Low oil-return type electromagnetic control oil sprayer

An electromagnetic control and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of reduced pressure relief rate in the control chamber, increased fuel temperature in the fuel tank, and slower needle valve rise rate, etc. , to achieve the effects of saving compression work, speeding up pressure building and pressure relief, and reducing oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

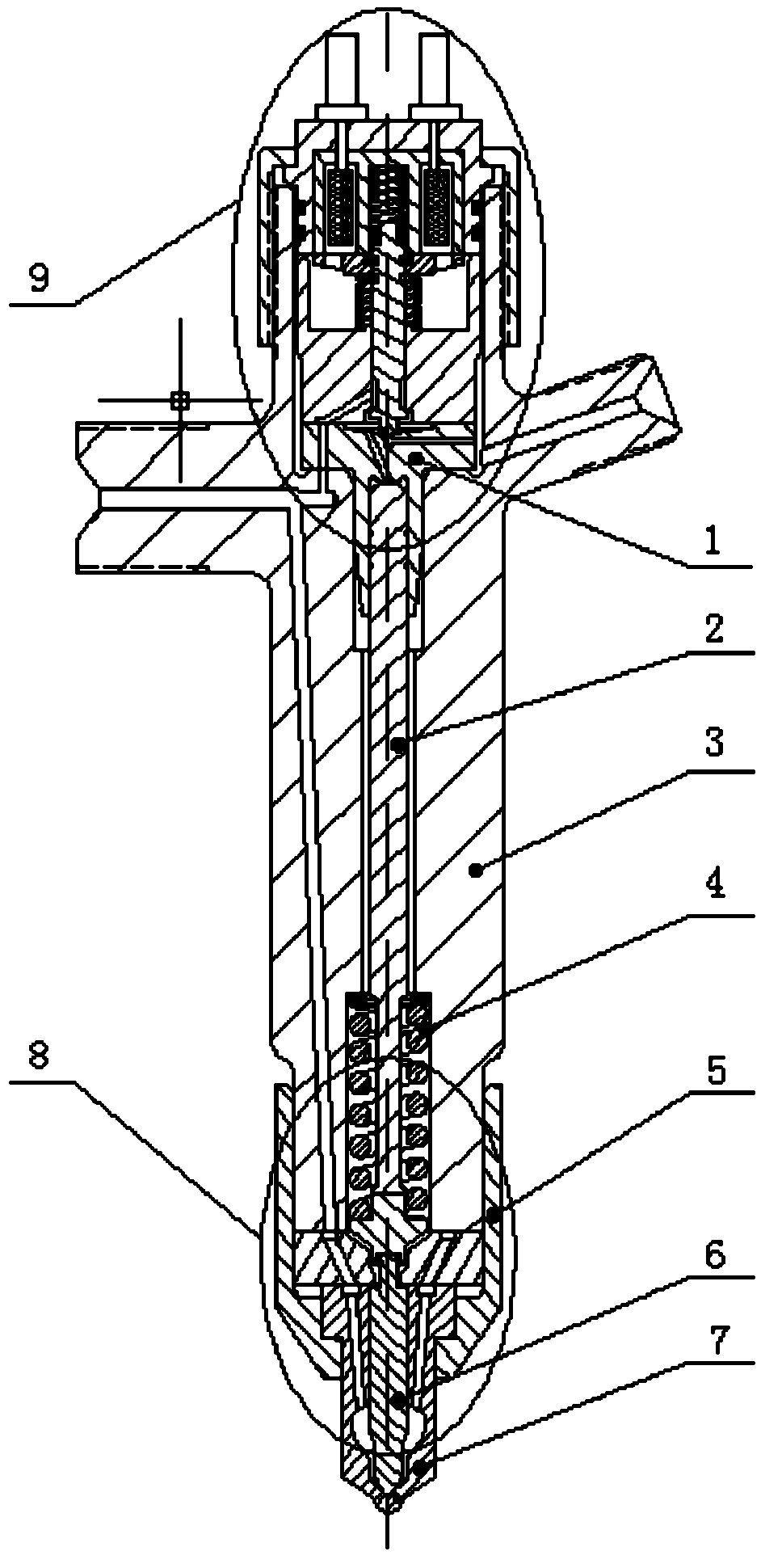

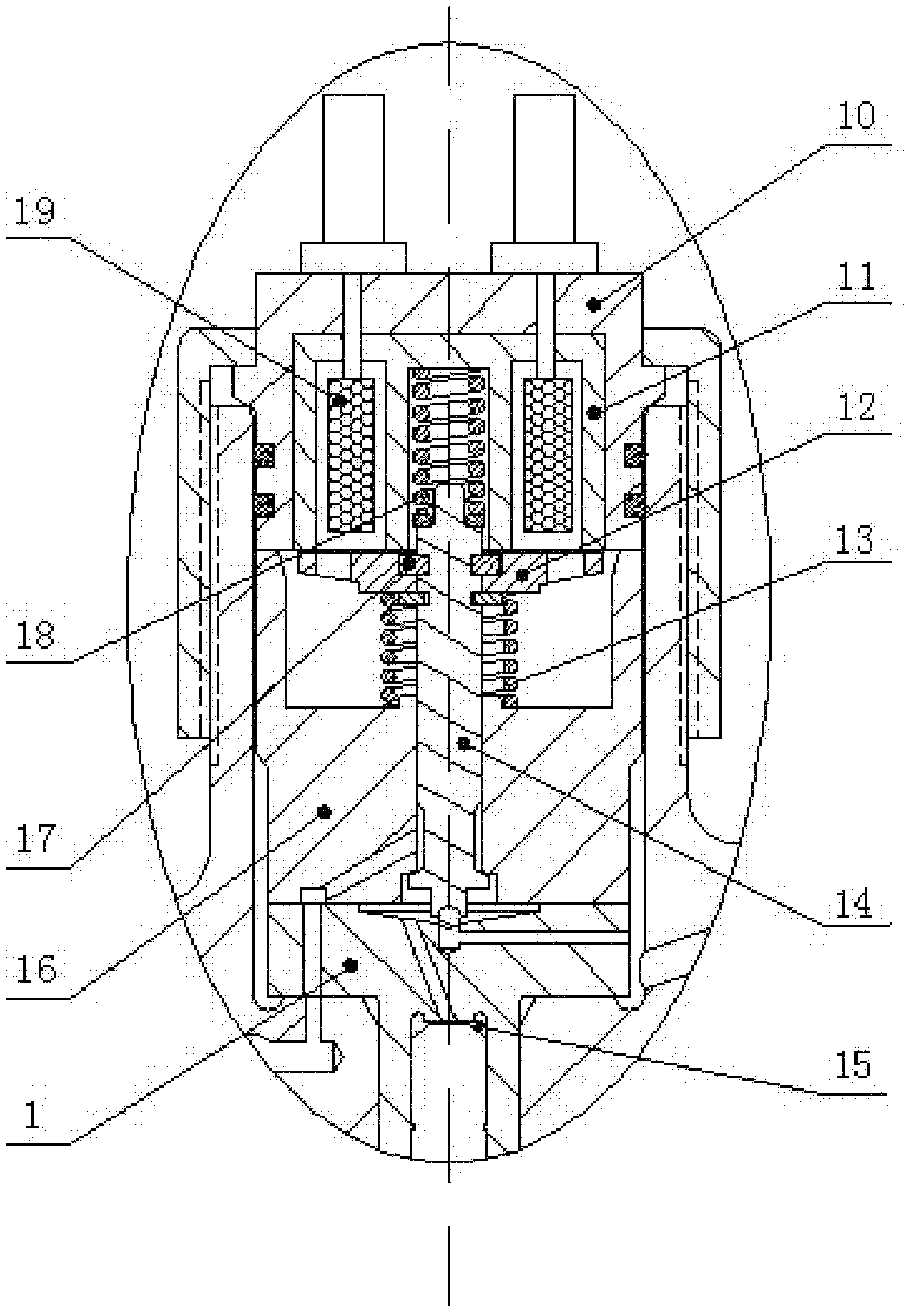

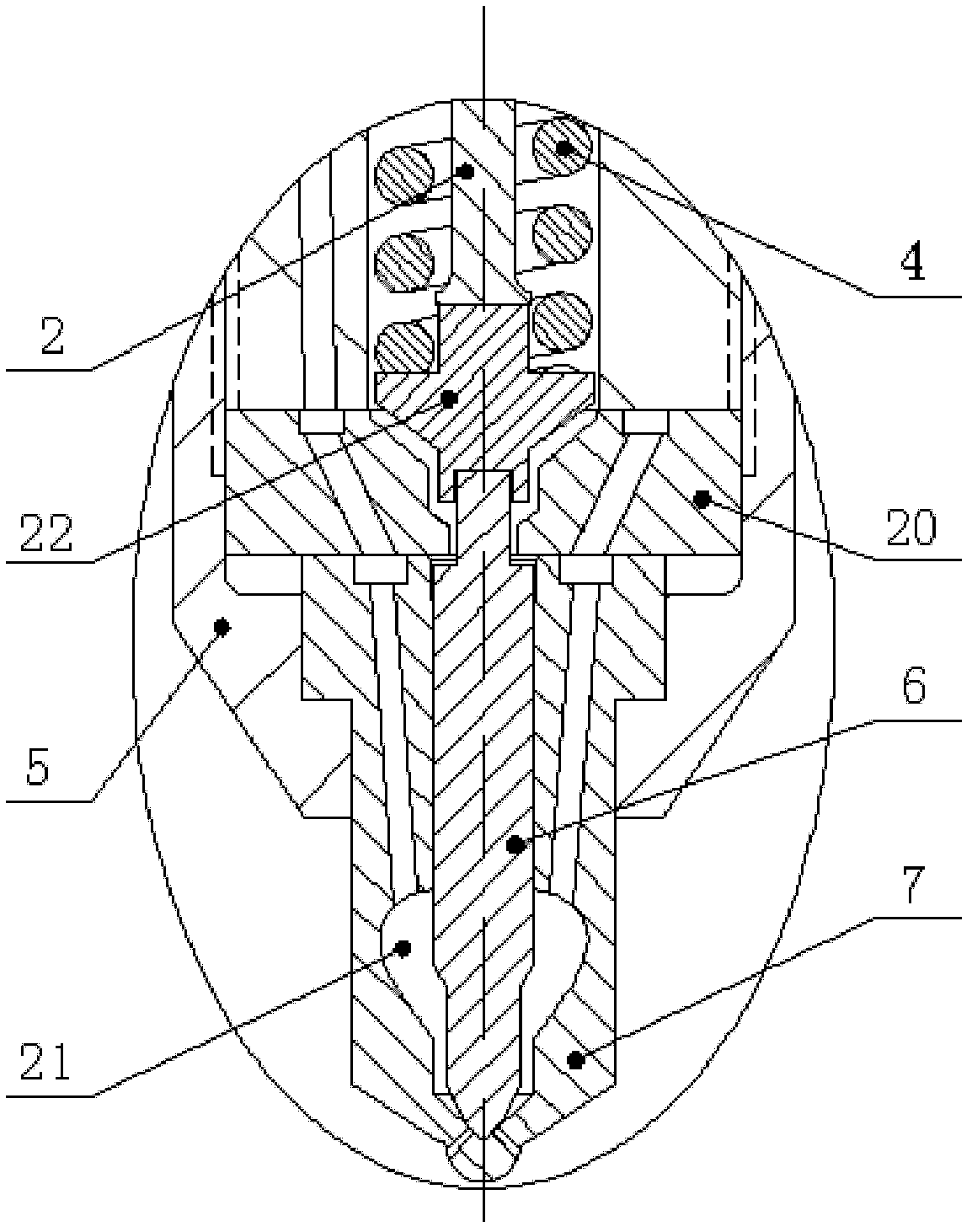

[0019] combine Figure 1~4 , solenoid valve body 10, electromagnet 11, coil 19, armature 12, stop ring 17, control spool return spring 18, double sealing surface control spool 14, large spring 13, spring seat 16, and control cavity 1 The electromagnetic valve control part 9 of the low oil return electromagnetic control injector is provided. The double sealing surface control spool 14 is clamped on the armature 12 by the stop ring 17 and connected as a whole, and moves together with the armature 12 through the electromagnetic force of the electromagnet 11 on the armature 12 . The control cavity 1 is processed with an oil inlet circuit, a sealed ball valve seat and an oil drain circuit. The oil inlet circuit is connected with the high-pressure oil pipe and the oil inlet hole on the spring seat 13. The road is connected. Injection nozzle 7, needle valve 6, limit orifice plate 20, tight cap 5, needle valve return spring 4, needle valve return spring seat 22, control piston 2 and...

Embodiment approach 2

[0023] Such as Figure 5 As shown, the inlet of the accumulator chamber 23 is connected with the high-pressure oil pipe, and the outlet is connected with the oil tank 21 and the oil inlet passage of the control chamber 15 . Electromagnetic valve body 10, electromagnet 11, coil 19, armature 12, stop ring 17, control spool reset spring 18, double sealing surface control spool 14, large spring 13, spring seat 16, and control cavity 1 jointly constitute The solenoid valve control part 9 of the low oil return accumulator type electromagnetic control injector. The double sealing surface control spool 14 is clamped on the armature 12 by the stop ring 17 and connected as a whole, and moves together with the armature 12 through the electromagnetic force of the electromagnet 11 on the armature 12 . The control cavity 1 is processed with an oil inlet circuit, a sealed ball valve seat and an oil drain circuit. The oil inlet circuit is connected with the outlet of the pressure storage cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com