Patents

Literature

89 results about "Collider" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A collider is a type of particle accelerator involving directed beams of particles. Colliders may either be ring accelerators or linear accelerators, and may collide a single beam of particles against a stationary target or two beams head-on.

Method of creating ultra-fine particles of materials using a high-pressure mill

Owner:CORNERSTONE TECH

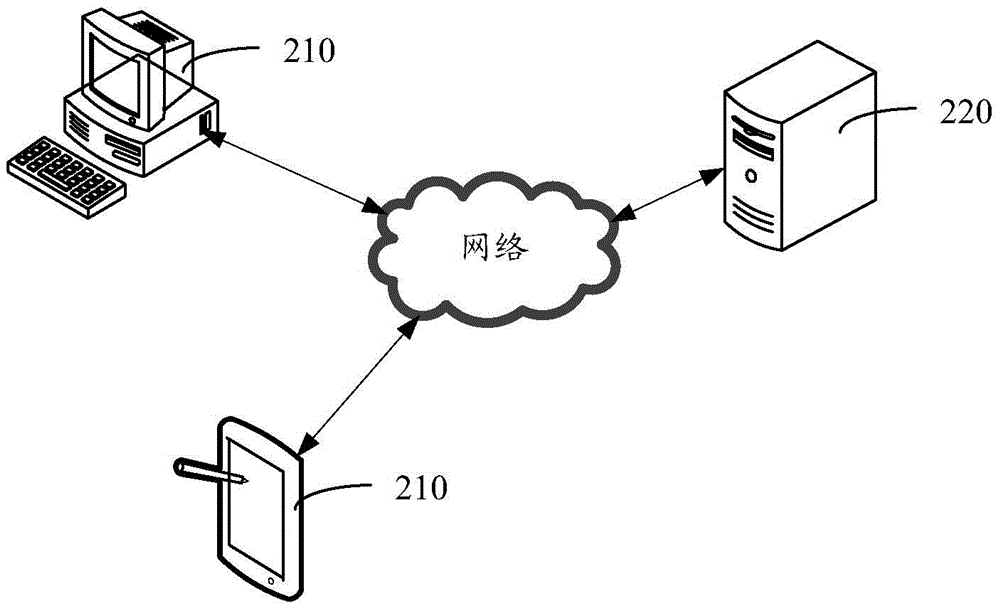

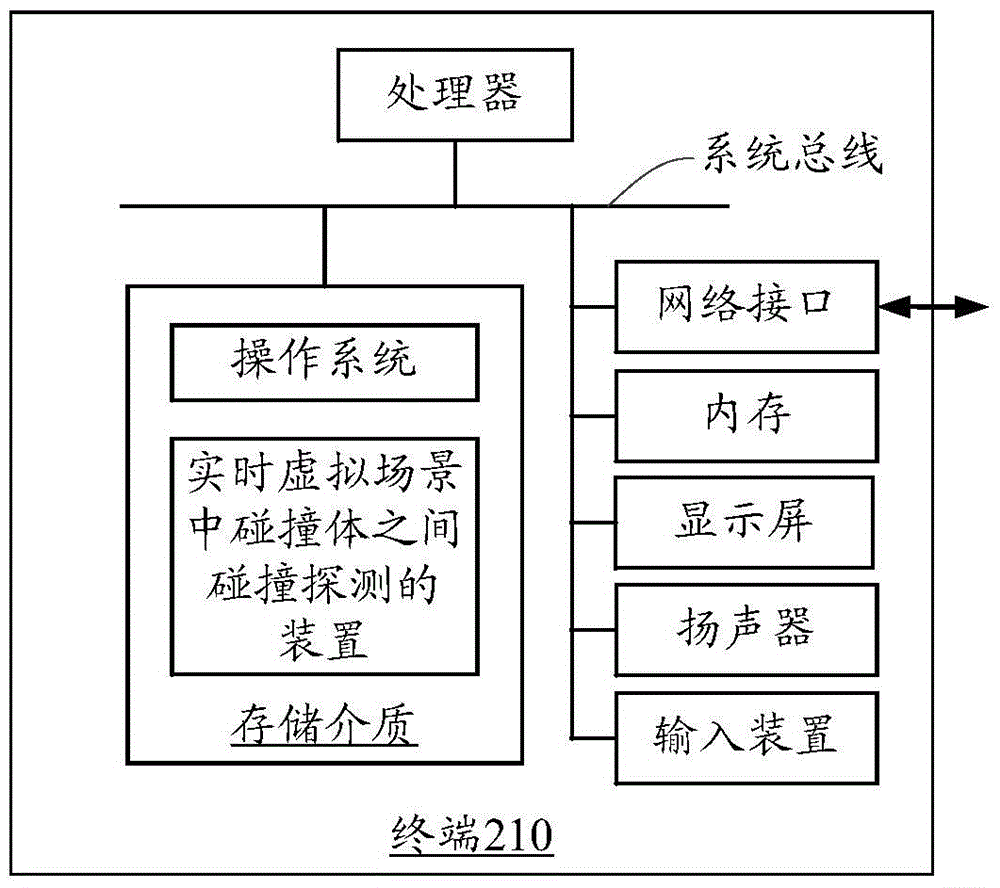

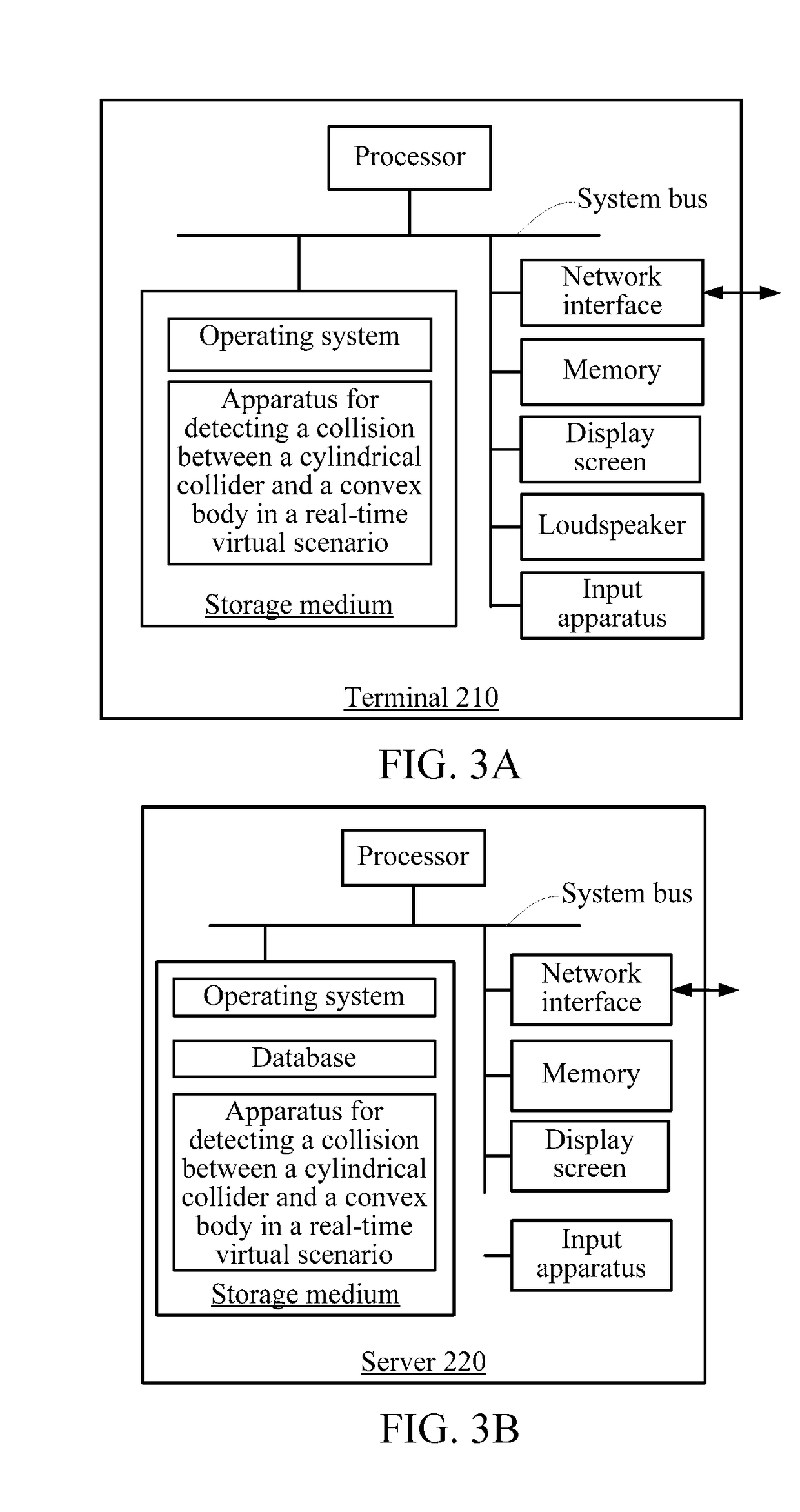

Method and device for detecting collision between colliders in real-time virtual scene

ActiveCN105488851ACollision implementationAvoid collisionImage analysisGeometric image transformationBinary space partitioningCollision detection

Owner:TENCENT TECH (SHENZHEN) CO LTD

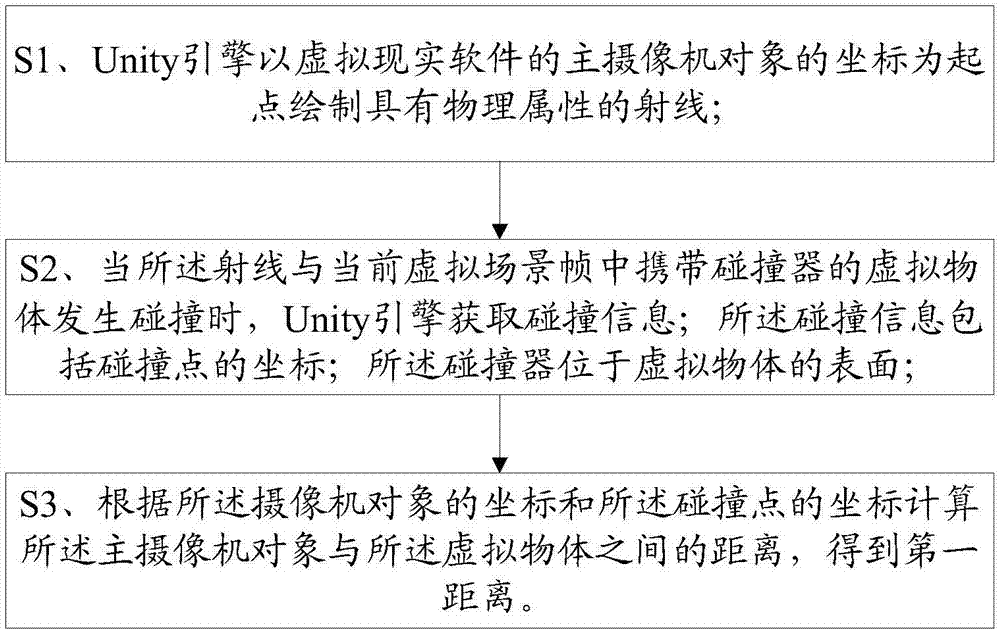

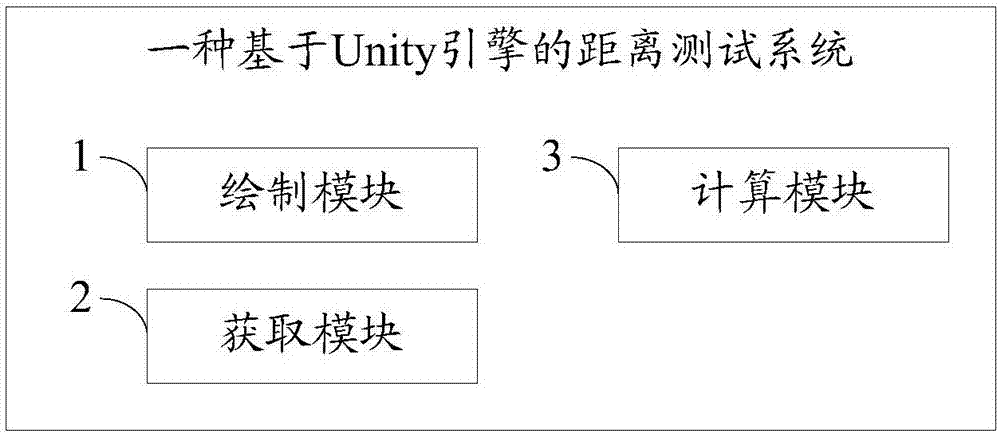

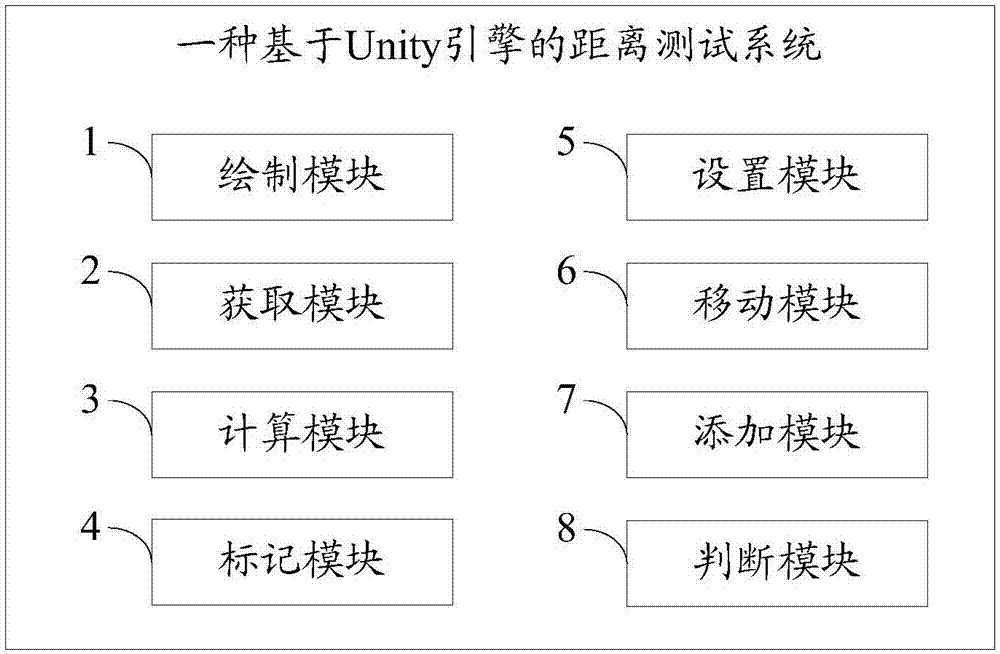

Unity engine-based distance test method and system

ActiveCN107392888AAccurately judge the interface layoutReasonable interface layoutImage enhancementImage analysisComputer visionVirtual reality

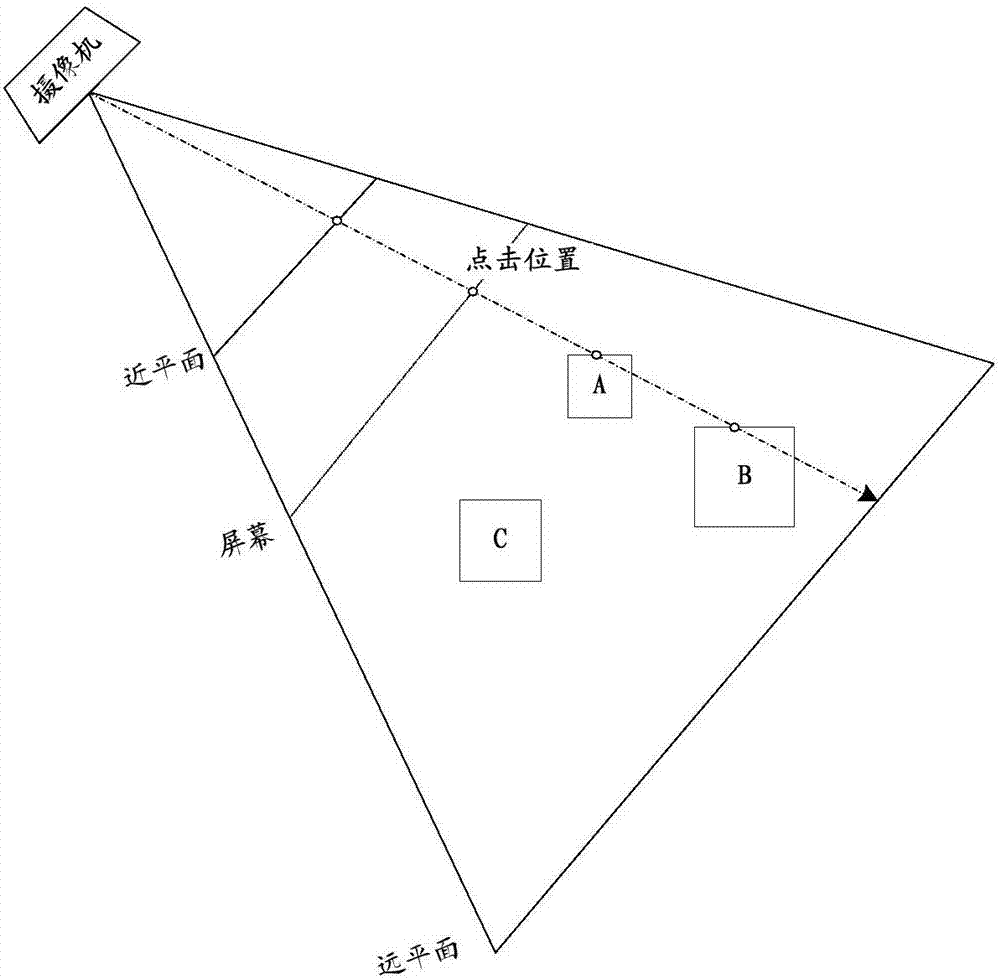

The invention relates to the field of tests, in particular to a Unity engine-based distance test method and system. A ray with a physical attribute is drawn by taking coordinates of a main camera object of virtual reality software as a starting point through a Unity engine; when the ray is collided with a virtual object carrying a collider in a current virtual scene frame, the Unity engine obtains collision information, wherein the collision information comprises coordinates of collision points, and the collider is located on the surface of the virtual object; and a distance between the main camera object and the virtual object is calculated according to the coordinates of the camera object and the coordinates of the collision points, so that a first distance is obtained. The accuracy of testing the distance between a main camera and the virtual object in a virtual scene is improved.

Owner:FUJIAN TQ DIGITAL

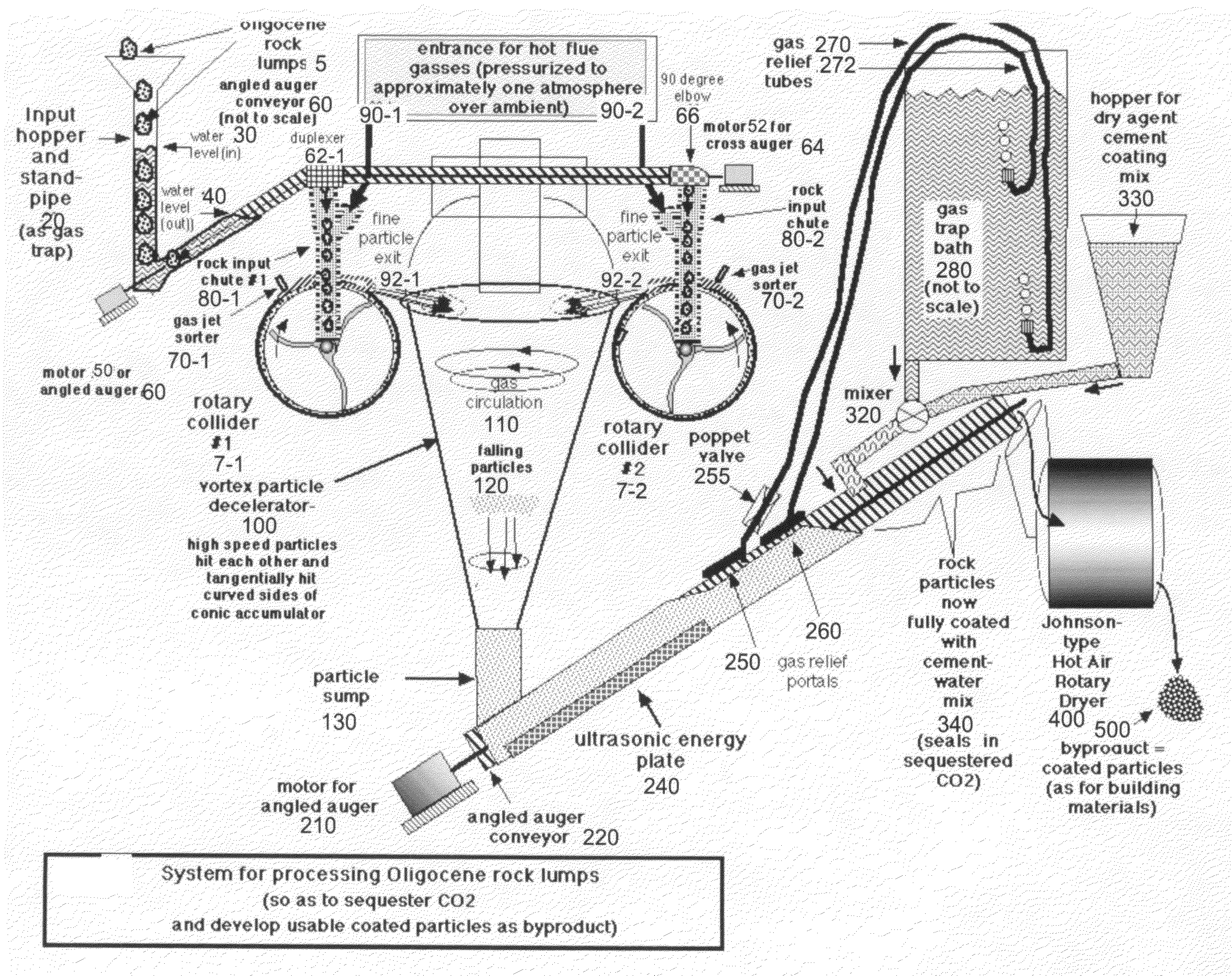

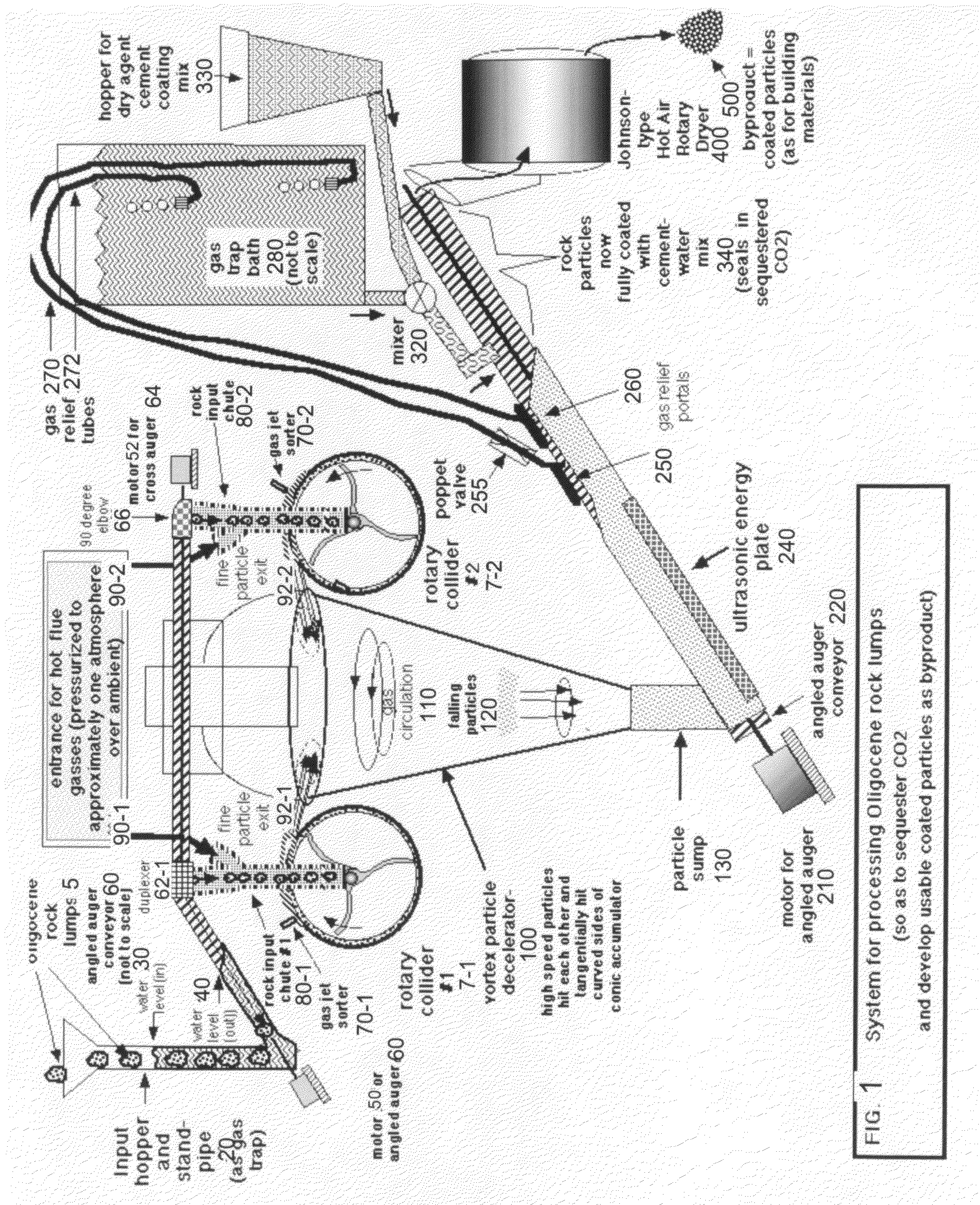

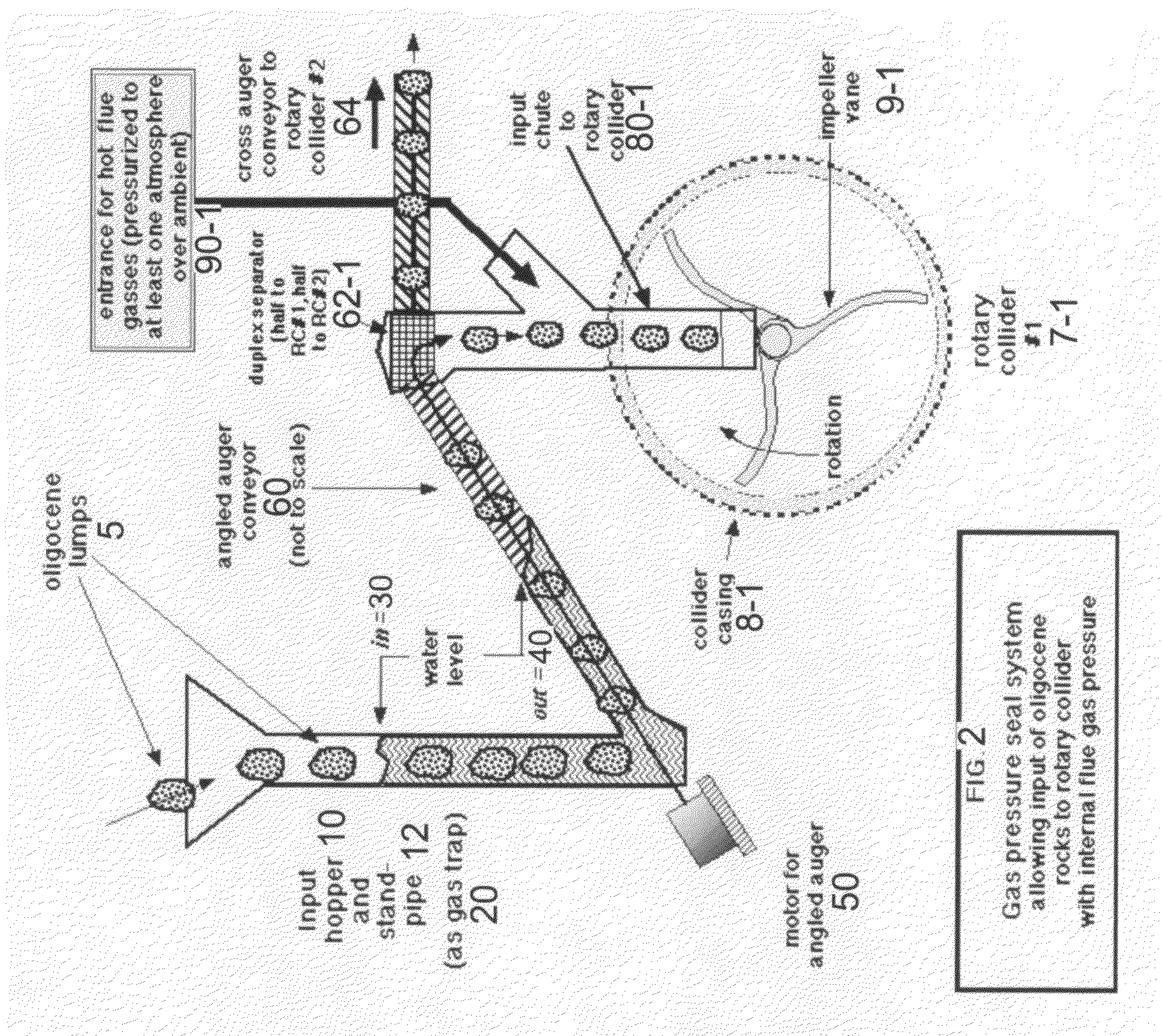

Coal burning methods & apparatus

InactiveUS20100141013A1Processing speedUnderground miningPaving detailsProcess engineeringCoal particle

Coal burning waste gases, notably carbon dioxide (CO2), can be removed or sequestered, and the distribution and utilization of coal as a safe, efficient, and convenient heat source can be improved.Carbon dioxide, a waste gas as from a coal burning process, can be sequestered within freshly fractured rock particles, such as Oligocene rock serpentine, using an adapted version of a rotary collider to fracture down hens-egg sized incoming rocks in a pressurized waste gas. The process sorts the small, fractured rocks and coats them after CO2 sequestration with a cementitious coating for use as a component of building material.In order to improve the transport and delivery of mined coal it is an advantage to fracture the coal and coat the particles with an aqueous liquid. The methods and apparatus deal with the improved delivery of said liquid-coated coal particles for current and new customers who become interested in using coal as an economical heating fuel.

Owner:LAHR ROY JEREMY

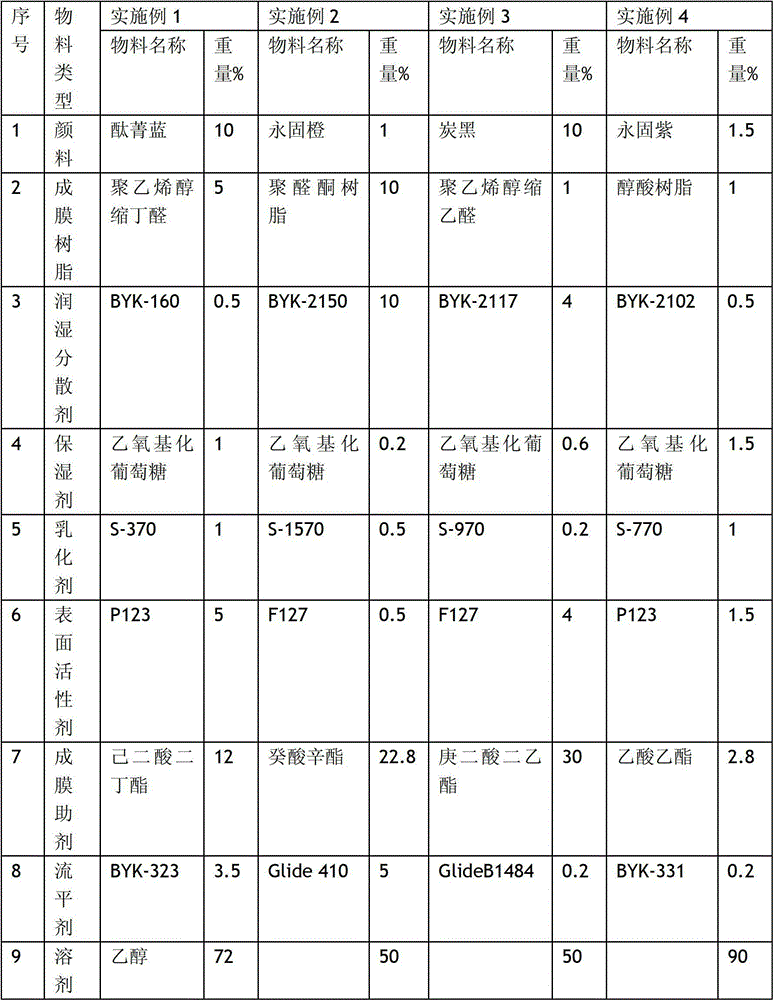

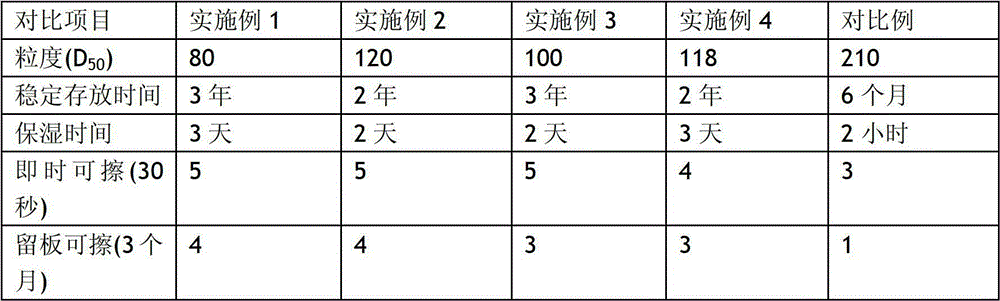

Erasable white board ink and manufacturing method thereof

ActiveCN102746742AExcellent long-term storage stabilityNo settlement occursInksWhiteboardEngineering

The invention provides erasable white board ink and a manufacturing method thereof. The ink comprises the following components in percent by weight: 1-10% of pigment, 1-10% of film forming resin, 0.5-10% of wetting dispersing agent, 0.2-5% of wet storage agent, 0.2-1% of emulsifying agent, 0.5-5% of surface active agent, 2-30% of film forming additive, 0.2-5% of flatting agent and 50-90% of solvent. The manufacturing method for the erasable white board ink comprises the following manufacturing steps of: firstly dispersing and mixing the pigment, the film forming resin, the storage agent, the emulsifying agent, the wetting dispersing agent and an appropriate solvent at high speed, and then treating the components by using a high voltage collider and a high speed sand mill to obtain color paste; and adding the surface active agent and the film forming additive to the color paste, and diluting the color paste by using the solvent to obtain the final ink. The ink provided by the invention has the advantages of good stability in long term storage process, quick-drying, real-time erasability, erasibility of the ink remained on a white board for long term, long moisture preserving time and fine particles.

Owner:SHANGHAI NNW NEW MATERIALS TECH

Method of producing nano-calcium carbonate

InactiveCN101172636ASimple processing methodImprove stabilityCalcium/strontium/barium carbonatesNanostructure manufactureCalcium hydroxideParticulates

The invention discloses a method for preparing nanometer calcium carbonate, comprising the steps as follows: the raw material quicklime or Calcium Hydroxide is added in water to prepare suspending liquid of 8 to 12 percent, and mixed fully; while mixing, mixed carbon dioxide / air gas containing 28 to 30 percent carbon dioxide is fed to perform carbonization reaction, wherein, the gas feeding rate is 3 to 10 liter per minute, and the absorptivity constant of the carbon dioxide is controlled to 0.7 to 2.5 per second, the temperature in the whole carbonization process is 28 to 40 DEG C, and the reaction is stopped until the PH value of the suspending liquid declines to between 6.8 to 7.2; the suspending liquid is filtered and injected into two X-shaped channels which are ready, the calcium carbonate particulate is adjusted to a nanometer collider in diameter of 20 to 80 nanometer for splitting, emulsifying, dispersing, and synthesizing the nanometer calcium carbonate solution. The invention has the advantages of simple technique and method, good product quality, good stability, convenient operation and low cost, is applicable for the middle-sized and small-sized enterprisers involving in the industries including rubber, paint, plastic, printing ink, medicine, food, and health care product, etc.

Owner:陈杰

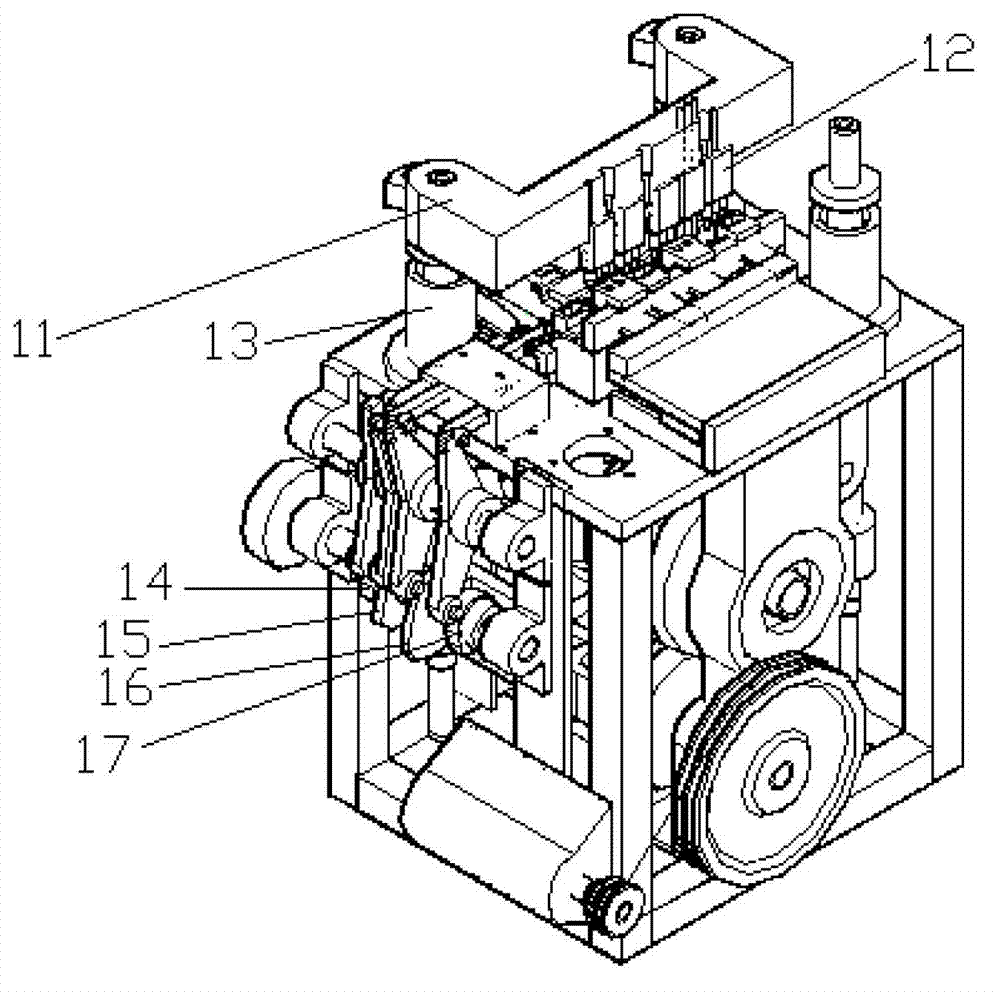

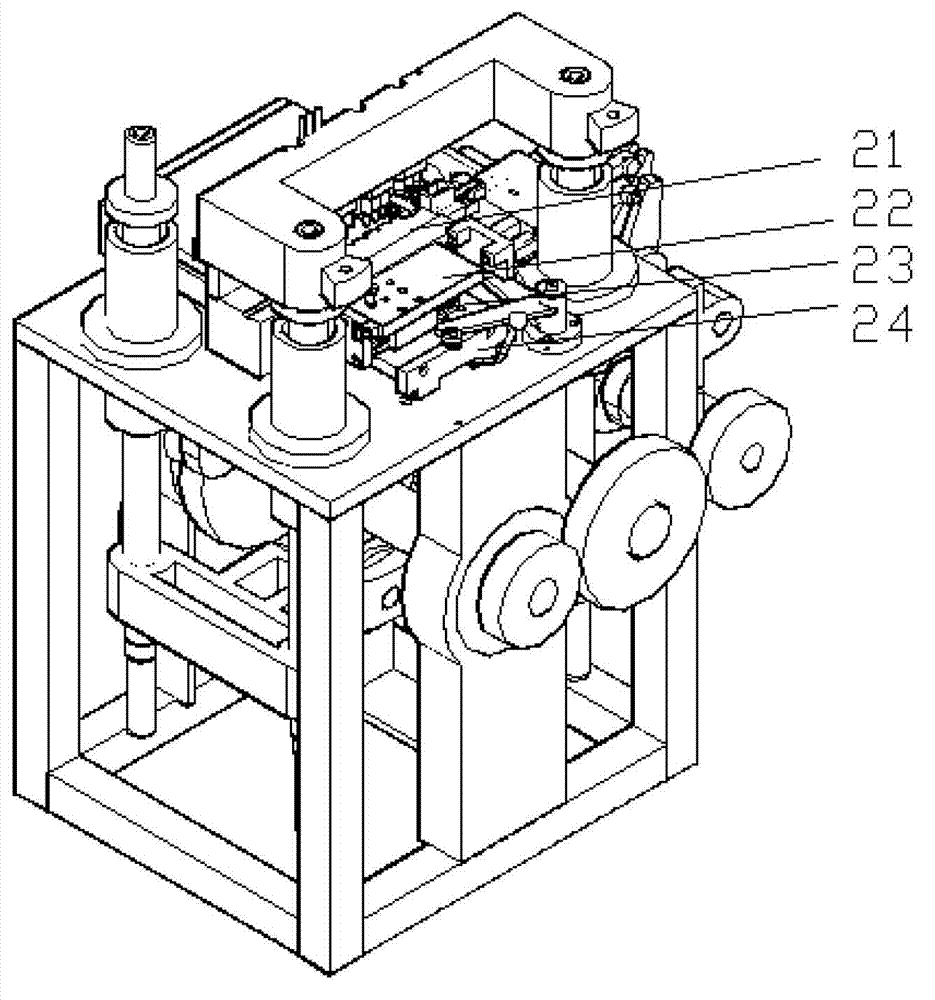

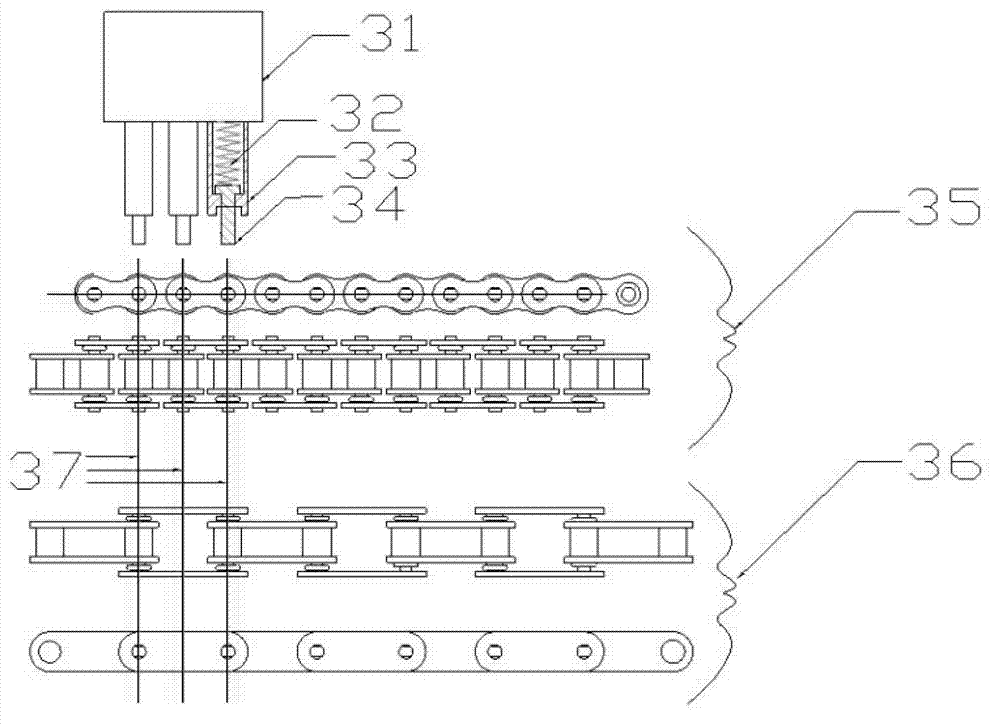

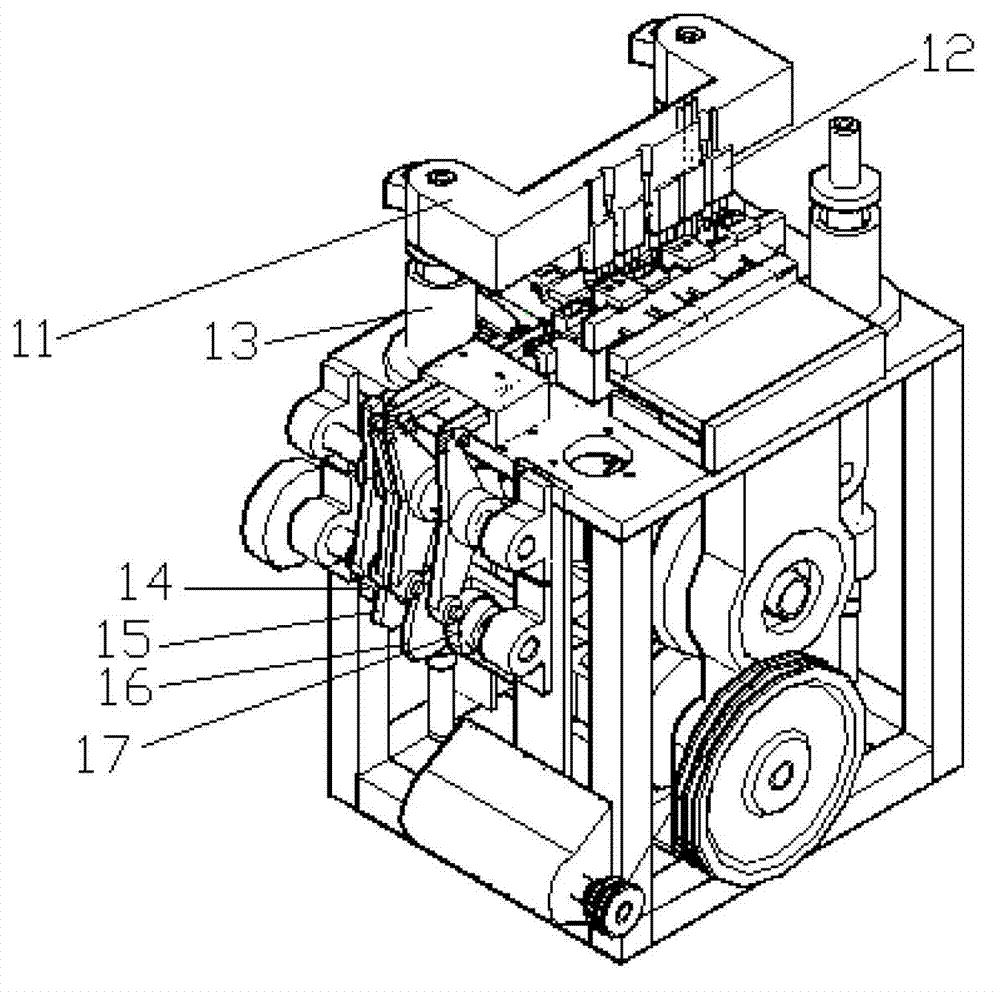

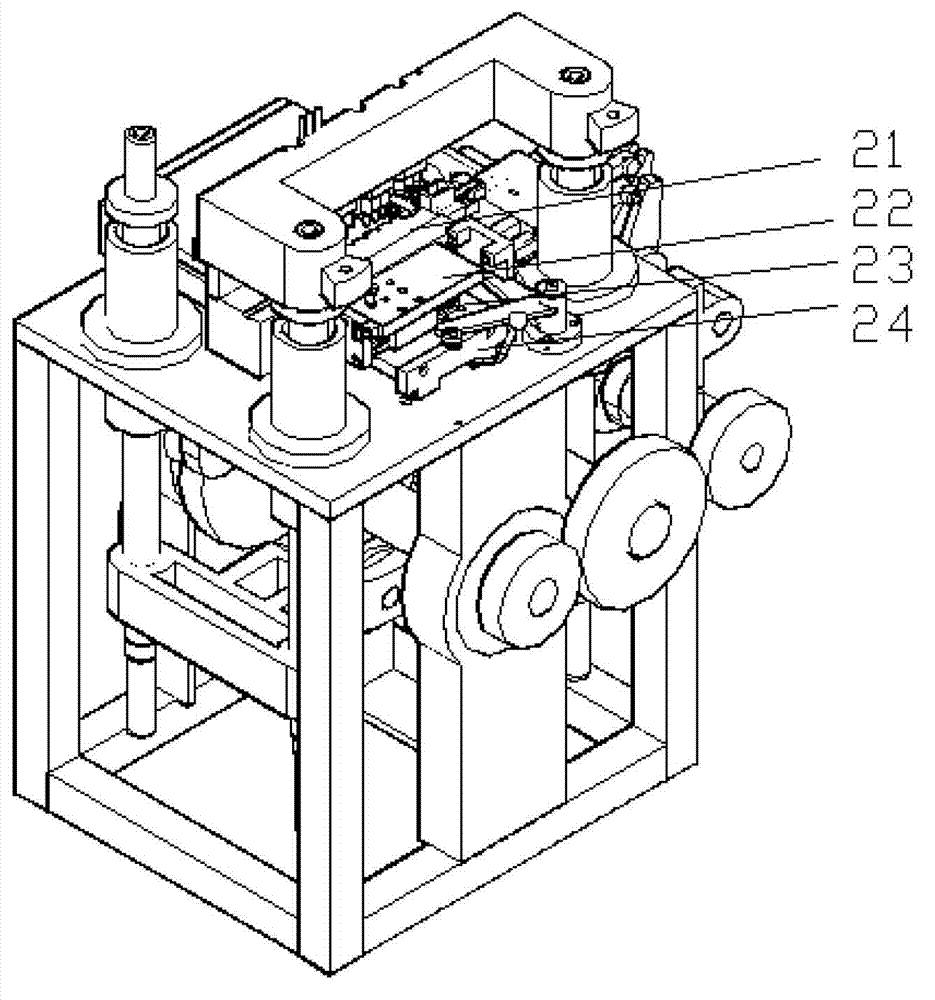

Chain press fitting method

The invention relates to a chain press fitting method and belongs to the technical field of a chain transmission part machining machine of a common part of a machine. The chain press fitting method comprises the following steps of: (1) providing a press fitting assembly; (2) assembling an inner lower chain plate and a sleeve; (3) covering a roller on a sleeve; (4) arranging an inner upper chain plate into the upper end of the sleeve; (5) assembling two pin shafts and an outer lower chain plate with one ends of two inner single sections; and (6) assembling an outer upper chain plate with the two pin shafts. When the assembling is started and a single-pitch chain needs to the assembled, any two adjacent colliders are mounted on pressing die collider seats of a single-double-pitch chain common type assembling machine; and only the colliders at the two sides are mounted on the pressing die collider seats when a double-pitch chain needs to be assembled. Preferably, five pressing die collider seats are arranged; and each pressing die collider seat corresponds to the press fitting step. According to the chain press fitting method disclosed by the invention, the single-pitch chain can be mounted on one assembling machine and the double-pitch chain can also be assembled.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

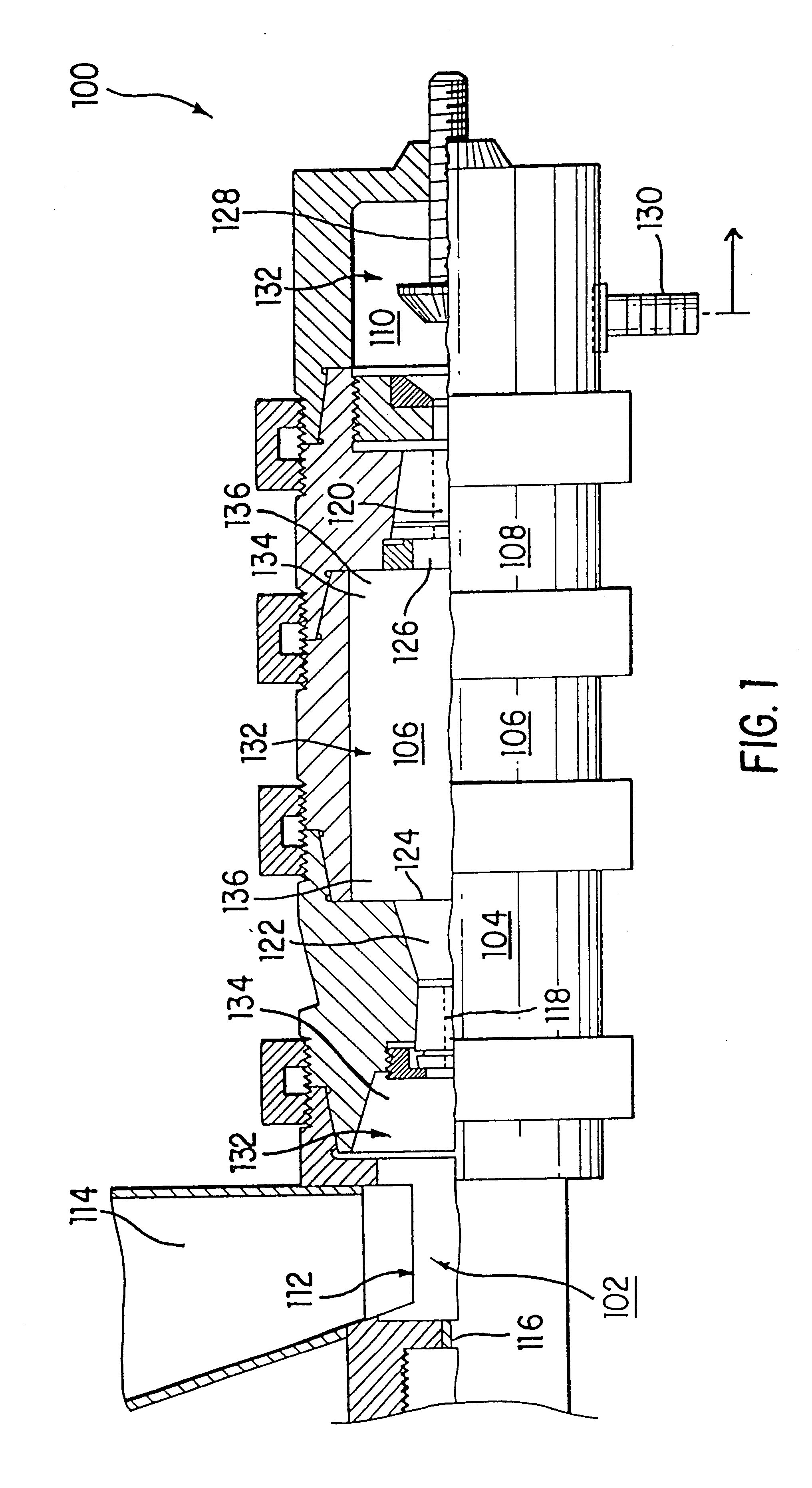

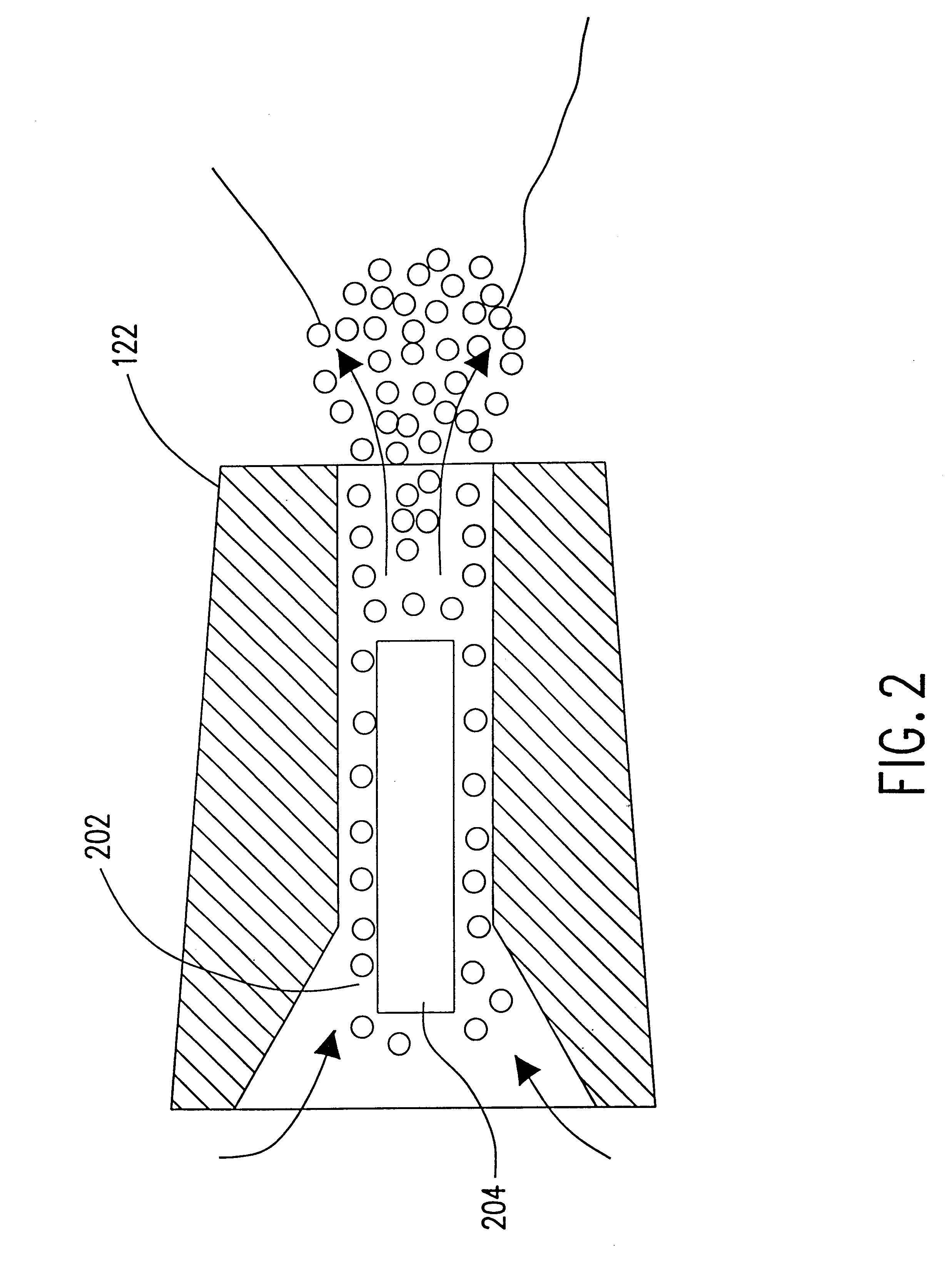

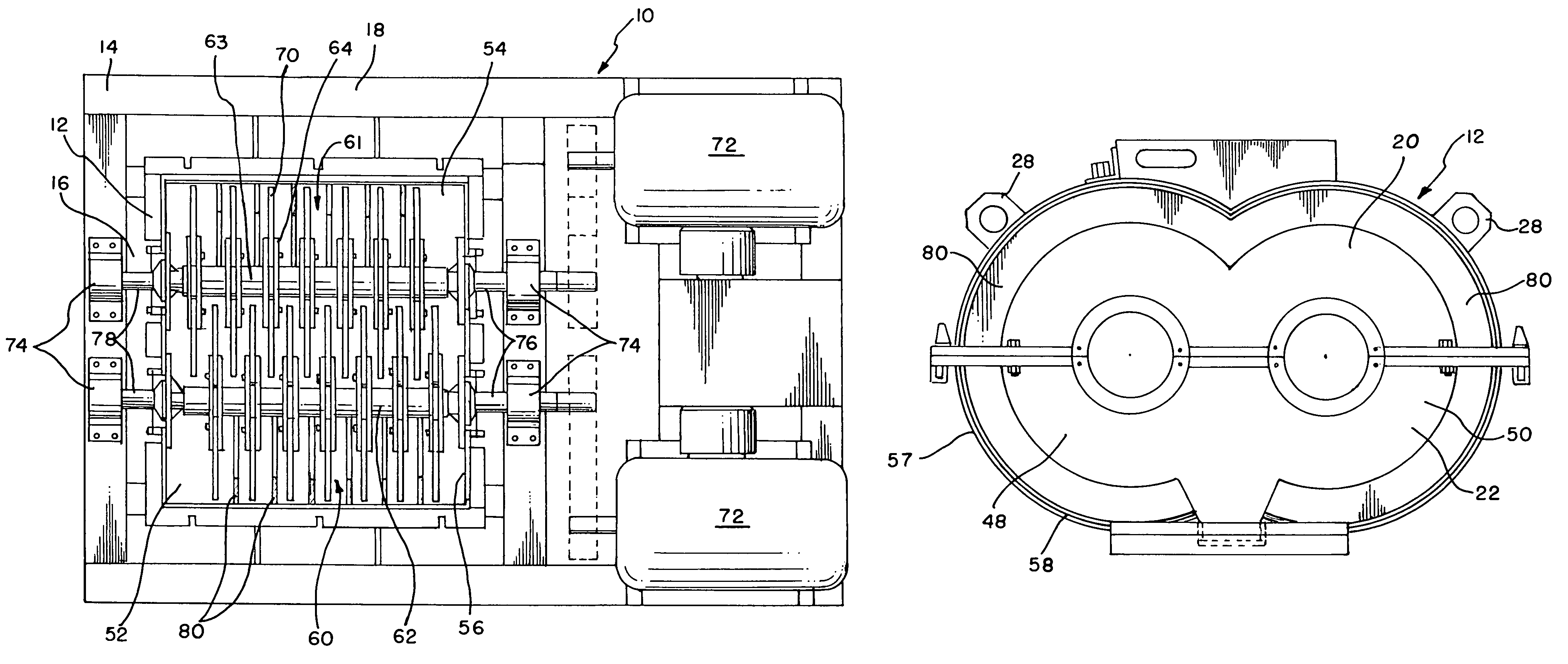

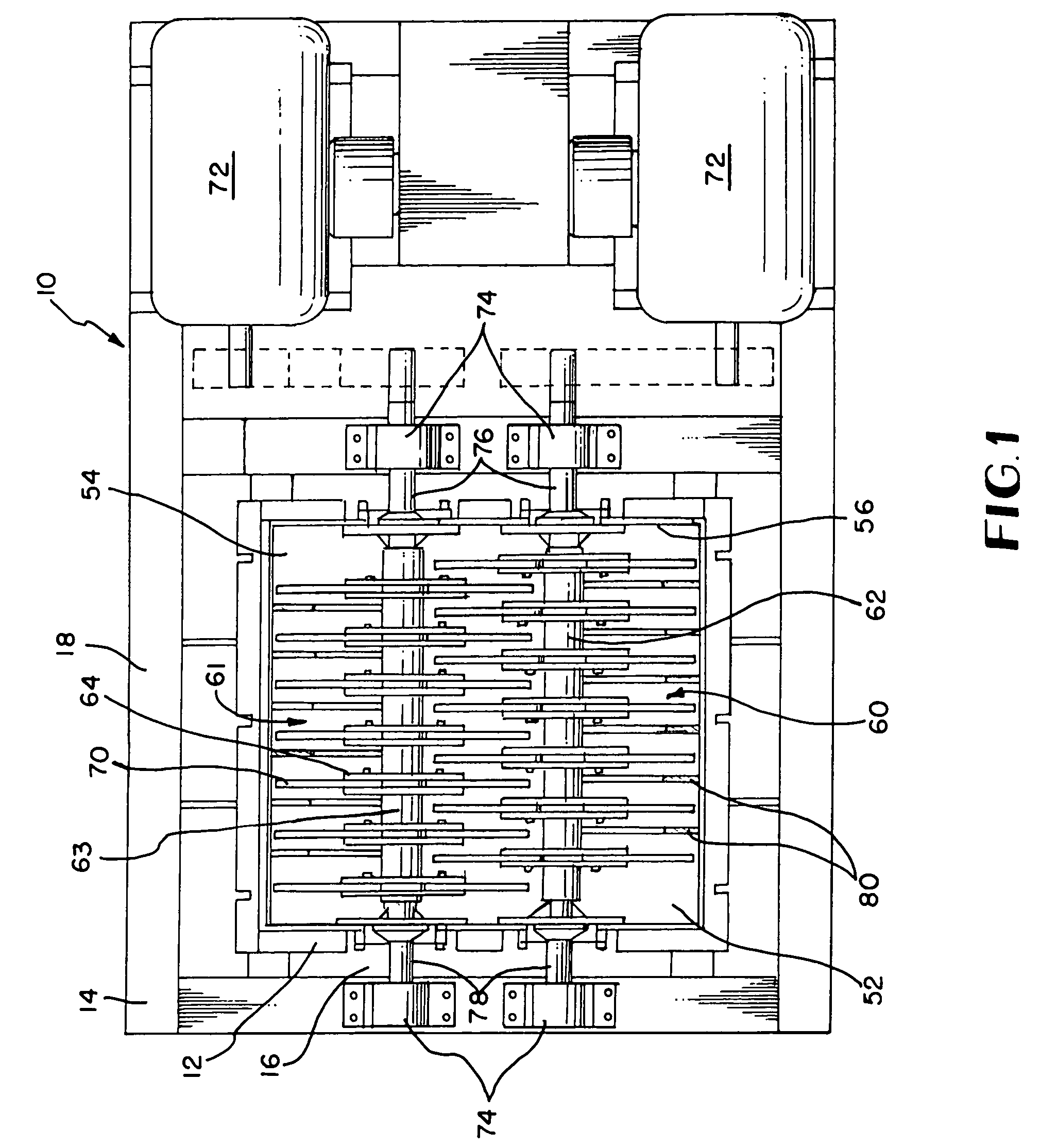

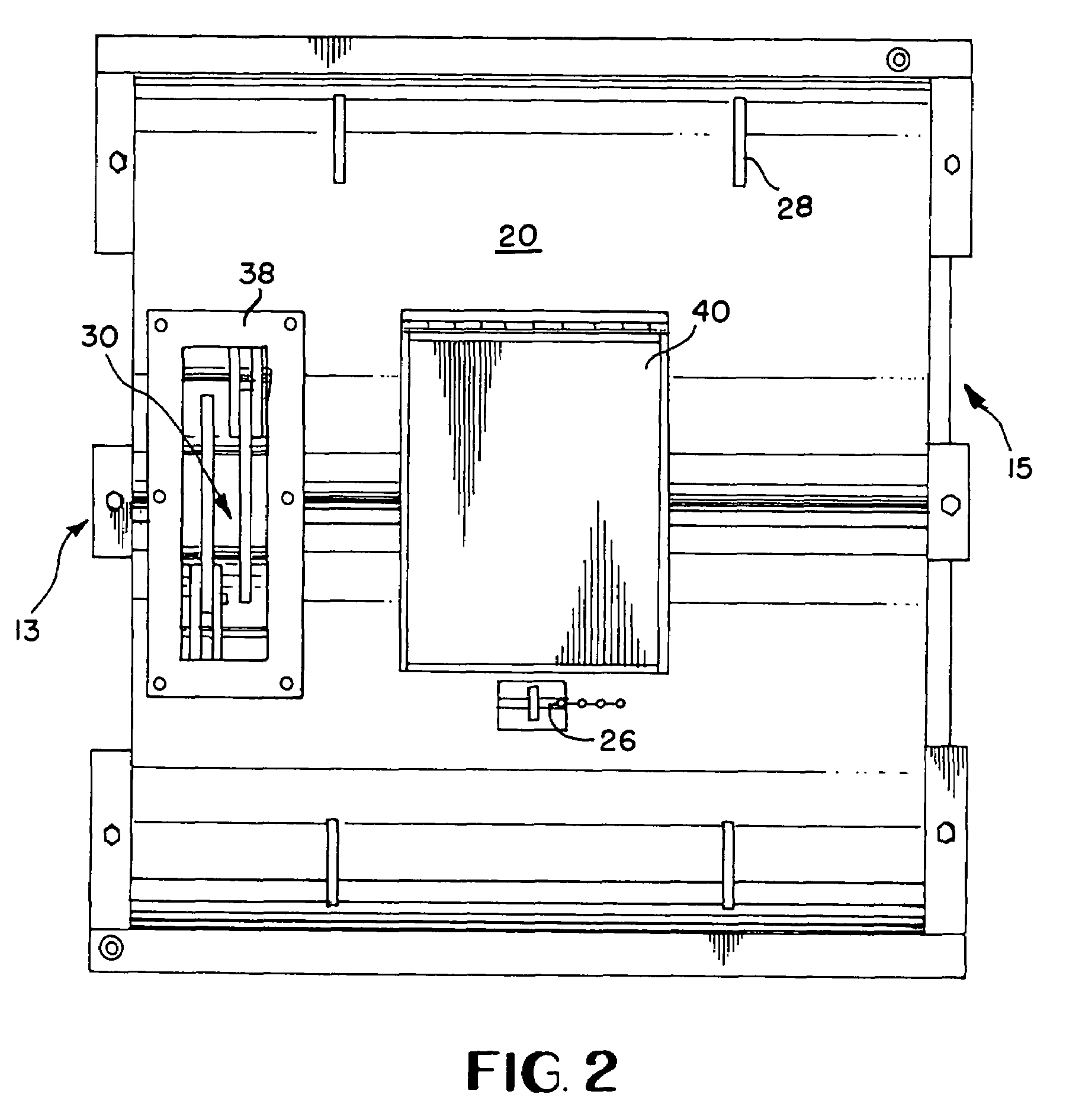

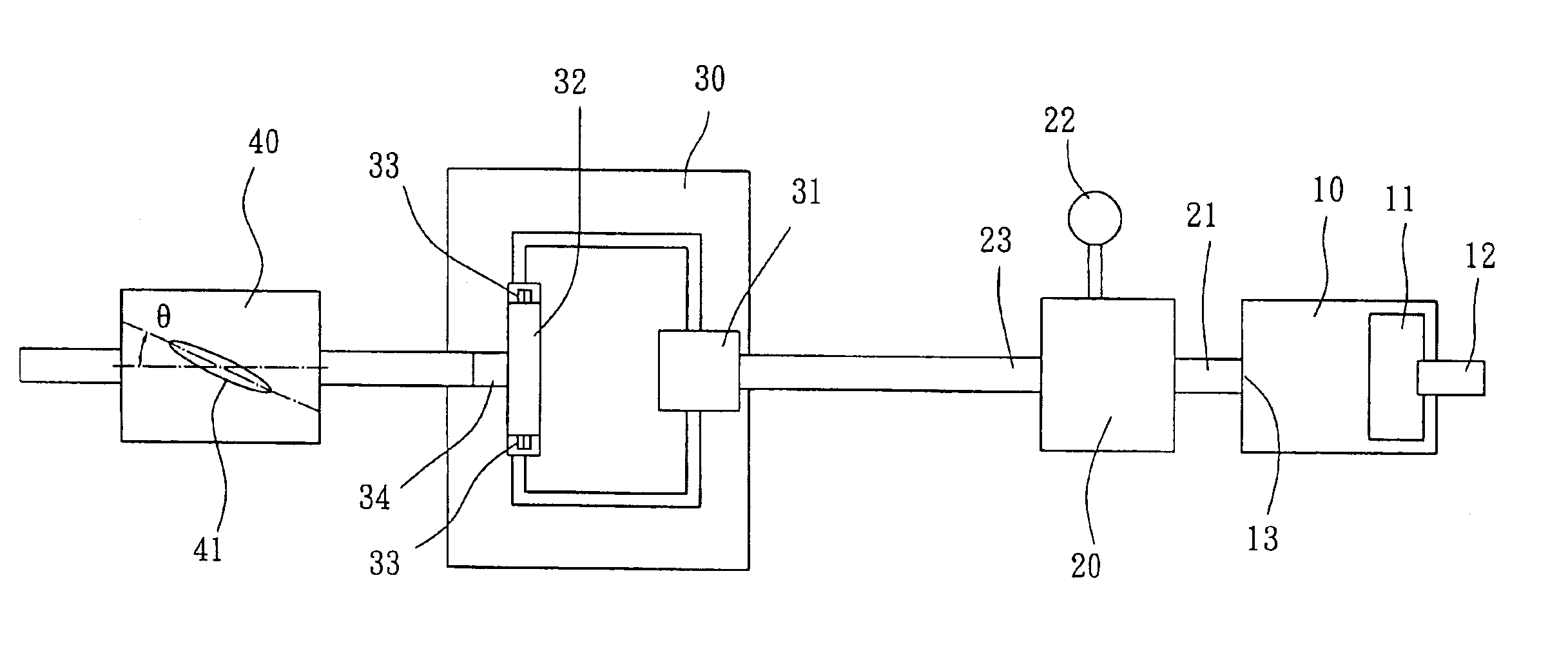

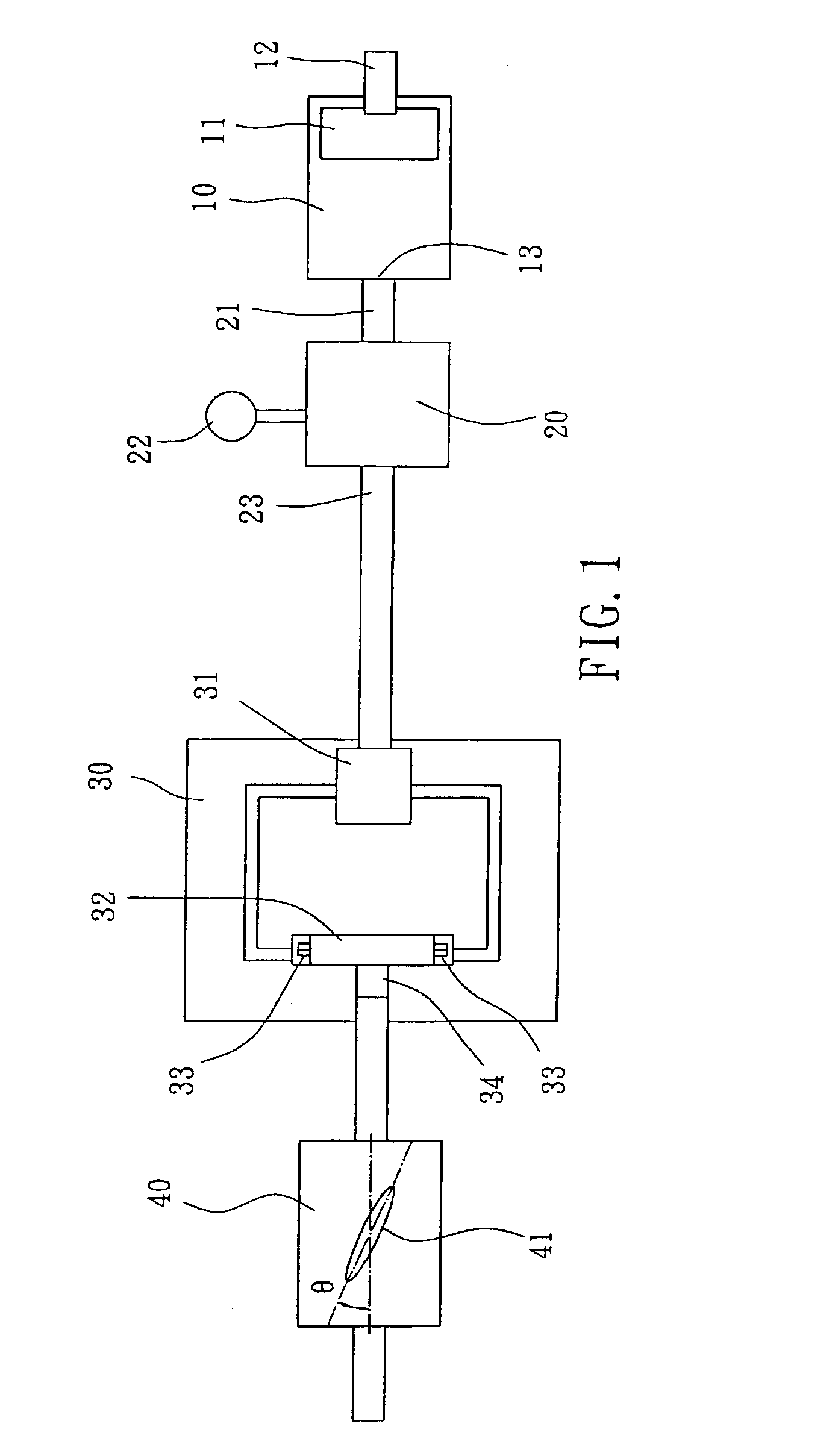

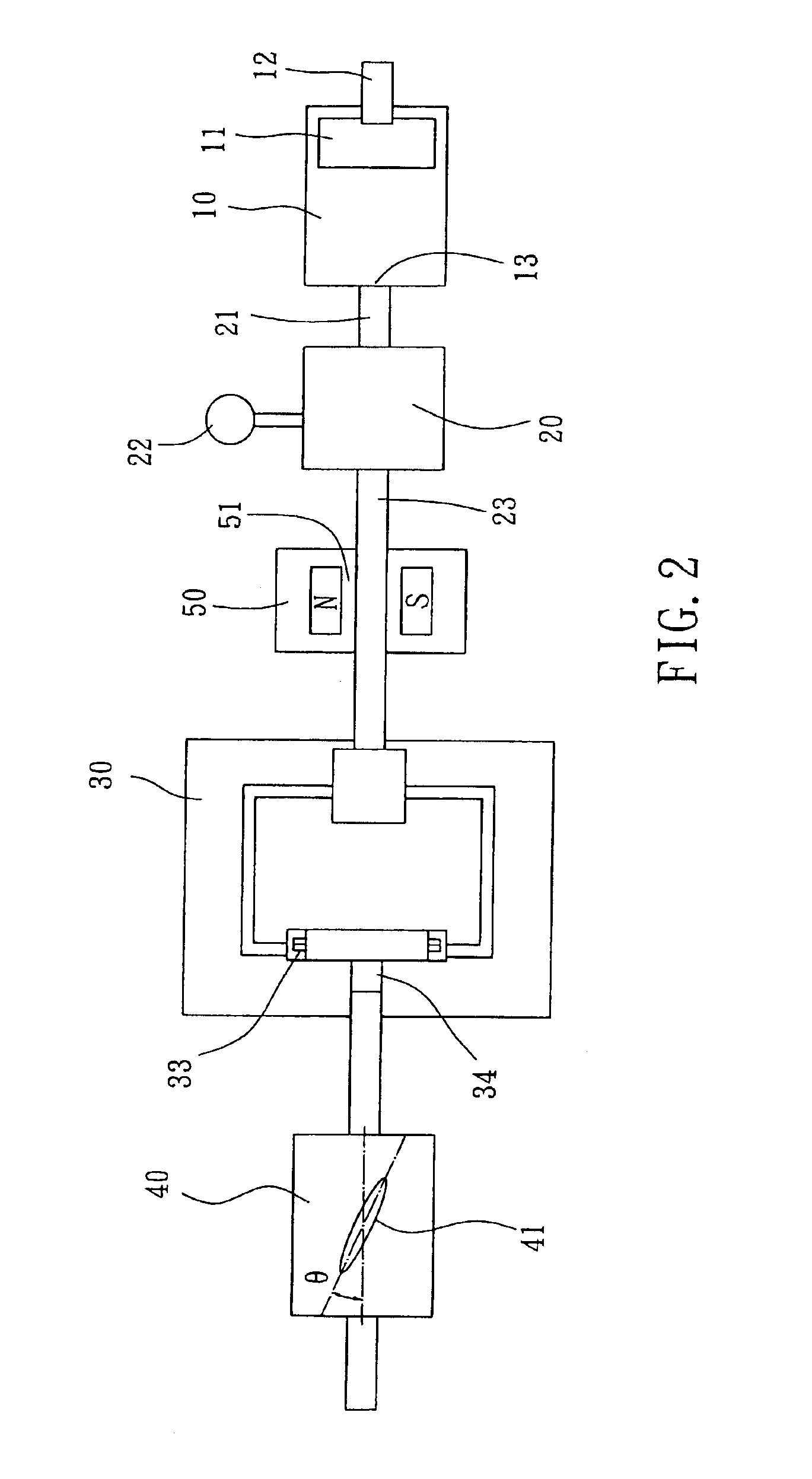

Collider

ActiveUS7055769B2Reduce rateExtended retention timeCocoaGrain treatmentsEngineeringMechanical engineering

A material collider having a pair of rotor assemblies respectively housed within a pair of interconnected cylindrical chambers with a plurality of disc members secured thereto, at least one thrust guide secured to the disc members and a weir secured to the inner periphery of the cylindrical chambers.

Owner:BISHOP DEBORAH PIERCE

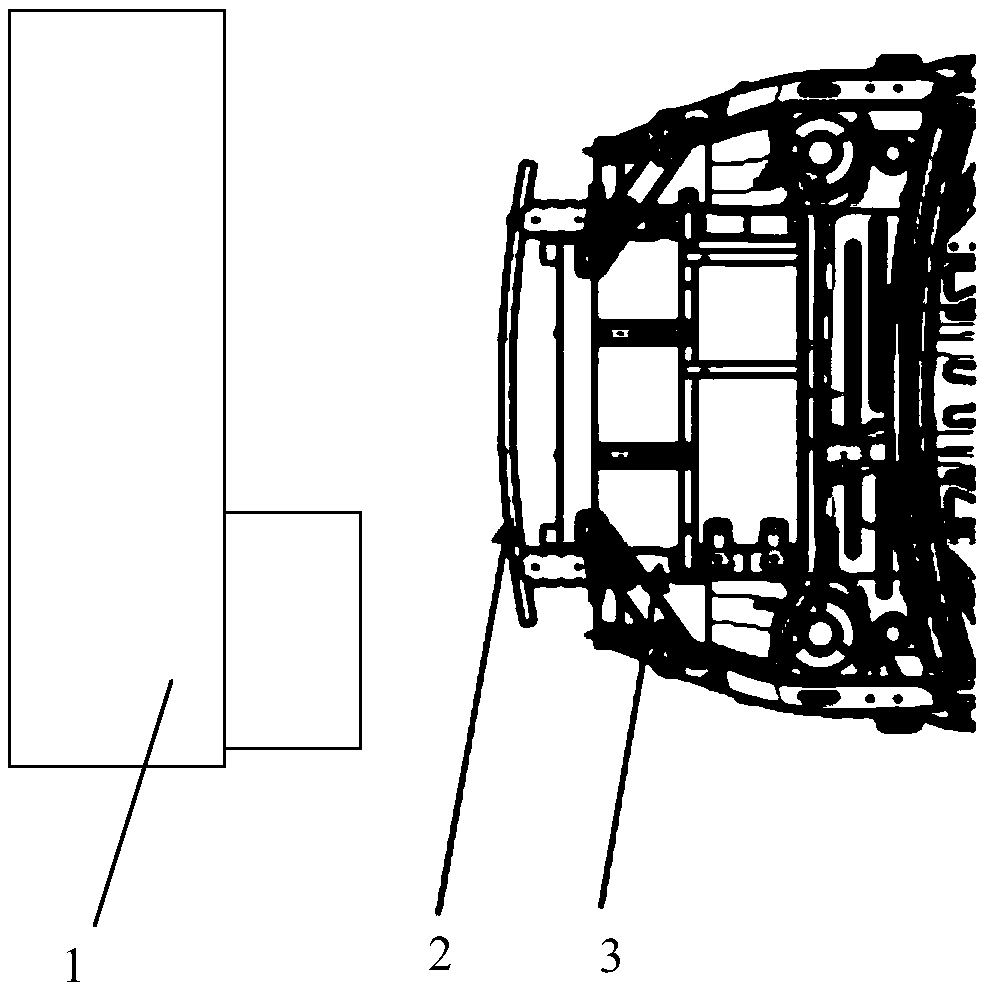

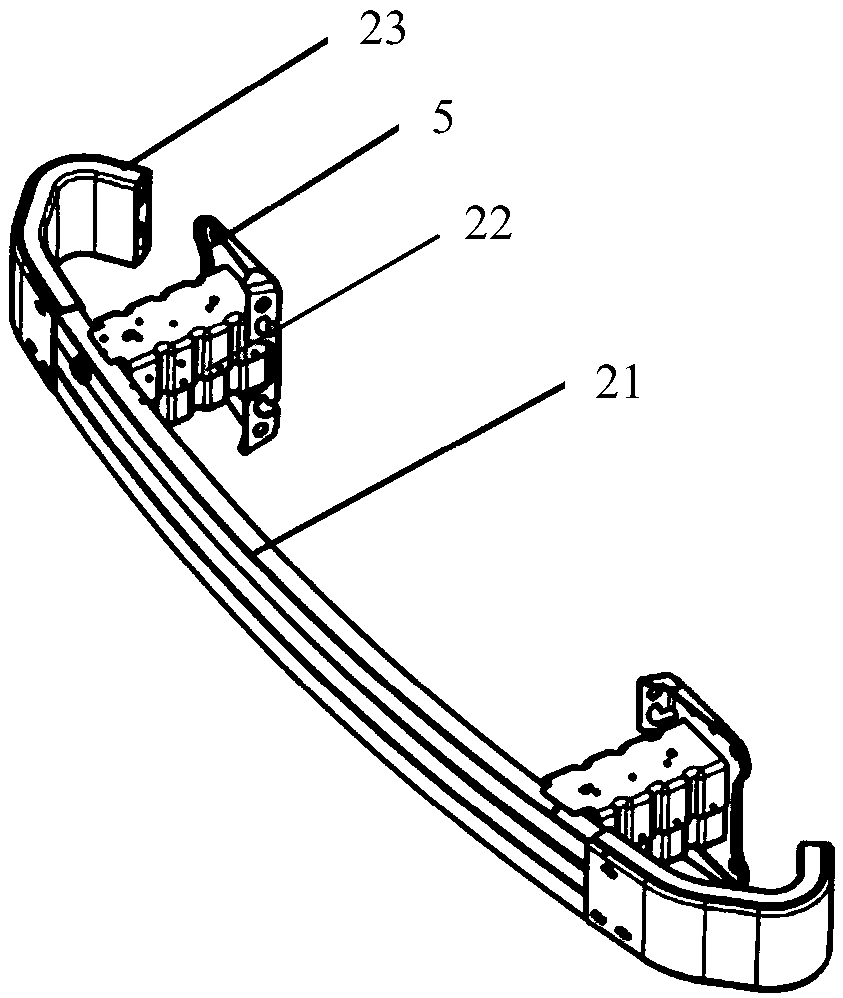

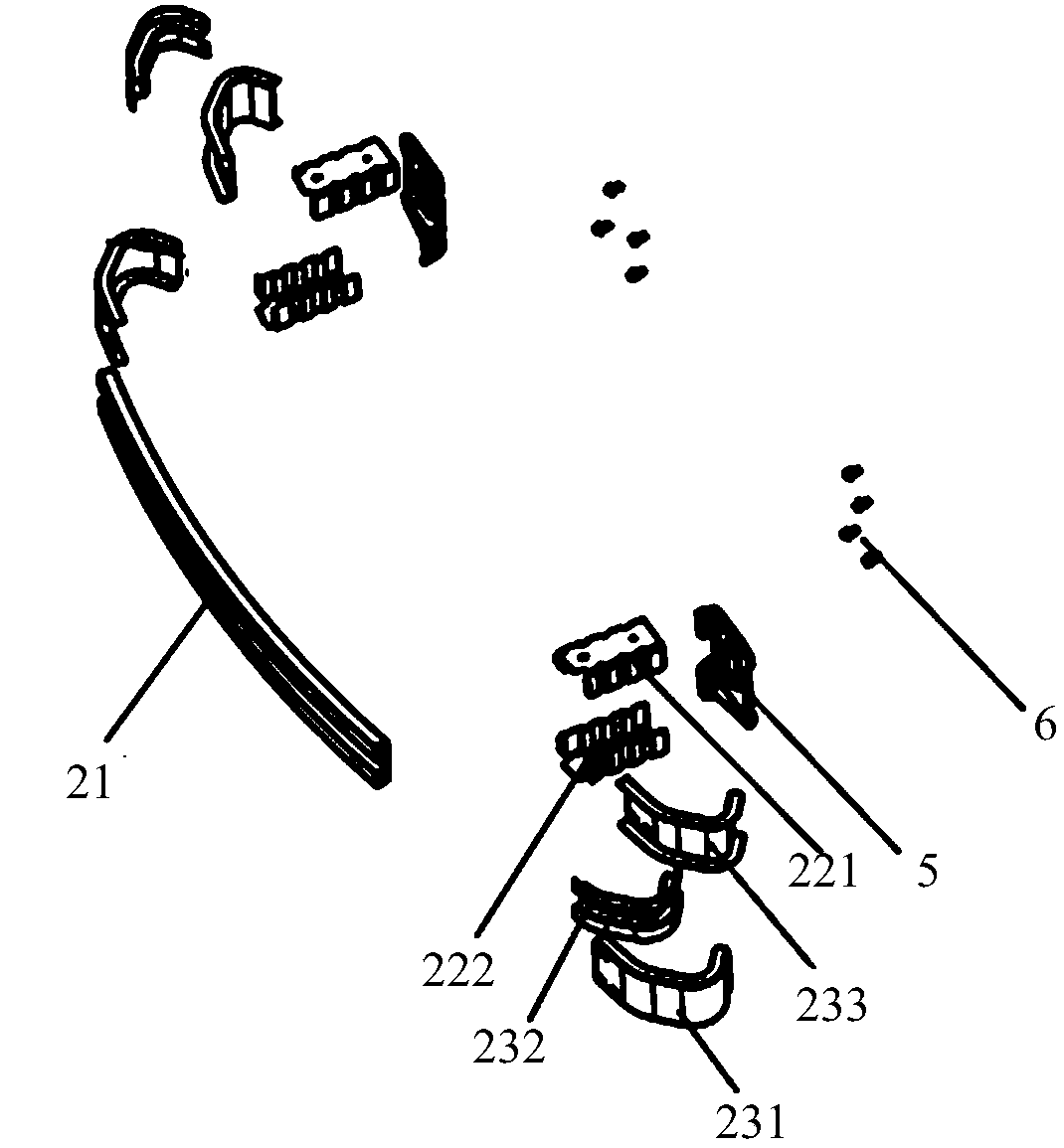

Vehicle collision-proof beam

The invention relates to a vehicle collision-proof beam, which comprises a main beam, an energy absorbing box and a flange, wherein the main beam is connected with a front longitudinal beam of an vehicle through a flange and a bolt, an energy absorbing box is arranged between the main beam and the flange, two mirror-symmetrical side beams are respectively arranged at left and right ends of the main beam, each side beam structure is of a hook type, one end of the hook type is connected with the main beam, and the other end of the hook type is suspended and pointing to a body shotgun structure.In accordance with that prior art, As that vehicle is in a small offset collision process, After the vehicle is impacted by the collider, because two side beams are added to the side of the main beam,the length of the whole anti-collision beam is increased, and the yield strength of the two side beams is higher than that of the energy absorbing box, the energy absorbing box on the side of the collision will collapse and absorb energy first, and then the side beam will collapse and bend to impact the front longitudinal beam. As a result, the vehicle deviates from the collider with the drivingpassenger along the projection plane of the collision direction, thereby reducing the passenger injury index and protecting the safety of passengers.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

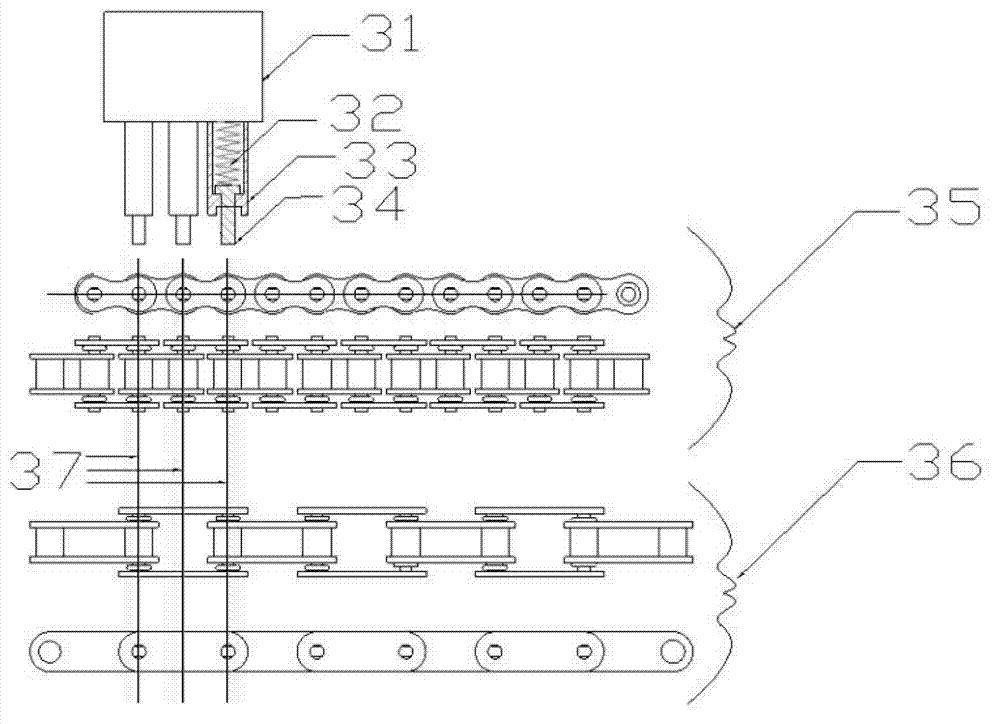

Single-double-pitch chain common type assembling method

The invention relates to a single-double-pitch chain common type assembling method and belongs to the technical field of a chain transmission part machining machine of a common part of a machine. The method comprises the following steps of: (1) providing a single-double-pitch chain common type assembling machine; (2) arranging a chain plate, a sleeve, a roller and a pin shaft into a material cabin; (3) putting the chain plate, the sleeve, the roller and the pin shaft in the material cabin into a blanking seat through a guide pipe; pushing a material feeding pushing sheet by a driving system and pushing a part in the blanking seat into a tool position in a press fitting assembly; and (4) processing the chain plate, the sleeve, the roller and the pin shaft by the press fitting assembly in the step (3) and outputting a continuous chain. When the assembling is started and a single-pitch chain needs to the assembled, any two adjacent colliders are mounted on pressing die collider seats; and only the colliders at the two sides are mounted on the pressing die collider seats when a double-pitch chain needs to be assembled. With the adoption of the single-double-pitch chain common type assembling method disclosed by the invention, both the single-pitch chain and the double-pitch chain can be mounted on one assembling machine.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

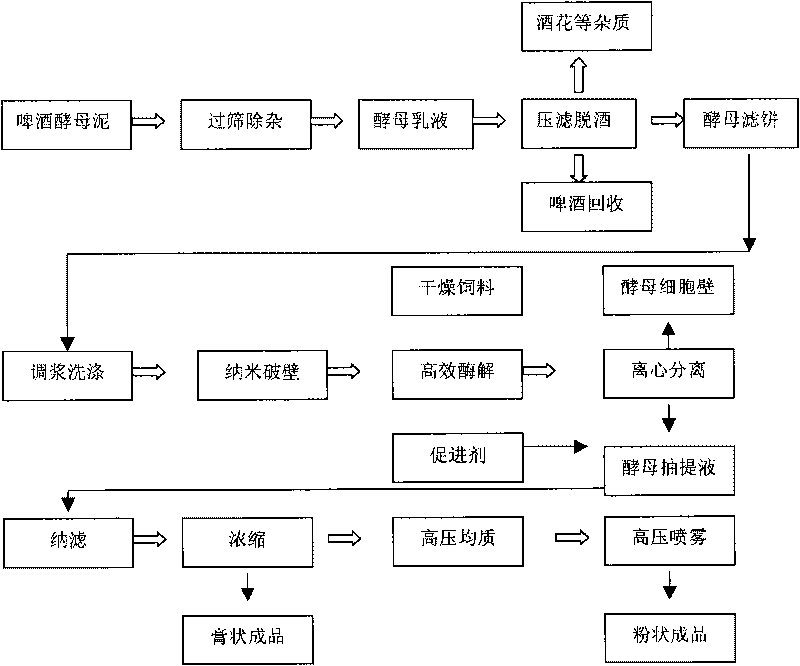

Method for preparing personalized biological culture medium raw material from beer waste yeast

InactiveCN101748076AImprove bioavailabilityIncreased level of controlFungiMicroorganism based processesYeastGlucanase

The invention discloses a method for preparing a personalized biological culture medium raw material from beer waste yeast, which comprises the following steps: (1) breaking the wall of beer waste yeast by using a collider at 30-45 DEG C under 70-100 MPa, thereby obtaining the wall-broken yeast; (2) mixing the wall-broken yeast, and one or a plurality of proteases or glucanases at 45-65 DEG C for3-24 hours to obtain the yeast enzymolysis solution, wherein the proteases are selected from papains or neutral proteases, and the mixing time is preferably 5-15 hours; and (3) centrifugating the yeast enzymolysis solution, and filtering through a nanofiltration membrane with the molecular weight of 1000, thereby obtaining the biological culture medium raw material. The invention also discloses the beer waste yeast personalized biological culture medium raw material obtained by using the method, and applications thereof.

Owner:溧阳杰康诺酵母科技有限公司 +2

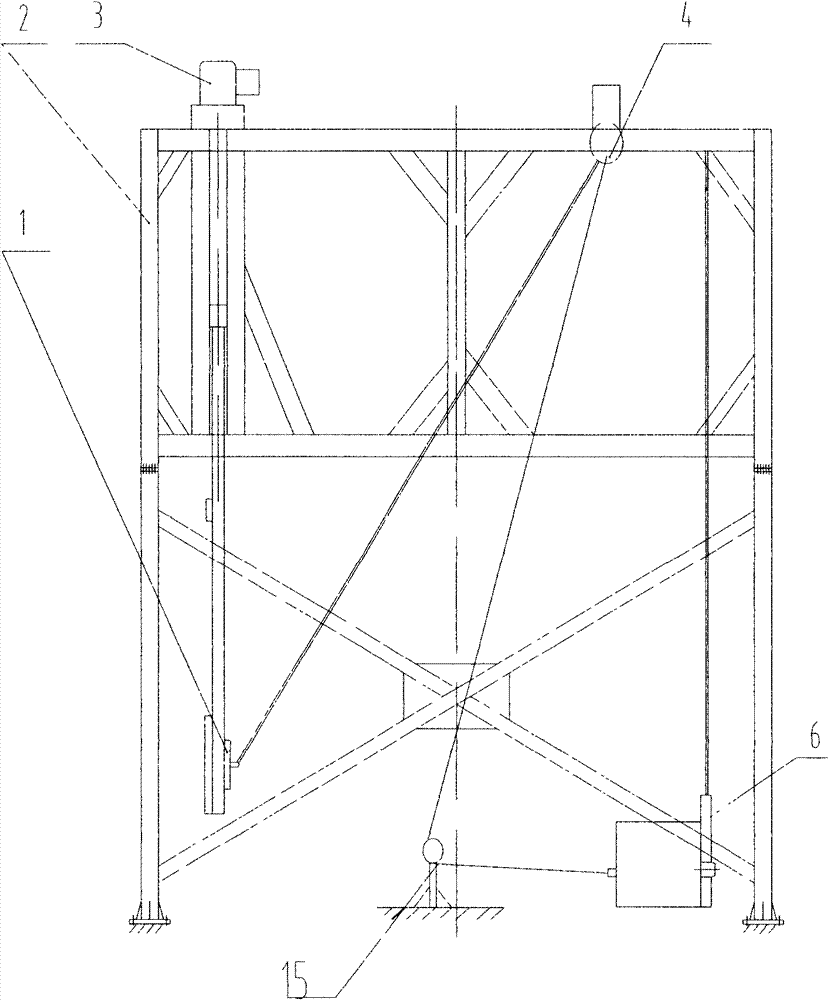

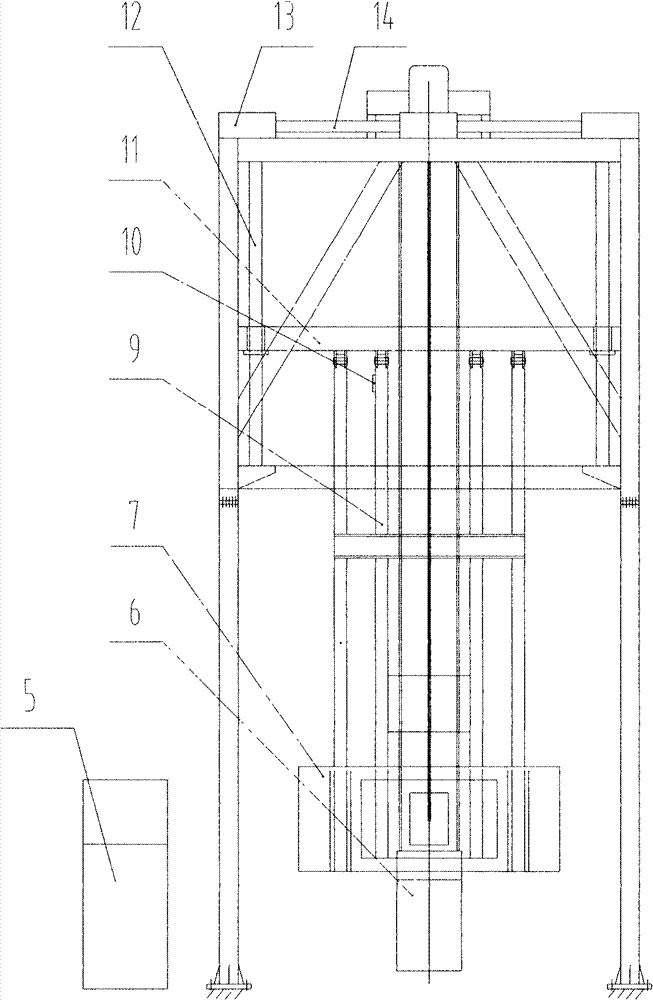

Device for detecting automobile cab and front and rear end protecting device

ActiveCN102818708AGuaranteed test accuracyImprove data basisVehicle testingShock testingElectricityCar driving

The invention discloses a device for detecting an automobile cab and a front and rear end protecting device. The detecting device structurally comprises a main body frame, wherein the main body frame is fixedly arranged on the ground and has certain height, length and width; a speed reducer is arranged at the upper end of the left side of the main body frame; a pendulum bob is arranged at the lower end of the speed reducer through a spindle elevating mechanism; a protecting device is further arranged on the pendulum bob; a hoisting motor is arranged at the upper part of the frame; a steel cable for hoisting the pendulum bob is arranged between the hoisting motor and the pendulum bob; an electric sucker is arranged at the rear end of the pendulum bob; a collider is arranged at the right end of the frame; an electric sucker is arranged at one end of the collider; the electric sucker is connected with the hoisting motor through a cable; a power-off protecting device is further arranged on the device; and a camera and a data acquisition system are arranged well before the experiment. The detecting device has the beneficial effects that the system can be used for easily observing the dynamic response and deformation situations of a sample in the collision process, has more acquired data, and is high in testing precision, simple in structure and easy to operate.

Owner:招商局检测车辆技术研究院有限公司

Manufacturing method for polymer fiber containing tea material component

ActiveCN103060945ADeodorizingAntibacterialMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a manufacturing method for a polymer fiber, especially to a manufacturing method for a polymer fiber containing a tea material component. The method comprises the following steps: step 1, draining and baking a tea material and sieving the completely dried tea material to remove impurities; step 2, crushing the dried and sieved tea material into small pieces with a machine and pressurizing the small pieces in a high pressure vessel; step 3, subjecting the small pieces to decoloring and de-oiling by using a CO2 supercritical extraction method; step 4, placing the colorless and oil-free small tea material pieces in a sealed cabin with numerous colliders on its low temperature negative pressure inner ring wall and carrying out high speed rotation; step 5, respectively fusing and mixing fine tea material powder with different plastic powder materials according to different melting points and carrying out cooling; and step 6, carrying out molding by using a conventional wire drawing method so as to obtain the polymer fiber containing the tea material component. With such a technical scheme, the invention has the following advantages and beneficial effects: the manufacturing method is simple, and the manufactured polymer fiber has deodorizing, antibacterial and UV-resistant functions.

Owner:TRYD TEXTILE FIBER TECH

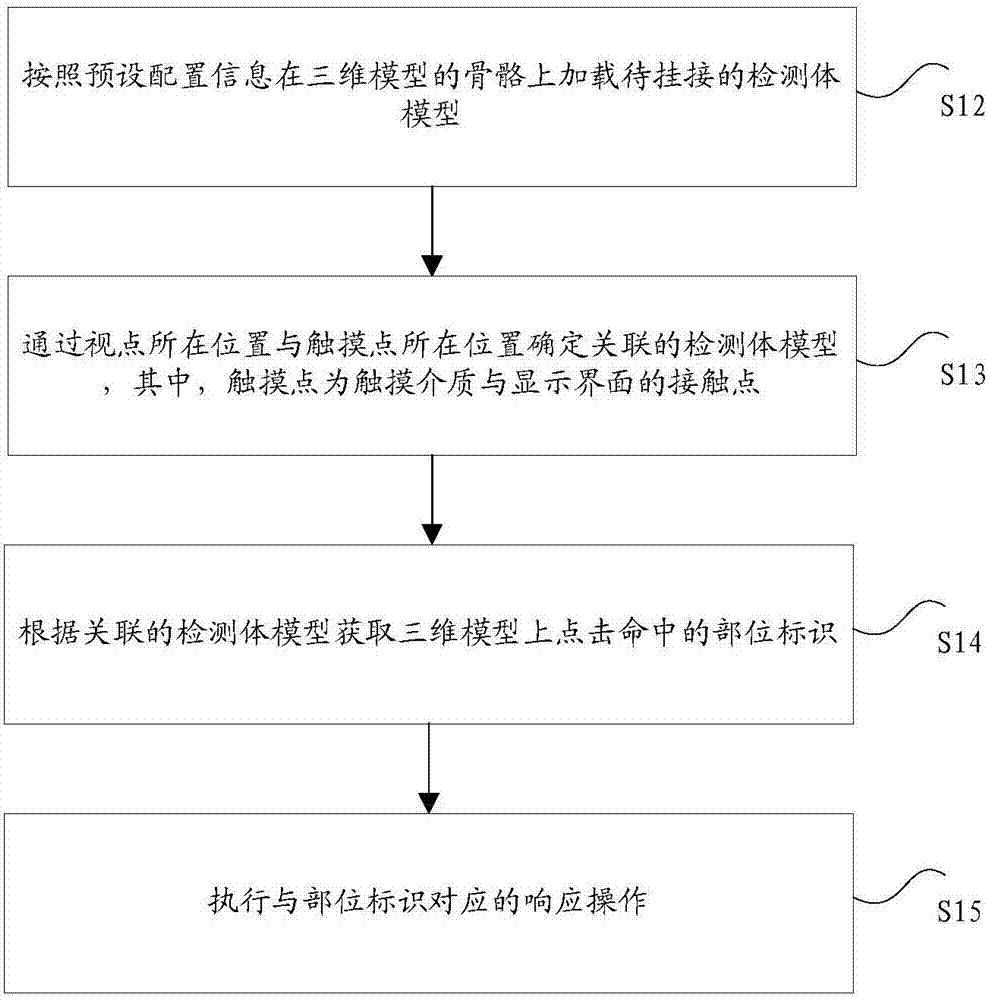

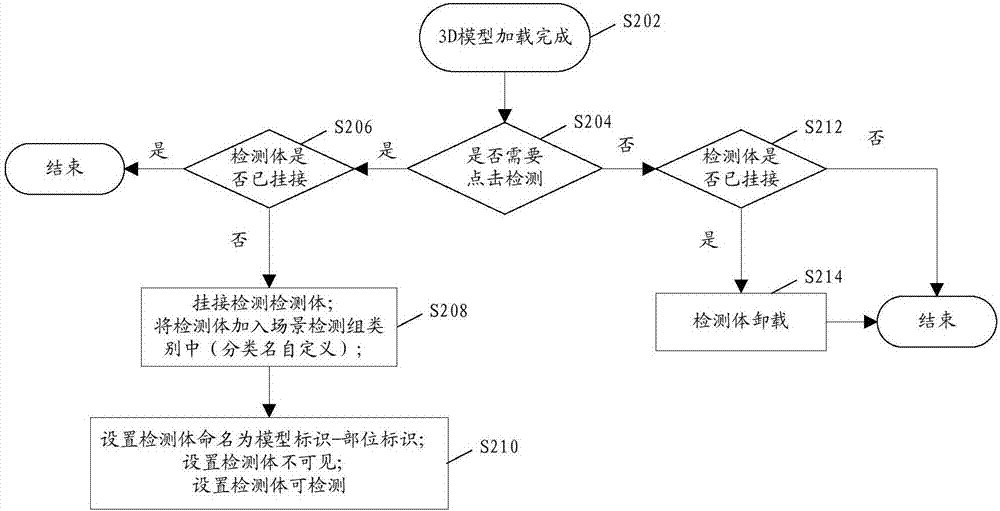

Portion click processing method of three-dimensional model and apparatus thereof, storage medium and processor

ActiveCN106960475AImprove effectivenessImage data processingInput/output processes for data processingViewpointsComputer vision

The invention discloses a portion click processing method of a three-dimensional model and an apparatus thereof, a storage medium and a processor. The method comprises the following steps of according to preset configuration information, loading a detection body model to be hitched on a skeleton of the three-dimensional model; through a position of a viewpoint and a position of a touch point, determining an associated detection body model, wherein the touch point is a contact point of the touch medium and a display interface; according to the associated detection body model, acquiring a hit portion identification through clicking on the three-dimensional model; and executing a response operation corresponding to the portion identification. In a click detection scheme provided by a correlation technology, a condition that a collider is dynamically loaded according to configuration information is not supported and collider following detection of a 3D model under different motion states is not supported either. In the invention, the above technical problems are solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

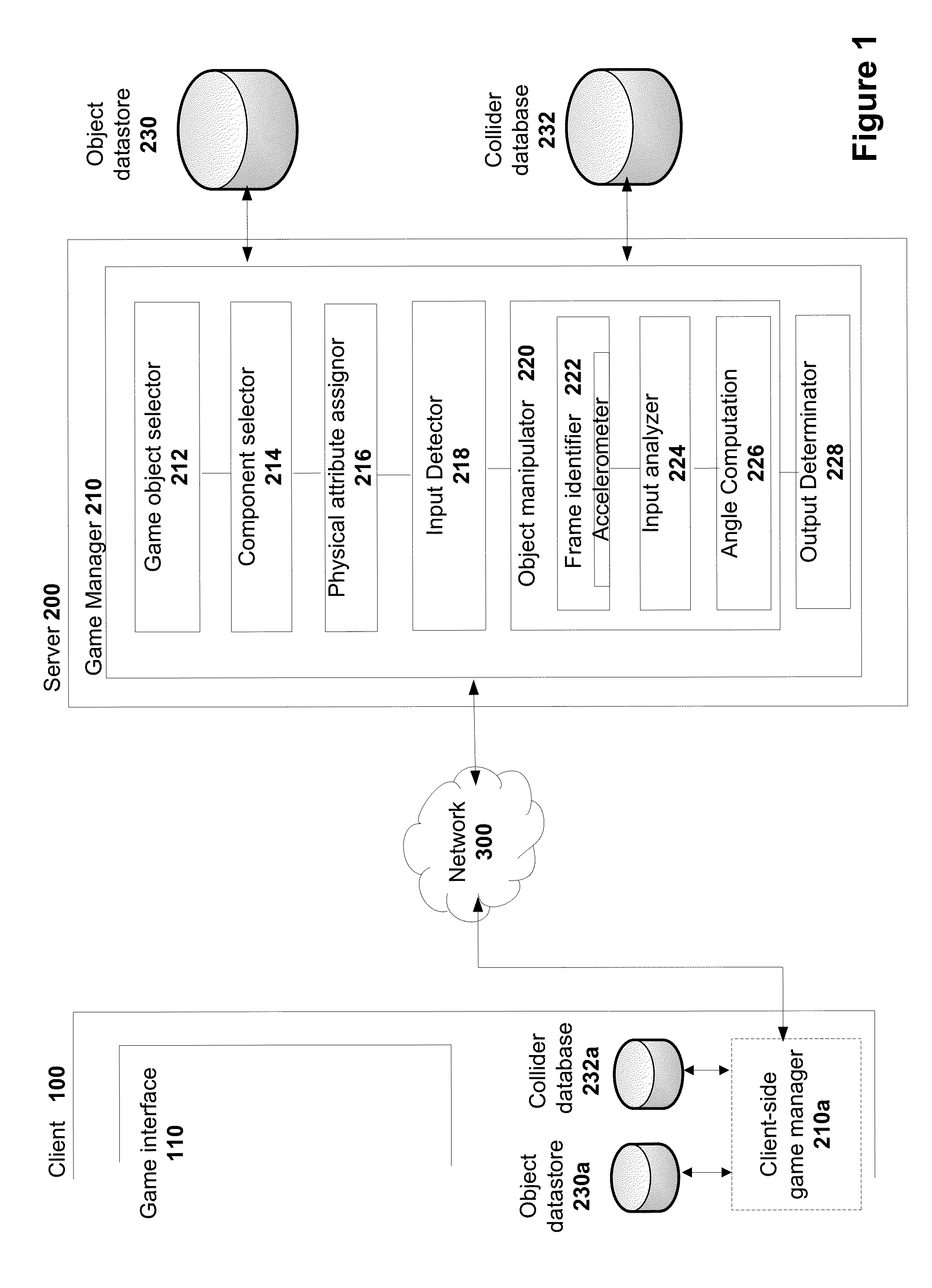

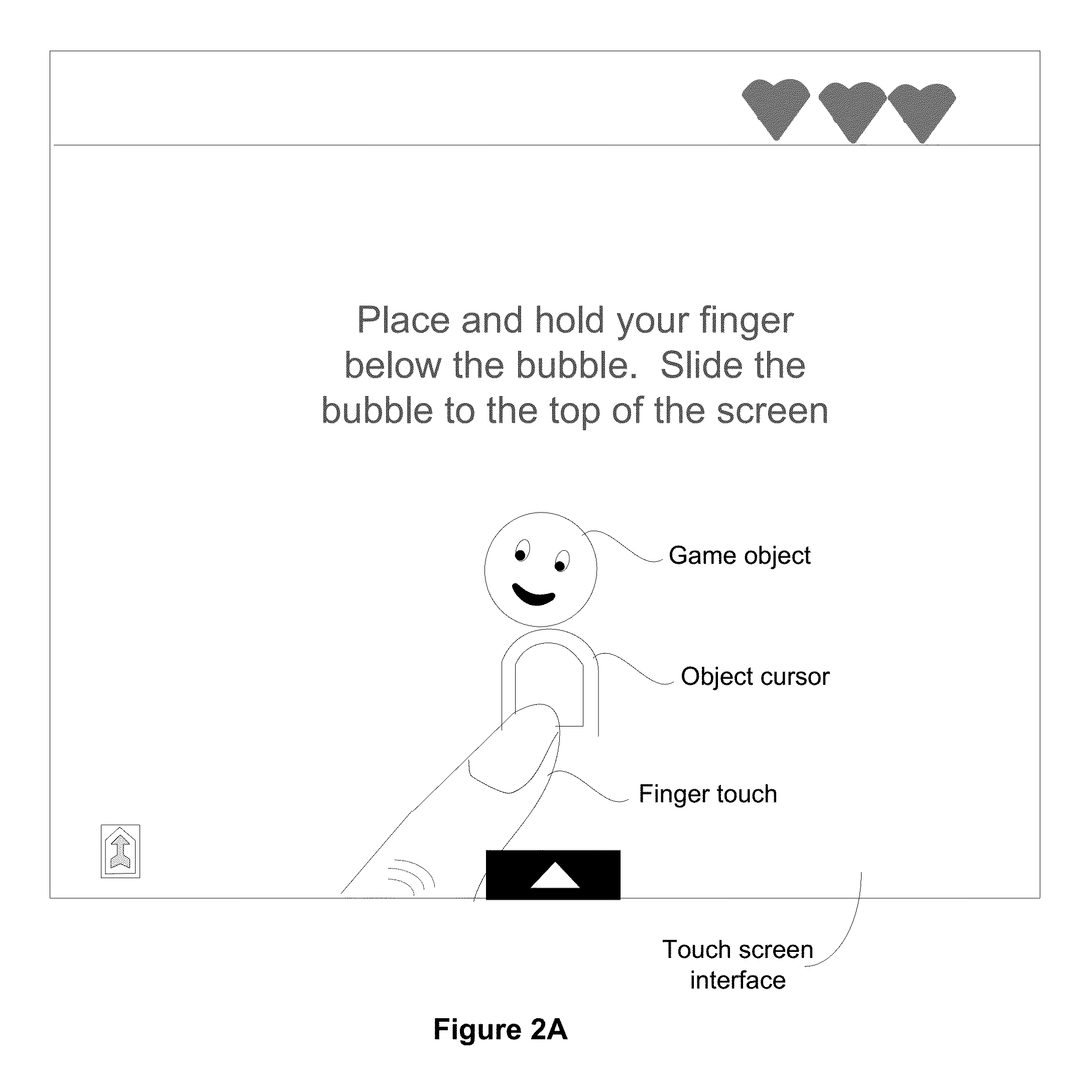

Methods for Using Touch-Screens to Simulate Balancing and Manipulation of Curved Object During Gameplay

Methods and computer programs include associating a three-dimensional collider component and a rigid body component to a two-dimensional game object used in the game play. The three-dimensional collider component and the rigid body component define a plurality of physics attributes to enable control of physical behavior of the game object. A second three-dimensional collider component is associated with a game cursor that is used for providing user input to the gameplay. The game cursor is defined as a two-dimensional object with at least a portion of the game cursor having a spherical contour. User input is detected at a touch screen interface of a computing device that is rendering the gameplay. The user input causes the spherical contour of the game cursor to control movement of the game object within the game scene of the gameplay, the movement being adjusted in accordance to physics attributes of the game object.

Owner:ZYNGA

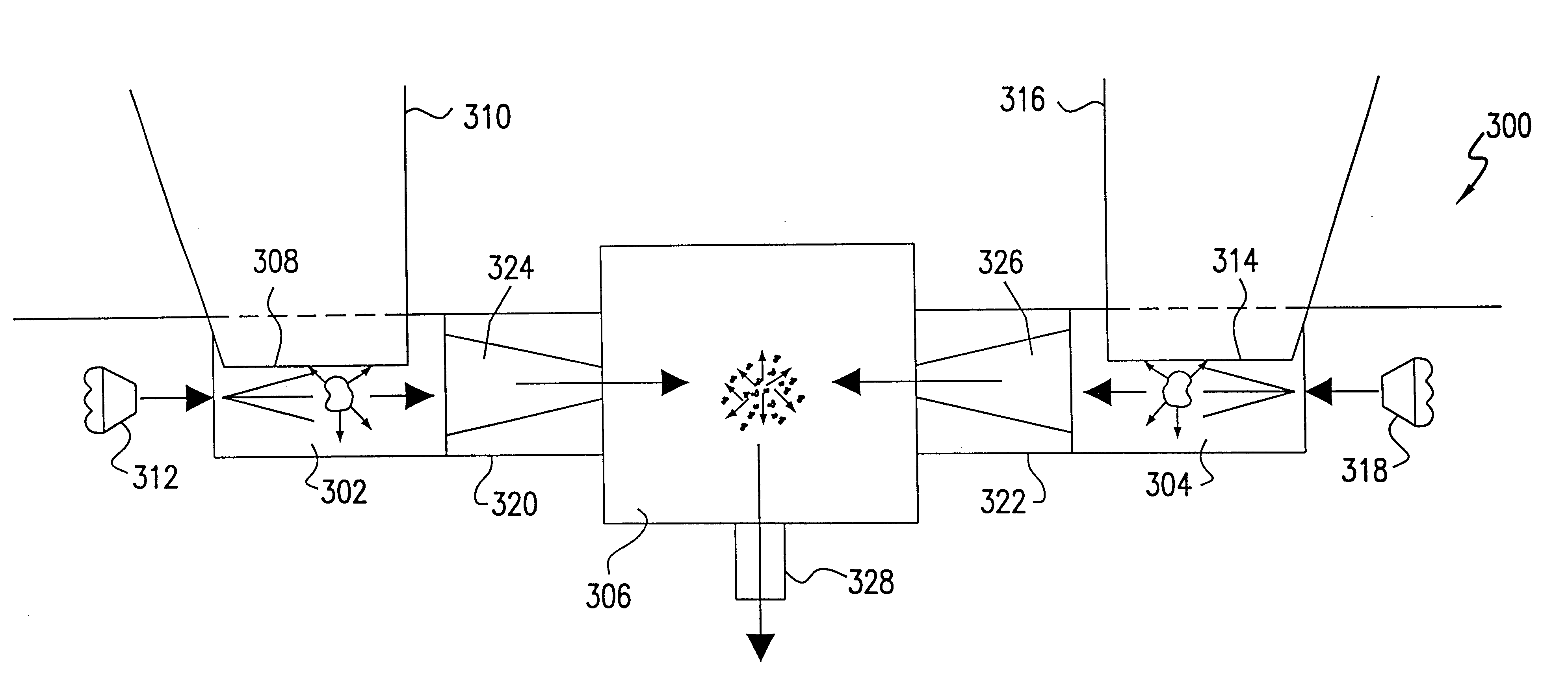

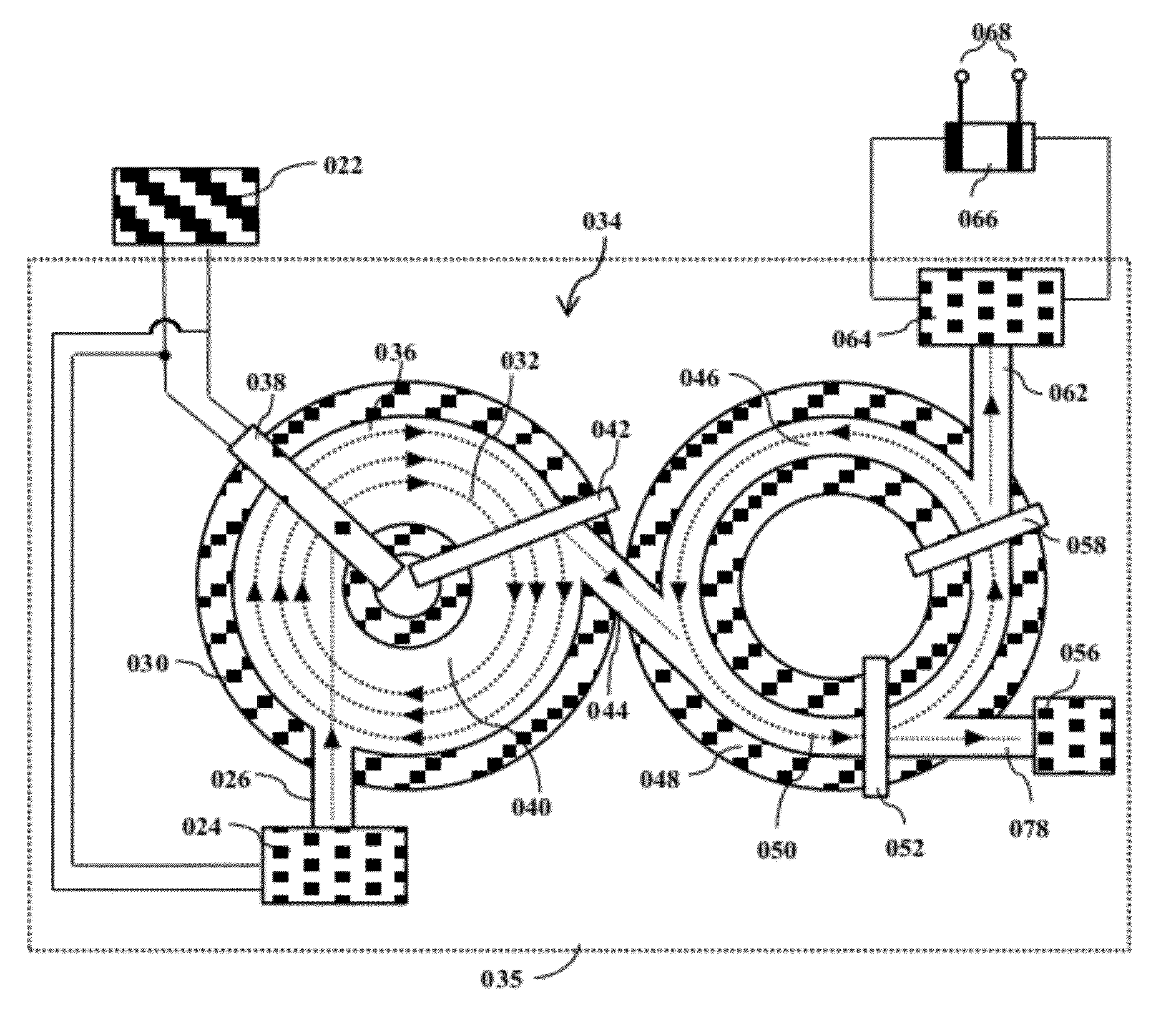

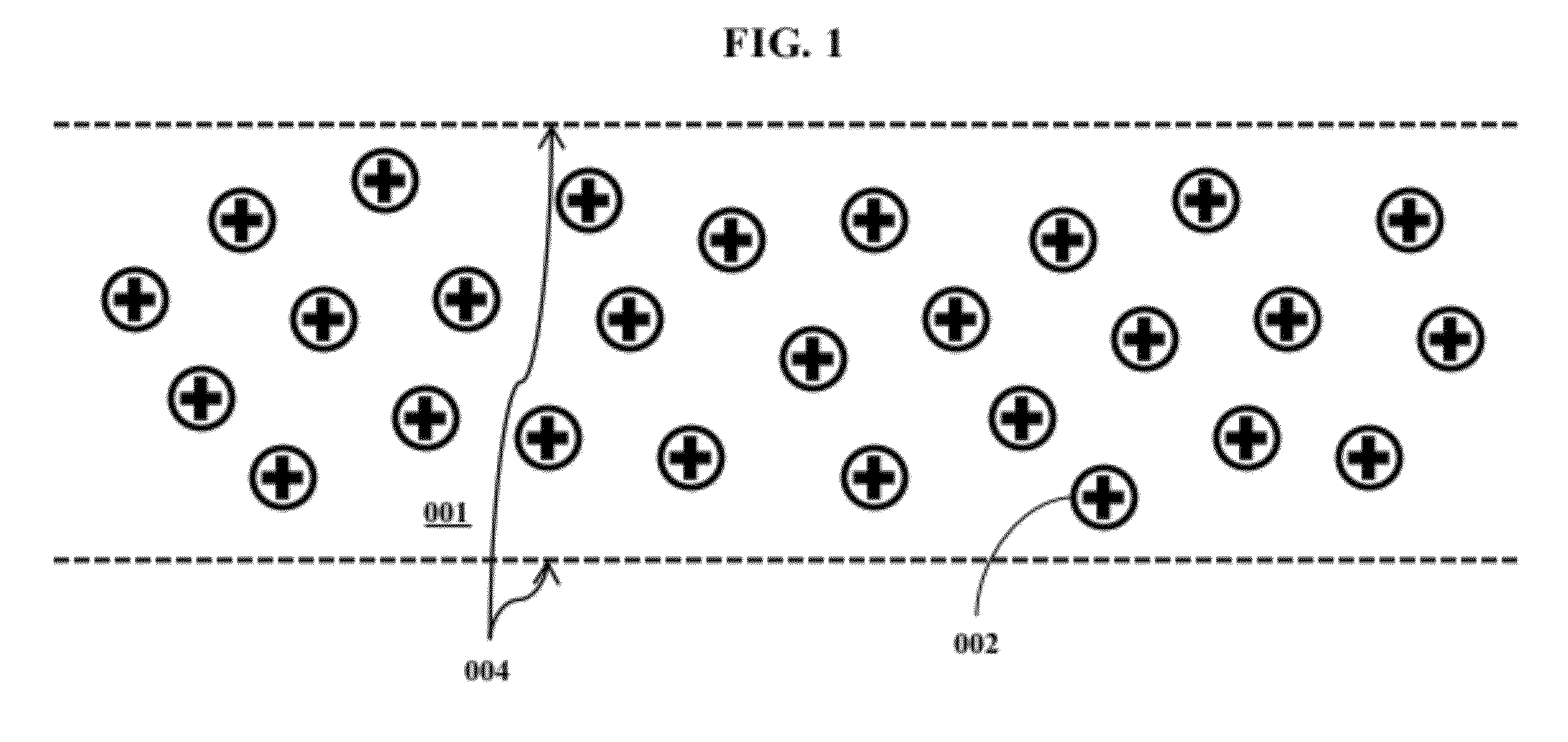

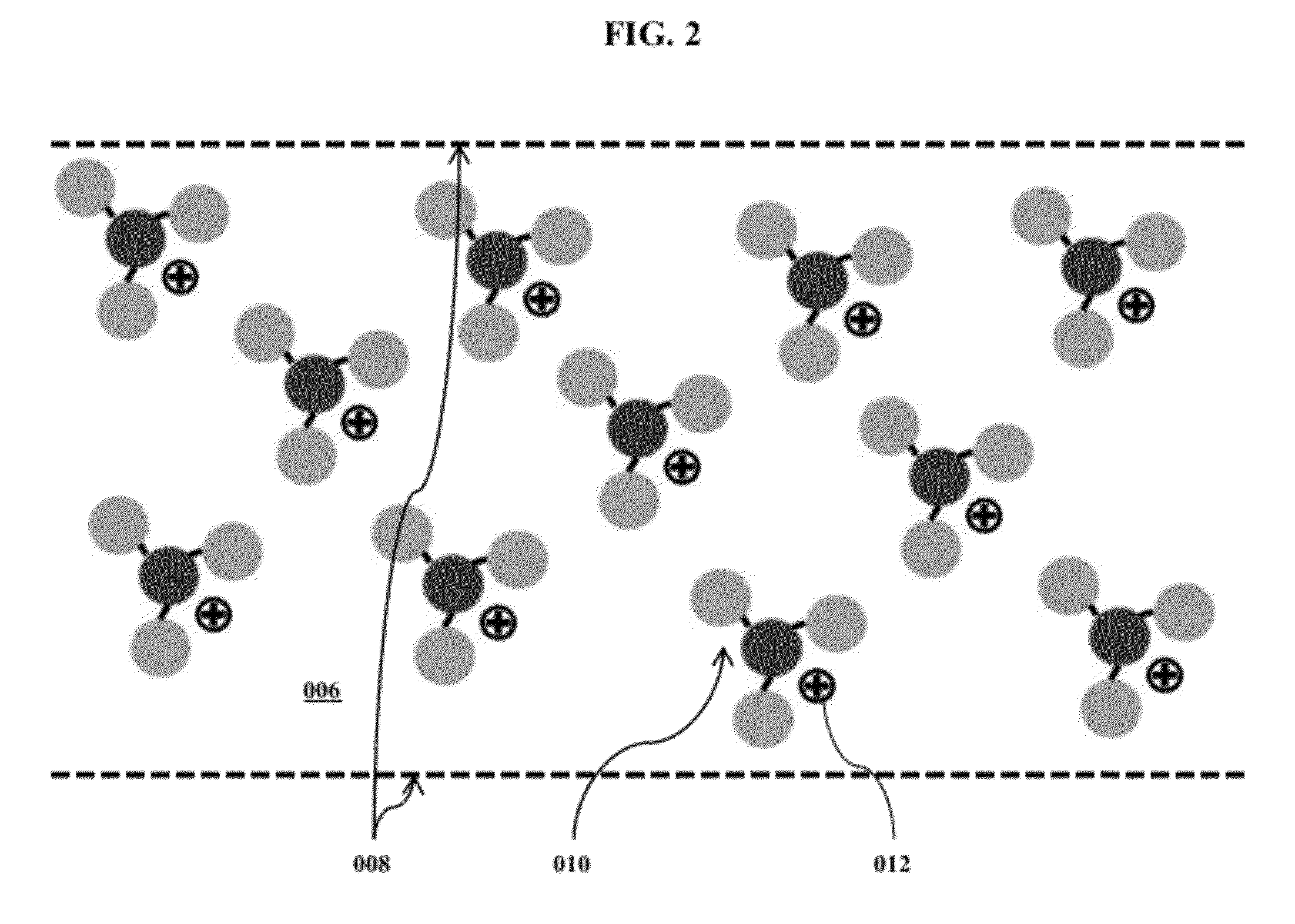

Apparatus and method for energy storage with relativistic particle acceleration

InactiveUS20120286702A1Limited and no loss of energySmall sizeMagnetic induction acceleratorsBeam energyEngineering

An energy storage device is proposed that utilizes acceleration of particles to near relativistic velocities to store energy in the kinetic energy of accelerated particles. Designs and models are provided for a commercially feasible device that implements the concept. The device allows tremendous performance capabilities across many parameters including energy density. Multiple innovations are also proposed for methods to reconvert the kinetic energy of accelerated particles back to electricity. In addition, certain innovations are proposed for accelerated particle beam control, beam particle designs and beam confinement rings. The device is different from existing particle collider storage rings in that it maximizes total beam energy, not energy per particle by accelerating particles to velocities substantially less than the speed of light. In addition, it includes innovations to meet the requirements of the commercial market with specific applications in markets such as grid level storage and energy storage for vehicles.

Owner:BAZAZ GAURAV

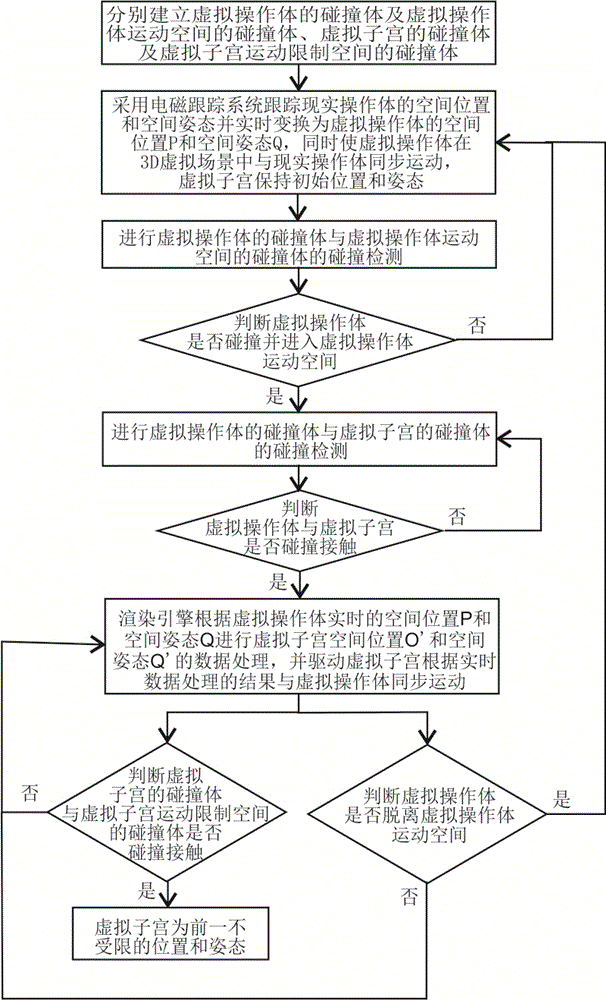

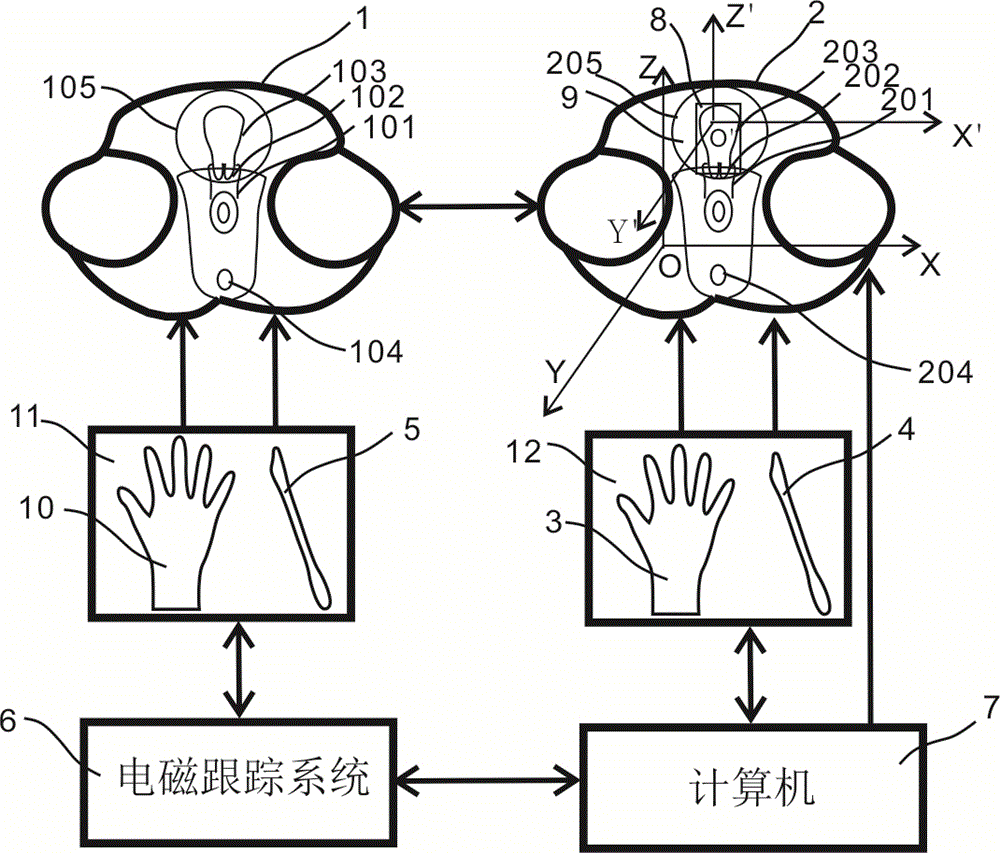

Gynecologic examination virtual-real synchronous simulation method

ActiveCN105788395AMotion synchronizationEasy to observeCosmonautic condition simulationsEducational modelsCollision detectionSimulation

A gynecologic examination virtual-real synchronous simulation method disclosed by the present invention comprises the steps of establishing a collider of a virtual operating body, a collider of the motion space of the virtual operating body, a collider of a virtual uterus and a collider of the motion limitation space of the virtual uterus; enabling the virtual operating body to move synchronously with a real operating body in a 3D virtual scene; carrying out the collision detection on the colliders; finally carrying out the determination, the data processing and the motion rendering. By the gynecologic examination virtual-real synchronous simulation method of the present invention, the gynecologic examination simulation training comprising the virtual and real synchronous examination operations, such as the palpation, the gently scrape, the gently brushing, the smearing, the lifting, the pressing, etc., of the virtual uterus can be realized, the synchronous real operation and virtual simulation operation of the gynecologic examination bimanual examination, vagino-recto-abdominal examination and instrumental examination is realized, and the teachers and the students are convenient to observe and evaluate the gynecologic examination training technique.

Owner:TIANJIN TELLYES SCI INC

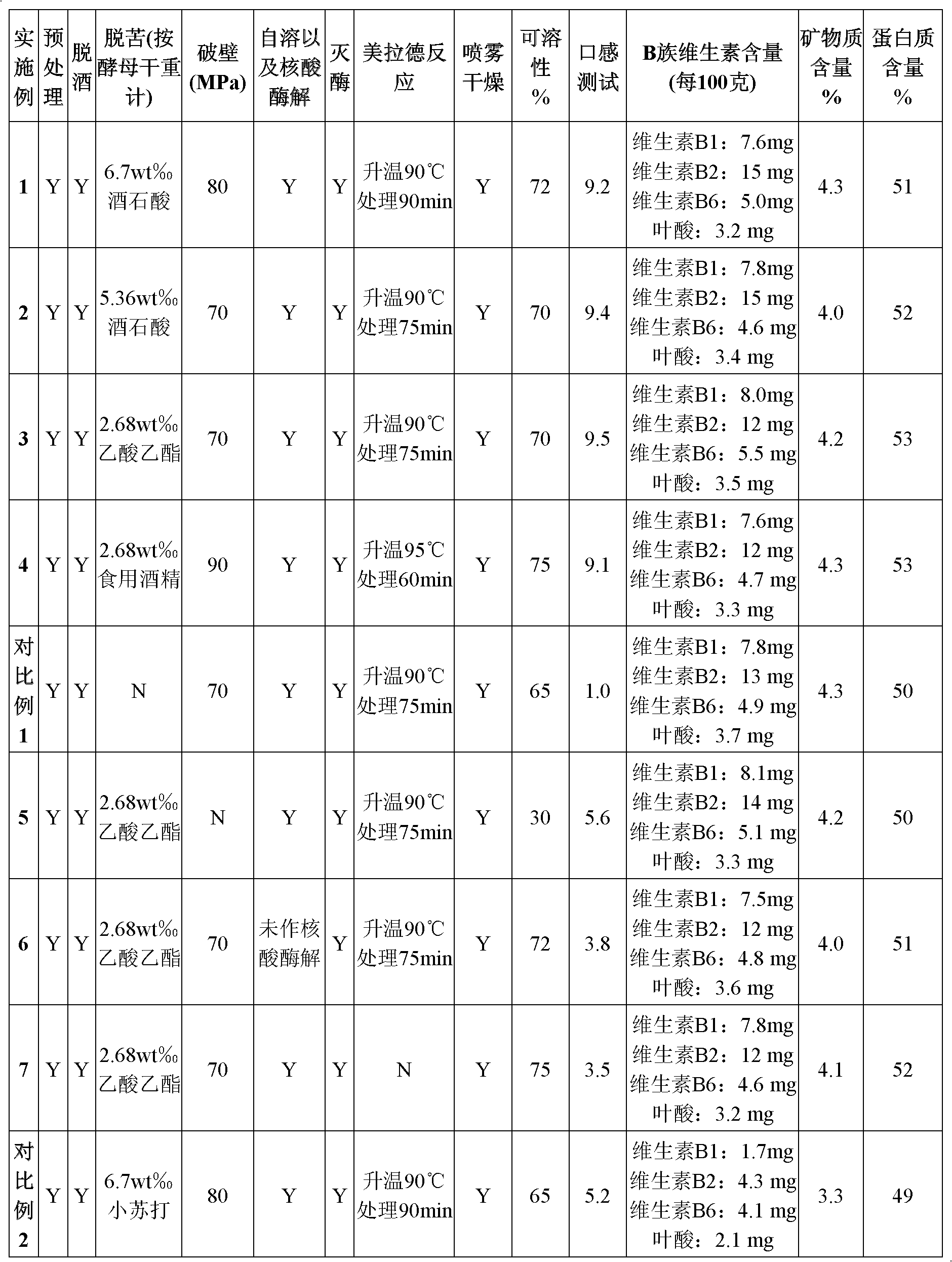

Production method for edible beer yeast powder

The invention provides a production method for edible beer yeast powder. Particularly, the production method for the edible beer yeast powder comprises the processes of: beer yeast pre-treating; alcohol removing; debitterizing; wall breaking by using a nanometer collider; autolyzing and nuclease enzymolyzing; spray drying and the like. According to beer yeast produced by using the method disclosed by the invention, the protein content from the beer yeast powder is larger than or equal to 50wt%, the vitamin B is rich, the mineral substance content from the beer yeast powder is 3.5-8wt%, and the edible beer yeast powder has the characteristics of high absorptivity, pure taste, rich nutrition and the like. The production method for the edible beer yeast powder, disclosed by the invention, is high in additional value, and is suitable for industrial production.

Owner:溧阳杰康诺酵母科技有限公司 +2

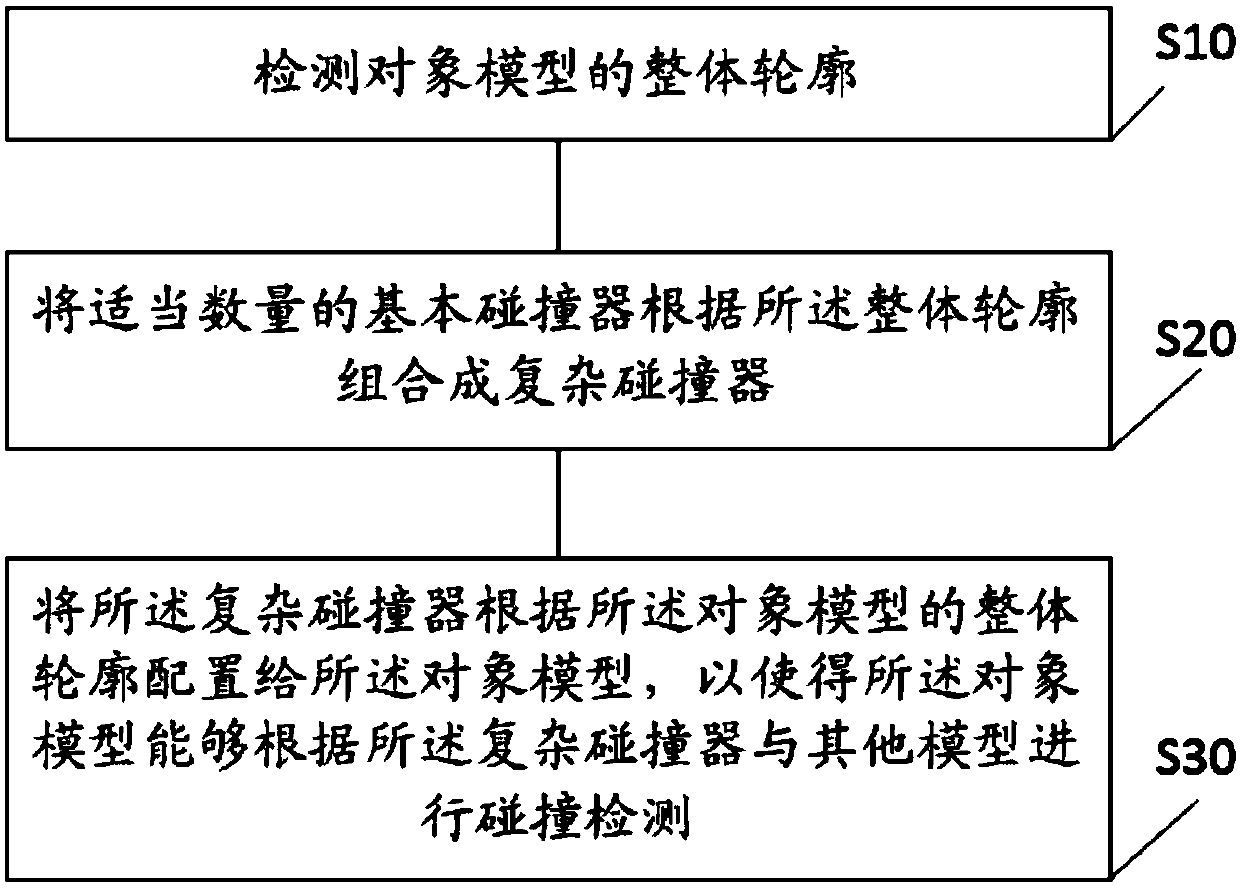

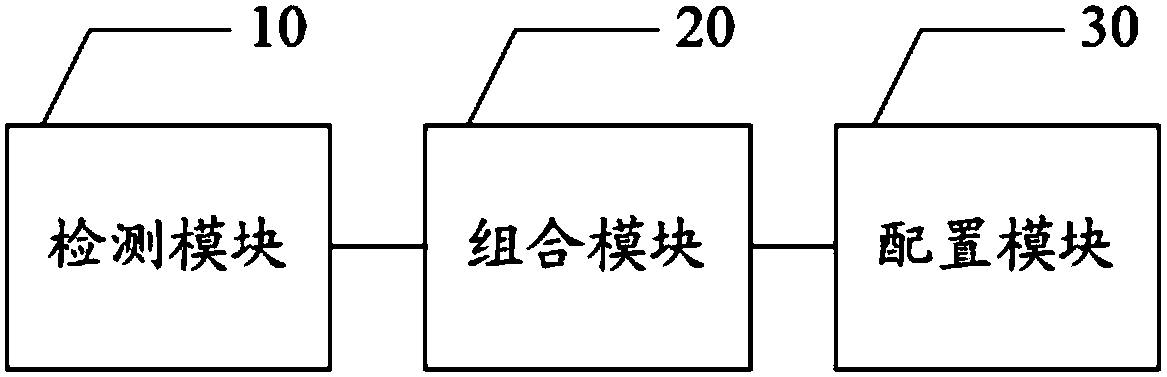

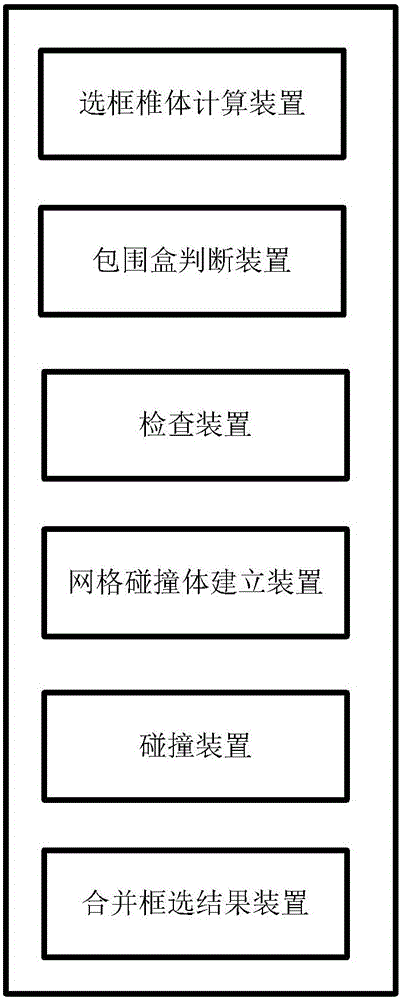

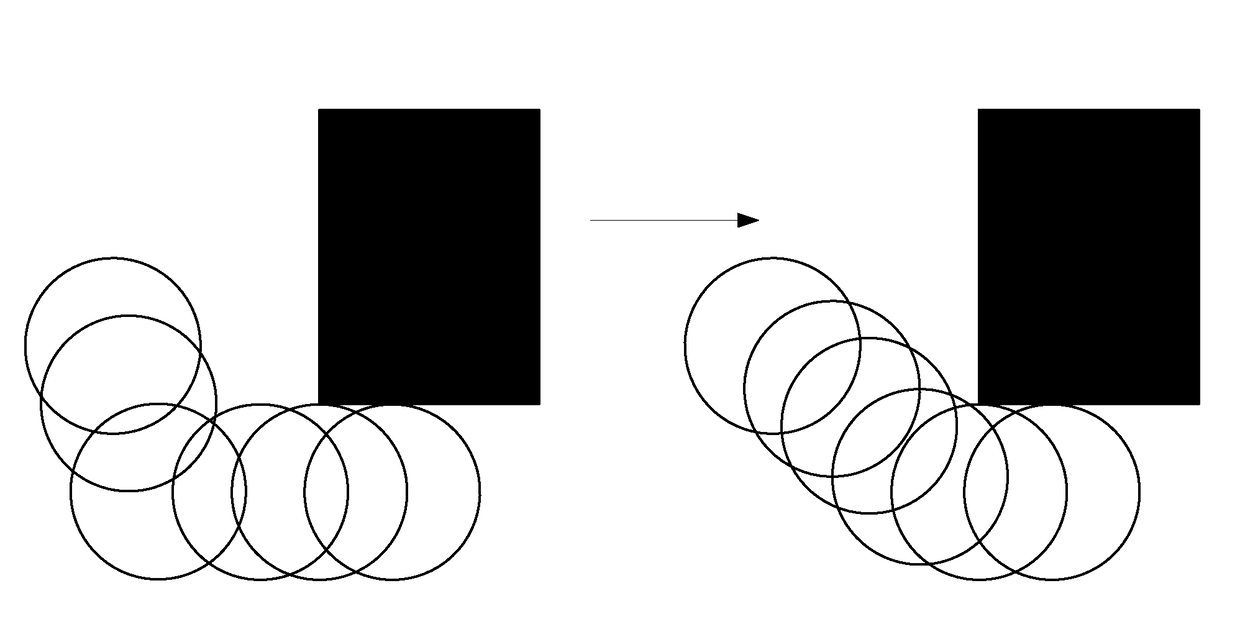

Method and device for forming complex collider, terminal device and storage medium

InactiveCN107789832ASolve the dangling problemSolve the problem of Caton phenomenonVideo gamesCollision detectionDevice form

The invention discloses a method for forming a complex collider. The method comprises the following steps that an overall outline of an object model is detected; adequate number of basic colliders arecombined to form the complex collider according to the overall outline; the complex collider is configured to the object model according to the overall outline of the object model, and then the object model can conduct collision detection with other models according to the complex collider. The invention further discloses a device forming the complex collider, a terminal device and a storage medium. The overall shape of the complex collider is close to or similar with the shape of the object model, the problems of model inlaying and model suspending can be solved, the vivid game effect is achieved, and the game experience of the user is improved.

Owner:广州市雷军游乐设备有限公司

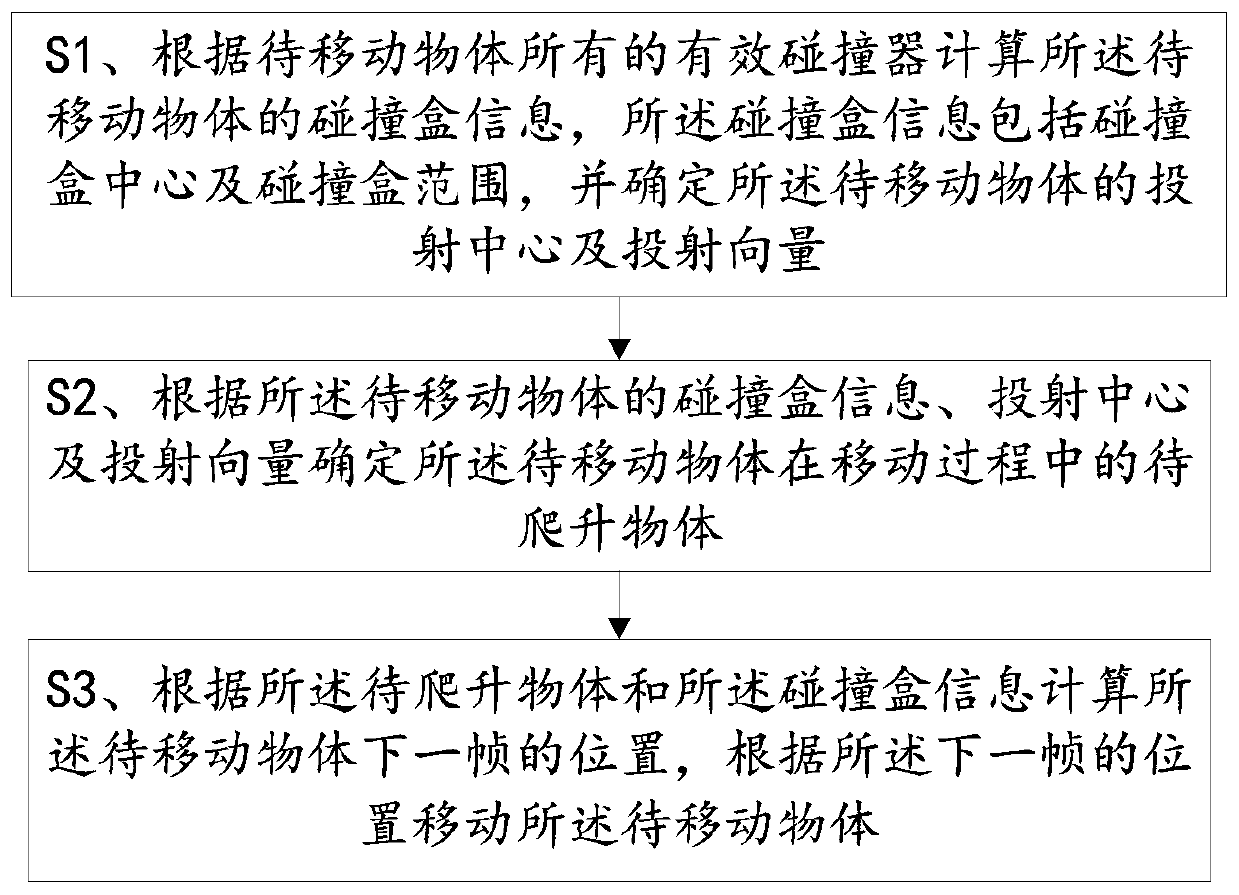

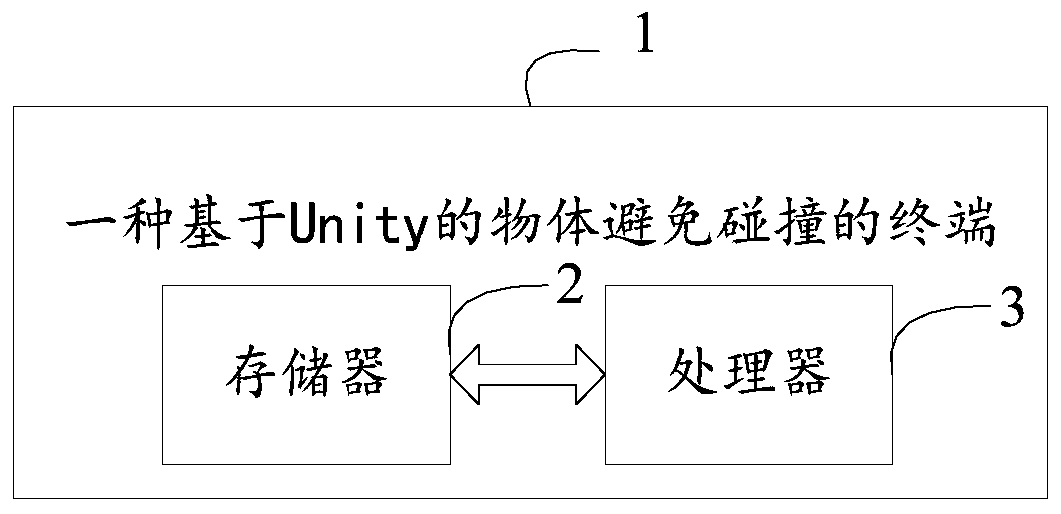

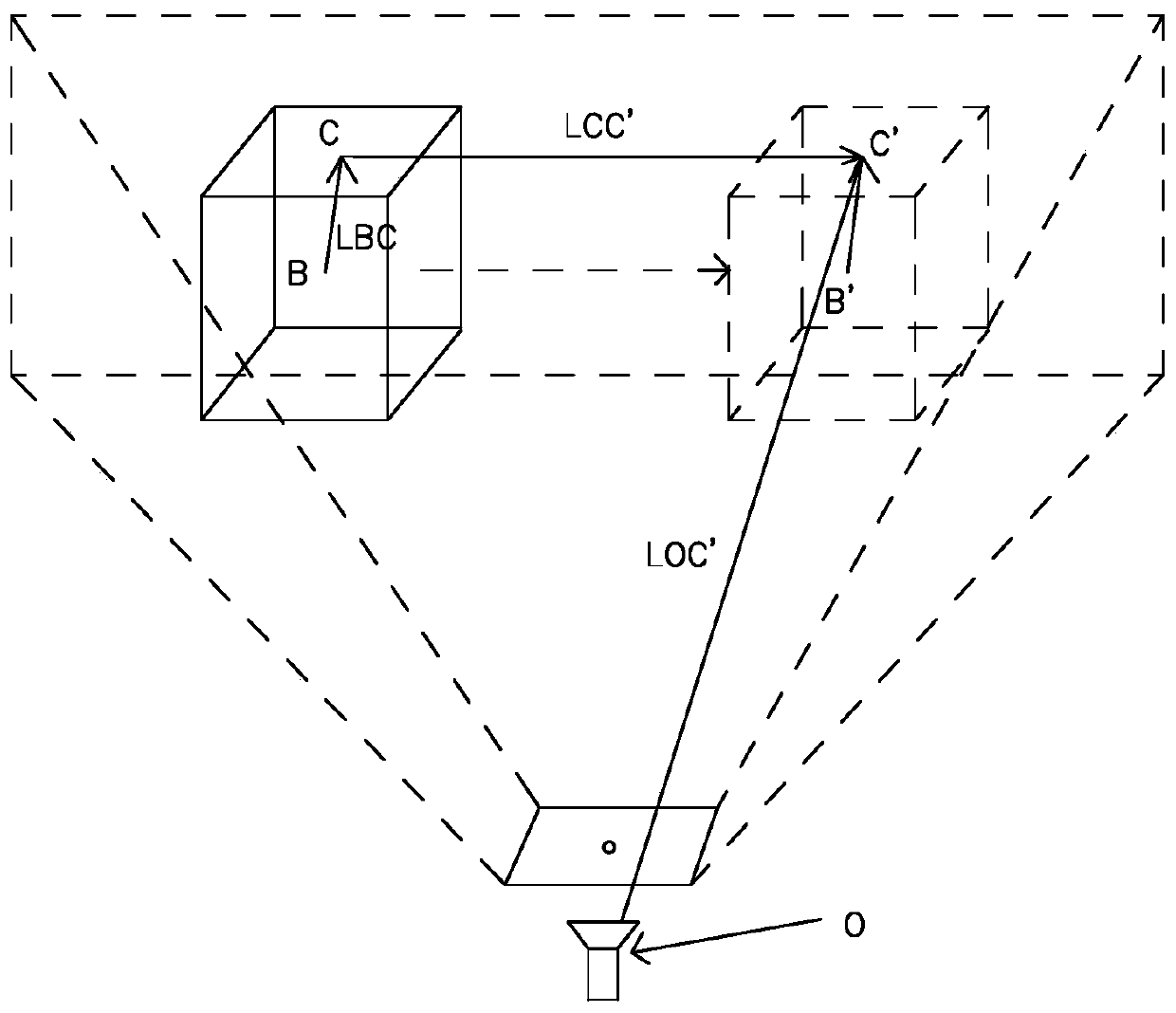

A Unity-based object collision avoidance method and terminal

The invention discloses a unity-based object collision avoidance method and terminal. The method comprises steps of calculating collision box information of a to-be-moved object according to all effective colliders of the to-be-moved object; according to the collision box information, the projection center and the projection vector of the to-be-moved object, determining a to-be-climbed object of the to-be-moved object in the moving process; calculating a position vector of a next frame of the to-be-moved object according to the to-be-climbed object and the collision box information so as to move the to-be-moved object. The automatic climbing of the to-be-moved object in the moving process can be realized under the condition that the specific shape and the structural particularity of the to-be-moved object are not concerned, so that collision is avoided, the reusability of codes for realizing automatic climbing when the object moves is improved, and the code editing efficiency is improved.

Owner:FUJIAN TQ DIGITAL

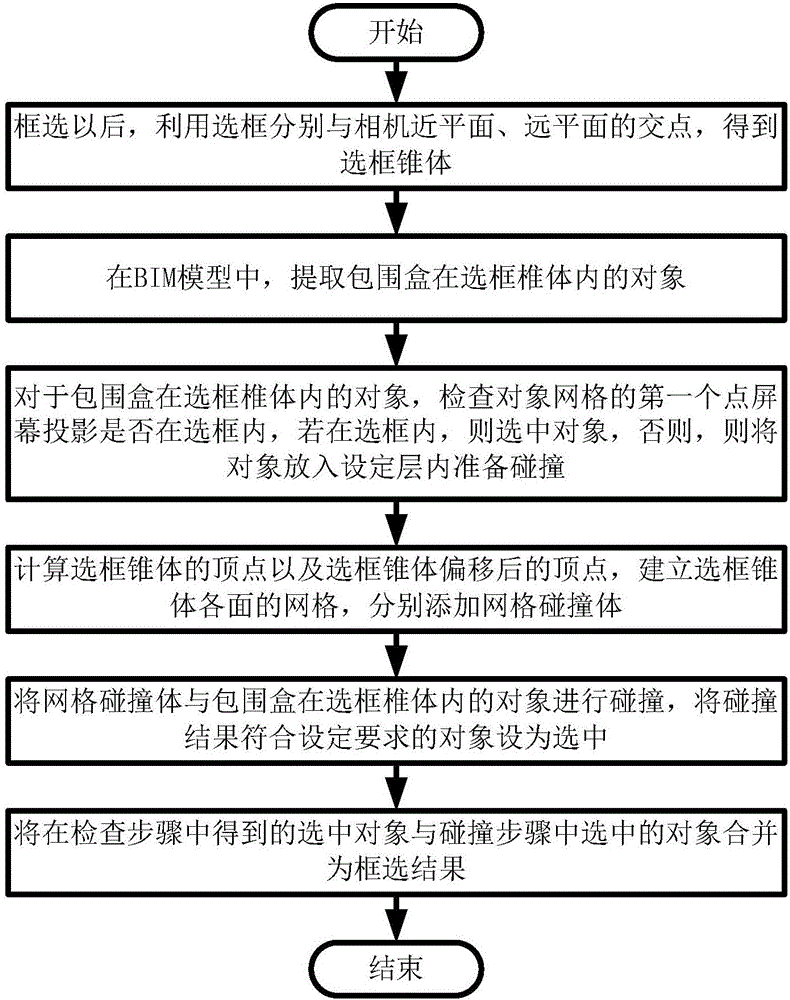

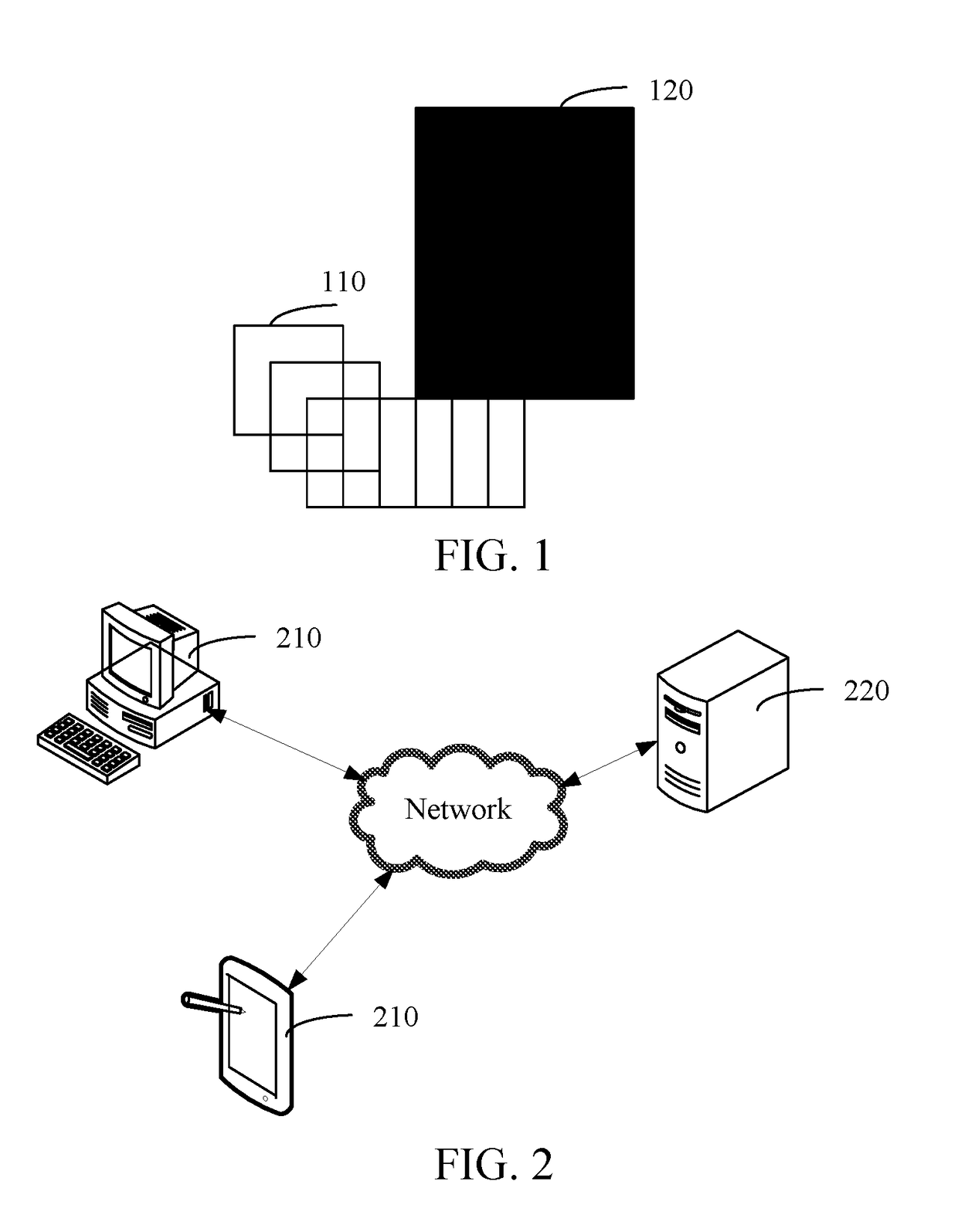

Frame selection method and system based on large BIM (Building Information Modeling) model

ActiveCN106251397AIncrease frame selection speedReduce collision3D modellingPhysics engineCollision detection

The invention provides a frame selection method and a system based on a large BIM (Building Information Modeling) model. The method comprises steps of selected frame cone calculation, surrounding box judgment, checking, mesh collider building, collision and frame selection result combination. By using multiple times of pre-selection, the number of objects in need of collision detection is reduced to the minimum, the frame selection speed of the large BIM model is improved, a large number of objects outside the selected frame can be reasonably selected, objects completely in the selected frame are selected at an extremely low cost, and collision detected by using a physical engine can be reduced greatly.

Owner:SHANGHAI TONGZHU INFORMATION TECH

Method for detecting collision between cylindrical collider and convex body in real-time virtual scenario, terminal, and storage medium

ActiveUS20180040101A1Improve handling efficiencyImprove operational fluencyProgramme-controlled manipulatorImage enhancementSimulationComputer terminal

A method for detecting a collision between a cylindrical collider and a convex body in a real-time virtual scenario performed at a computer includes: converting a cylindrical collider into a preset polygonal prism concentric to the cylindrical collider; transforming the preset polygonal prism to a local coordinate system of the convex body; obtaining a projection of the cylindrical collider on one or more testing axes according to each testing axis and the location of the preset polygonal prism in the local coordinate system of the convex body, and obtaining a projection of the convex body on each testing axis; and in accordance with a determination that the projections of the cylindrical collider and the convex body intersect with each other on each testing axis, moving the cylindrical collider away from the convex body in the real-time virtual scenario to avoid the collision.

Owner:TENCENT TECH (SHENZHEN) CO LTD

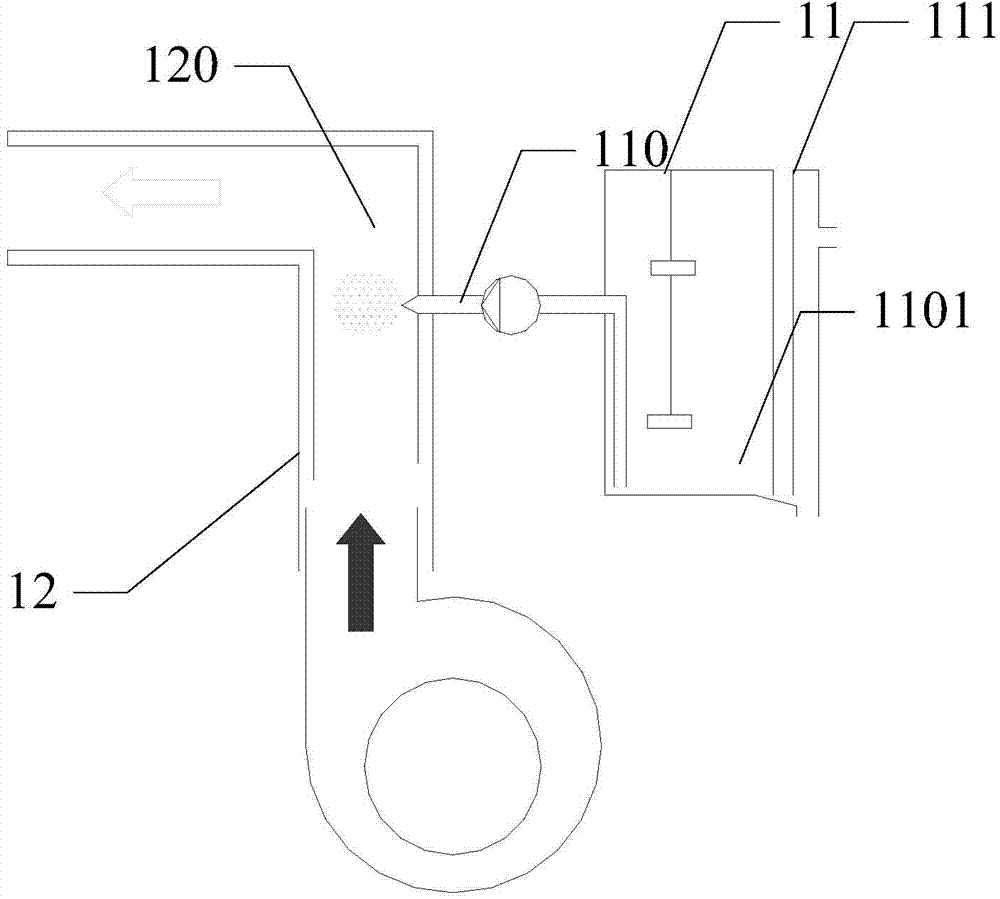

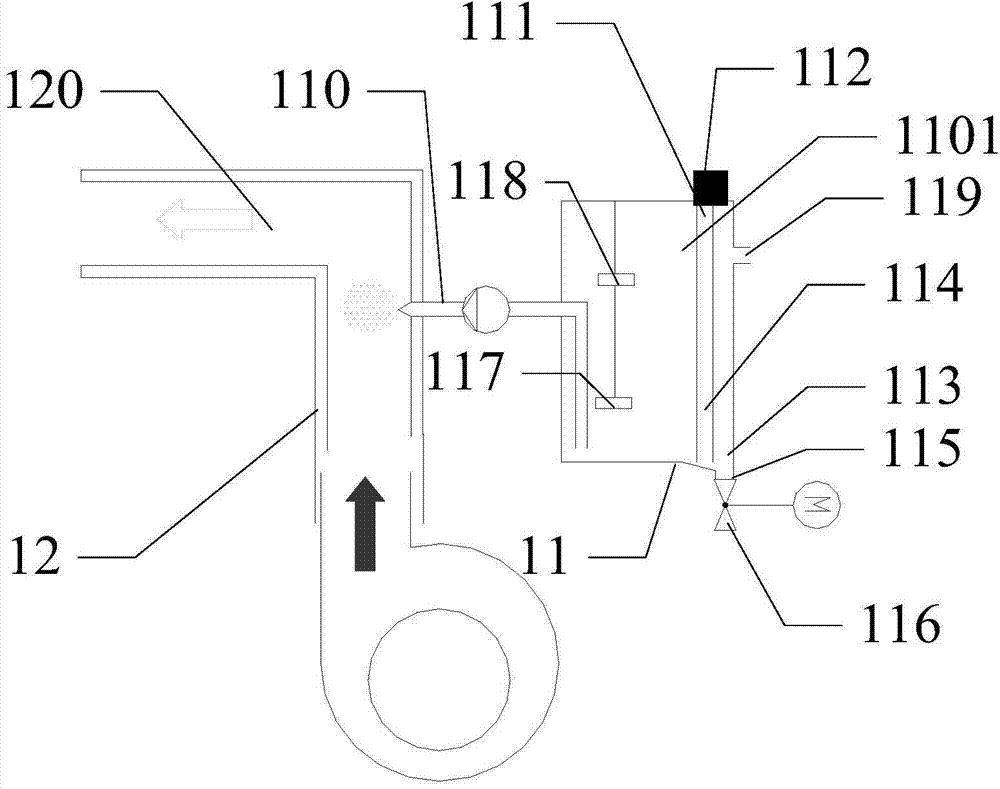

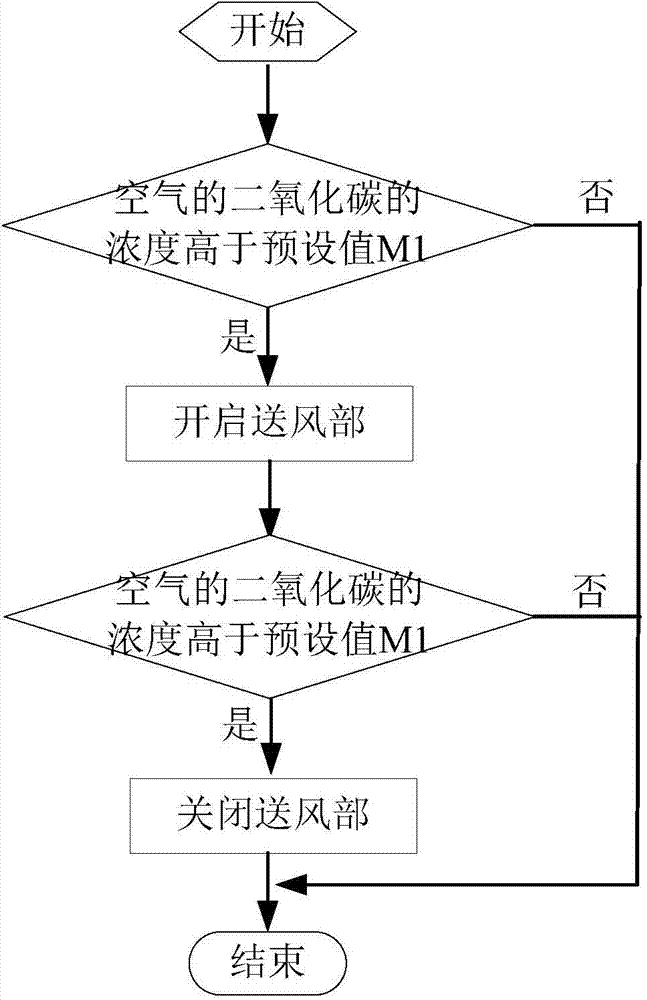

Auxiliary conditioning unit of air conditioner

InactiveCN103542511AIncrease humidityImprove air freshnessCondensate preventionSpace heating and ventilation safety systemsHigh energyWater vapor

The invention discloses an auxiliary conditioning unit of an air conditioner. The auxiliary conditioning unit comprises a condensate water collection portion and an air supply portion. The air supply portion is provided with an air supply pipeline, the condensate water collection portion is provided with an injection structure and a water collection structure, one end of the injection structure is communicated with the air supply pipeline of the air supply portion, and the other end of the injection structure is communicated with the water collection structure. Condensate water generated by the air conditioner is collected through the condensate water collection portion, the injection portion injects the collected condensate water into the air supply pipeline to be combined with air delivered by the air supply portion to form vapor which is used for humidifying an enclosed environment of the air conditioner, the condensate water is delivered through the injection structure, carbon dioxide concentration and humidity of an enclosed space of the air conditioner are regulated effectively to improve air humidity and freshness of the enclosed space of the air conditioner, the technical problem of high energy consumption caused by the fact that a high-power motor is adopted to drive a distribution collider to collide with small-diameter flow so as to generate atomized moisture is avoided, and the auxiliary conditioning unit is more energy saving.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

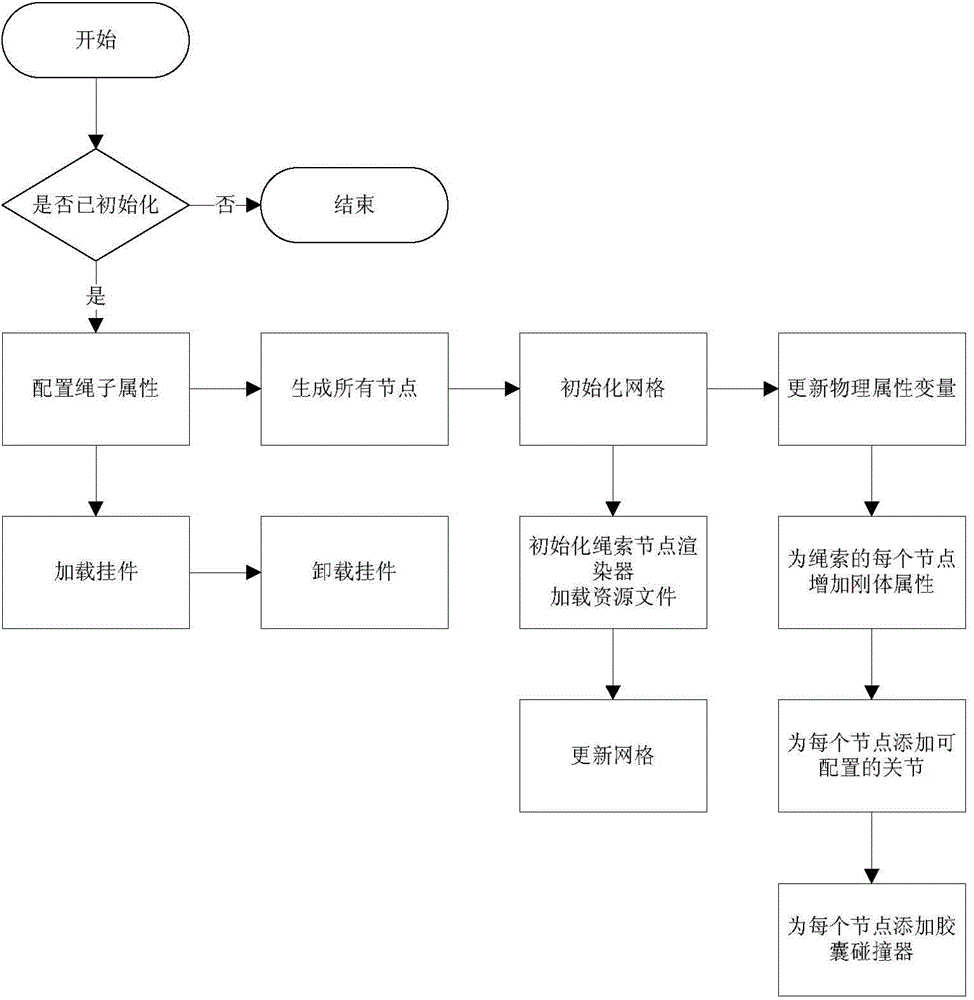

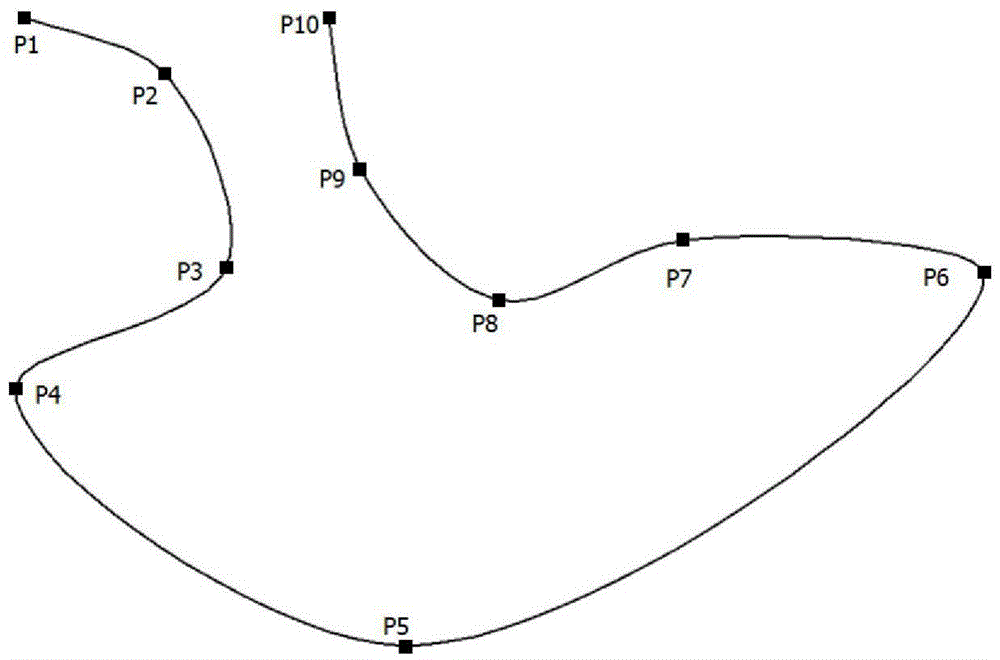

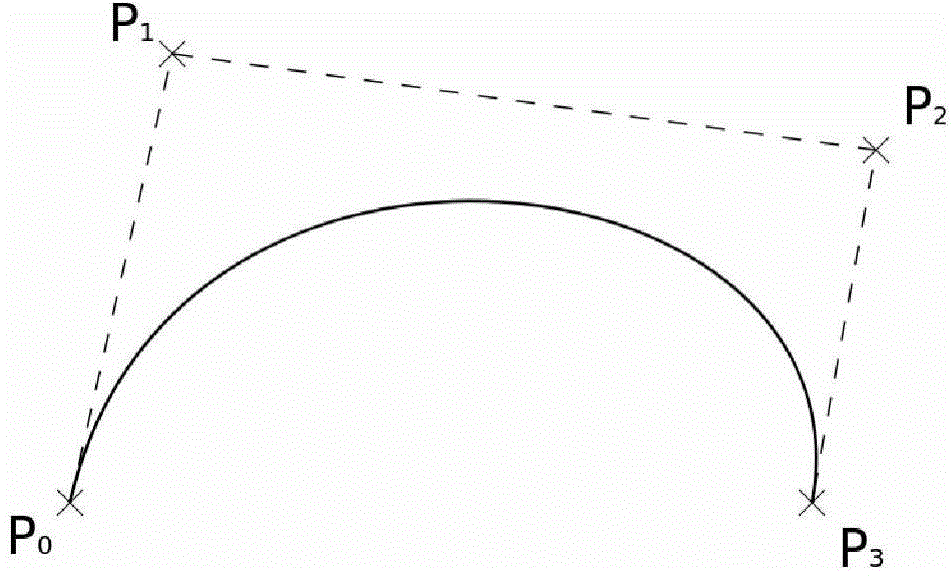

Simulation method for 3D (three-dimensional) rope

InactiveCN104572088AImplement scaling changesSimplified quantitySpecific program execution arrangements3D modellingOperating systemRigid body

The invention discloses a simulation method for a 3D (three-dimensional) rope. The simulation method comprises the following steps: (a) initializing the 3D rope; (b) performing rope attribute configuration, and performing configuration adjustment on attributes of the rope, wherein the configuration adjustment comprises hanging part loading or unloading; (c) generating all nodes after the rope attribute configuration is ended; initializing a network, and then, updating the network wherein the step of initializing the network comprises the flows of initializing a rope node renderer so as to load a resource file; (d) then, start updating the physical attribute variable of the 3D rope, wherein the step of updating the physical attribute variable of the 3D rope concretely comprises the flows of adding rigid body attribute for each node of the rope, adding a configurable joint for each node, and adding a capsule collider for each node. According to the simulation method disclosed by the invention, the integral shape of the rope is controlled by applying the Catmull-Rom Splines curve and the Bezier curve, and moreover, the extension change of the rope is realized by controlling the length of each node and the number of the nodes, and therefore the number of triangles is reduced.

Owner:FUJIAN UNIV OF TECH

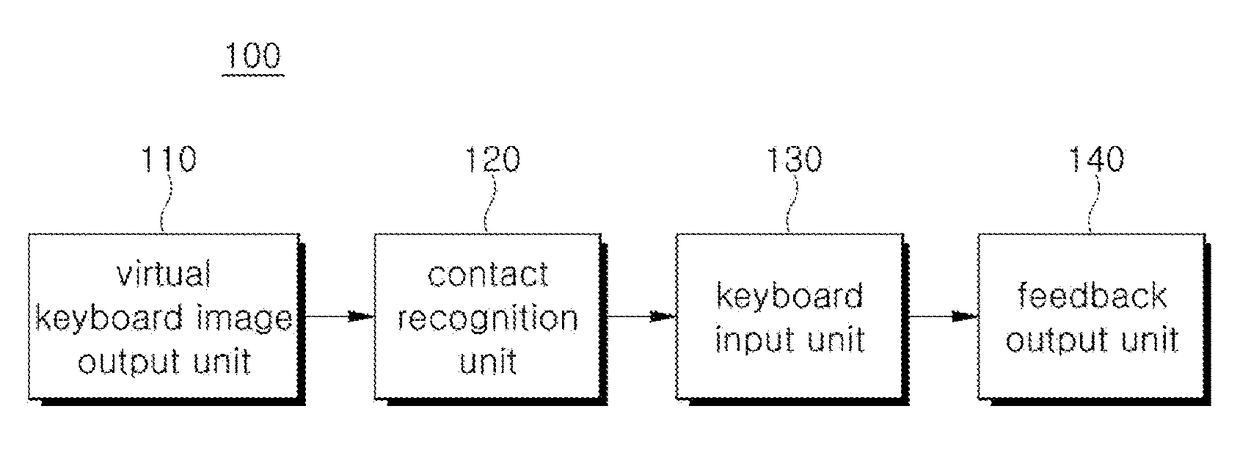

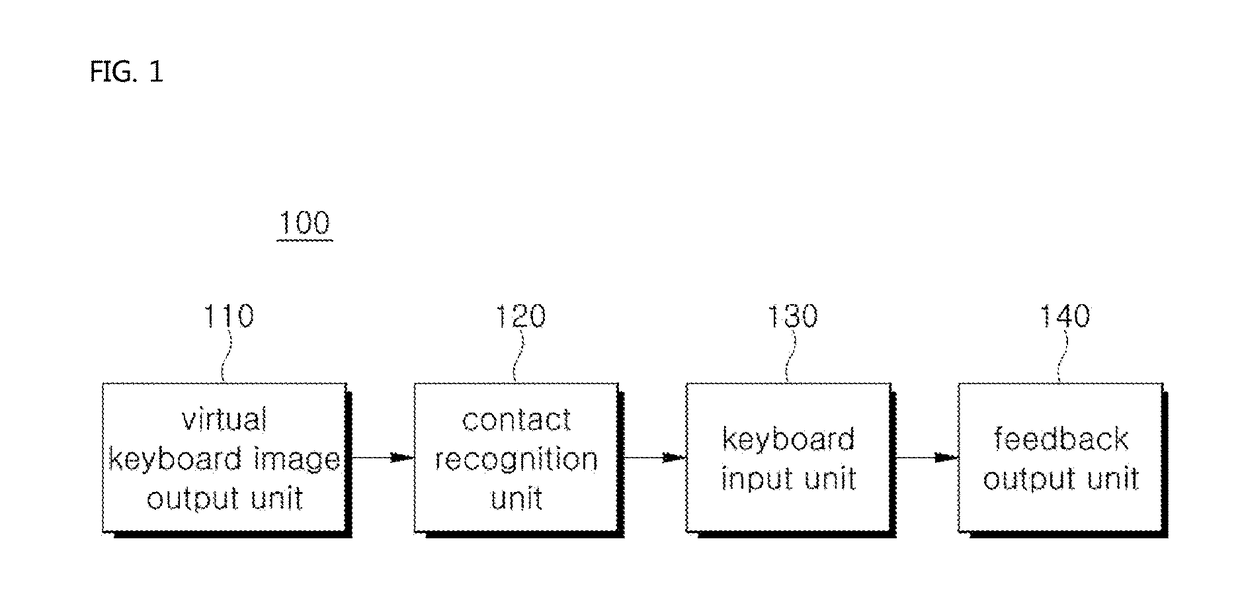

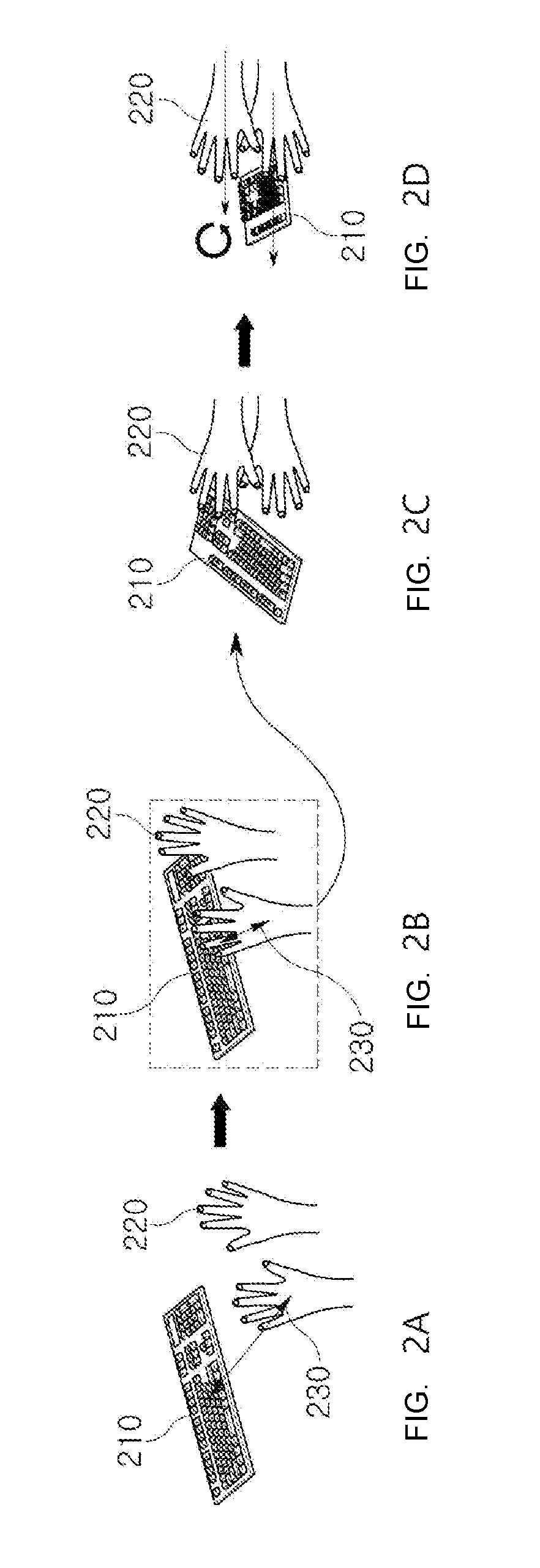

Apparatus for outputting virtual keyboard and method of controlling the same

ActiveUS9927869B2Convenience and efficiencyInput/output for user-computer interactionSound input/outputVirtual spaceMultiple input

Disclosed is an apparatus for outputting a virtual keyboard, the apparatus including: a virtual keyboard image output unit determining coordinates of a virtual keyboard image by using hand information of a user and outputting the virtual keyboard image; a contact recognition unit determining a contact state by using collision information between a virtual physical collider associated with an end point of a user's finger and a virtual physical collider associated with each virtual key of the virtual keyboard image; a keyboard input unit providing multiple input values for a single virtual key; and a feedback output unit outputting respective feedback for the multiple input values. Accordingly, input convenience and efficiency may be provided by outputting the virtual keyboard in a three dimensional virtual space and reproducing an input method using a keyboard form that is similar to the real world.

Owner:KOREA INST OF SCI & TECH

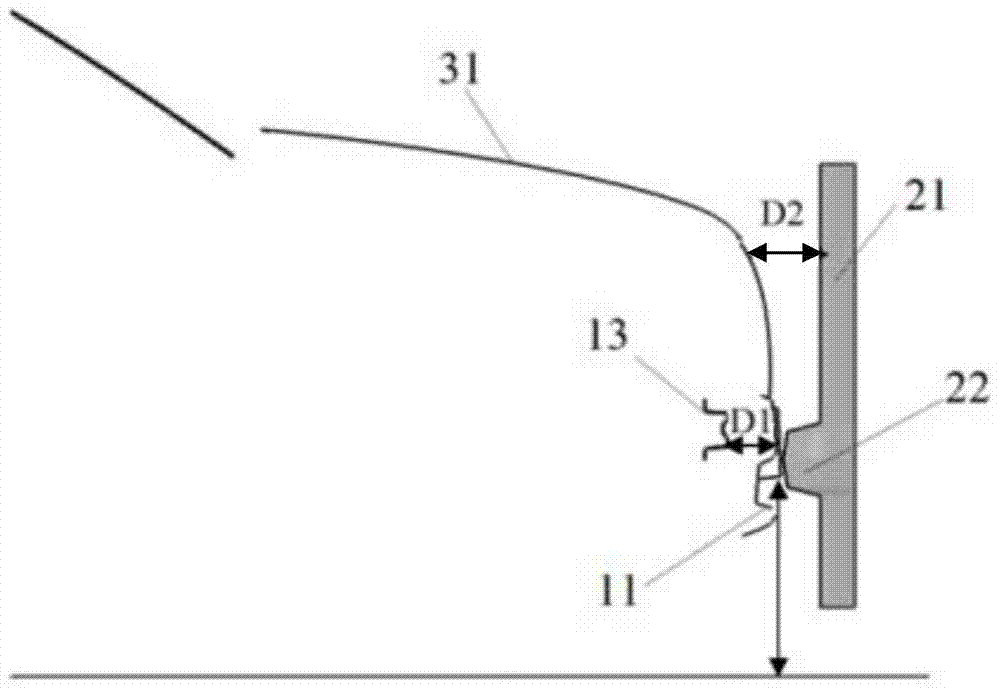

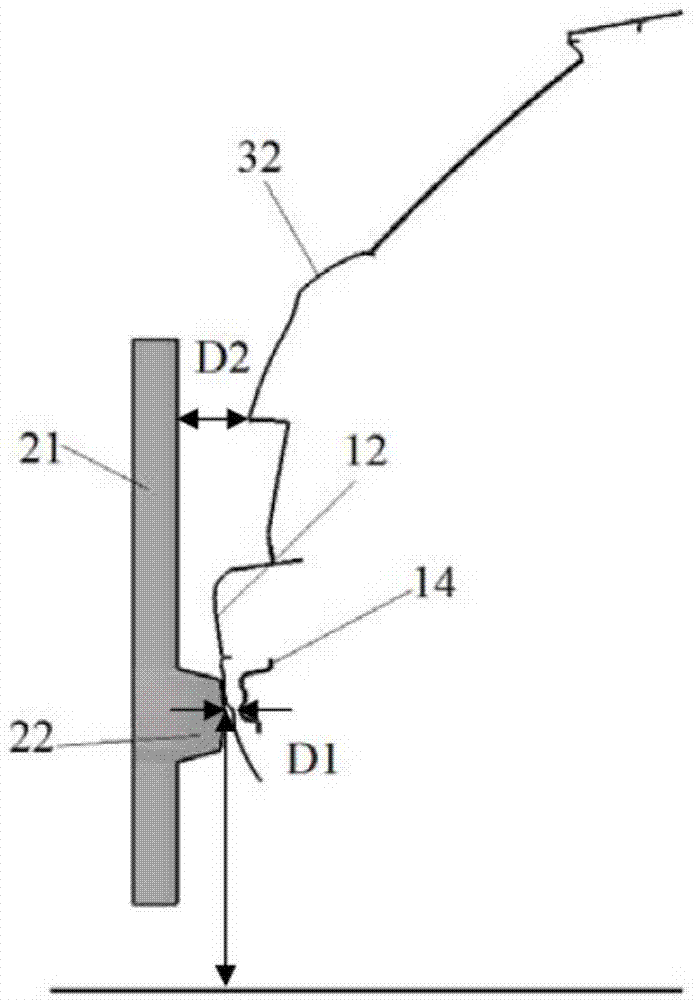

Automobile and design method thereof and checking method for automobile protective device

InactiveCN104850673AAvoid risk of damageImprove performanceSpecial data processing applicationsLow speedEngineering

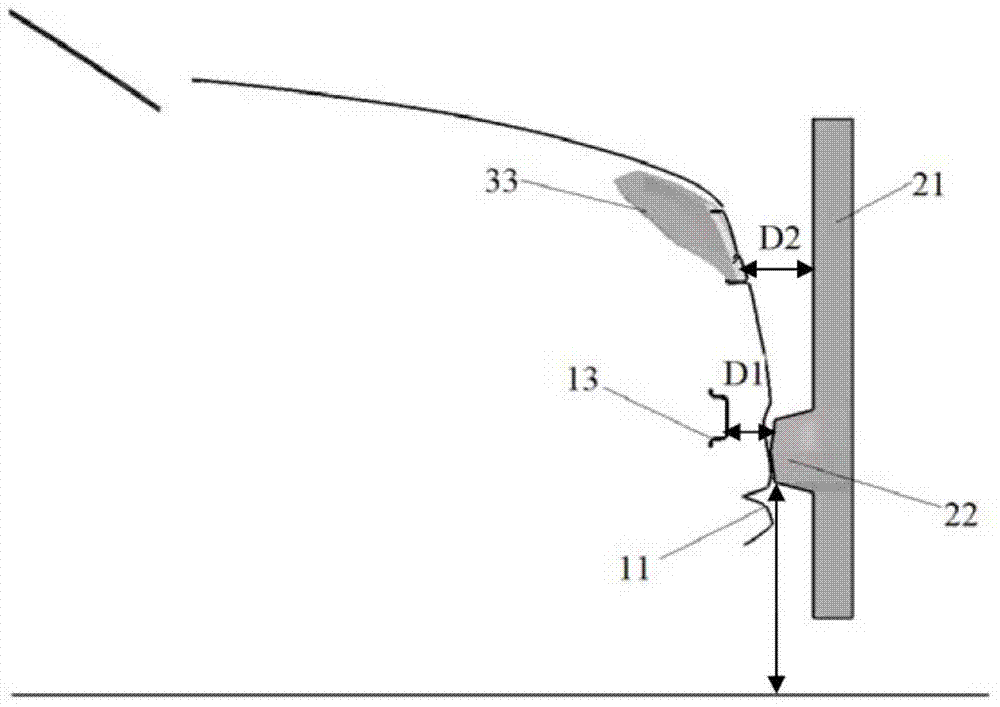

The invention discloses a checking method for an automobile protective device. The checking comprises the following steps: determining a ground level, the modeling of an automobile, and a collider, wherein the collider comprises a main body part and a collision part, tangently setting the surface of the collision part and the surface of a fender-guard skin at a tangent point; measuring the distance D1 between the tangent point on the surface of the collision part and the point on the surface of a fender-guard beam, and a minimum distance D2 between the surface of the main body part and the point on an important component of the automobile; computing relative gap deltaD=D2-D1, when deltaD is more than D0, regarding that the automobile protective device meets the security requirement. The invention further provides an automobile and a design method thereof. Through the adoption of the above technical scheme, the checking of the protective device at the design stage can be realized so that the design is convenient to modify, the checking cost and the design period are reduced; and the potential damage risk of the important component in the low speed collision process can be avoided in the development and design stage of a new model, and the performance of the automobile product is further improved.

Owner:BEIQI FOTON MOTOR CO LTD

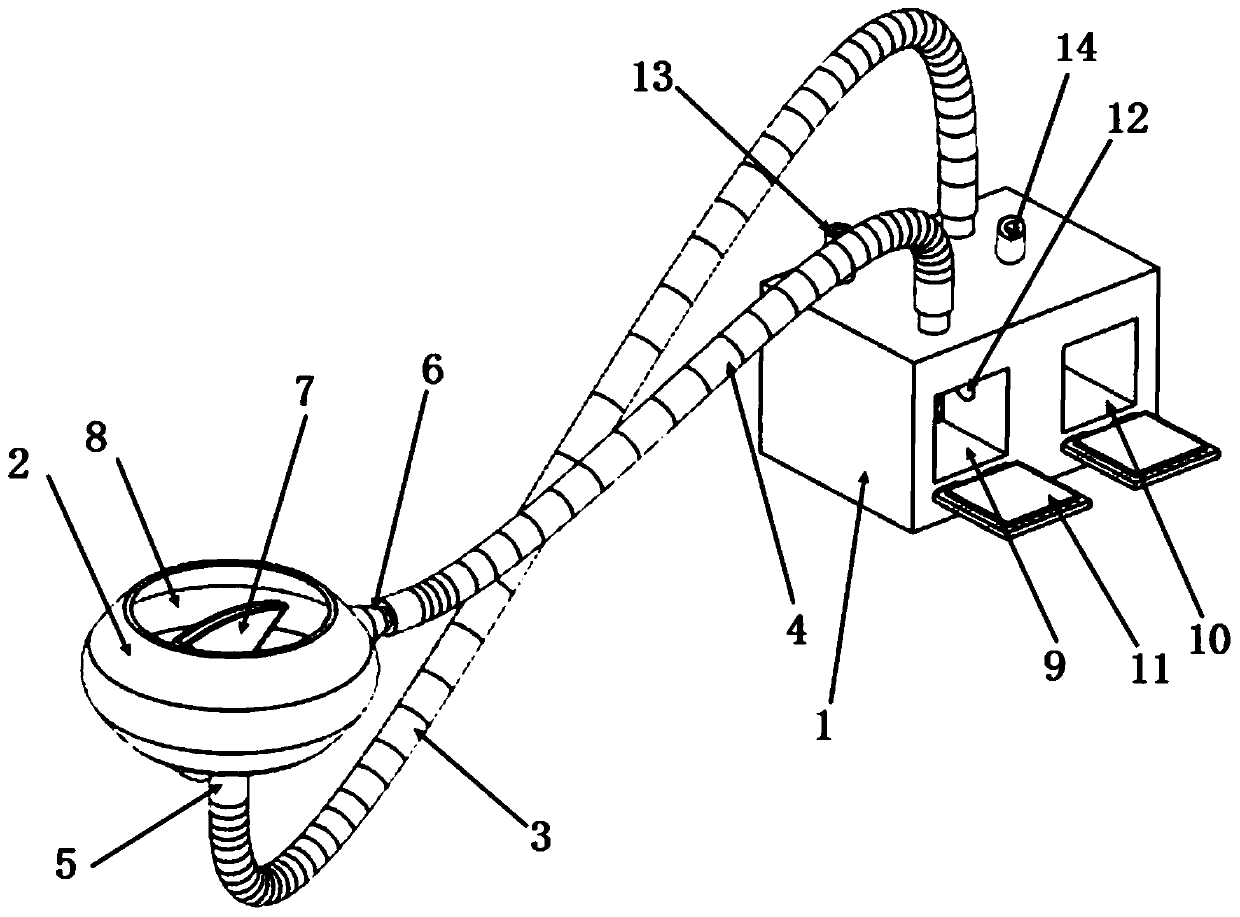

Accurate measuring device and method for detecting dust falling efficiency of spray nozzles of different models

ActiveCN108223001AMaximize dust suppression efficiencyMining devicesDust removalArchitectural engineeringSpray nozzle

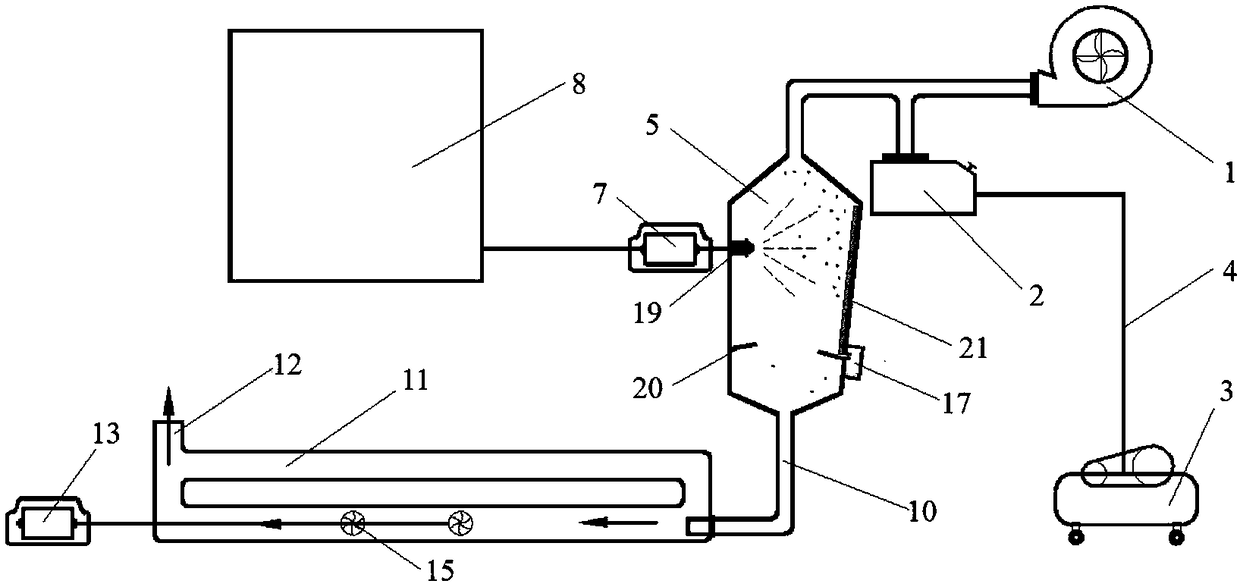

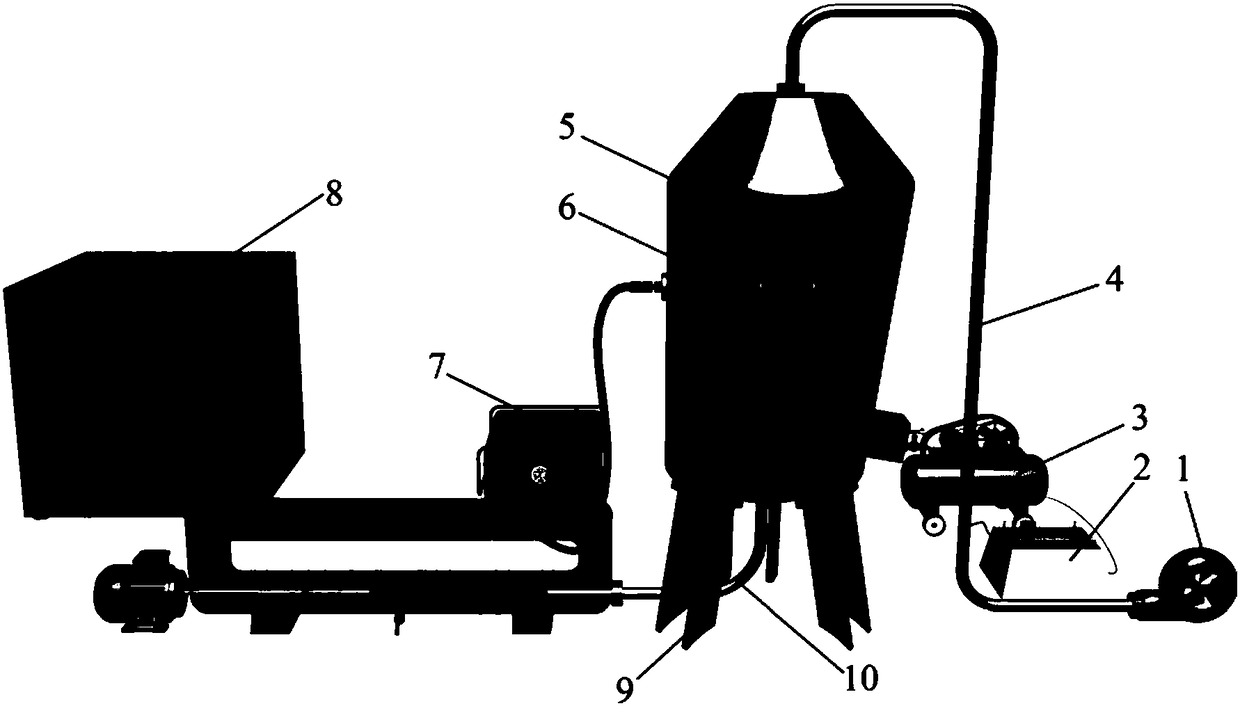

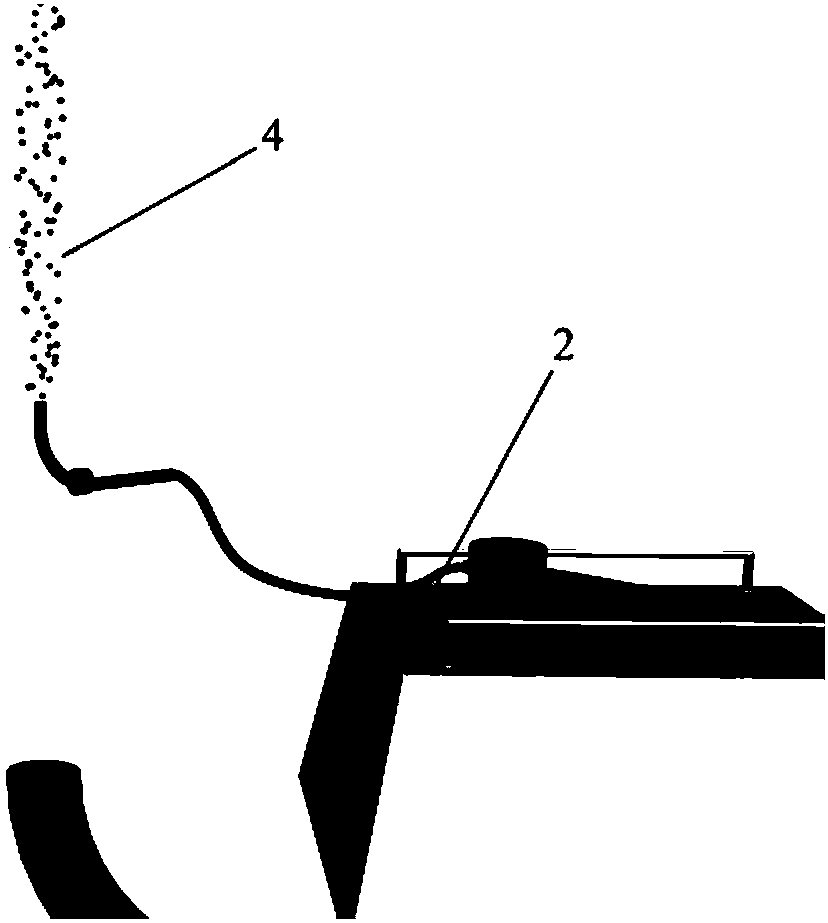

The invention discloses a mining accurate measuring device and method for detecting the dust falling efficiency of spray nozzles of different models. An air blower communicates with a dust outlet of afirst dust generator through a first branched pipe and communicates with a dust inlet of a dust fog collider through a second branched pipe, the first branched pipe communicates with the second branched pipe, and the corresponding spraying nozzles in the dust fog collider communicate with a water tank through a pressurizing pump. The bottom of the dust fog collider communicates with a circular type dust collector through a first pipeline, and a stirring mechanism is arranged in the circular type dust collector and connected with a motor. Under the environment of an experiment, the dust falling efficiency of the spray nozzles of the different models on dust of different particle sizes and characteristics can be compared, the optimum particle size range of dust capturing through fog drops generated by all the spray nozzles is obtained, effective reference and technology support can be provided for design of the spray nozzle selected model and atomizing scheme of different dust generation operation areas of a coal mine, and thus the suitable spraying nozzles are mounted on the different coal mine work faces to achieve maximization of the dust falling efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

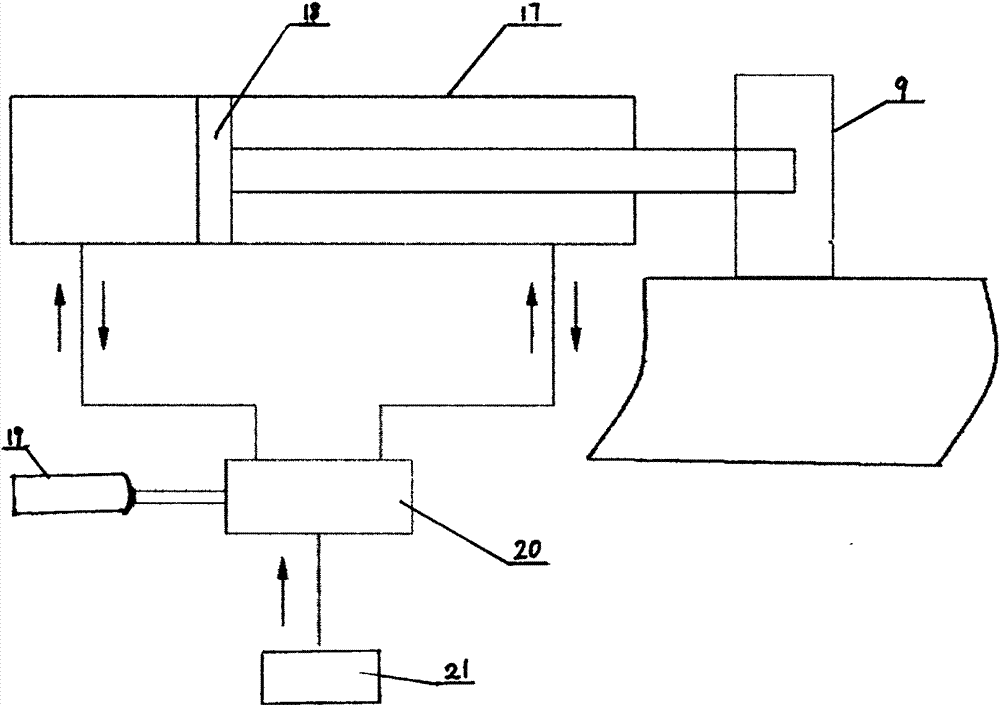

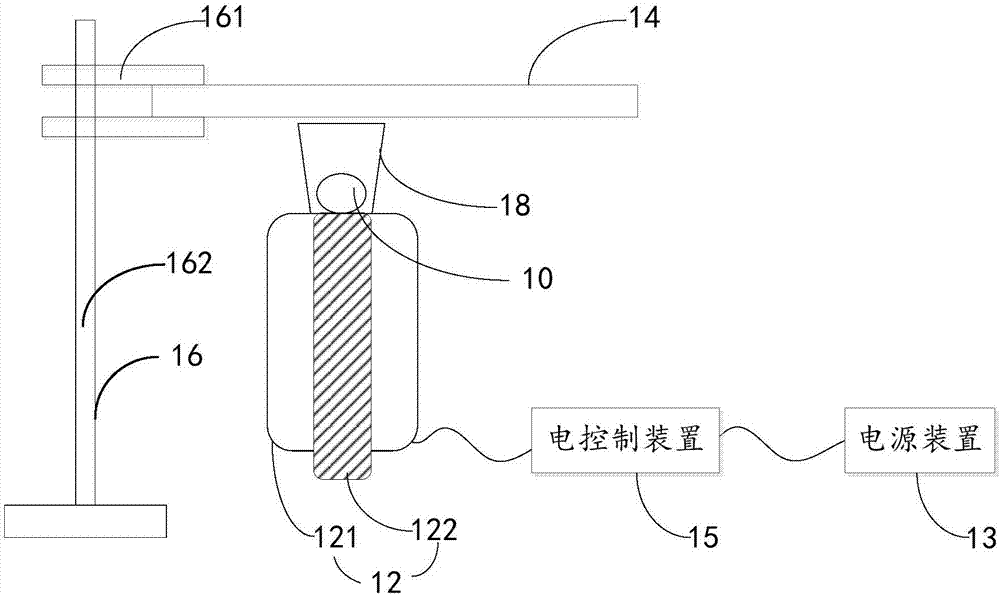

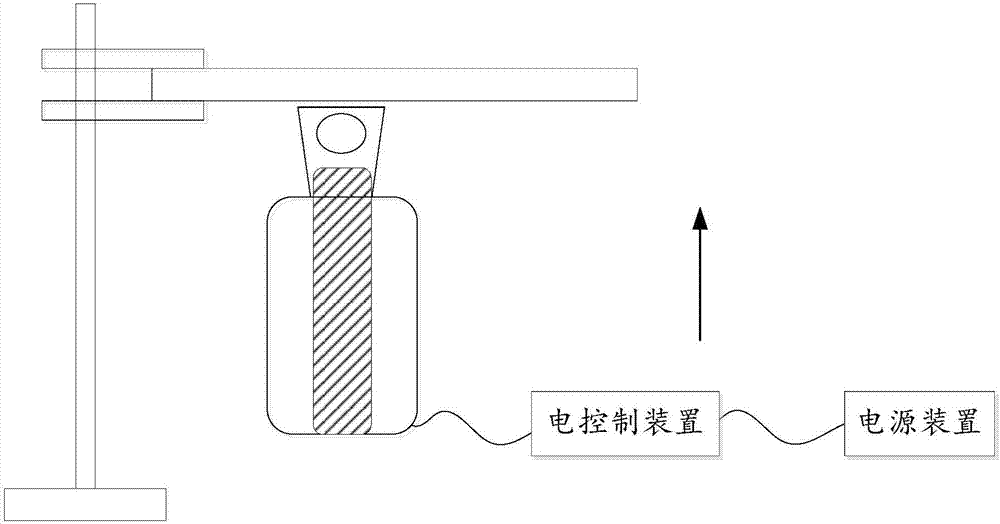

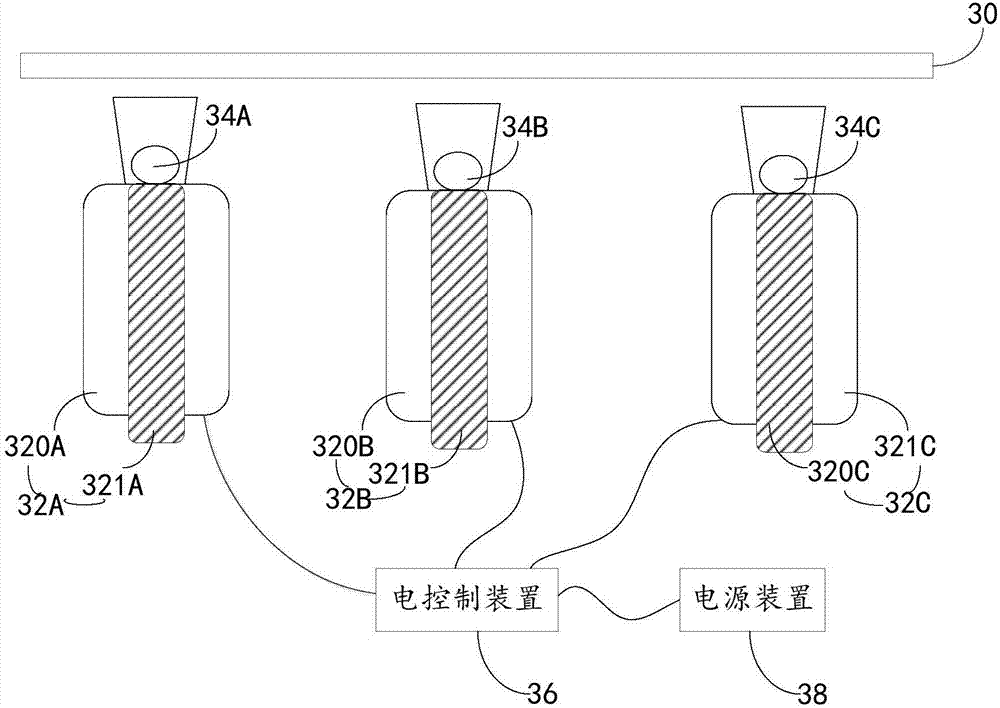

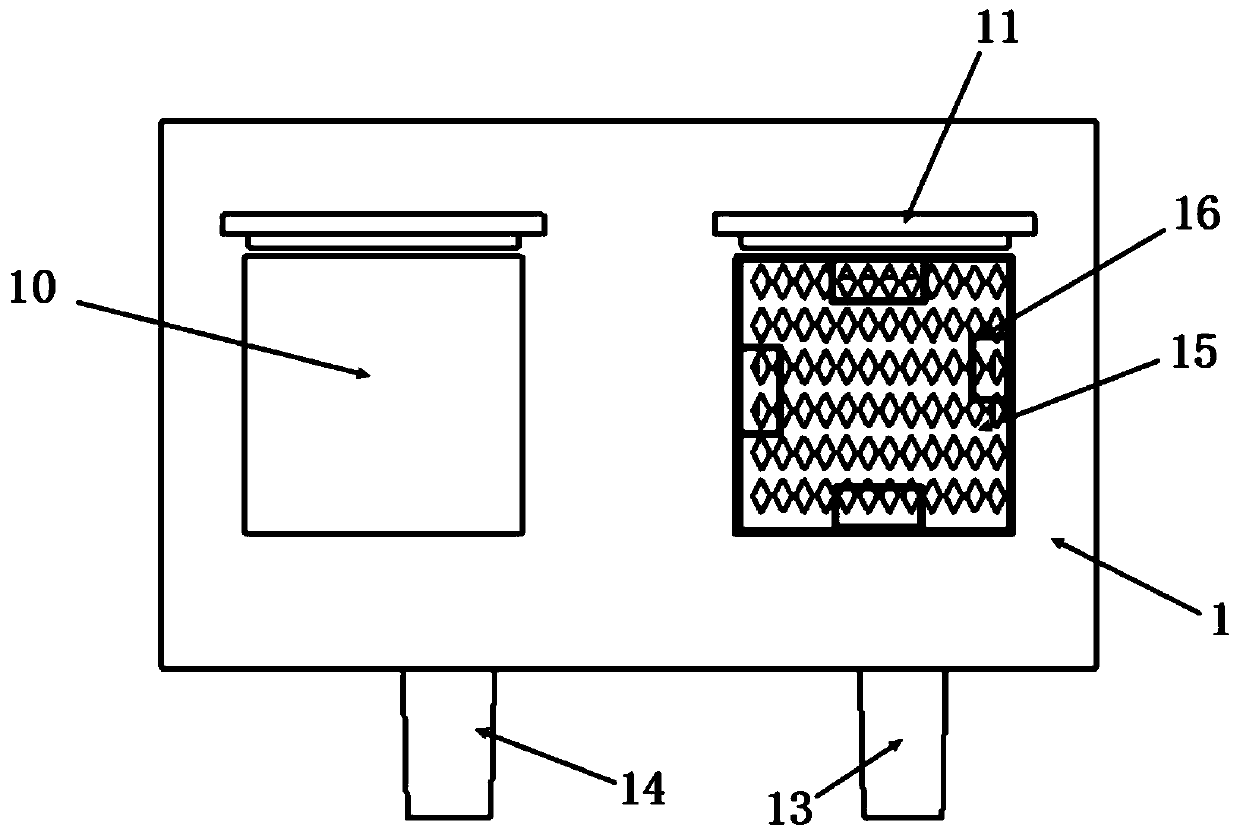

Bubble detection system and bubble detection method for display panel

The invention discloses a bubble detection system and a bubble detection method for a display panel. The detection system comprises a collider and a drive device, wherein the drive device comprises a drive element and a motion element; the drive element drives the motion element to move; the motion element collides with the collider or drives the collider to crash into the display panel to measure the bubble condition of the display panel, wherein the motion direction of the motion element faces toward the display panel. According to the bubble detection system and the bubble detection method for the display panel, the accuracy of the bubble detection result can be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Ship body section weld seam derusting device

InactiveCN110497322ASolve the problem of generating a lot of dustImprove cleaning efficiencyAbrasive machine appurtenancesClosed loopWeld seam

The invention discloses a ship body section weld seam derusting device. The ship body section weld seam derusting device comprises a main engine and a working cover; the working cover comprises a cavity with an opening; the opening of the cavity faces a to-be-derusted weld seam; the cavity is provided with a first joint and a second joint which communicate with the cavity; the main engine comprises an output portion and a receiving portion; the output portion communicates with the first joint through a first pipeline and is used for delivering high-pressure gas mixed with a collider into the cavity and sprinkling the high-pressure gas onto the to-be-derusted weld seam; and the receiving portion communicates with the second joint through a second pipeline and is used for recycling and conveying the collider and dropped iron rust into the receiving portion. Through an output-receiving closed loop structure, junction is performed on the derusting-receiving process, the collider collides with the iron rust attached to the weld seam, the iron rust is vibrated to fall off and then directly enters the receiving portion along with the gas flow in the cavity instead of being discharged outof the cavity, the whole derusting-receiving process is isolated from the outside, and thus the problem that a large amount of dust is generated by a traditional derusting mode is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Nanomaterial processing system

A nanomaterial processing system is constructed to include a compressor adapted to compress a flow of air / liquid into a high-pressure flow of air / liquid, a material feeder adapted to feed a material into the high-pressure flow of air / liquid passing out of the compressor, enabling the fed material to be mixed with the high-pressure flow of air / liquid into a high-pressure material flow; a shunt collider adapted to shunt the high-pressure material flow into two sub-flows and to let the shunt sub-flows to collide into a collided material flow, and a high-speed cutting unit, which uses a diamond coating-coated cutting wheel to cut solid substances the collided material flow.

Owner:YEU MING TAI CHEM INDAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com