A lightweight bearing housing structure

A bearing seat, lightweight technology, applied in the direction of lubrication of turbine/propulsion device, cooling of turbine/propulsion device, cooling of engine, etc., can solve the problems of complex mold design, high processing cost, waste, etc., and optimize the internal The effect of space utilization, simple structure and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

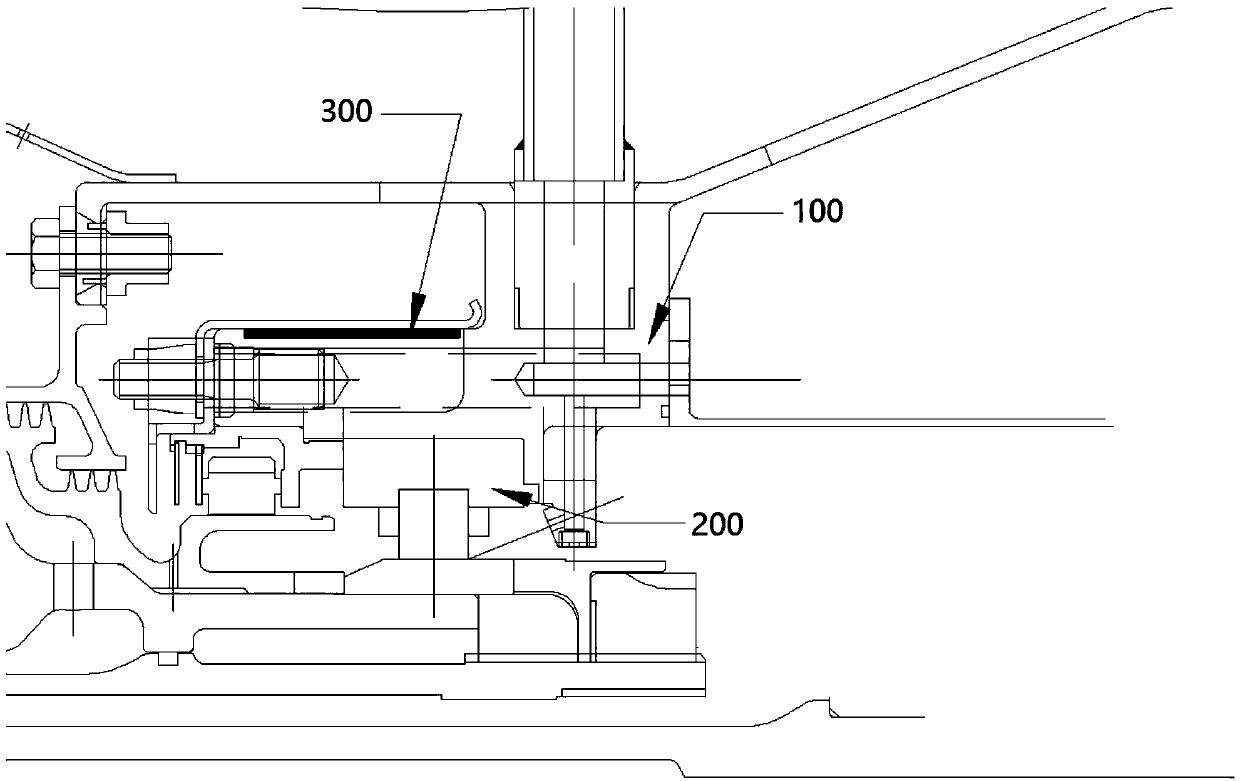

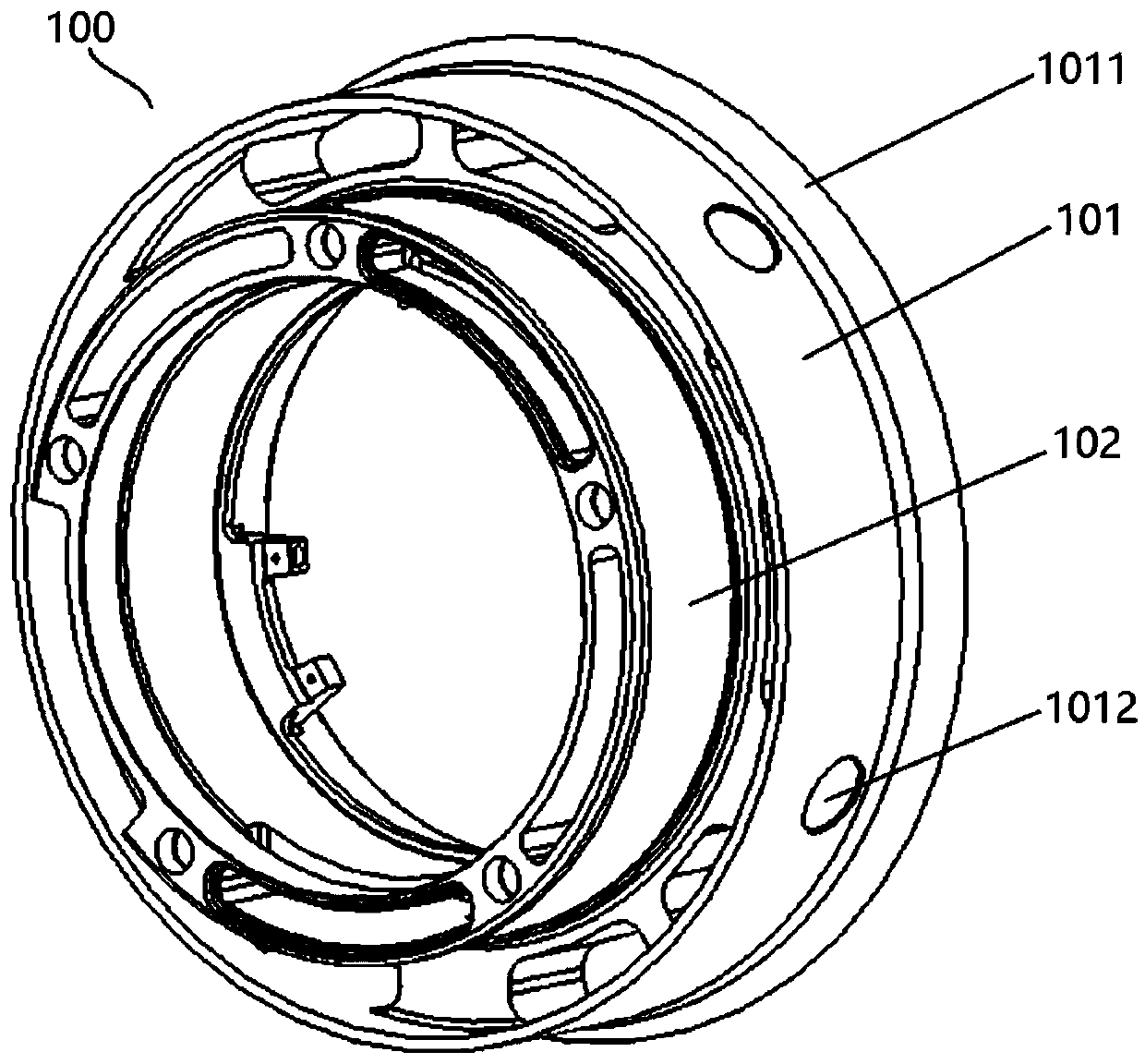

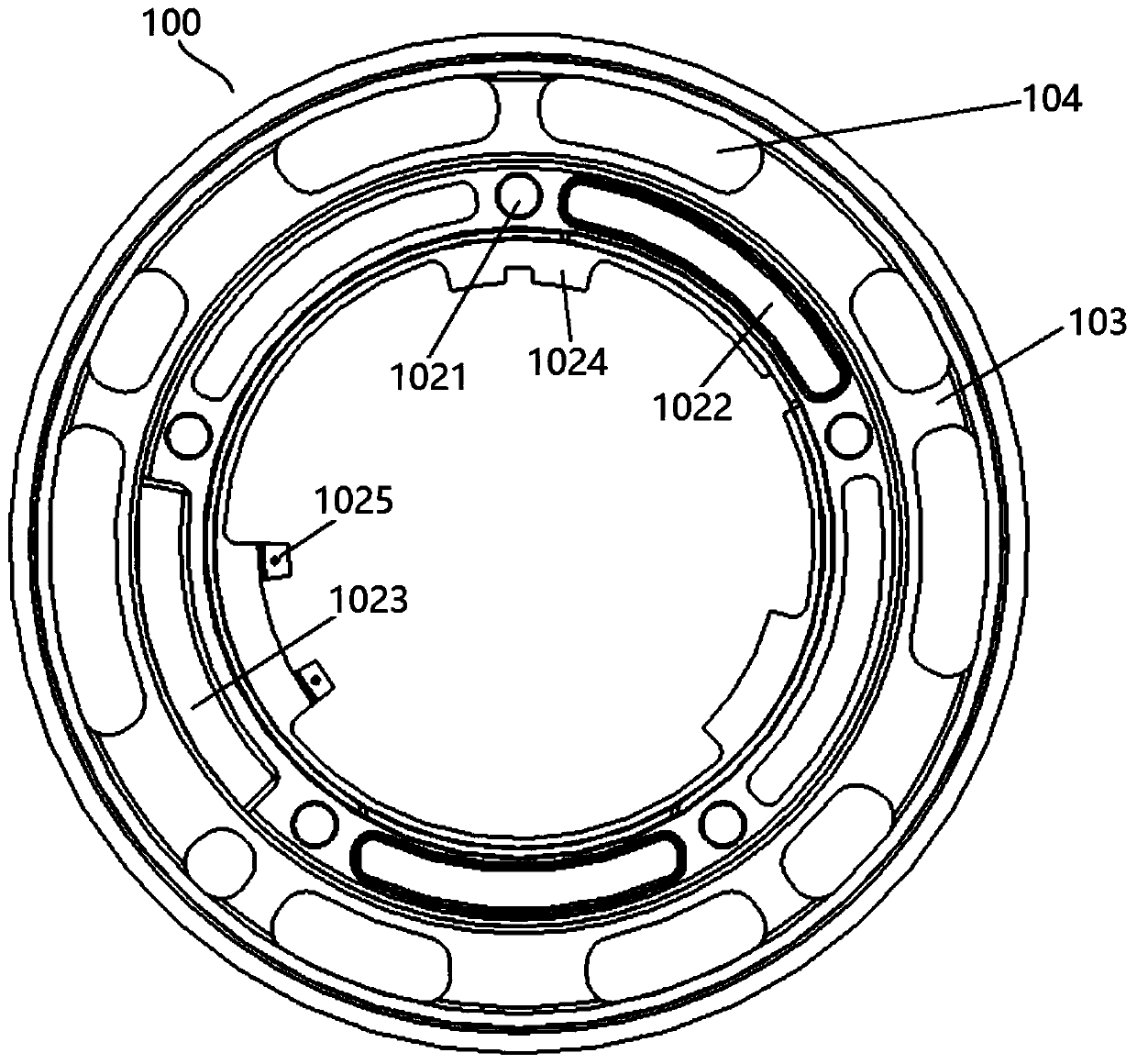

[0032] Such as Figure 1~3 As shown, the lightweight bearing housing structure 100 of the present invention is arranged in the casing of the gas turbine / aero-engine, which can realize the ventilation, cooling and lubricating oil supply of the bearing cavity. The outer ring 101 of the bearing seat and the inner ring 102 of the bearing seat, the bearing 200 is arranged on the inner wall of the inner ring 102 of the bearing seat.

[0033] The front end of the bearing seat outer ring 101 protrudes from the bearing seat inner ring 102, and is turned outward to form a conical structure 1011, which is used to transmit the axial force of the bearing; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com