconducting wire, which is specifically implemented according to the following steps:

[0067] Step 1. Heat the mold with an outer diameter of Φ101mm to 150°C, keep the temperature for 1 hour, then place a NbTi rod with a diameter of Φ78mm in the center of the mold, and then pour the molten copper water into the mold, the casting temperature is 1150°C, and the casting speed is is 250mm / min, and the mold cooling water flow is 1m 3 / h, and finally obtain NbTi / Cu single core rod by demoulding;

[0068] Step 2. Use a roller die to draw a single mandrel with a diameter of Φ100mm to Φ70mm, and the processing rate per pass does not exceed 5%, then use a conventional peeling die and a drawing die to draw to Φ0.985mm, and the thickness of electroplated Ni is 5μm. Cut the Ni-plated single-core thin wire with a diameter of Φ1.0mm to a fixed length of 2000mm;

[0069] Step 3. Insert the single-core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com