Volumetric quantitative jet valve

An injection valve, volumetric technology, applied in the direction of injection device, lift valve, valve device, etc., can solve the problems of not meeting the technical requirements of electronic products, difficult to control the amount of glue, difficult to meet the viscosity, etc., to achieve easy use and maintenance , Shorten the gas path, reduce the effect of the striker movement position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

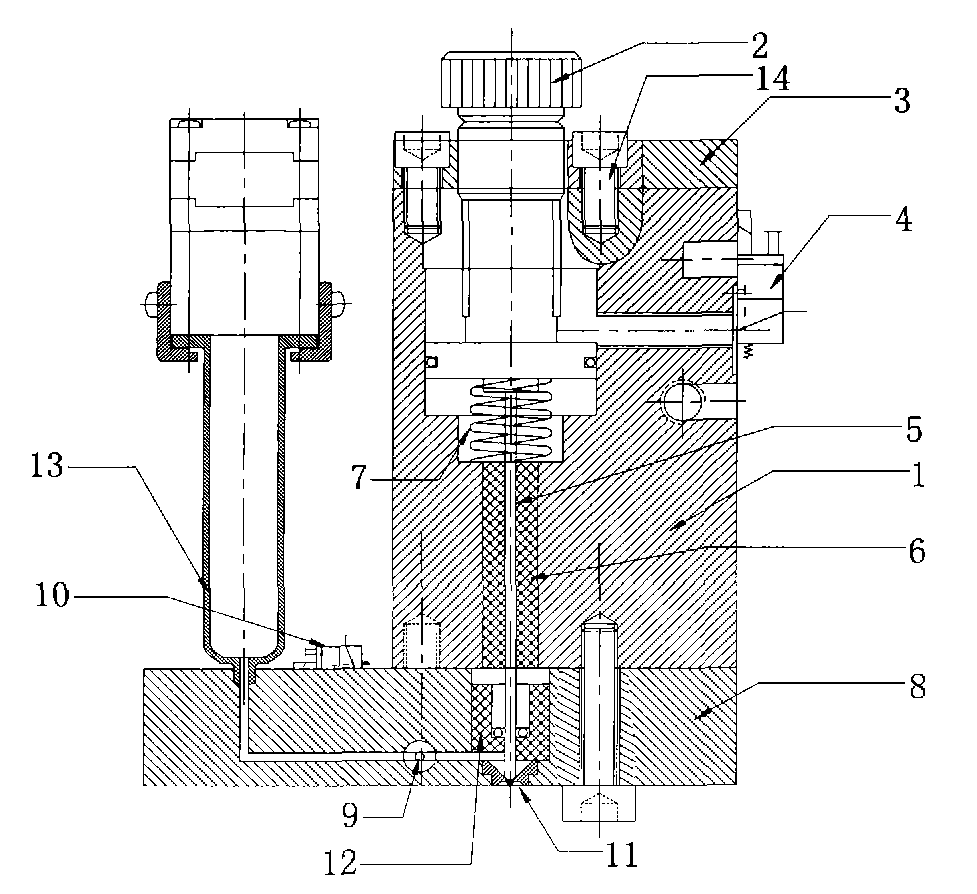

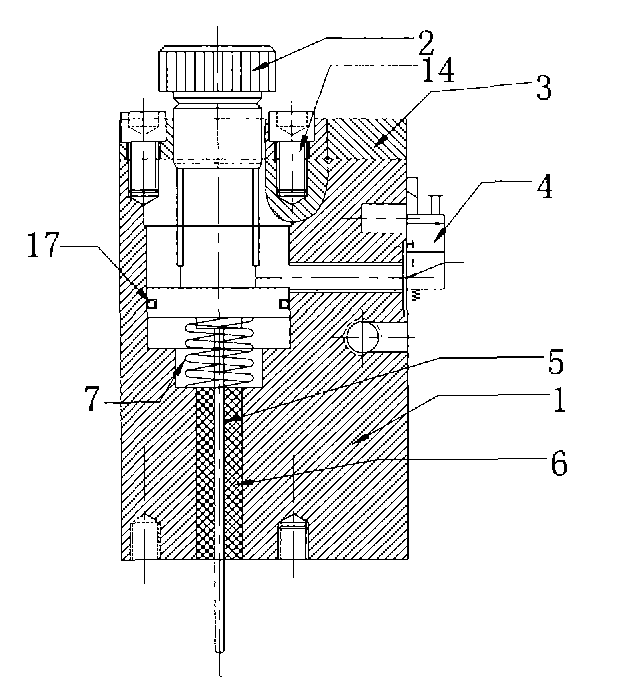

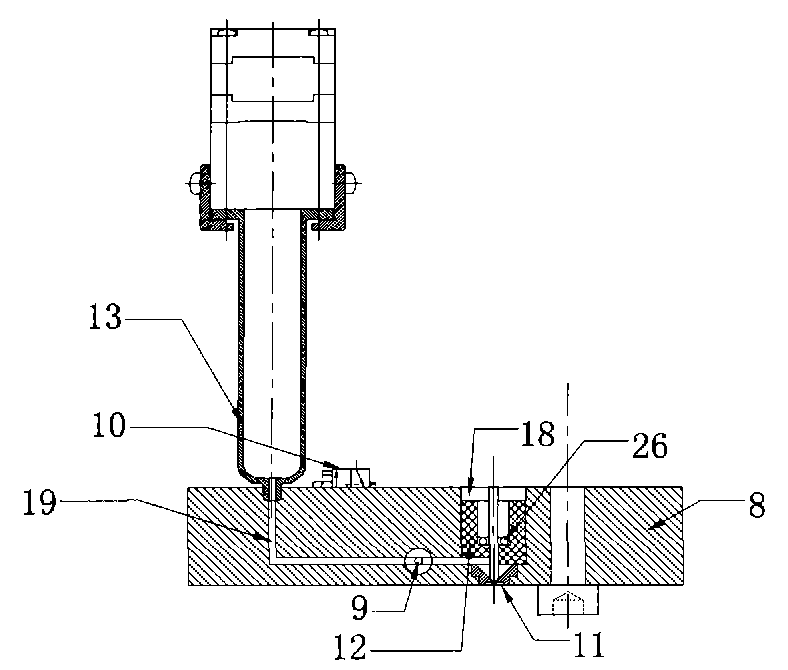

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. like figure 1 As shown, the volumetric quantitative injection valve of the present invention is composed of a power source assembly and a fluid control box assembly. Four screws are used to pass through the fluid control box, and the fluid control box is fixedly installed on the mounting hole on the power source assembly to form a Volumetric quantitative injection valve.

[0027] like figure 2 and Figure 4 As shown, the power source assembly is provided with a cylinder A1, and the cylinder A1 has a vertical through hole, and the through hole is gradually reduced from top to bottom and divided into four coaxial holes: the first screw hole 11, the second hole 12, The third hole 13 and the fourth hole 14 . A fifth hole 15 is formed on the side of the cylinder A1. The axis of the fifth hole 15 is perpendicular to the second hole 12 and communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com