Method for preparing personalized biological culture medium raw material from beer waste yeast

A technology of beer waste yeast and culture medium, which is applied in the field of preparation of beer waste yeast personalized biological culture medium raw materials, and can solve the problems of incapable scale production, low product yield, and technical limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

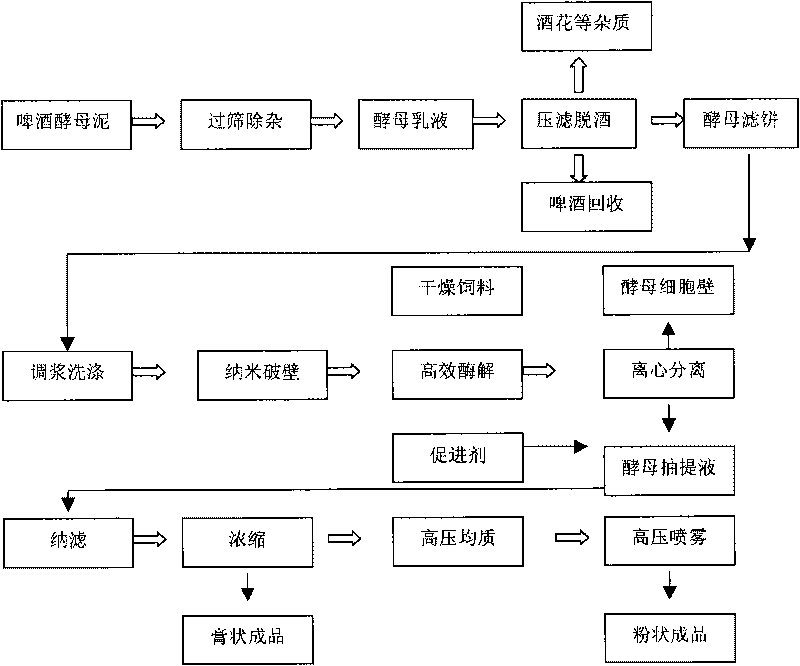

Image

Examples

preparation example Construction

[0038] The invention provides a preparation method of a biological culture medium raw material, comprising the steps of:

[0039] (1) breaking the wall of the waste beer yeast through a nano collider under the conditions of 30-45°C and 70-100Mpa to obtain the broken yeast;

[0040] (2) Mix the broken yeast and one or more substances selected from protease or dextranase at 45-65°C for 3-24 hours to obtain yeast hydrolyzate; the protease is selected from papain or dispase; and

[0041] (3) centrifuging the yeast enzymatic hydrolyzate and performing nanofiltration with a molecular weight of 1000 to obtain a raw material for a biological culture medium.

[0042] In the enzymolysis part of step (2), it can be carried out in a variety of ways, such as mixing the broken yeast, glucanase and enzymolysis accelerator to obtain the yeast enzymolysis solution, the mixing time is 3-24 hours, relatively Preferably for 5-15 hours, the mixing temperature is 45-65°C, preferably 51-55°C; or ...

Embodiment 1

[0094] Production Method No.1 of Beer Waste Yeast Personalized Biological Medium Raw Material

[0095] 1500Kg of fresh beer yeast stock solution with a water content of 86% and a material temperature of 7.8°C was sieved twice through 100 mesh and 120 mesh, and the beer with useful value was recovered after dealcoholization by a plate and frame filter press. After beating, use a filter press machine to cycle filter and wash twice to obtain relatively high-purity yeast milk, and then use a nano-collider to physically break the wall under high pressure, pressure: 85Mpa, break the wall once, and the yeast liquid after breaking the wall Enter the reaction vessel and heat up rapidly to 95°C in 30 minutes and keep the temperature for 20 minutes, and quickly cool down to 55°C and add 10% globin peptide to carry out papain (enzyme activity 80IU, the consumption of papain is based on the dry matter of yeast clean milk , 0.2w / w%) enzymatic hydrolysis for 12 hours, the yeast enzymolysis s...

Embodiment 2

[0099] Production Method No.2 of Beer Waste Yeast Personalized Biological Medium Raw Material

[0100]1500Kg of fresh beer yeast stock solution with a water content of 86% and a material temperature of 7.8°C was sieved twice through 100 mesh and 120 mesh, and the beer with useful value was recovered after dealcoholization by a plate and frame filter press. After beating, use a filter press machine to cycle filter and wash twice to obtain relatively high-purity yeast milk, and then use a nano-collider to physically break the wall under high pressure, pressure: 85Mpa, break the wall once, and the yeast liquid after breaking the wall Enter the reaction vessel and rapidly heat up to 95°C in 30 minutes and keep the temperature for 20 minutes, and quickly cool down to 55°C and add 15% molasses yeast to carry out neutral protease (enzyme activity 80IU, the consumption of neutral protease is based on the dry matter of yeast clean milk 5w / w%) enzymatic hydrolysis for 10 hours, the yeas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com