Patents

Literature

341results about How to "Motion synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

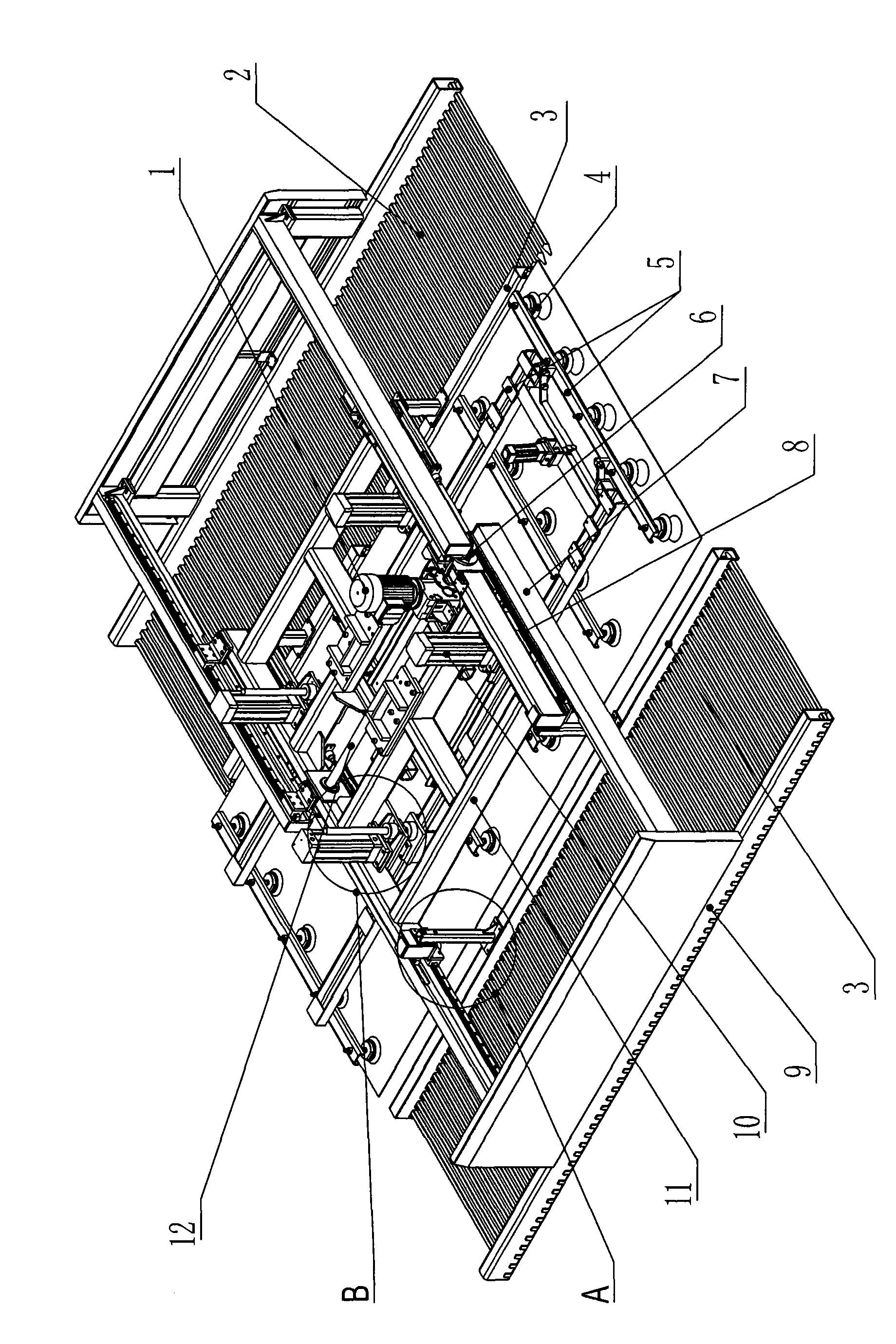

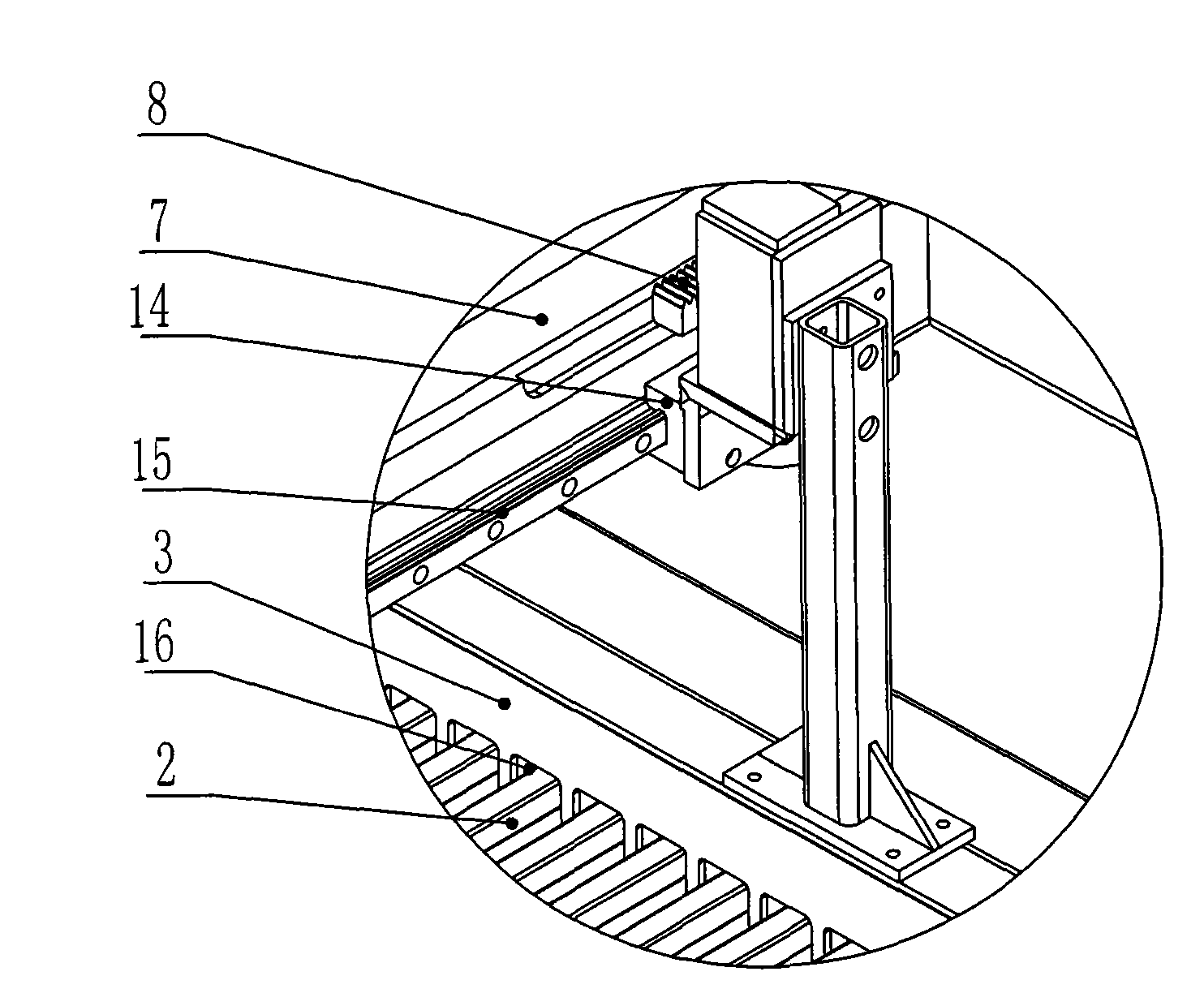

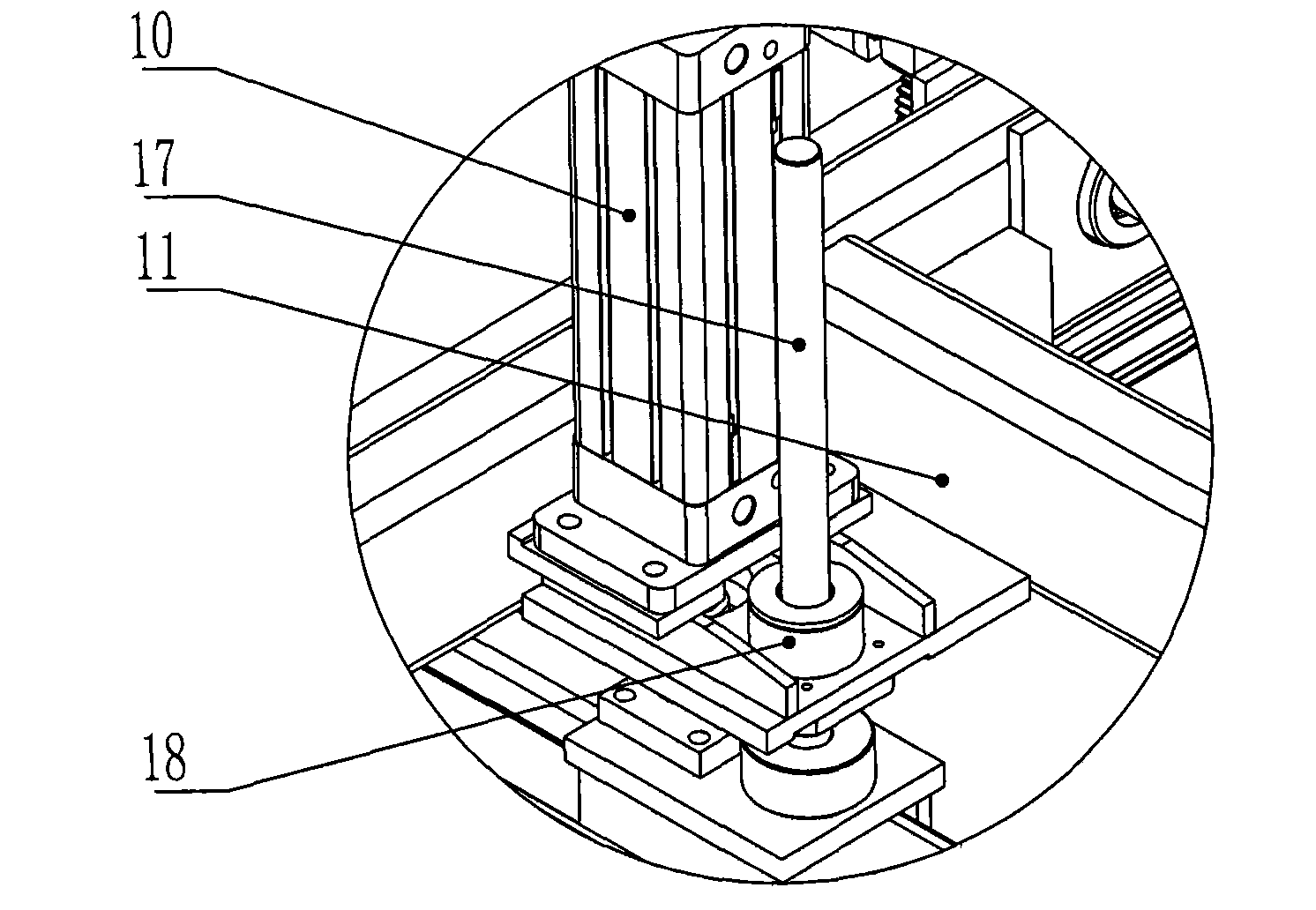

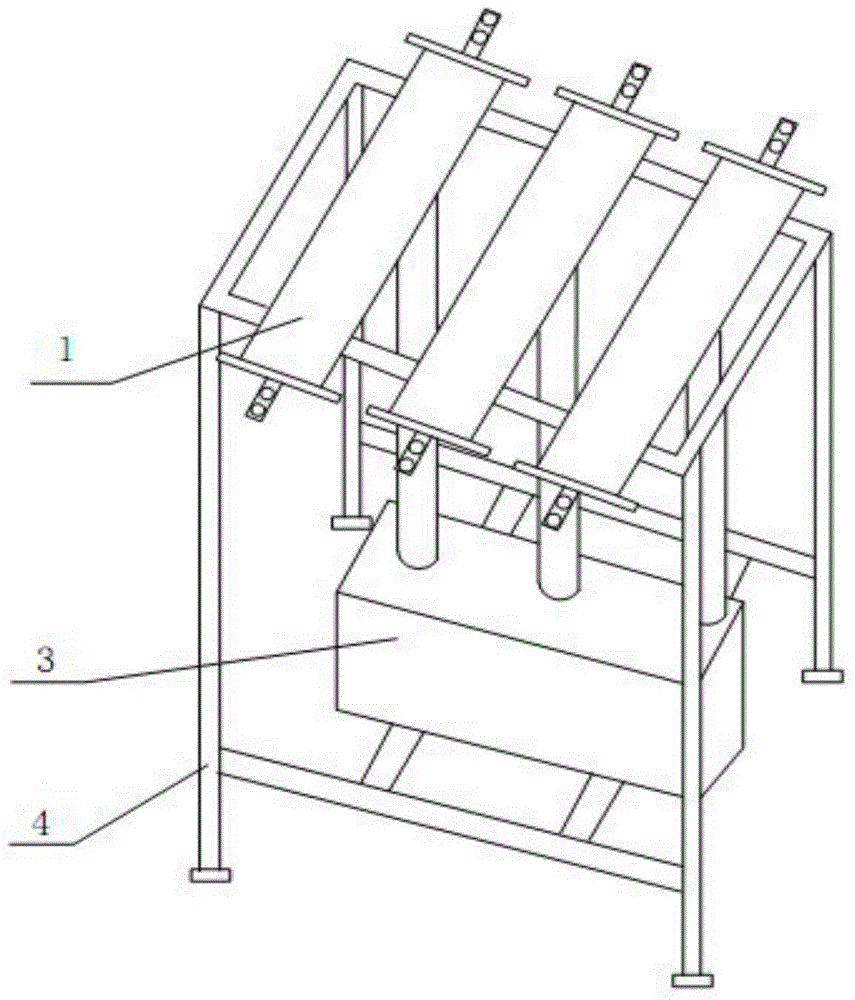

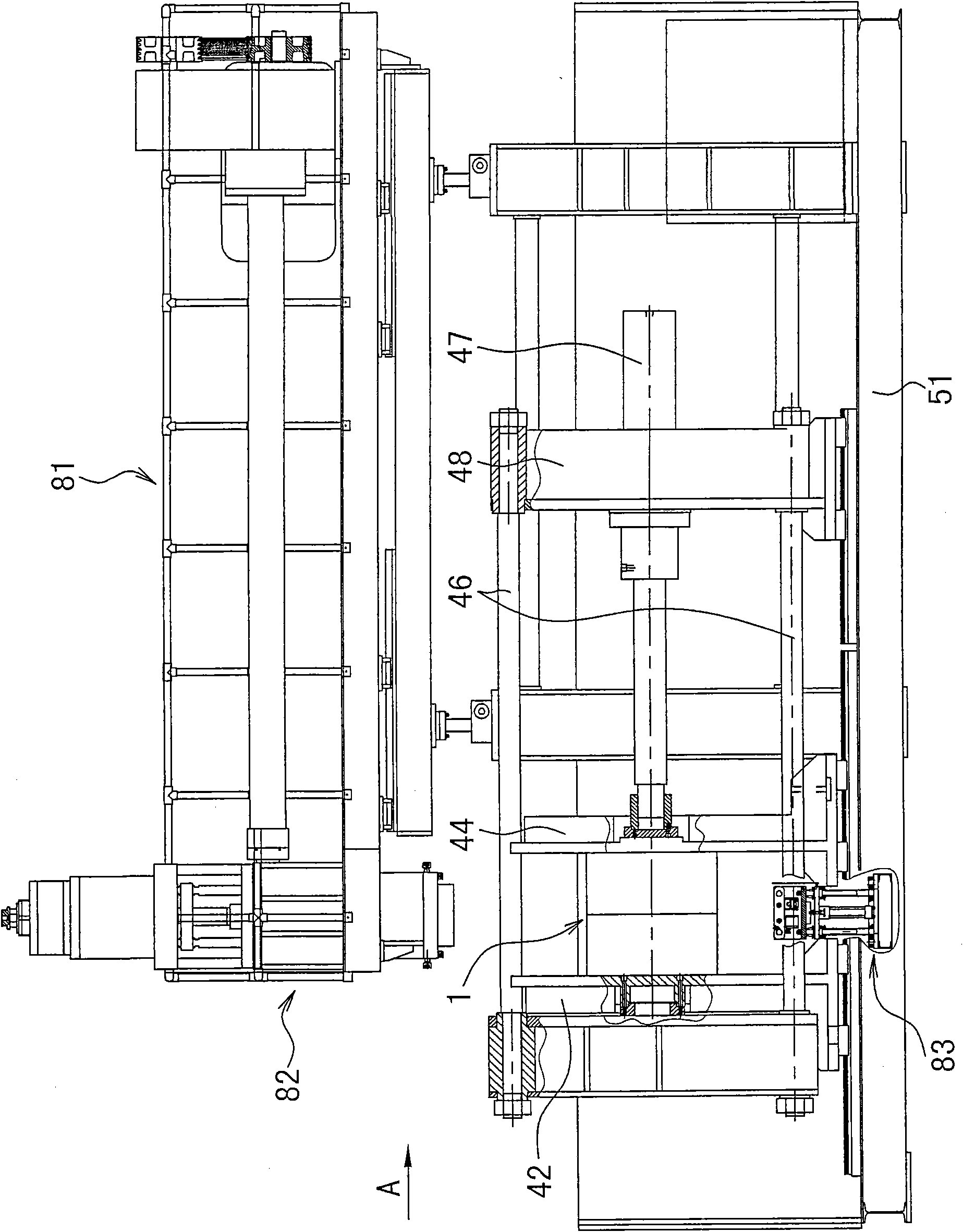

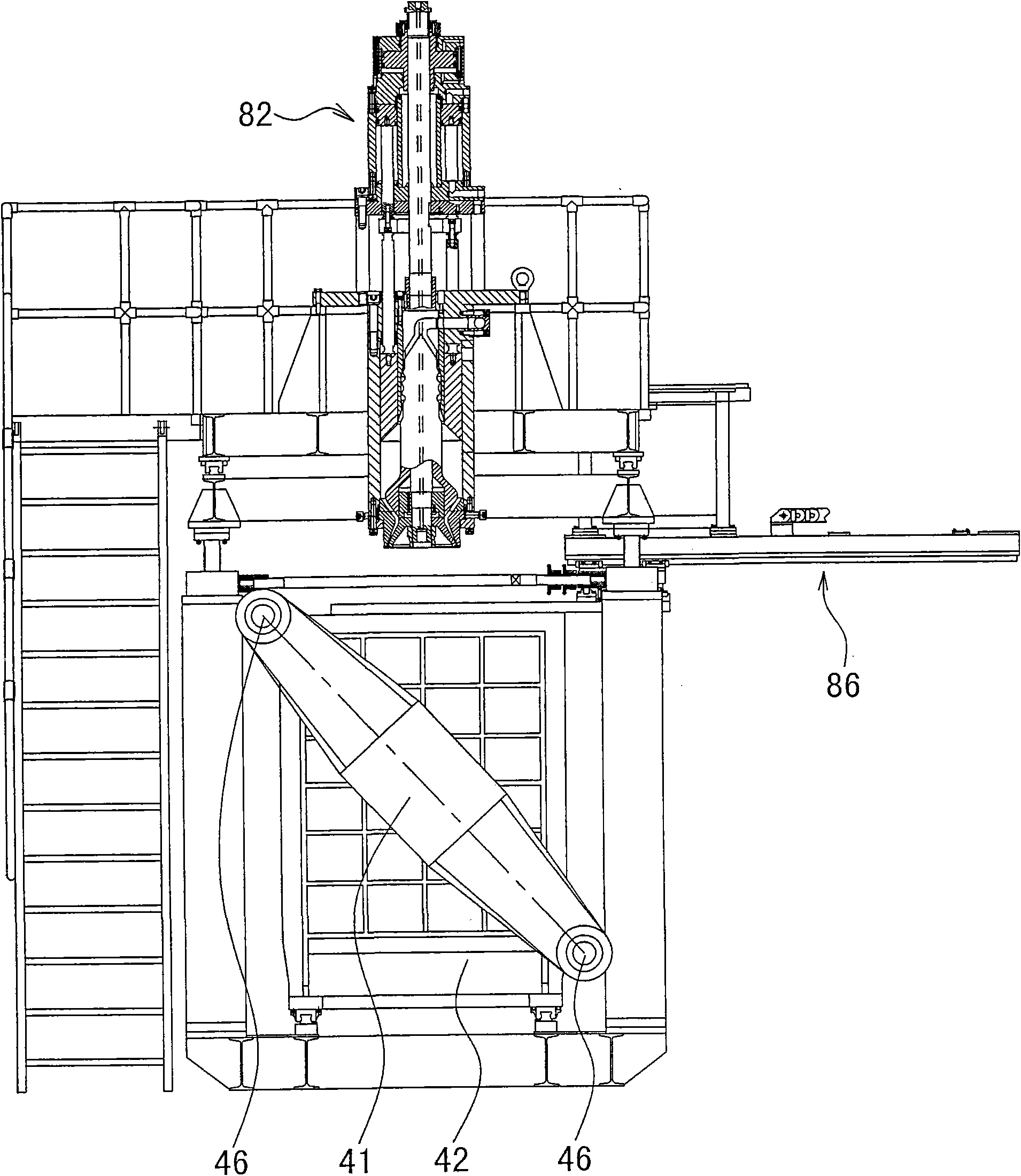

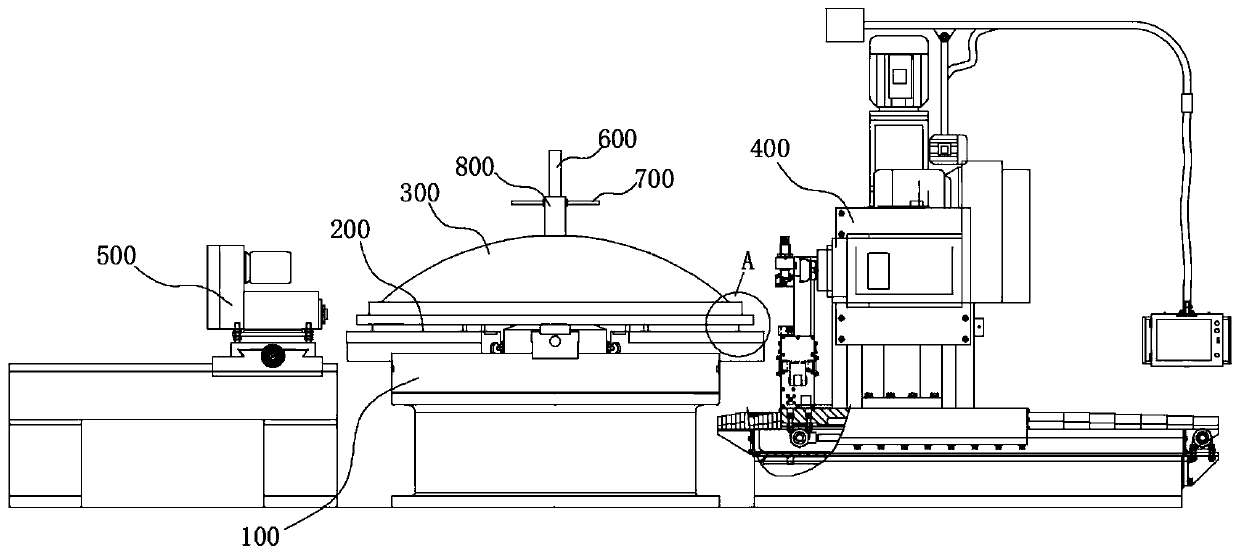

Laser-cutting automatic loading and unloading manipulator

ActiveCN101628362ASynchronous liftingMotion synchronizationGripping headsLaser beam welding apparatusDrive shaftEngineering

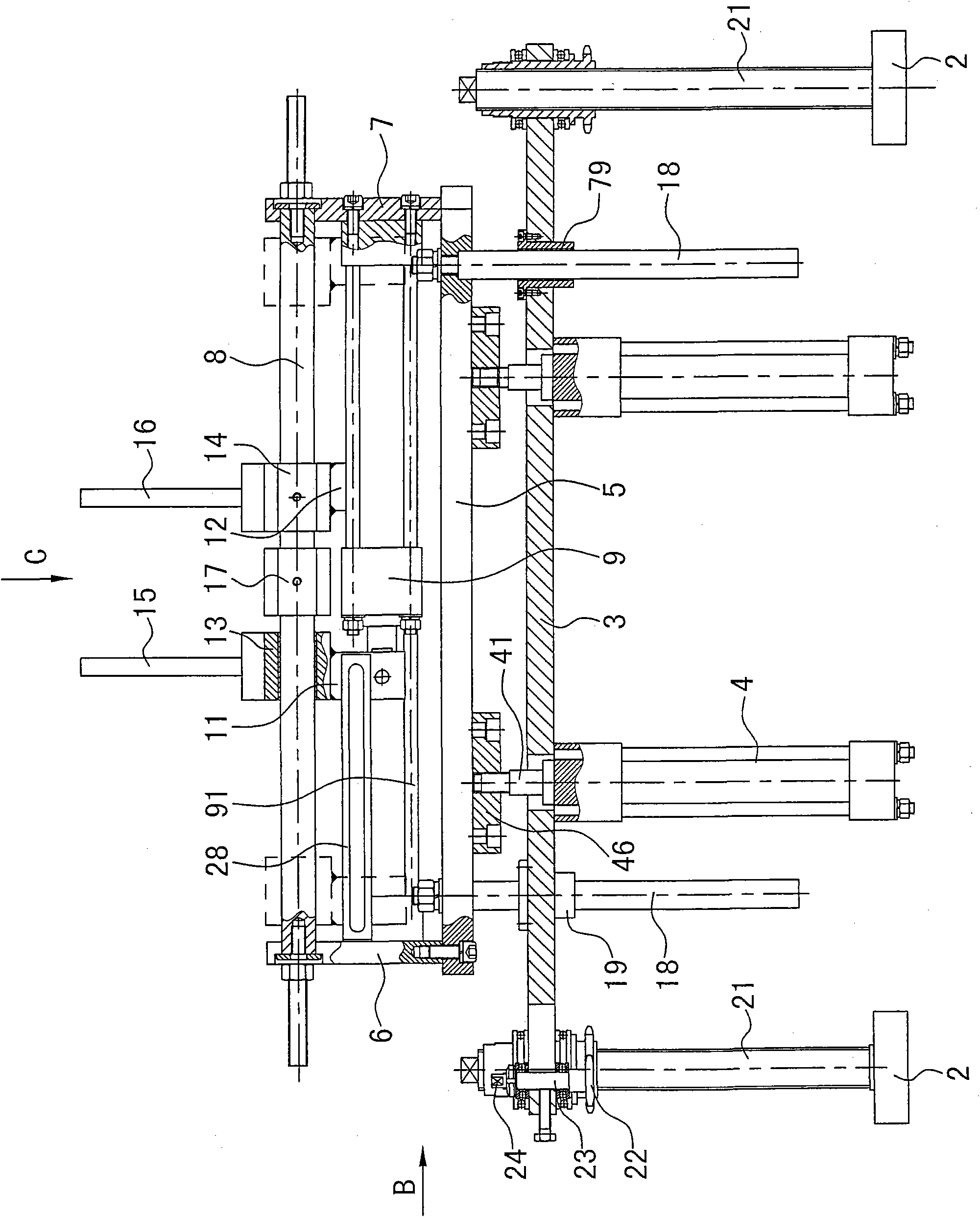

The invention discloses a laser-cutting automatic loading and unloading manipulator in the field of lathes, which comprises a grid-shaped sucking disk rack, wherein a plurality of sucking disks are arranged at the lower side of the sucking disk rack, a support rack connected with a feeding mechanism of a lathe is arranged above the sucking disk rack, and a lifting mechanism that drives the sucking disk rack to do ascending and descending motion is arranged on the support rack; a reducer motor is also arranged on the support rack, the middle part of a transmission shaft is connected with the reducer motor by a transmission way, the transmission shaft is arranged on the support rack through a bearing, two ends of the transmission shaft are respectively provided with gears, the upper side and the lower side of each gear are respectively meshed with a gear rack, the gear racks are arranged on four parallel beams, the beams and the support rack are connected by a guide slider mechanism, outer end parts of the two beams positioned at the lower side of the gear and outer end parts of the two beams positioned at the upper side of the gear are respectively connected with a horizontally-arranged unloading fork, the two unloading forks are positioned in a same horizontal height, and stopping rods are respectively arranged at the upper sides of the adjacent ends of the two unloading forks. The invention can automatically load and unload and improve the production efficiency.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

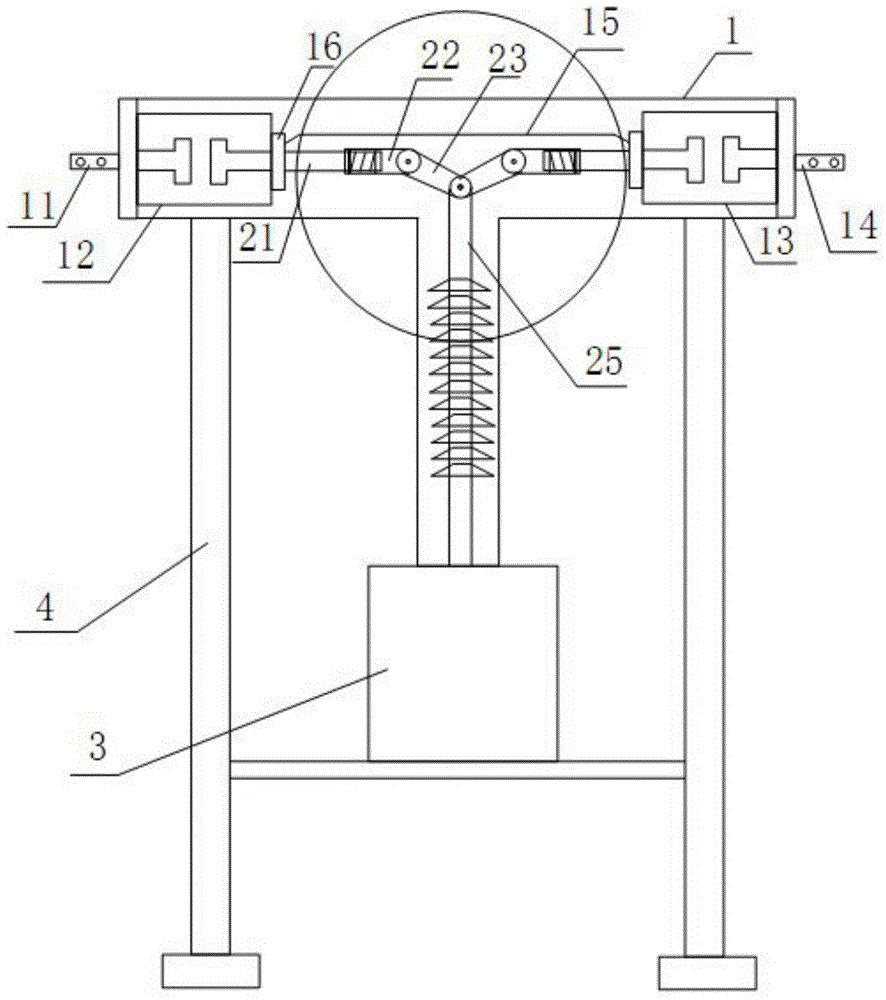

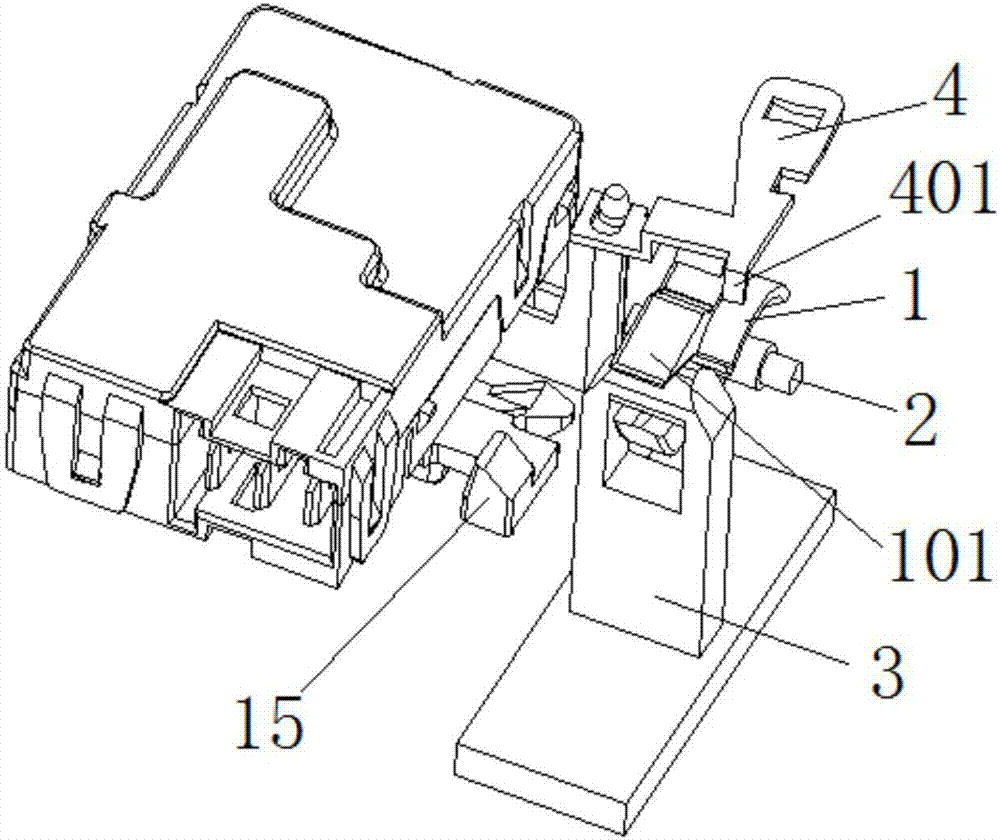

High-voltage double-break circuit breaker

ActiveCN104576175AImprove the effective breaking voltage levelShorten closing and opening timeHigh-tension/heavy-dress switchesAir-break switchesHigh voltageVacuum interrupter

The invention discloses a high-voltage double-break circuit breaker. The high-voltage double-break circuit breaker comprises circuit breaker casings and driving mechanisms, wherein two arc extinguishing chambers are symmetrically arranged in the circuit breaker in a left and right manner, a certain distance is formed between the arc extinguishing chambers, movable cover-plate ends of the arc extinguishing chambers are oppositely arranged, a fixed contact and a movable contact are arranged in each arc extinguishing chamber, the movable contacts are electrically connected with each other and are connected with one ends of connecting-rod mechanisms, and the fixed contacts are led out of the arc extinguishing chambers; the driving mechanisms are connected with the other ends of the connecting-rod mechanisms at the same position through insulated tension rods, the driving mechanisms drive the insulated tension rods to move up and down so as to drive the connecting-rod mechanisms to synchronously move, and further the gathering movement and the separating movement of the movable contacts and the fixed contacts are synchronously realized, wherein the leading-out terminals of the two fixed contacts are used as the circuit access terminals of the circuit breaker. The high-voltage double-break circuit breaker disclosed by the invention solves the problem that the switching voltage of vacuum circuit breakers is not high, and besides, the time for opening or closing a brake is shortened; the mechanical structure is simple, and the reliability of the circuit breaker is improved.

Owner:SUZHOU SHIYUAN SPECIAL ELECTRIC

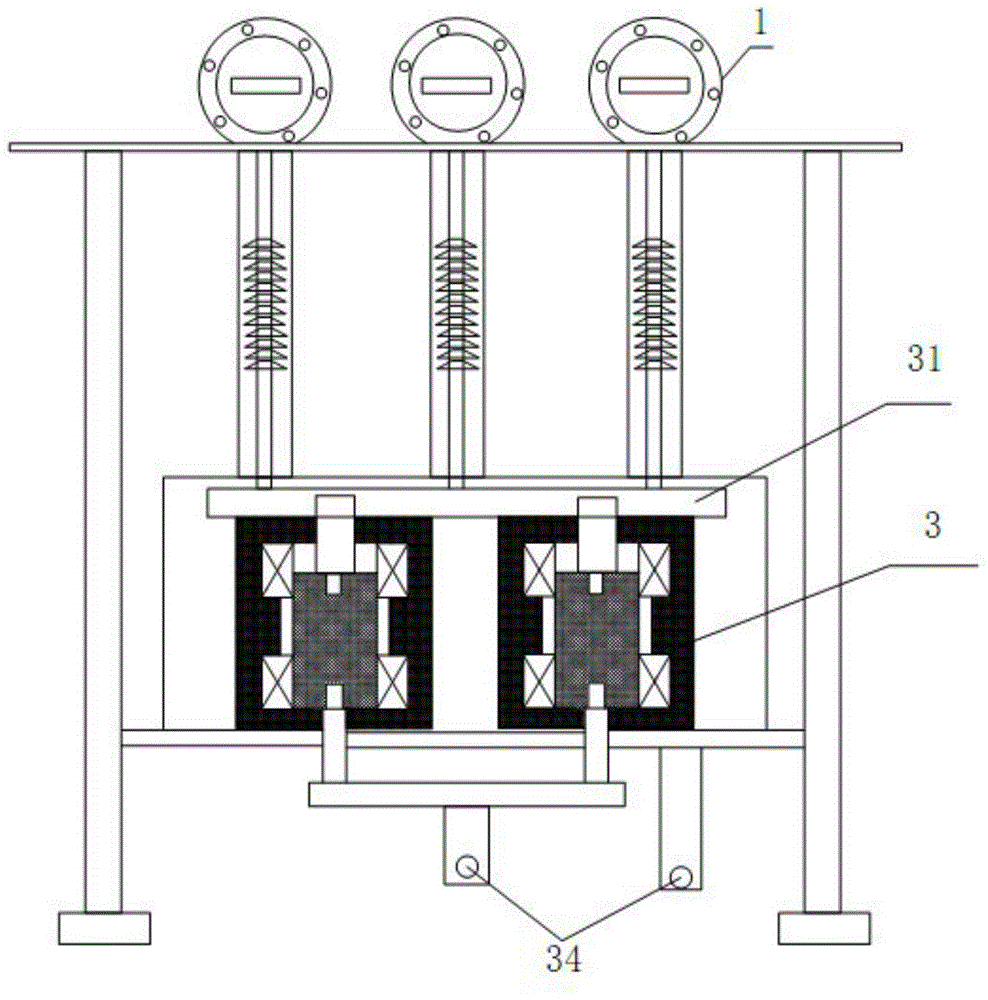

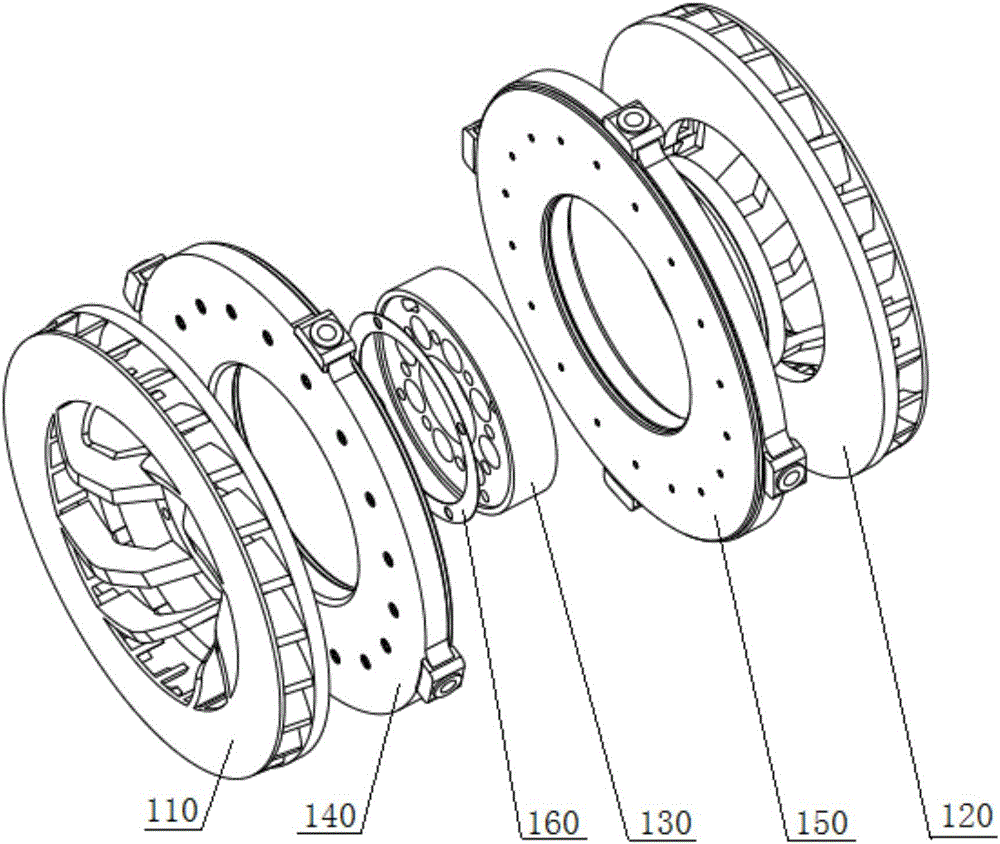

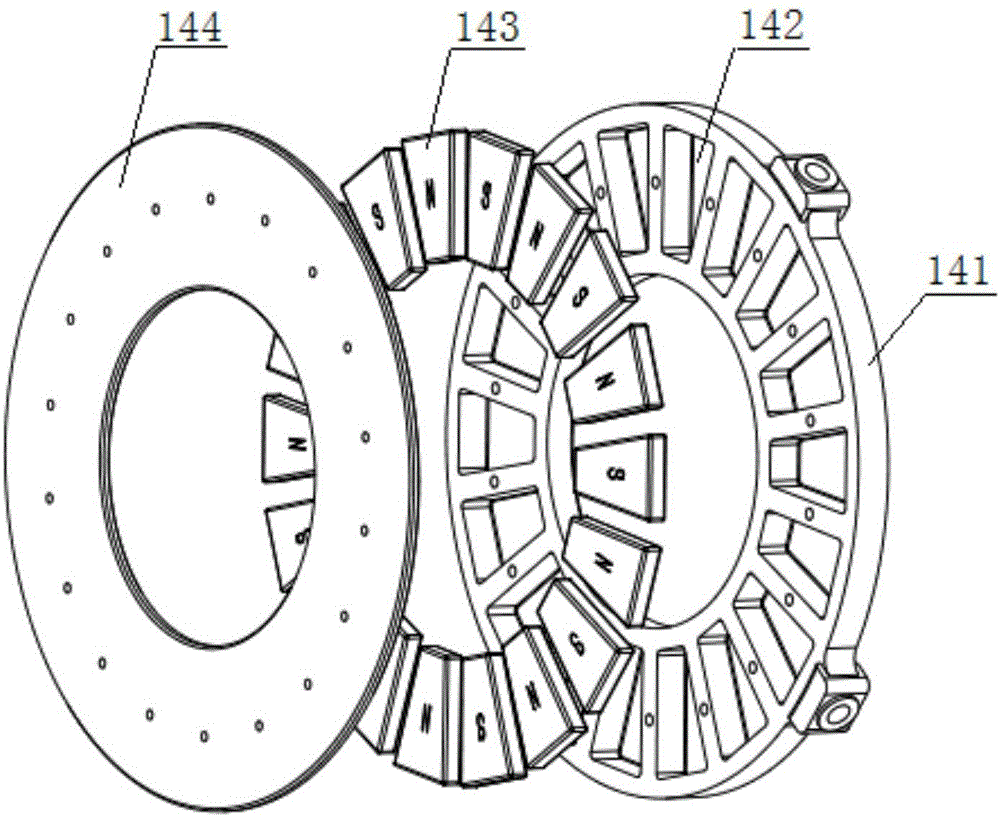

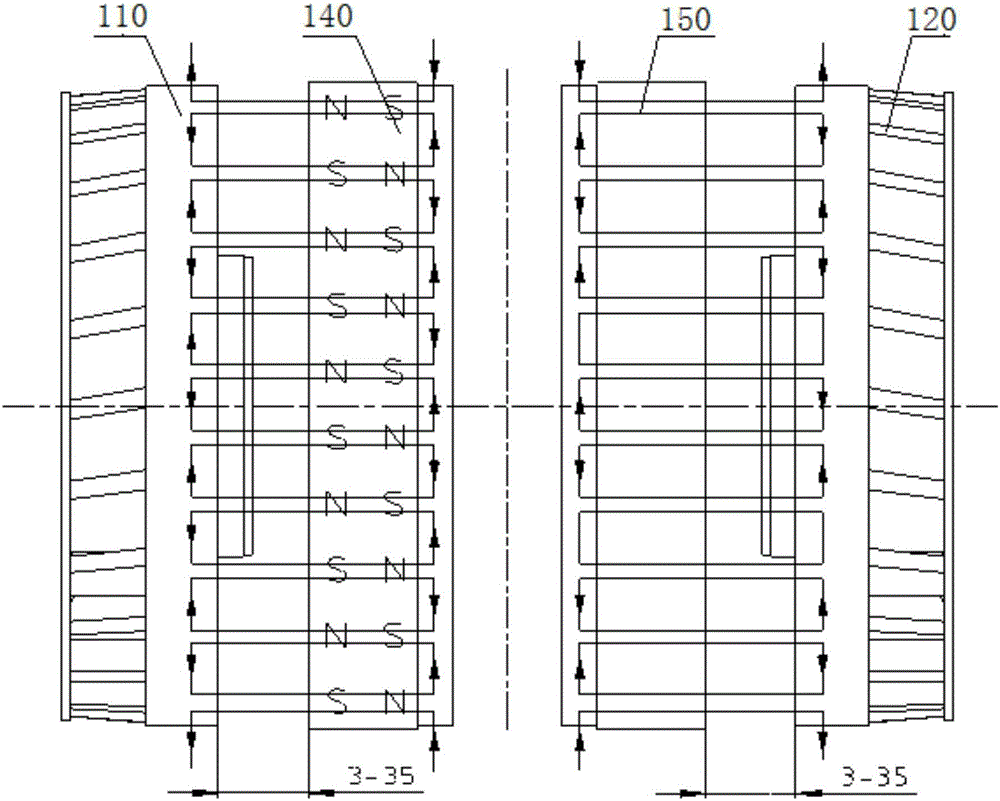

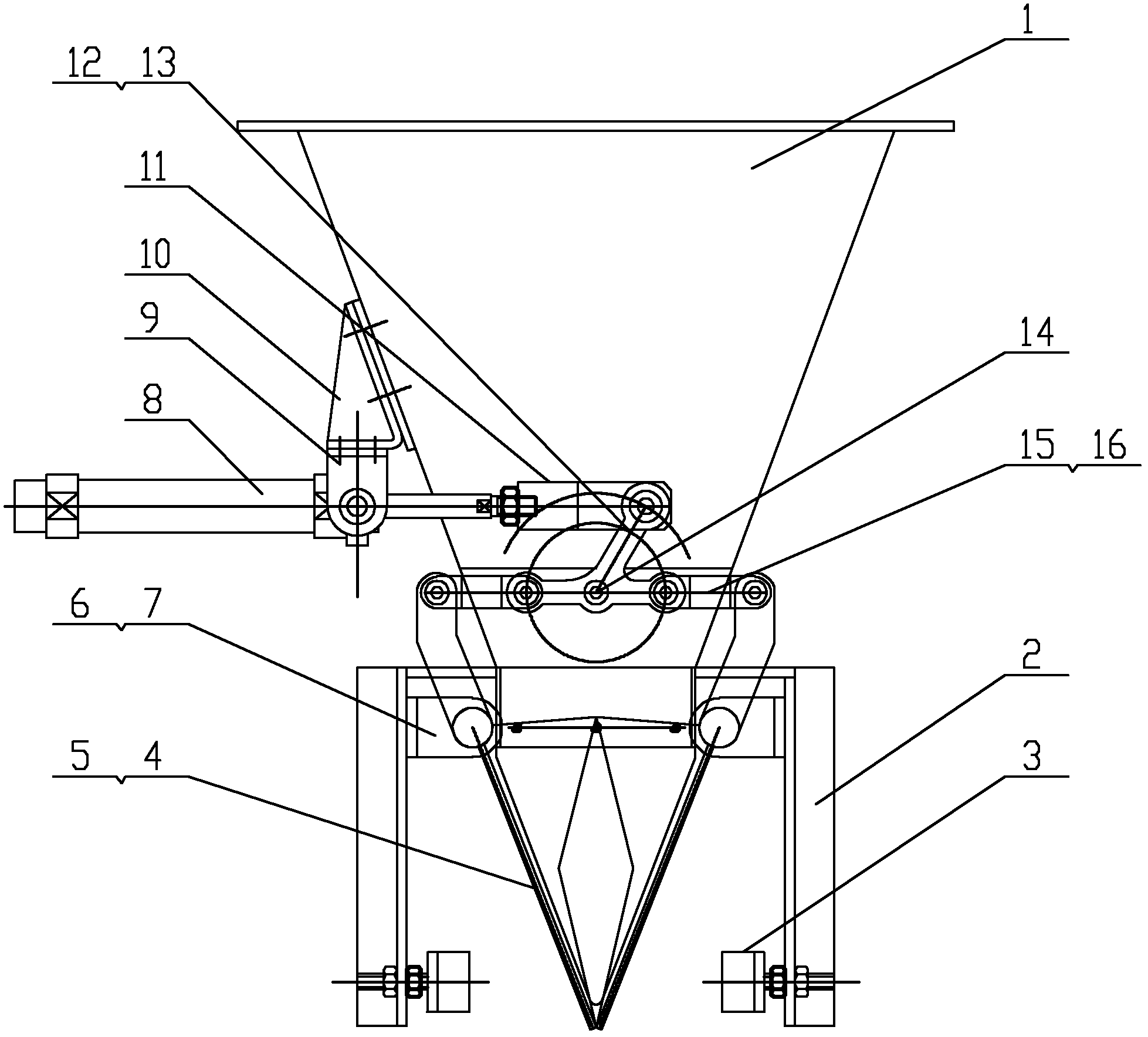

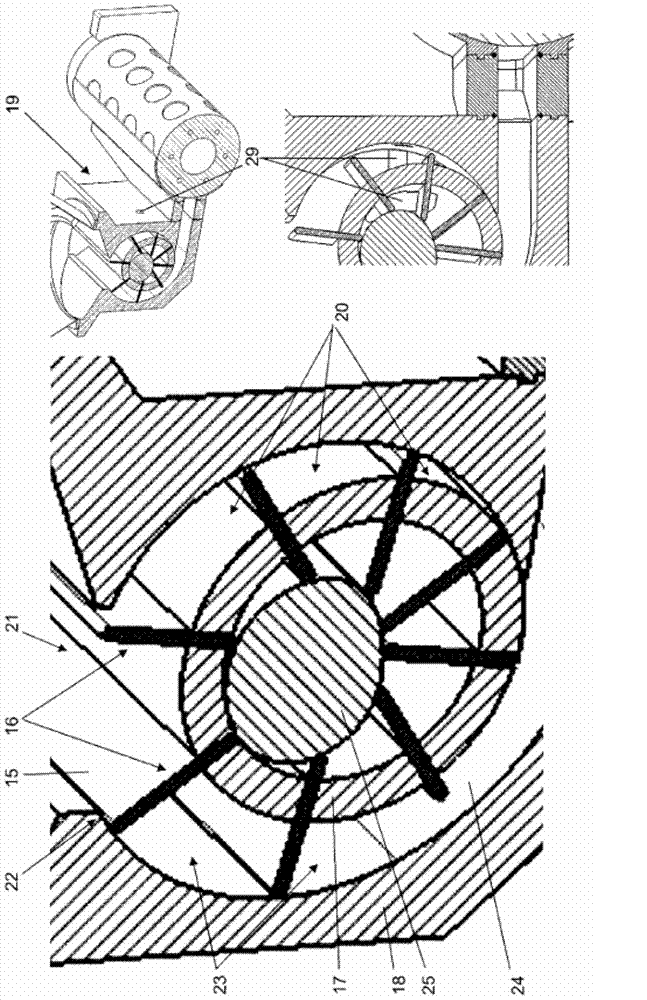

Vehicular disk-type permanent magnet eddy current retarder

PendingCN106712417AOvercome the disadvantage of high power consumptionSave electricityElectrodynamic brake systemsElectric machinesVehicle frameAxial force

The invention discloses a vehicular disk-type permanent magnet eddy current retarder, comprising a first rotor, a second rotor, a first stator, a second stator, a support frame, a connecting rod and an execution mechanism, wherein the first rotor and the second rotor are coaxially arranged at interval; the first stator and the second stator are coaxially arranged between the first rotor and the second rotor; the support frame is fixedly connected with a vehicle gearbox shell or a frame; the middle part of the connecting rod is connected with the extension end of the support frame by adopting a cylindrical pair, and two ends of the connecting rod respectively form spherical hinges with the peripheral edges of the first stator and the second stator; and the execution mechanism is articulated with the other extension end of the connecting rod. A high-performance neodymium iron boron permanent magnet provides a magnetic field, so that power supply is not needed, and the defect of power consumption of an electric eddy current retarder is overcome; two disks are articulated together by the connecting rod via a joint bearing to avoid axial force caused by non-uniform air gaps on two sides, and simultaneously, the maximum axial resistance is skillfully converted into circumferential rotation and axial motion to reduce the driving force.

Owner:MAGNA MAGNETOMOTIVE CO LTD

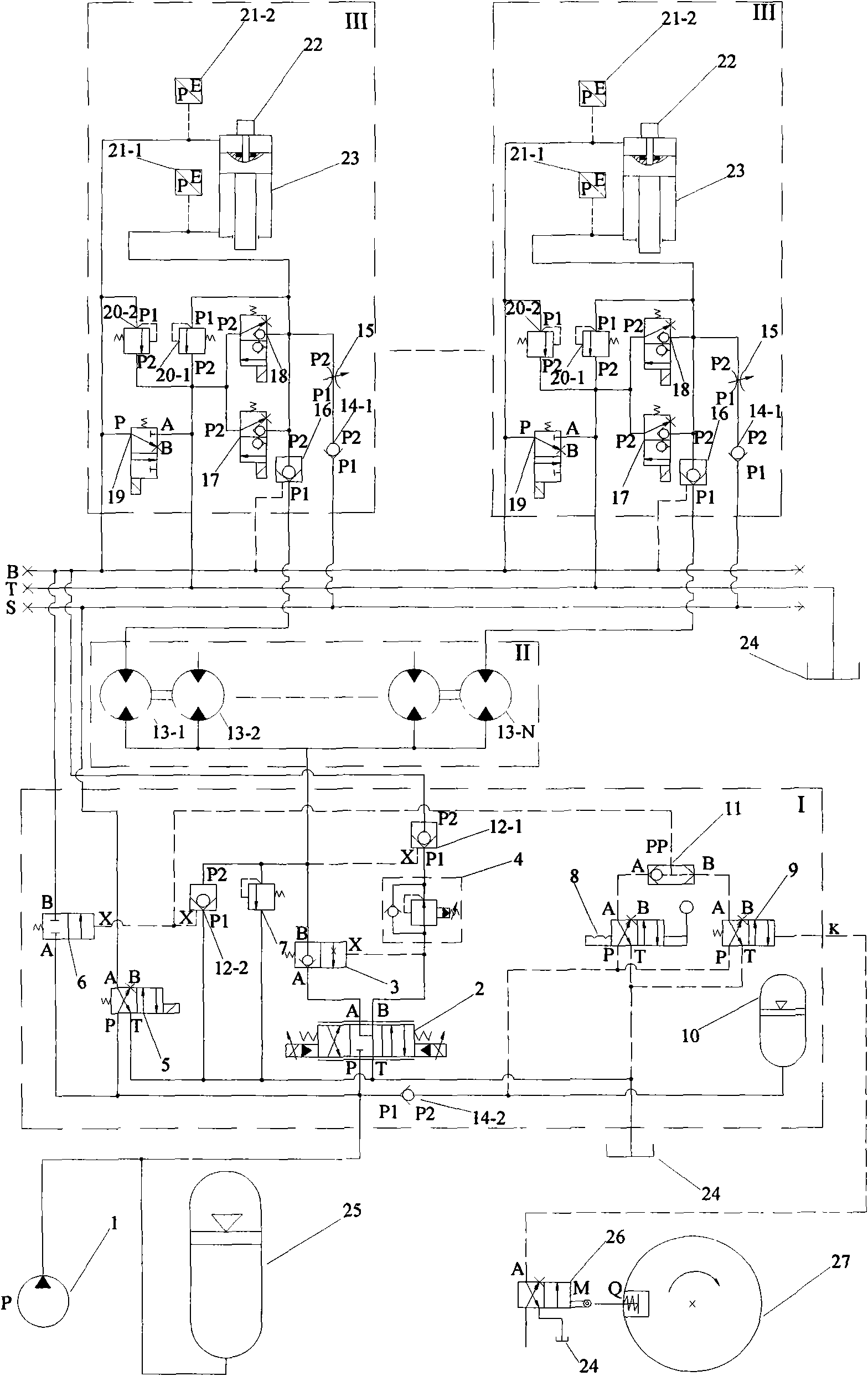

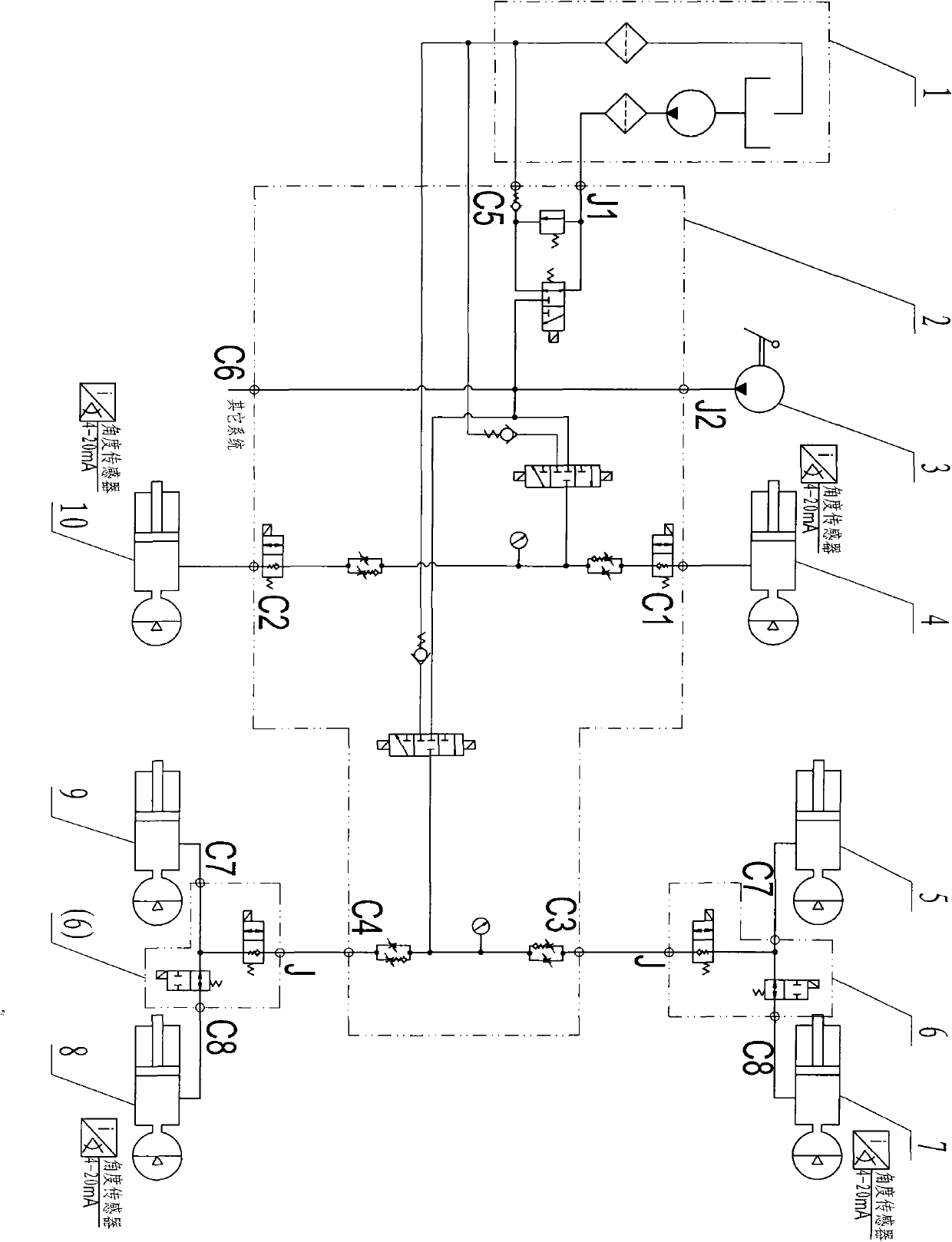

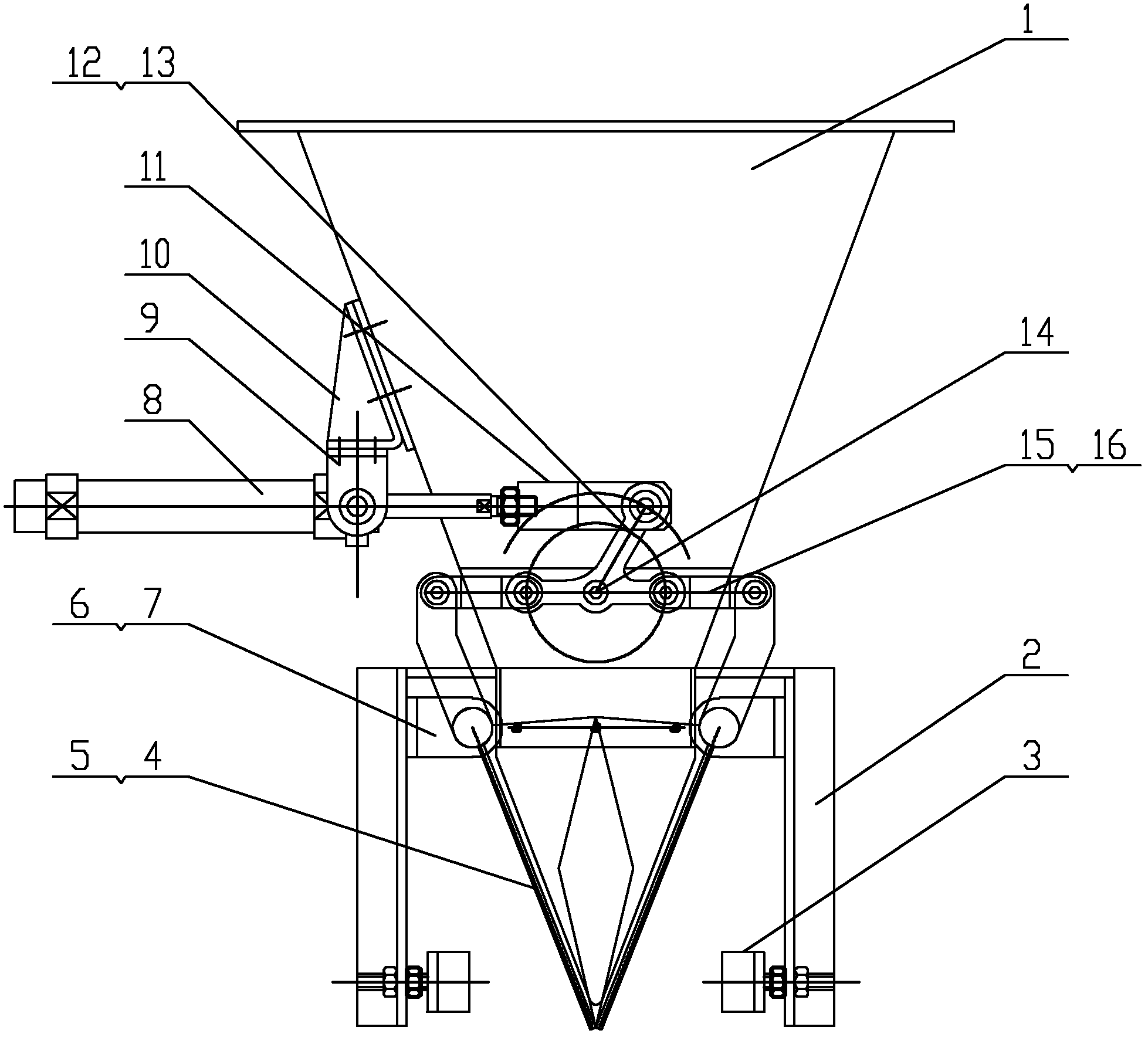

Water turbine cylinder valve machine electrohydraulic control system with function of runaway turnoff

InactiveCN101624961ASlow ascentIncrease ascent speedHydro energy generationMachines/enginesWater turbineServomotor

The invention discloses a water turbine cylinder valve machine electrohydraulic control system with a function of runaway turnoff, which consists of a control valve assembly, flow-dividing motors and oil distributing modules; wherein, the output of the control valve assembly is respectively connected with N synchronous flow-dividing motors and corresponding N oil distributing modules; a servomotor is respectively connected on the tail end of each oil distributing module as an executive device of a hydraulic system; the flow-dividing motor is radial plunger type and carries out flow dividing on hydraulic oil to ensure that the input and output oil amount of each servomotor hydraulic cylinder are equal, meanwhile, the oil distributing module is provided with two fine adjustment and rough adjustment electromagnetism ball valves to ensure that the synchronous control of corresponding servomotor meets the requirement of designing through accurately controlling flow entering into the servomotor by PLC. The invention can control the speed of the servomotor by controlling the flow of an electro-hydraulic proportional direction valve to realize hydraulic-electric synchronous and speed control with high precision, and a machine unit can be turned off immediately under the combined action of an over-speed protection device and a control system with the function of runaway when the machine unit is over speed.

Owner:TIANJIN UNIV

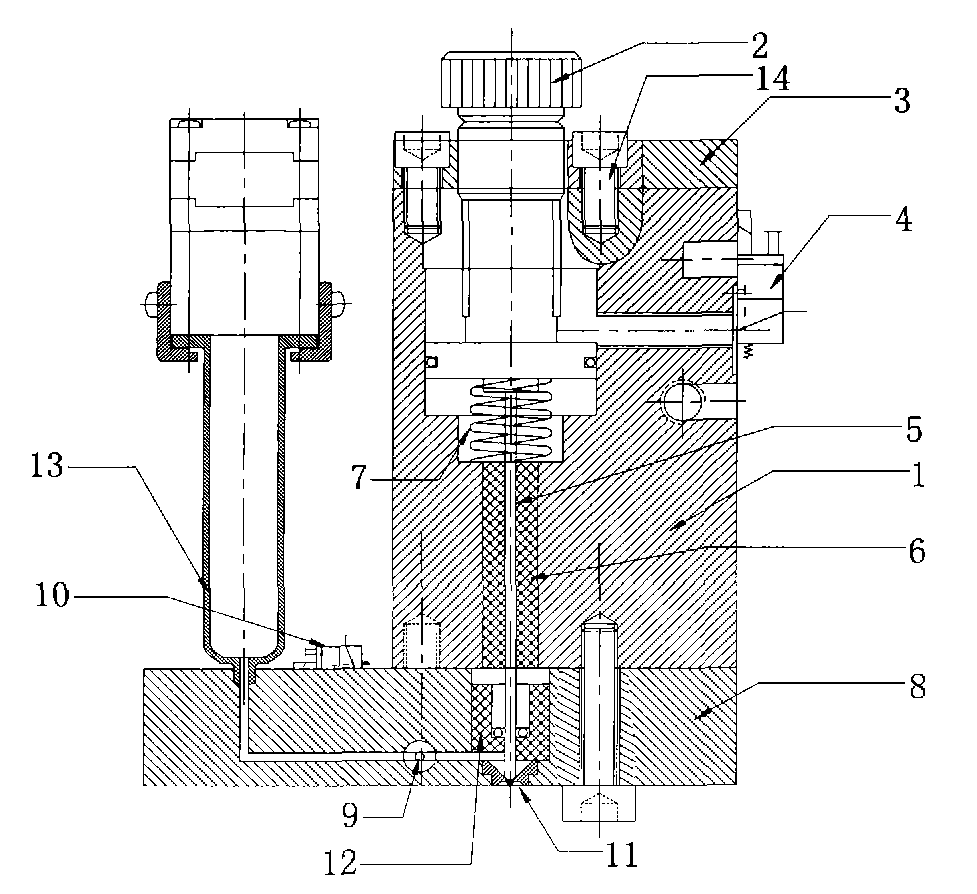

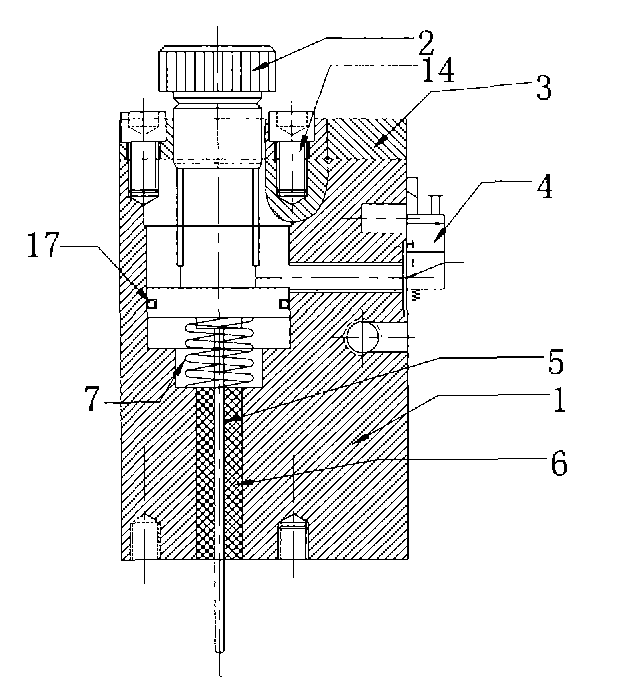

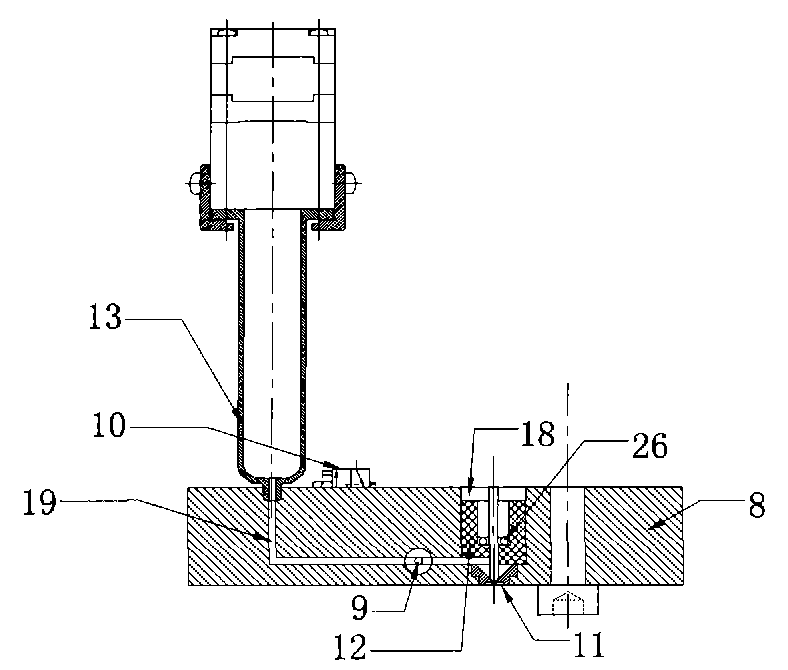

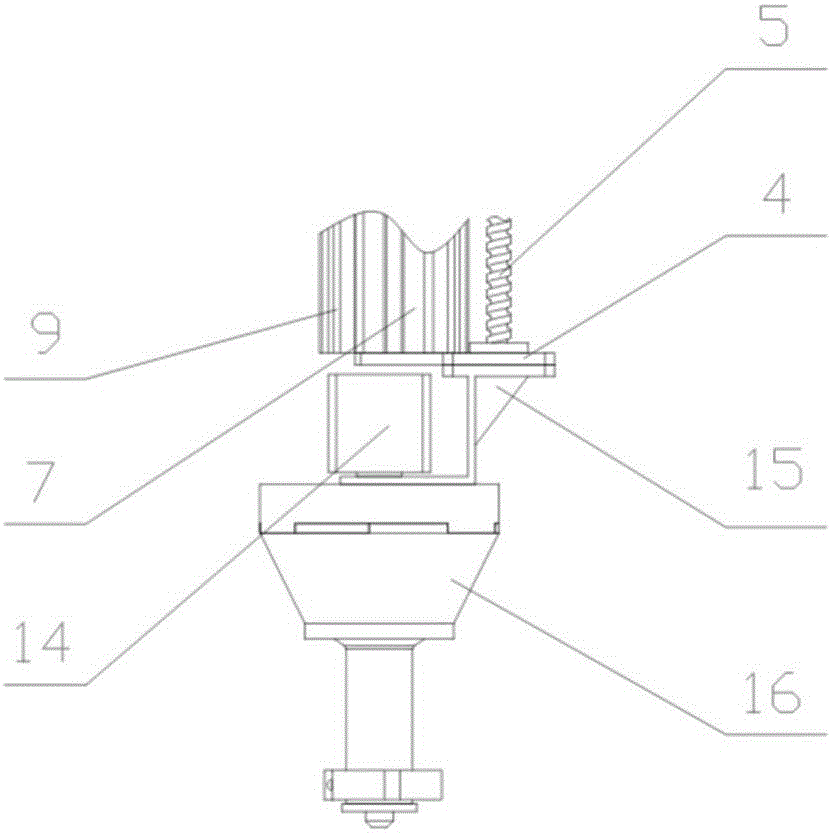

Volumetric quantitative jet valve

InactiveCN101972728AReduce movement position deviationShort gas pathLiquid surface applicatorsSpraying apparatusAdhesiveEngineering

The invention discloses a volumetric quantitative jet valve which aims to solve the technical problems of accurately controlling the jet volume of packaging materials and enabling the jet volume to be adjustable. The volumetric quantitative jet valve of the invention is provided with a jet cavity with an outlet and a striker arranged in the jet cavity, wherein the striker moves to the outlet of the jet cavity when being driven by the power and restores to the original position under the action of the restoring force; the jet cavity is closed and is connected with a hole pipe with a valve; thehole pipe is connected with a charging barrel; and when the striker is driven by the power and moves, the valve is in a closed state. Compared with the prior art, the invention has the characteristics that the valve is arranged between a closed inner cavity in the shape of an inverted cone and a glue inlet hole pipe, so that when the striker downward strikes the glue in the inner cavity of a nozzle, the glue is jetted from the outlet and can not flow back to the glue inlet hole pipe, and the same valve body can be matched with strikers of different diameters to be suitable for different jet volume. The invention is suitable for adhesives, packaging materials, welding glue, paint and lubricating oil for jetting and filling glue and welding components in the electronic industry process.

Owner:陈时雄

Seat base plate and seat with same

ActiveCN103876498AMeet different needsResilience is smallStoolsReclining chairsEngineeringFront and back ends

The invention relates to a seat base plate and a seat with the same. The seat base plate comprises a pallet main base, a seat support plate, a movable support part and a pair of movable support plates, wherein the seat support plate is arranged above the pallet main base; the front end of the movable support part is connected with the seat support plate in a pivoting way, the lower end of the movable support part is connected with the pallet main base in a pivoting way, and the rear end of the movable support part is connected with a seat backrest; the front end and the rear end of the movable support part can pivot by taking the lower end as a supporting point; the pair of movable support plates are arranged in front of the movable support part; the upper end and the lower end of each movable support plate are connected with the seat support plate and the pallet main base in a pivoting way, respectively, so that the seat support plate can be supported in a balanced way when moving along with the movable support part; an elastic part for resisting the backward rotation of the movable support part is arranged on a pivot through which the movable support part is connected with the pallet main base. After the seat base plate is adopted, a user can feel a proper sense of pressure when leaning against the backrest, and the friction between the backrest and the back of the user can be reduced.

Owner:SHANTOU LISHI FURNITURE

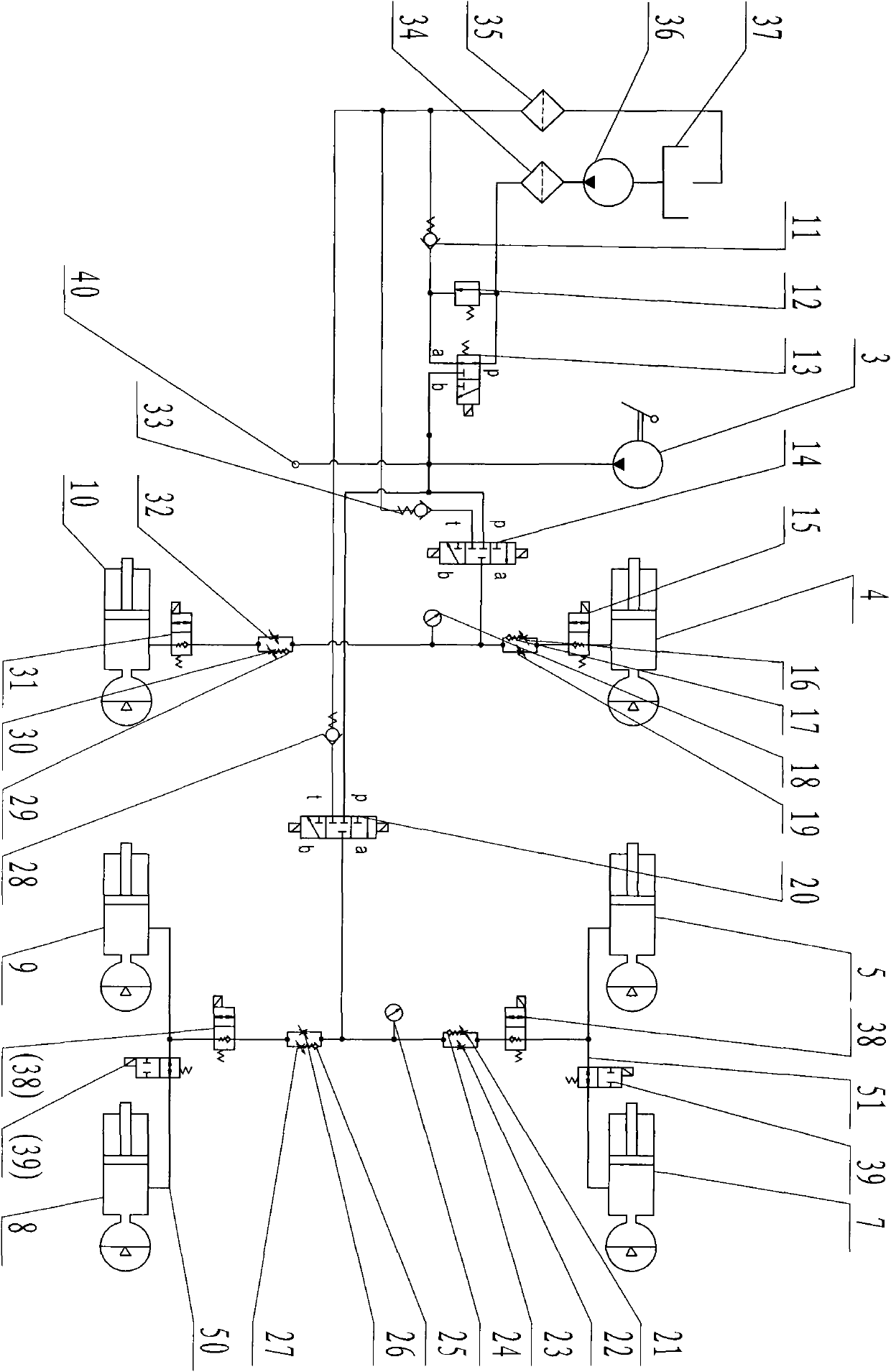

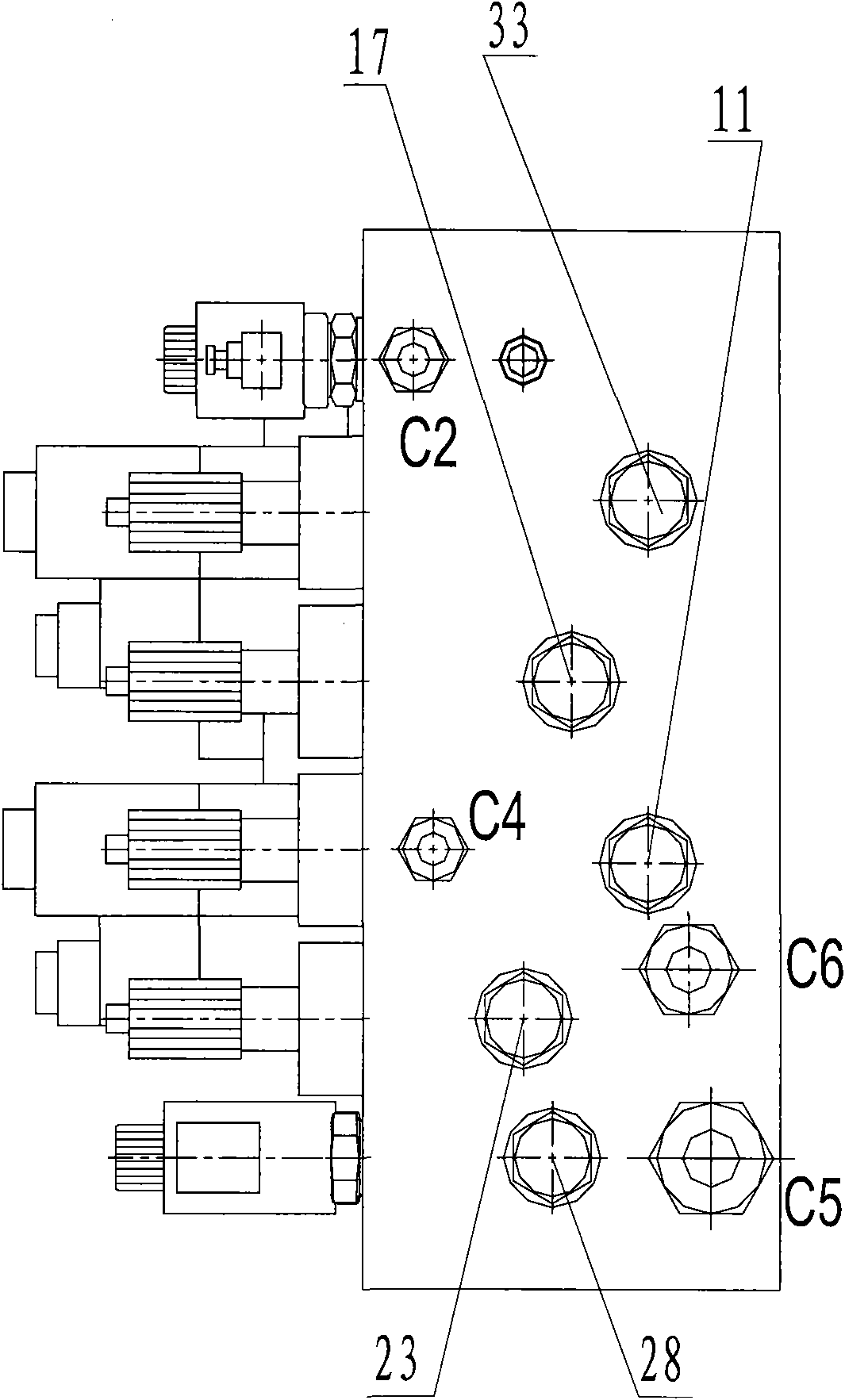

Modularized vehicle position regulating system

ActiveCN102673341ASave layout spaceImprove mechanical propertiesResilient suspensionsHydropneumatic suspensionControl valves

The invention relates to a modularized vehicle position regulating system which regulates the position of a vehicle, and consists of a system power source, a hydraulic device, an oil gas suspension, an electric control unit and a sensor, wherein the system power source, the hydraulic device and the oil gas suspension are connected together through a pipeline, the oil gas suspension comprises at least two left oil gas suspensions and at least two right oil gas suspensions, the hydraulic device comprises a suspension device control combination and a communication hydraulic lock combination, the communication hydraulic lock combination is used for realizing the functions of suspension balancing and hydraulic locking, the suspension device control combination mainly comprises an overflow valve, an unloading valve, a suspension control valve, a right suspension hydraulic lock, a left suspension hydraulic lock, a right throttle valve set and a left throttle valve set, and the overflow valve and the unloading valve are connected in parallel; and an oil outlet end b of the unloading valve is respectively connected with the oil inlet ends of a front suspension control valve and a rear suspension control valve through the pipeline, and the oil outlet ends of the front suspension control valve and the rear suspension control valve are sequentially connected with the throttle valve sets and the suspension hydraulic locks in series.

Owner:CHINA NORTH VEHICLE RES INST

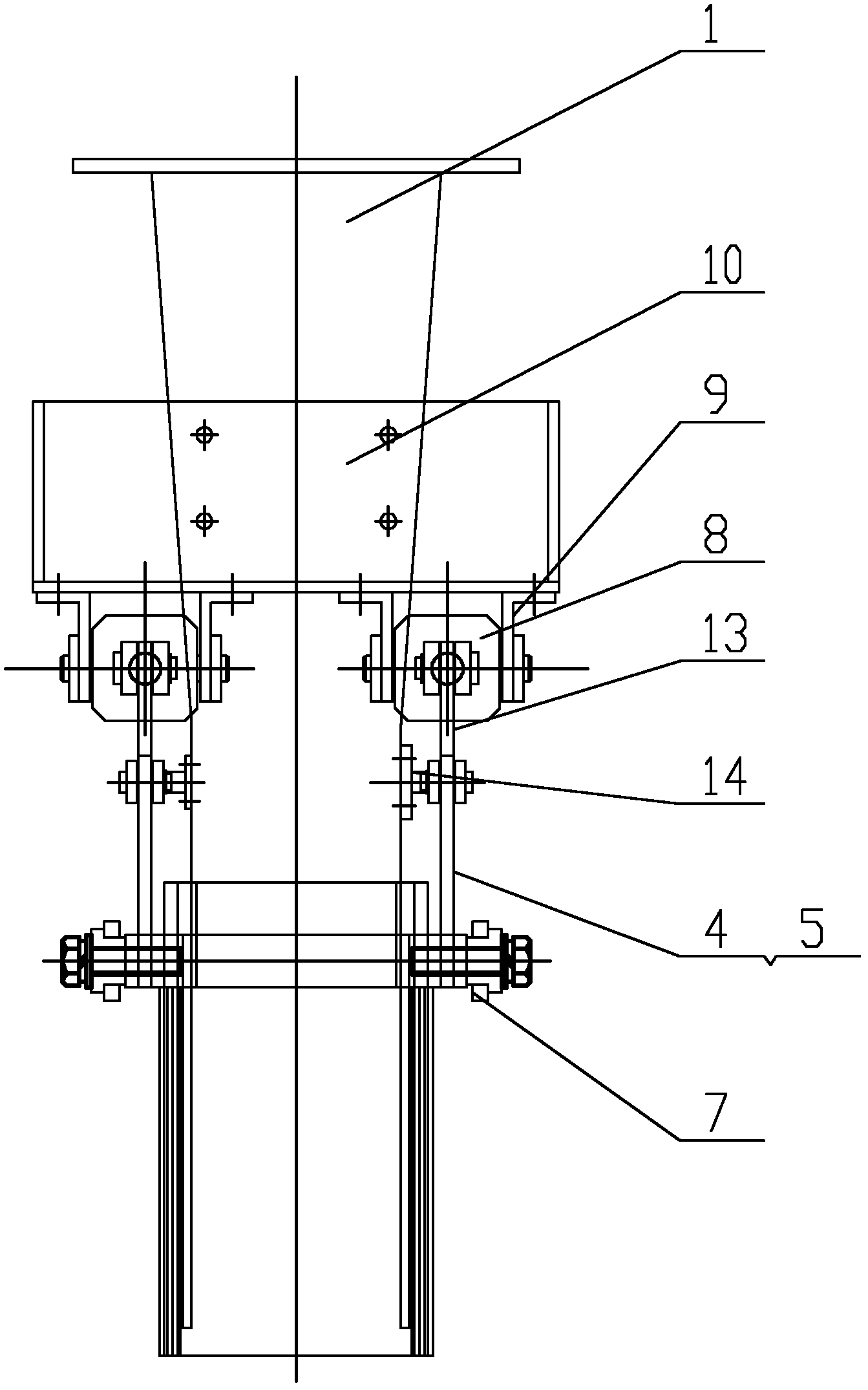

Bag clamping mechanism in automatic bagging machine

The invention relates to a bag clamping mechanism in an automatic bagging machine. For the bag clamping mechanism, bag clasping supports are welded on the lower end of a discharge hopper body; valve bearings are fixed on the bag clasping supports by bolts; a left valve and a right valve are respectively hinged on the valve bearings by bolts through a sliding bearing; the supports are arranged on the discharge hopper by bolts; cylinder mounting frames are arranged on the supports by bolts; cylinders are hinged on the cylinder mounting frames; cylinder connection pieces are connected on ends ofcylinder piston rods by threads; a center hole of a three-arm connection rod is sheathed on a rotating shaft; the rotating shaft is arranged on the discharge hopper body by bolts; the cylinder connection pieces are hinged with one end of the three-arm connection rod through a first pin shaft; and the other two ends of the three-arm connection rod are respectively connected with the left valve andthe right valve through a connection rod and a second pin shaft. The bag clamping mechanism has the advantages of simple, compact and reasonable structure, and is flexible and reliable in action, wherein, the left valve and the right valve work synchronously, thus being applicable to the automatic bagging equipment.

Owner:WUXI NAITE ELECTROMECHANICAL INTEGRATING TECH

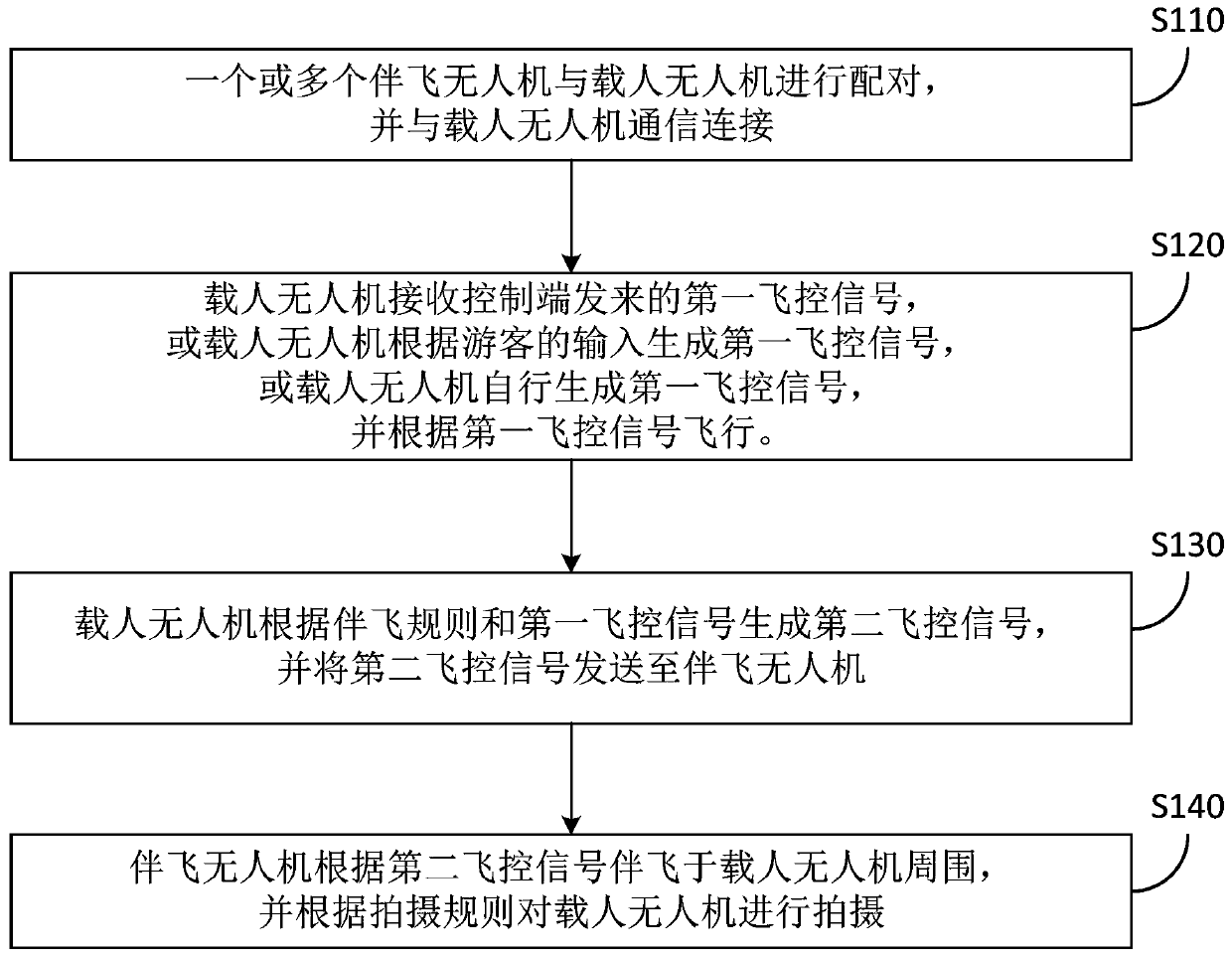

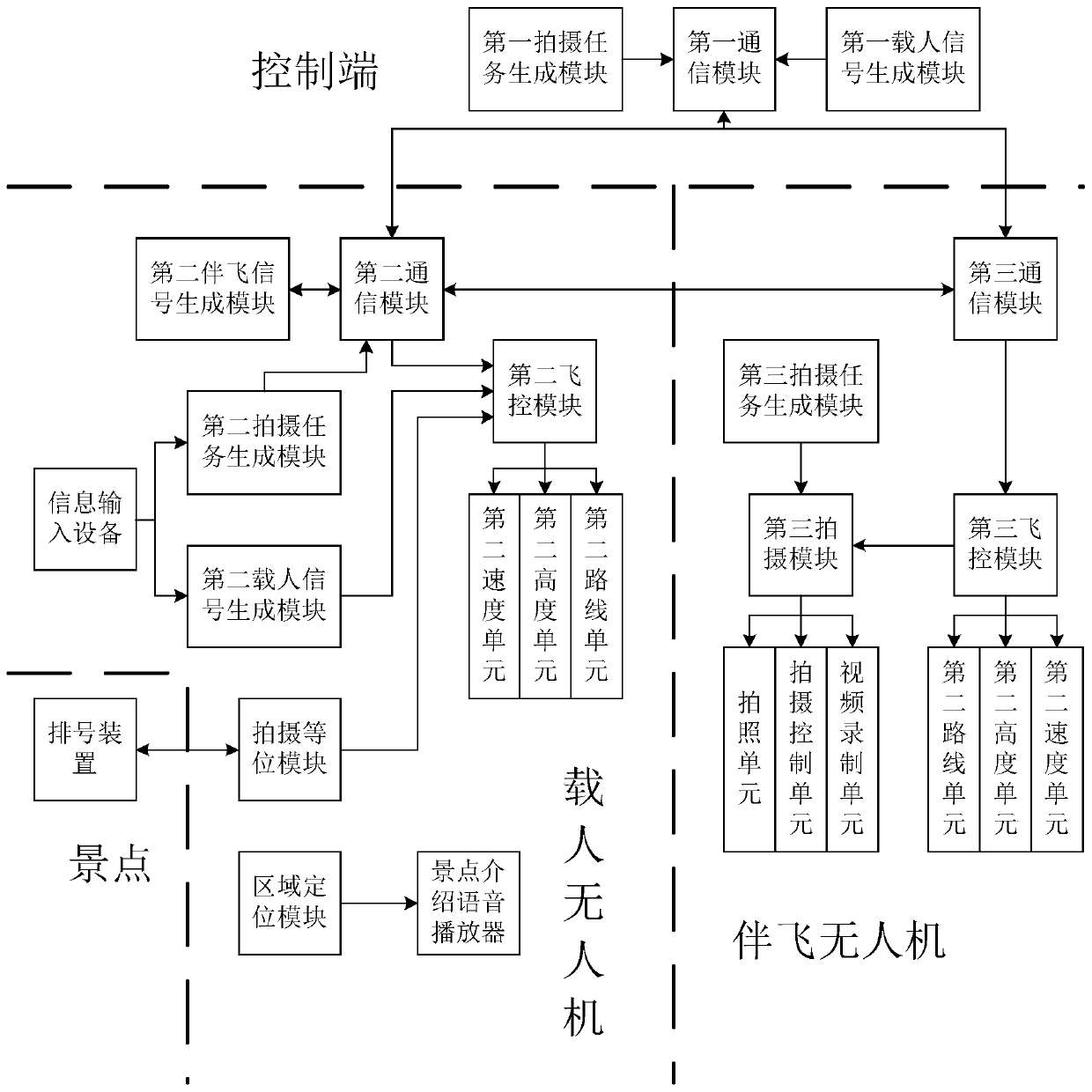

Passenger-carrying drone flight method and system applied to aerial sightseeing in scenic spot

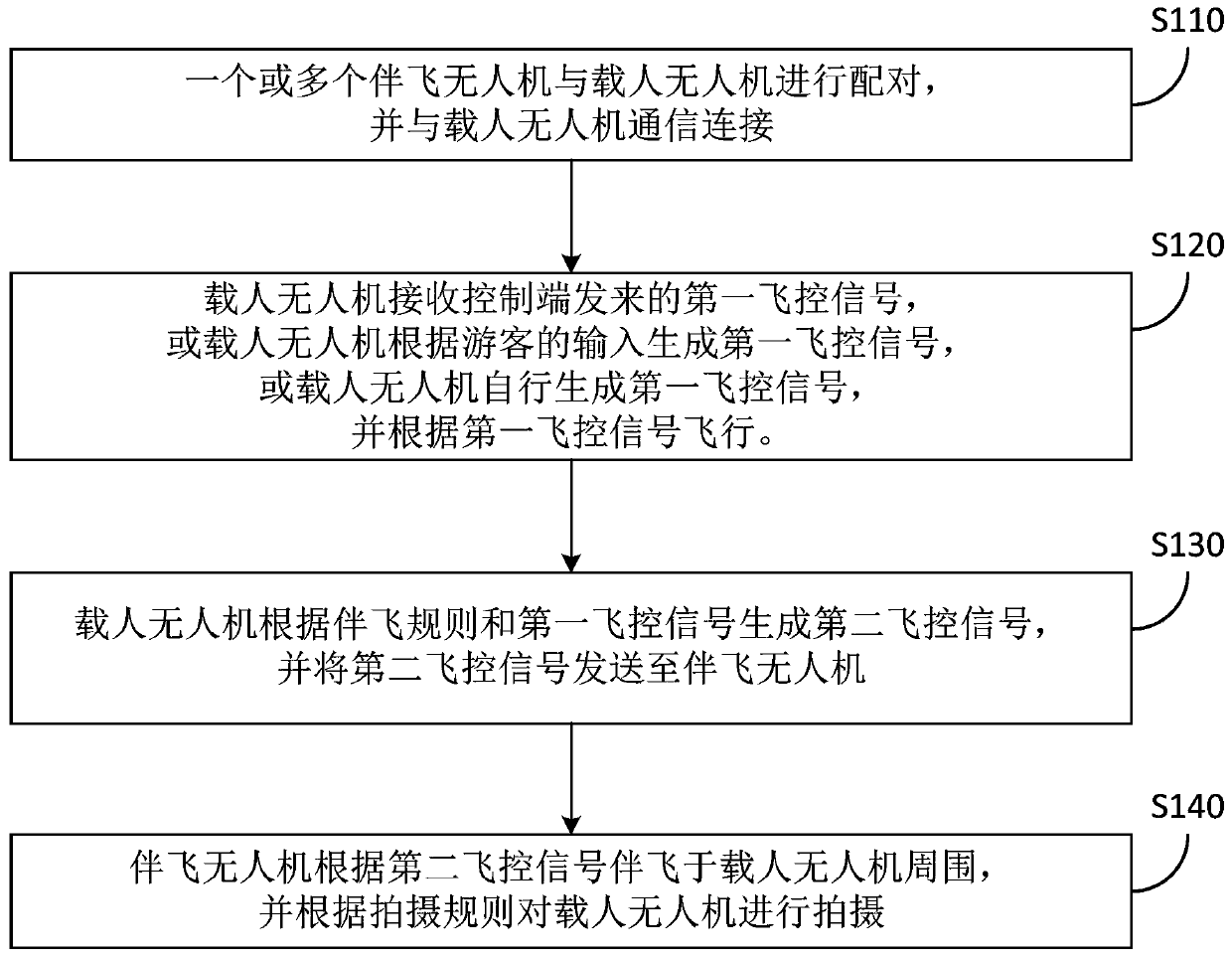

ActiveCN109917799AMeet the needs of aerial selfiesImprove the shooting effectAttitude controlPosition/course control in three dimensionsTravel modeControl signal

The invention relates to the technical field of drones, and particularly discloses a passenger-carrying drone flight method and system applied to aerial sightseeing in a scenic spot. The method comprises steps: an accompanying drone and a passenger-carrying drone are paired, communication connection with the passenger-carrying drone is carried out, the passenger-carrying drone receives a first flight control signal sent by a control end and flies according to the first flight control signal, the passenger-carrying drone generates a second flight control signal according to an accompanying ruleand the first flight control signal, the second flight control signal is sent to the accompanying drone, the accompanying drone accompanies around the passenger-carrying drone according to the secondflight control signal and photographs the passenger-carrying drone according to a photographing task. The method and the system use the passenger-carrying drone to provide an aerial sightseeing travel mode for a tourist, a new travel sightseeing experience is brought to the tourist, when the tourist takes the passenger-carrying drone for sightseeing in the scenic spot, the tourist is photographedfrom the outer part of the passenger-carrying drone through the accompanying drone, and photographing of the aerial tourist from an aerial perspective is realized.

Owner:特斯联智能工程有限公司

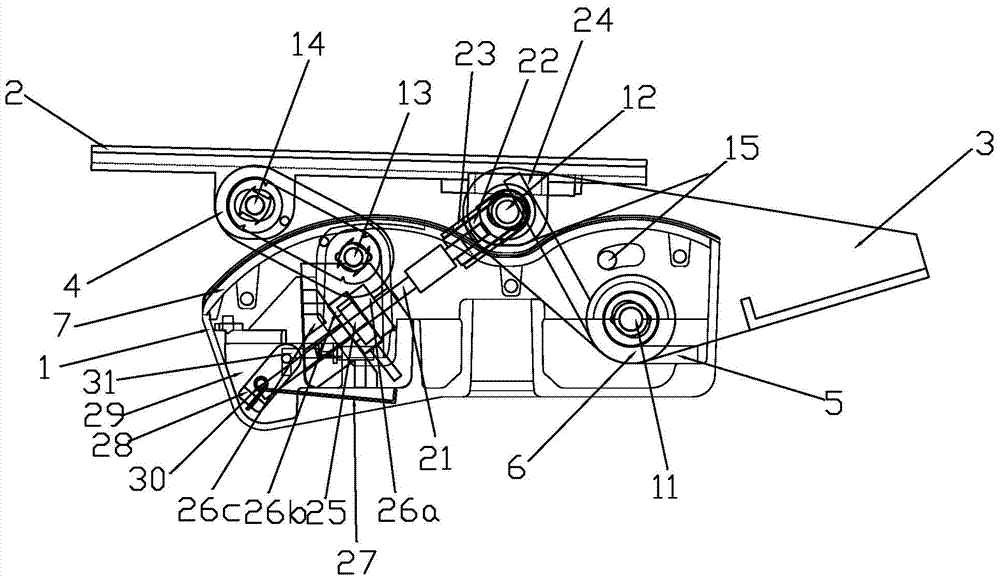

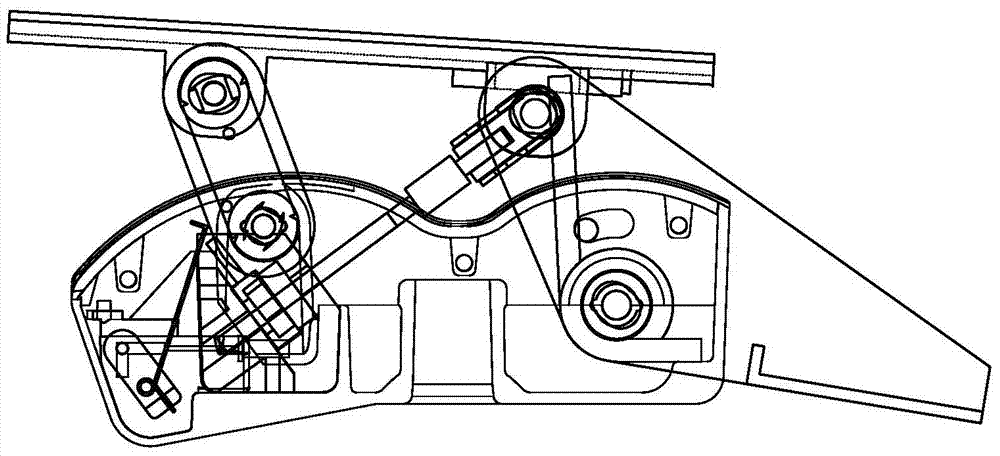

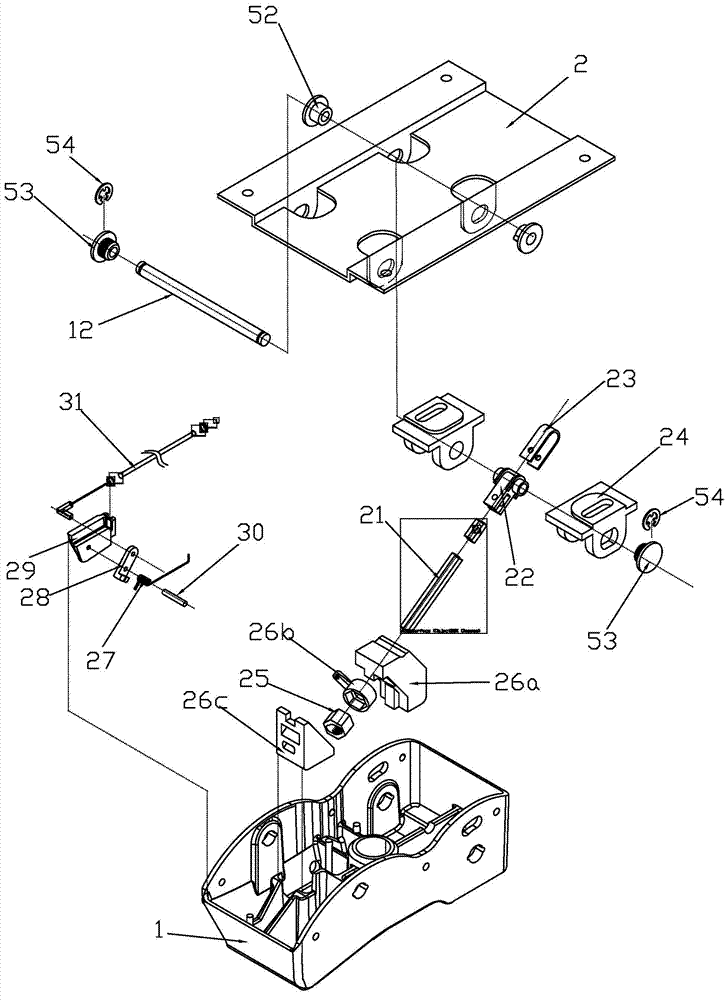

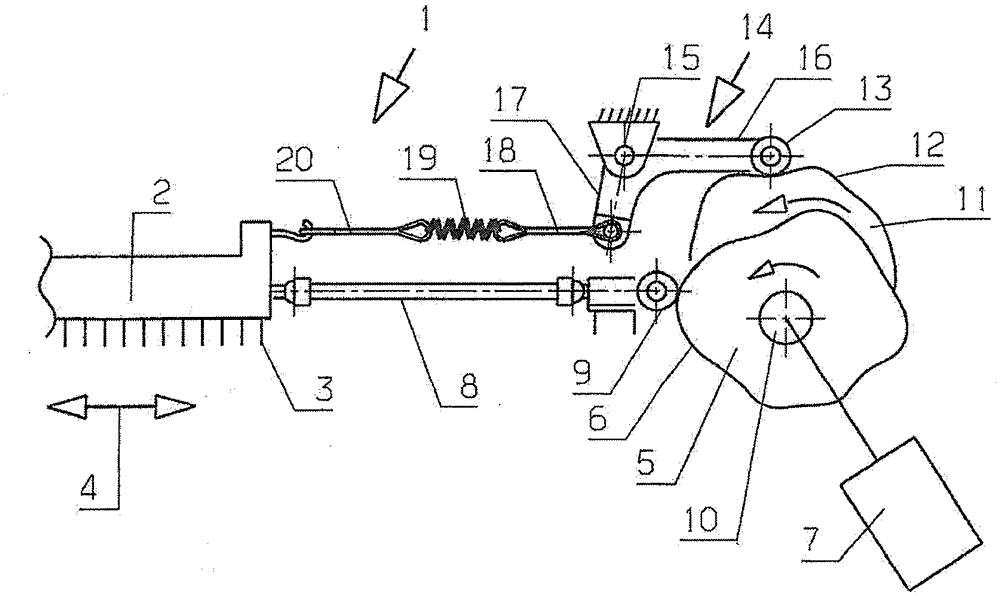

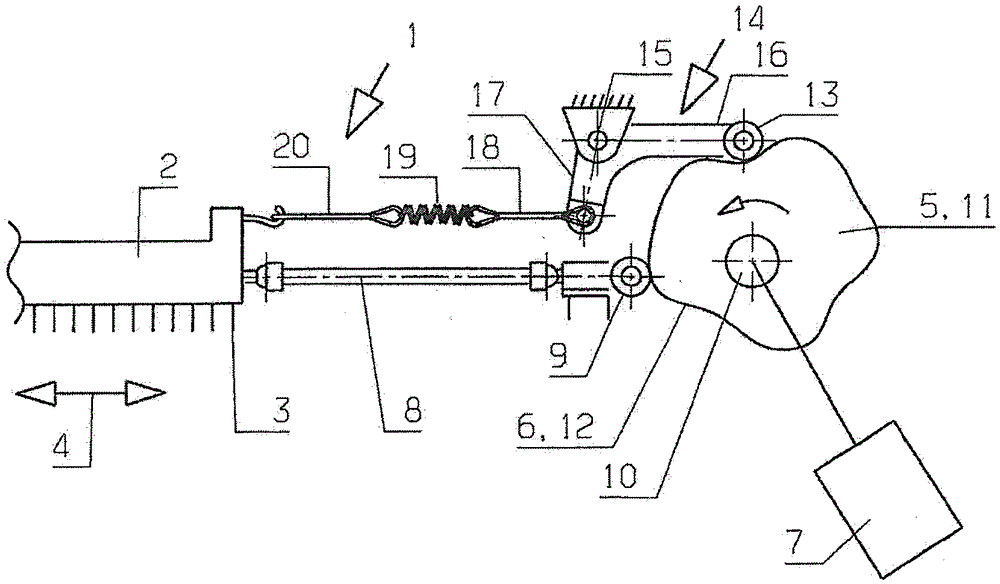

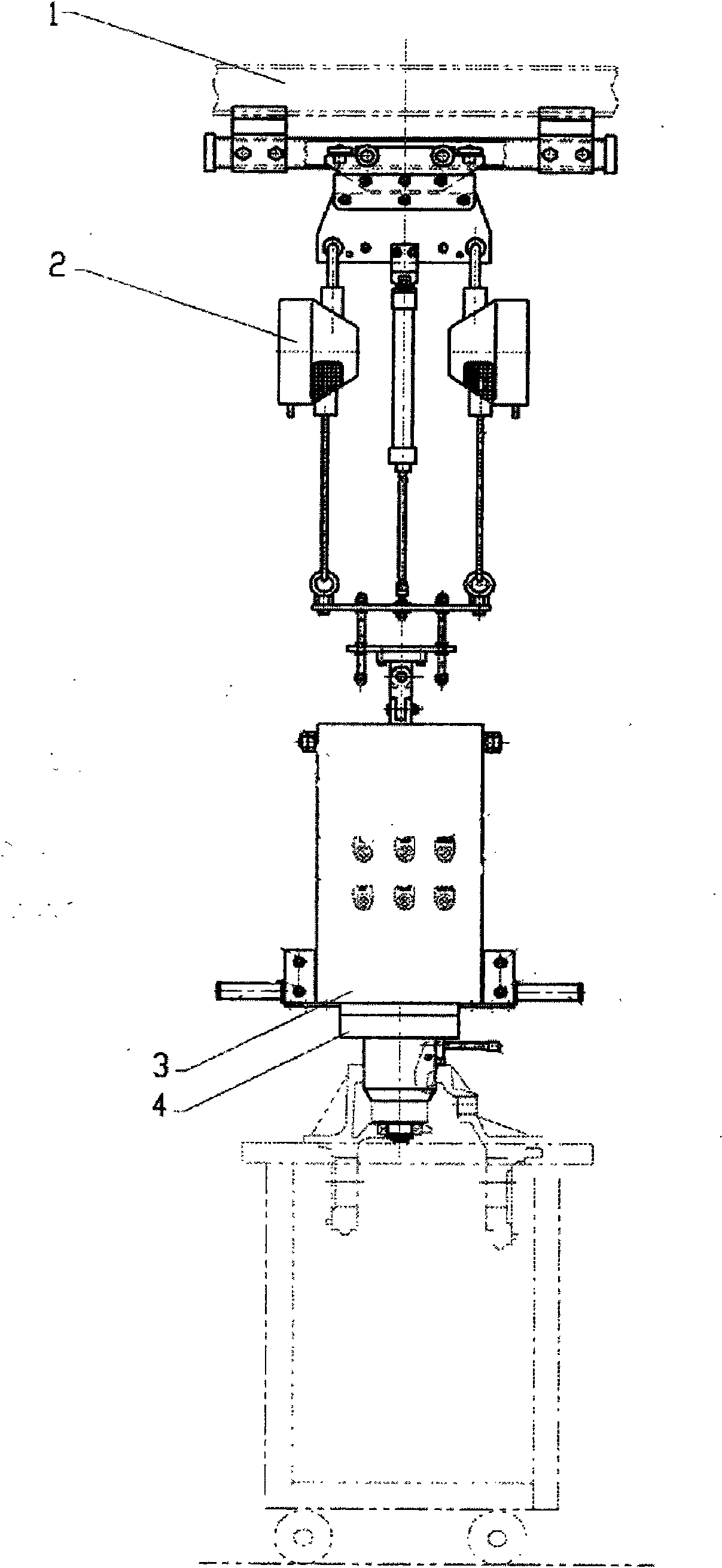

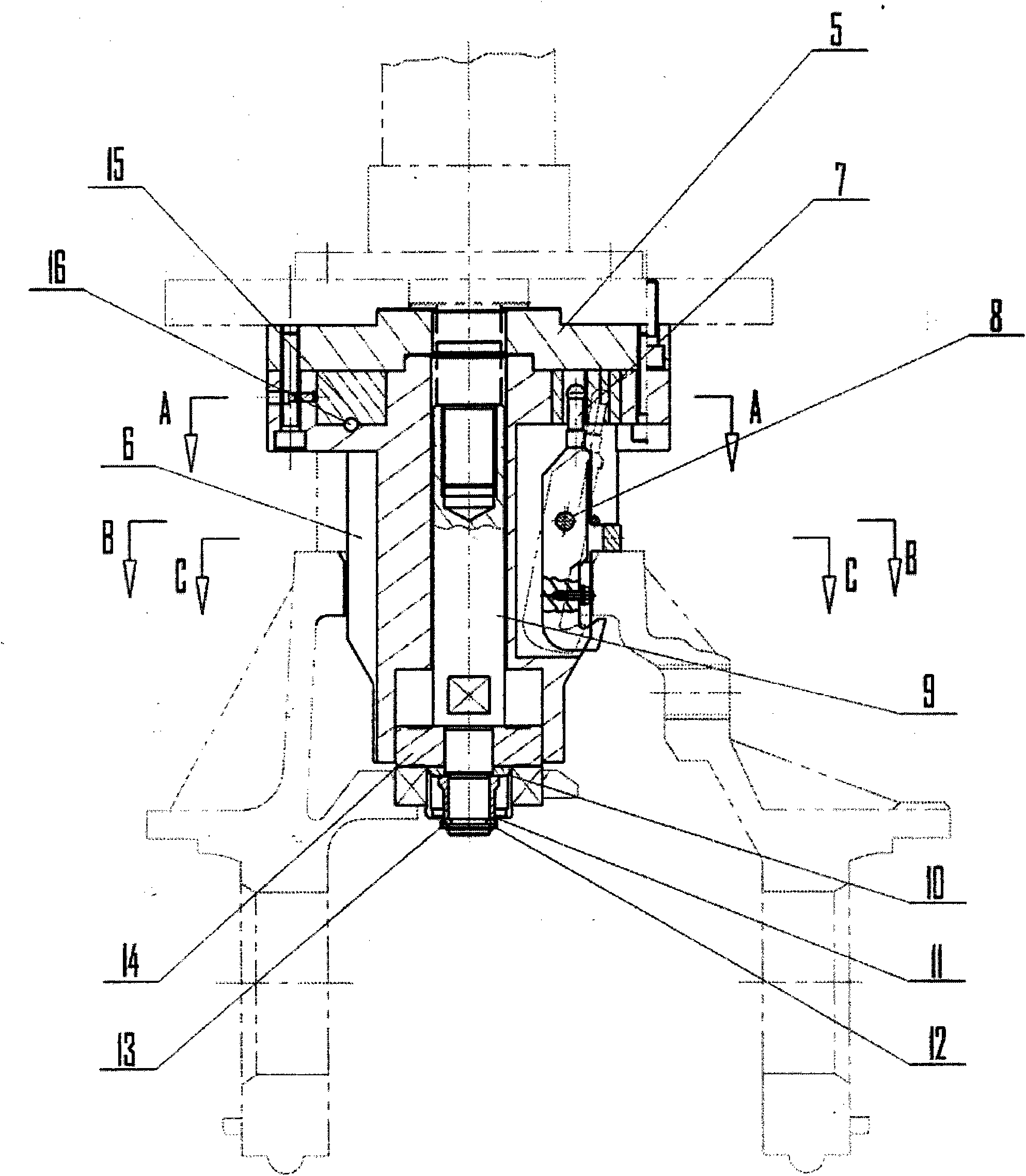

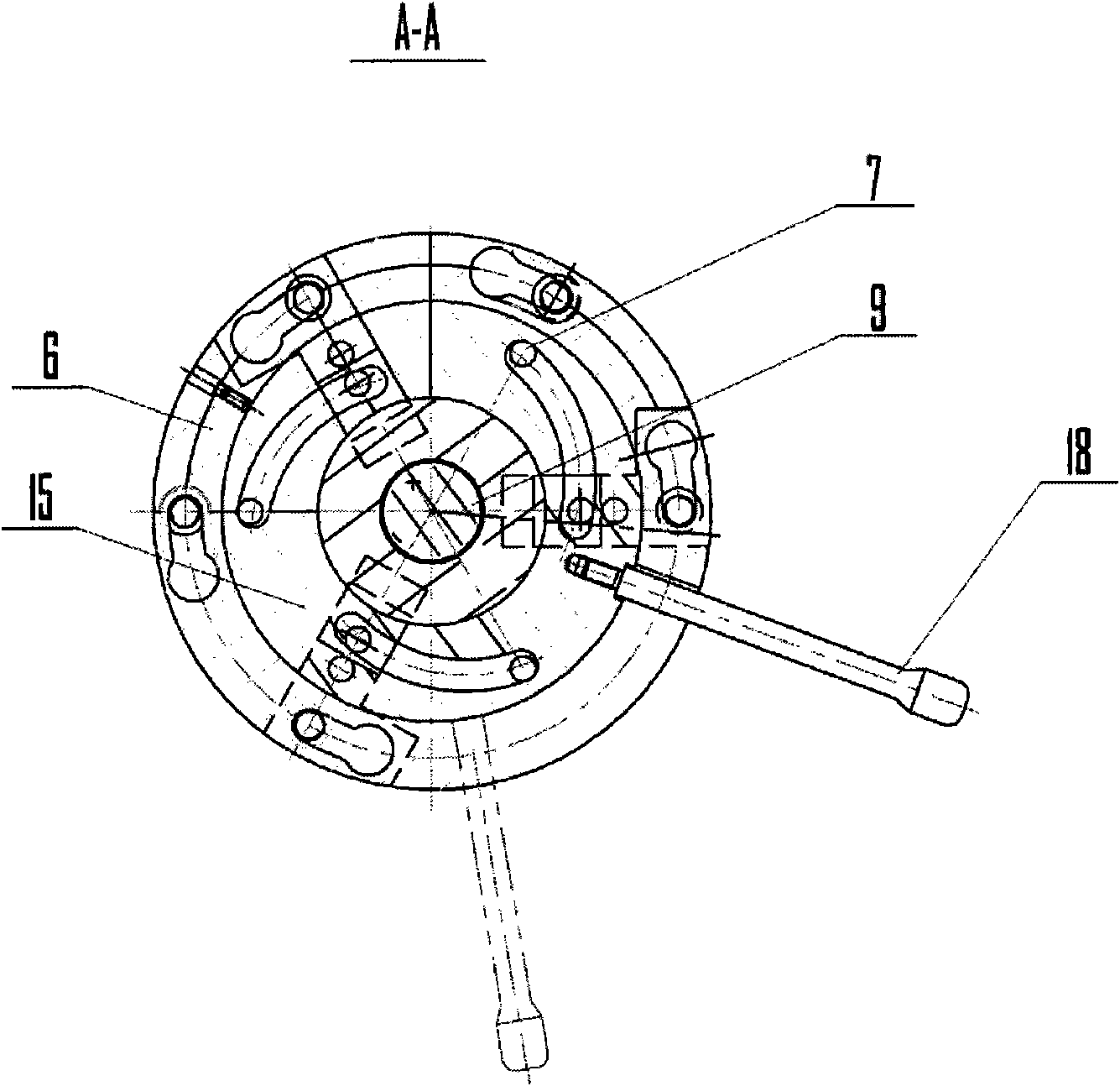

Electro-hydraulic point switch

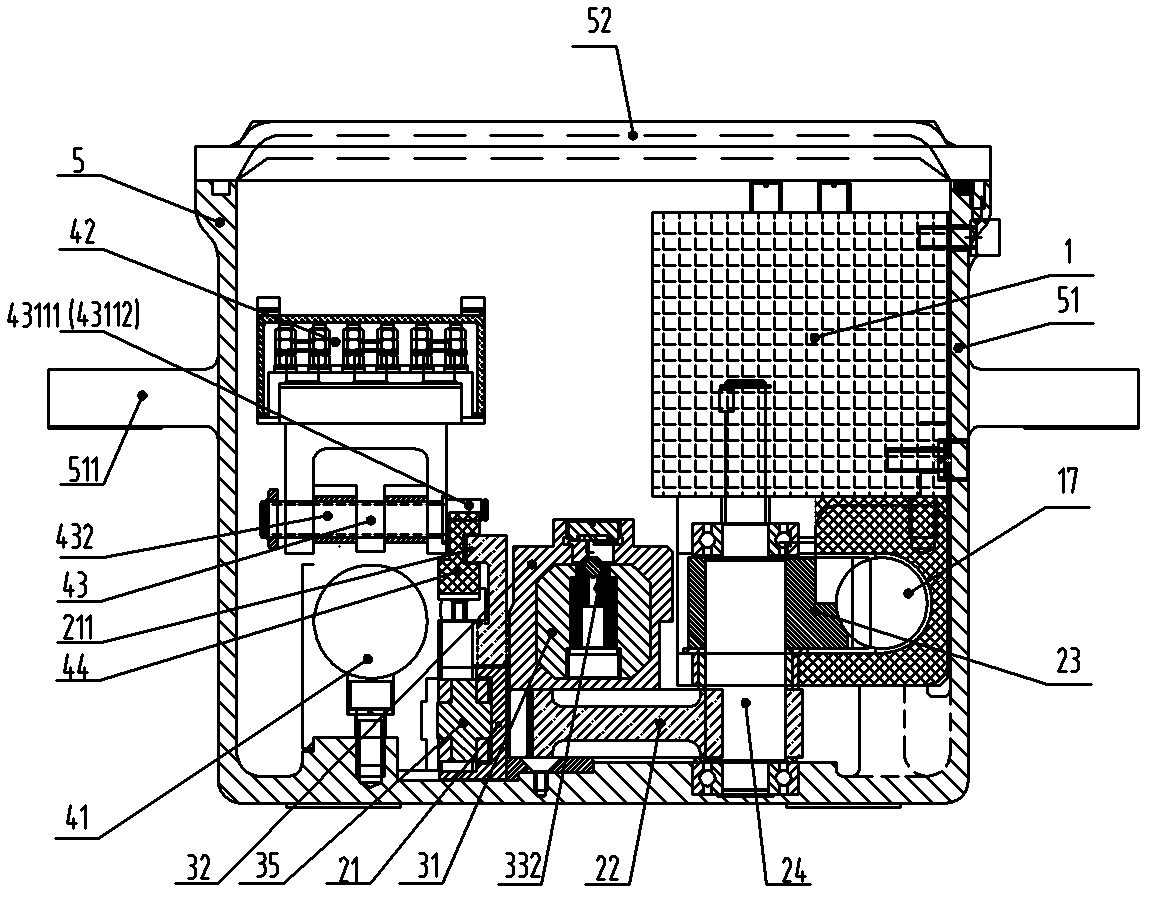

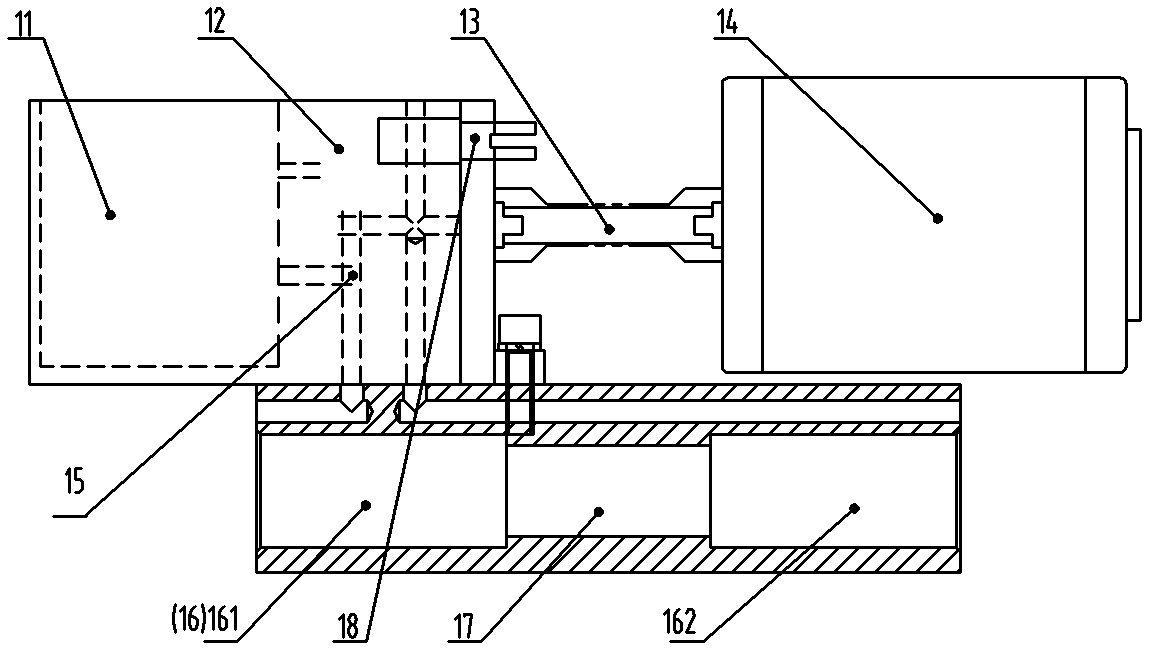

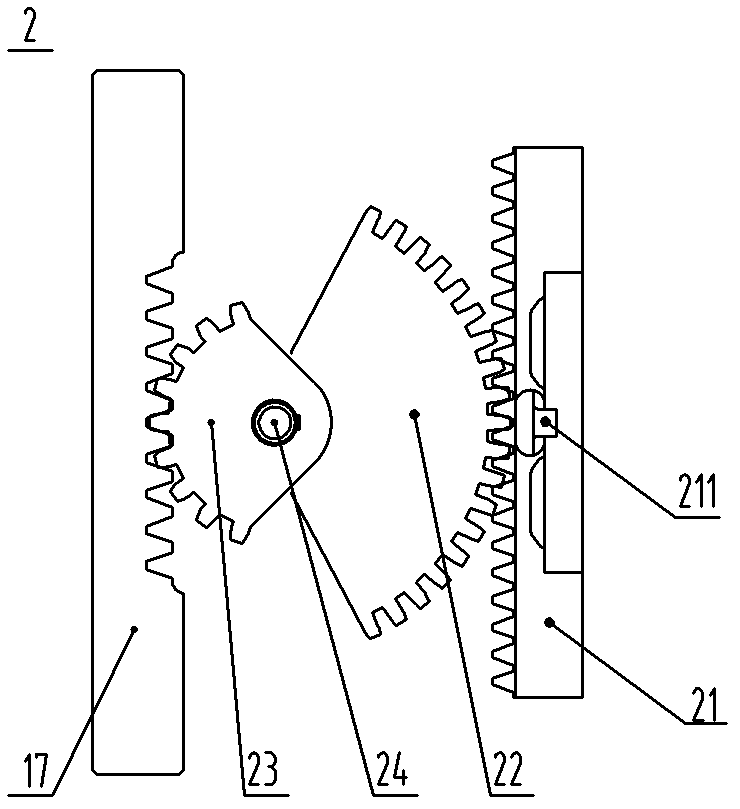

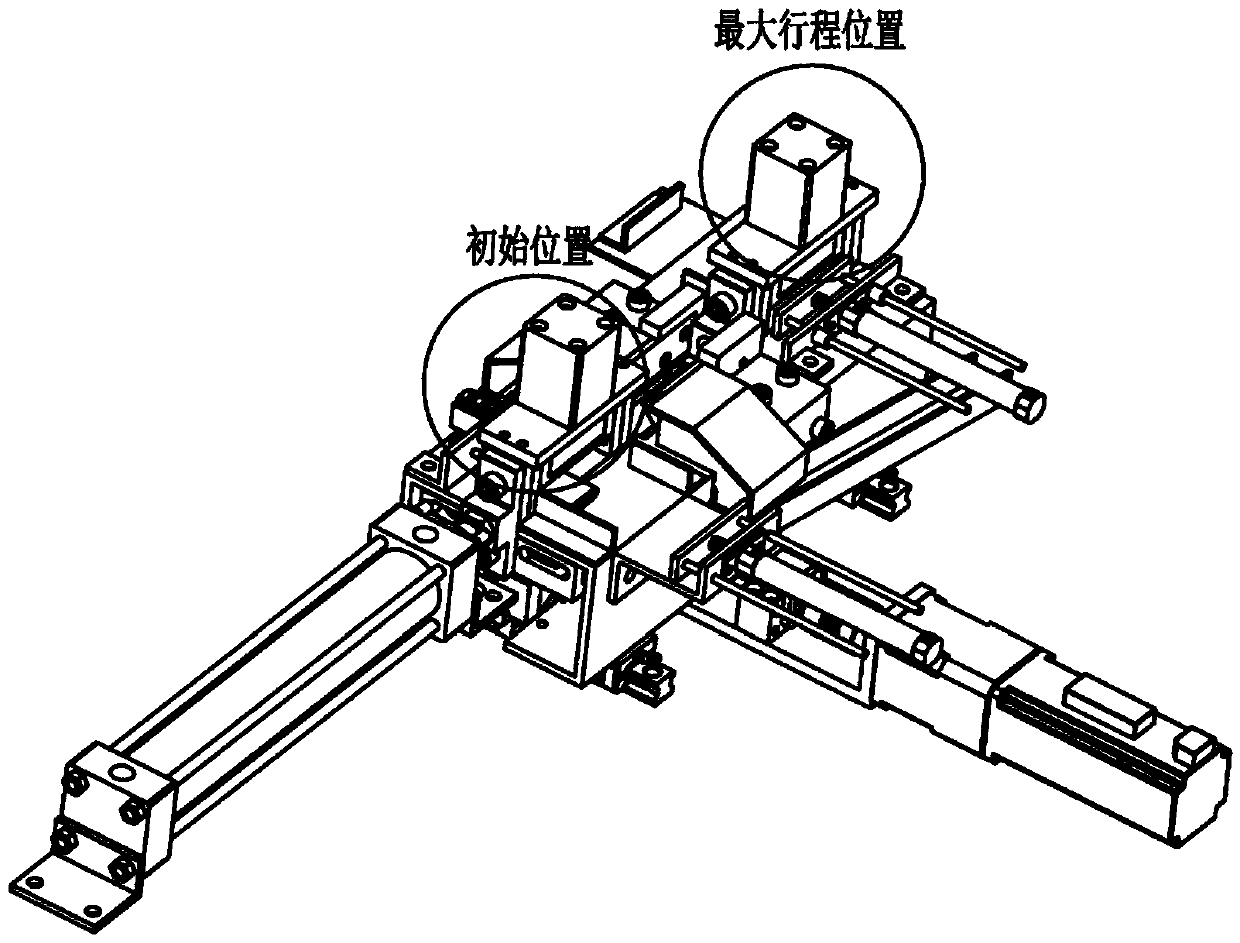

ActiveCN102602427AMotion synchronizationReduce movement distanceElectric devices for scotch-blocksFluid-pressure devices for scotch-blocksLocking mechanismElectro hydraulic

The invention discloses an electro-hydraulic point switch, comprising a motor, a hydraulic assembly, a transmission mechanism, a switch-and-lock mechanism and an expressing mechanism, which are interconnected, wherein a cylinder in the hydraulic assembly is a double-acting cylinder; a cylinder body is fixed, in which a piston moves; a rack tooth shape is processed on a piston rod in the hydraulic assembly to form a piston rack; and the piston rack is connected with the switch-and-lock mechanism and the expressing mechanism by the transmission mechanism composed of gears and racks so as to enable an acting rod for driving a point rail in the switch-and-lock mechanism to move and lock, and enable the expressing mechanism to correspondingly act on to give out the placing or non-placing related expression. The point switch can accurately push a plurality of point switches with point rail conversion switches to act synchronously. The point switch can accurately convert locking and unlocking action parts, effectively shorten the actual movement distance of an expressing part so as to drastically reduce the appearance size of the whole machine and convert into a manual operation mode conveniently and safely, and has the advantages of simplicity and lightness in operation and good sealing performance of the whole machine.

Owner:TIANJIN HUIHUANG LUYANG TECH

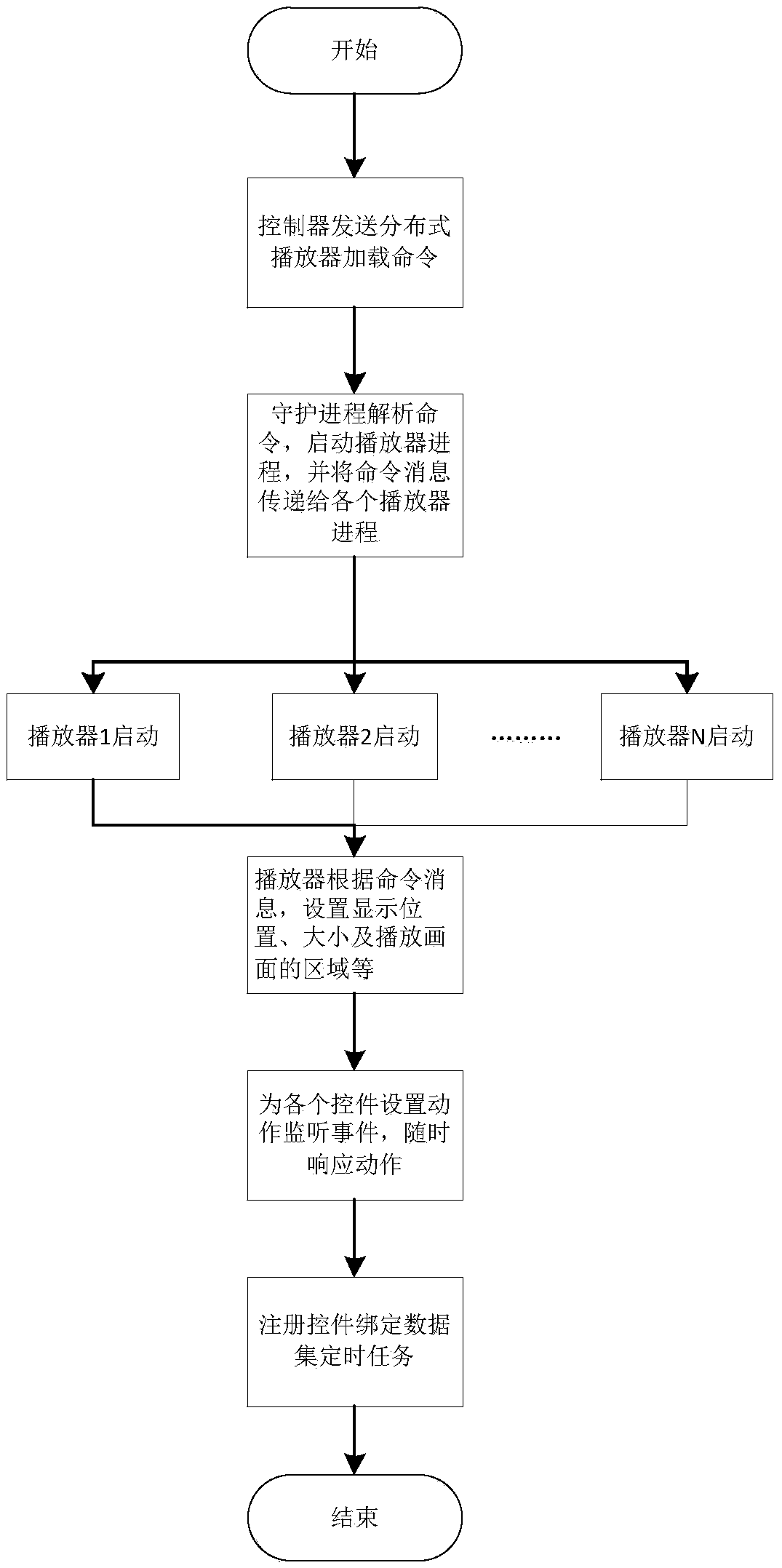

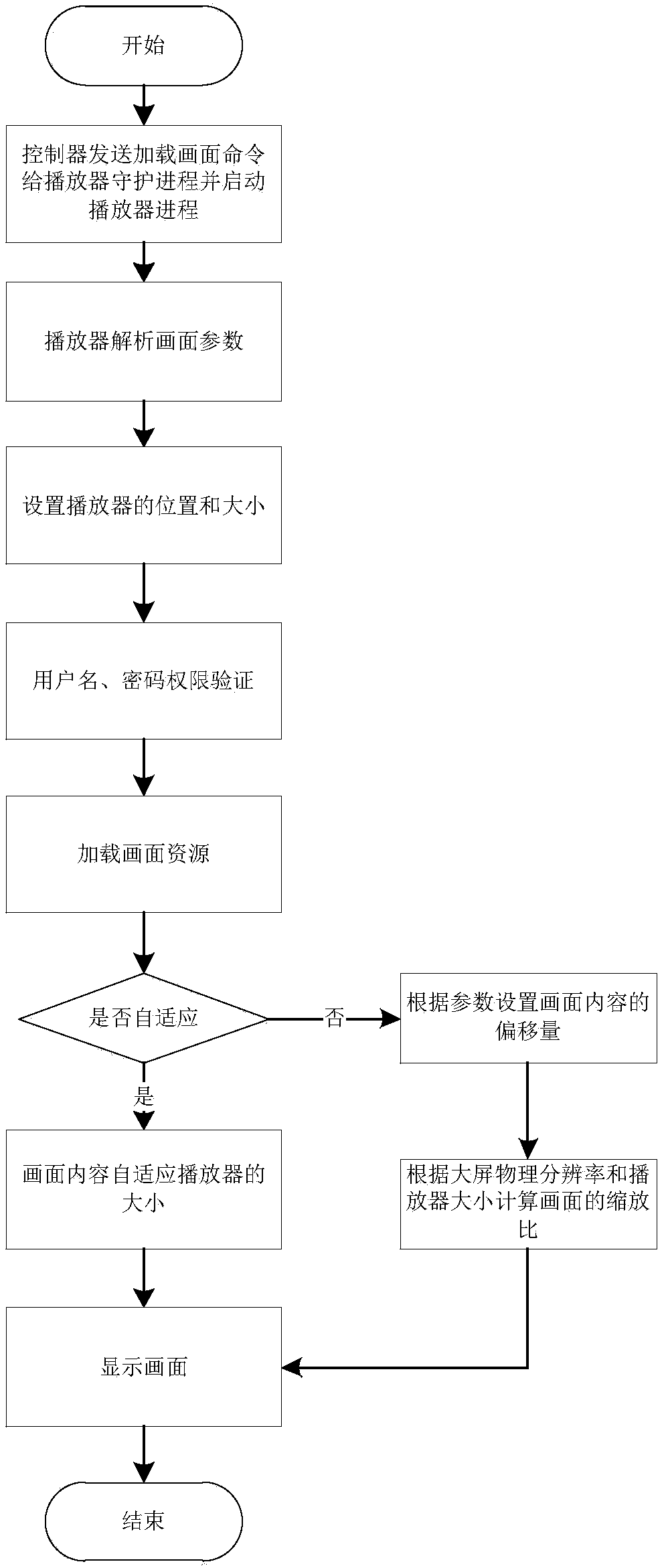

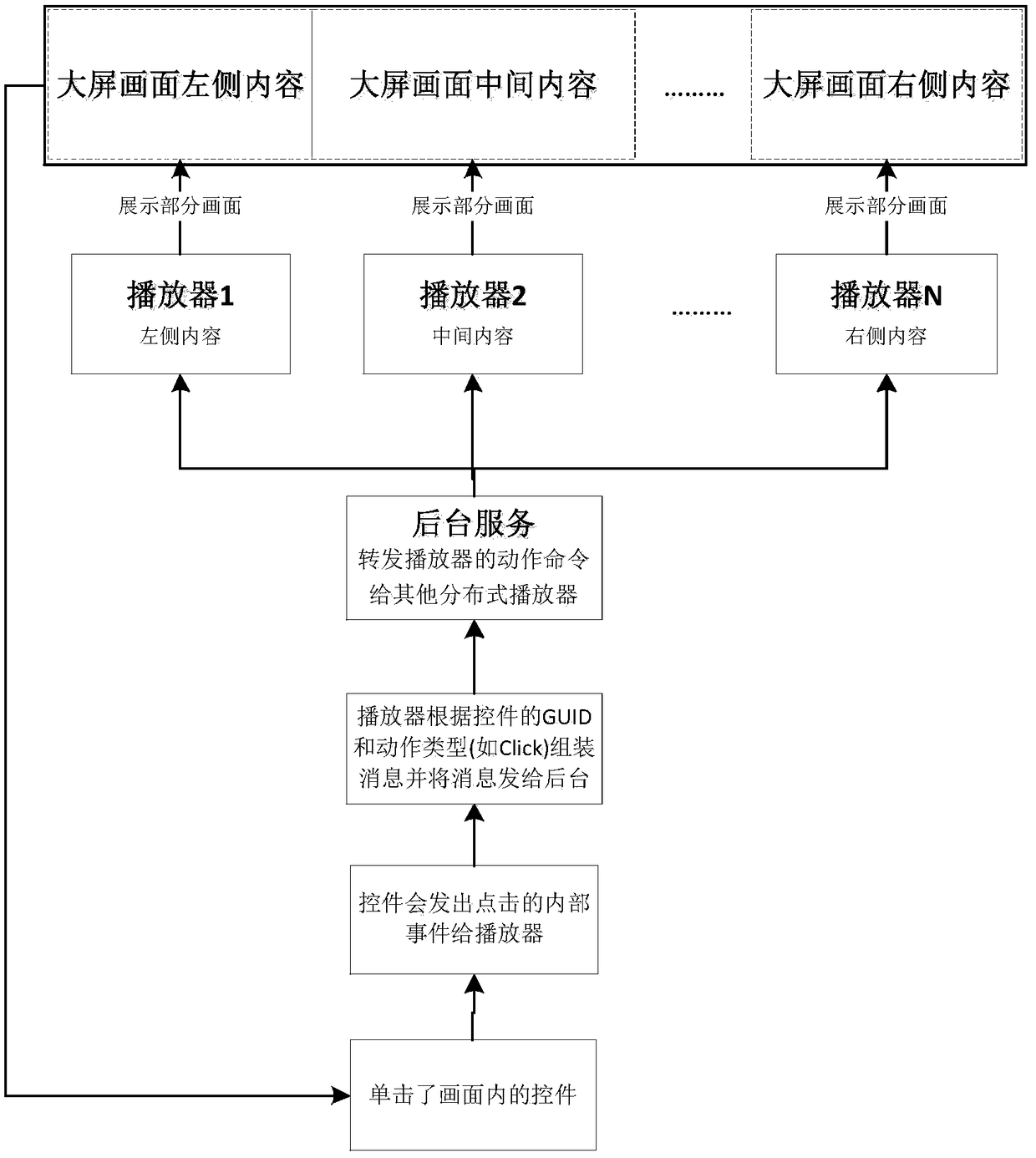

Distributed picture rendering and picture playing control method, apparatus and device

ActiveCN109164997ARealize real-time controlReal-time updateProgram initiation/switchingExecution for user interfacesData synchronizationCommand and control

The invention discloses a distributed picture rendering and picture playing control method, which comprises the following steps: a player monitors a picture distributed rendering display, a player monitors a picture control action synchronization and a picture control data synchronization; the player monitors a picture control action synchronization and a picture control data synchronization. Theinvention provides a distributed playing software system of a large screen visualization platform. Through an asynchronous, event-driven network application framework, control commands and control data are pushed directly to the client, the real-time synchronization of control actions and data of distributed player software pictures is realized, and the problem of picture rendering and synchronization when super-resolution or multiple graphics workstations display the same picture is effectively solved.

Owner:NARI INFORMATION & COMM TECH

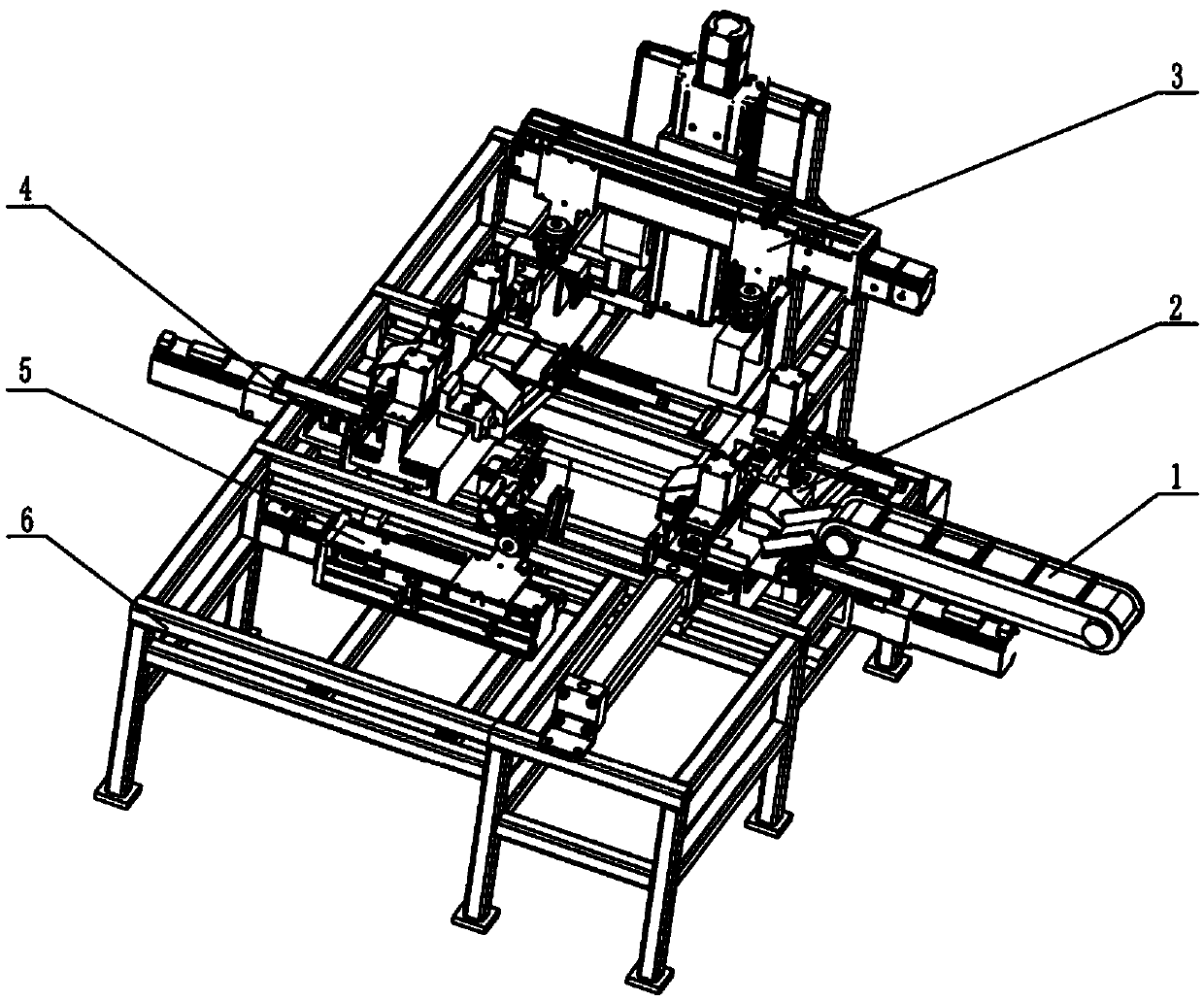

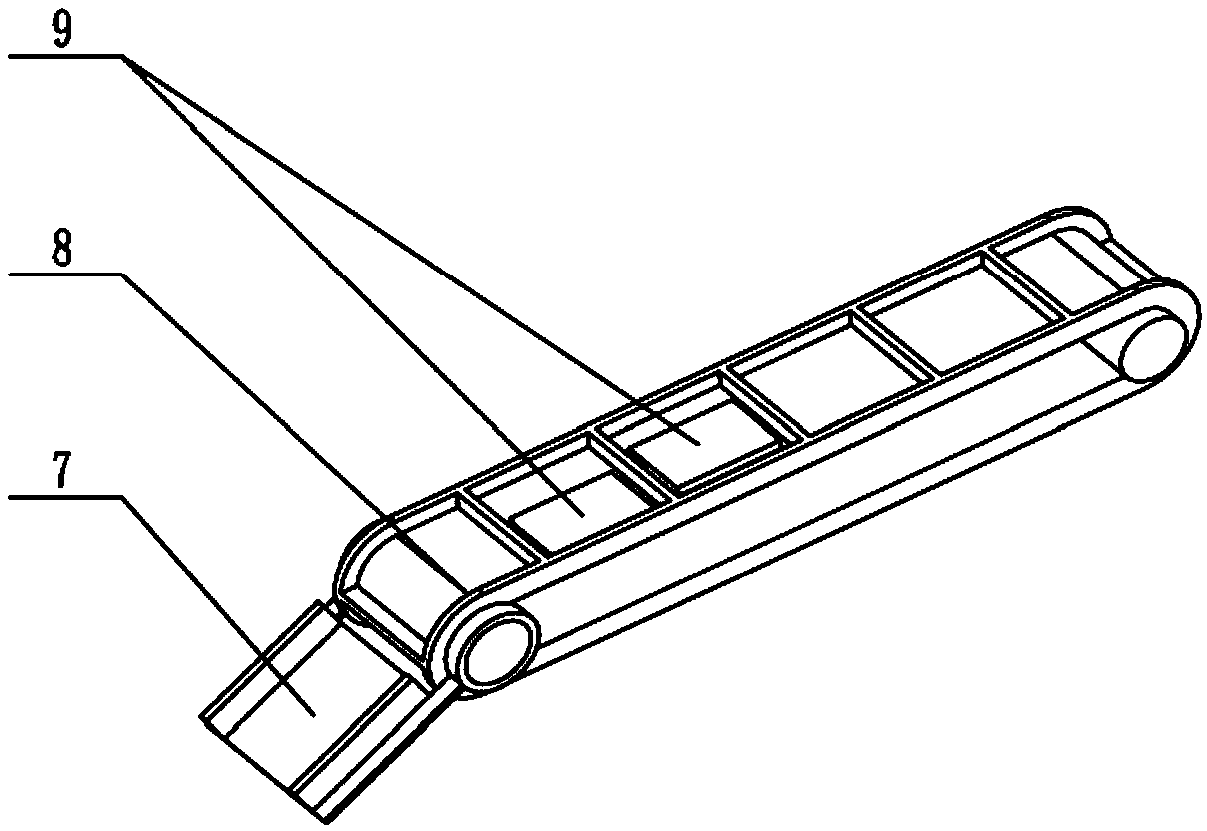

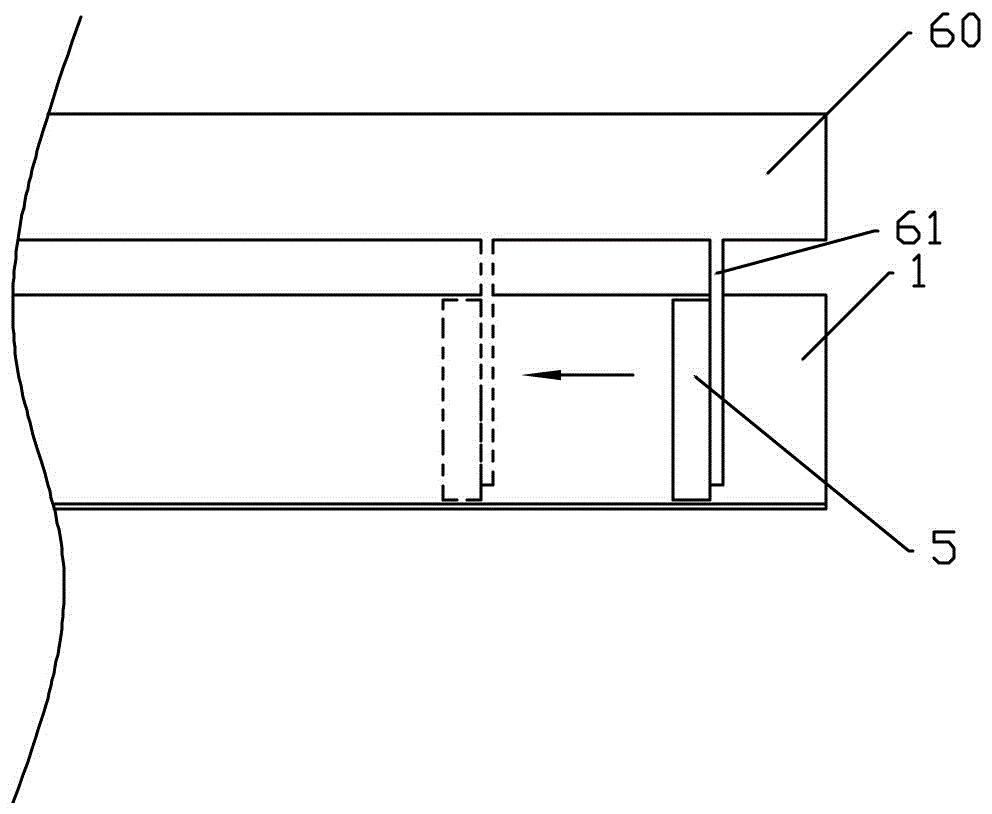

Device and method for disassembling square lithium ion batteries of multiple specifications

ActiveCN109672003AHigh degree of automationNo human intervention requiredSolid waste disposalTransportation and packagingControl systemAssembly line

The invention discloses a device and a method for disassembling square lithium ion batteries of multiple specifications. The device comprises a control system and an assembly line type disassembling system. The assembly line type disassembling system comprises an intermittent feeding device (1), a first automatic edge cutting device (2), a station conversion device (3), a second automatic edge cutting device (4) and a separating and core taking device (5). The control system controls all parts of the disassembling system to conduct the assembly line type operation. The intermittent feeding device conveys waste lithium ion batteries to the first automatic edge cutting device to complete the edge cutting operation on the two symmetrical sides of the batteries. The station switching device rotates the cut batteries by 90 degrees and conveys the cut batteries to the second automatic edge cutting device to complete the edge cutting operation on the other two sides of the batteries. The separating and core taking device separates and collects upper and lower meter shells and battery cells. The lithium ion battery disassembling device is high in automation degree and high in adaptability.The discharging and safety problems in the lithium ion battery disassembling process are effectively guaranteed in a knife-cutting disassembling mode. The separation of a battery cell and a battery shell is achieved to the maximum extent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

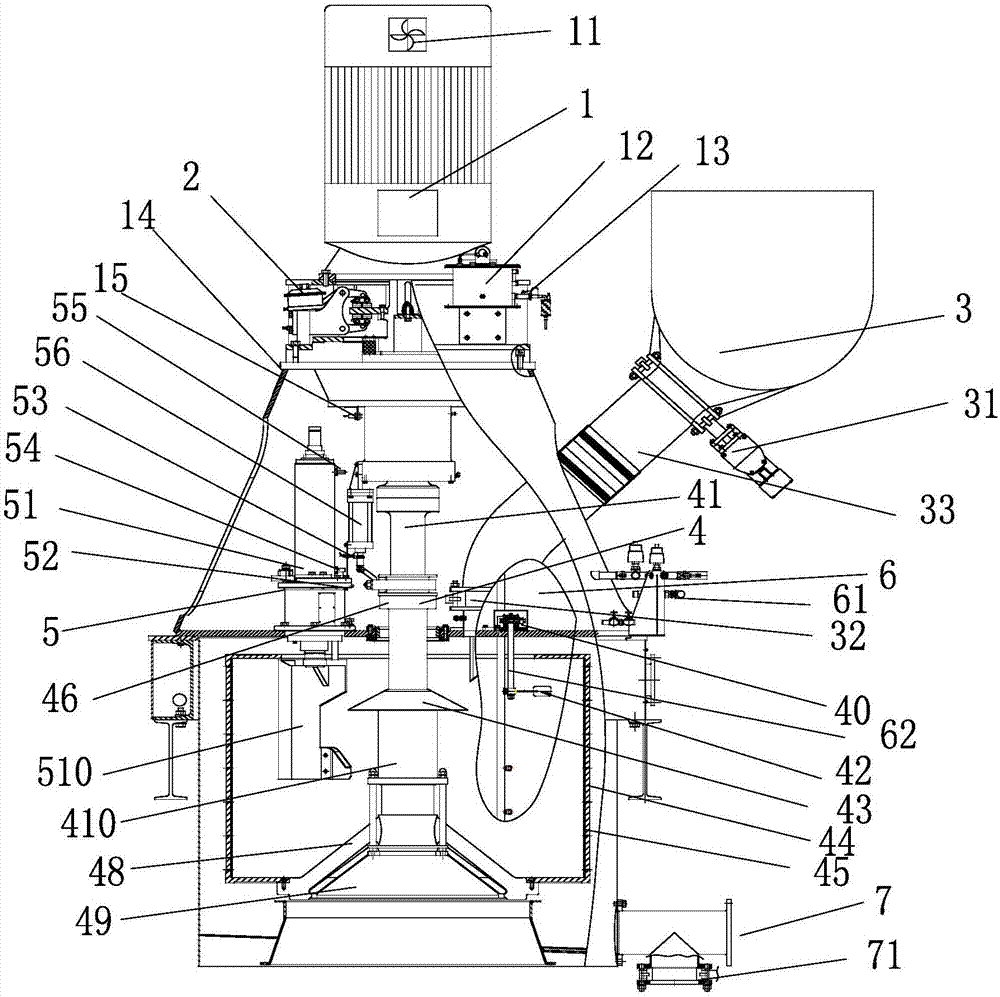

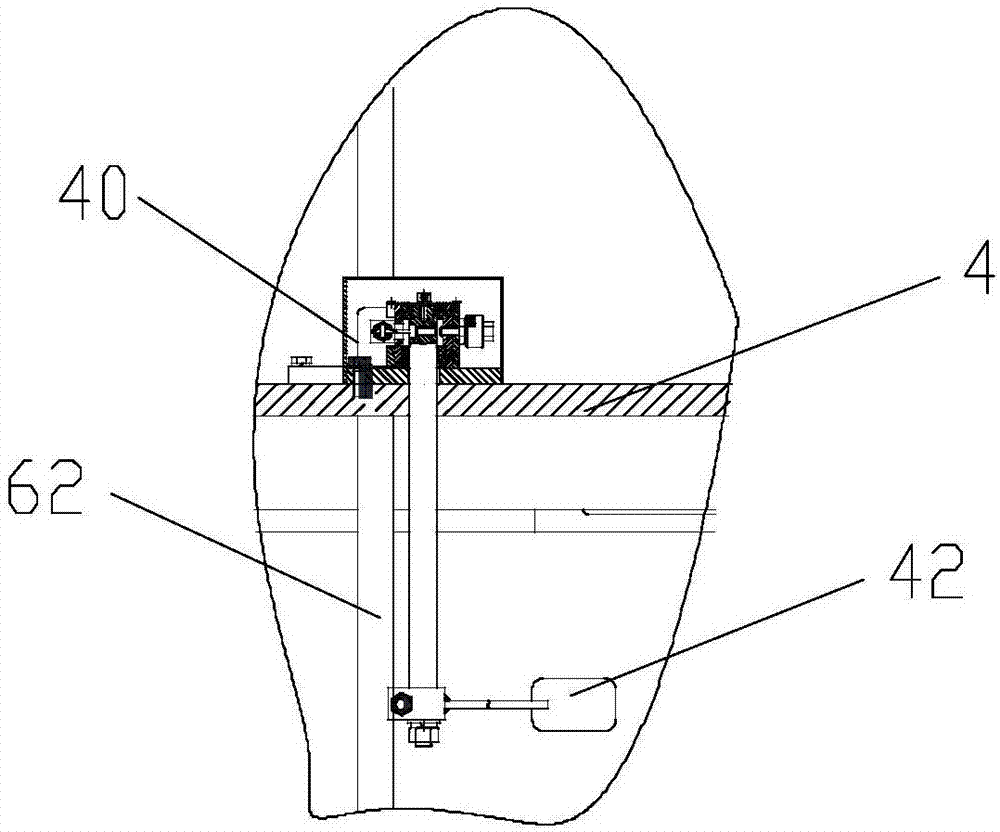

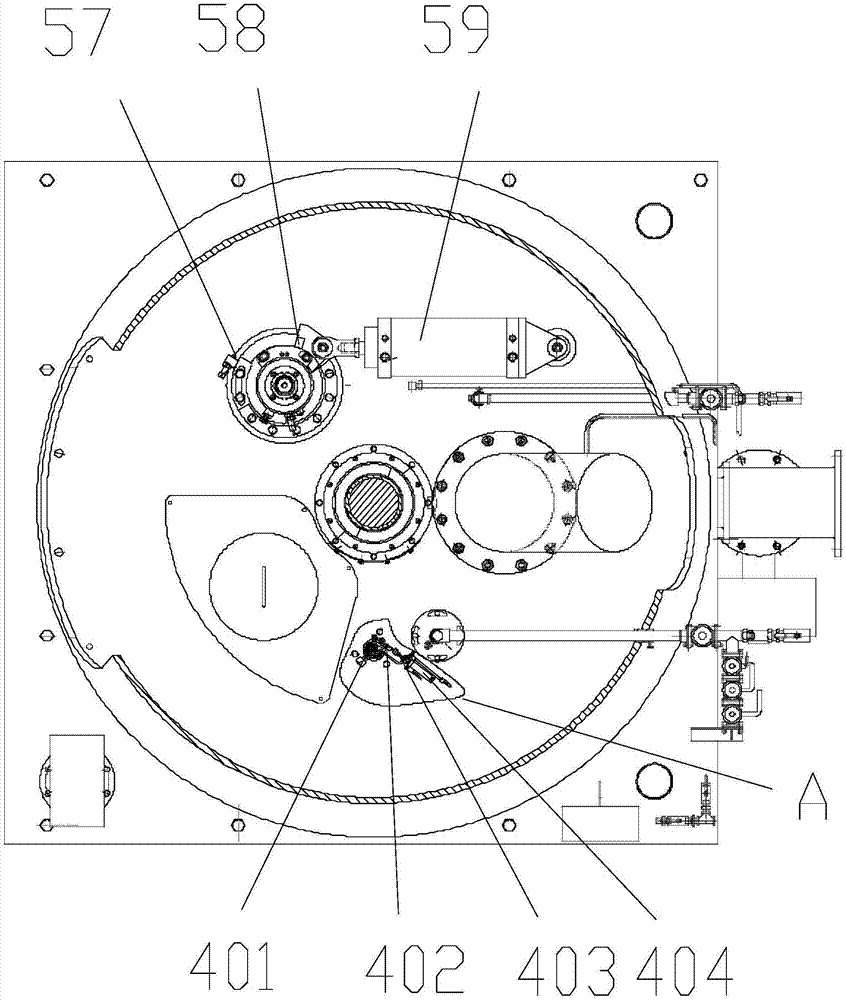

Centrifugal machine for synchronous display through human-computer interface

InactiveCN107350093AMotion synchronizationSynchronize display actionsCentrifugesHuman–machine interfaceWater vapor

The invention discloses a centrifugal machine for synchronous display through a human-computer interface. The centrifugal machine comprises a driving device, a brake device, a feeding device, a screen basket device, an unloading device, a water vapor cleaning device and a PLC control unit, wherein the feeding device comprises two butterfly valves; the unloading device comprises three detection proximity switches for detecting positions of a scraper of the unloading device and a screen basket hood in real time and obtaining corresponding position signals; the PLC control unit collects opening information of the two butterfly valves, detection information of the three detection proximity switches and rotating speed information of a motor, and synchronously displays dynamic pictures of parts in real time through the human-computer interface and simulates real-time actions of the parts after processing. The centrifugal machine for synchronous display through the human-computer interface disclosed by the invention achieves synchronization of human-computer display and actions in operating process of the device, and in particular can display actions of mechanical parts in the screen basket, for example, the scraper, the screen basket hood, a material limiter, the water vapor cleaning device, the screen basket and the like.

Owner:广州广重分离机械有限公司

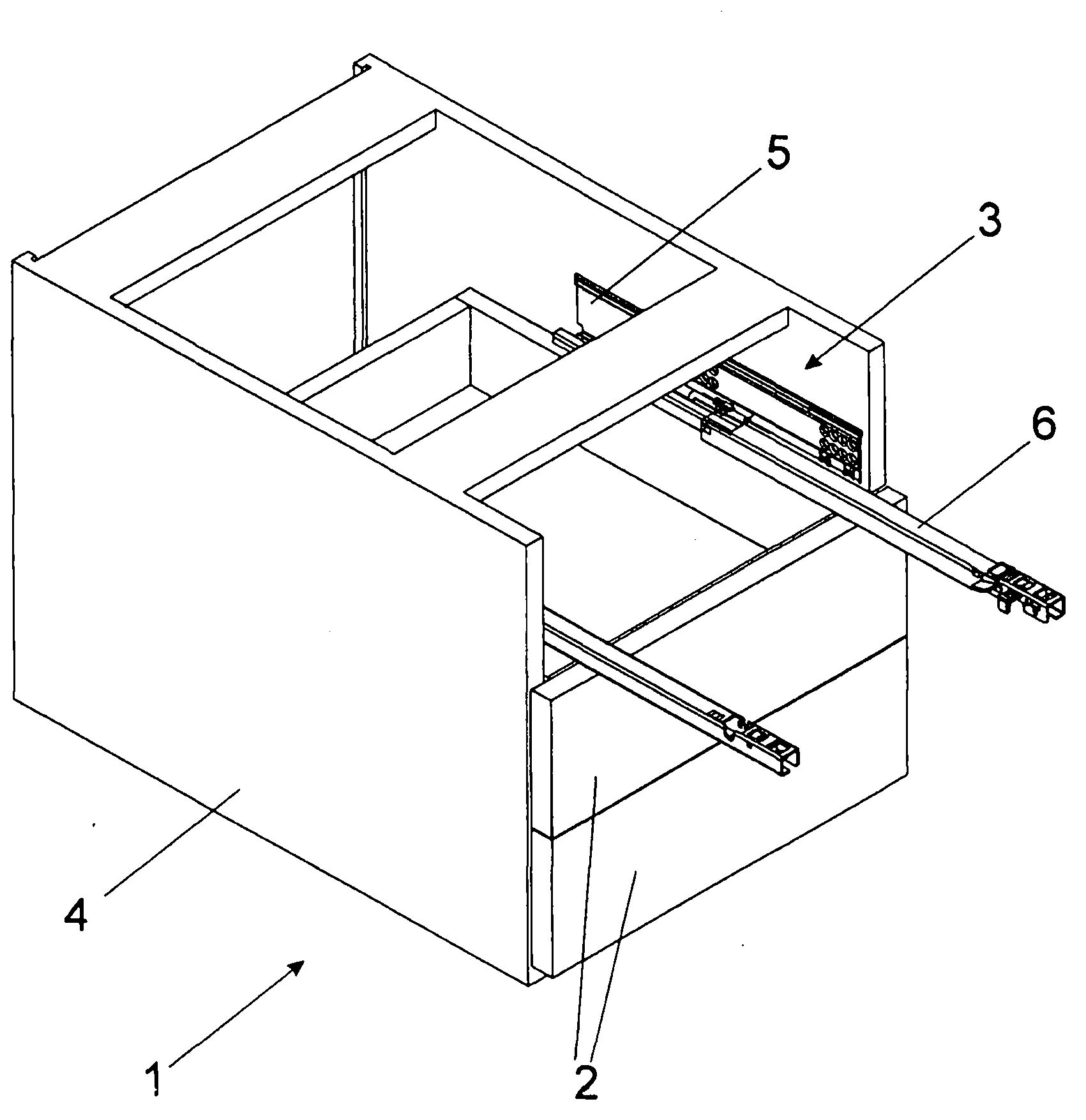

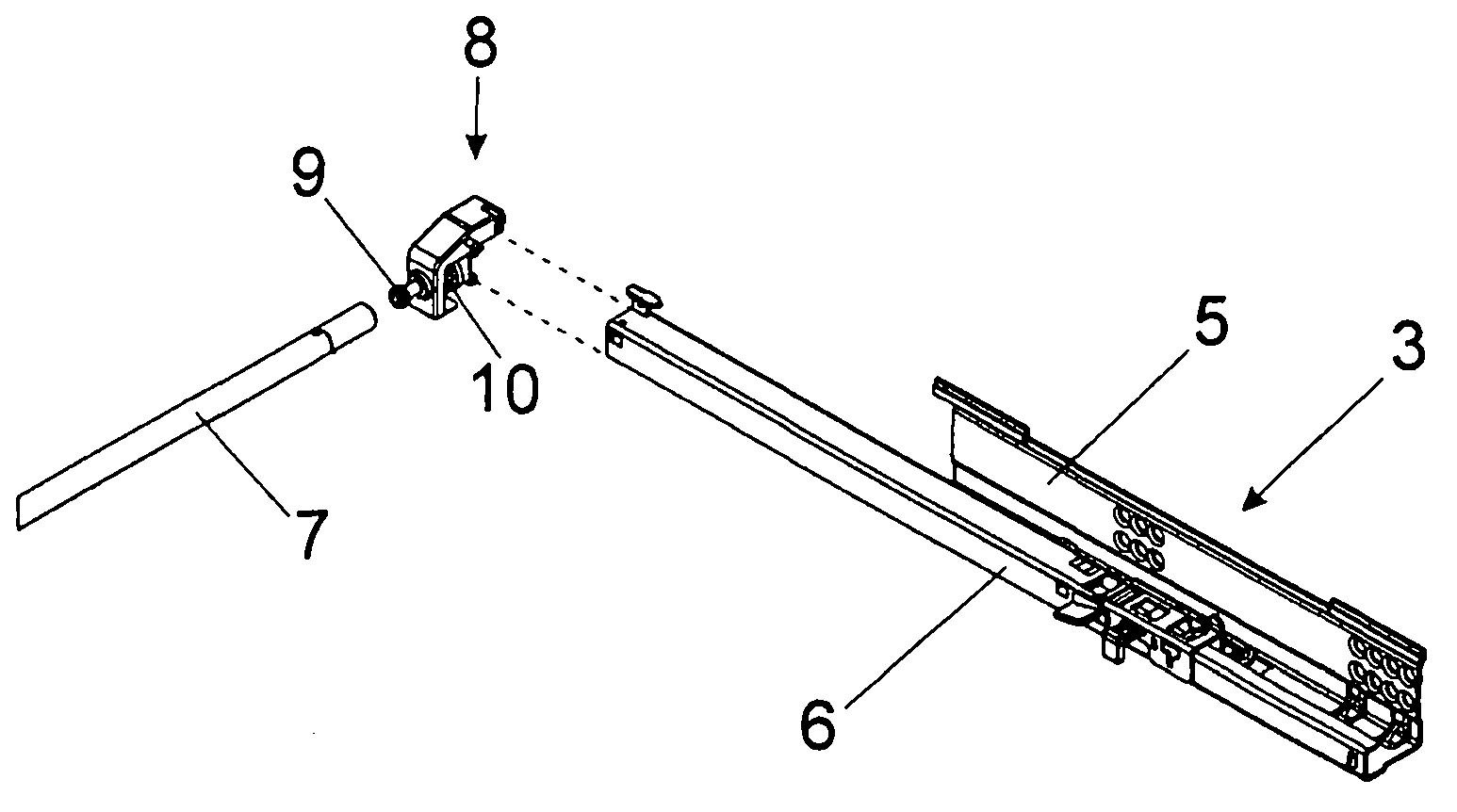

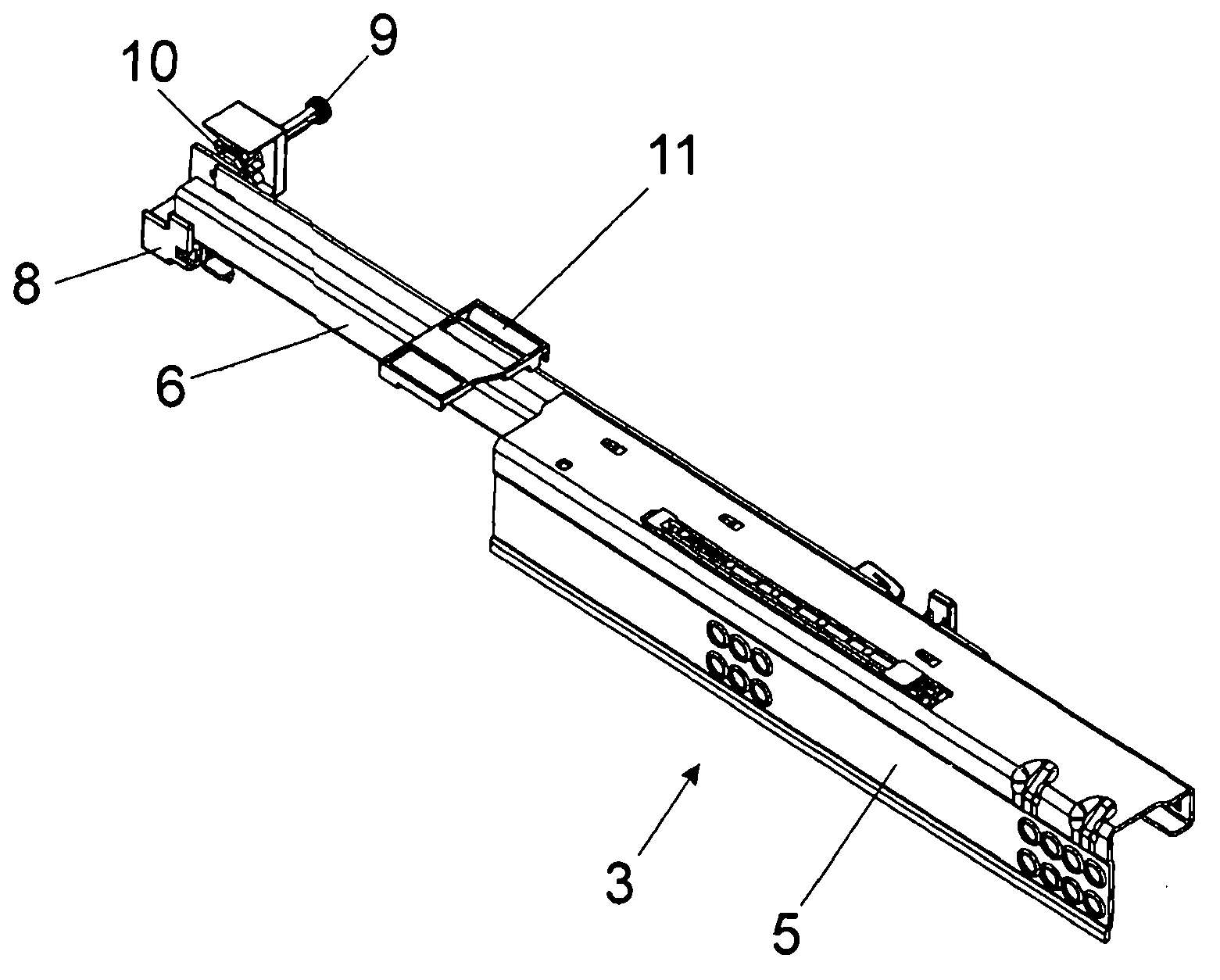

Device for attaching functional part to guide rail of drawer pulling-out guider

ActiveCN103228180AWith fastening possibilityFastens comfortably and quicklyDrawersMechanical engineeringClassical mechanics

Owner:JULIUS BLUM GMBH

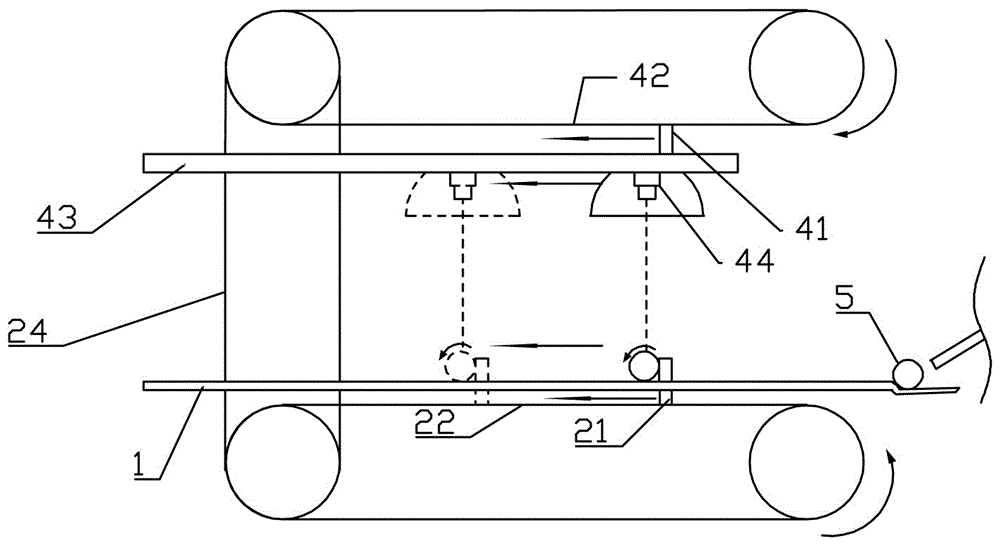

Workpiece inspection device

InactiveCN106706652AAvoid shaking from side to sideImprove shooting accuracyOptically investigating flaws/contaminationImage detectionMechanical engineering

The invention relates to a workpiece image detection device, in particular to a workpiece inspection device. The workpiece inspection device comprises a machine frame, a flat plate, a pushing part for pushing a cylindrical workpiece to roll on the flat plate and a shooting mechanism; the shooting mechanism comprises a camera for shooting the cylindrical workpiece. The workpiece inspection device is characterized by further comprising a camera transporting part for pushing the camera; the camera transporting part is fixedly connected with the camera and is positioned above the flat plate, the speed of the camera transporting part is equal to that of the pushing part, the moving direction of the camera transporting part is parallel to and the same as that of the pushing part. The invention aims to provide a high-precision automatic detection device for the cylindrical workpiece.

Owner:CHONGQING SUTENG MACHINERY MFG

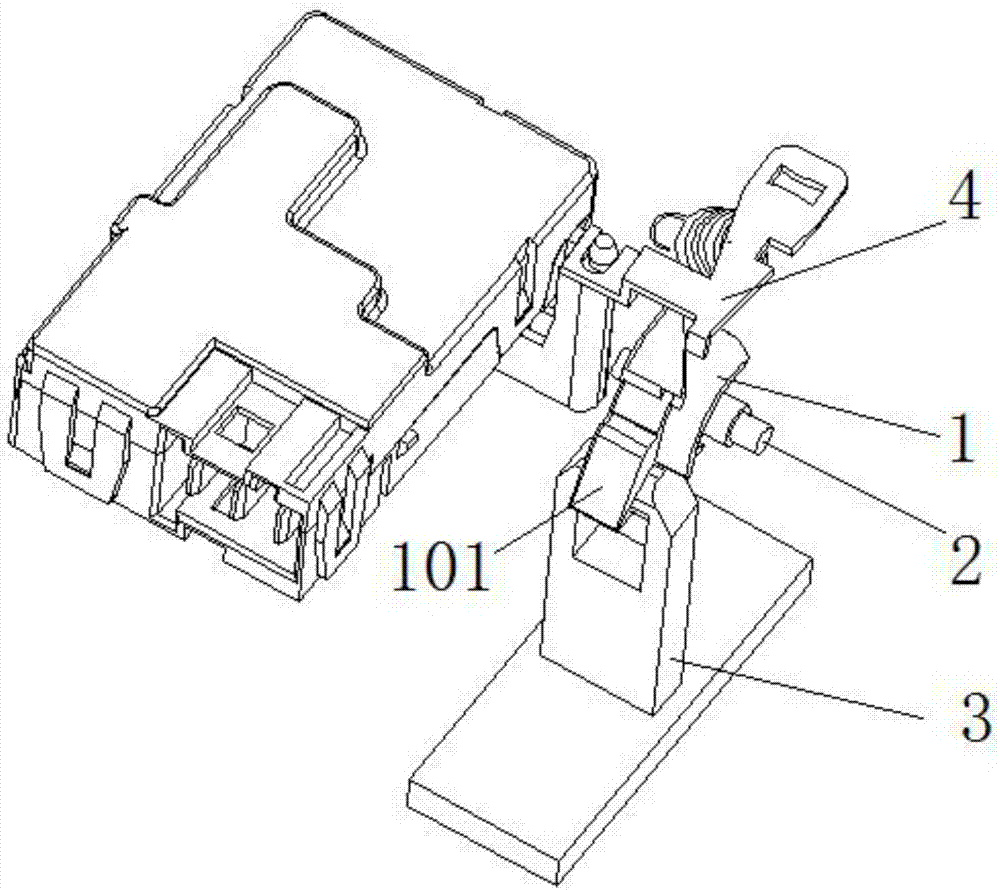

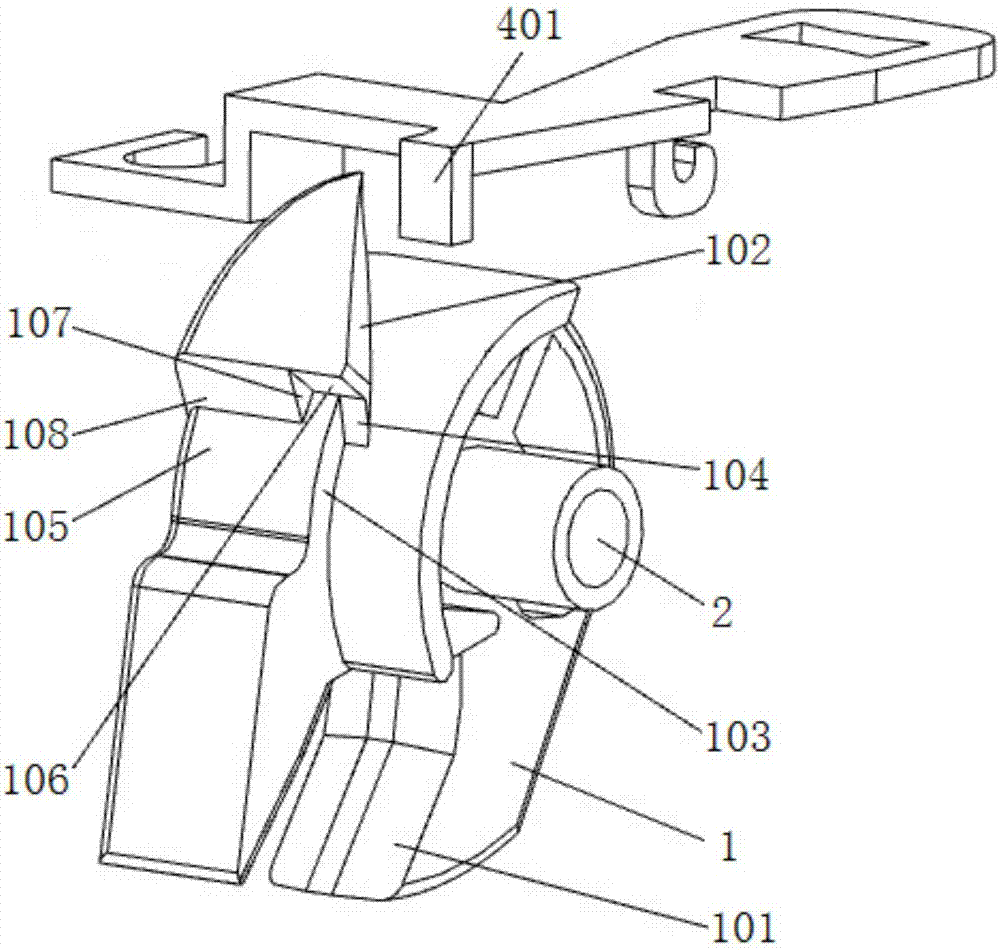

Door lock rotating device and washing machine door lock with same

ActiveCN107245846ABlock lock failedThere will be no failure to lock the door lockOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention provides a door lock rotating device and a washing machine door lock with the same, and belongs to the technical field of washing machine door locks. A door lock rotating matching structure comprises a rotating piece, a rotating piece resetting elastic part, a lock catch, a lock catch resetting elastic part and a locking matching structure; when a door is closed, a door hook is inserted into a lock shell, the rotating piece drives the locking matching structure to rotate, the locking matching structure guides the lock catch to move to a lock catch locking position, and then the rotating piece is locked; and when the door is opened, the door is pushed slightly in the direction of closing the door, the rotating piece continuous driving the locking matching structure to rotate, the locking matching structure guides the lock catch to move to a lock catch resetting position, the rotating piece rotates, and then the door hook is unlocked. The door lock rotating matching structure can be quite conveniently used on the outside of a door panel of a washing machine, a handle for pulling the door is not required, and moreover, the door lock rotating matching structure can also be used on a washing machine with a handle on the outside of a door panel, and is wide in application range and convenient to use.

Owner:WENZHOU TIANJIAN ELECTRIC APPLIANCE

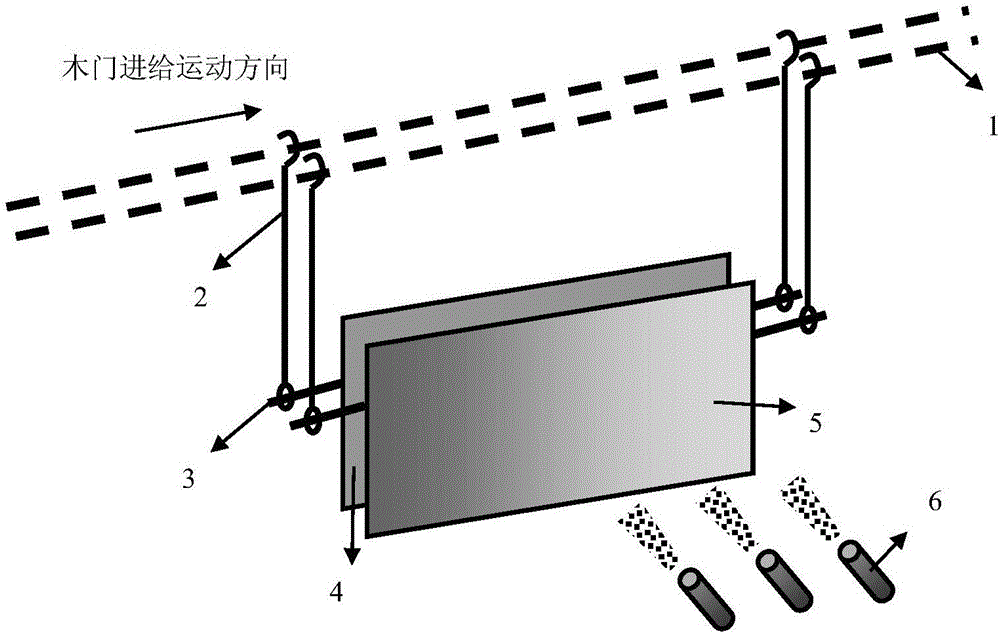

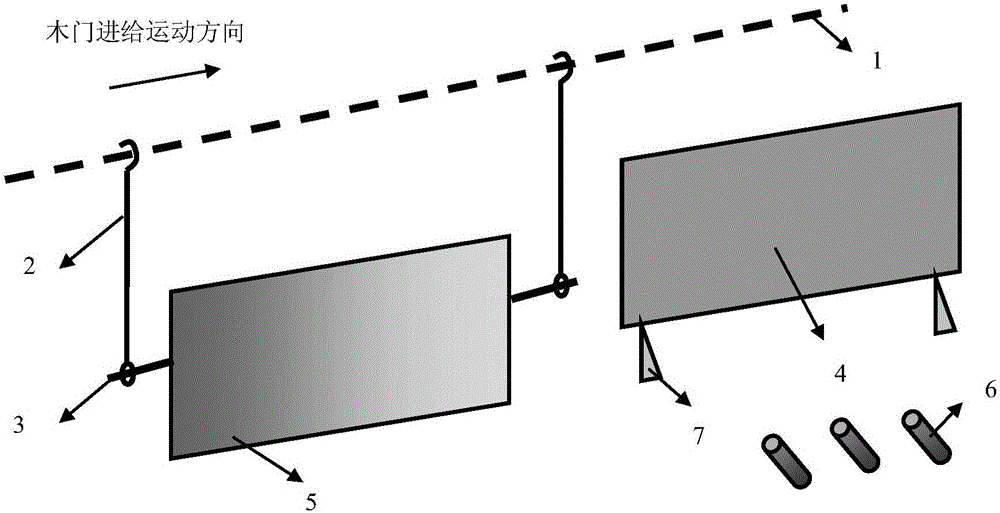

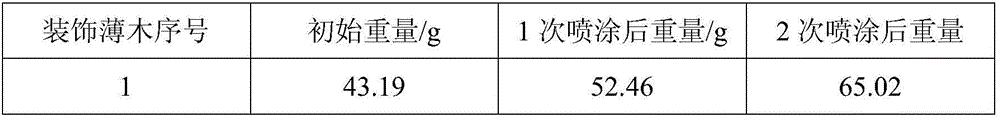

Method for improving quality of electrostatic surface coating of wooden door

ActiveCN106391428ADoes not reduce adhesionImprove the quality of electrostatic sprayingLiquid surface applicatorsCoatingsMechanical engineeringSurface coating

The invention discloses a method for improving the quality of an electrostatic surface coating of a wooden door. The method for improving the quality of the electrostatic surface coating of the wooden door comprises the steps that the wooden door is prepared; and spraying is conducted, specifically, a grounding conductive board is adopted to be placed on the back side of the wooden door during spraying, and in the electrostatic spraying process, the wooden door is located between an electrostatic spraying gun and the grounding conductive board. By adoption of the method for improving the quality of the electrostatic surface coating of the wooden door, the problems that in the conventional electrostatic spraying process of the wooden door, the thickness of a coating is nonuniform, the painting rate is instable, and painting is difficult during secondary spraying or finish paint spraying can be solved; and meanwhile, no humidification treatment needs to be conducted on the surface of the wooden door, so that the adhesive force of a paint film is not reduced, and the electrostatic spraying quality is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

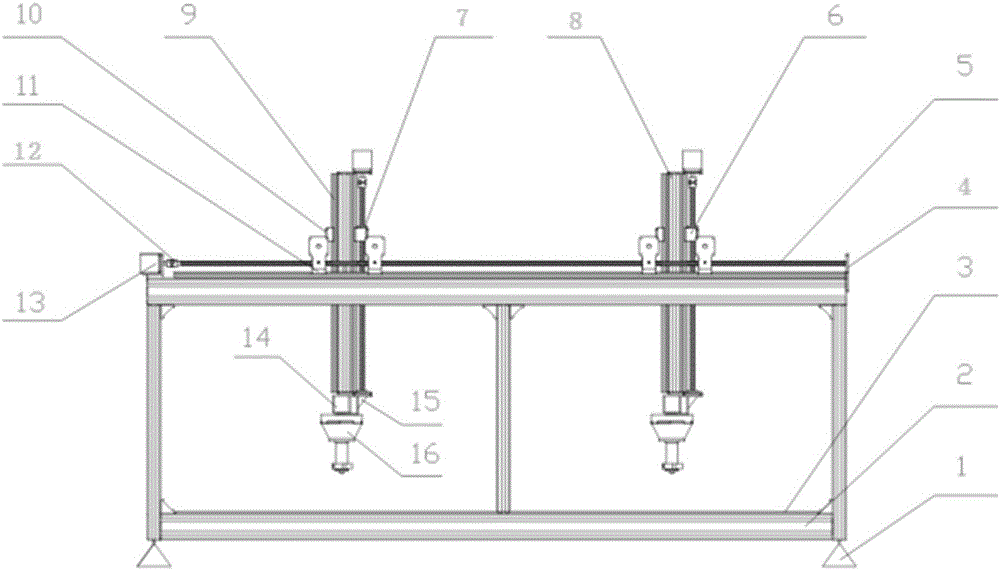

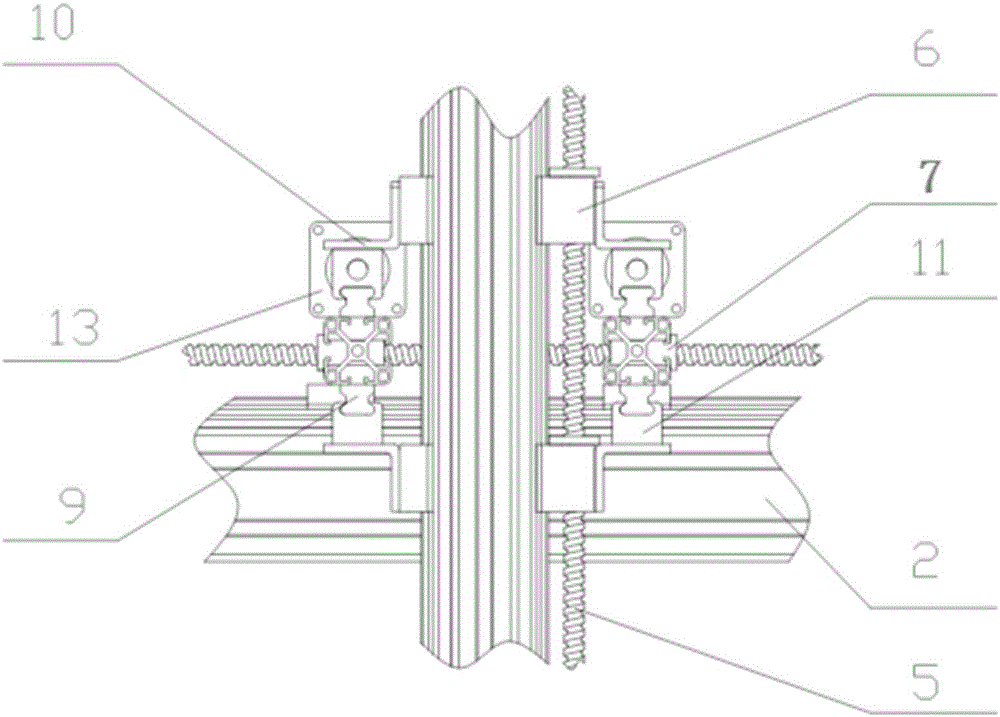

Industrial double-beam area divided type 3D printer

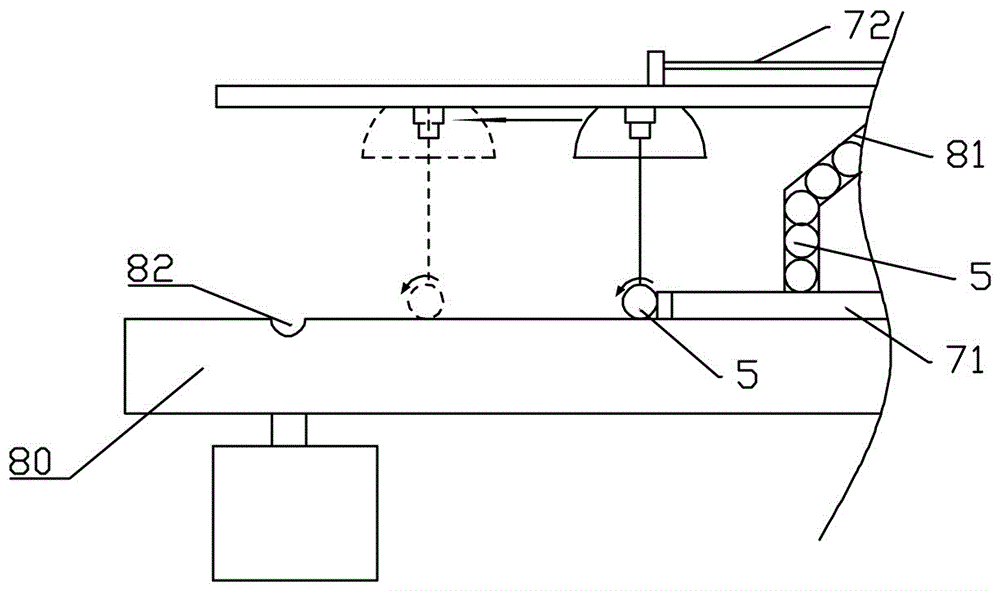

InactiveCN106313502AGuaranteed stabilityMotion synchronization3D object support structuresApplying layer meansMulti materialBall screw drive

The invention discloses an industrial double-beam area divided type 3D printer, and belongs to the technical field of digital machining. The defects that at present, a printer is limited in printing space, low in forming speed and incapable of carrying out multi-material printing and multi-area simultaneous printing are overcome. Due to motor ball screw drive and liner sliding rail and sliding block positioning, stable and rapid printing operation is achieved. Modules of CNC, a laser engraving spraying head and the like are attached to a machine body, the function of the printer is enriched and expanded, and one printer has multiple purposes. Development of the industrial large-breadth FDM 3D printer can greatly fill up the vacancy of large industrial product design molding and artware design molding on market, due to the rapid integral equal-proportion forming, the design achieving progress can be greatly shortened, a large amount of time, money and other costs can be saved, the cost of the printer is relatively low, the integration degree is high, and market generalizability and practicability are very high.

Owner:JILIN UNIV

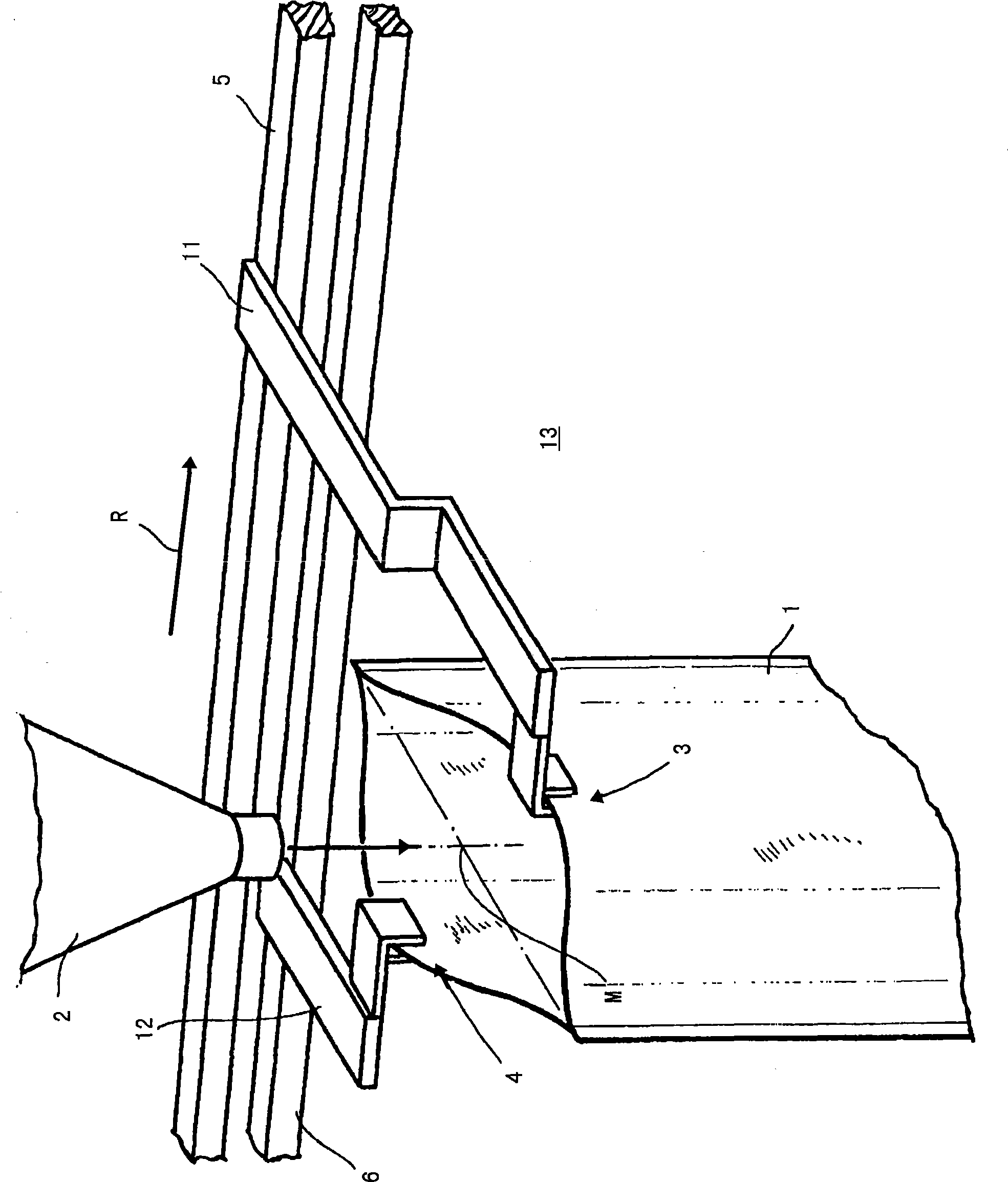

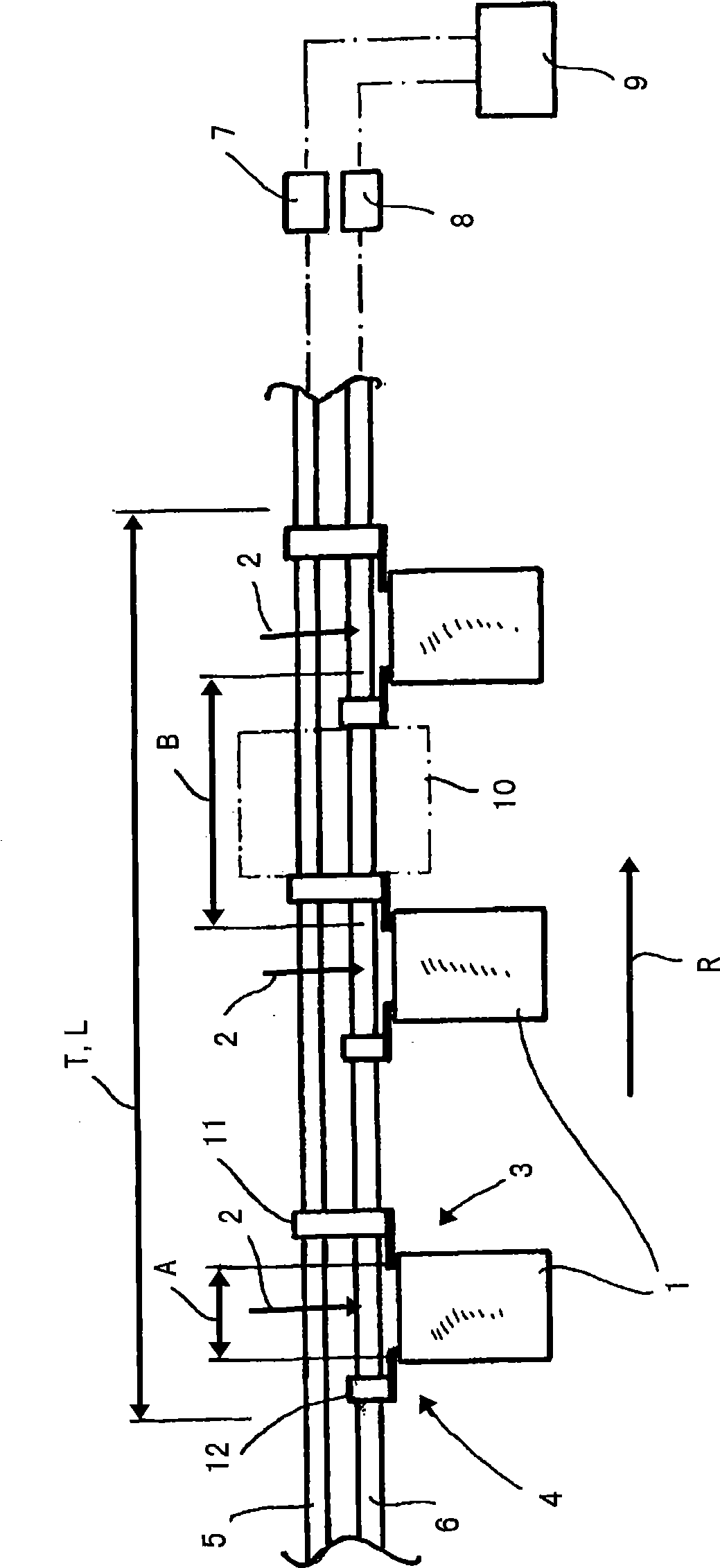

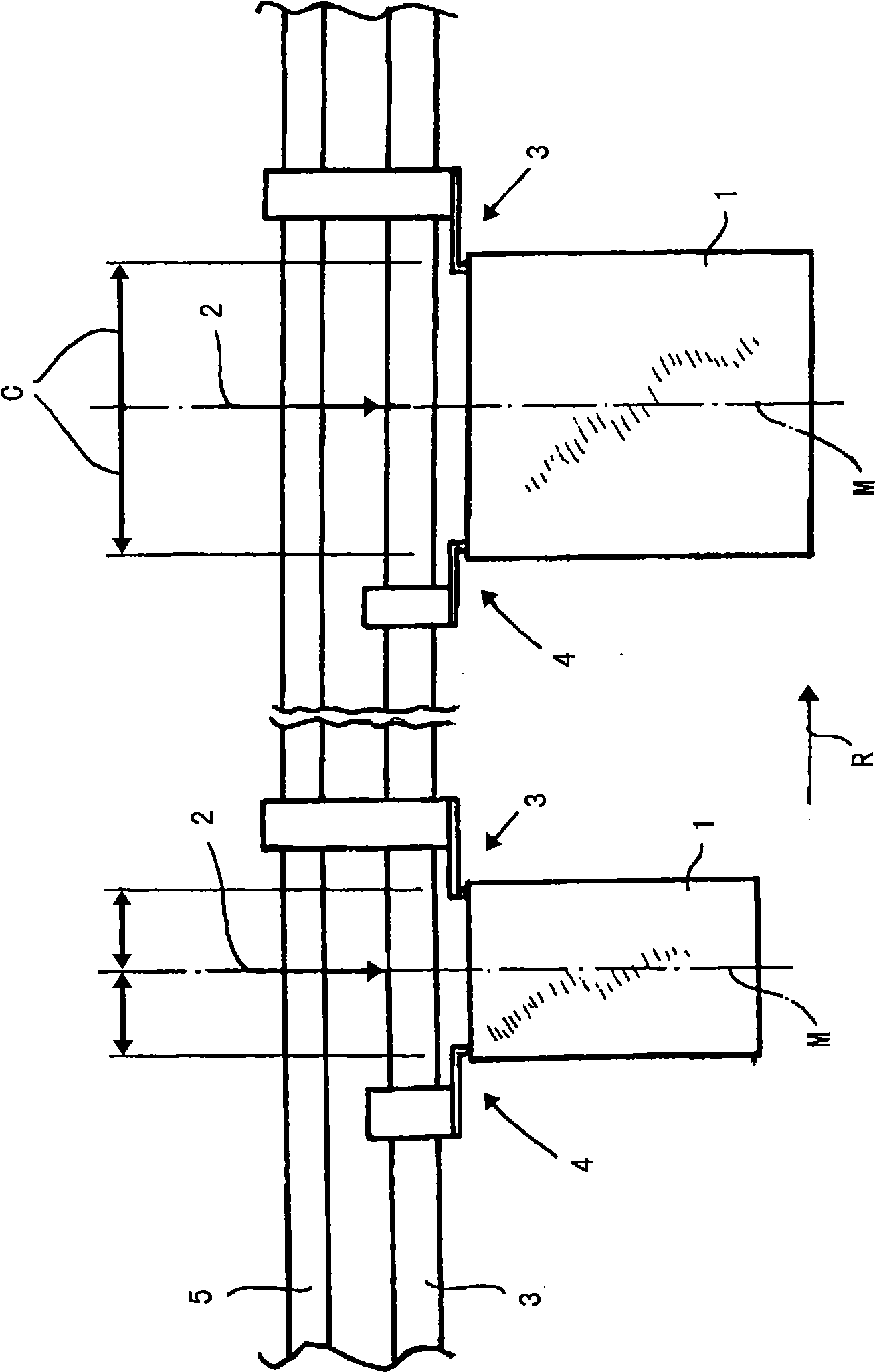

Guide bar assembly for a warp knitting machine

ActiveCN106167955ASimple structureLess risk of vibrationWarp knittingEngineeringMechanical engineering

The invention discloses a guide bar arrangement (1) of a warp knitting machine which has at least one guide bar (2), transverse moving devices (5-7) acting on the guide bar (2) in an exclusive drive direction and a pull back arrangement acting opposite to the drive direction. It is wanted to agree a high working speed with a high accuracy. For this purpose, the pull back arrangement has pull back drive devices (11-17).

Owner:KARL MAYER STOLL R&D GMBH

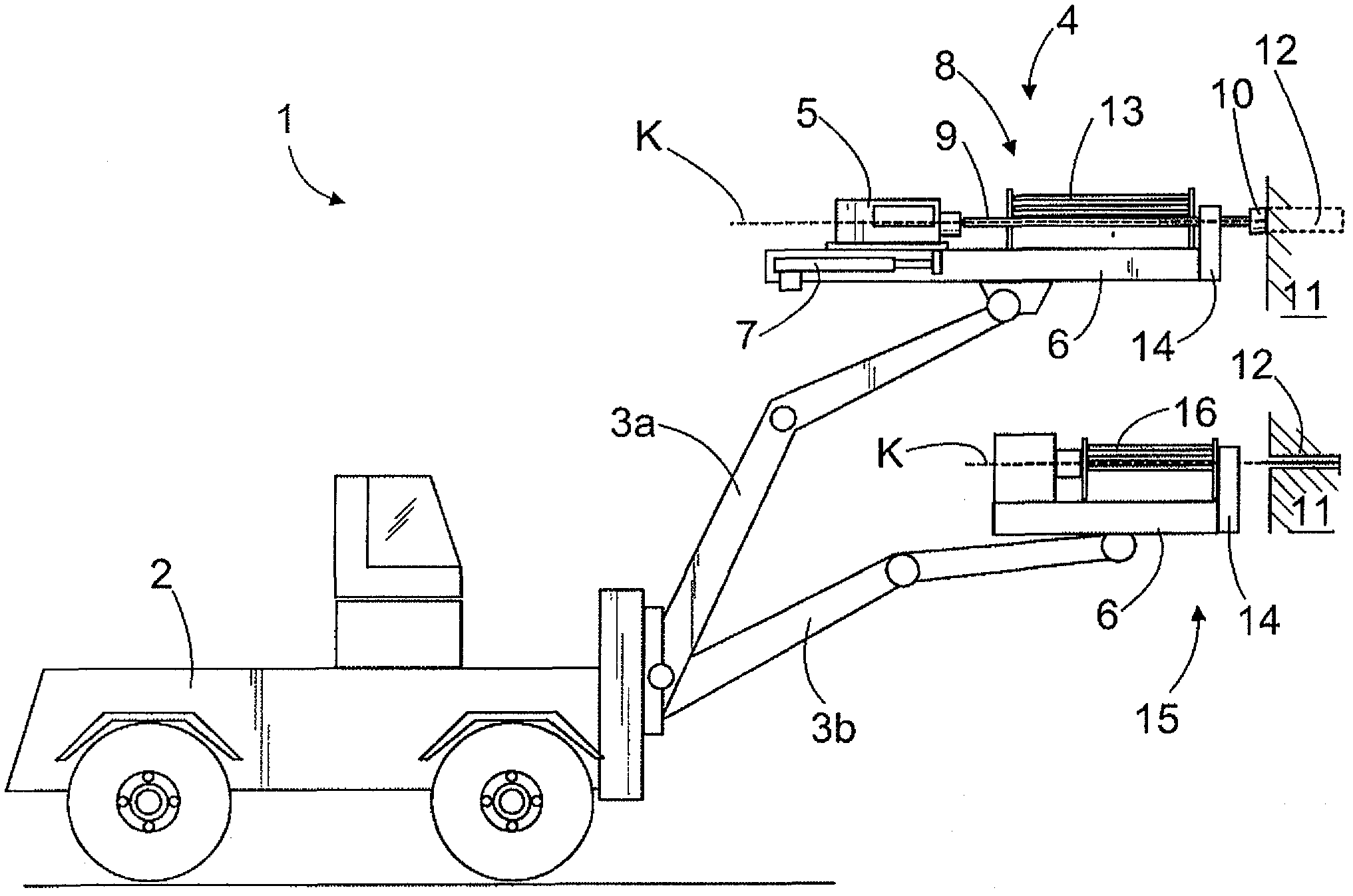

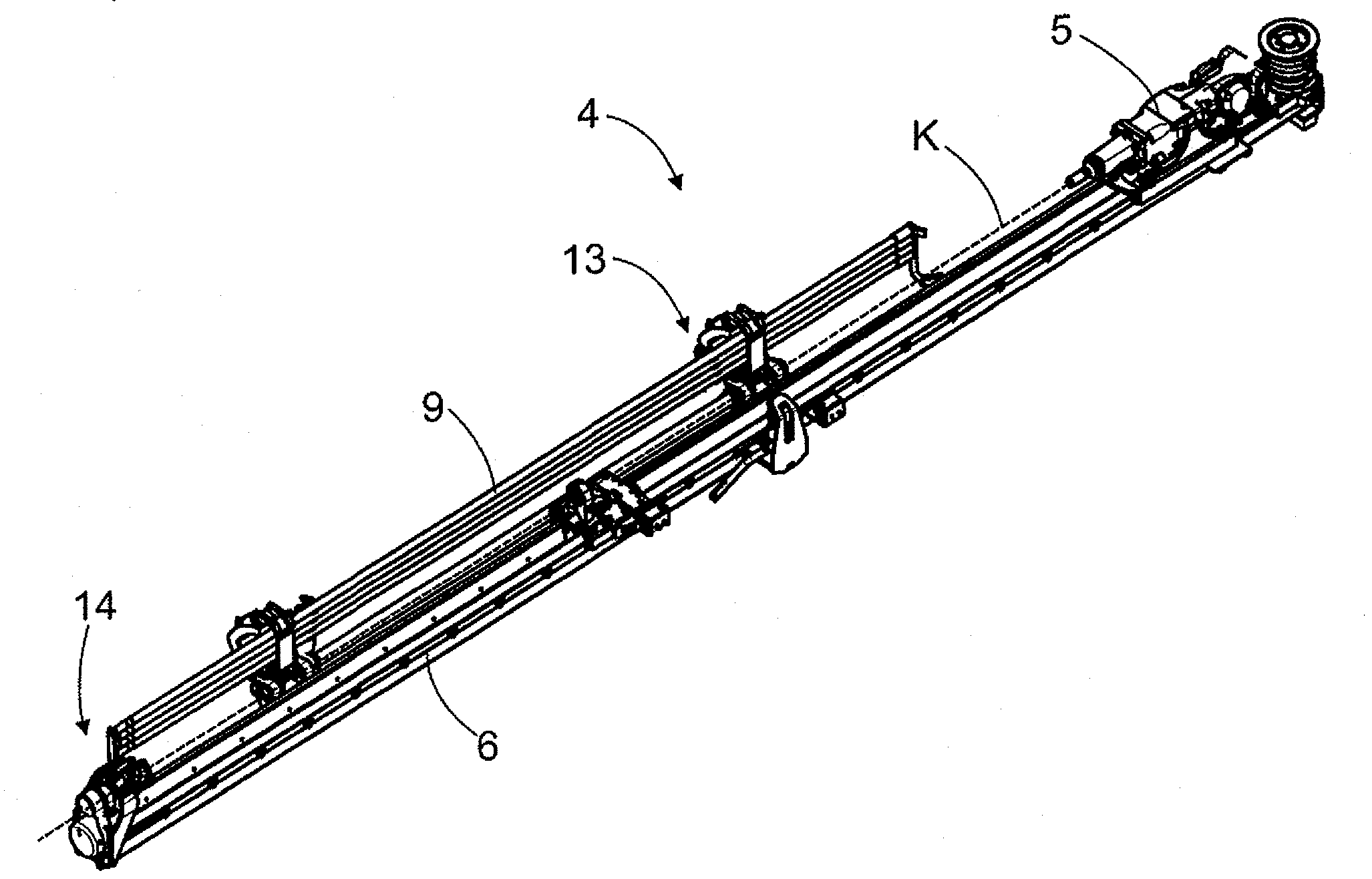

Mobile bearing press

ActiveCN102091928AMotion synchronizationAvoid damageMetal working apparatusField conditionsMobile bearing

The invention relates to a mobile bearing press which is used for a pressing axle reducer assembly bearing. A pneumatic pressing machine adopts a gas-liquid booster cylinder and is movably hung on a guiding rail, and a counter force rod mechanism is connected with the pneumatic pressing machine. When in pressing, a press block inlaid with a magnet is connected with a shaft by a screw, an outer ring of the bearing is adsorbed on the press block, a handle of the counter force rod mechanism is rotated, and a clamping jaw extends out to hook the inner end surface of a reducer shell bearing saddle hole so as to finish the bearing pressing under the action of the booster cylinder. Due to the pneumatic pressing and hanging, the whole press is light, can move freely on the preset guiding rail and cover a plurality of assembly trolleys, and can press bearings synchronously with the assembly line under the condition of occupying the space beside the assembly line as little as possible; the mobile bearing press can press bearings instead of manual beating, and improve the assembling quality of the assembly line; the mobile bearing press improves the traditional assembly line of bearing pressing and guarantees smooth and consistent pressing process under harsh requirements of the field conditions; and the mobile bearing press reduces the labor intensity of operators.

Owner:DONGFENG DANA AXLE

Compressing apparatus and control method for multi-cylinder synchronously pressurizing

InactiveCN1603633ASolve the imbalanceMotion synchronizationServomotorsHydraulic cylinderMaster cylinder

More than a kind of cylinders synchronization pressurize contracts the installment and the control method, including the cylinder place, a main hydraulic cylinder or the master cylinder installs in the cylinder place plate girder central spot, at least two vice- hydraulic cylinders or vice- air cylinder in cylinder place marginal distribution; Enters for the stage, hydraulic fluid either the compression gas actuates the host hydraulic cylinder or the master cylinder impetus plate girder completes the fast advancement and the recycling, sufficient hydraulic pressure or sufficient barometric pressure; The cylinder place is motionless, hydraulic fluid or the compression gas actuates the host actuation cylinder, drives the plate girder to complete the fast advancement, vice- cylinder follow-up, sufficient hydraulic pressure, barometric pressure; The pressure period, the high pressure hydraulic fluid or the high pressure barometric pressure actuates the host vice- cylinder to pressurize together the plate girder. The recovery phase, advocates the actuation cylinder initiative movement, actuates the plate girder recycling; The vice- cylinder through the plate girder oppression passive retraction or voluntarily the retraction, realizes the multi- cylinders system synchronized movement.

Owner:北京中水长固液分离技术有限公司

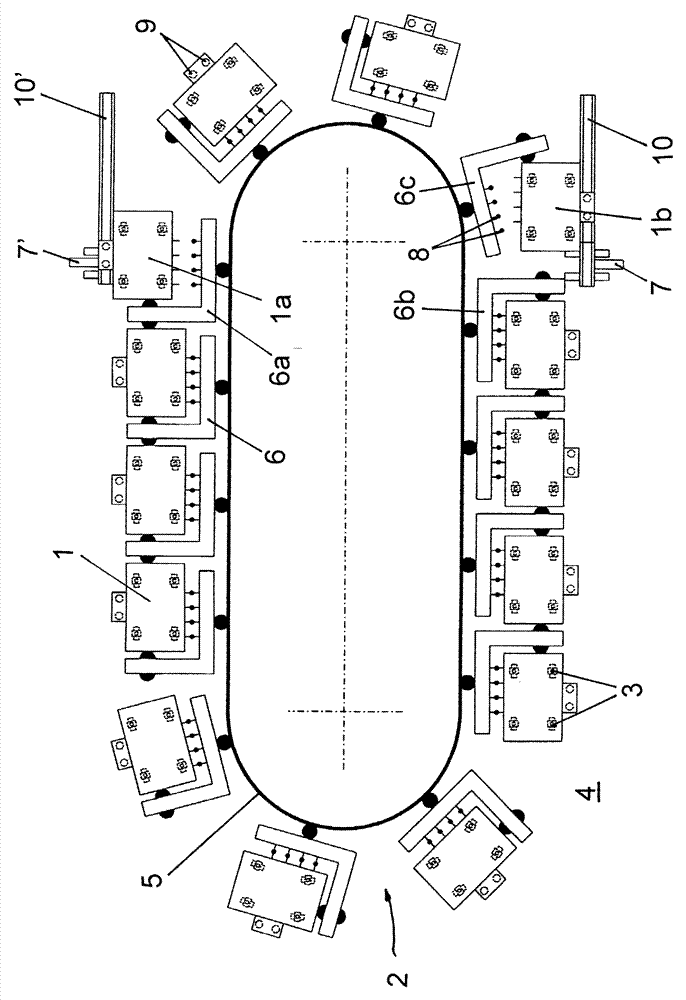

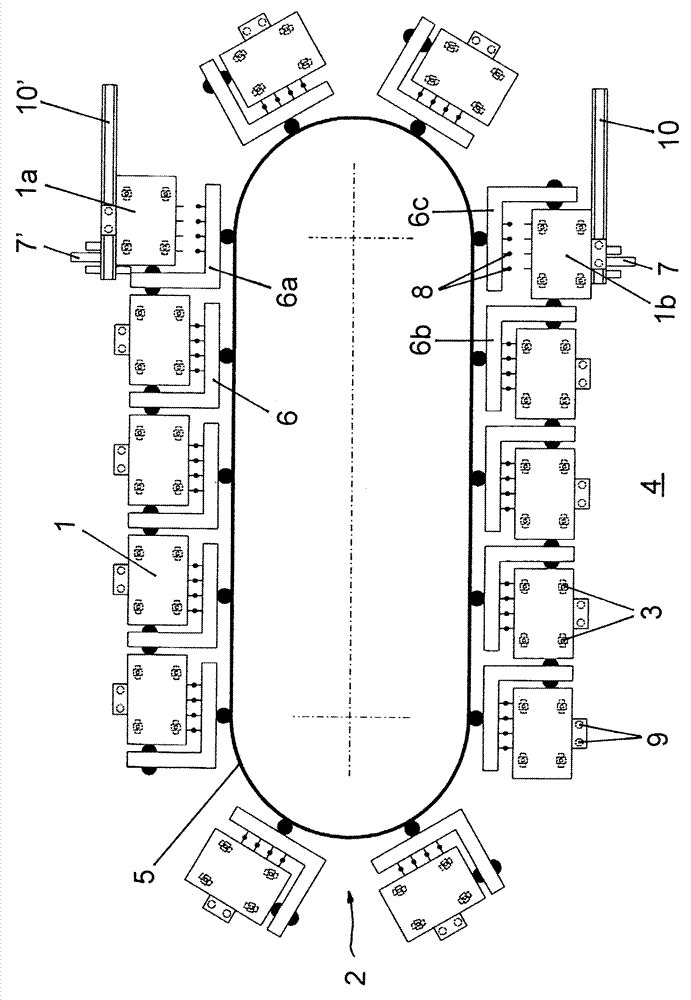

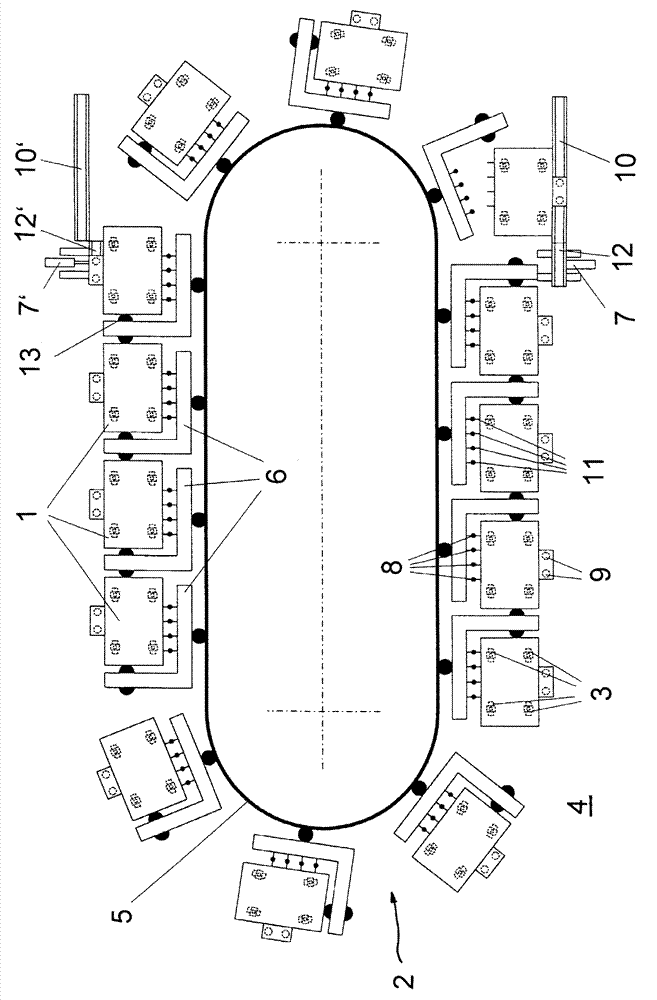

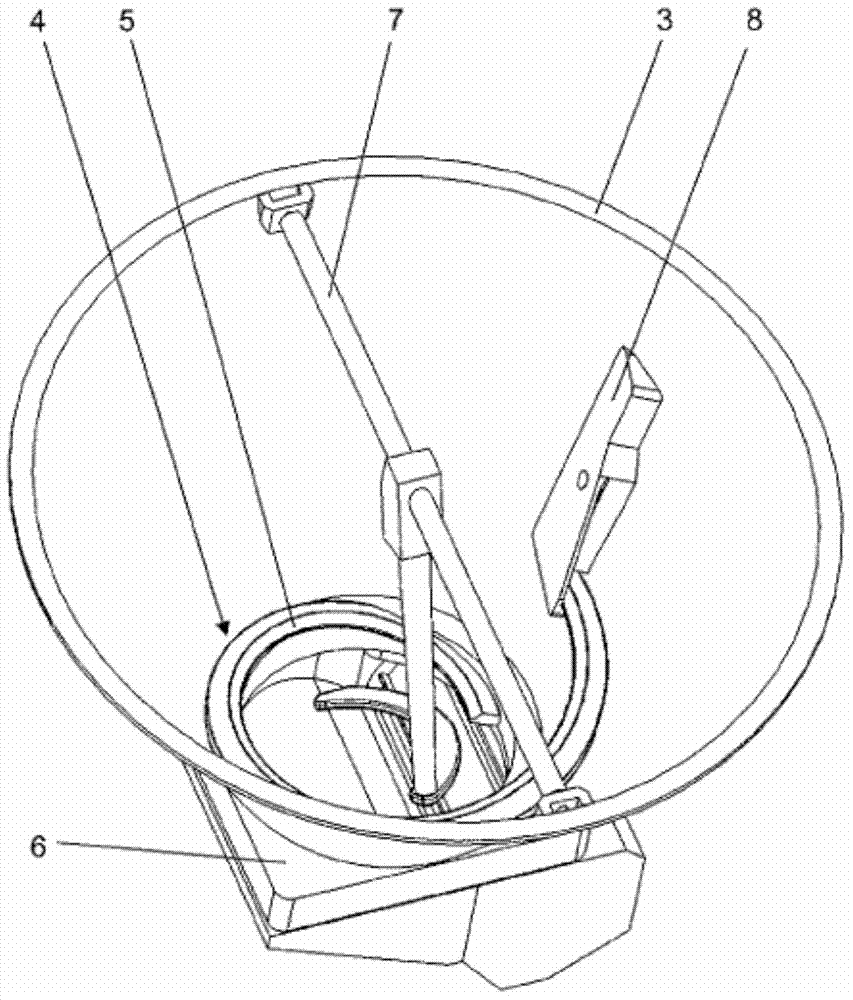

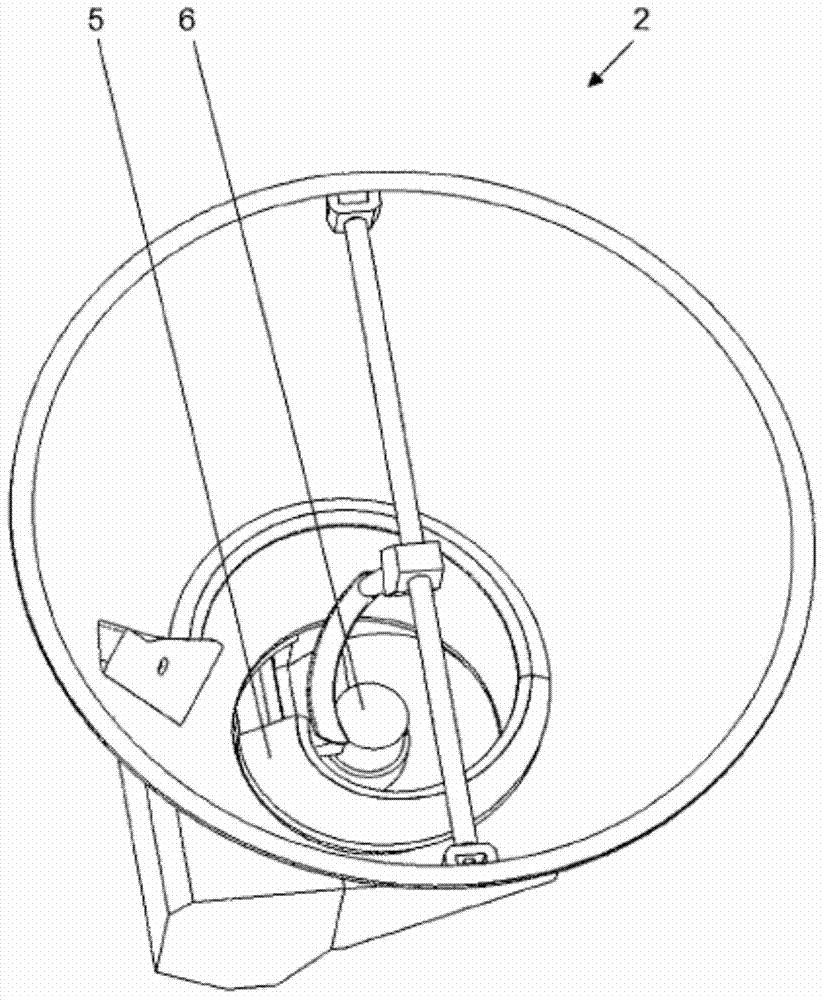

Method and device for the production of form parts

ActiveCN103862611ASimple introductionFavorable introductionPipe supportsLarge fixed membersProduction lineManufacturing engineering

The invention relates to a method for the production of form parts from multi-component reactive plastic material, especially from polyurethane, wherein a plurality of moulds are moved by means of mould carriages (1) at least temporarily along a closed, preferably oval, production line (2). To allow a simple and quick import and export of mould carriages in the respectively out of the production line the invention proposes that the mould carriages (1) are provided with rolls (3) and are moved on a stationary ground (4) by the same and that a plurality of supply carriages (6) are arranged along the closed production line (2) at a conveying element (5), which supply carriages (6) are moved by means of the conveying elements (5), wherein a mould carriage (1) is approached to a not occupied supply carriage (6) and is coupled with the same to introduce the mould carriage (1); into the production line (2), wherein for the movement along the production line (2) the mould carriage (1) is guided and moved by the supply carriage (6) in a coupled state between the mould carriage (1) and the supply carriage (6) and wherein the mould carriage (1) is decoupled from the supply carriage (6) and is moved away from the production line (2) for taking the mould carriage (1) out of the production line (2), wherein here the mould carriage (1) is moved with its roils (3) on the stationary ground (4). Furthermore, the invention relates to a respective device.

Owner:HENNECKE

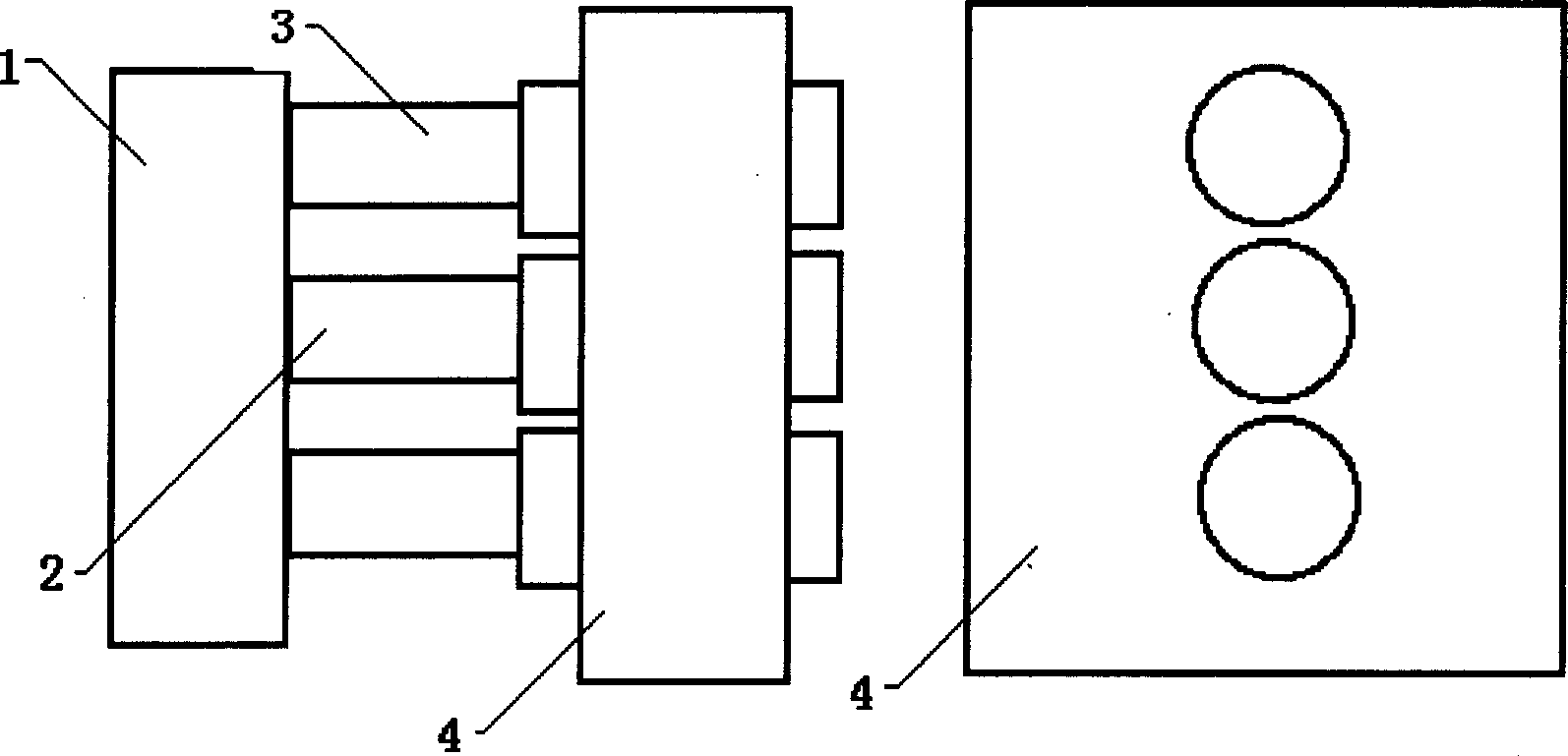

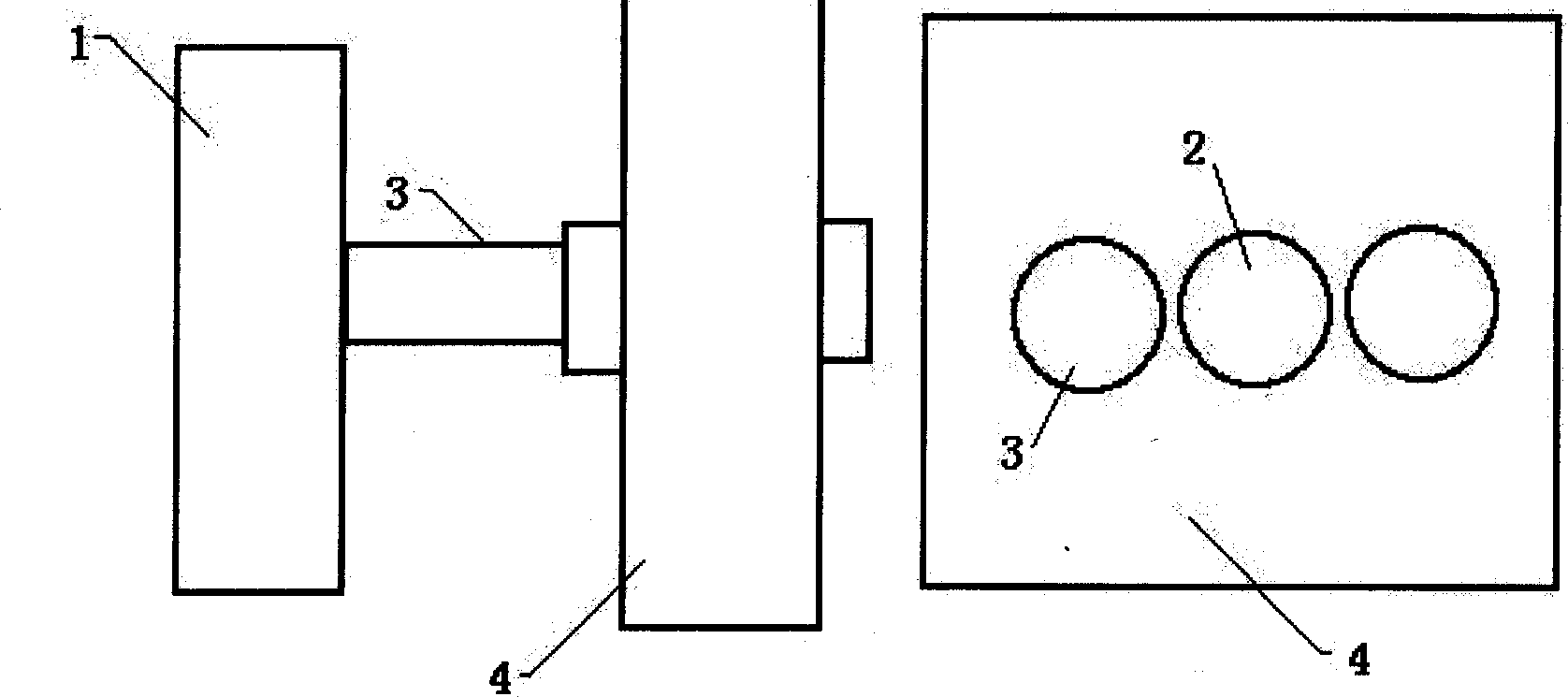

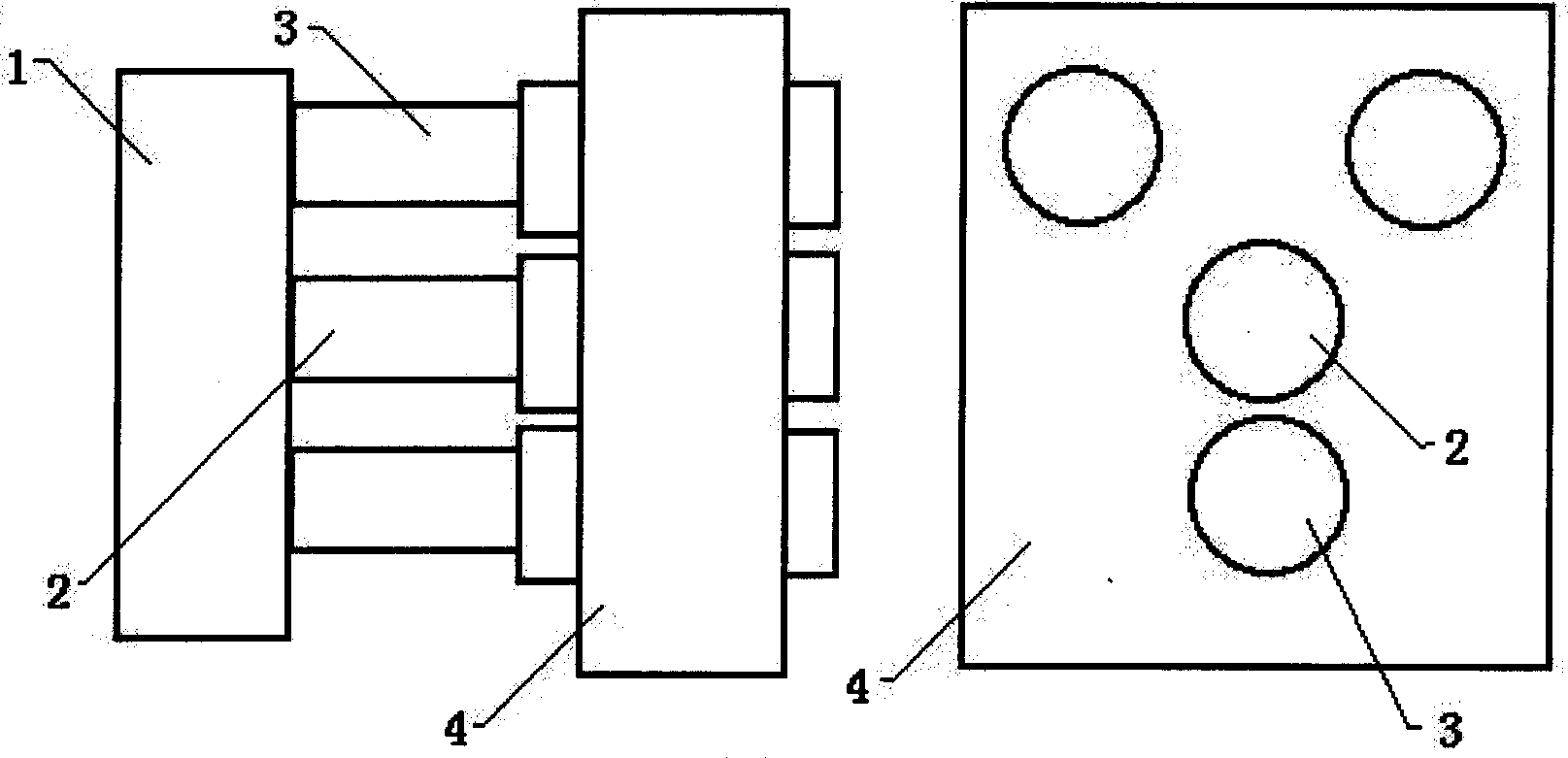

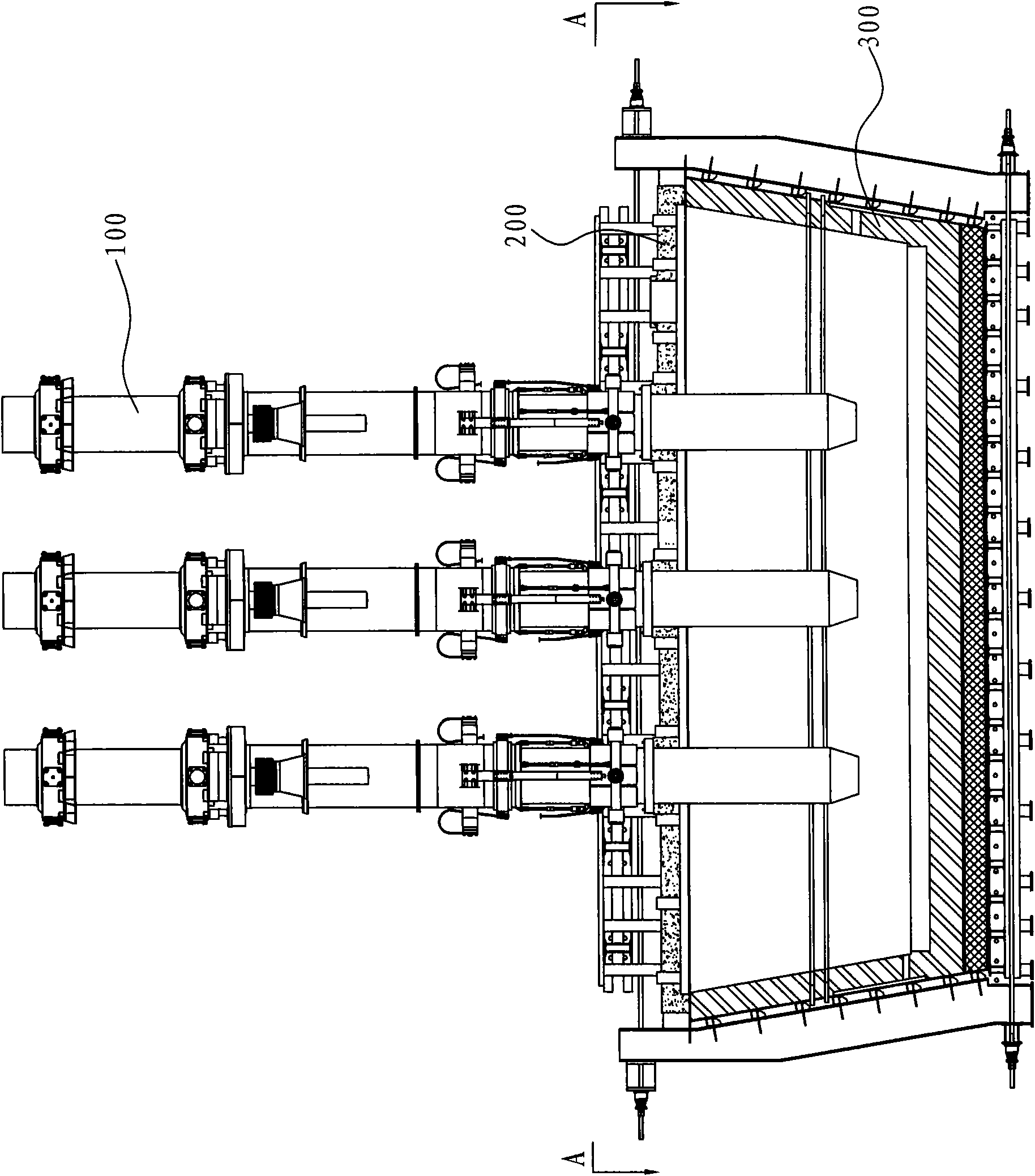

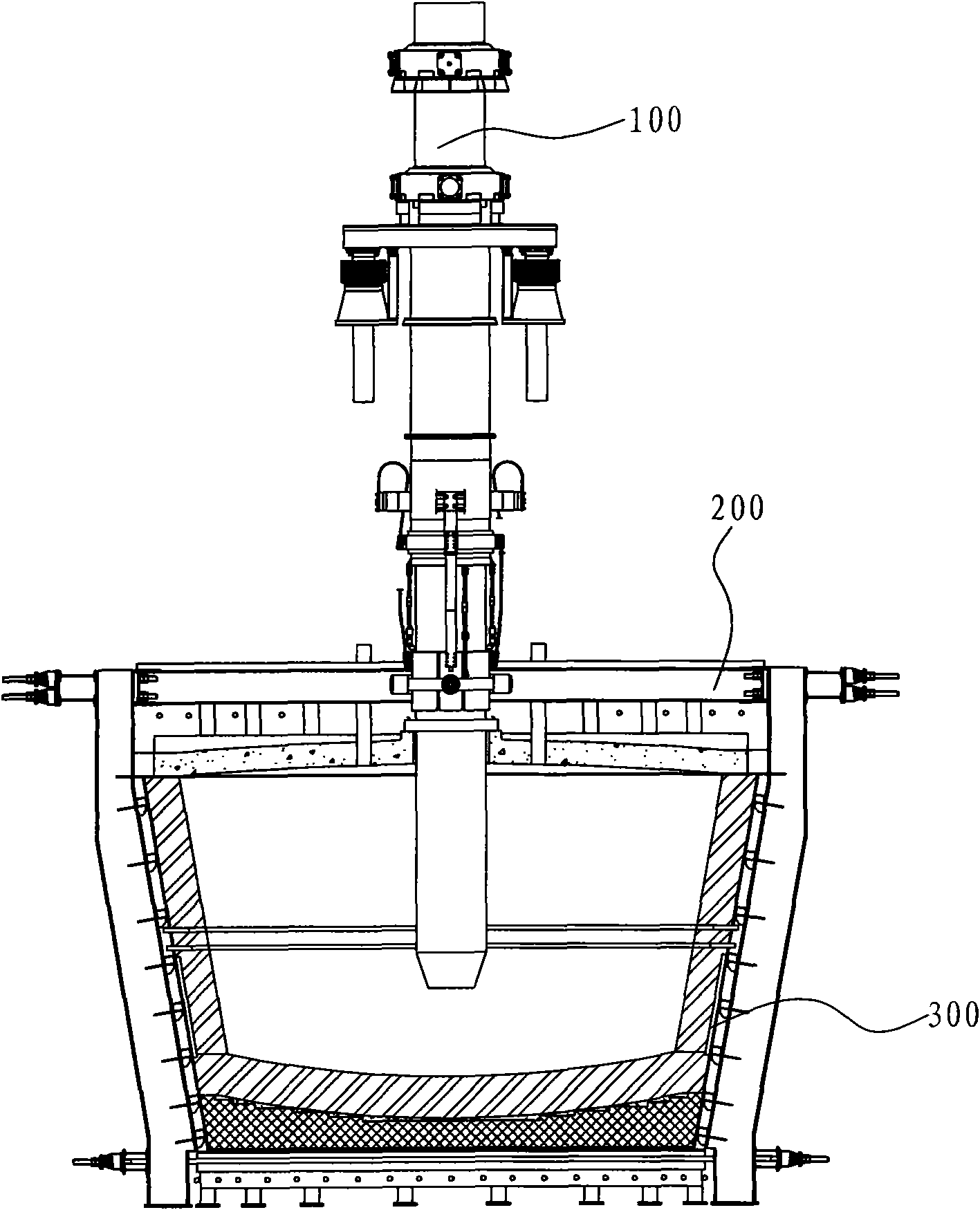

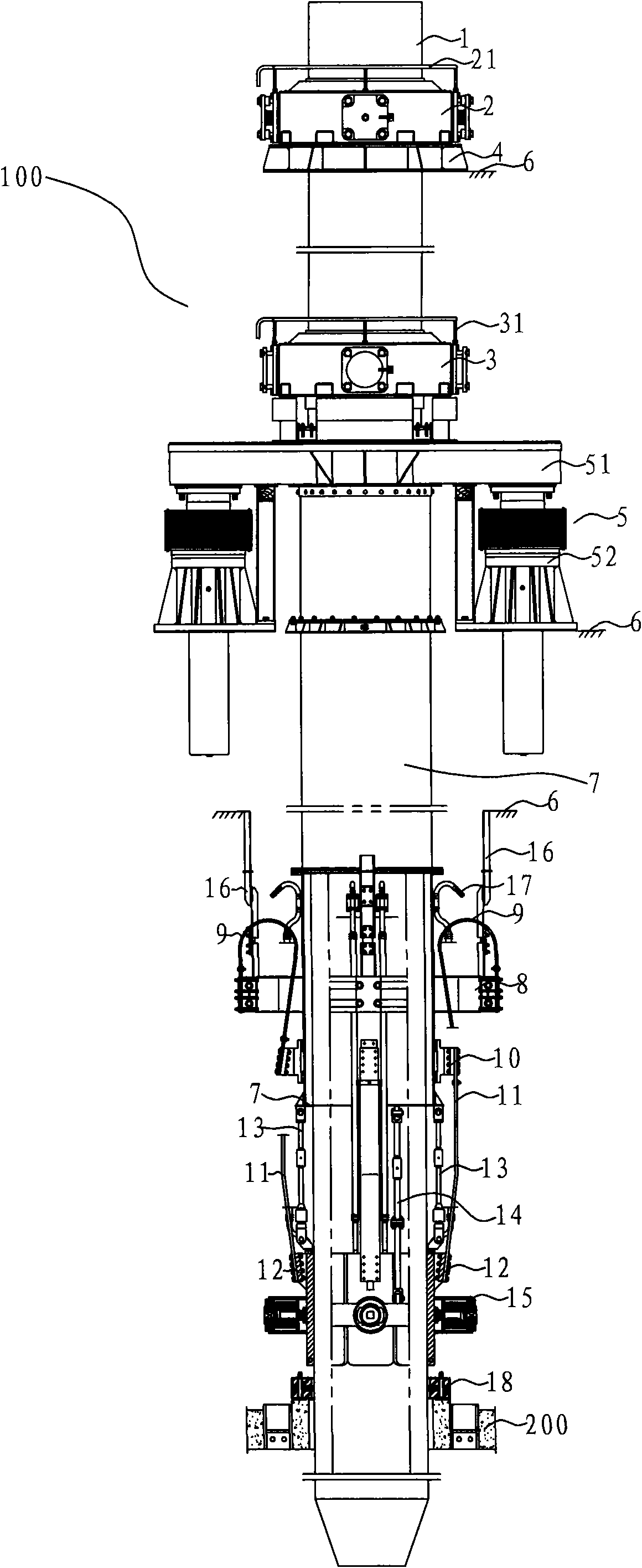

Plastic hollow container extruding and blowing machine

The invention relates to a plastic hollow container extruding and blowing machine, which comprises a plasticizing system, a die head extrusion system and a blow molding system which are arranged on astander, wherein the blow molding system comprises an air blowing mechanism and a die opening and closing mechanism; the die opening and closing mechanism comprises a front template and a back template which are connected with each other through a pull rod; a die is arranged between the front template and a middle template, and the die comprises two die cavities; and a die opening and closing synchronization mechanism is arranged between the middle template and the back template. The plastic hollow container extruding and blowing machine is characterized in that the inner walls of the two diecavities are provided with material supporting rod grooves, a base is fixed under the die and is connected with a retaining plate through an up-down adjusting device, the retaining plate is provided with a hoist cylinder, a piston rod of the hoist cylinder is connected with a transverse plate, the transverse plate fixes a horizontal guide post through a left-right vertical plate which is providedwith a first expansion oil cylinder and a second expansion oil cylinder, the moving directions of two piston rods of the expansion oil cylinders are opposite to each other, the two piston rods fix a material supporting block which is provided with a material supporting rod matched with the material supporting rod grooves, the material supporting block is sleeved on the horizontal guide post, the middle part of the horizontal guide post is provided with a blowing pin fixing block which is provided with a blowing pin, and the blowing pin is matched with an air blowing hole at the bottom of the die.

Owner:鼎浩(长兴)包装科技有限公司

Electrode device

ActiveCN101769685AEasy to operateImprove efficiencyElectric heating for furnacesElectricityElectrode

The invention discloses an electrode device, comprising an electrode main body, an upper band-type brake, a lower band-type brake, a lifting mechanism and a conductive mechanism. The upper band-type brake is used for tightly holding and releasing the electrode main body; the lower band-type brake is used for tightly holding and releasing the electrode main body, located below the upper band-type brake, installed on the lifting mechanism and moves together with the lifting mechanism; and the conductive mechanism electrically contacts with the electrode main body and synchronously moves along with the lifting mechanism relative to the electrode main body. The electrode device is convenient to compensate the consumption quantity of the electrode and has high operation efficiency.

Owner:CHINA ENFI ENGINEERING CORPORATION

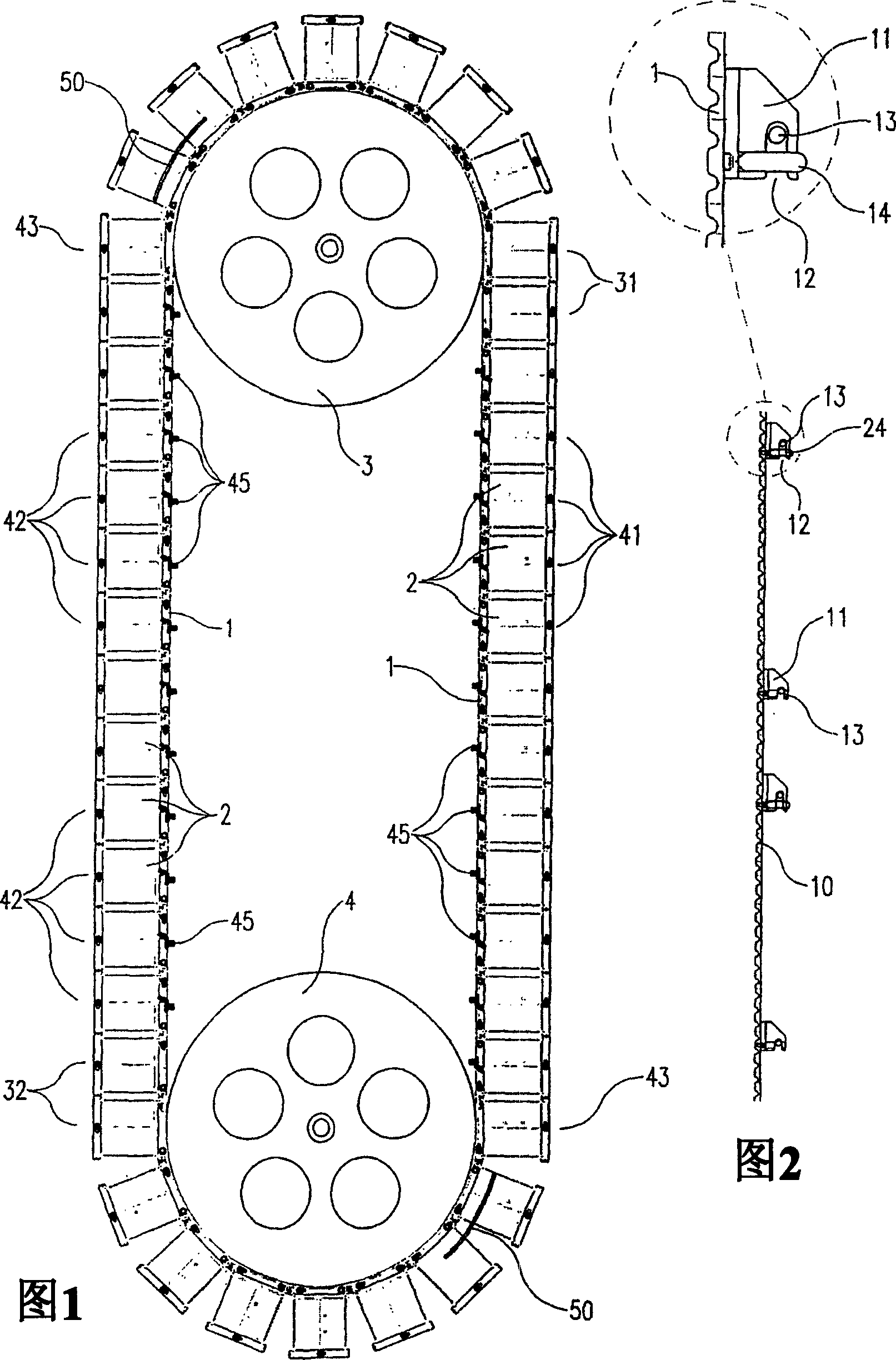

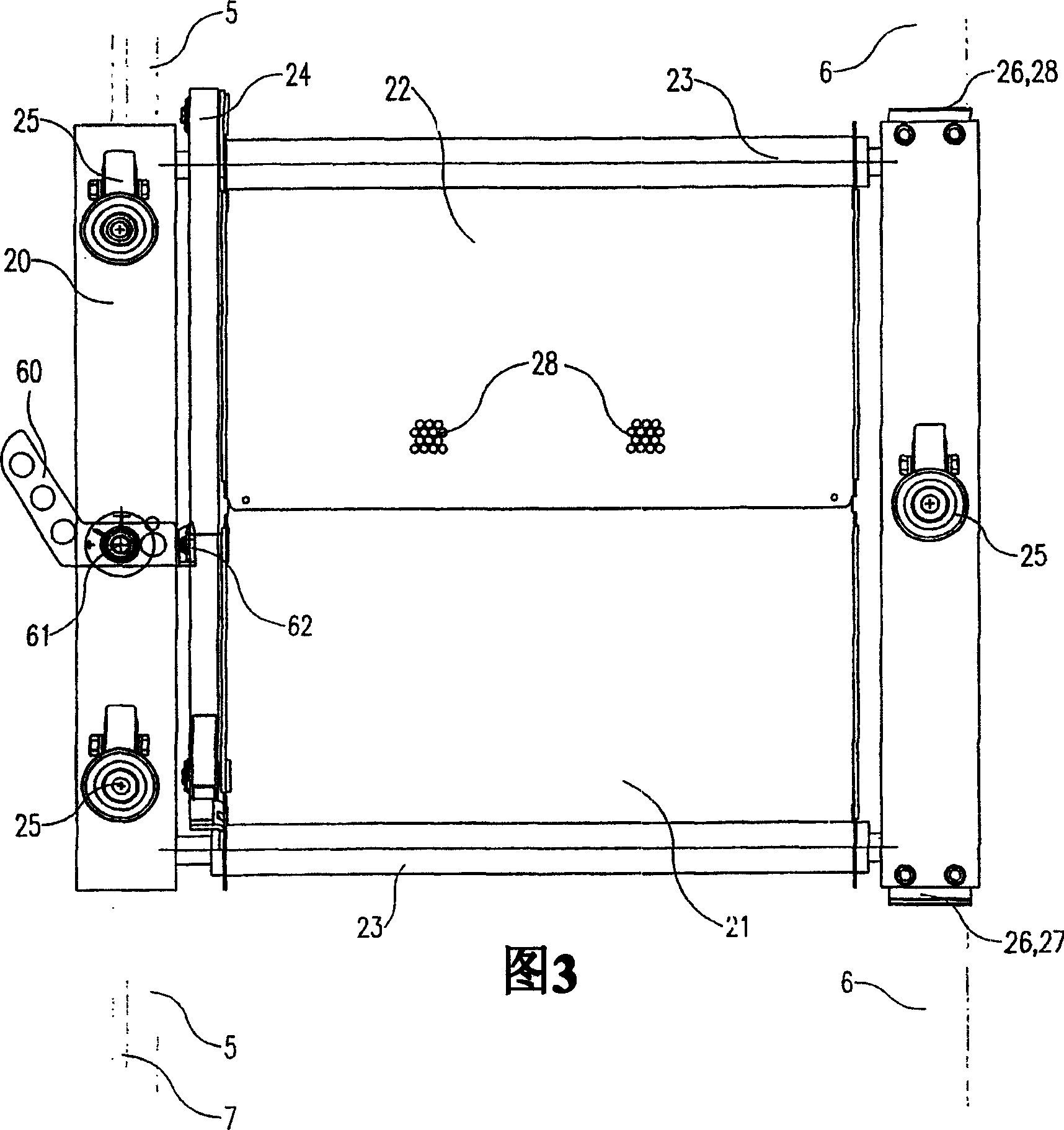

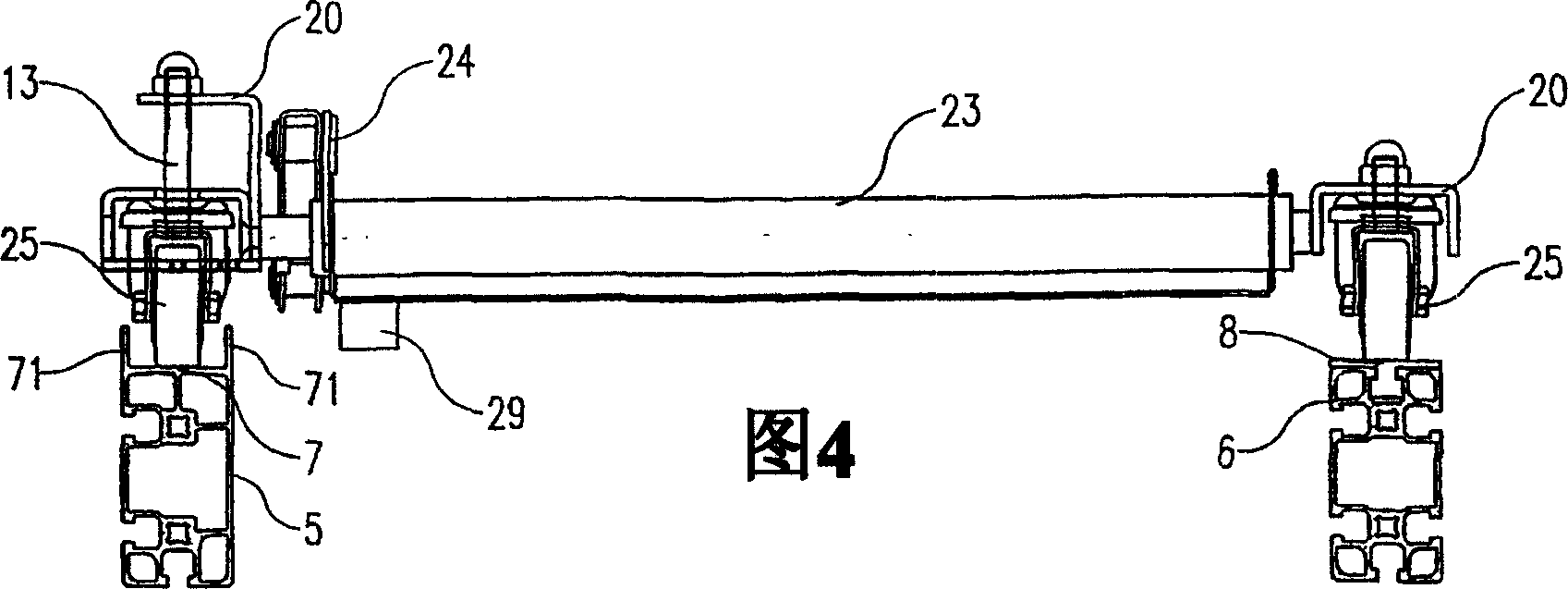

Apparatus and transport container for transport and controlled discharge of a load

InactiveCN1589219AEffective bufferMotion synchronizationConveyorsConveyor partsCouplingLocking mechanism

An apparatus for transport and controlled discharge of a load, comprising a frame with a guide (5, 6, 9) for at least one displaceable transport container (2), a drive means (1) for carrying the transport container in an endless track, a resetting device (50) for placing a transport container in a starting position and a discharge station (41, 42, 43) for selectively relieving a transport container of a load. The transport containers are provided with a movable carrying panel (21, 22) for receiving of the load thereon, comprising at least two tilt trays which extend between tilt axes (23) located on both sides. The tilt trays (21, 22) can be selectively titled between a transporting position and a downward hanging discharge position, and are provided with a locking mechanism (60-62) for locking the tilt trays in the transport position. The resetting device is adapted to co-act with a passing opened transport container to place the tilt trays thereof in the transport position, and the discharge station is able to selectively unlock the locking mechanism of a passing transport container to thus release the tilt trays. A coupling (24) is placed between the tilt trays (21, 22) to impose a tilting movement of the one tilt tray on the other tilt tray.

Owner:EUROSORT

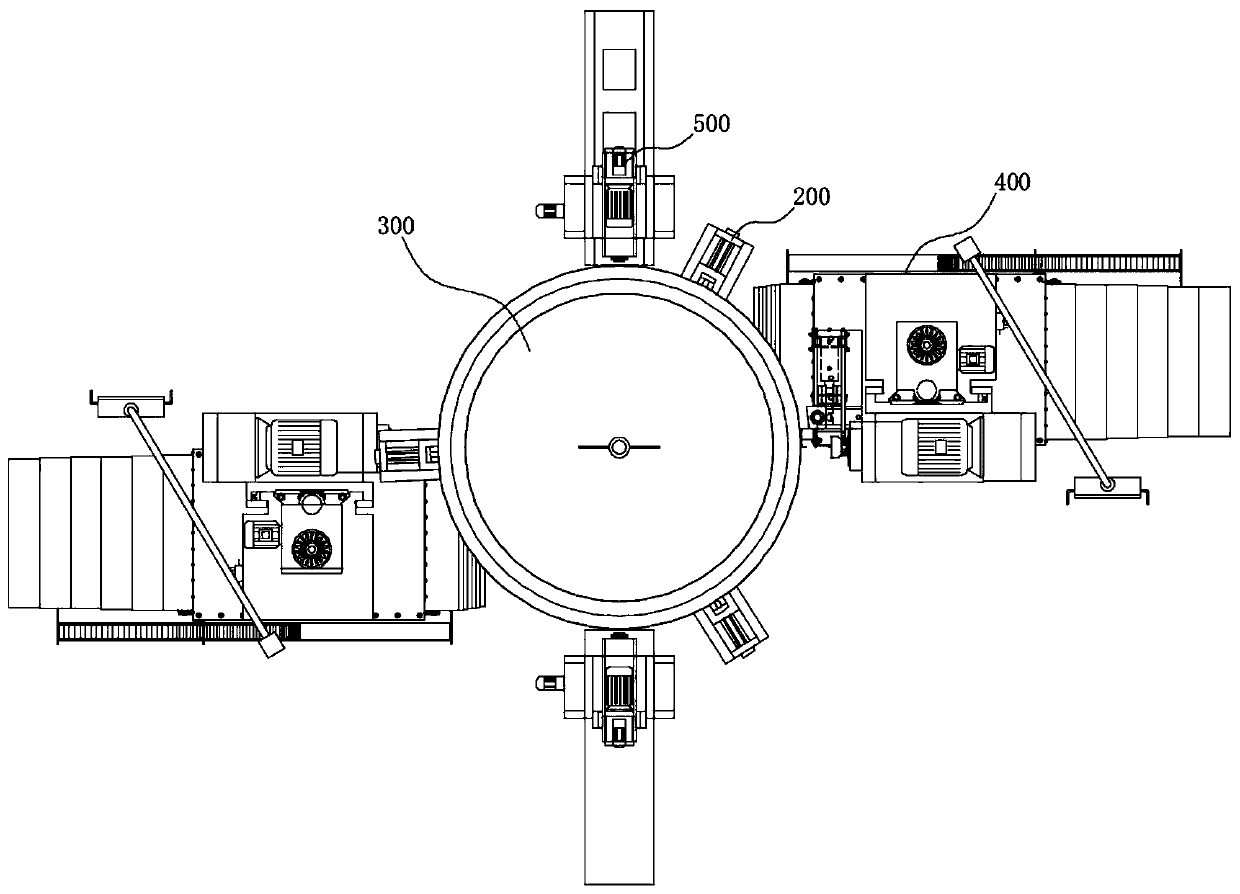

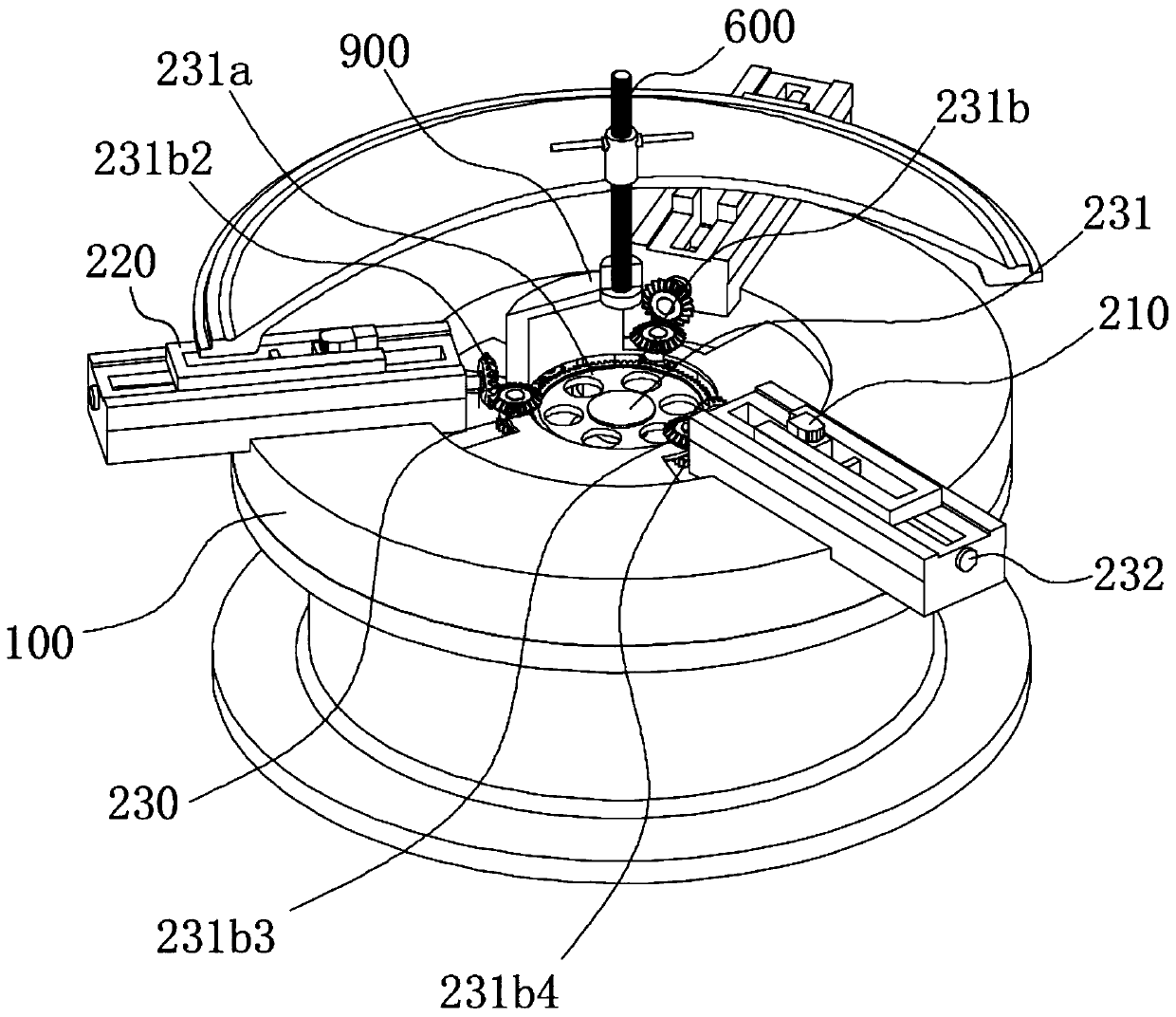

Outer tooth milling machine

ActiveCN110788409AStable processingThere will be no problem of interference with milling gear machiningOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

The invention relates to an outer tooth milling machine. The outer tooth milling machine comprises a machine frame. A rotary table is installed on the machine frame. A tooth milling device and an exhaust groove machining device are arranged around the rotary table. Clamping devices are arranged on the rotary table and are used for clamping and positioning corresponding workpieces to make the to-be-machined outer ring walls of the workpieces in a machined state. The outer tooth milling machine is reasonable in layout, stable in structure, capable of automatically positioning and clamping workpieces with different sizes and making the outer ring walls of the workpieces with the different sizes in the machined state, and high in applicability, and meets existing using requirements.

Owner:安徽金马热能设备有限公司

Mass supply system

ActiveCN104244722ASmall inertiaEasy to replaceMeat processingRotary piston pumpsEngineeringMechanical engineering

Owner:GEA FOOD SOLUTIONS BAKEL

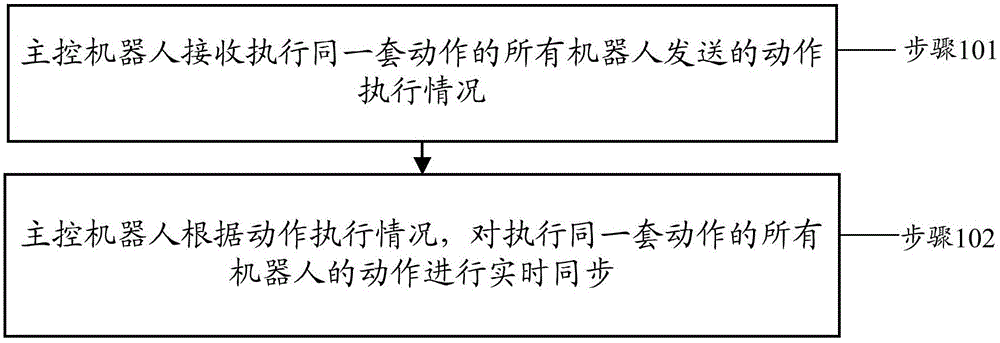

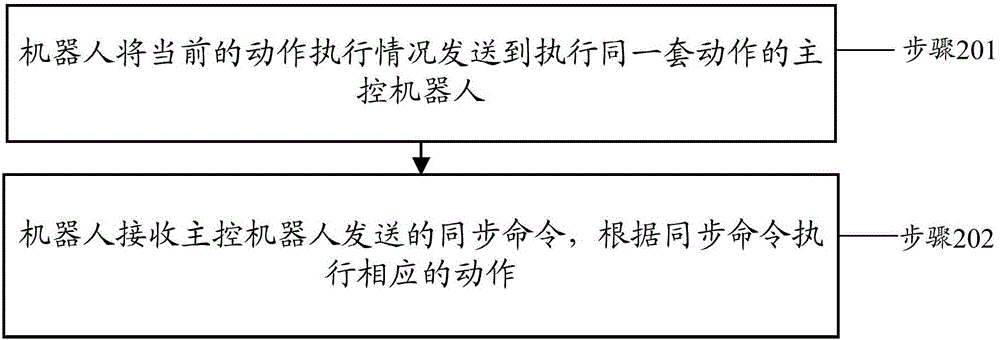

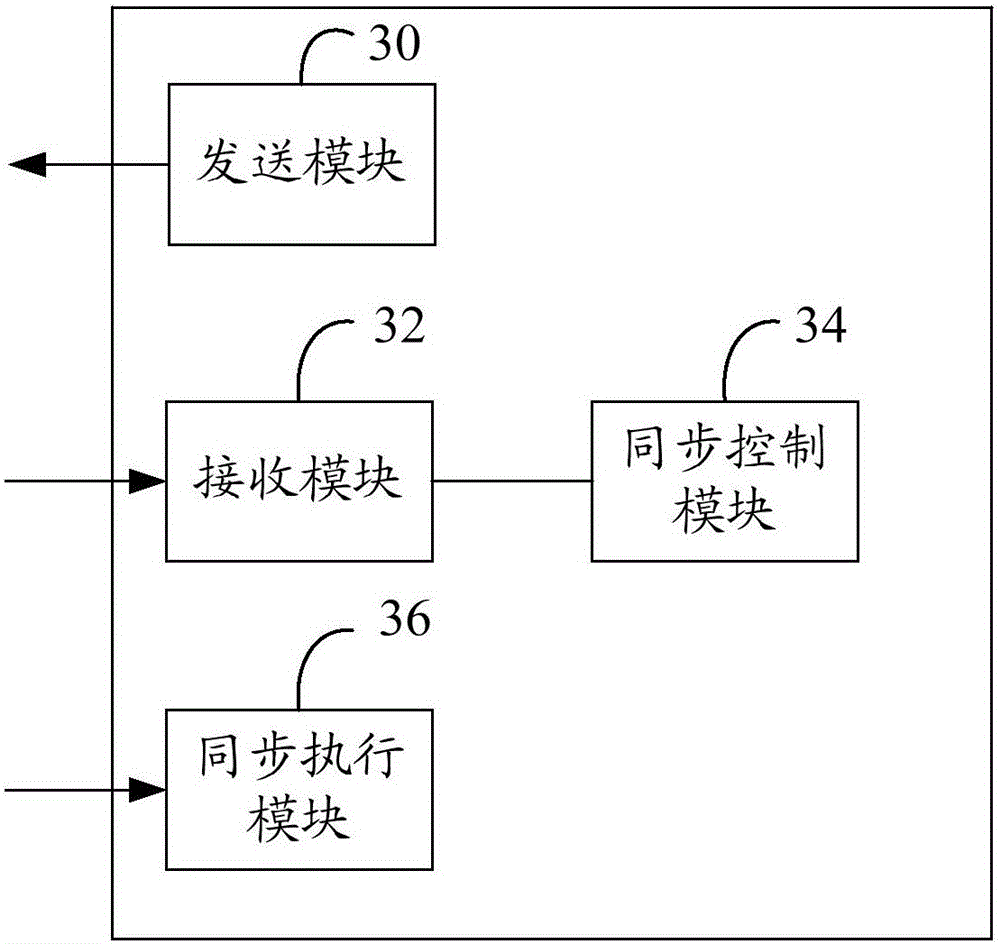

Method and device for robot motion synchronization

ActiveCN105785821AMotion synchronizationSolve the problem of inconsistent actionsManipulatorProgramme control in sequence/logic controllersSimulationRobot motion

The invention discloses a method and a device for robot motion synchronization. The method comprises steps that motion execution states sent by all robots executing the same set of motions as a main control robot are received by the main control robot; motions of all the robots executing the same set of motions are synchronized by the main control robot in real time according to the motion execution states. Through the method, robot motion synchronization can be realized, and the performance effect is guaranteed.

Owner:HAIER YOUJIA INTELLIGENT TECH BEIJING CO LTD +1

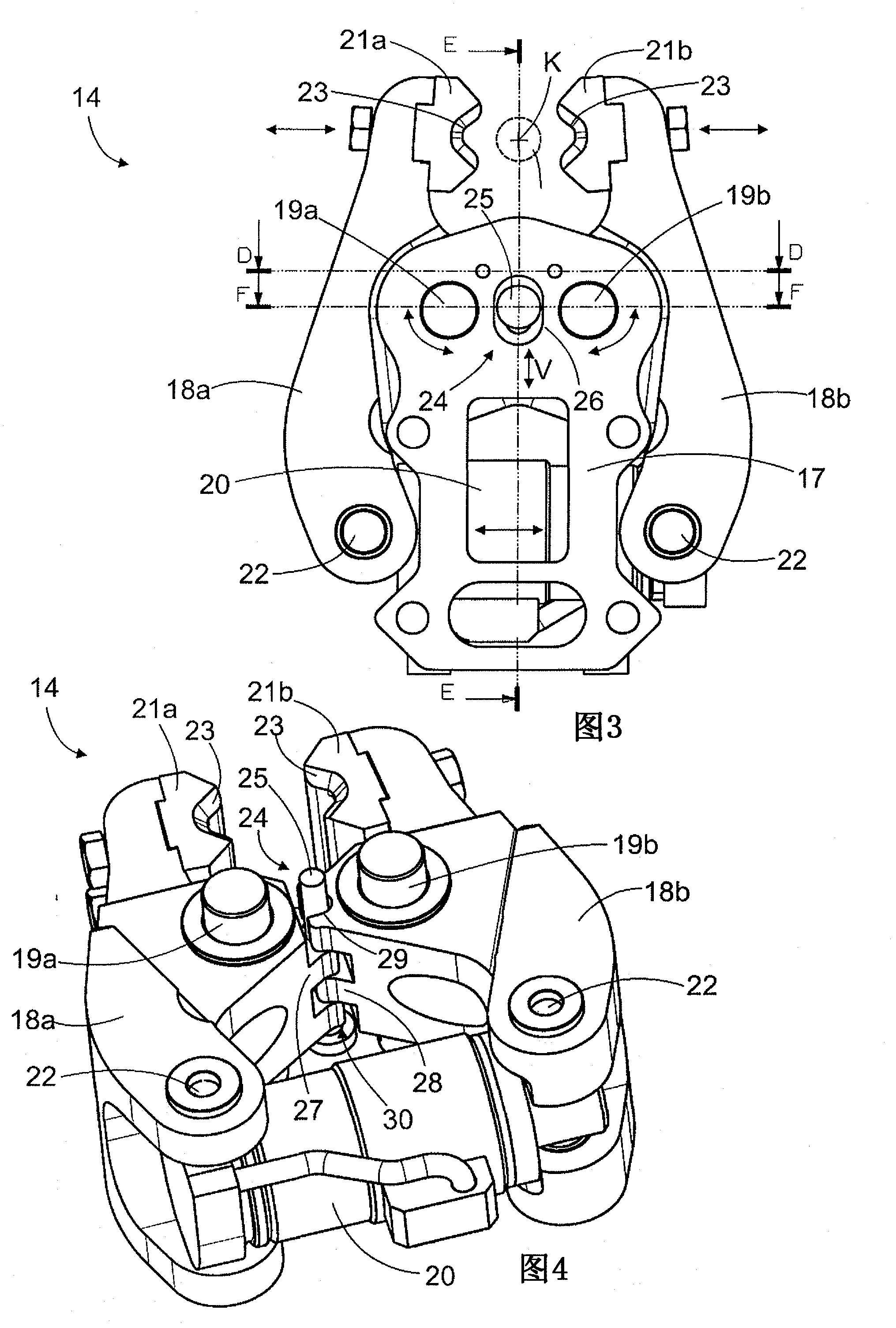

Method for using retainer, and retainer

ActiveCN102216555AReduced external dimensionsEasy to operateDrilling rodsDrilling casingsEngineeringActuator

The invention relates to a method for using a retainer, and to a retainer. The retainer(14) comprises a first clamping arm (18a) and a second clamping arm (18b) provided with clamping jaws (21a, 21b) for clamping a drill rod (9), a rock bolt or the like. The clamping arms are turned in relation to their pivot points (19a, 19b) by an actuator (20), whereby the clamping jaws move either towards or away from each other. On the portion between the pivot points of the clamping arms there are shape members that interconnect the movements of the clamping arms to make them interdependent and thus synchronize the movements of the clamping arms in both directions of movement of the clamping arms.

Owner:SANDVIK MINING & CONSTR OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com