Ship body section weld seam derusting device

A hull and rust technology, which is applied in the field of derusting devices for hull segmented welds, can solve the problems of endangering workers' health, a large amount of rust dust, and low work efficiency, and achieve the effects of increasing coverage, improving recovery efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

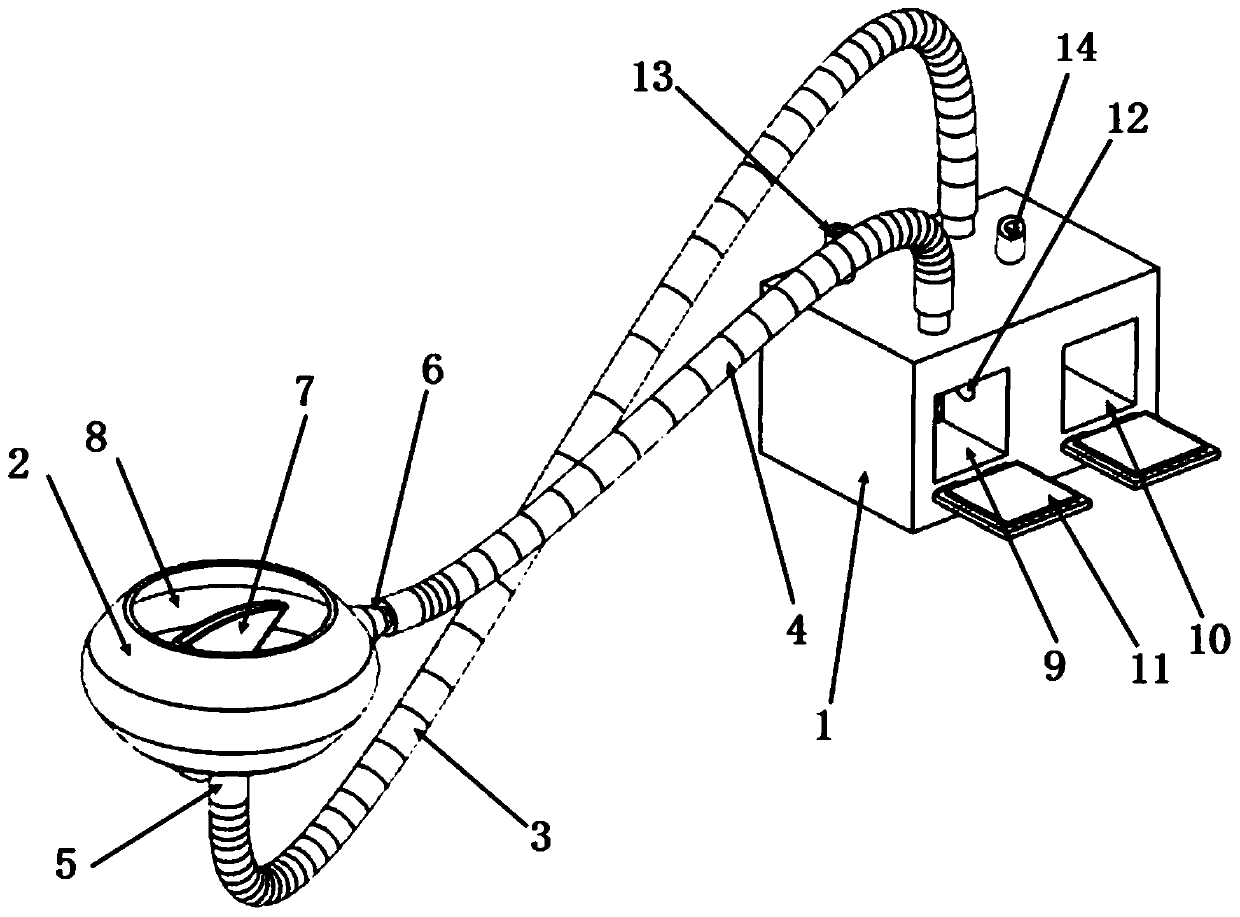

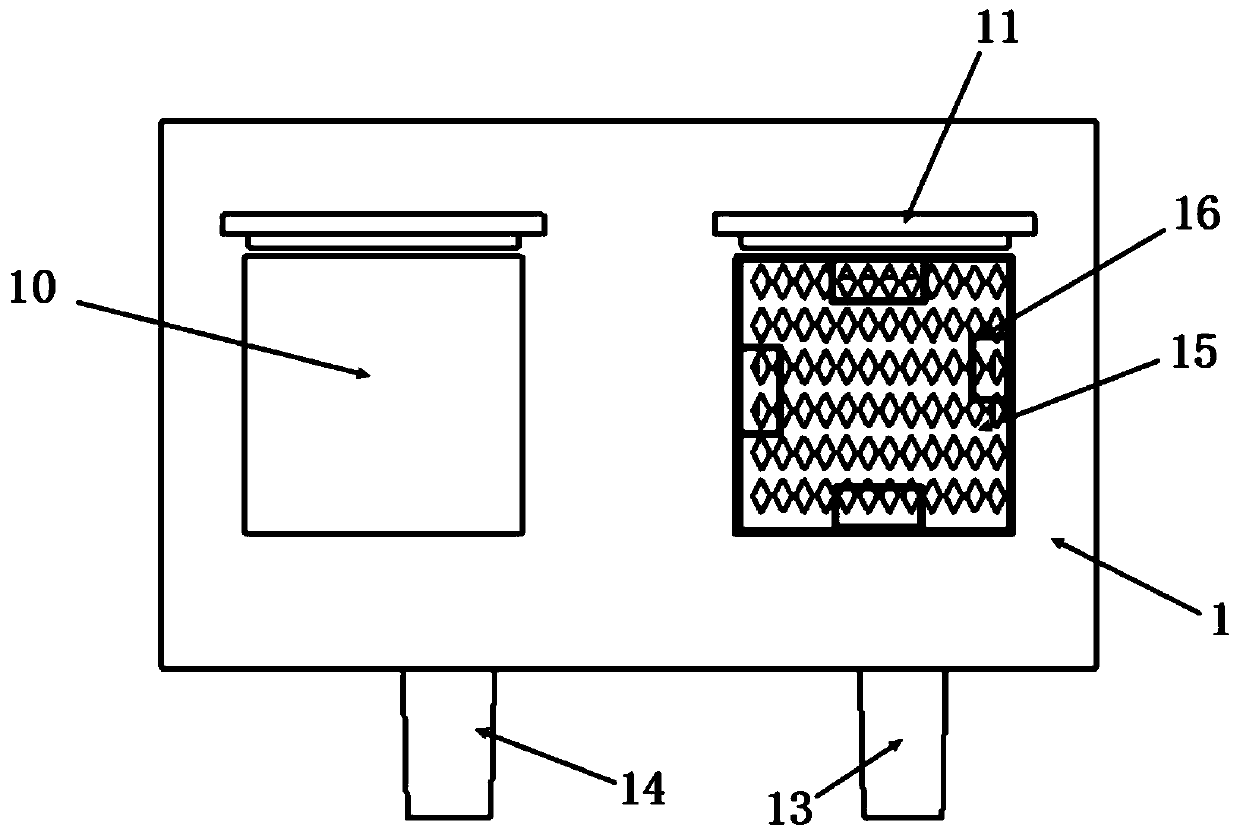

[0033] In a typical implementation of the present application, such as Figure 1-Figure 2 As shown, a rust removal device for hull segment welds is proposed.

[0034] It includes a main machine 1 and a working cover 2, the working cover includes a cavity 8 with an opening, the opening of the cavity faces the weld seam with rust removal, and the cavity is provided with a first joint 5 communicating with the cavity and the second joint 6, the main engine includes an output part and a receiving part, the output part communicates with the first joint through the first pipe 3, and the output part transports the high-pressure gas mixed with the collision body into the cavity and sprays it on the On the weld to be derusted, the rust at the weld is separated from the weld by the impact of the collision body, and the receiving part is connected to the second joint through the second pipeline 4, and the receiving part is used to recover the collision body and the fallen rust .

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com