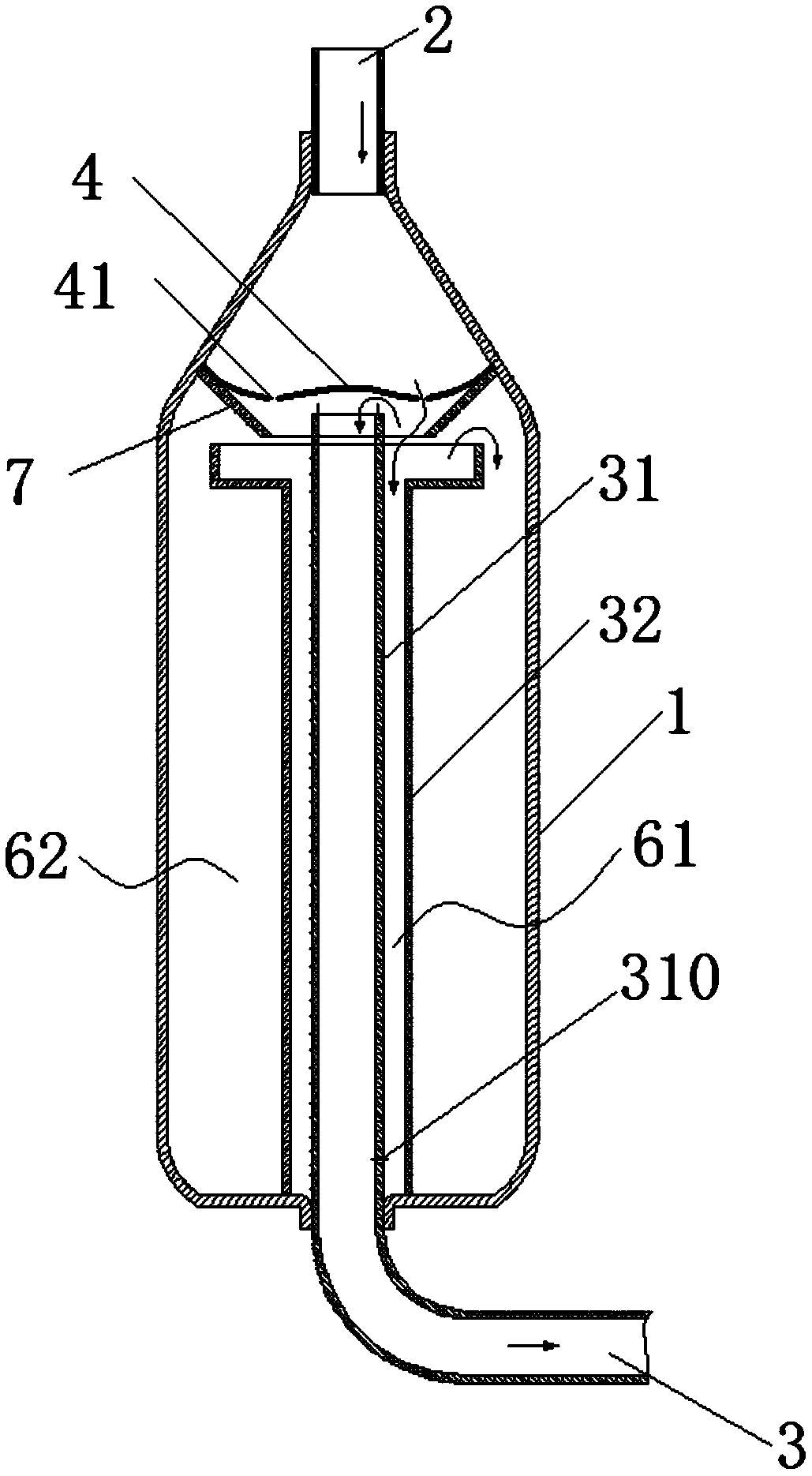

Liquid storage tank applied to compressor

A liquid storage tank and compressor technology, applied in the field of compressor accessories, can solve problems such as uneven oil return, achieve smooth oil return, avoid suction with liquid, and maintain stable oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

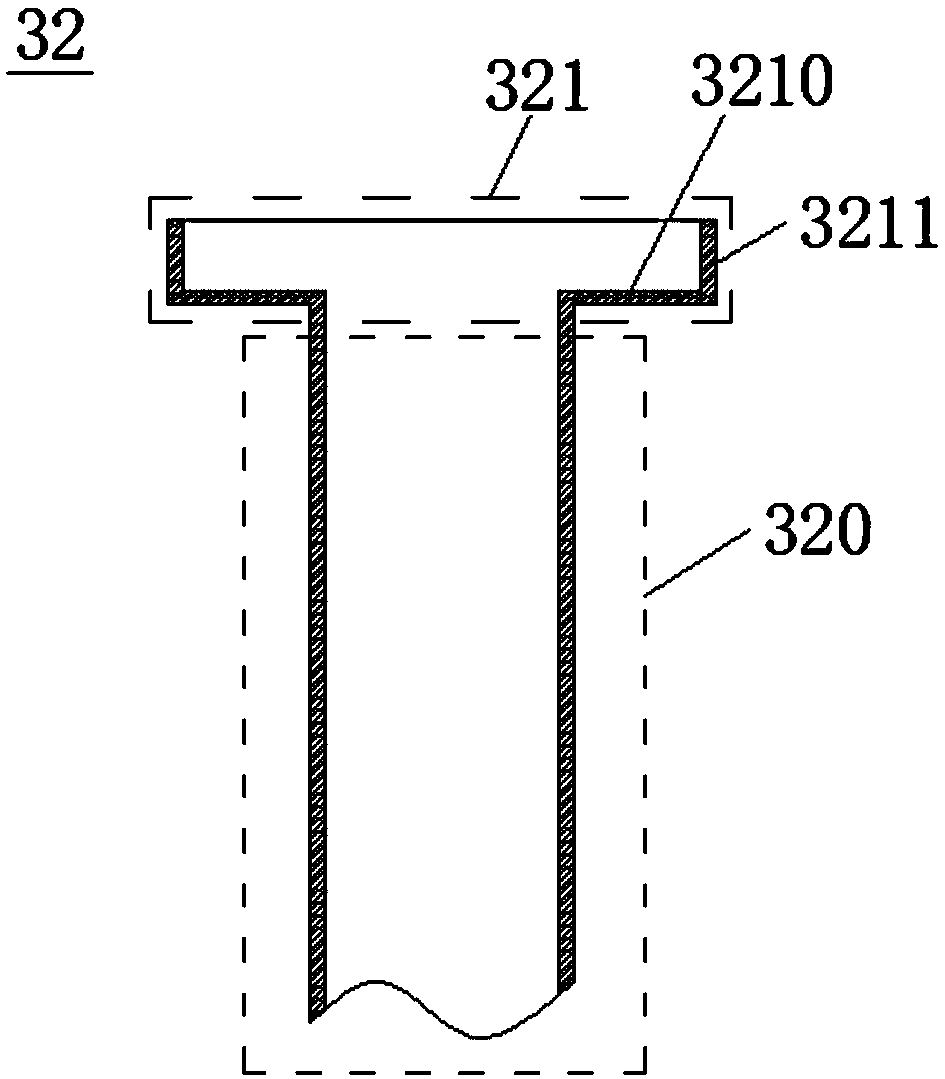

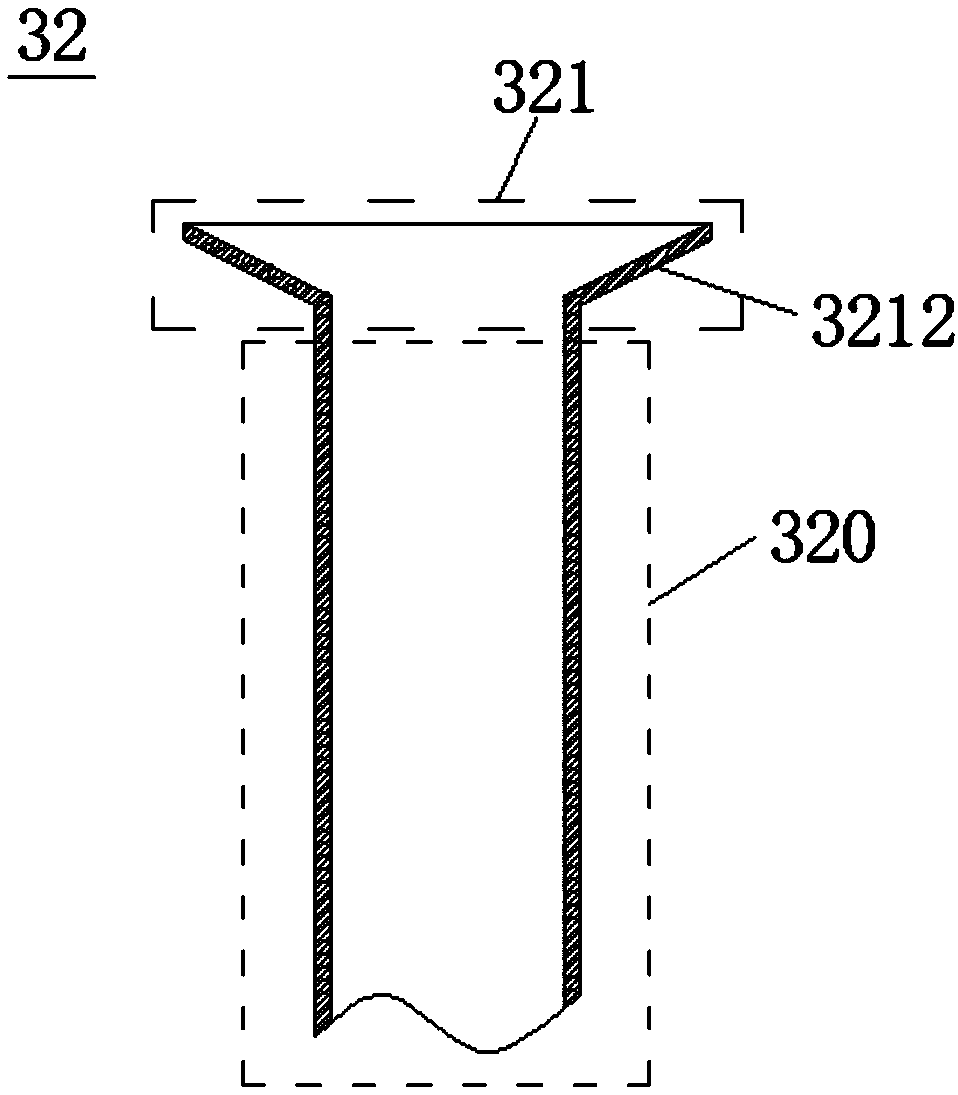

Embodiment Construction

[0024] The following description and the accompanying drawings sufficiently illustrate specific embodiments herein to enable those skilled in the art to practice them. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of the embodiments herein includes the full scope of the claims, and all available equivalents of the claims. Herein, the terms "first", "second", etc. are only used to distinguish one element from another element without requiring or implying any actual relationship or order between these elements. In fact the first element can also be called the second element and vice versa. Furthermore, the terms "comprising", "comprising" or any other variation thereof are intended to cover a non-exclusive inclusion such that a structure, means or apparatus comprising a series of elements includes not only those elements but also other elements not expressly listed elements, or also elements inherent in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com