Refractory brick end milling and dedusting device

A dust removal device and a technology for refractory bricks, applied in the field of grinding machines, can solve problems such as a large amount of dust in refractory bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

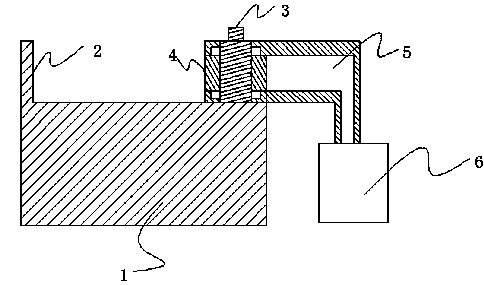

[0010] Such as figure 1 As shown, the refractory brick end mill dust removal device is composed of a working table 1, a limit baffle 2, an end milling mechanism 3, a milling cutter 4, a pipeline 5 and a dust remover 6, wherein the upper surface of the working table 1 A vertical limit baffle 2 is provided on the left side, and an end milling mechanism 3 is provided on the right side of the upper surface of the worktable 1 .

[0011] Such as figure 1 As shown, the end milling mechanism 3 includes a milling cutter 4 and a milling cutter cover, the milling cutter cover communicates with a pipeline 5 , and the other end of the pipeline 5 is connected to a dust collector 6 .

[0012] Place the refractory bricks on the work table 1 and push the refractory bricks forward along the direction of the limit baffle 2, the dust cut by the milling cutter 4 will be absorbed and removed by the dust collector 6 through the pipe 5, thereby preventing the dust from scattering to the greatest ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com