Patents

Literature

191 results about "Returned Amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The quantity of a product that has been returned. (NCI)

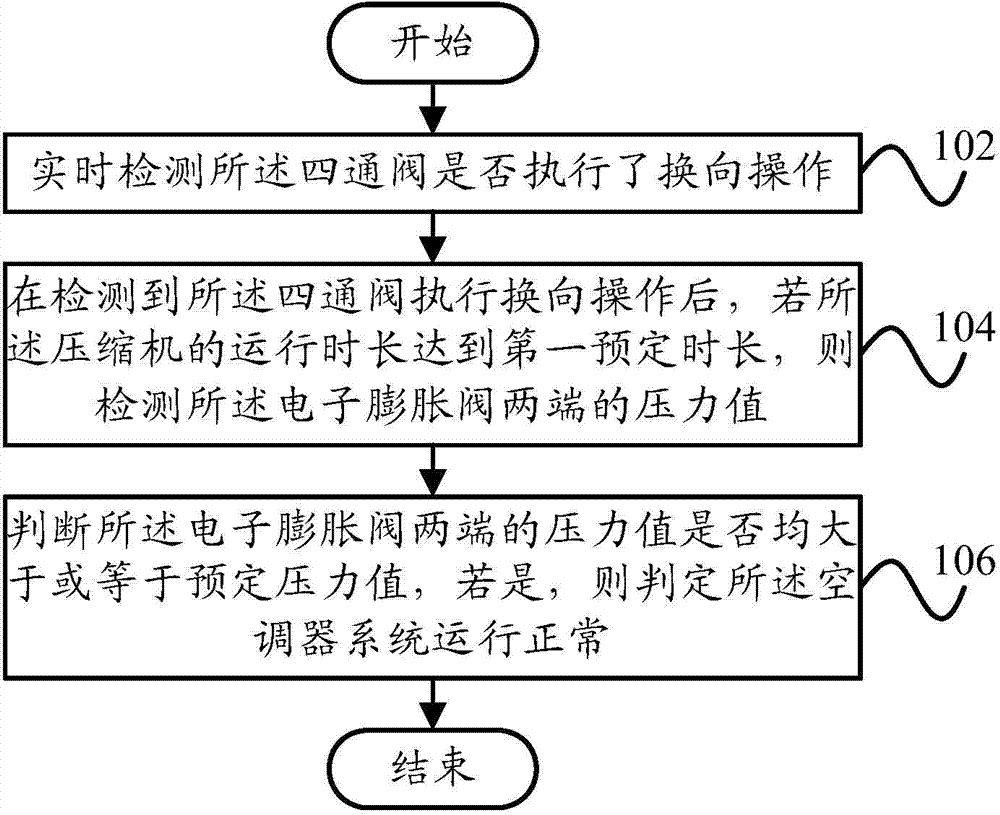

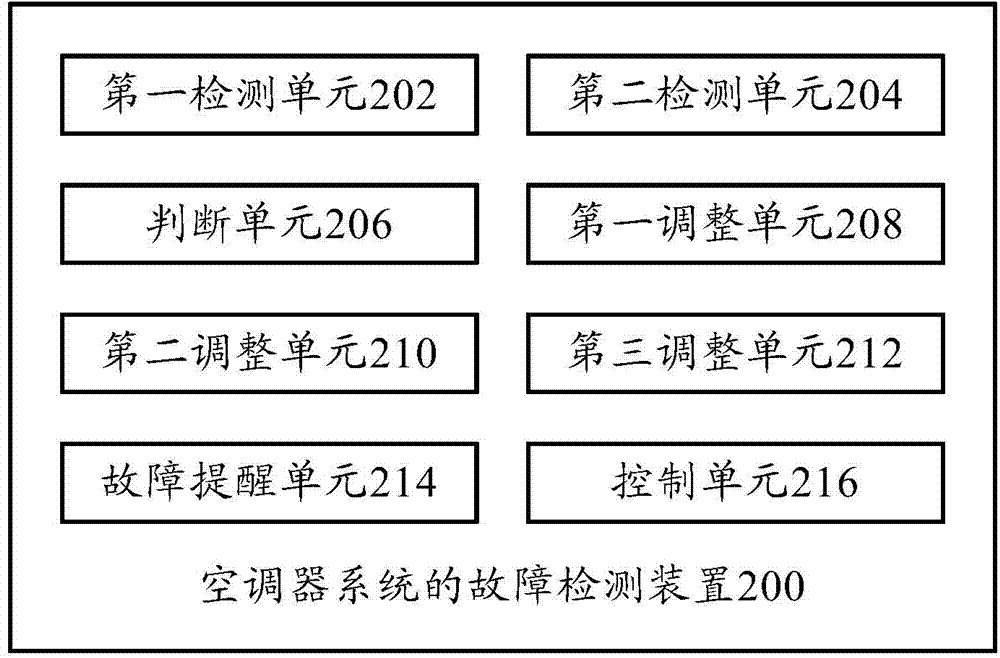

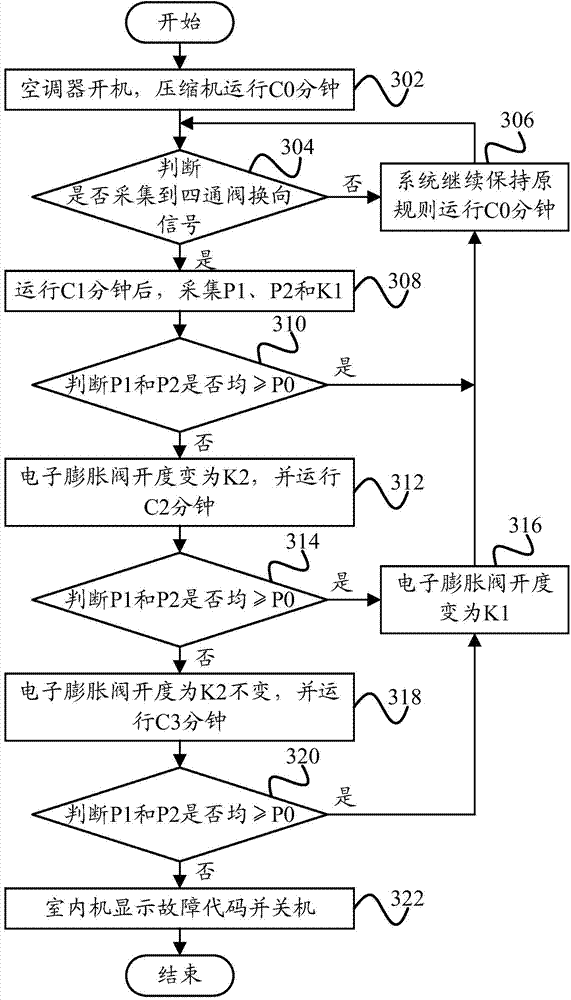

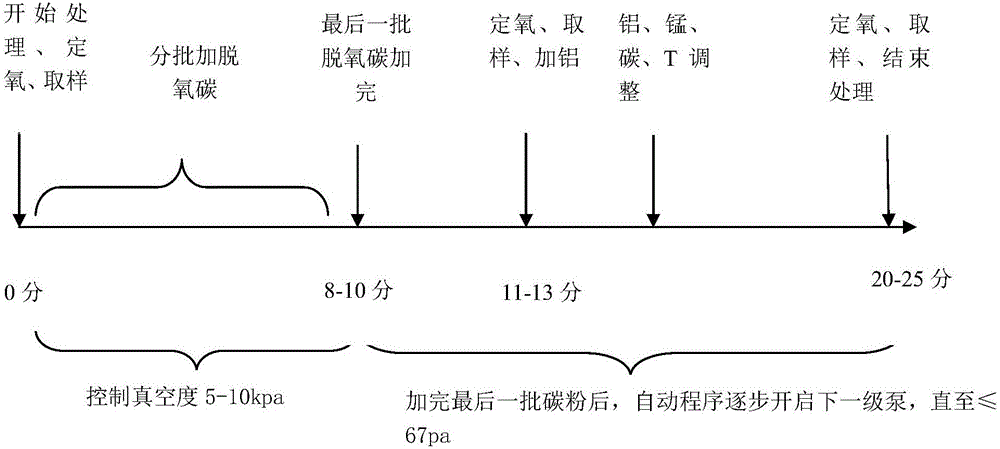

Fault detection method and device of air conditioner system

ActiveCN104776570AReduce capacityReduce the required powerMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEngineering

The invention provides a fault detection method and device of an air conditioner system. The air conditioner system comprises a refrigeration system consisting of a compressor, a four-way valve, an indoor heat exchanger and an outdoor heat exchanger, and an electronic expansion valve for controlling the oil return amount of the compressor. The fault detection method comprises the steps of detecting whether the four-way valve executes a reversing operation or not in real time; after it is detected that four-way valve executes the reversing operation, if the running duration of the compressor reaches a first preset duration, detecting pressure values of the two ends of the expansion valve; judging whether the pressure values of the two ends of the electronic expansion valve are greater than or equal to a preset pressure value or not; and if so, judging that the air conditioner system runs normally. By adopting the technical scheme provided by the invention, the problem of greasy blockage in the expansion valve before and after defrosting of the air conditioner can be detected in time, the situation that the capacity and power of the air conditioner is decreased due to idle operation of the compressor is avoided, the service life of the compressor is guaranteed, and the use comfort of the new refrigerant air conditioner is also improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

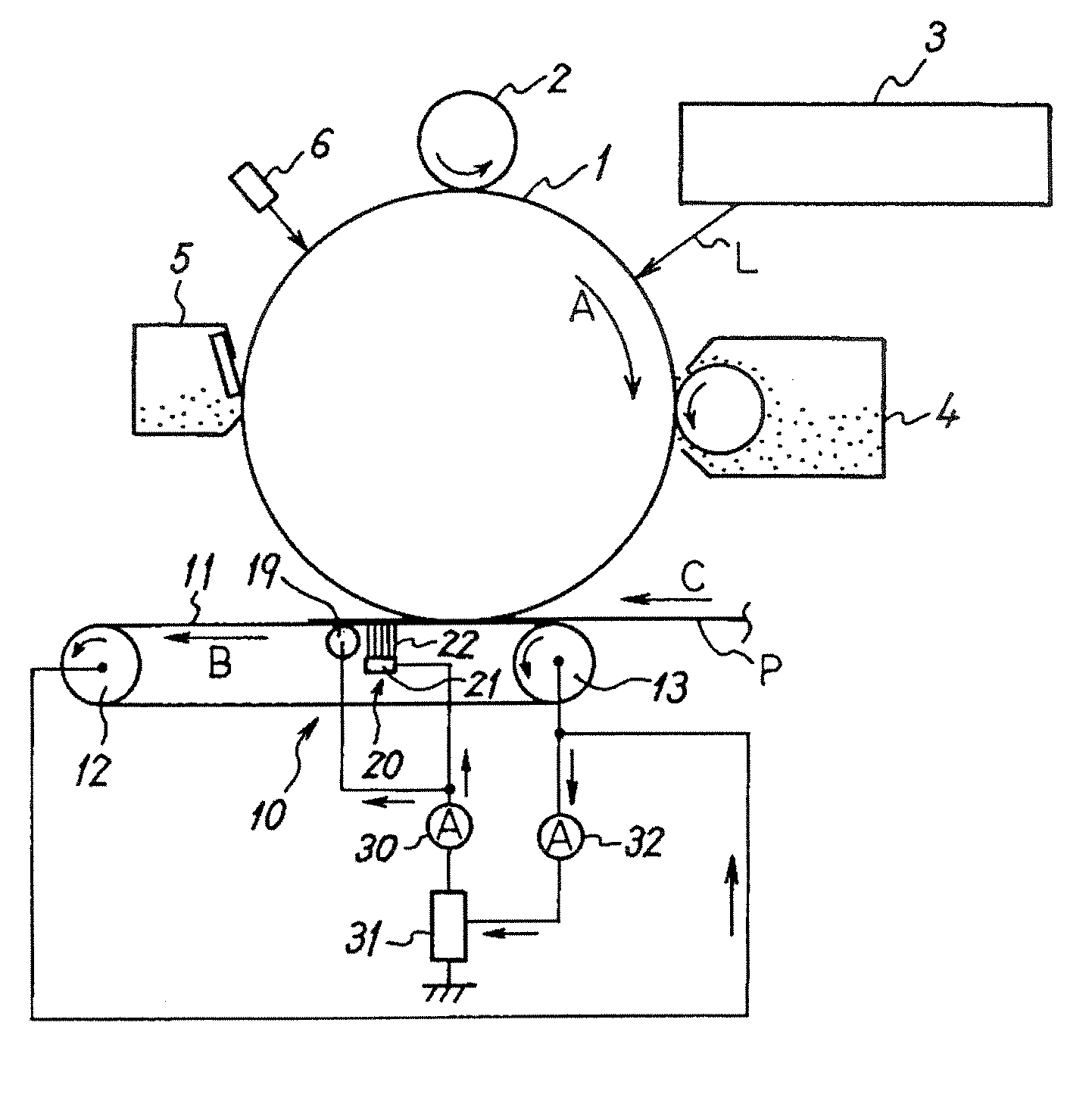

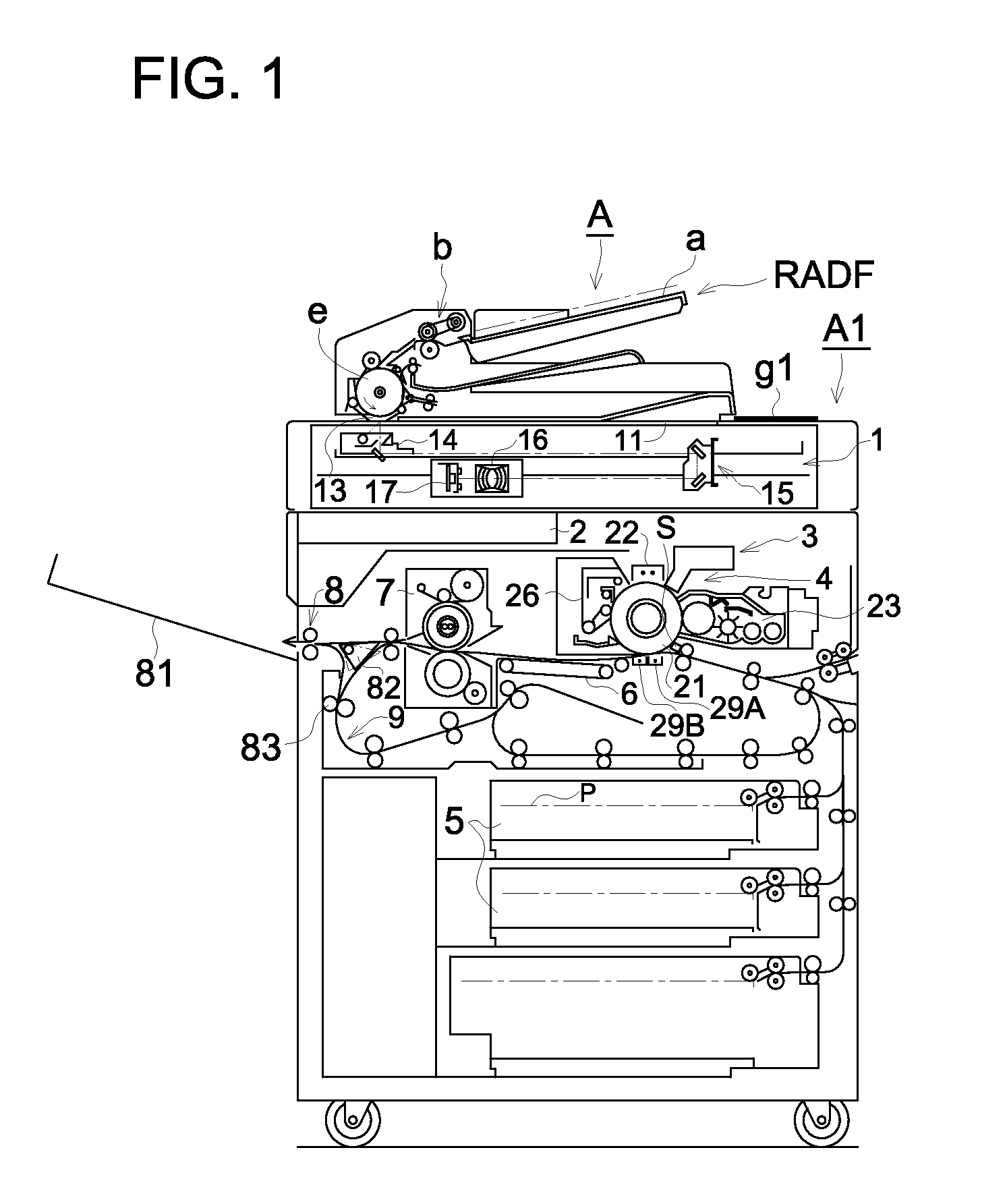

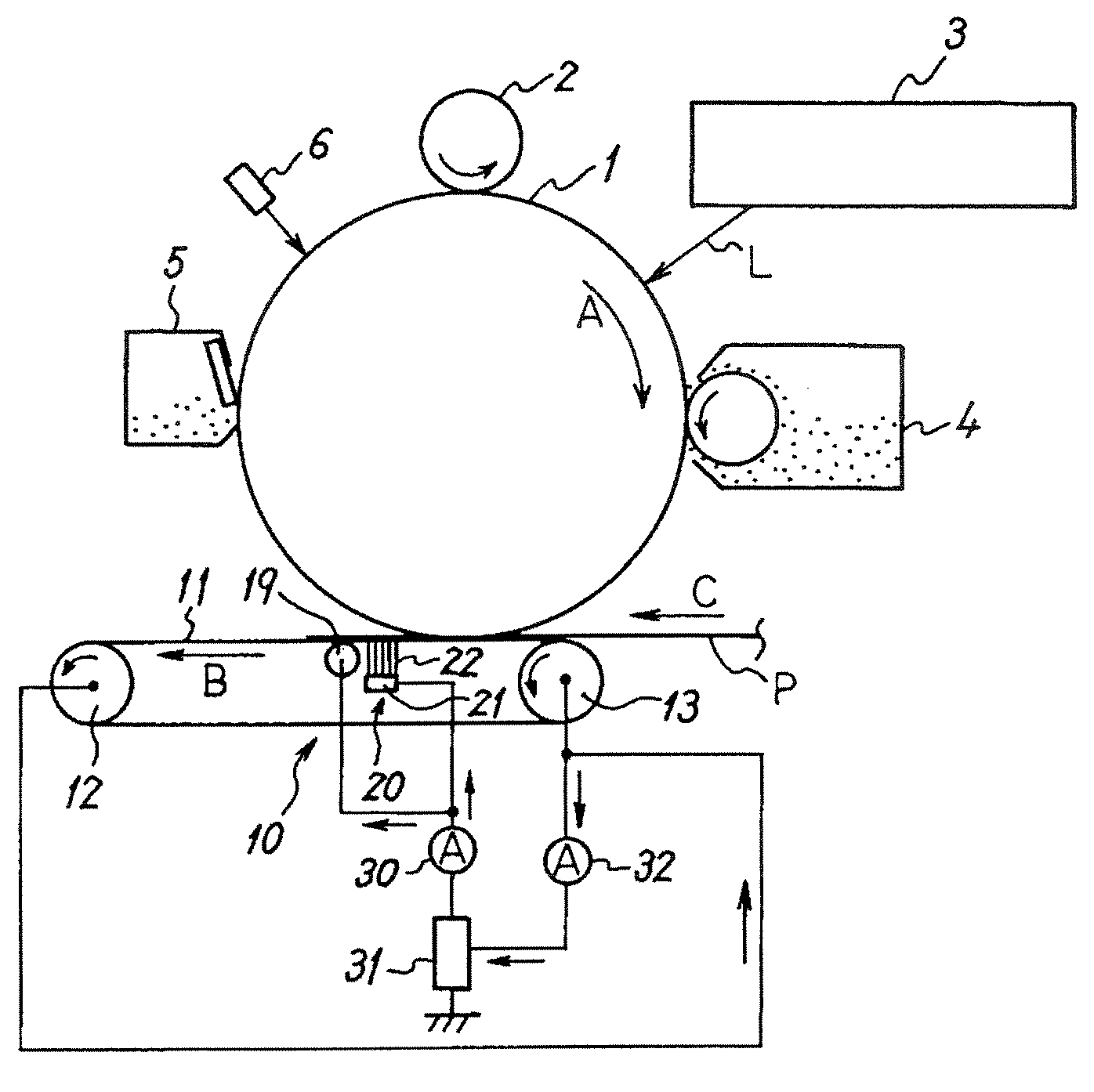

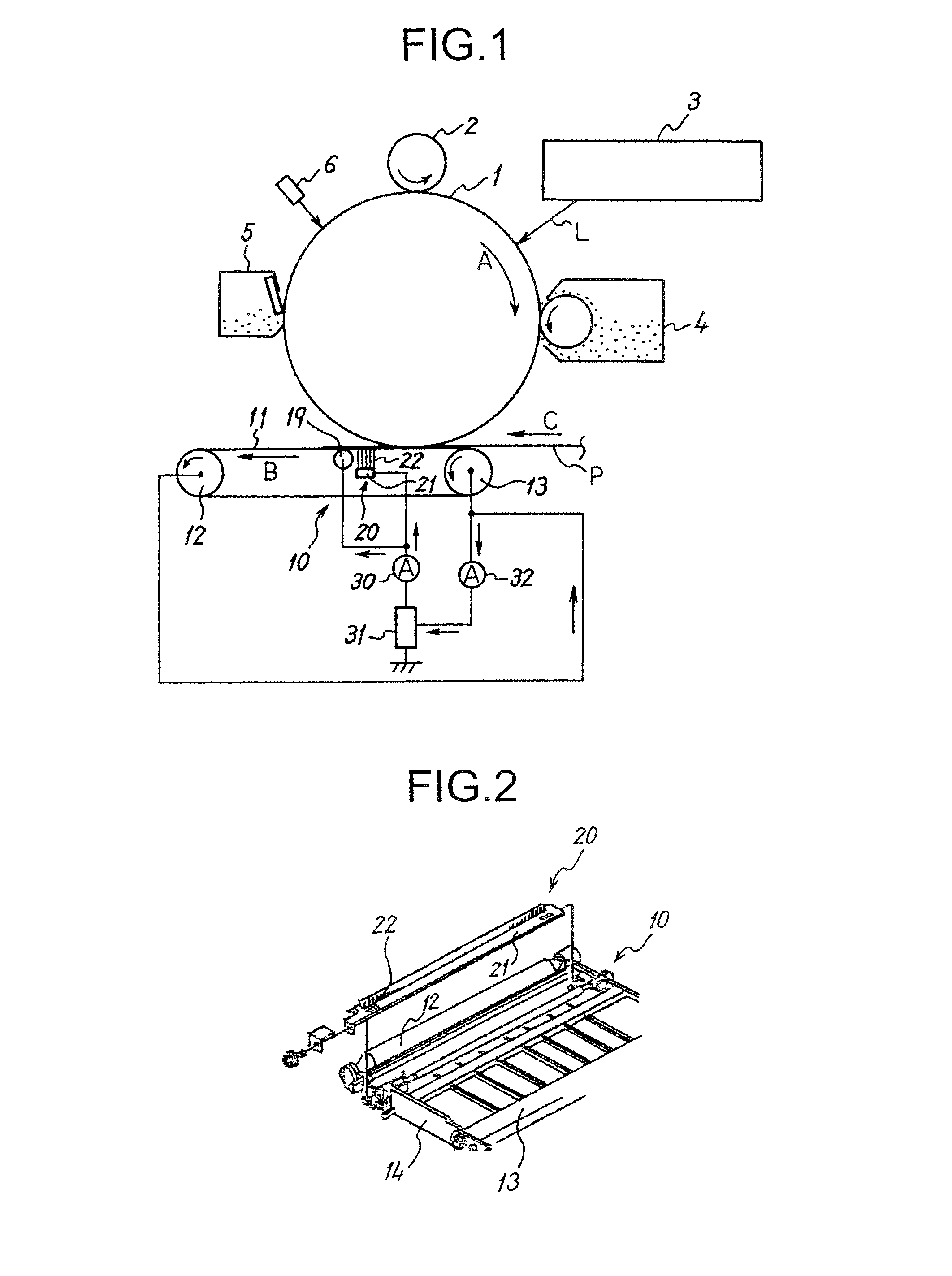

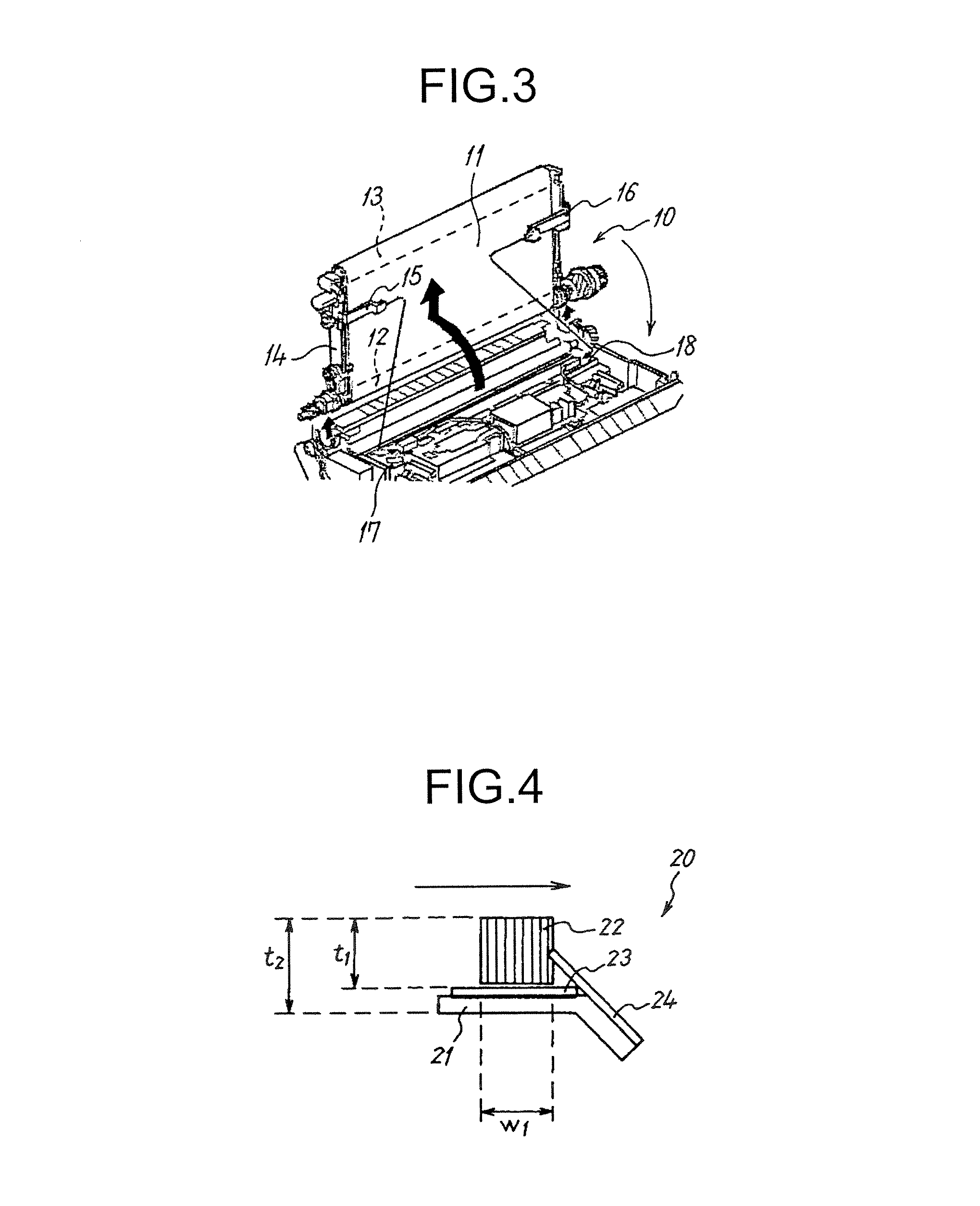

Brush member and transfer device and image forming apparatus using the same

InactiveUS20070014597A1Solve problemsElectrographic process apparatusReturned AmountStatic friction coefficient

In an image forming apparatus, a transfer brush with length of raised bristles on the surface of a metal holder equal to or smaller than 5.8 millimeters is used. Alternatively, a transfer brush with a maximum bristle inclination amount of raised bristles in a brush unit including a plurality of bristles equal to or smaller than 0.53 millimeter or a transfer brush with a maximum bristle inclination return amount of raised bristles in the brush unit equal to or smaller than 0.30 millimeter is used. An amount of biting into a paper conveyor belt in the brush unit is set to a value equal to or smaller than 2.5 millimeters. A paper conveyor belt with hardness of the rear side equal to or lower than 78 Hs is used. Alternatively, a paper conveyor belt with a coefficient of static friction on the rear surface equal to or lower than 0.75 is used.

Owner:RICOH KK

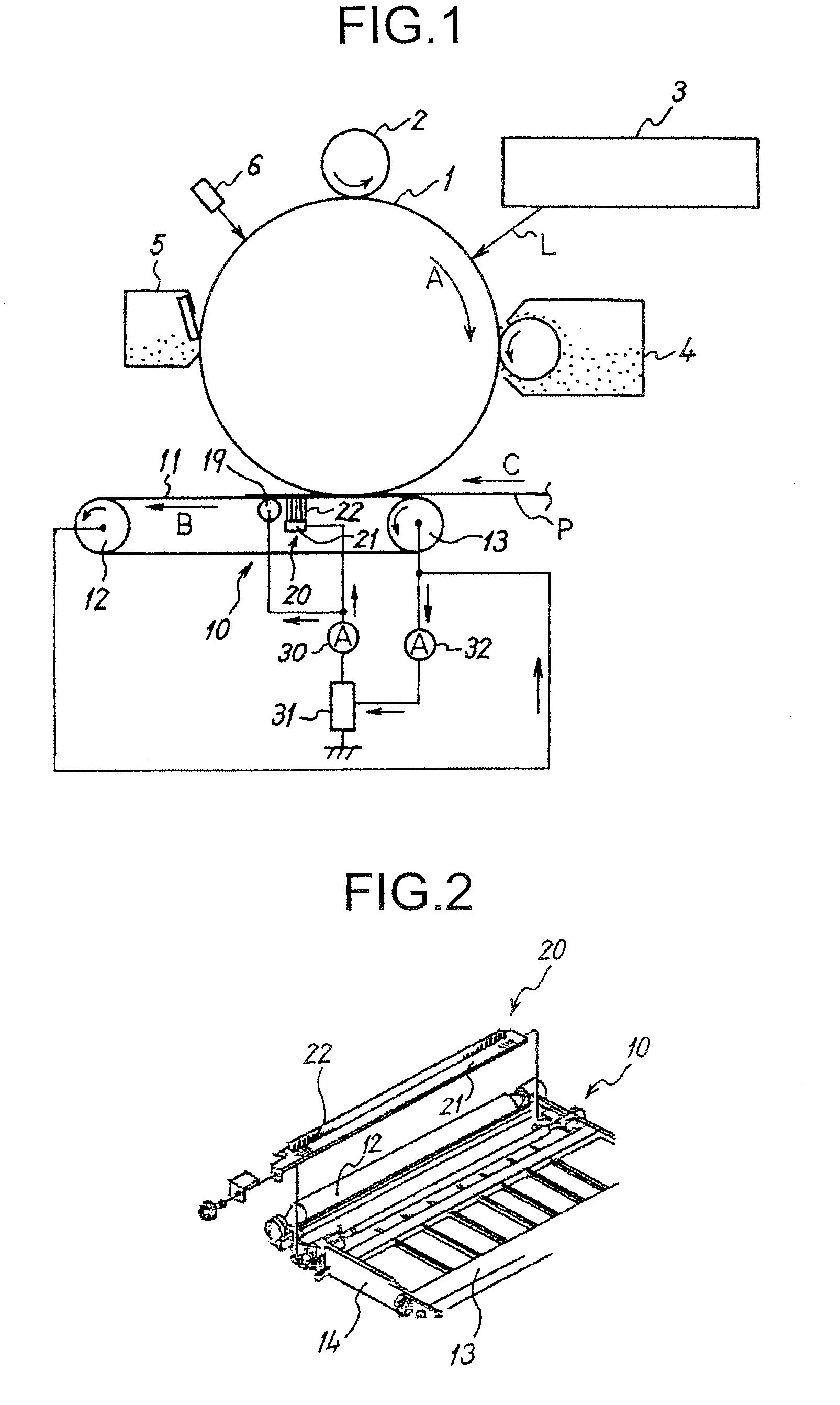

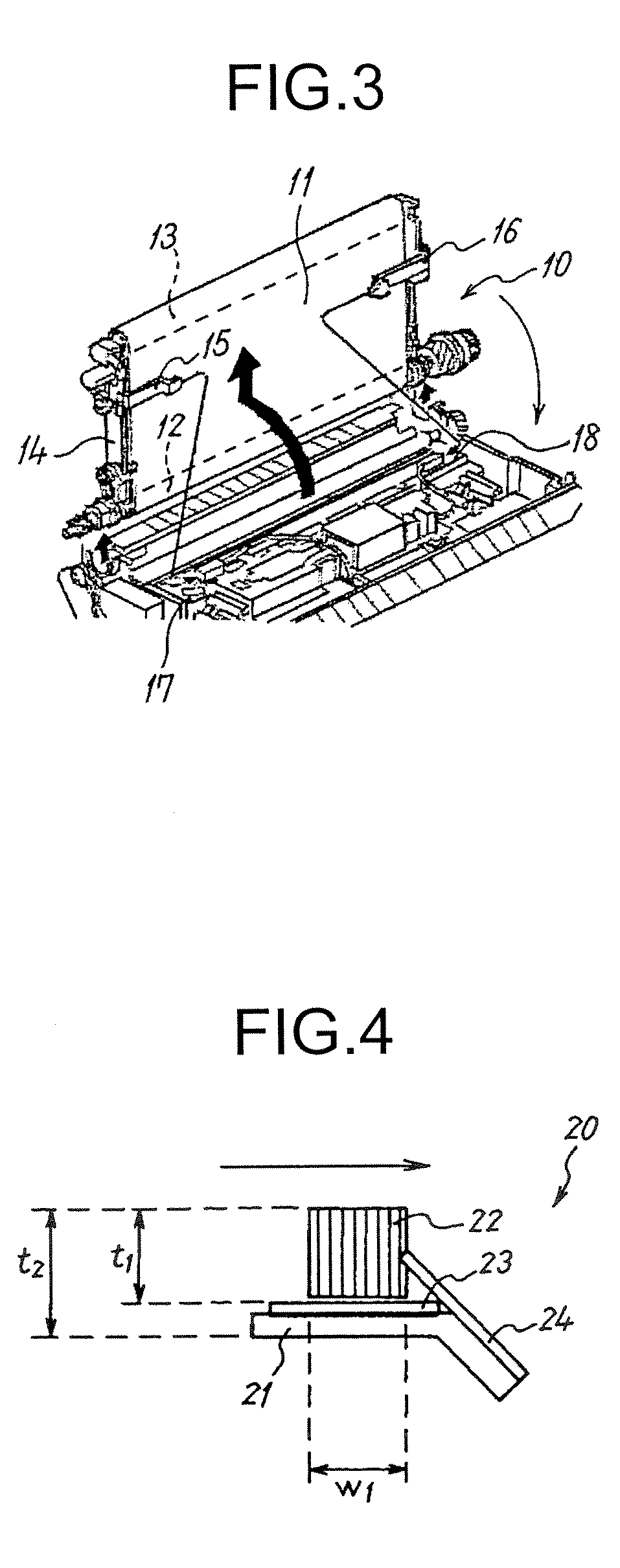

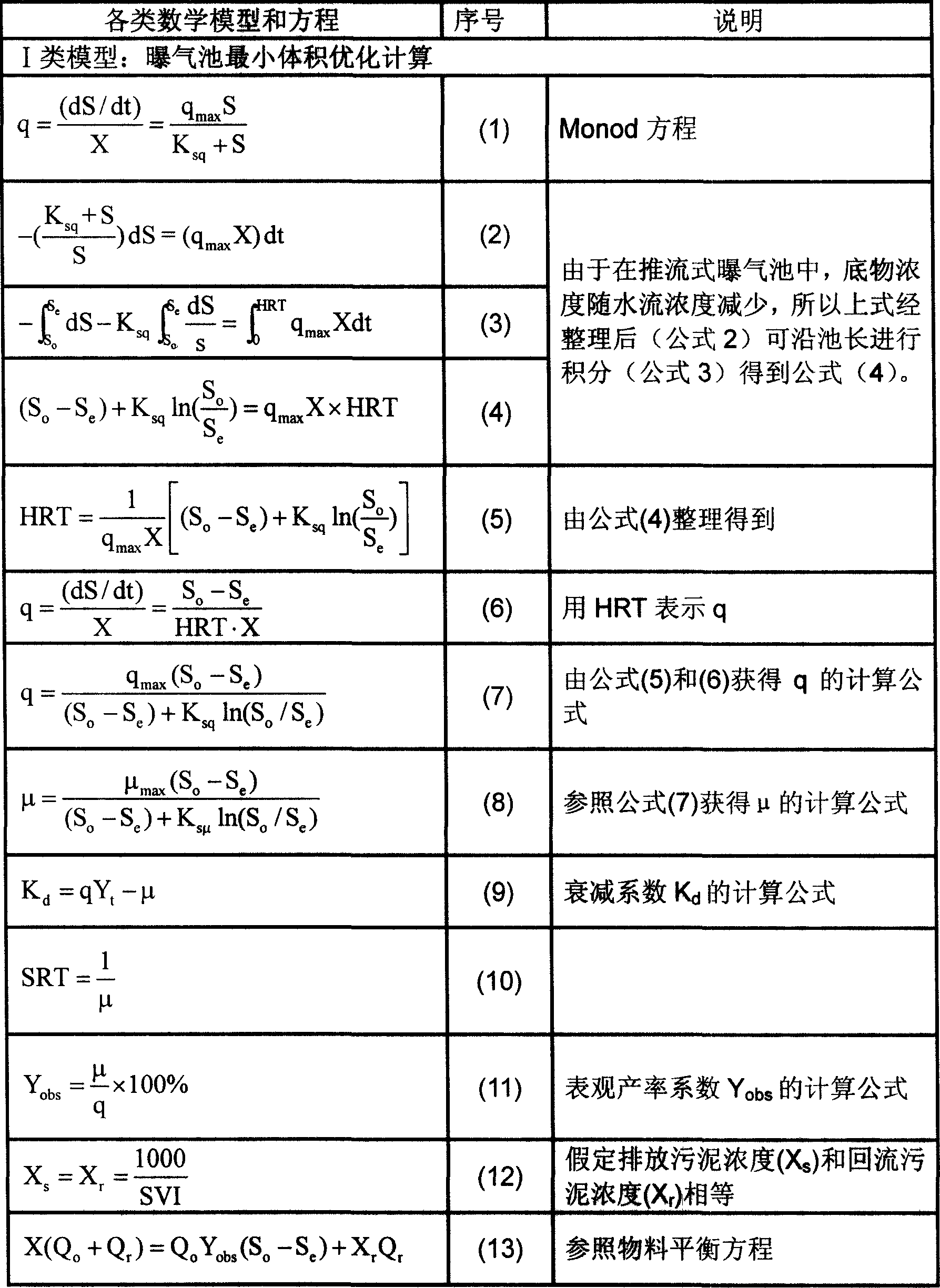

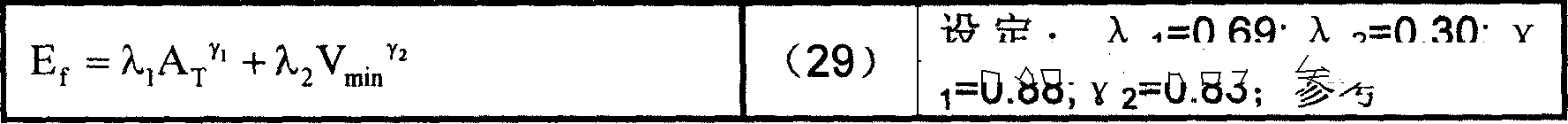

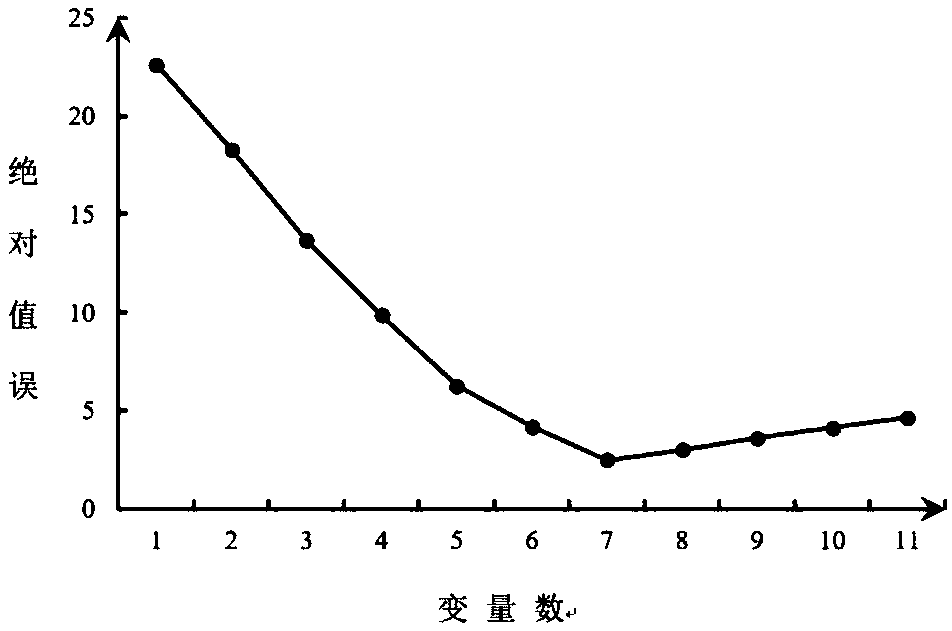

Optimization regulating method for waste water bio-treatment system process

InactiveCN101045574AOptimal control of reactor volumeOptimizing control volumeTreatment using aerobic processesSustainable biological treatmentActivated sludgeMaterial balance

An optimizing control method for the biologic treating system of sewage features that starting from the technological parameters of the sewage treating system, the kinetic parameters of sewage, the minimal volume of reactor, the materials balancing principle, Monod equation and the circulating variables including BOD content, biomass concentration and returned amount are used to create a mathematical model for the sewage treating technology.

Owner:NANJING UNIV

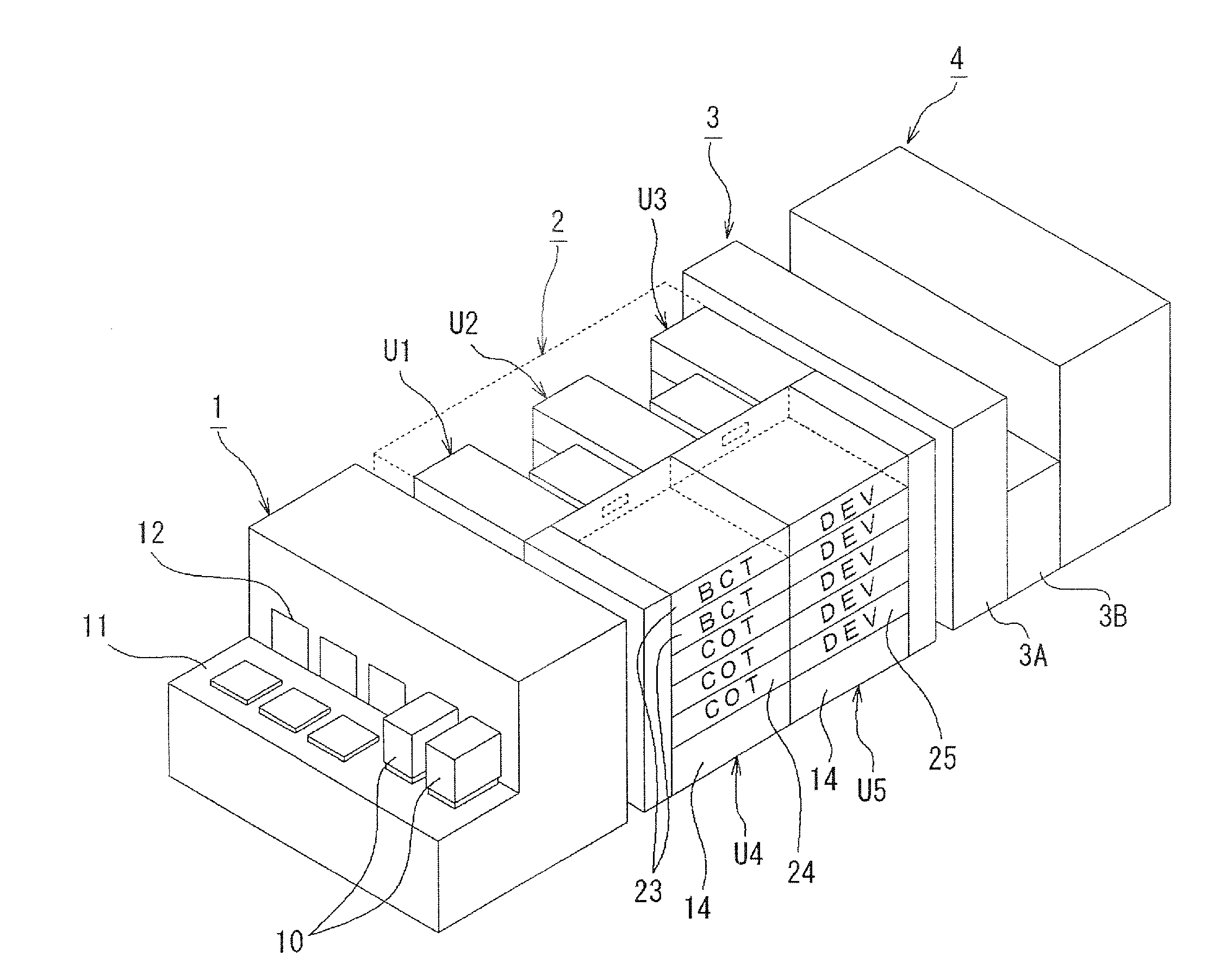

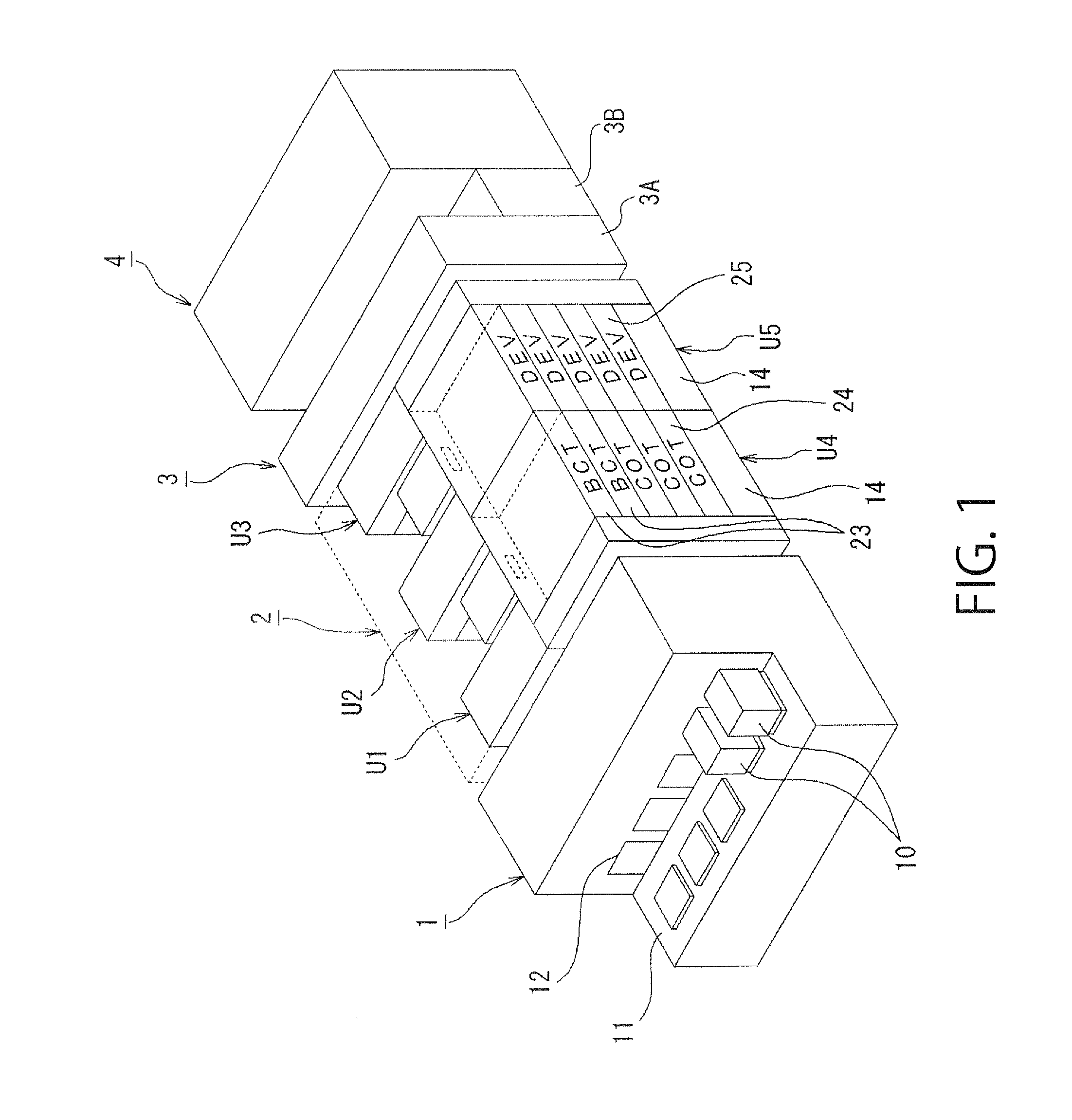

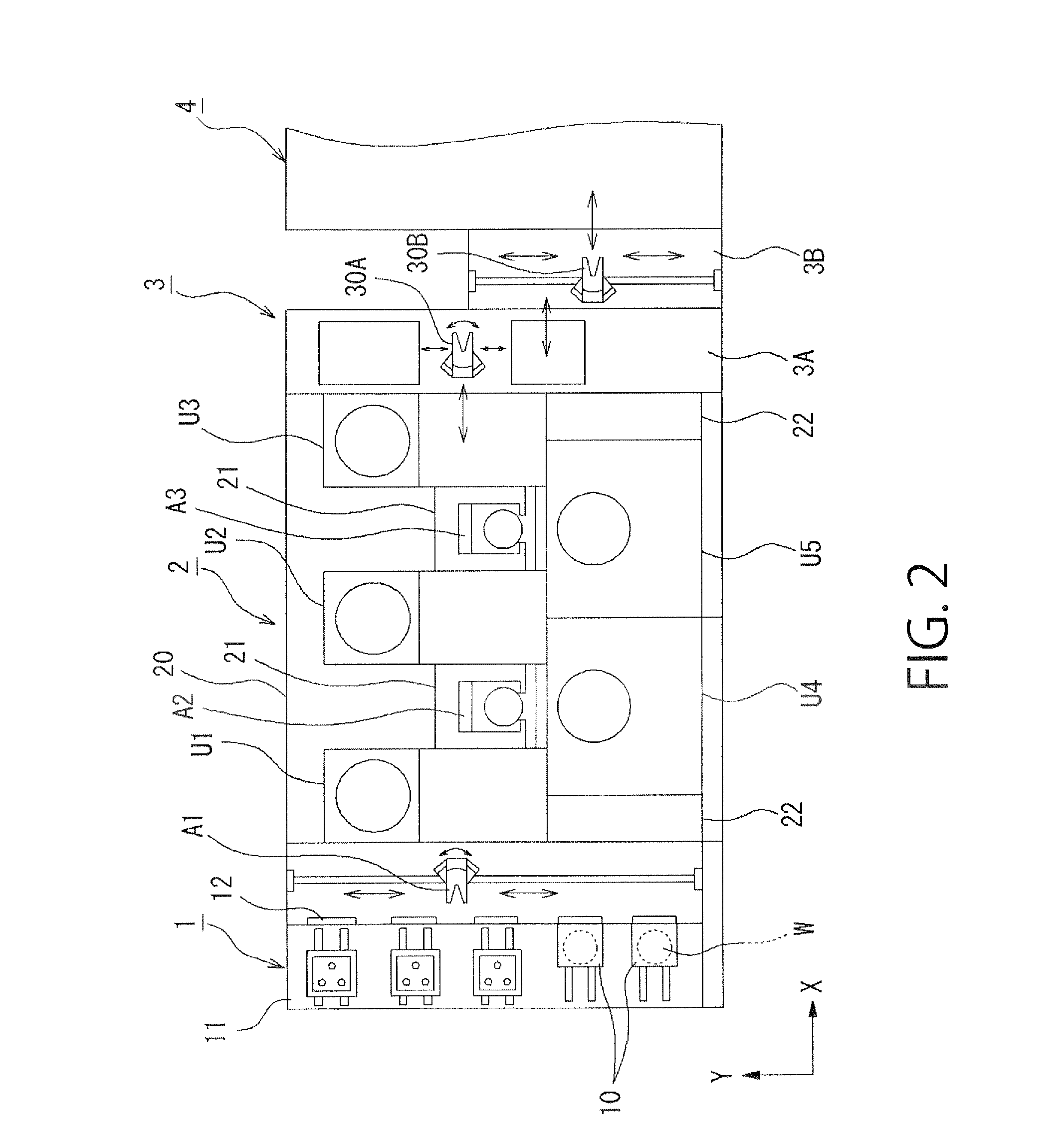

Liquid processing apparatus, liquid processing method, and storage medium for liquid process

ActiveUS20140174475A1Reduce throughputEfficient removalFluid parameterFlexible member pumpsResistControl signal

A filtration efficiency, which is similar to the filtration efficiency obtained when a plurality of filters are provided, can be obtained by one filter, and decrease in throughput can be prevented. Based on a control signal from a control unit 101, a resist liquid L is sucked into a pump 70 through a filter. A part of the resist liquid sucked in the pump is discharged from a discharge nozzle 7. The remaining resist liquid is returned to a supply conduit 51b on a primary side of the filter. A process is synthesized by adding a replenishment amount equal to the discharge amount to the return amount. The discharge of the synthesized process liquid and the filtration thereof by the filter are performed the number of times corresponding to a rate between the discharge amount and the return amount.

Owner:TOKYO ELECTRON LTD

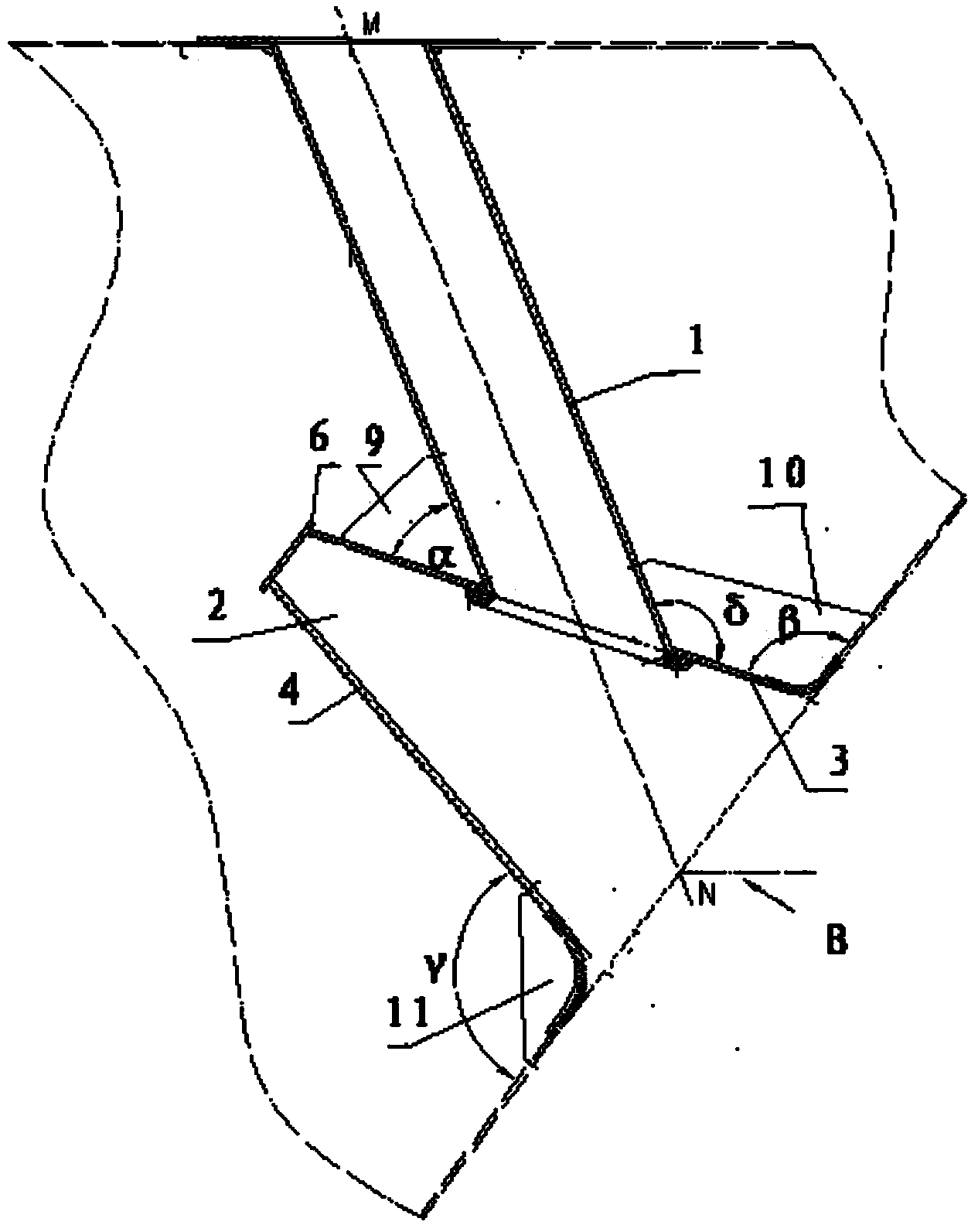

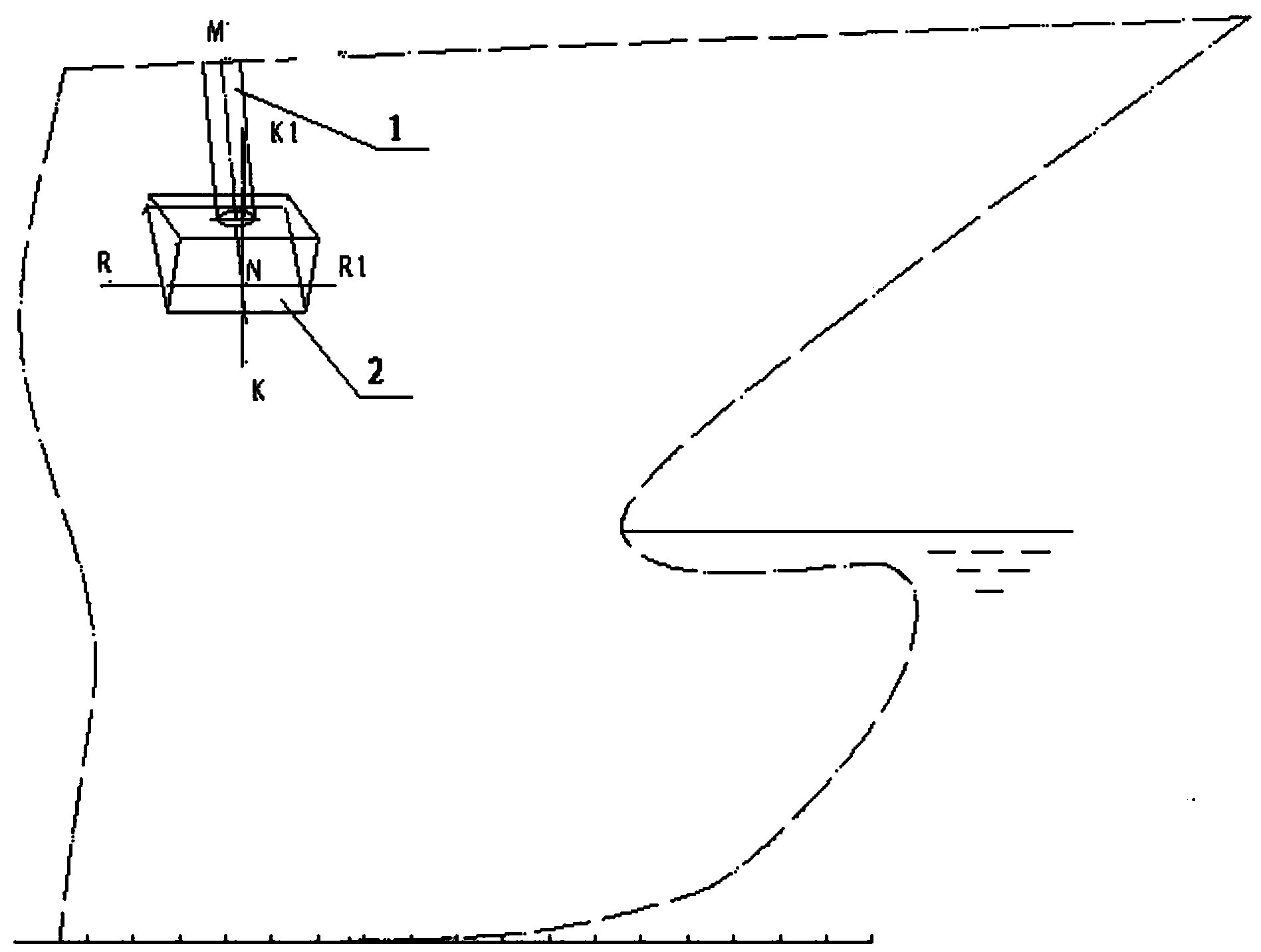

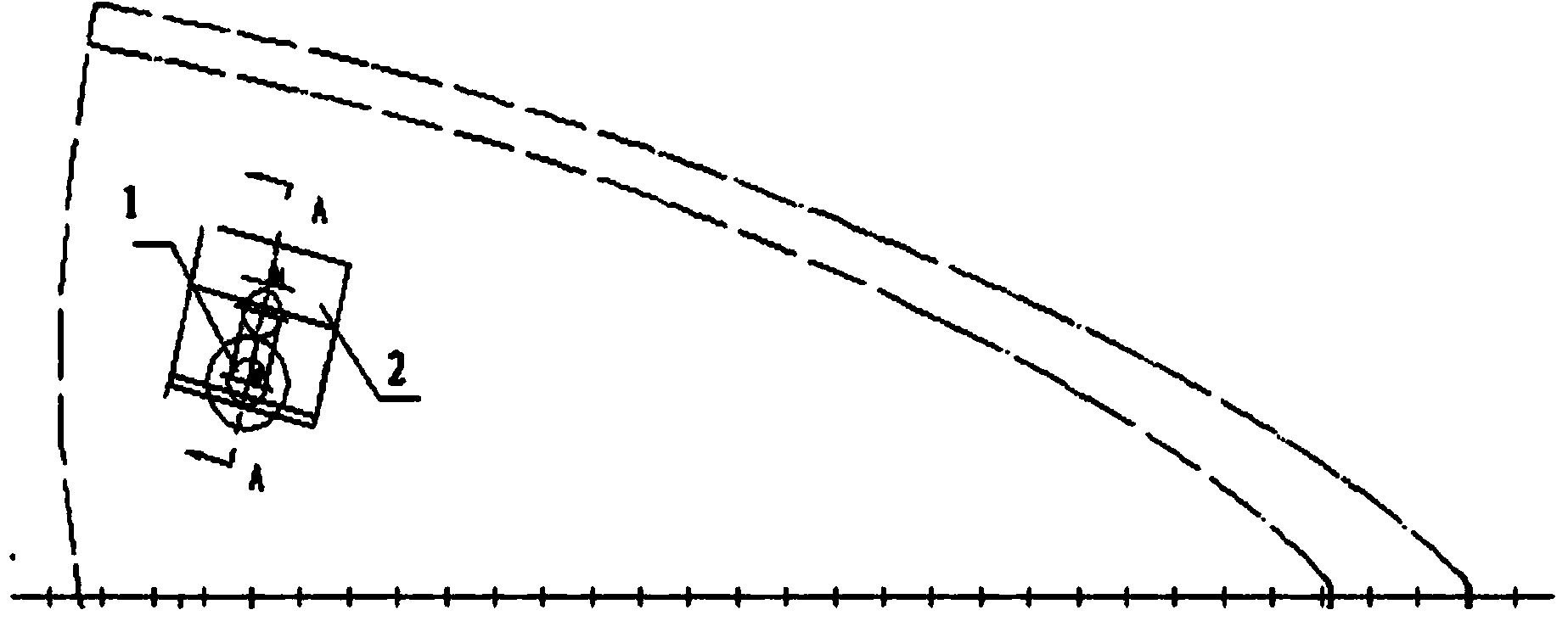

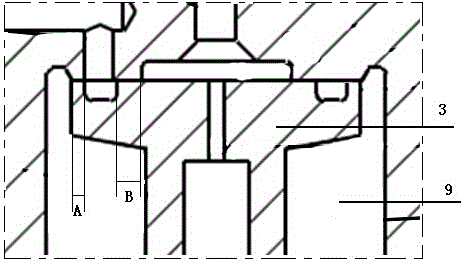

Hidden anchor recess and manufacturing installation technology

InactiveCN103523174ABreakthrough installation accuracy is not highHigh precisionVessel partsMarine engineeringReturned Amount

The invention relates to a hidden anchor recess. Sides of a first elbow plate and a second elbow plate are symmetrically welded at the two sides of an anchor recess side plate. Bottom plates of the first elbow plate and the second elbow plate are welded to an outer plate respectively. One side of a third elbow plate is welded to an anchor recess top plate and the other side of the third elbow plate is welded to the inner side of an anchor chain tube. The first side of a fourth elbow plate is welded to the outer side of the anchor chain tube, the second side of the fourth elbow plate is welded to the anchor recess top plate and the third side of the fourth elbow plate is welded to the outer plate. One side of a fifth elbow plate is welded to an anchor recess bottom plate and the other side of the fifth elbow plate is welded to the outer plate. In an inner field stage, all parts of the hidden anchor recess and the five elbow plates are welded and assembled and the hidden anchor recess is welded to the outer plate at one time in a slipway stage. According to the hidden anchor recess, a plurality of elbow plates are added on the outer side of the anchor recess and the included angles between the anchor recess and other devices are fixed, the sizes of parts are determined at one time and precision of manufacturing the parts is improved. Work of the anchor recess is completed in the inner field in advance instead of being performed in the slipway. Work loads and the waste and return amount of the slipway are reduced, the period of shipbuilding is shortened and shipbuilding cost is reduced.

Owner:WUCHANG SHIPBUILDING IND

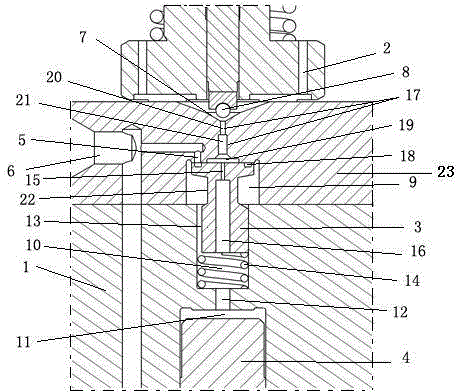

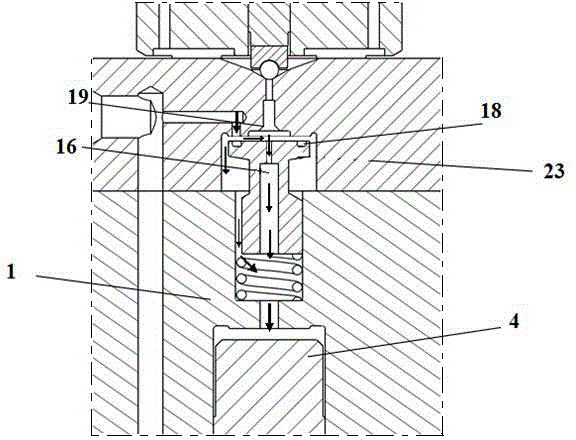

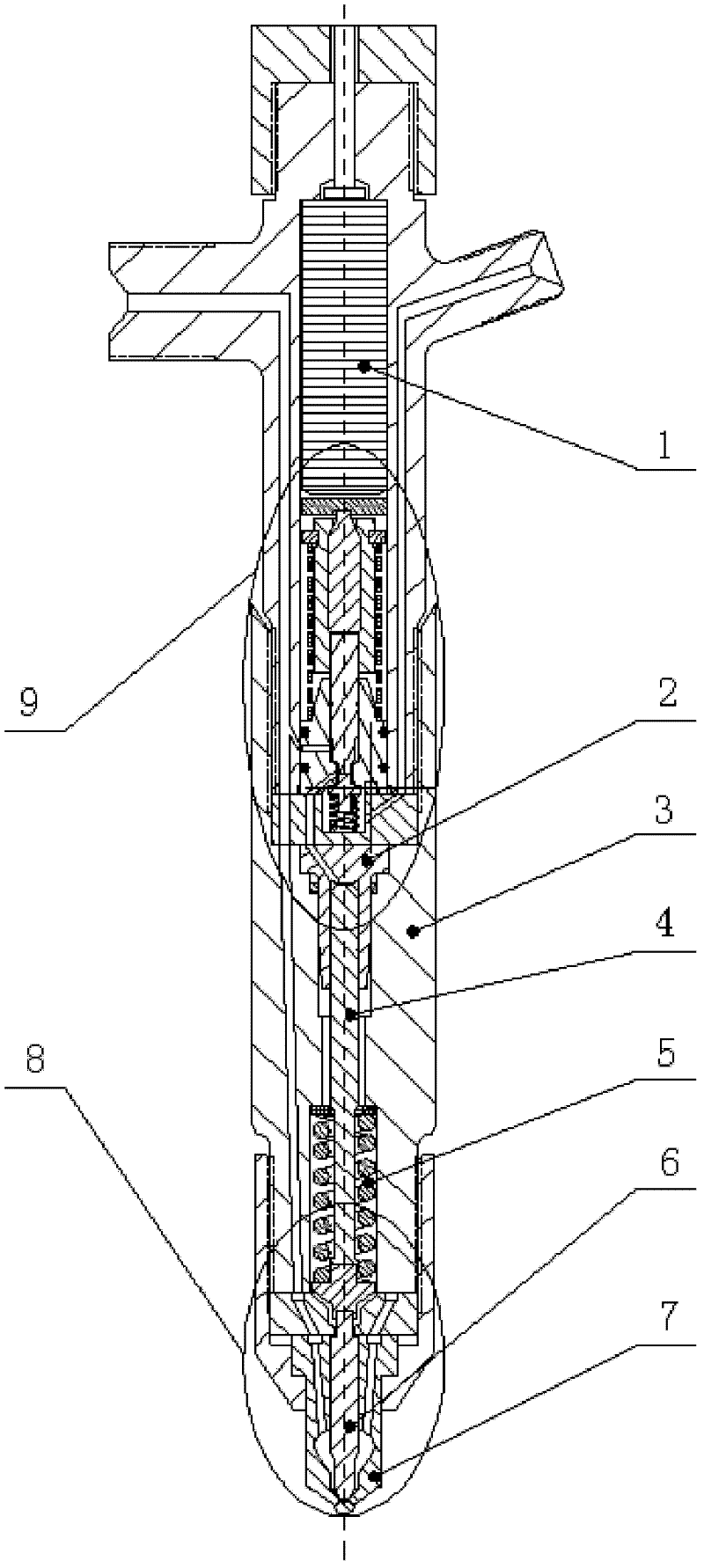

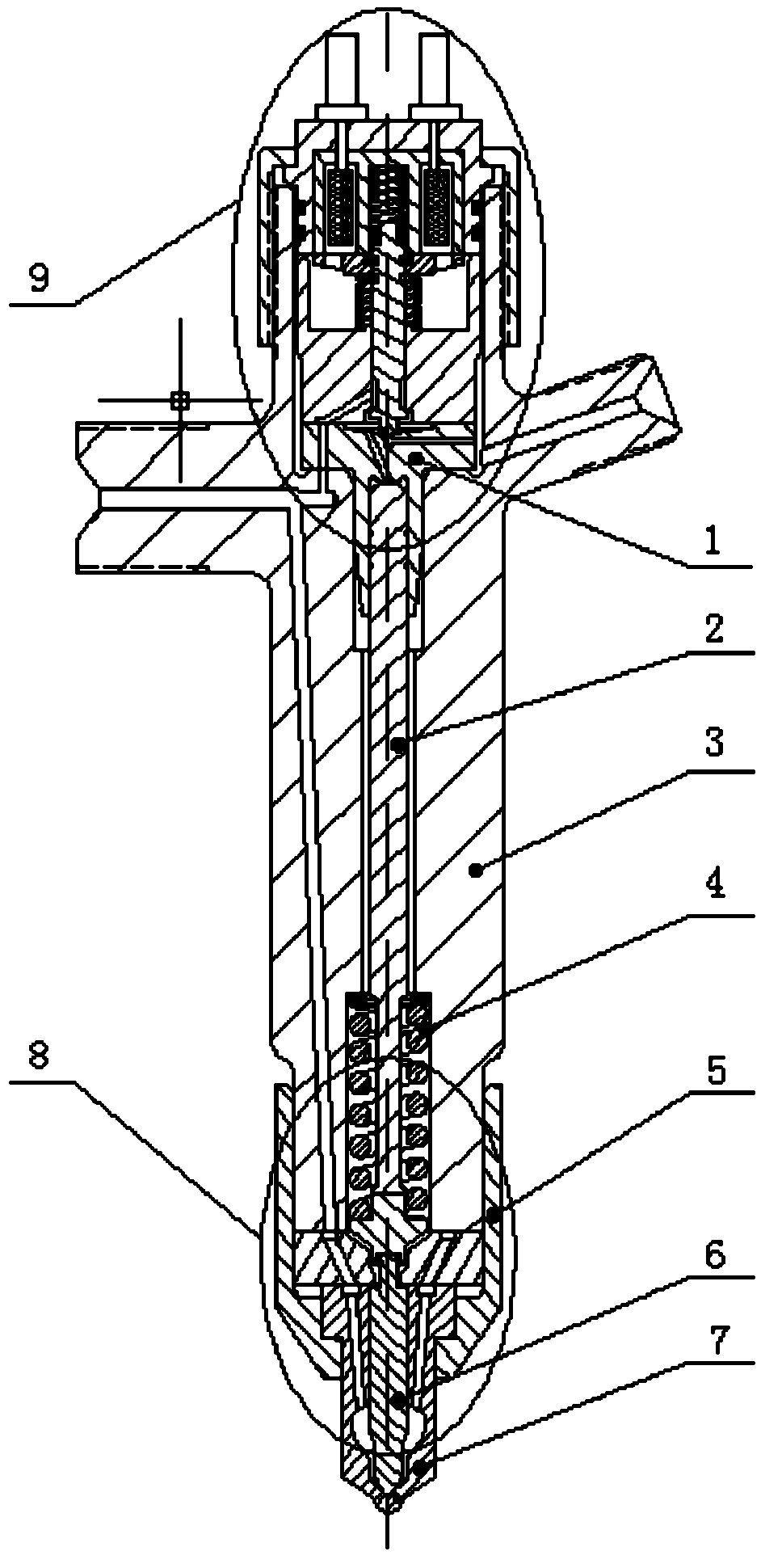

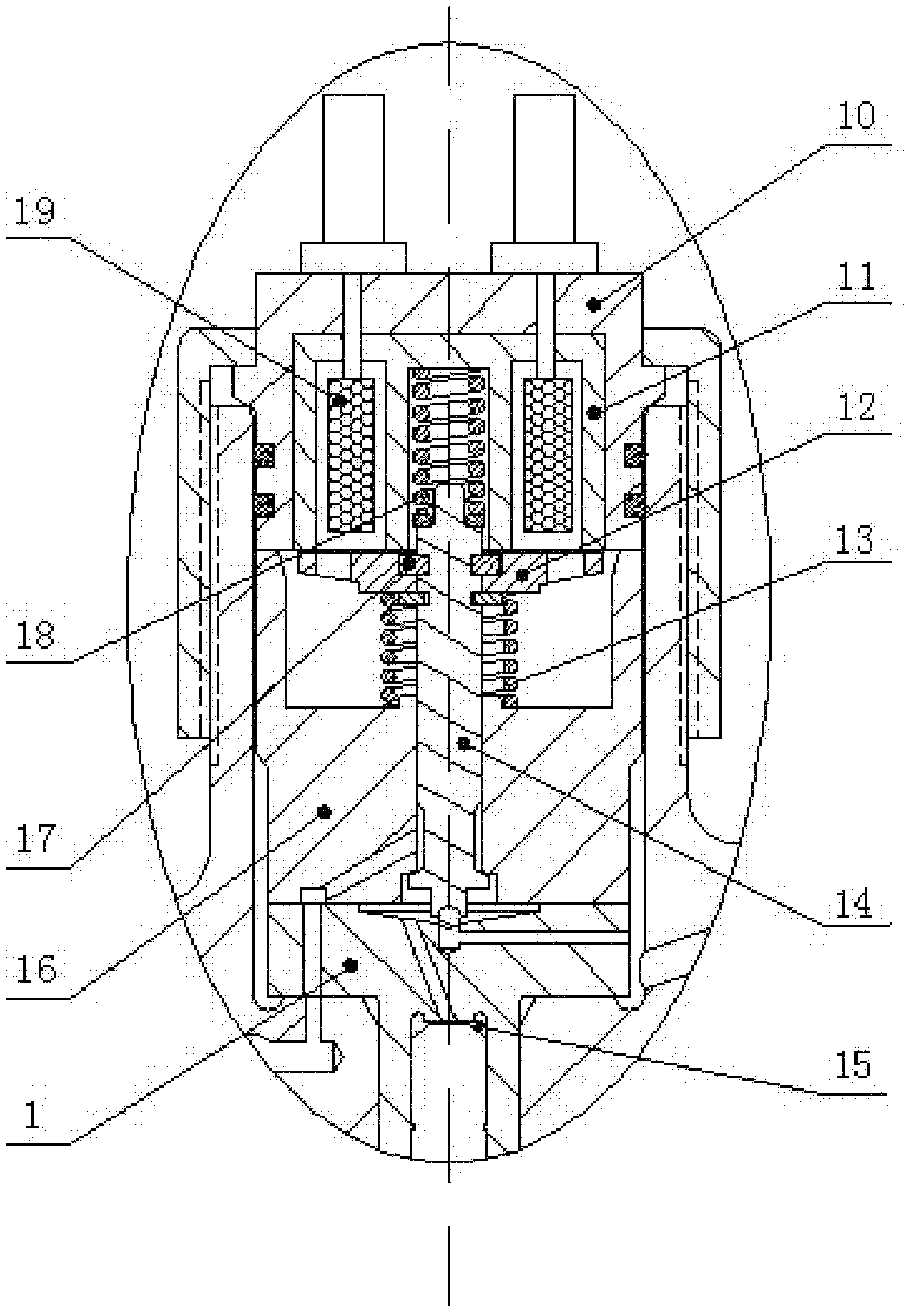

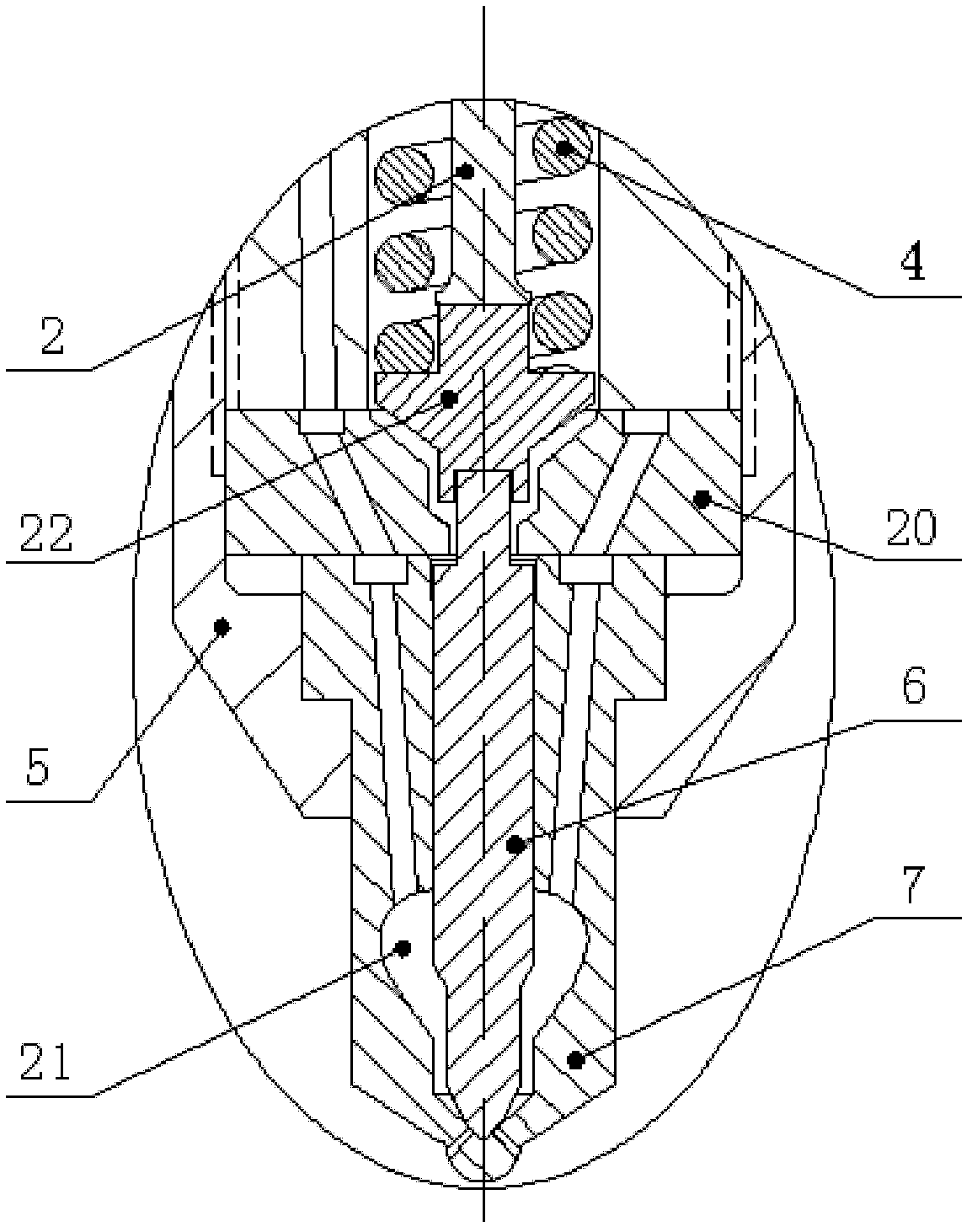

Novel common-rail oil injector

ActiveCN104481767AGuaranteed stabilityImprove reliabilityFuel injection apparatusMachines/enginesCommon railControl valves

The invention discloses a novel common-rail oil injector, which comprises an oil injector shell body. A pore plate is arranged at the upper end of the oil injector shell body. A control valve seat is mounted at the upper end of the pore plate. A low-pressure oil duct is installed inside the control valve seat. Oil cavities are installed inside the oil injector shell body and the pore plate. The oil cavities are respectively communicated with a high-pressure oil duct and the low-pressure oil duct. The high-pressure oil duct is connected with an oil inlet. A sealing surface and a switching valve are arranged between the low-pressure oil duct and the oil cavities. Compared with the prior art, the novel common-rail oil injector has the advantages that when injecting oil, the communication process of the high-pressure oil duct and the low-pressure oil duct is short, the high-pressure fuel entering a control cavity will be cut off, the oil return amount is greatly reduced, the oil injection efficiency of the novel common-rail oil injector is increased, the oil temperature rising of the oil injector is reduced, the working stability of the novel common-rail oil injector is ensured, the reliability of the novel common-rail oil injector is improved, also the energy consumption of a flushing pump is reduced, and the novel common-rail oil injector creates conditions for pressure injection of the common-rail system.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +1

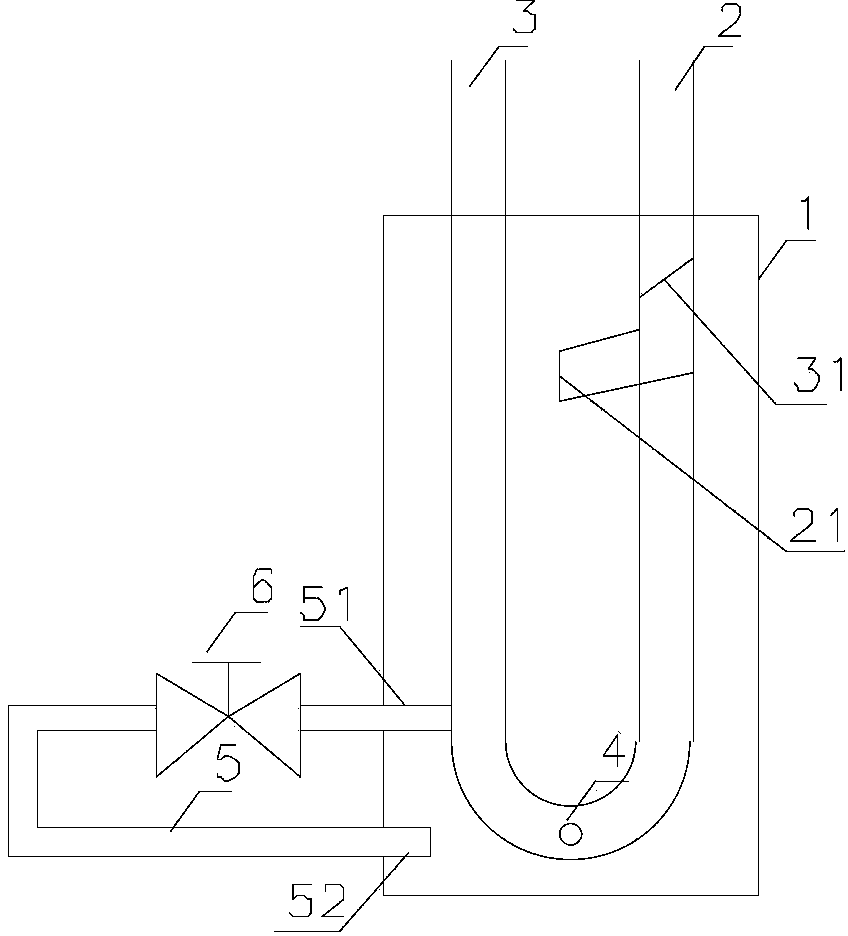

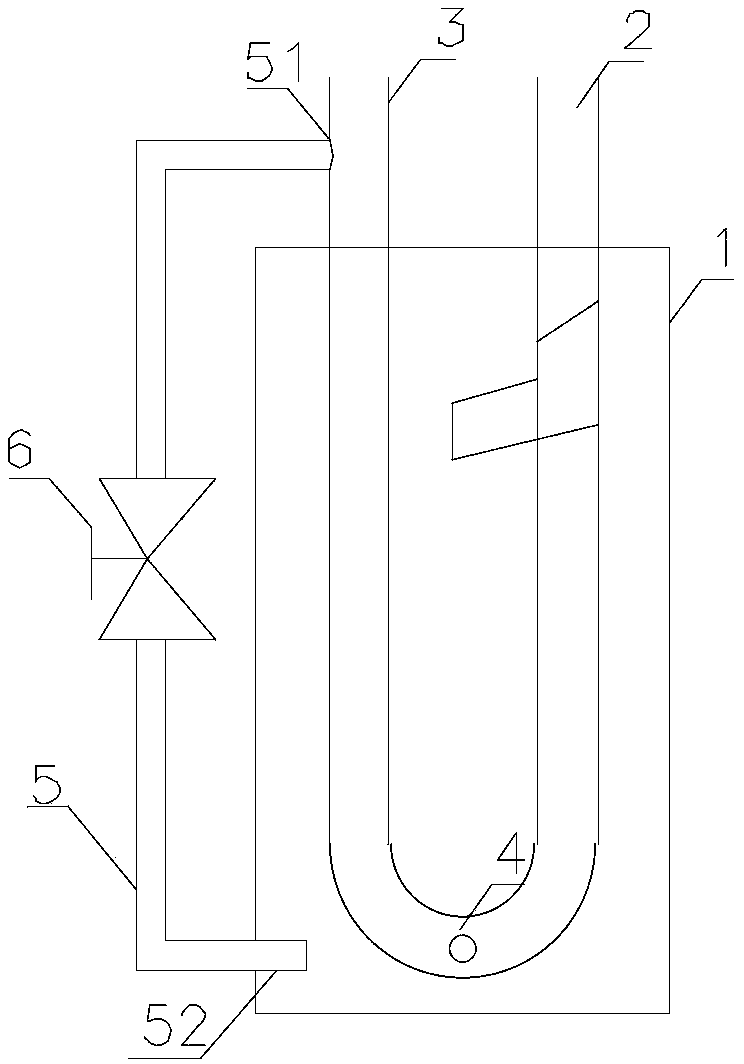

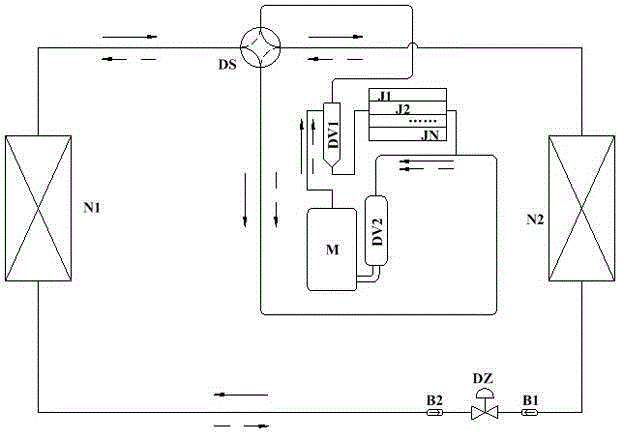

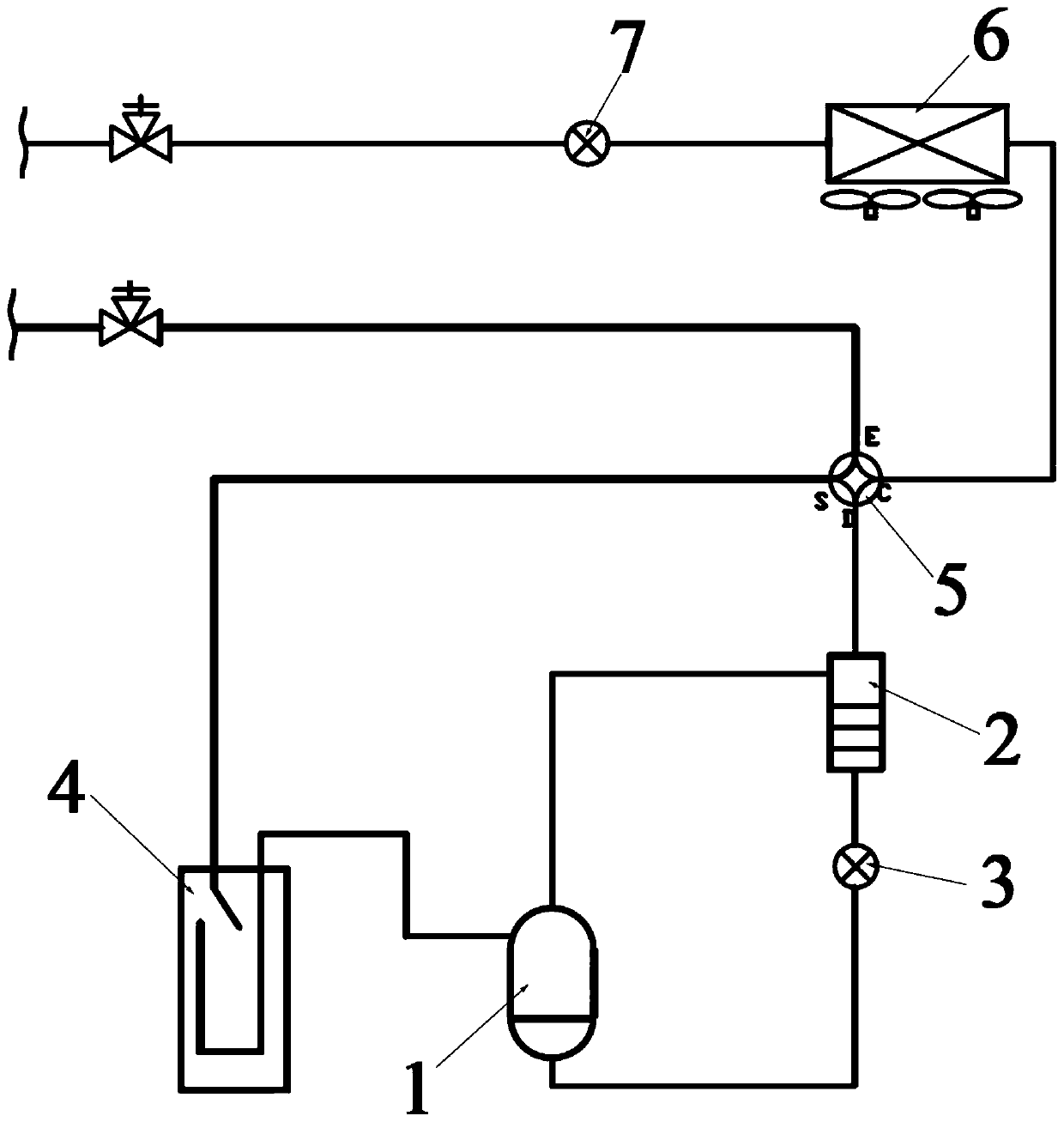

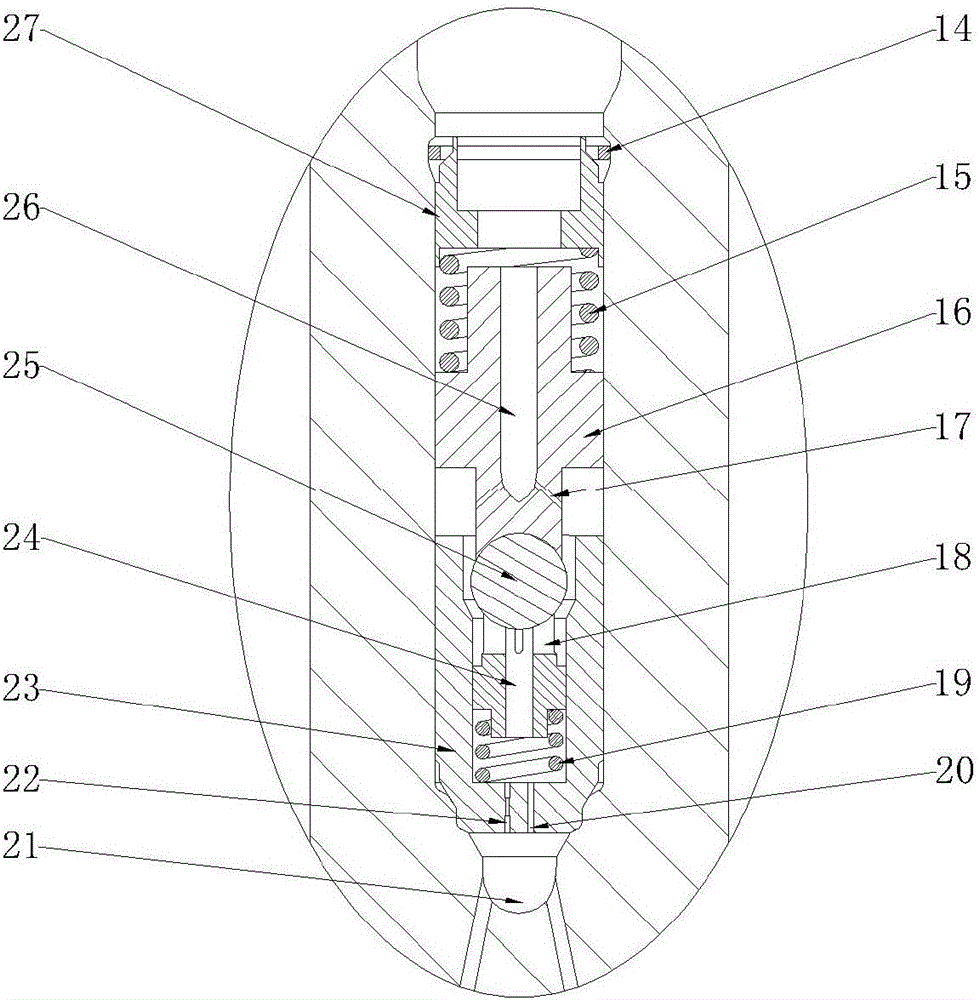

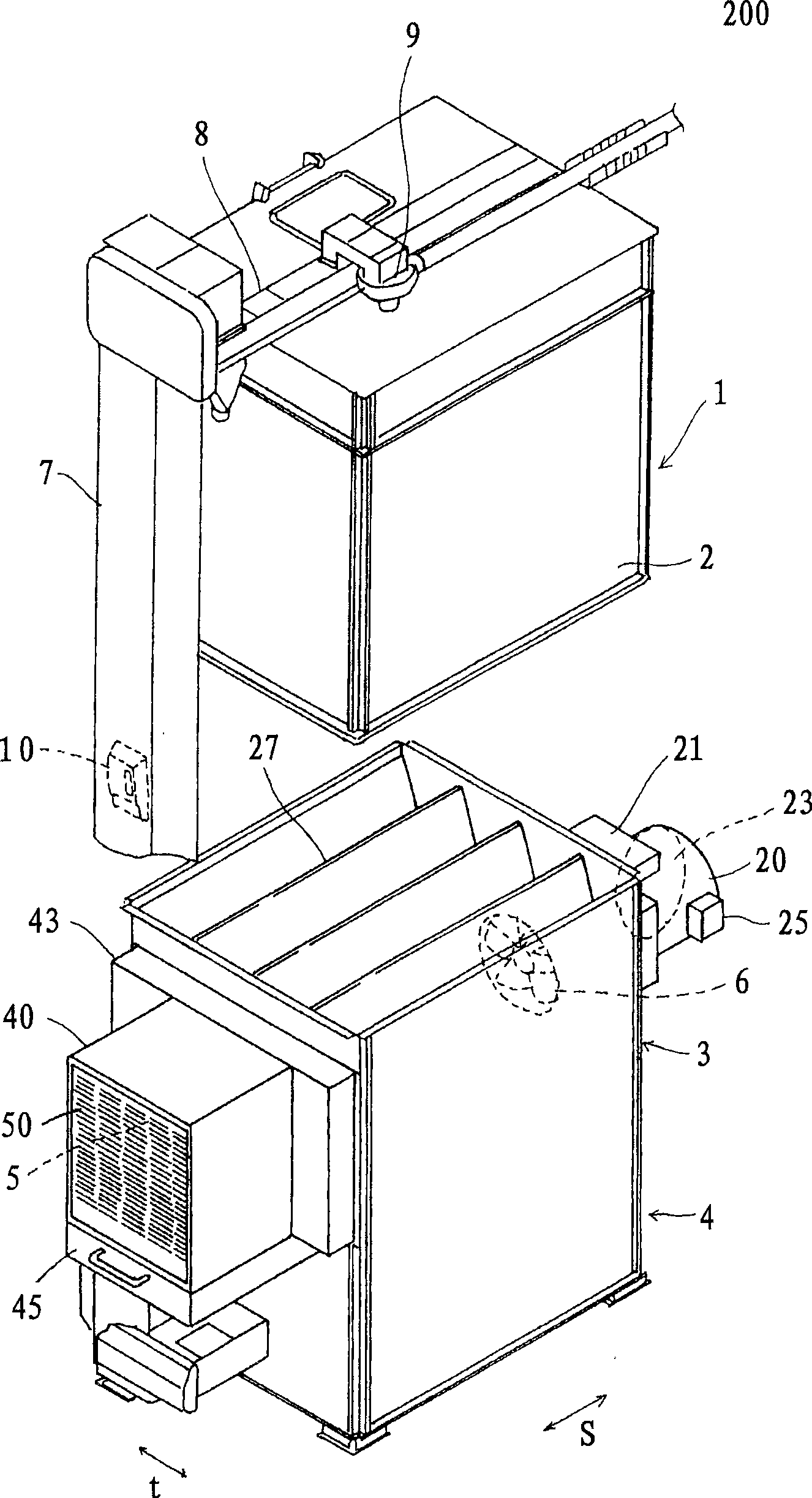

Gas and liquid separator, air conditioner and air conditioner liquid return control method

InactiveCN104279804AGuaranteed uptimeImprove reliabilityRefrigeration safety arrangementVapor–liquid separatorEngineering

The invention provides a gas and liquid separator. The gas and liquid separator comprises a shell, an air inlet pipe and an air outlet pipe. One end of the air inlet pipe and one end of the air outlet pipe are located inside the shell, and the other end of the air inlet pipe and the other end of the air outlet pipe are located outside the shell and communicated with a pipeline of an air conditioning system. The air outlet pipe is provided with an oil return hole. The gas and liquid separator further comprises a second oil return device. The second oil return device comprises an oil return pipe and an oil return valve. The first end of the oil return pipe is arranged on the air outlet pipe, and the second end of the oil return pipe is communicated with a gas and liquid separator liquid storage part; the oil return valve is arranged on the oil return pipe. Because the second oil return device is arranged, the oil return amount or liquid return amount can be controlled by controlling the opening of the oil return valve on the oil return pipe. The invention further provides an air conditioner and an air conditioner liquid return control method. The oil return amount or liquid return amount of the air conditioning system is controllable, so that smooth operation of the air conditioner is guaranteed, and the reliability of the air conditioner is greatly improved.

Owner:GREE ELECTRIC APPLIANCES INC

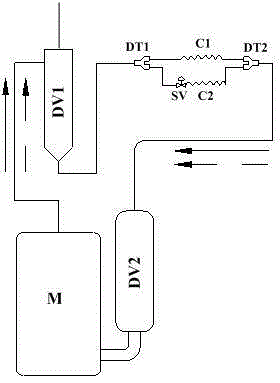

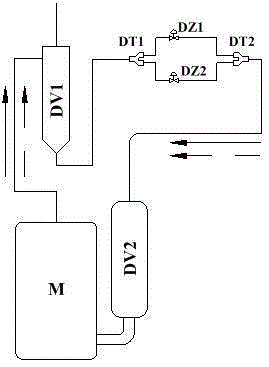

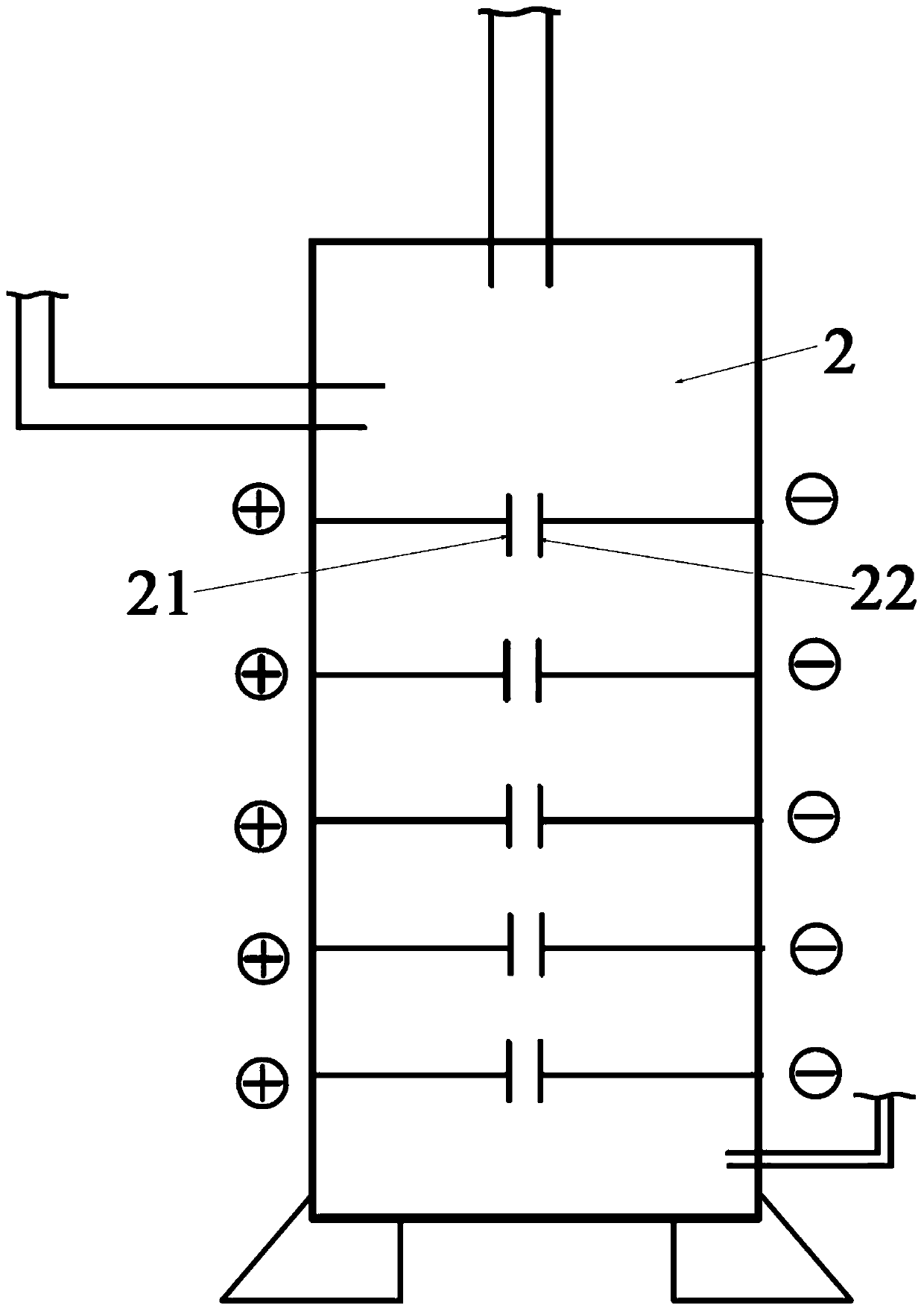

Oil-returning control method and oil-returning device for compressor as well as air conditioner

ActiveCN105299979AGuaranteed normal oil returnReduce normal oil returnMechanical apparatusFluid circulation arrangementEngineeringMechanical engineering

The invention discloses an oil-returning control method and an oil-returning device for a compressor as well as an air conditioner. The air conditioner comprises the compressor, an oil separator, an oil-returning pipeline and a controller, wherein an inlet of the oil separator is connected with an exhaust port of the compressor and receives gas-oil mixtures exhausted by the compressor for separation; the oil-returning pipeline is connected between an oil outlet of the oil separator and the compressor and returns oil separated by the oil separator to the compressor; a plurality of throttling pipelines are arranged in the oil-returning pipeline and in parallel connection; and the controller is used for regulating the working frequencies of the compressor and carrying on gate control on the throttling pipelines according to the working frequencies of the compressor. According to the oil-returning control method and the oil-returning device for the compressor as well as the air conditioner, a plurality of throttling pipelines are arranged in parallel in the oil-returning pipeline of the compressor, and gate control on each oil-returning pipeline is carried on according to different working frequencies of the compressor, so that the compressor can be guaranteed to return oil normally in various working conditions, and the oil-returning amount is guaranteed.

Owner:青岛海信网络能源股份有限公司

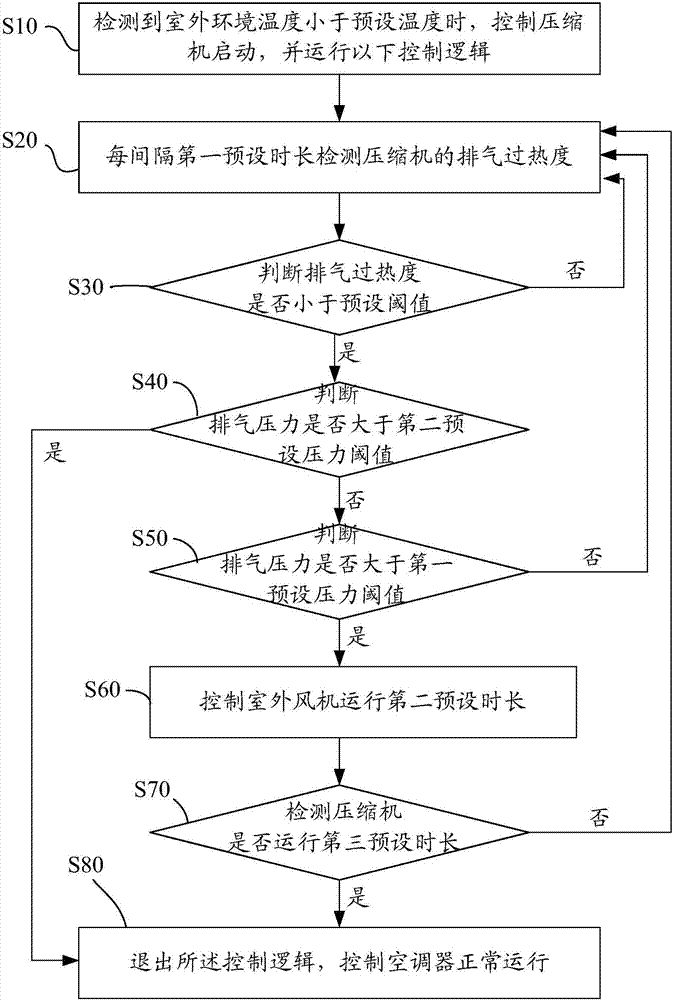

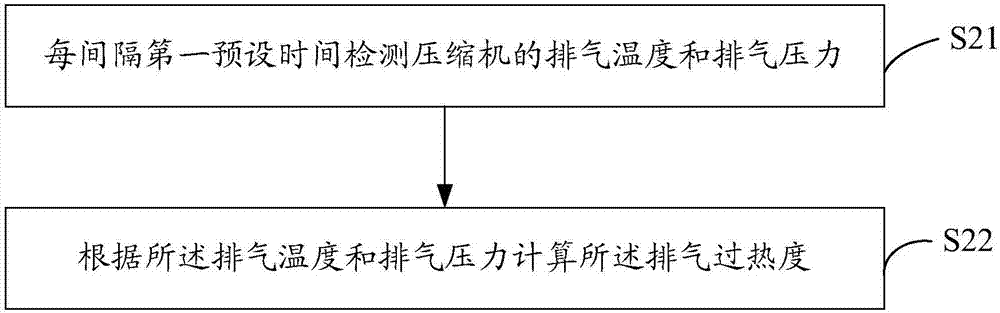

Control method of air conditioner, air conditioner and storage medium

ActiveCN107062564AIncrease oil returnExtend your lifeMechanical apparatusSpace heating and ventilation safety systemsLife timeControl theory

The invention provides a control method of an air conditioner, the air conditioner and a storage medium. The control method of the air conditioner is mainly used for startup of a compressor in a low-temperature environment, and when detection shows that the outdoor environment temperature is lower than a preset temperature, the compressor is started and enters the following logics that the exhaust superheat degree of the compressor is detected every first preset duration, an outdoor fan is controlled to operate by a second preset duration when the exhaust superheat degree is lower than a preset threshold value and the exhaust pressure of the compressor is higher than a first preset pressure threshold value, the control logic is stopped when detection shows that the operation time of the compressor reaches a third preset duration, and the air conditioner operates normally for refrigeration. By means of the control method of the air conditioner, the compressor can keep the exhaust superheat degree all the time after being started, the situation that too much refrigeration oil is dissolved when a gaseous refrigerant is quickly condensed into a liquid refrigerant, and consequently oil starvation of an air conditioner system is caused is avoided, the oil return amount of the compressor in case of low-temperature start is improved, and the service life of the compressor is prolonged.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

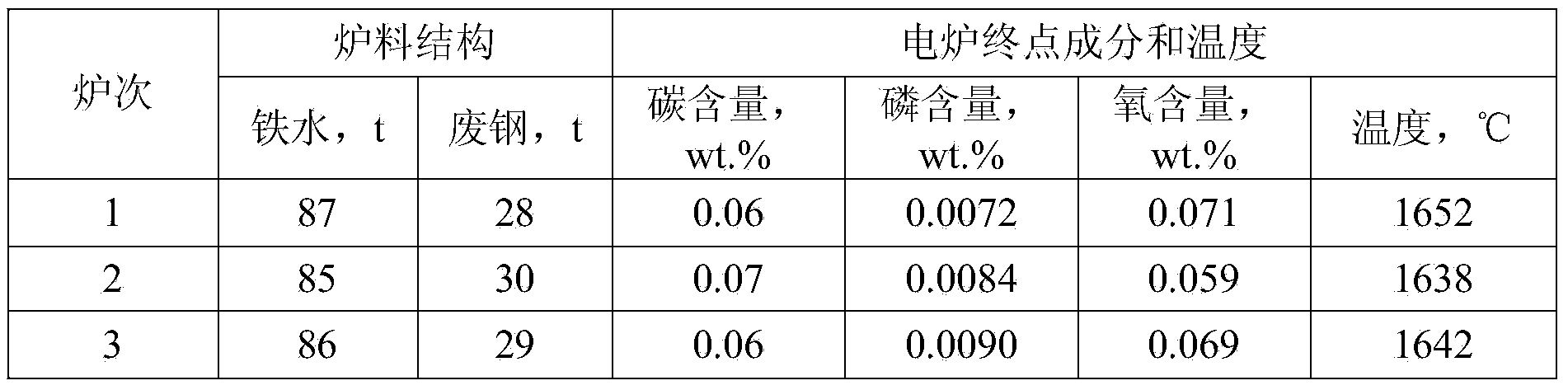

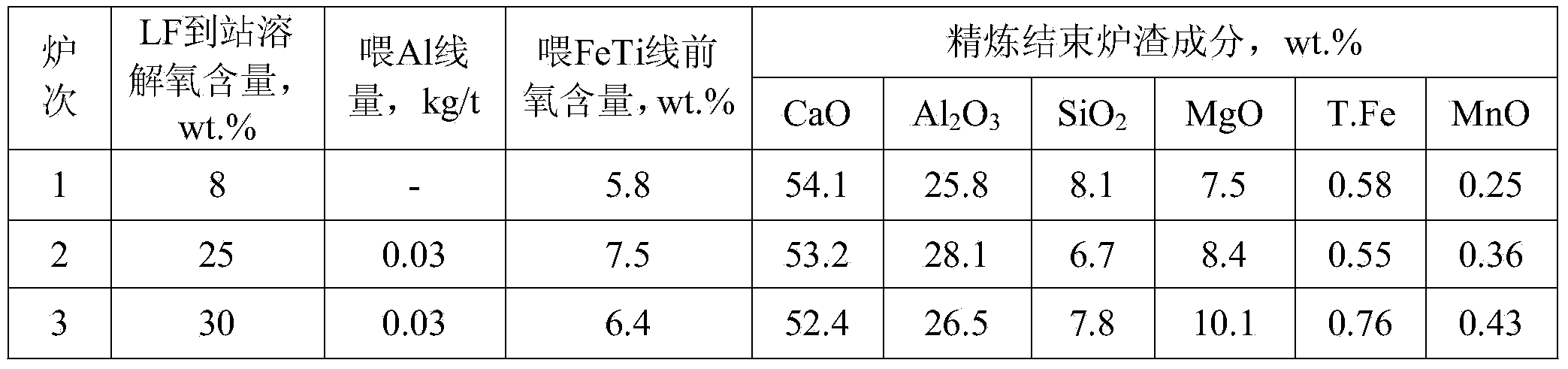

Smelting method of steel for low-silicon high-titanium welding wire

ActiveCN104278197ASiO <sub>2</sub> Low contentReduce contentProcess efficiency improvementElectric furnaceSlagTitanium

The invention discloses a smelting method of steel for a low-silicon high-titanium welding wire. The method comprises an electric furnace smelting procedure, a ladle refining procedure and a small square billet continuous-casting procedure. According to the method disclosed by the invention, 20%-80% by weight of steel ladle top slag after electric furnace tapping is stripped, synthetic slag and lime are added in a refining process to manufacture fresh slag, so that the silicon return amount of molten steel in the refining process is greatly reduced; the problem of nozzle blocking in a continuous-casting process can be effectively solved due to high cleanliness of the molten steel, and thus more than three furnaces are continuously poured smoothly; and the problem of surface quality of a casting billet can be solved by adopting special crystallizer protecting slag.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Calcium-based desulfurization slag-regulating agent for vanadium-titanium-containing molten iron, preparation method thereof and desulfurization slag-regulating method

The invention provides a calcium-based desulfurization slag-regulating agent for vanadium-titanium-containing molten iron, a preparation method thereof and a desulfurization slag-regulating method. The preparation method comprises the following step: uniformly mixing 60-80 parts by weight of active lime powder, 10-20 parts by weight of fluorite powder and 10-15 parts by weight of sodium carbonate powder, thus obtaining the calcium-based desulfurization slag-regulating agent. The calcium-based desulfurization slag-regulating agent comprises the following components in percentage by weight: no more than 0.10% of S, no more than 0.10% of P, 60-80% of CaO, 8-18% of CaF2, 10-15% of Na2CO3, 2-8% of SiO2 and no more than 1% of Al2O3. The desulfurization slag-regulating method comprises the following steps: adding the above-mentioned calcium-based desulfurization slag-regulating agent into vanadium-titanium-containing molten iron, and performing desulfurization slag regulation on the vanadium-titanium-containing molten iron. According to the invention, the desulfurization efficiency of vanadium-titanium-containing molten iron can be improved; the sulfur return amount after desulfurization of molten iron can be reduced; and the iron loss during slag removal can be reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

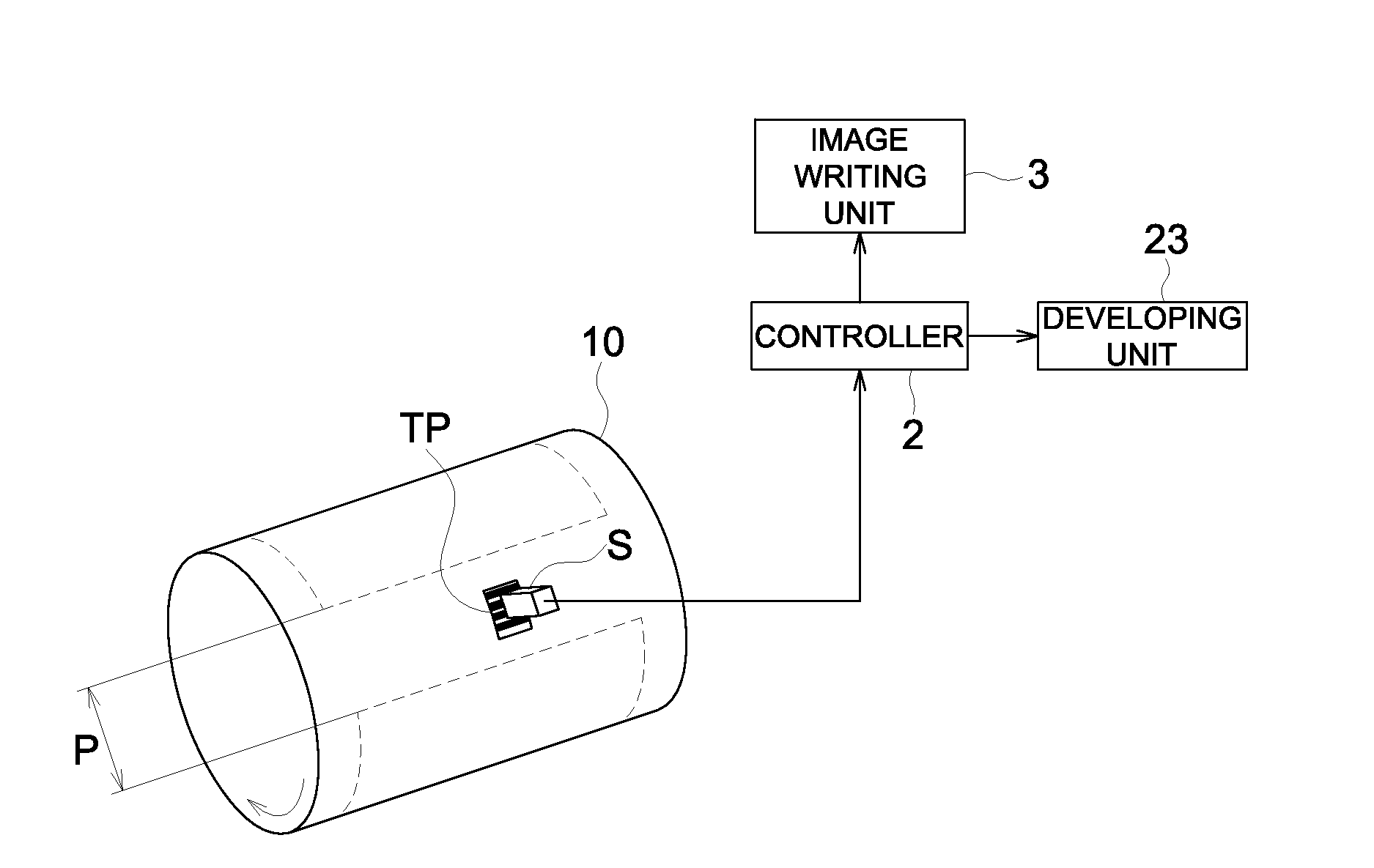

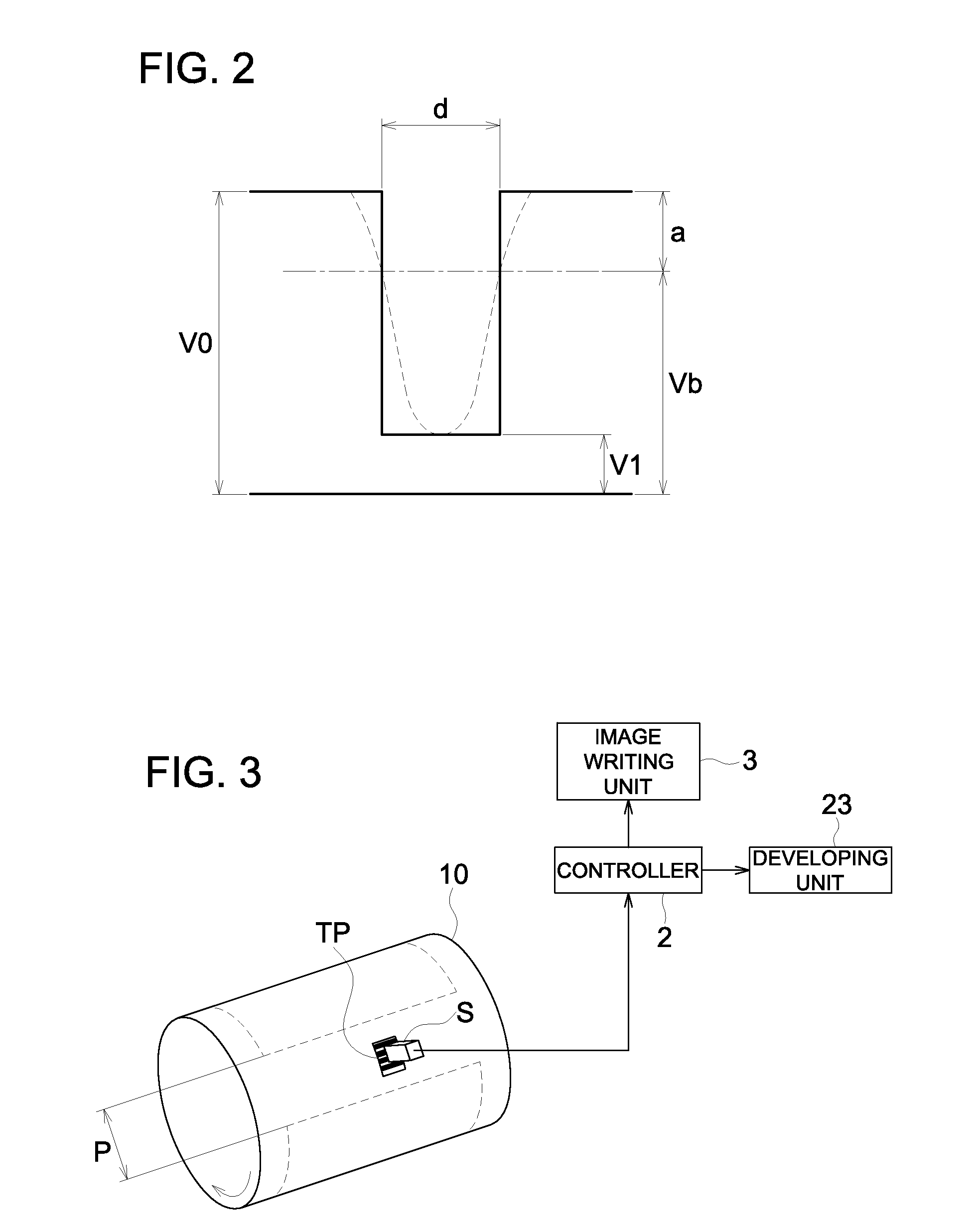

Image forming apparatus

An image forming apparatus includes: a photoreceptor, a charging unit which charges the photoreceptor; an exposing unit which forms a latent image onto the photoreceptor; a developing unit which develops the latent image to a toner image; a sensor which detects a line width of a toner patch formed on the photoreceptor by the exposing unit and the developing unit; and a controller which changes a background voltage based on the line width detected by the sensor during an image forming operation so that the line width is secured within a predetermined line width. The controller returns the background voltage to value adjacent to an initial setting background voltage and changes the light amount of the exposing unit by a light amount corresponding to a returning amount of the background voltage.

Owner:KONICA MINOLTA BUSINESS TECH INC

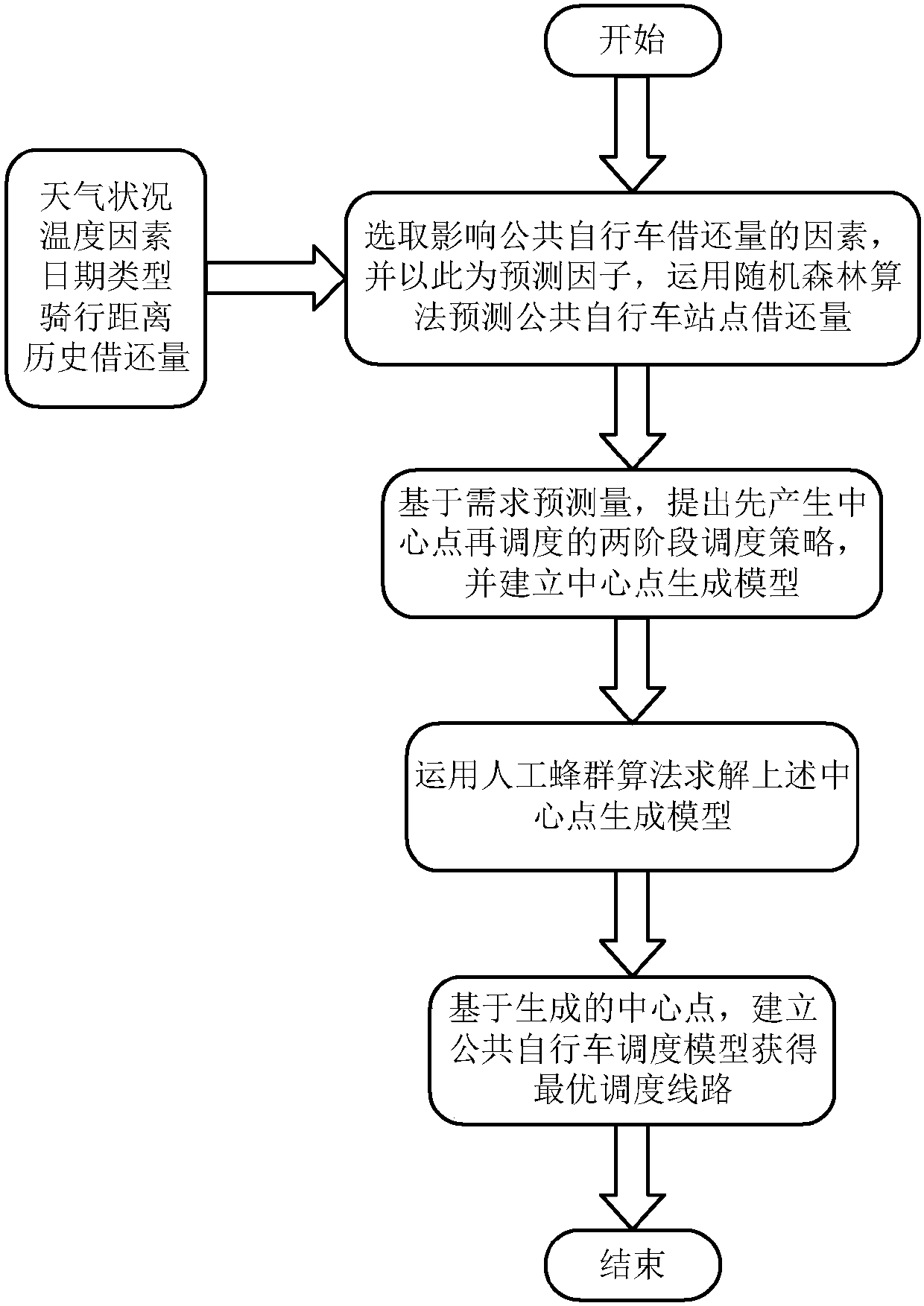

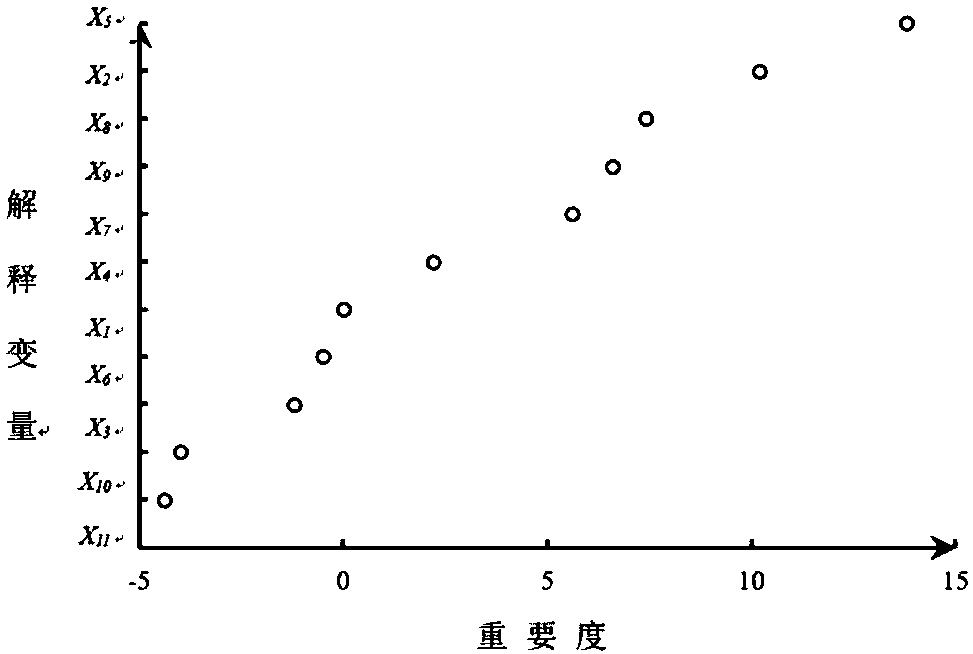

Static scheduling method for public bikes based on demand prediction and central radiation network

ActiveCN108038578AHigh scheduling costAccurately determineForecastingArtificial lifeRush hourOptimal scheduling

The invention discloses a static scheduling method for public bikes based on demand prediction and a central radiation network. The method comprises the steps of carrying out demand prediction on eachstation by taking the central radiation network as a framework based on existing public bike stations, and finally determining an optimal scheduling path. The method mainly comprises the following steps: (1) analyzing multiple factors which influence the demands of the public bikes, predicting borrowing and returning amounts of each station in rush hours by taking the factors as prediction factors through a random forest (Random Forest, RF for short) algorithm; (2) based on a demand prediction amount of each station, putting forwards a two-stage scheduling strategy for firstly generating a central point and then carrying out scheduling based on the central point, and establishing a central point generation model; (3) solving the central point generation model by virtue of an artificial bee colony algorithm; and (4) establishing a public bike scheduling model based on the generated central point, so as to obtain the optimal scheduling path.

Owner:SOUTHEAST UNIV +1

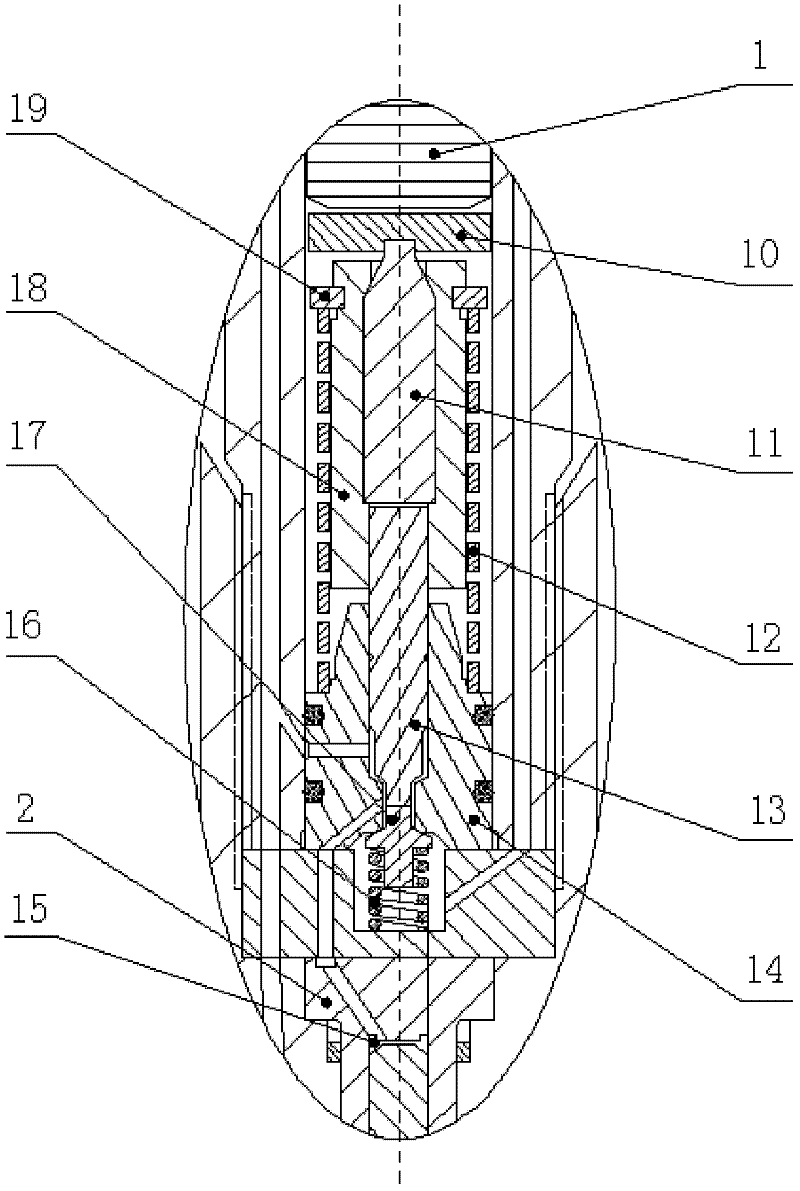

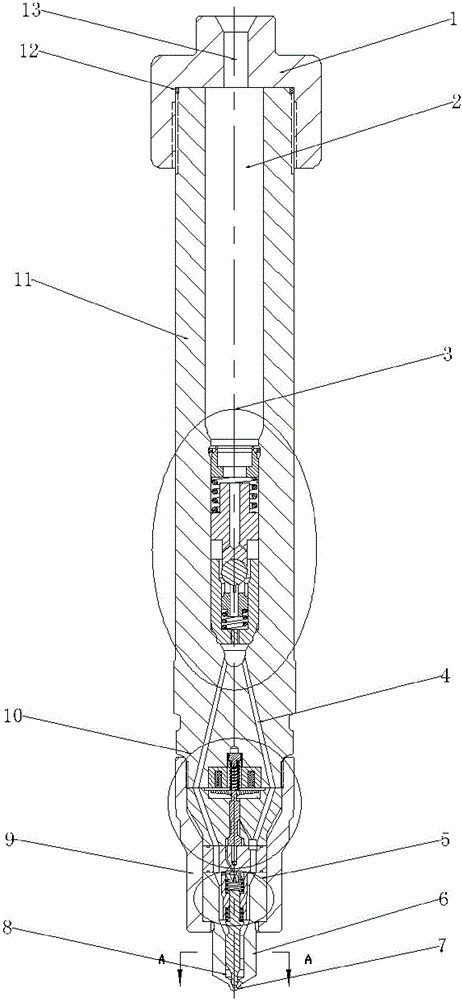

Low oil return type piezoelectric control fuel injector

InactiveCN102374085AAvoid direct releaseSave compression workFuel injection apparatusMachines/enginesFluid couplingFuel tank

The invention aims at providing a low oil return type piezoelectric control fuel injector, which comprises a piezoelectric element, a piezoelectric control valve part, a control piston, a needle valve reset spring and a fuel nozzle part that are arranged in a fuel injector body and connected in sequence, wherein the control piston is arranged in a control cavity body; the piezoelectric control valve part comprises a hydrodynamic coupler, a control valve and a reset spring which are connected in sequence, wherein the hydrodynamic coupler comprises a hydrodynamic coupler shell, a transform piston, a valve piston, an adjusting disc, a hollow body and a valve seat; the transform piston and the valve piston are connected and are both arranged in the hydrodynamic coupler shell; the hollow body and the adjusting disc are arranged on the hydrodynamic coupler shell; the upper end of the hollow body is blocked on the adjusting disc; the lower end of the hollow body is supported on the valve seat; and a control cavity is arranged above the control piston. The low oil return type piezoelectric control fuel injector can prevent high-pressure fuel oil from directly discharging to a low-pressure oil path, thereby reducing the oil return amount, saving the compression work of an oil-fired oil pump and reducing the temperature rise of an oil tank.

Owner:HARBIN ENG UNIV

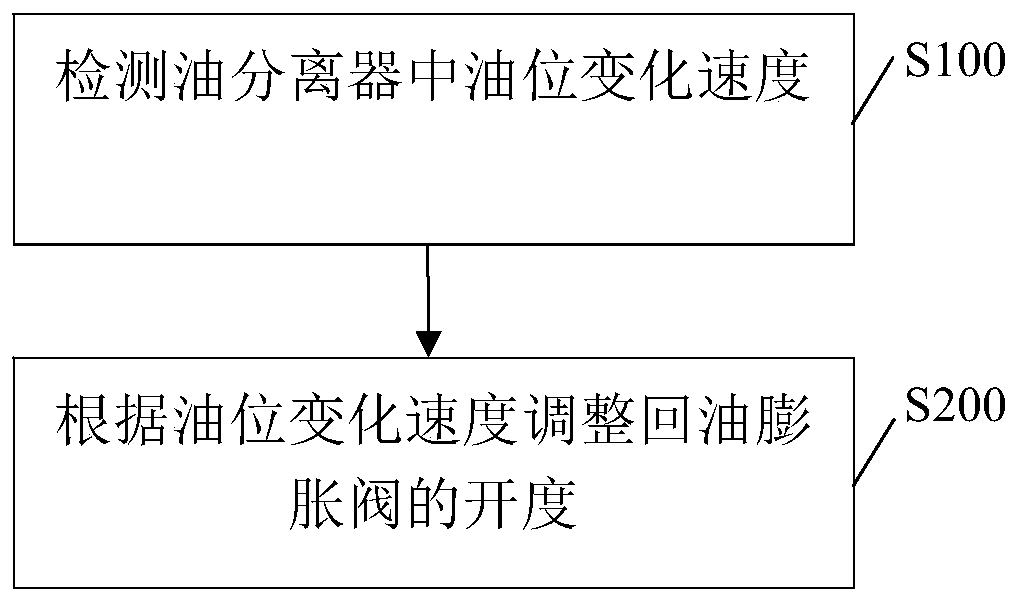

Air conditioner oil return control method and system, storage medium and air conditioner

ActiveCN110595110AStable and balanced oil quantityCompressorRefrigeration safety arrangementStable equilibriumPetroleum engineering

The invention discloses an air conditioner oil return control method and system, a storage medium and an air conditioner. The method includes the steps that the oil level change speed in an oil separator is detected in real time; and the opening degree of an oil return expansion valve is adjusted according to the oil level change speed. The system oil quantity requirement can be judged according to the oil level change speed in the oil separator, the oil return amount is controlled by adjusting the opening degree of the oil return expansion valve of the oil separator, and it is ensured that the system oil quantity is in the stable equilibrium state all the time.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

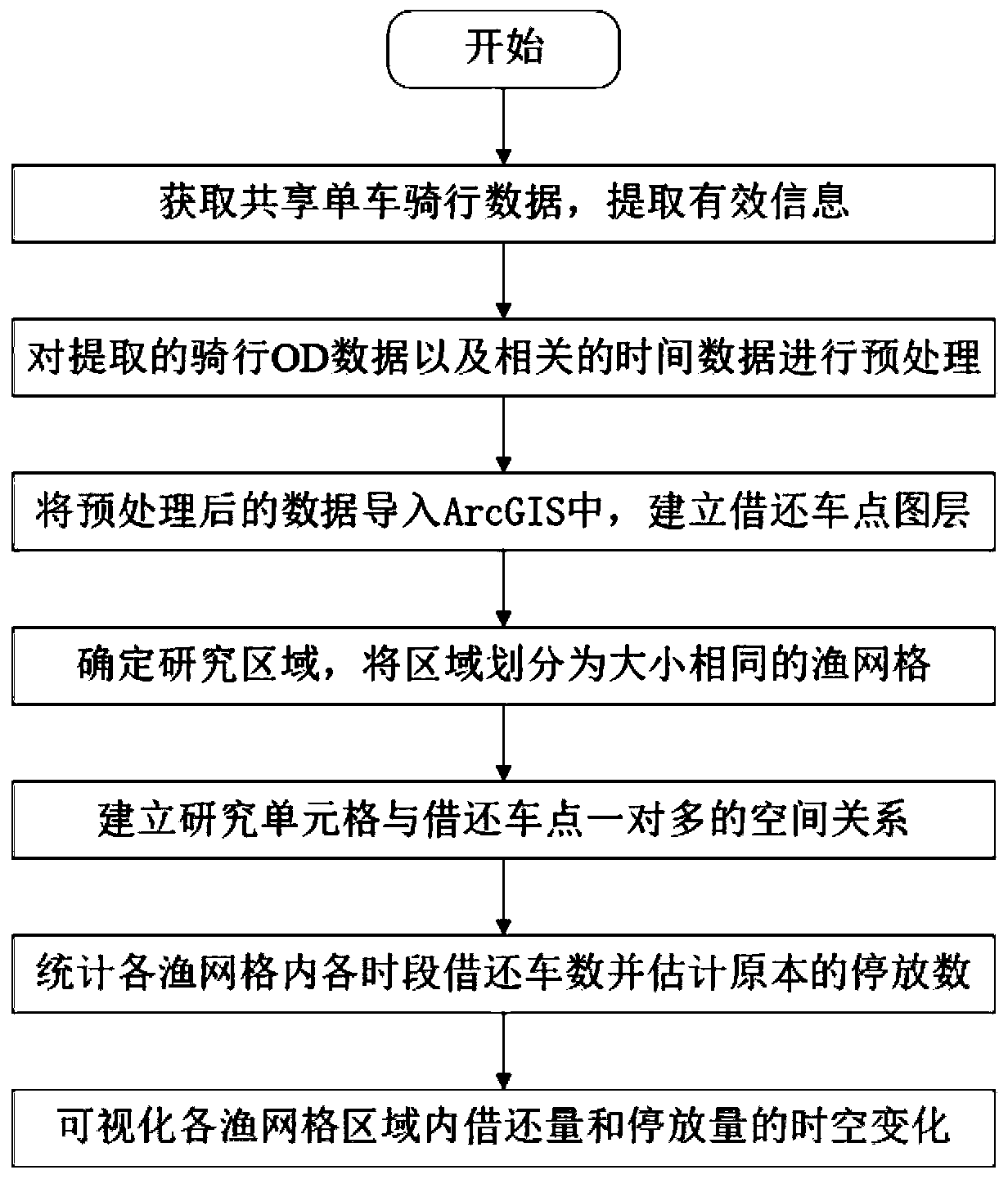

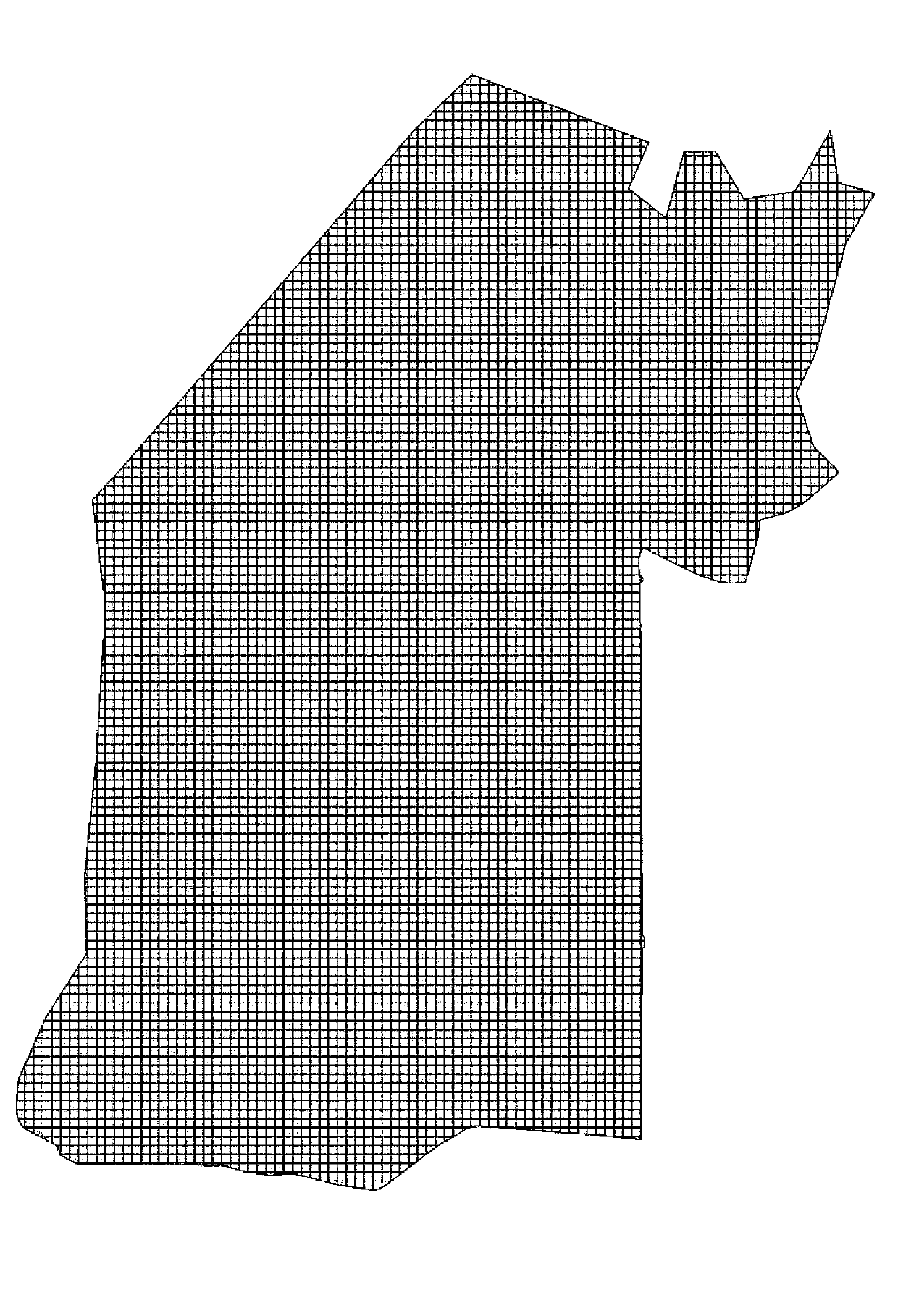

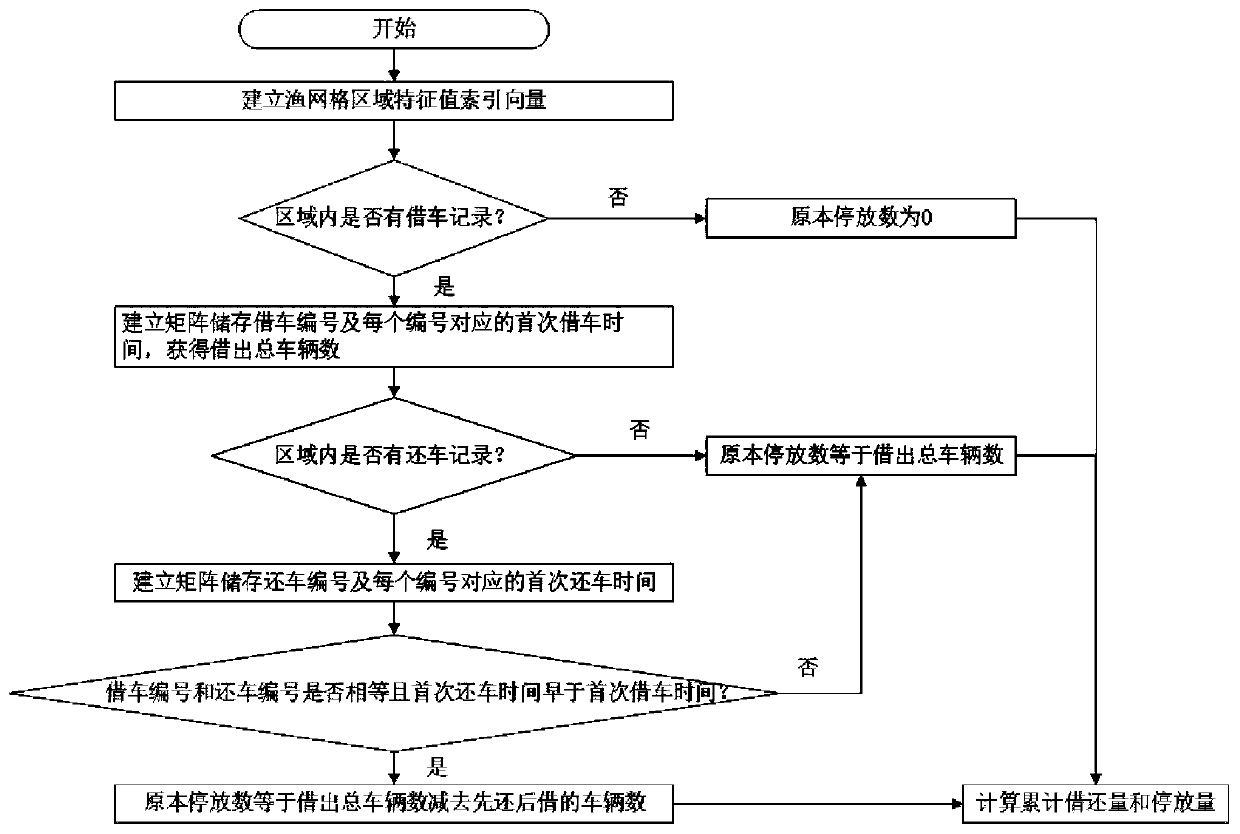

A shared bicycle borrowing, returning and parking space-time distribution visualization method based on OD data

The invention discloses a shared bicycle borrowing, returning and parking space-time distribution visualization method based on OD data. The method includes; starting from the riding data of the shared bicycle, carrying out effective information extraction on original data; preprocessing: inputting the data as initial data of the ArcGIS; dividing the research area into fishing net grids with the same scale by using ArcGIS; establishing the relationship between each fishing net grid and a shared bicycle borrowing and returning point spatially; based on the attribute data of the borrowing and returning points in each fishing net grid, counting the number of borrowed and returned vehicles in each time period in each fishing net grid, estimating the parking number before the zero point of theresearch day, then obtaining the accumulated borrowing and returning amount and parking amount of each time period in each area, and finally visualizing the space-time borrowing and returning characteristics and parking characteristics of the shared bicycles. According to the method, a solid foundation is laid for research on site selection, dynamic scheduling and the like of the shared bicycle recommended parking spot.

Owner:SOUTHEAST UNIV

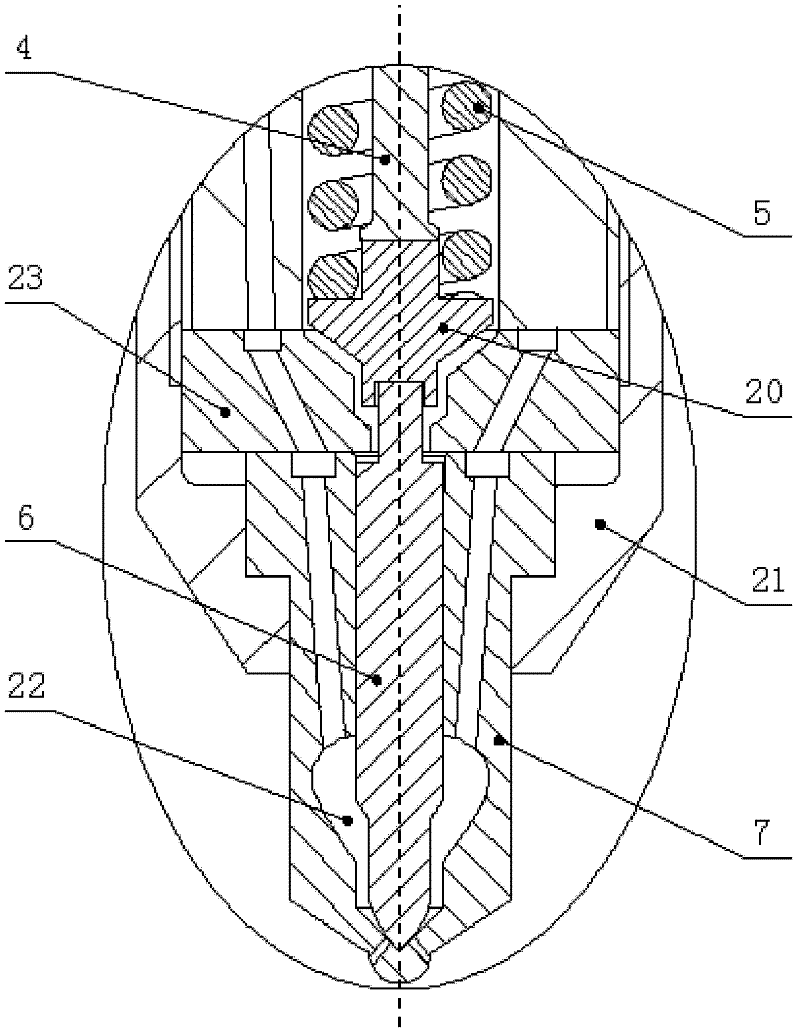

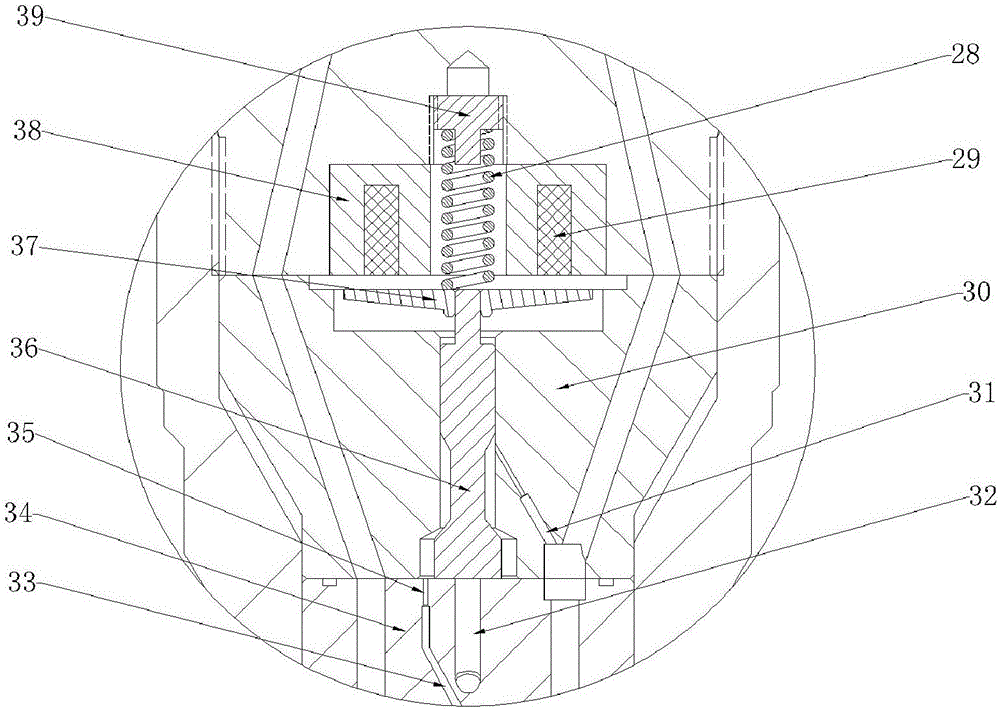

Low oil-return type electromagnetic control oil sprayer

InactiveCN102434346AAvoid enteringSave compression workFuel injection apparatusMachines/enginesSolenoid valveSprayer

The invention aims at providing a low oil-return type electromagnetic control oil sprayer, which comprises an electromagnetic valve part, a control piston, a return spring, an oil nozzle part which are installed in an oil sprayer body and connected in sequence. The control piston is installed in a control cavity body, and the electromagnetic valve part comprises a coil, an electromagnet, an armature, a control valve core return spring, a stop ring and a control valve core which are all installed in the electromagnetic valve body. The coil and the control valve core return spring are installed in the electromagnet connected with the armature, the control valve core is clamped on the armature through the stop ring, one end of the control valve core is connected with the control valve core return spring, and the other end of the control valve core is connected with the control cavity body. The low oil-return type electromagnetic control oil sprayer can close an oil inlet way of a control cavity during oil spraying process of the oil sprayer and prevent high pressure fuel oil from entering the control cavity so as to reduce oil return amount, save oil pump compression work of the fuel oil, reduce temperature rising of an oil tank, simultaneously improve oil spraying effect and economical performance and motive power performance of an engine.

Owner:HARBIN ENG UNIV

Two-way-oil-inlet resonance bypass type electronic-control fuel injector

ActiveCN106545448ASmall pressure fluctuationsImprove economyMachines/enginesSpecial fuel injection apparatusResonanceSolenoid valve

The invention aims at providing a two-way-oil-inlet resonance bypass type electronic-control fuel injector comprising a fuel injector head, a fuel injector body, a flow-limiting valve assembly, an electromagnetic valve assembly, a needle valve assembly and a spray nozzle. The flow-limiting valve assembly is located in a pressure storage cavity, and it is ensured that under the condition of the large fuel injection quantity, fuel injection processes of all cylinders are stable. A resonance through hole and a resonance throttling hole are machined in the bottom of the flow-limiting valve assembly, and fluctuation of fuel passing through the flow-limiting valve assembly is reduced according to the wave superposition principle. The electromagnetic valve assembly and the needle valve assembly are arranged on the lower portion. A two-position three-way valve form is adopted for an electromagnetic valve so that the dynamic oil return amount can be decreased. A control slide block is arranged in a control cavity and makes contact with a middle block so as to play a role in decreasing the fuel injection speed at the initial stage of injection and accelerating the needle valve seating response. The two-way-oil-inlet manner is adopted for the control cavity, and therefore the pressure buildup speed is further increased, and the rapid response characteristic of the fuel injector is achieved. No static pressure differences exist in the fuel injector, and the fuel injector is free of static leakage.

Owner:HARBIN ENG UNIV

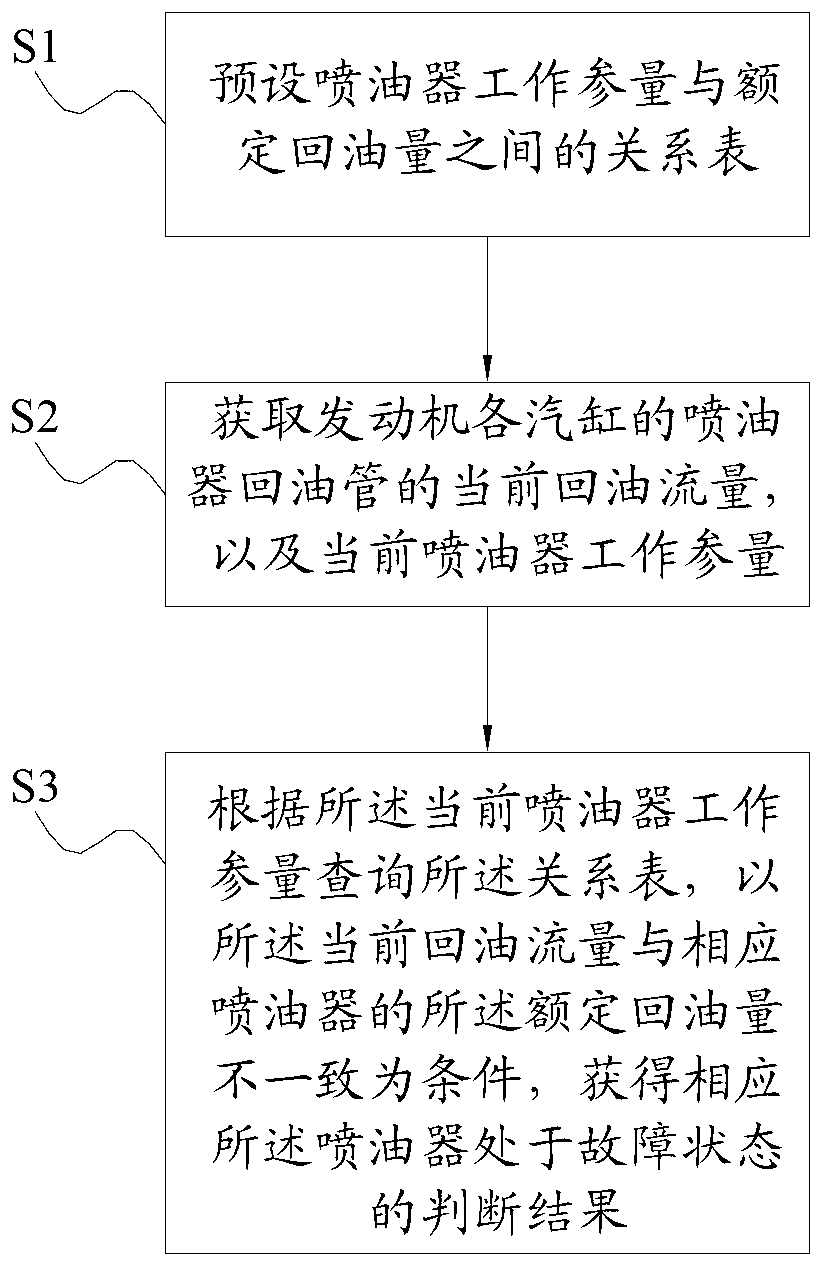

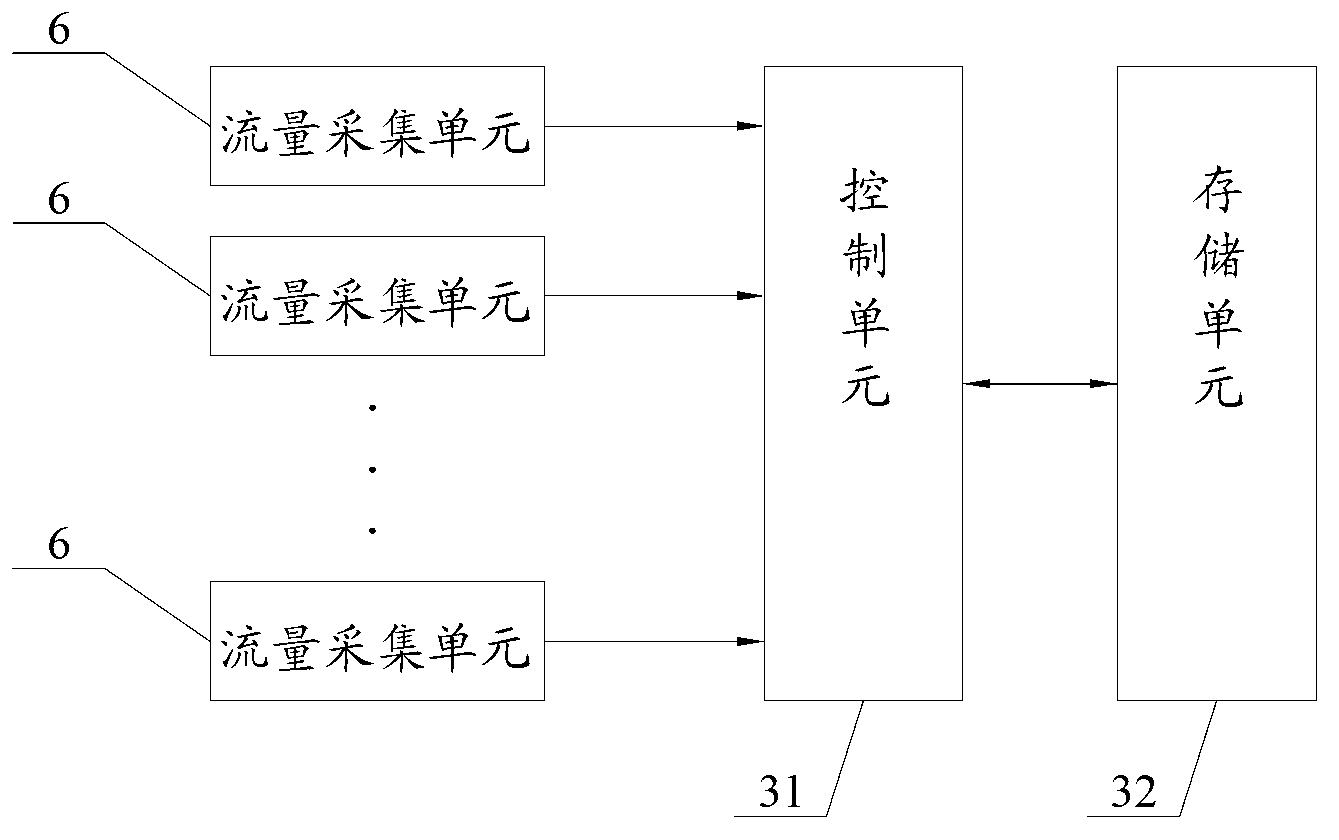

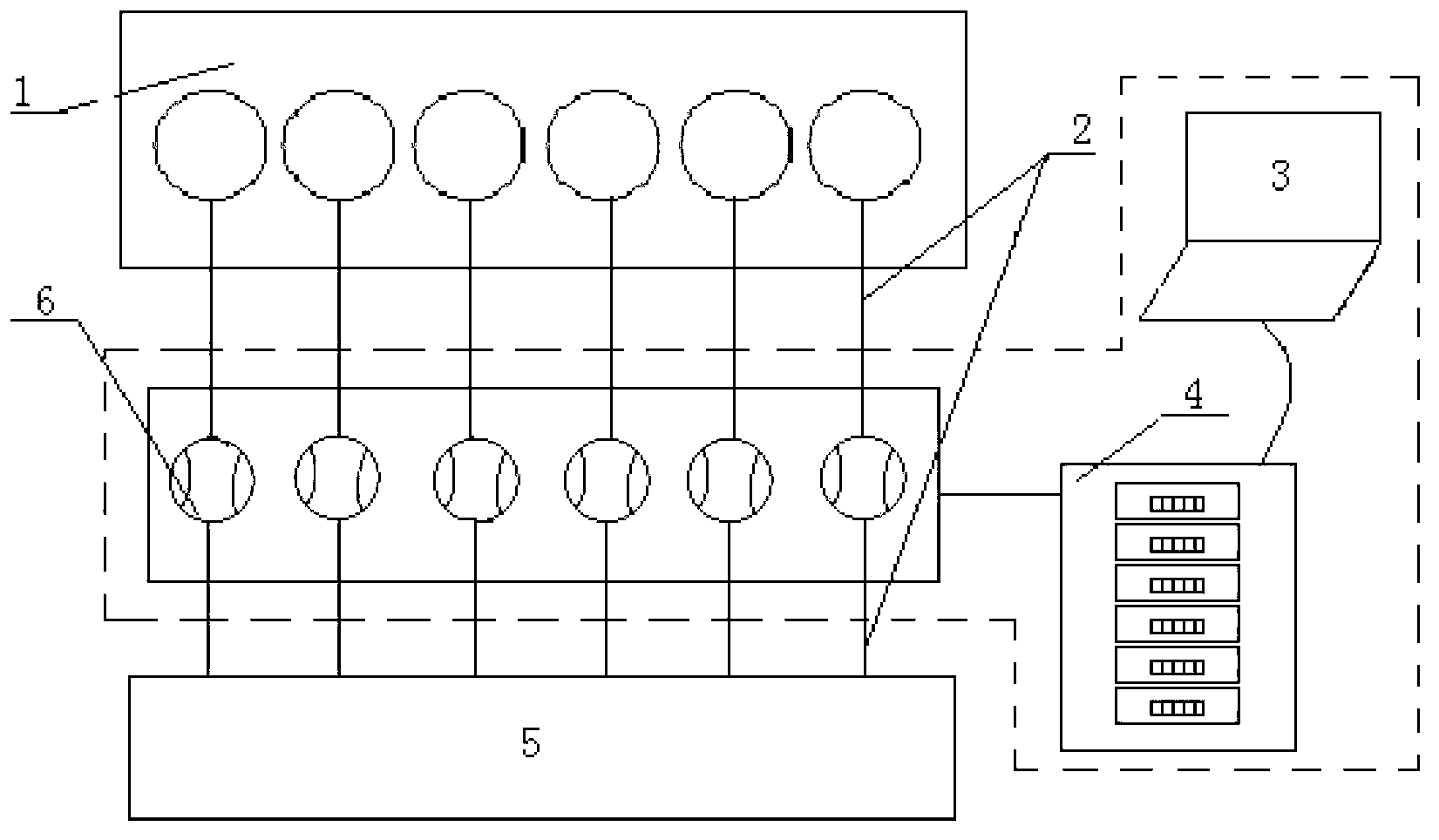

Oil injector fault checking method and device

ActiveCN103321809AImprove work efficiencyEasy to operateElectrical controlInternal combustion piston enginesUltimate tensile strengthPetroleum engineering

The invention discloses an oil injector fault checking method. The method includes presetting a relation table between working parameters and rated oil return amount of oil injectors; and in a working state of an engine, executing the steps: acquiring current oil return flow of an oil injector oil return pipe of each air cylinder of the engine and working parameters of the current oil injector; inquiring the relation table according to the working parameters of the current oil injector, and acquiring a judging result that the corresponding oil injector is in a fault state on the condition that the current oil return amount is inconsistent with the rated oil return amount of the corresponding oil injector. Operation can be performed in a work site of the engine without detaching the oil injectors, the method is simple to execute in operation, faulted oil injectors can be judged accurately and rapidly, working efficiency of maintenance staff is improved, and labor intensity is reduced. In addition, a device is low in cost and can be configured in engine maintenance sites. On the basis, the invention further provides an oil injector fault checking device.

Owner:WEICHAI POWER CO LTD

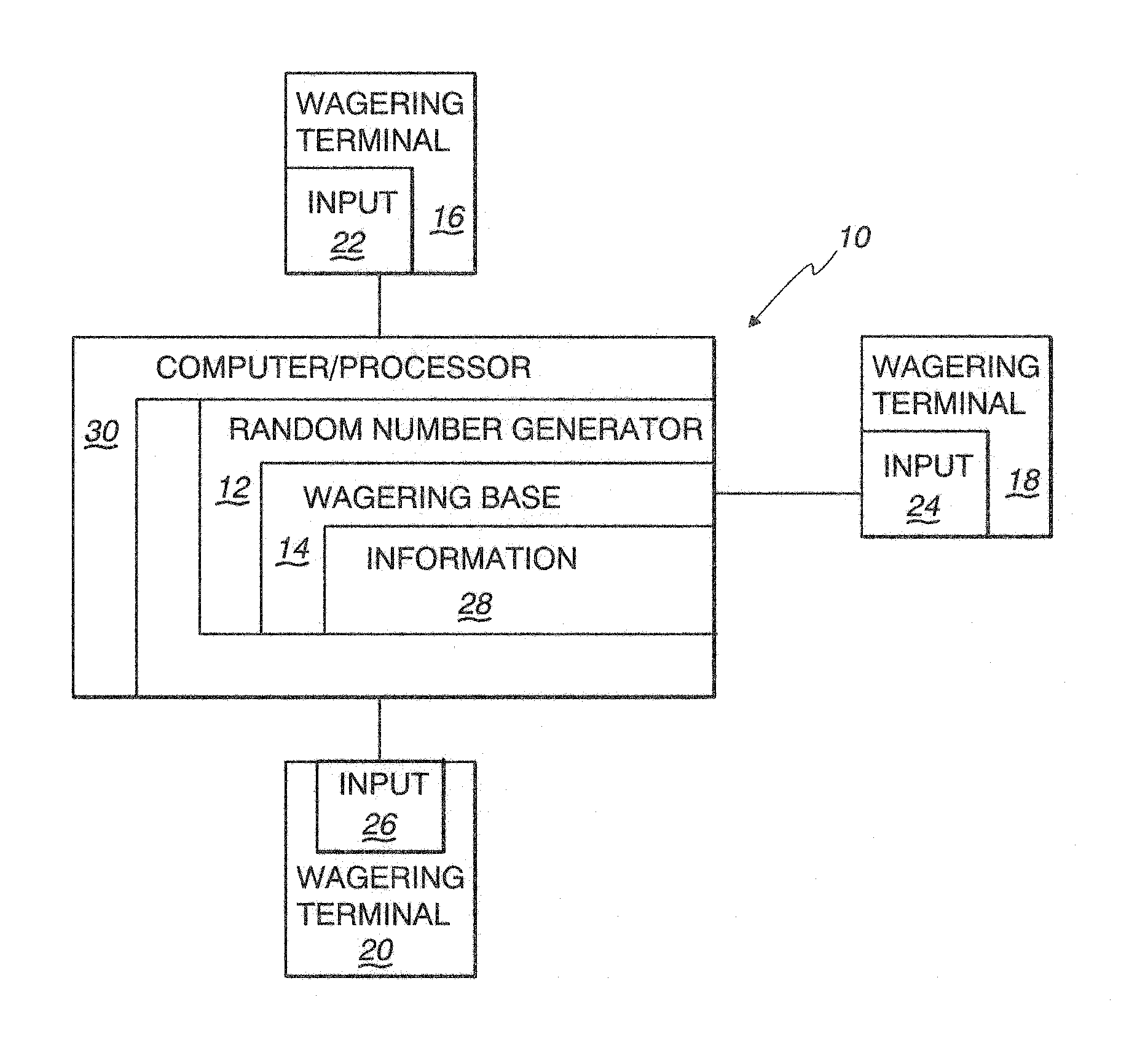

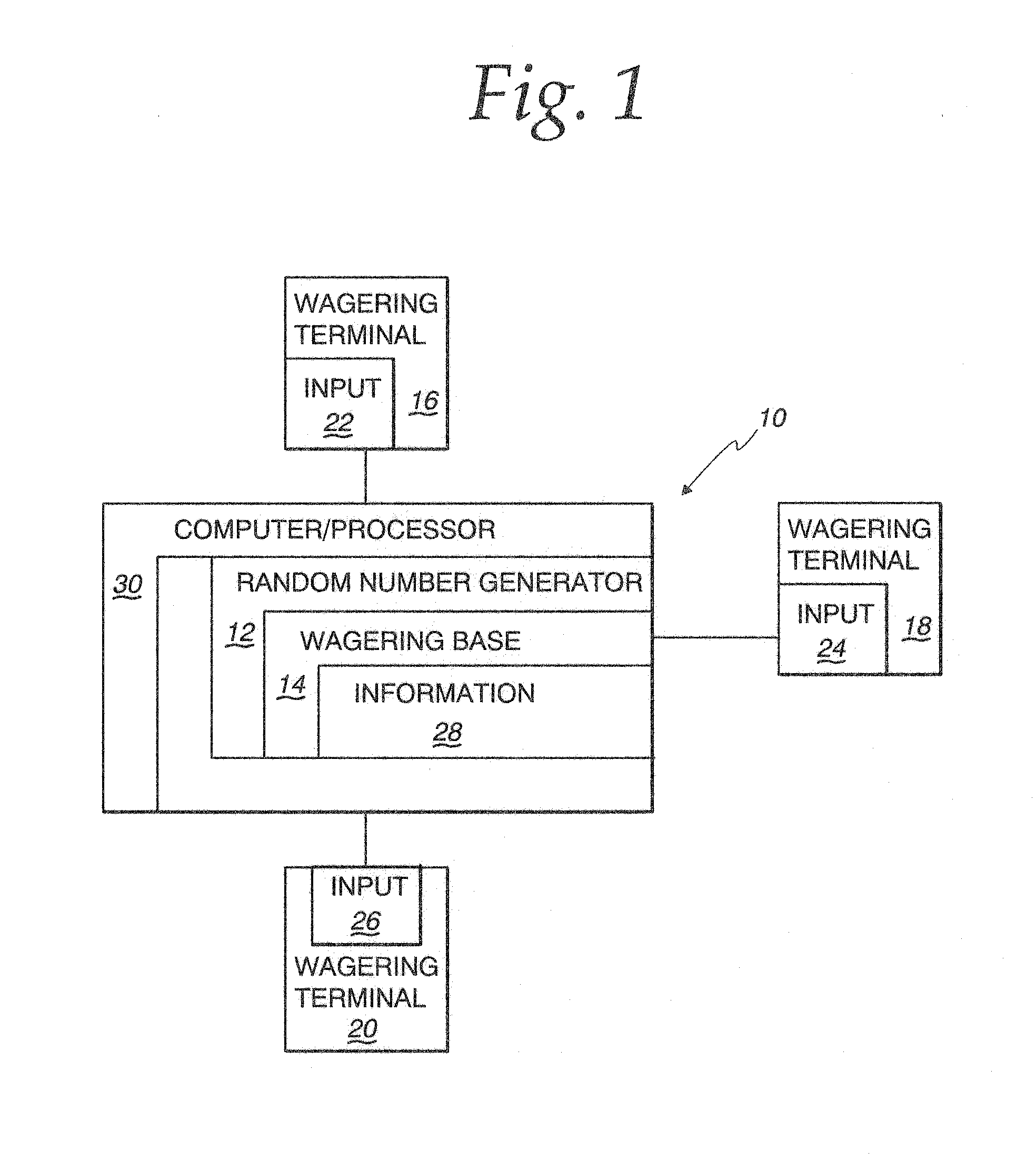

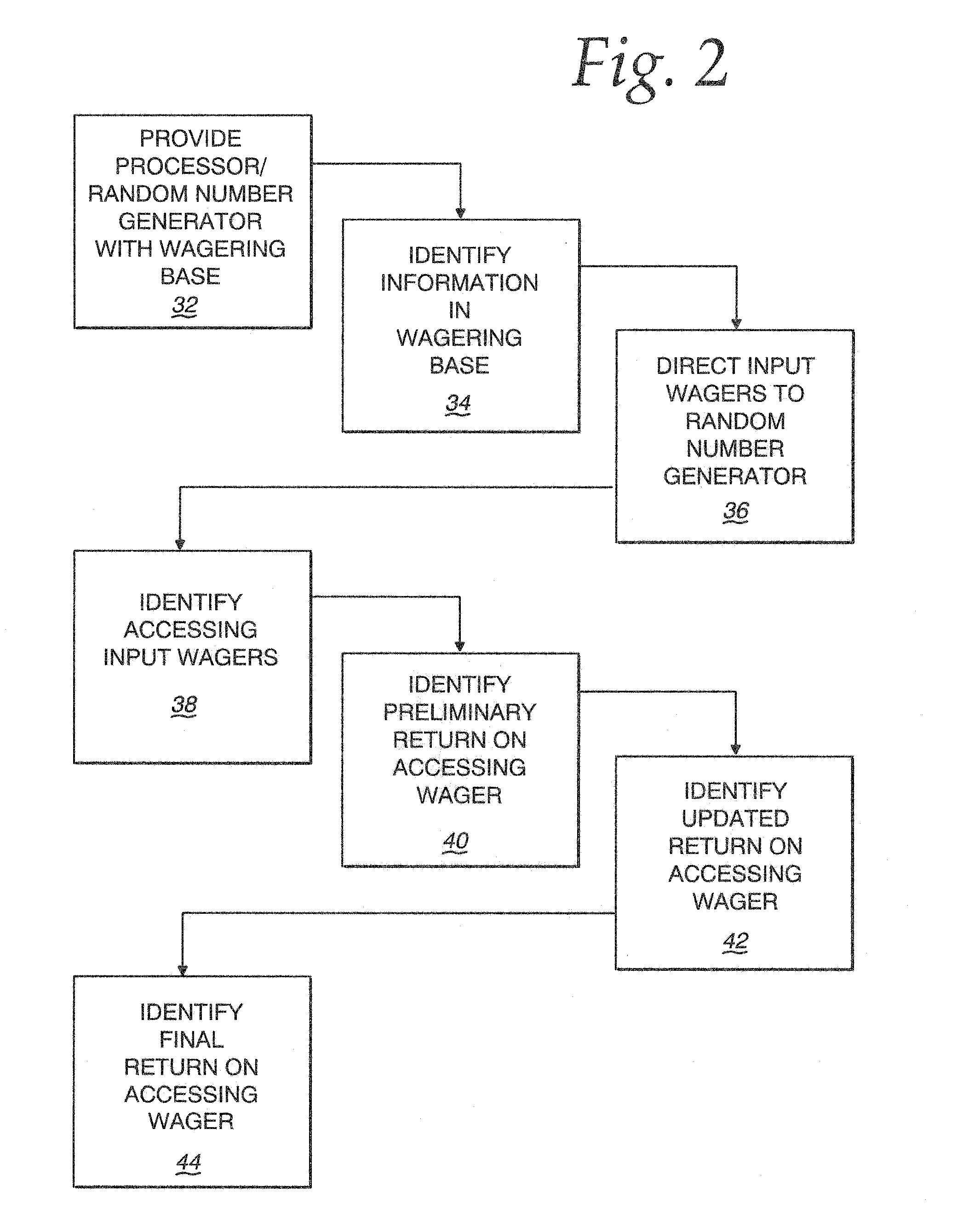

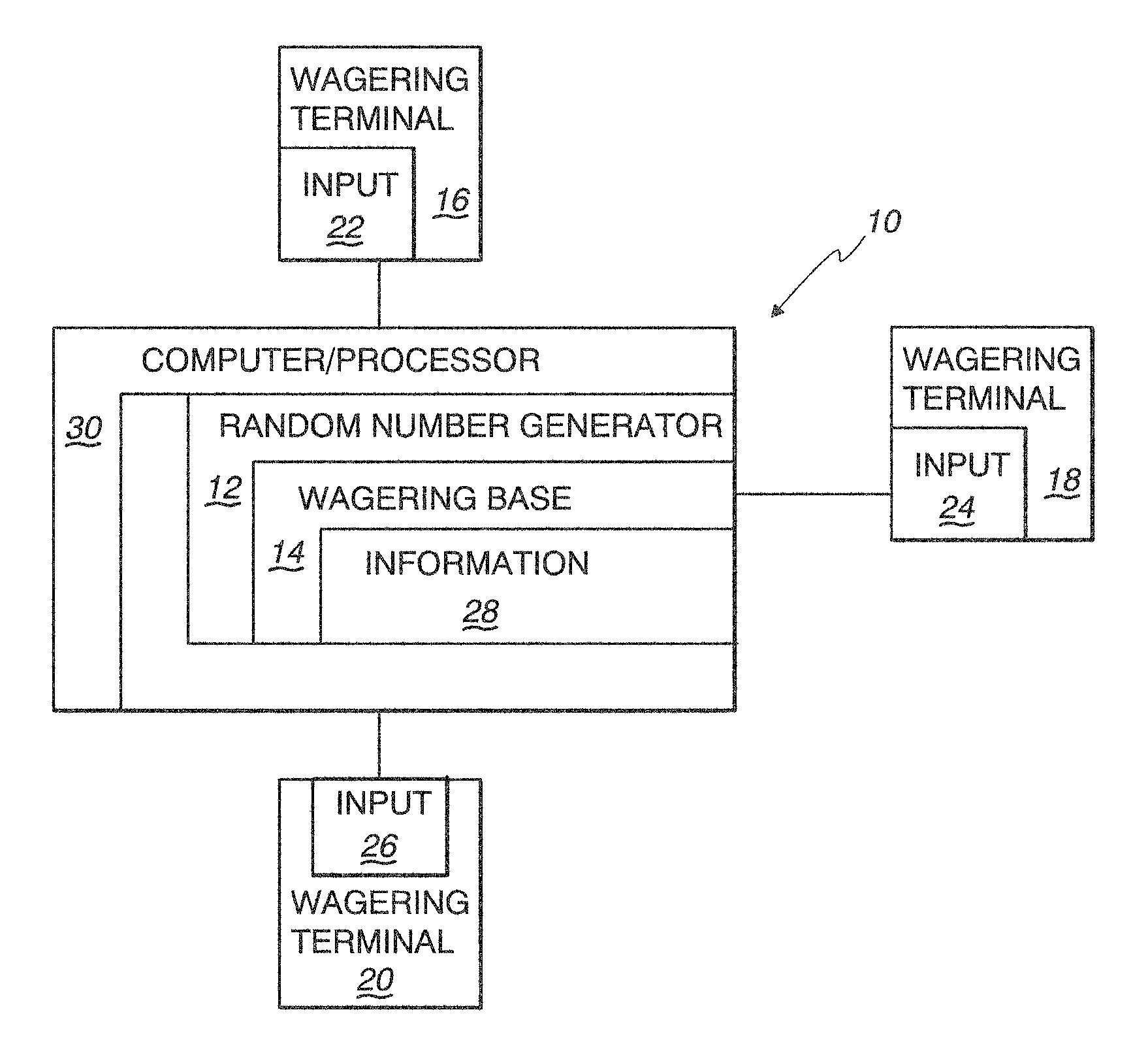

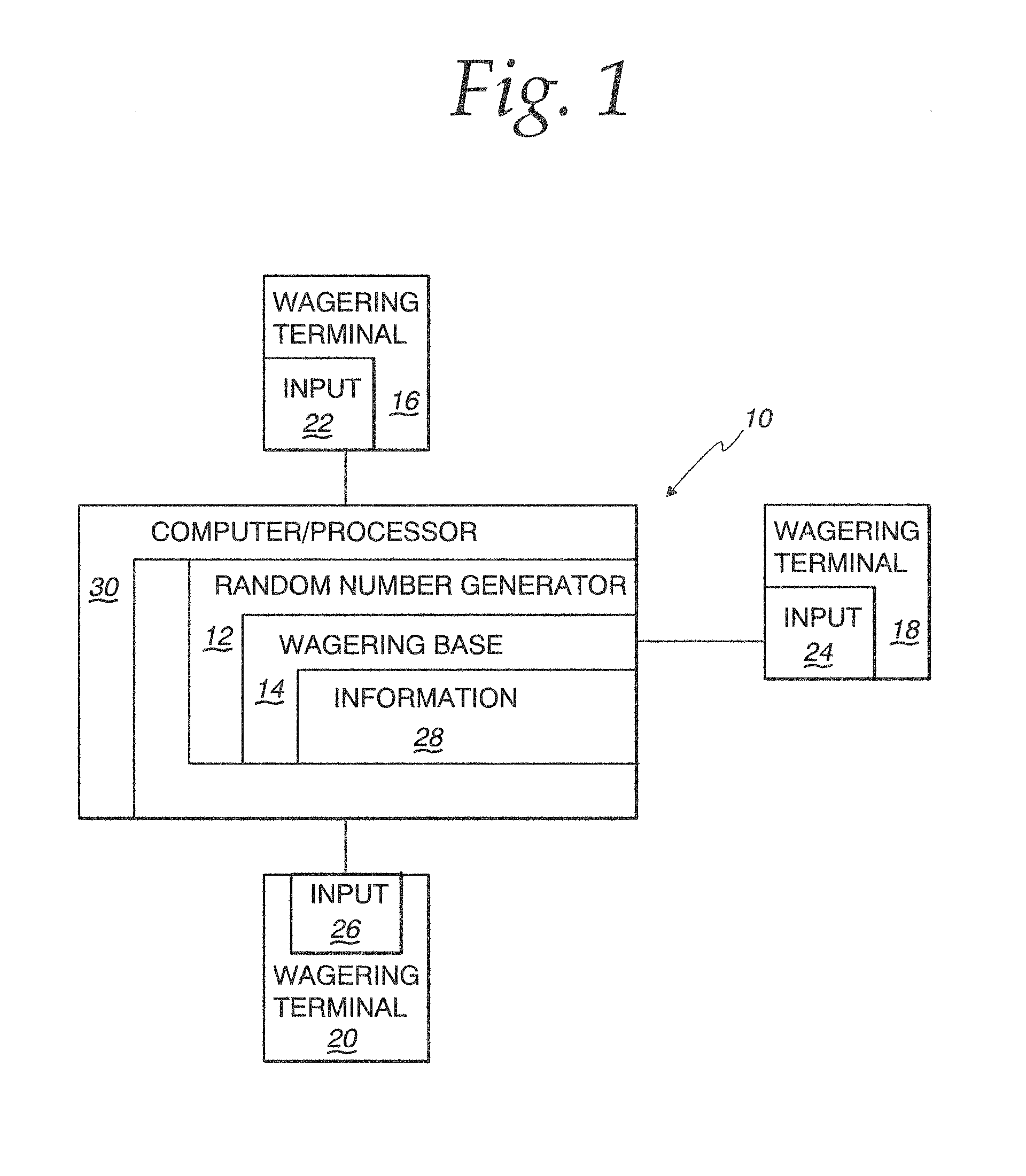

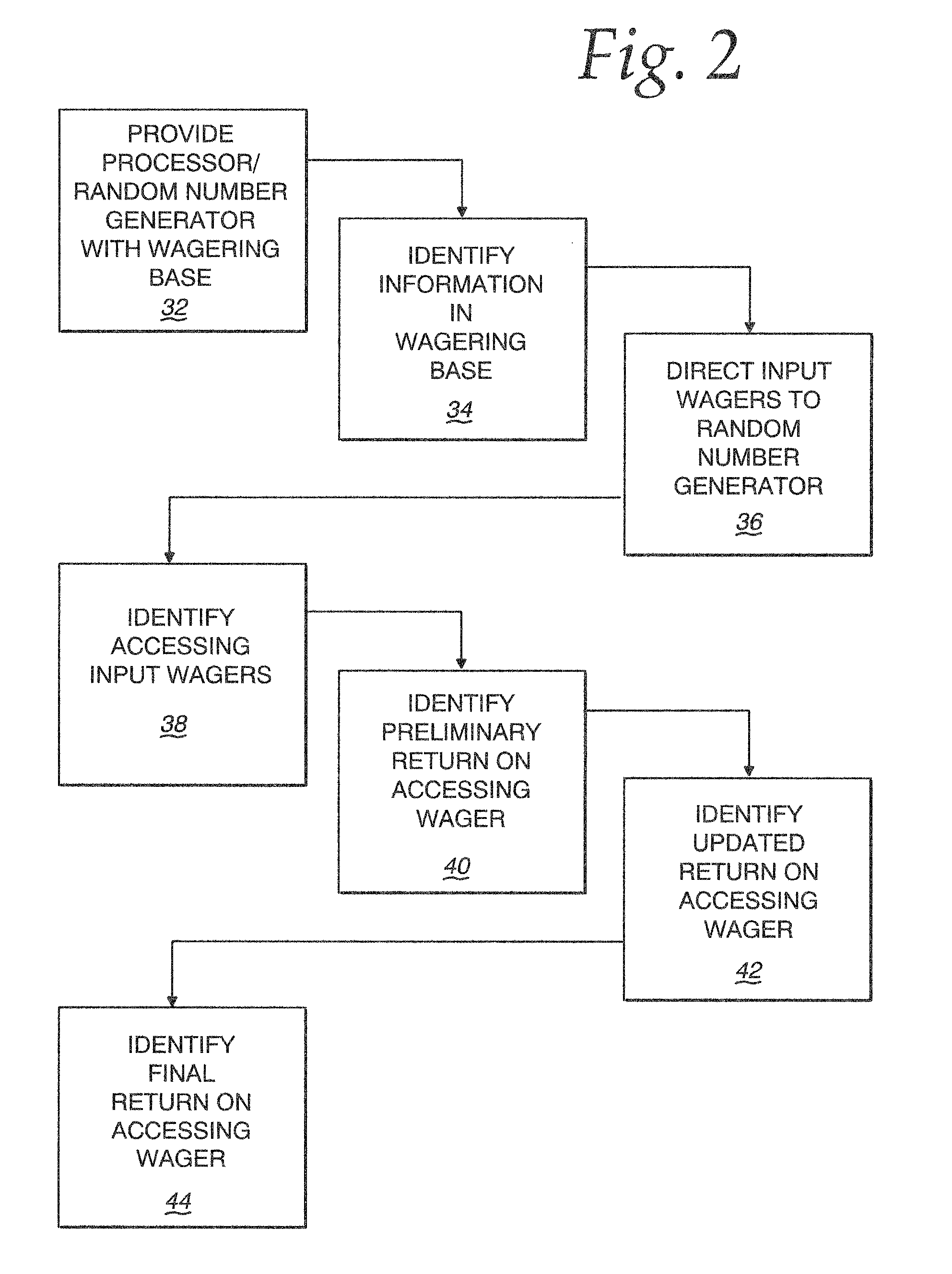

Pari-mutuel bonus round for historical racing device

ActiveUS20140287805A1Efficient and effectiveSolve the real problemApparatus for meter-controlled dispensingVideo gamesNumber generatorCanis lupus familiaris

A method of, and system for, wagering. The method includes the step of providing a random number generator that has a wagering base that is derived at least in part from the outcome of at least one horse / dog race or jai alai game that has previously been completed. Certain information in the wagering base is based at least in part on the outcome of the at least one horse / dog race or jai alai game and is accessible through an input wager, with the probability of accessing the certain information in the wagering base through an input wager being different. Input wagers are directed to the random number generator during the wagering period from each of multiple locations. Between when preliminary and final return amounts are identified for a first input wager that accesses the certain information, based at least in part upon the number of input wagers that have accessed the certain information, an updated return amount is identified for the first input wager.

Owner:HRT IP LLC

Brush member and transfer device and image forming apparatus using the same

In an image forming apparatus, a transfer brush with length of raised bristles on the surface of a metal holder equal to or smaller than 5.8 millimeters is used. Alternatively, a transfer brush with a maximum bristle inclination amount of raised bristles in a brush unit including a plurality of bristles equal to or smaller than 0.53 millimeter or a transfer brush with a maximum bristle inclination return amount of raised bristles in the brush unit equal to or smaller than 0.30 millimeter is used. An amount of biting into a paper conveyor belt in the brush unit is set to a value equal to or smaller than 2.5 millimeters. A paper conveyor belt with hardness of the rear side equal to or lower than 78 Hs is used. Alternatively, a paper conveyor belt with a coefficient of static friction on the rear surface equal to or lower than 0.75 is used.

Owner:RICOH KK

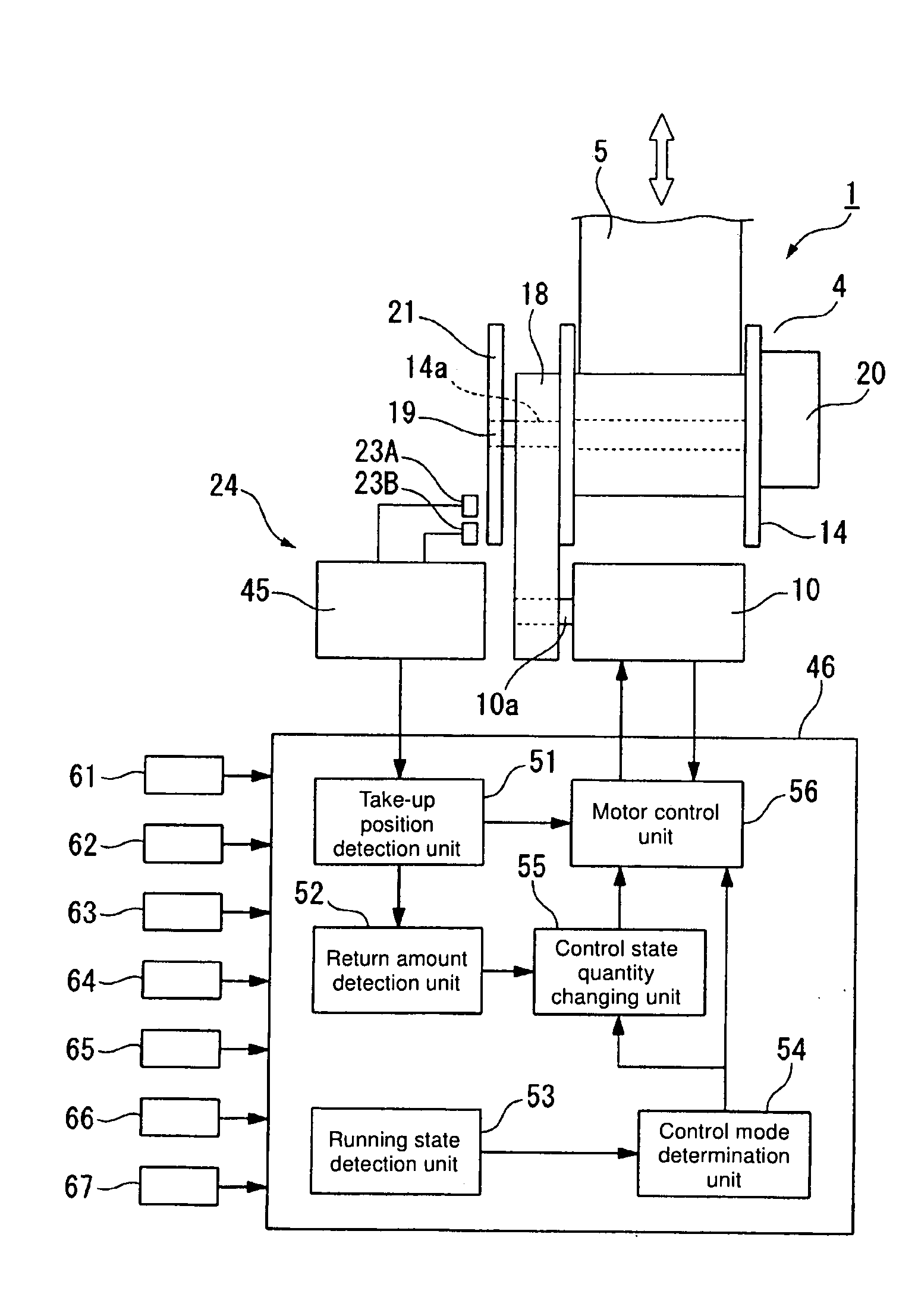

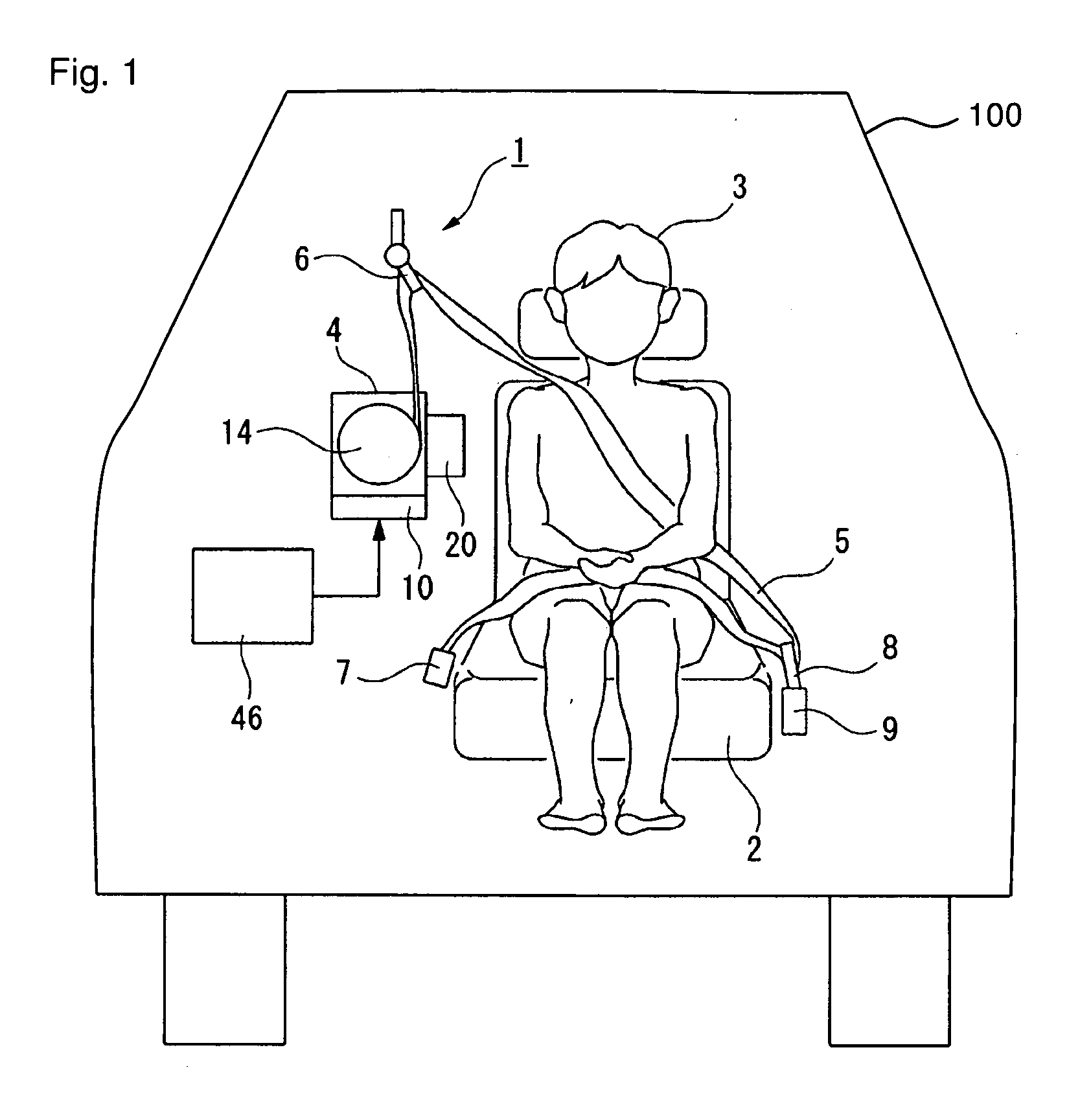

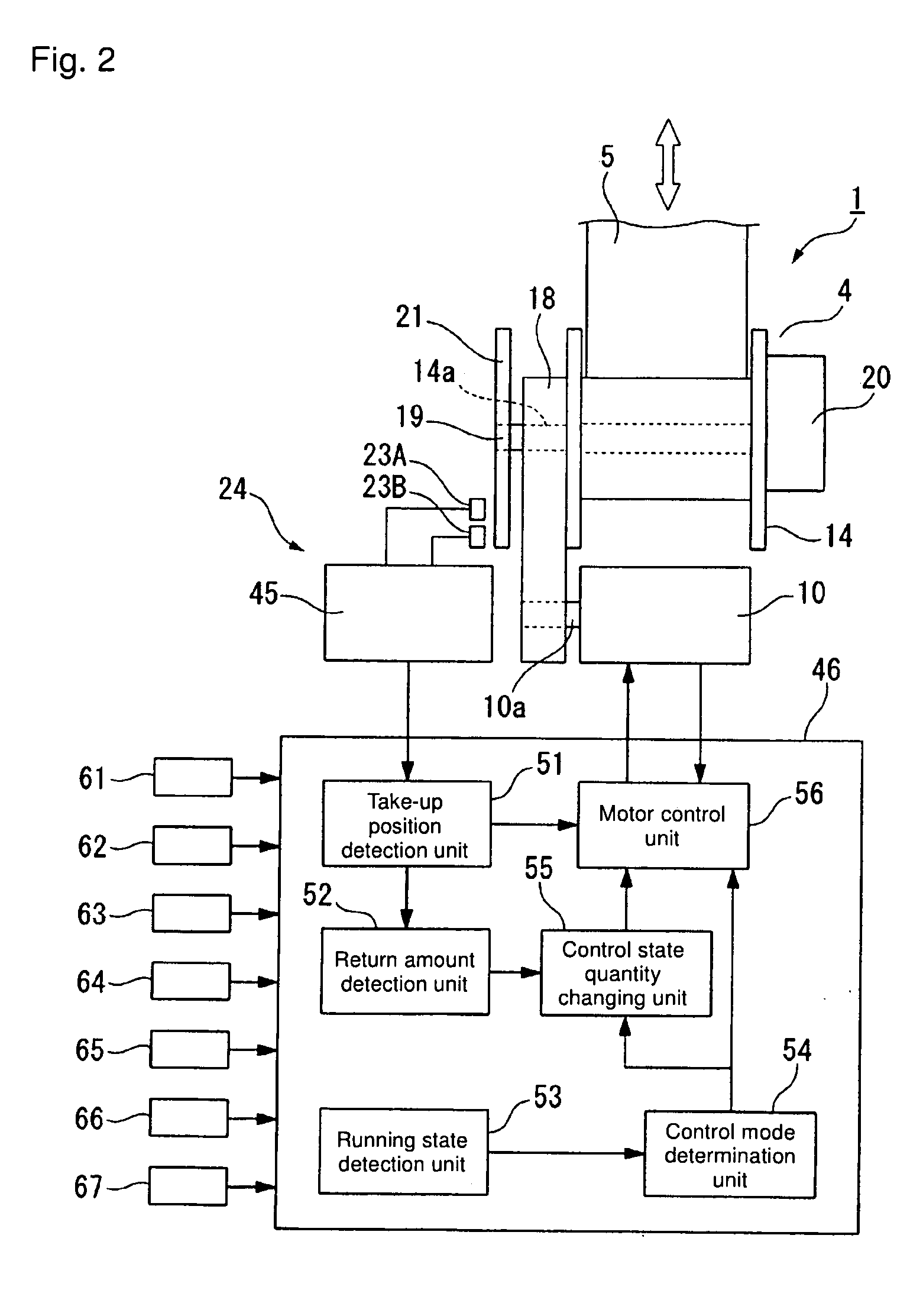

Vehicle seatbelt apparatus, vehicle having the vehicle seatbelt apparatus and method for controlling vehicle seatbelt

A vehicle seatbelt apparatus includes a belt, a belt reel, a position detector, a motor, a clutch, and a control device. The belt is wound around the belt reel. The position detector is configured to detect a rotational position of the belt reel. The motor is configured to rotate the belt reel. The clutch is configured to connect or disconnect the motor and the belt reel. The control device is configured to control the clutch and a current supplied to the motor. The control device includes a return amount detector which is configured to detect a return amount of the belt reel in a drawing direction of the belt based on the rotational position of the belt reel detected by the position detector after the belt is wound around the belt reel and then the clutch disconnects the motor and the belt reel.

Owner:HONDA MOTOR CO LTD

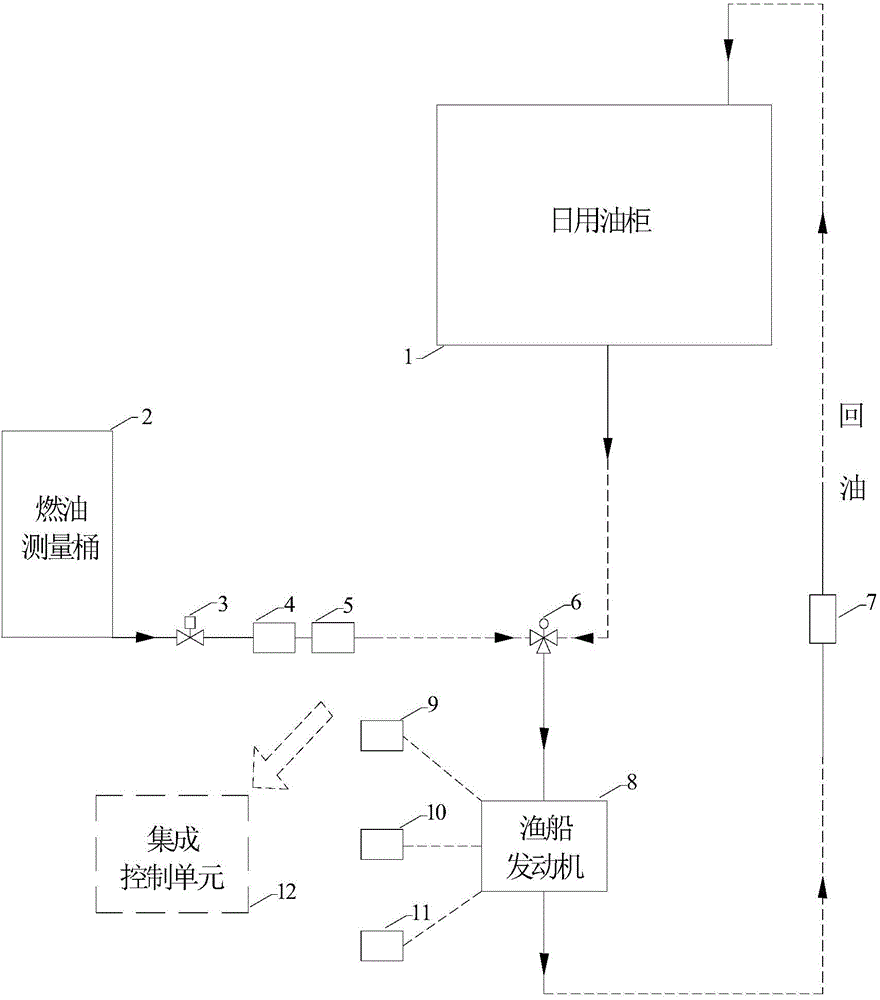

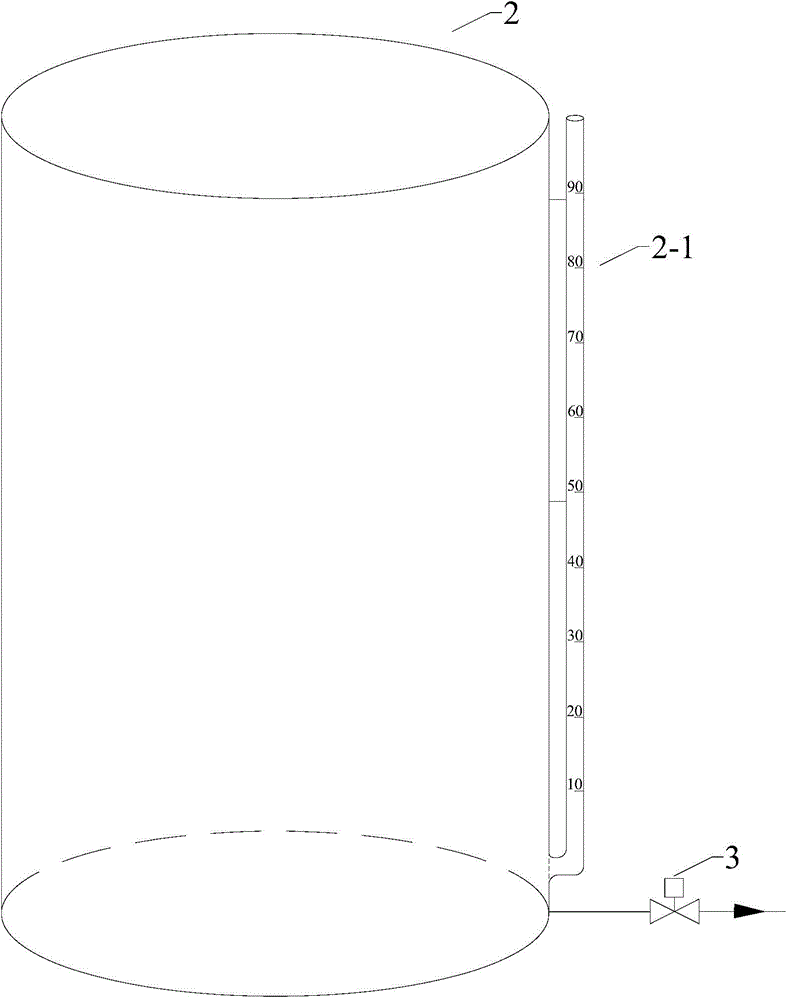

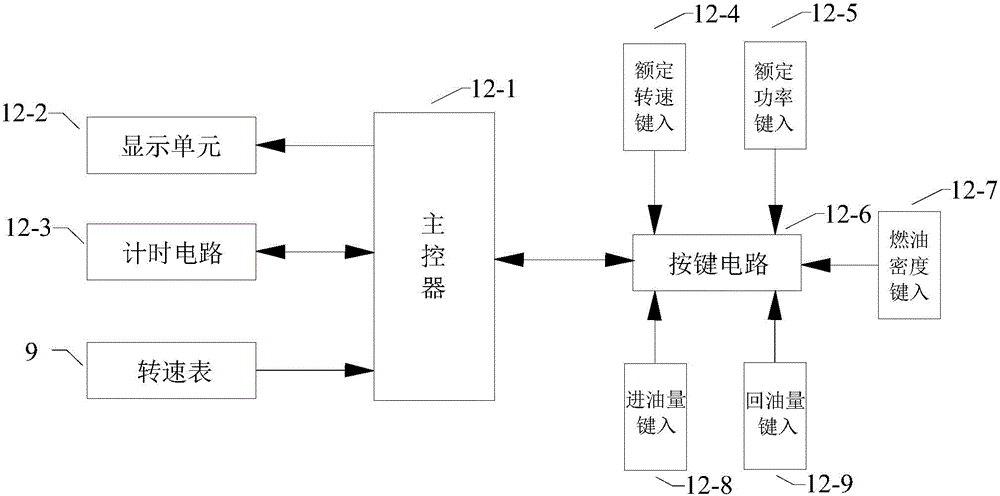

Actual ship measurement system and method for fuel consumption rate of fishing boat

InactiveCN104089668AAffect normal operationSimple structureRelative volume flow measurementsMarine engineeringElectron density

Owner:OCEAN UNIV OF CHINA

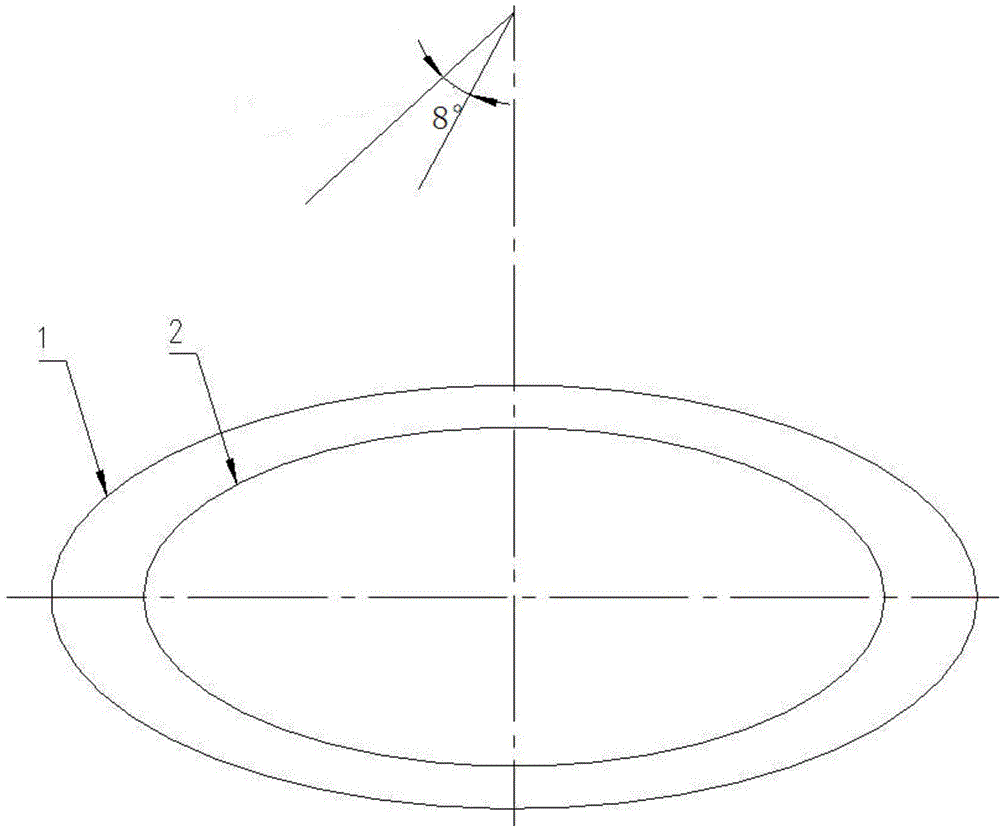

Blast furnace burden distribution method for improving agglomerate utilization efficiency

ActiveCN104131120AImprove utilization efficiencyIncrease usageBell-and-hopper arrangementBlast furnace detailsDistribution methodTwo step

The invention discloses a blast furnace burden distribution method for improving the agglomerate utilization efficiency. The method comprises the following steps: 1, weighing and screening agglomerates, returning agglomerates with the particle size of below 3mm as secondary return mines, and sending agglomerates with the particle size of 3mm or more to a blast furnace; and 2, controlling the burden distribution width of the agglomerates in the furnace to meet a condition that the tilting angle position difference in a burden distribution chute is 7-9DEG, and controlling the burden distribution to meet a condition that a distance from the radial edge of the agglomerates in the furnace to the wall of the furnace is 1 / 15-1 / 10 of the internal diameter of a hearth. The method breaks through restriction that the particle size of agglomerates in the furnace is not less than 4mm traditionally, allows the agglomerates with the particle size of 3-4mm to enter the furnace, and improves the small-particle-size utilization rate in order to improve the whole utilization efficiency of the agglomerates, reduce the mine return amount and alleviate the sintering pressure brought by production power; the conversion of an original coke-large particle size agglomerates-small particle size agglomerates three-step grading burden distribution mode to a coke-sintering two-step circulation burden distribution mode simplifies the burden distribution flow and improves the smelting efficiency.

Owner:武汉钢铁有限公司

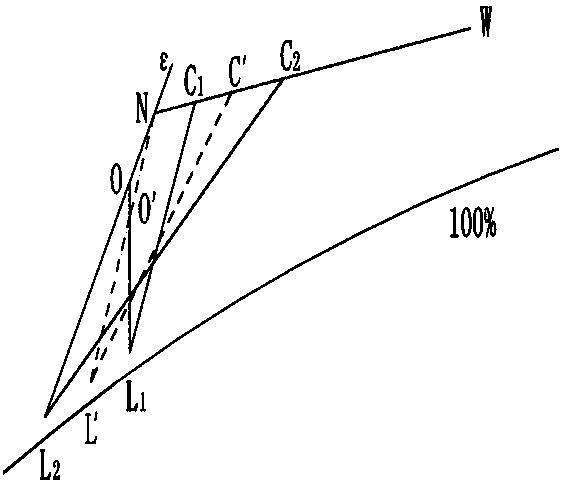

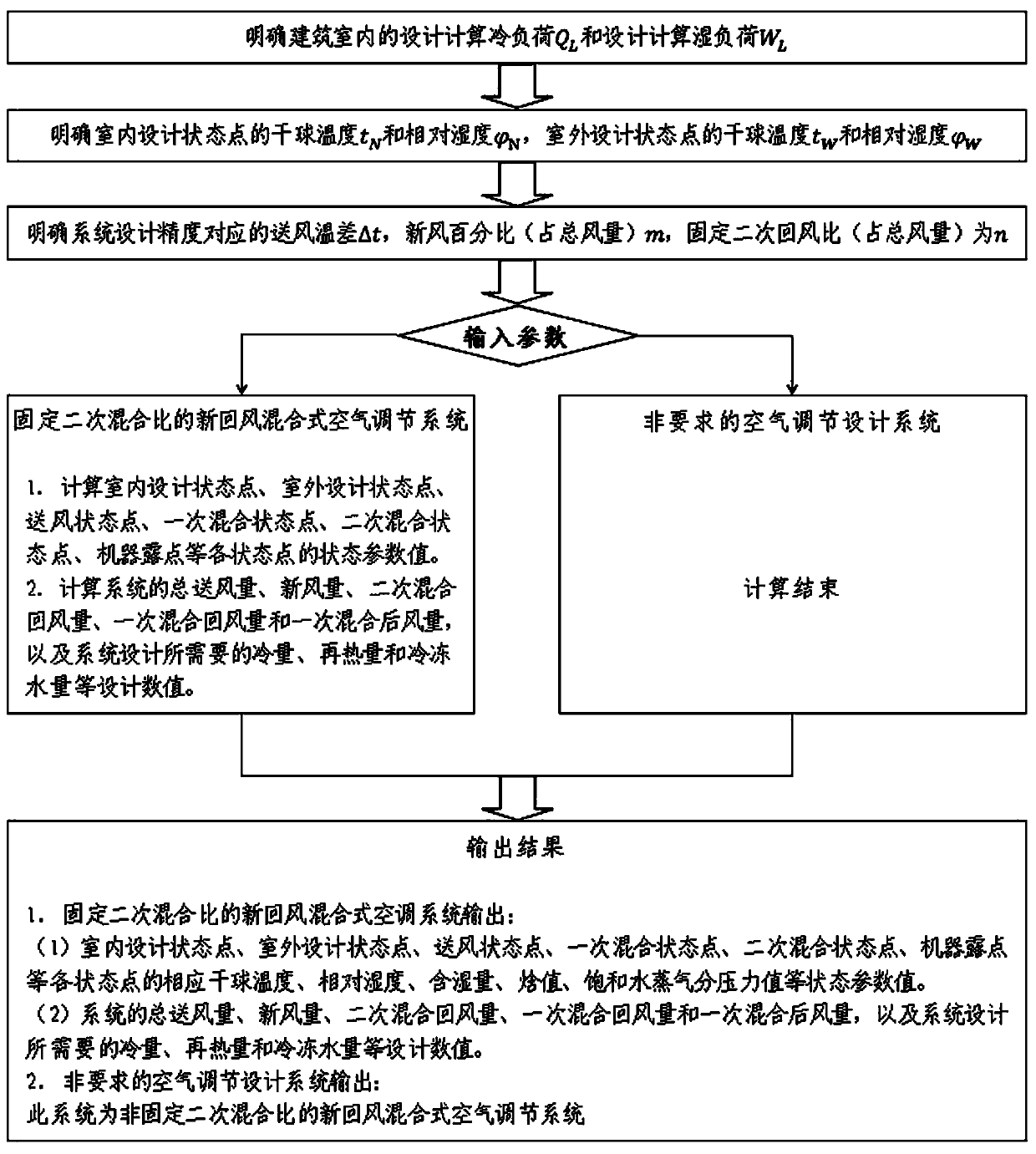

Calculating method of fresh return air mixed type air adjusting system with fixed secondary mixing ratio

ActiveCN107702272AImprove stabilityReduce energy wasteMechanical apparatusDesign optimisation/simulationSystems designAir volume

The invention relates to a calculating method of a fresh return air mixed type air adjusting system with a fixed secondary mixing ratio. The method comprises the following steps of: determining the dry-bulb temperature and relative humidity of an indoor design state point, the dry-bulb temperature and relative humidity of an outdoor design state point and the blowing temperature difference corresponding to the system design precision by determining the design calculating cold load and the design calculating wet load architectural indoors, wherein the fresh air percentage and the fixed secondary mixing ratio are target variables; acquiring the numerical values to calculate state parameter values of the indoor design state point, the outdoor design state point, a blowing state point, a primary mixing state point, a secondary mixing state point and state points of a dew point of a machine; and establishing a calculating mathematical model to calculate the general air volume, the fresh airvolume, the secondary mixing air return amount, the primary mixed return air amount and the primary mixed air volume of the system as well as a cooling capacity, quantity of reheat and refrigerationwater amount design numerical values needed by system design. The calculating method provided by the invention simplifies system control and operation complexity, and has relatively wide actual engineering application value.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Dryer

InactiveCN101424482AReduce moisture gradientReduced exhaust air returnMeat/fish preservationDrying gas arrangementsLower limitSteam pressure

The present invention provides a drying device which can dry continuously and stably with a high speed and can prevent the granular object rupture of corn. The drying device is provided with a control part (F1) which outputs a signal for reducing the returning amount of air exhausting to regulating devices (22, 23) when a state that the absolute humidity (HD) of drying air obtains the absolute humidity (HF) of saturated steam pressure or higher than the upper limit absolute humidity (beta*HF) that is set near the absolute humidity (HF) is detected; and outputs a signal for increasing the returning amount of air exhausting to the regulating devices (22, 23) when a state that the absolute humidity (HD) of drying air is lower than the lower limit absolute humidity (alpha*HF) lower than the absolute humidity (HF) of saturated steam pressure for a preset value is detected.

Owner:ISEKI & CO LTD

Air conditioner self-cleaning control method

ActiveCN110470070AReduce dilutionExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsVapor–liquid separatorFour-way valve

The invention relates to an air conditioner self-cleaning control method. The air conditioner comprises a refrigerant circulation loop composed of a compressor, a four-way valve, an outdoor heat exchanger, a throttling component, a stop valve, an indoor heat exchanger and a gas-liquid separator, wherein temperature sensors are respectively arranged on the compressor, the outdoor heat exchanger andthe indoor heat exchanger. The control method comprises a preheating process, a frosting process, a drying process I, a drying process II and a drying process III. According to the air conditioner self-cleaning control method, the cleaning effect of the air conditioner heat exchanger can be effectively enhanced, high-temperature sterilization can be achieved, and the heat exchanger can be kept dry; and in addition, the liquid return amount of the system can be controlled by controlling the exhaust superheat degree, the dilution of the liquid refrigerant to the oil is reduced, and the servicelife of the compressor is prolonged.

Owner:NANJING TICA AIR CONDITIONING CO LTD

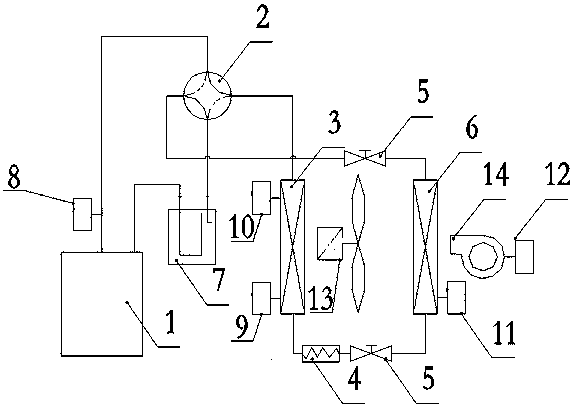

Ultra-low-carbon aluminum-killed steel vacuum carbon-loaded preliminary deoxidation process

The invention discloses an ultra-low-carbon aluminum-killed steel vacuum carbon-loaded preliminary deoxidation process. The process comprises the steps that the oxygen content and temperature of molten steel of a steel sample are measured before vacuum treatment, the arrival oxygen content and the slag oxygen return amount are measured, and the amount of carbon powder needed by deoxidation is calculated; the carbon powder is added into molten powder in batches to conduct deoxidation; the final batch of carbon powder is added in 3-5 min before decarbonization stage, the time interval between the batches is 1-2 min; sampling and oxygen probing are carried out in 3-5 min after the final batch of carbon powder is added, and the oxygen content is controlled to be 150-250 ppm; according to the oxygen probing result, the number of added aluminum pellets is calculated, and sampling is conducted in 5-7 min after addition of aluminum; and oxygen probing and sampling are carried out after 20-25 min, and the whole deoxidation treatment process is completed. By means of the process, consumption of added aluminum pellets can be reduced, and the cost can be lowered; the average aluminum consumption is lowered by 0.23 kg / t, and the cost is lowered by 3.45 Yuan / t. Meanwhile, the inclusion (Al2O3) content of molten steel is reduced by 5% or more.

Owner:武汉钢铁有限公司

Pari-mutuel bonus round for historical racing device

ActiveUS9218721B2Efficient and effectiveApparatus for meter-controlled dispensingVideo gamesCanis lupus familiarisNumber generator

A method of, and system for, wagering. The method includes the step of providing a random number generator that has a wagering base that is derived at least in part from the outcome of at least one horse / dog race or jai alai game that has previously been completed. Certain information in the wagering base is based at least in part on the outcome of the at least one horse / dog race or jai alai game and is accessible through an input wager, with the probability of accessing the certain information in the wagering base through an input wager being different. Input wagers are directed to the random number generator during the wagering period from each of multiple locations. Between when preliminary and final return amounts are identified for a first input wager that accesses the certain information, based at least in part upon the number of input wagers that have accessed the certain information, an updated return amount is identified for the first input wager.

Owner:HRT IP LLC

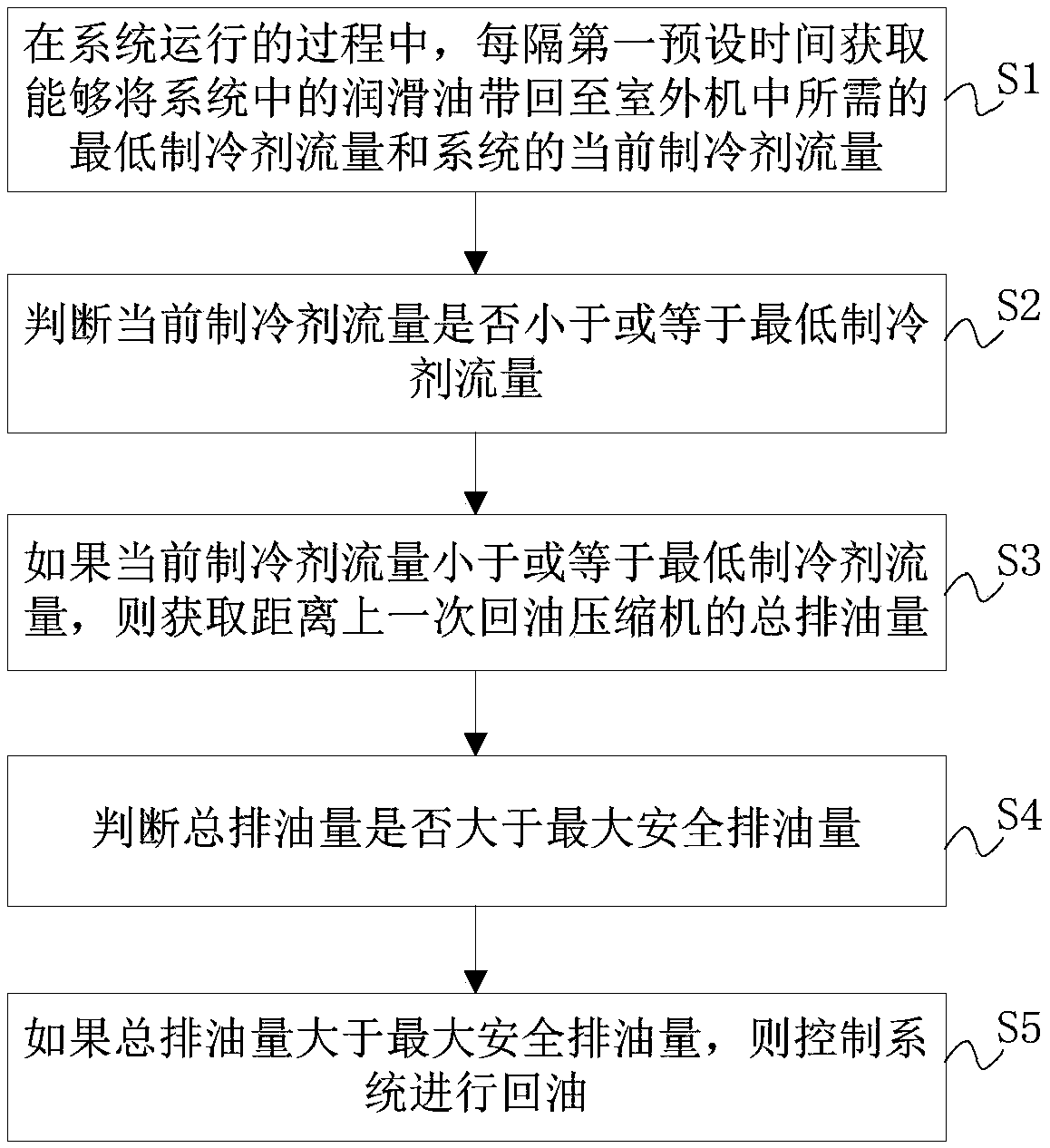

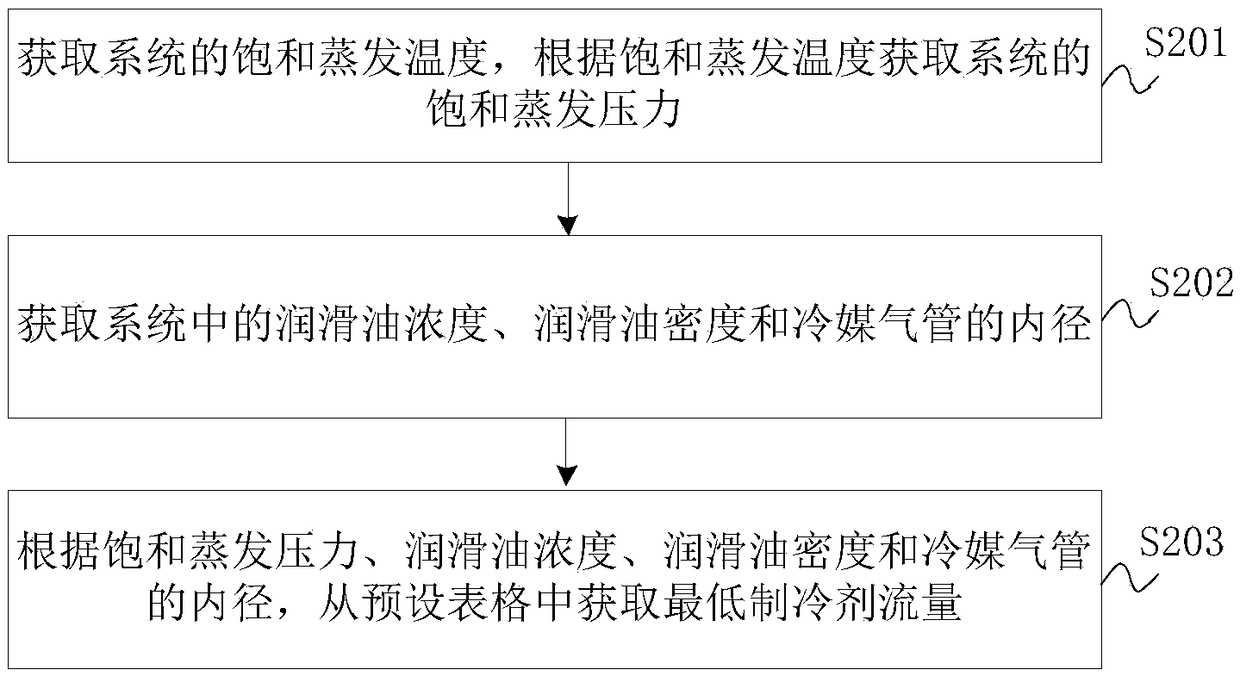

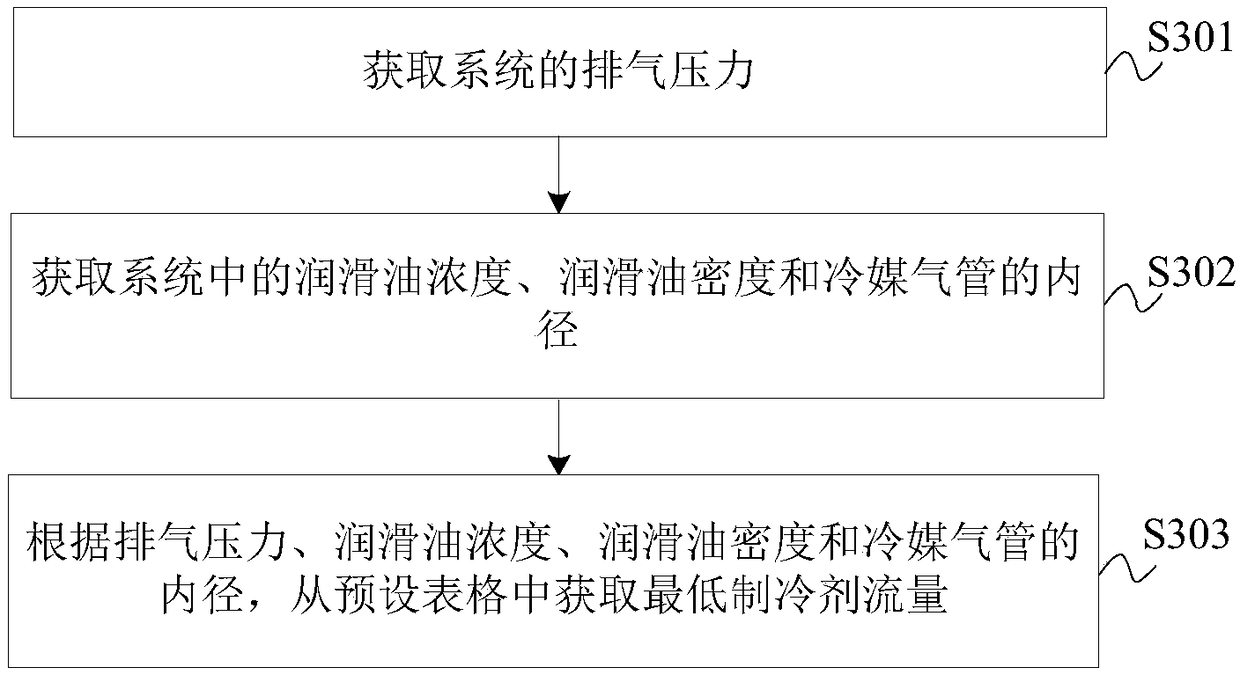

Multi-split system and oil return control method and device of multi-split system

ActiveCN108759174AImprove capacity and energy efficiencySimple methodCompressorCompression machinesControl systemRefrigerant

The invention discloses a multi-split system and an oil return control method and device of the multi-split system. The method comprises the following steps that in the operation process of the system, the minimum refrigerant flow needed for bringing lubricating oil in the system into an outdoor unit and the current refrigerant flow of the system are acquired every a first preset time; whether thecurrent refrigerant flow is smaller than or equal to the minimum refrigerant flow or not is judged; if the current refrigerant flow is smaller than or equal to the minimum refrigerant flow, the totaloil discharging amount of last time of an oil return compressor is acquired; whether the total oil discharging amount is larger than the maximum safe oil discharging amount or not is judged; and if the total oil discharging amount is larger than the maximum safe oil discharging amount, the system is controlled for oil return. Thus, it can be guaranteed that the situation that the compressor operates in an oil starvation manner due to the large oil discharging amount and small oil return amount is avoided, the capacity and energy efficiency of the multi-split system are effectively improved, and the method is simple and practicable.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com